Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Narrow particle distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for producing an ultrahigh molecular weight polyethylene (UHWMP) and method for producing an UHWMP using the same

InactiveUS6559249B2High bulk densityNarrow particle distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceUHMWPE polyethylene

The present invention provides a catalyst for producing an ultra high molecular weight polyethylene and also a method for preparation of an ultra high molecular weight polyethylene with the use of said catalyst. The catalyst of the present invention is prepared by a process comprising: (i) producing a magnesium compound solution by contact-reacting a magnesium compound and an aluminum or boron compound with alcohol; (ii) contact-reacting the said solution with an ester compound containing at least one hydroxy group and a silicon compound containing an alkoxy group; and (iii) producing of a solid titanium catalyst by adding a mixture of a titanium compound and a silicon compound thereto. The catalyst prepared by the present invention has excellent catalytic activity, and it helps to produce an ultra-high molecular weight polyethylene with large bulk density and narrow particle distribution without too large and minute particles.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Catalyst used for olefine polymerization or copolymerization, its preparation method and application

A catalyst for the polymerization or copdymerization of olefin is composed of Ti-contained solid component A, organoaluminium compound B and organosilicon compound C. Said A is prepared through dissolving magnesium halide in the mixture of organic epoxy compound, organophosphorus compound and inertial diluent, adding educing agent and magnesium halide or its derivatives to educe out Mg / Ti contained deposit, and carrying a surface modifier, a titanium halide or derivative and an electronic doner. It can be used for the polymerization of propene or copolymerization of propene-ethene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst, preparation method and application for olefin polymerization or copolymerization

This invention relates to a catalyst system which is used for alkenes polymerizing or copolymerization, it includes solid catalyst composition A that contains titanium and organic Aluminum compound B, silicoorganic compound C, in the composing process of catalyst composition A, use aldyl ester of aryl group mon-carboxylic acid and aldyl ester of fatty series or multielement carboxylic acid of aryl group for reasonable combination, among them aldyl ester of aryl group mon-carboxylic can play a role of assisting separating agent, it is useful to separate catalyst particle; Meanwhile it is used as electron donor, it also can load on the surface of catalytic agent together with compound of multielement carboxylic esters, improve the surface structure of catalytic agent, thus improve the catalyzing function of catalytic agent. This catalytic agent that is used for propylene polymerizing has high catalytic activity and anti- impurity function, particle appearance of catalytic agent is good, particles distribute narrowly, hydro-adjusting function of catalytic agent is good, it is useful for many polymerizing technology such as seriflux method, noumenon method and gas method, molecular weight distribution of polymer is narrow, particle appearance of polymer is good, fine grits is little; Its fine anti-impurity function can effectively reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

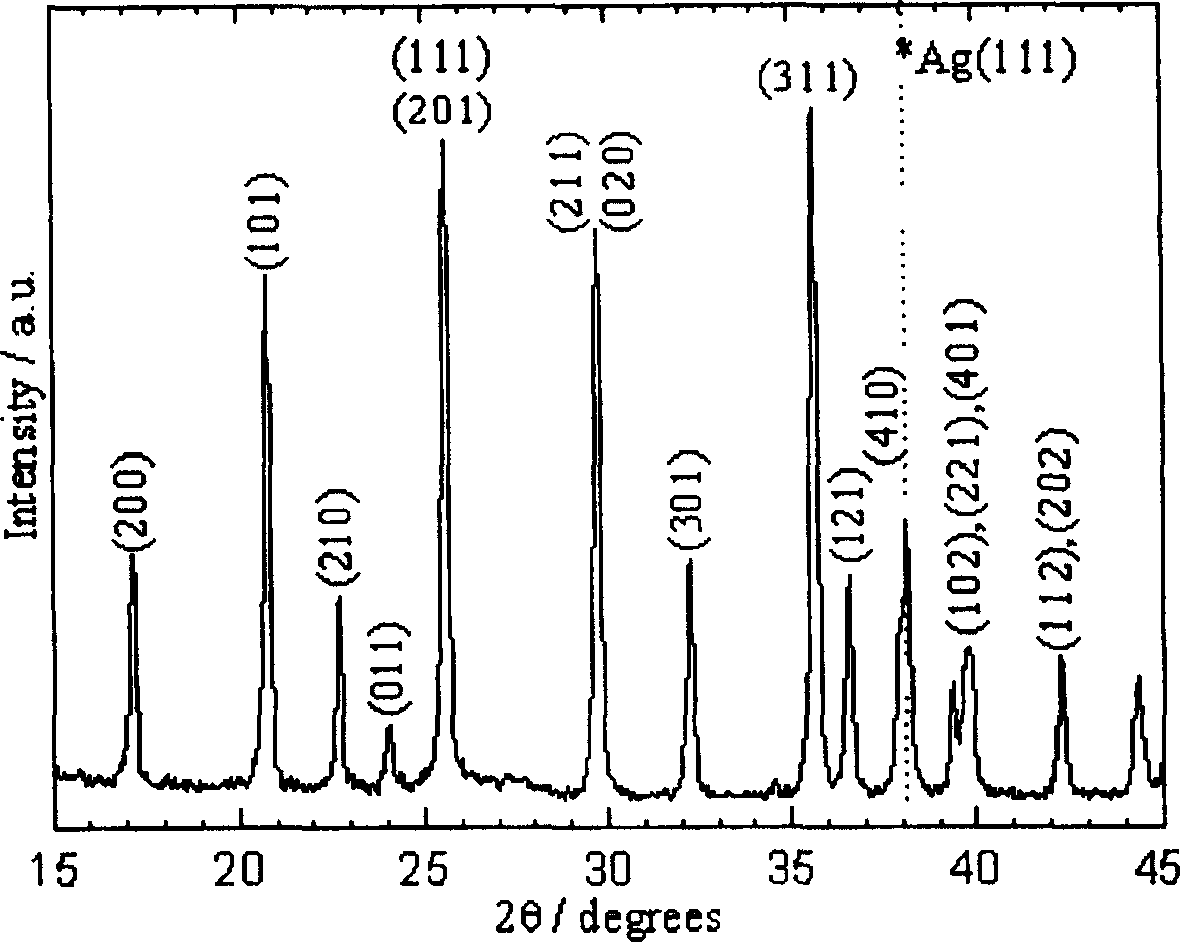

Method for preparing carbon coated lithium ferrous phosphate composite material including metal conductive agent

InactiveCN1649189AImprove electronic conductivityImprove protectionElectrode manufacturing processesPhosphatePhosphoric acid

This invention relates to a preparation method for LiFe PO4 / M / C compound positive material, the precursor of Li-Fe-PO4-M is synthesized with Li salt, Fe compound, phosphate, silver salt and organic acid as the raw materials by the sol-coagel method. Then the precursor mixed with pyrogenic-decomposed in inert atmosphere to get LiFePO4 / M / C compound positive material.

Owner:ZHEJIANG UNIV

Preparation method of alcohol solvent type high-purity silica sol

InactiveCN102120584ANarrow particle distributionHigh puritySilicon compoundsReaction temperatureSilica gel

The invention relates to the technical field of nano material preparation, aiming at providing a preparation method of alcohol solvent type high-purity silica sol. The method comprises the following steps: mixing an alcohol solvent, water and a catalyst and then adding the mixture as a base material to a two-stage reactor; and mixing the alcohol solvent and tetramethoxysilane and then adding the mixture in the base material at the feeding speed of 4-40 ml / min under the condition of stirring so as to react for 12-24 hours at the reaction temperature of 0-45 DEG C, thus the solvent type high-purity silica sol is obtained, wherein the solid content of the prepared silica sol is 7-10%, and the average size of the silicon dioxide particle in the silica sol is 8-20 nm. The preparation method is simple in process and is easy to operate, the reaction is controllable, and the distribution of silica sol particles is narrow; the purity of the silica sol is high, the solid content for once preparation is relative high; and aftertetramethoxysilane or tetraethyl orthosilicate is rectified, high-purity silica sol without mental ions can be prepared, and the prepared product is mainly used in the aspect of paints.

Owner:ZHEJIANG UNIV

Catalyst for ethene polymerization or multipolymer, preparing method thereof

A catalyst for polymerization or copolymerization of ethylene is prepared through dissolving magnesium halide in organic epoxy compound, organic phosphorus compound or inertial diluent, adding alkane educing aid, porous inertial carrier and halide of Ti, and educing. It is possible to add alcohol compound and / or electron donor. Its advantages are high activity and copolymerizing performance, and high sensitivity to hydrogen regulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst in use for polymerization or combined polymerization of ethylene, preparation and application

This invention provides a catalyst for ethylene polymerization or copolymerization and its synthesis. The catalyst comprises magnesium halide / inorganic matter composite carrier prepared by spray drying. This invention also provides the method for preparing the magnesium halide / inorganic matter composite carrier and the method for synthesizing the catalyst by using the composite carrier. The obtained catalyst has such advantages as high catalytic activity, no breakage of catalyst particles, and narrow particle size distribution. The polymer has such advantages as good particle morphology, little fine powder and high packing density.

Owner:CHINA PETROLEUM & CHEM CORP +1

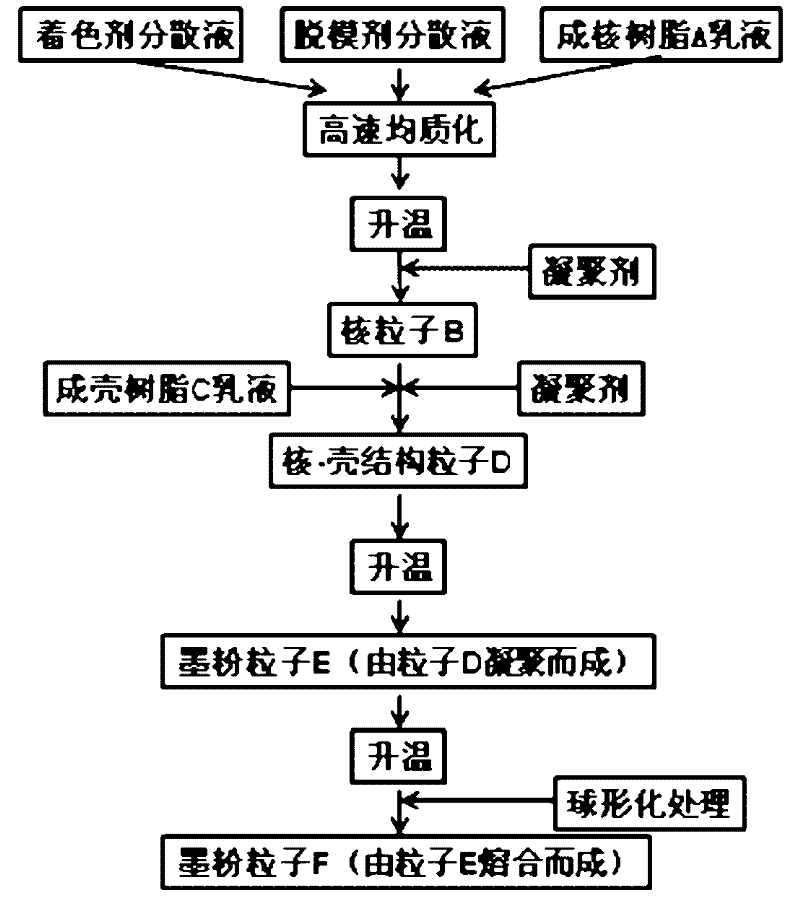

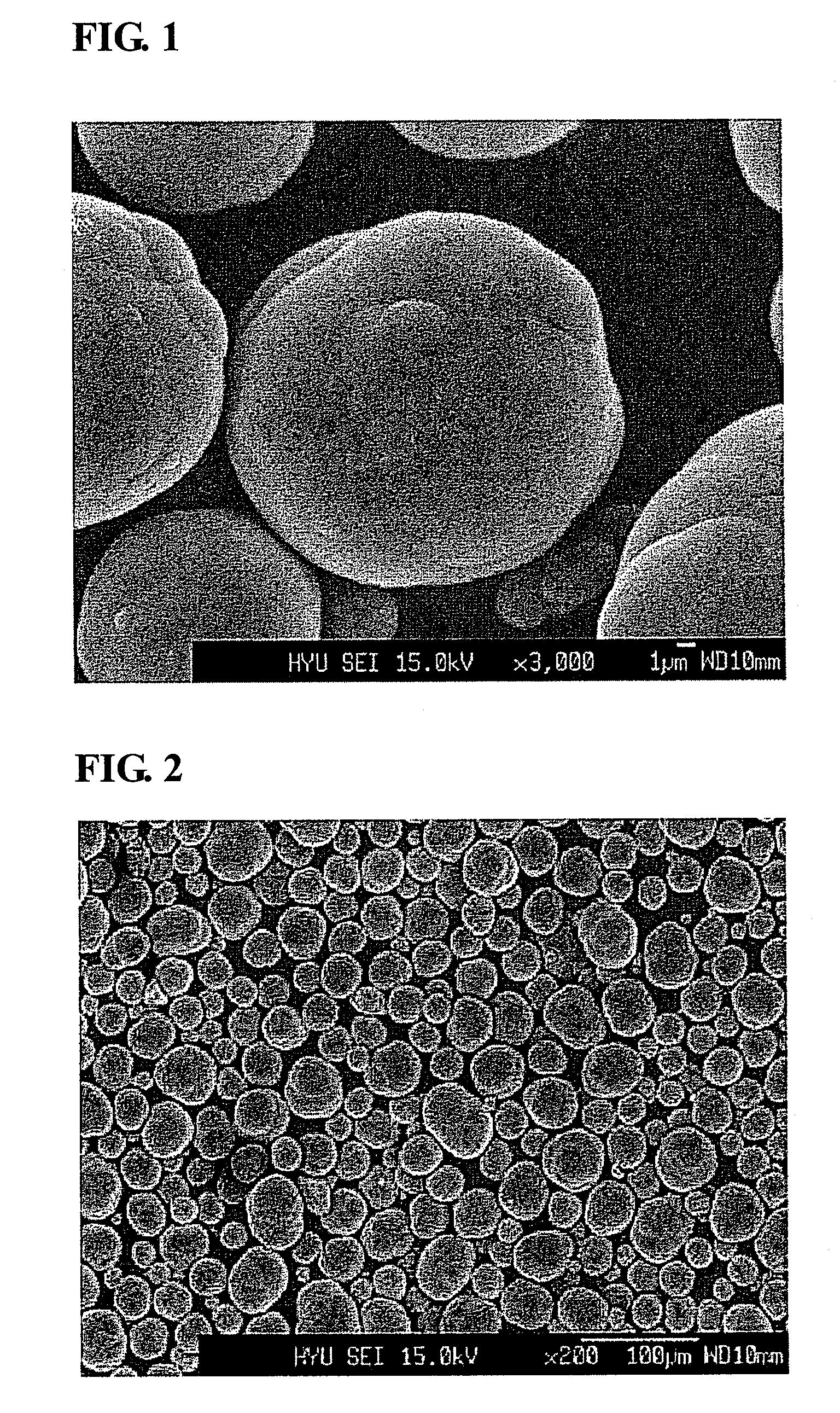

Colorful powdered ink used for static development and preparation method thereof

The invention provides a colorful powdered ink used for static development. Grains with nucleus-shell structures are formed into powdered ink grains in an agglomeration mode; the powdered ink grains contain a nucleus-forming resin A and a shell-forming resin C which are made of same or different components; and the total content of the two resins accounts for 60%-85% of the powdered ink grains. The invention also provides a preparation method of the colorful powdered ink, and the method comprises the following steps: quickly dispersing a colorant dispersing solution, a wax dispersing solutionand an emulsion of the nucleus-forming resin A, thereby forming agglomerated nucleus grains B in a system; then adding a mixture of the emulsion of the shell-forming resin C and a charge control agent, thereby agglomerating into the grains D with the nucleus-shell structures around the nucleus grains B; increasing the temperature so that the grains D with the nucleus-shell structures are agglomerated into powdered ink grains E; and performing spherical treatment on the powdered ink grains E, thereby forming the powdered ink grains F. The powdered ink grains F prepared according to the preparation method provided by the invention are excellent in spherical degree, narrow in grain distribution, excellent in electric property and excellent in durability. The problems of photosensitive drums and developing roller pollution caused by easy separation between a colorant and a release agent are solved.

Owner:SHENZHEN LEPUTAI TECH CO LTD

Three-dimensional micro-nano material composed of nano CoFe2O4 and preparation method thereof

ActiveCN102190483ASimple processReduce technical difficultyNanostructure manufactureDecorative surface effectsPolyolRoom temperature

The invention discloses a three-dimensional micro-nano material composed of nano CoFe2O4 and a preparation method thereof. The three-dimensional micro-nano material is of a double-hexagon flower dumbbell type opposite-connected structure and is obtained by the following steps: 1) adding tervalent iron salt and divalent cobalt salt in polyol, stirring to obtain transparent liquid, heating for reacting, and then cooling to room temperature and collecting precipitates; 2) centrifugally washing the precipitates with ethanol, and drying so as to obtain a yellow green cobalt ferrite precursor; and 3) firing the precursor so as to obtain the CoFe2O4 micro-nano structure with the double-hexagon flower dumbbell type opposite-connected structure. According to the invention, the process is simple and practicable, the distribution range of the obtain material particle is narrow, and the micro-nano material has the advantages of single dispersibility, single product phase and good reaction repeatability; and the synthesized material simultaneously has characteristics and advantages of a micro-nano structure and a nano structure.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Dry toner, method for manufacturing the same, image forming apparatus, and image forming method

InactiveUS20070184370A1High quality imagingQuality improvementDevelopersElectrographic process apparatusElectrical conductorOrganic solvent

A dry toner contains fine particles having average sphericity of 0.93 to 0.99, a content of the fine particles having a particle diameter of 2 μm or less in the dry toner is 20% by number or less. A method for manufacturing a dry toner includes a process for dispersing in an aqueous medium containing water and a water-soluble organic solvent, a toner composition contained in an organic solvent by using fine solid dispersing agent; and a process for contracting volume of the dispersed toner composition. Further, the image forming apparatus having a photoconductor; a charger for charging the photoconductor; a light irradiator for irradiating the electrophotographic photoconductor to form a latent electrostatic image; a developer for developing the latent electrostatic image to form a developed image; and a transfer for transferring the developed image to a recording material, and the developer contains the dry toner abovementioned.

Owner:RICOH KK

Dry toner, method for manufacturing the same, image forming apparatus, and image forming method

InactiveUS7419756B2High quality imagingReduce adhesionDevelopersElectrographic processes using charge patternElectrical conductorOrganic solvent

A dry toner contains fine particles having average sphericity of 0.93 to 0.99, a content of the fine particles having a particle diameter of 2 μm or less in the dry toner is 20% by number or less. A method for manufacturing a dry toner includes a process for dispersing in an aqueous medium containing water and a water-soluble organic solvent, a toner composition contained in an organic solvent by using fine solid dispersing agent; and a process for contracting volume of the dispersed toner composition. Further, the image forming apparatus having a photoconductor; a charger for charging the photoconductor; a light irradiator for irradiating the electrophotographic photoconductor to form a latent electrostatic image; a developer for developing the latent electrostatic image to form a developed image; and a transfer for transferring the developed image to a recording material, and the developer contains the dry toner abovementioned.

Owner:RICOH KK

Catalyst for ethylene homo-and co-polymerization

The present invention relates to a catalyst for homo-polymerization or co-polymerization of ethylene, or more particularly to a solid complex titanium catalyst for homo-polymerization or co-polymerisation of ethylene, said catalyst being produced by preparing a magnesium solution by contact-reacting a halogenated magnesium compound with alcohol, reacting said solution with an ester compound having at least one hydroxy group and a boron compound having an alkoxy group, and then reacting said solution with a mixture of a titanium compound and a silicon compound. The catalyst of the present invention has good activity, and the polymers produced by means of the catalyst herein has advantages in that the polymers have high bulk density with narrow particle distribution and a reduced amount of fines particles.

Owner:SAMSUNG GENERAL CHEMICALS CO. LTD

Penniform large-grain cerium-based composite oxide powder with high specific surface area and preparation method thereof

InactiveCN102134088AGood dispersionLarge specific surface areaNanotechnologyRare earth metal compoundsDispersityCerium

The invention relates to penniform large-grain cerium-based composite oxide powder with high specific surface area and a preparation method thereof. The preparation method comprises the following steps of: dripping a mixed solution of cerium-based salt and non-cerium-based salt (one or more of nitrates or sulfates of samarium, gadolinium, neodymium, yttrium, zirconium, lanthanum, barium, calcium and strontium) to a precipitant solution at 30-60 DEG C under stirring; keeping the pH of a reaction solution at 8-12, wherein the mole ratio of metal ions to a precipitant is 1: (2-6); carrying out aging reaction on the reaction solution at 60-80 DEG C for 6-20 hours to obtain precipitates; filtering and washing till filter liquor is neutral; drying the precipitates at 60-120 DEG C for 6-20 hours, and then calcining at 400-1100 DEG C for 4-20 hours to prepare the penniform large-grain cerium-based composite oxide powder. The products are grains which have good dispersity and uniform size; the grains are irregularly connected together through a large quantity of nano-plates and form penniform shapes; the average grain diameter of the grains is 1-20 micrometers; the specific surface area of the grains is 70-90 m<2> / g; and the thicknesses of the nano-plates are 20-100 nanometers.

Owner:DALIAN MARITIME UNIVERSITY

Ethylene slurry ring tube polymerization or copolymerization method

The invention relates to a kind of ethylene polymerization or co-polymerization method. The method contains the steps as follows: in ring-canal form reactor and condition of catalyst, procee polymerization reaction with ethylene and more than a C3-C8 alpha-alkene slurry, and the catalyst mentioned above contains the reaction product of titanium catalyst constituent and organic aluminium compound. Ethylene and alpha-alkene combined polymer manufactured by the method has low density, and needs little quantity of comonomer. So it can make the residual comonomer in polymer quantity decline badly, which already had flash vaporization and renovation with diluent in ring-canal polymerization reaction industrial art, and can improve the quality of end combined polymer. At the same time, the polymer also has high bulk density, and low fine powder content in resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

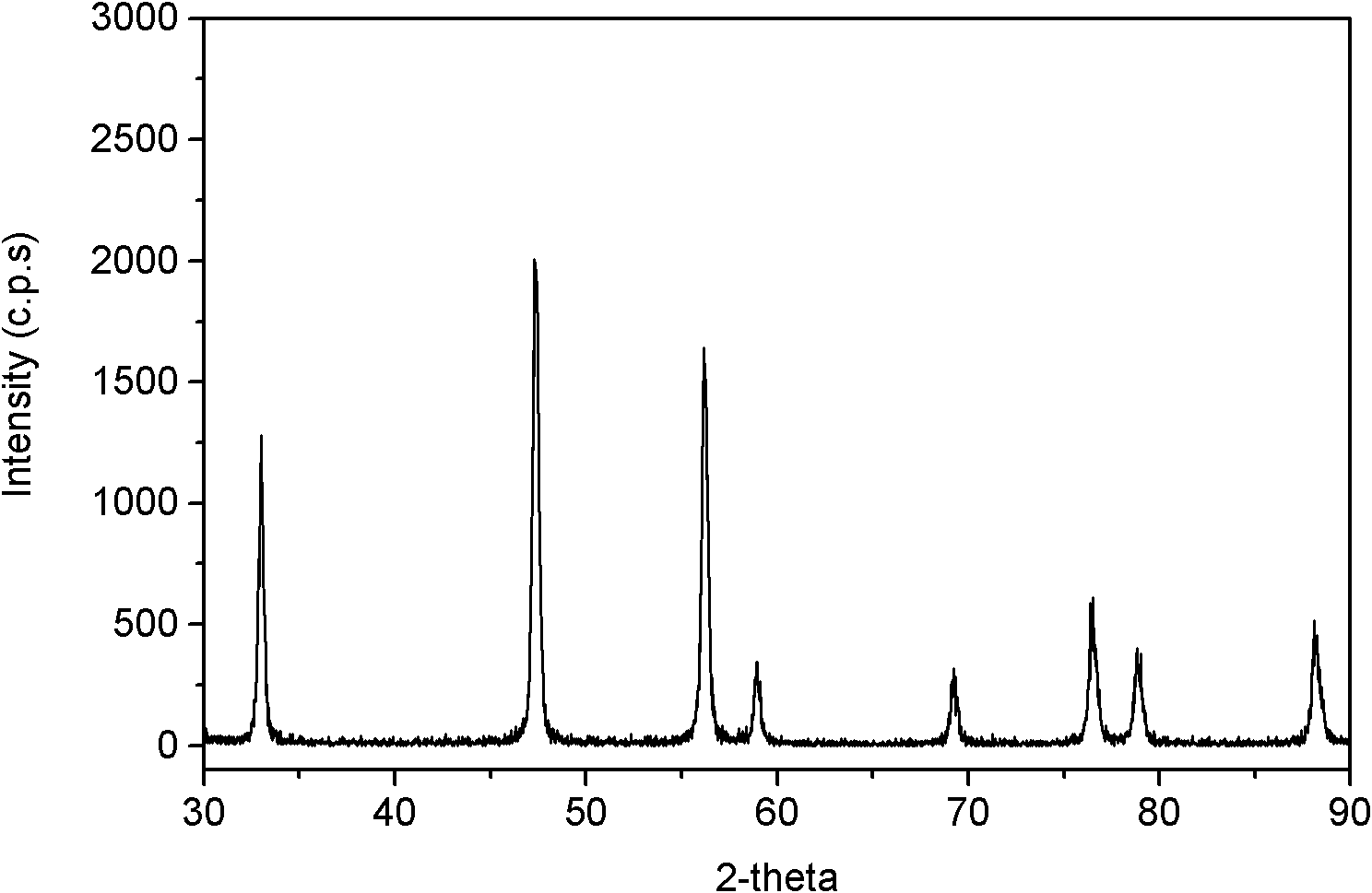

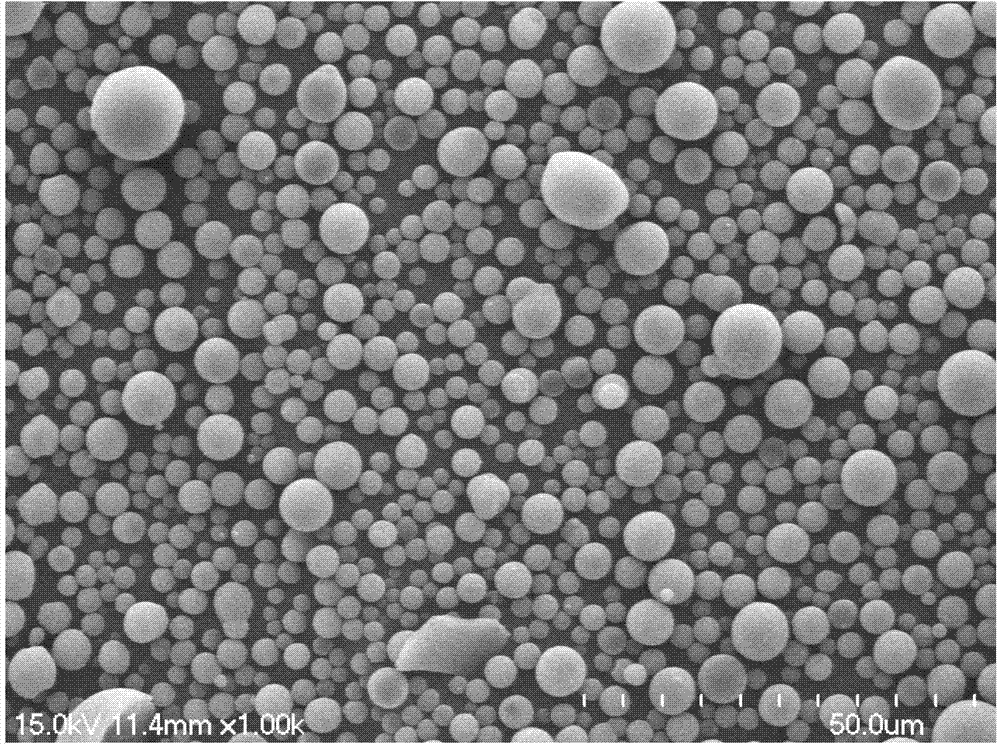

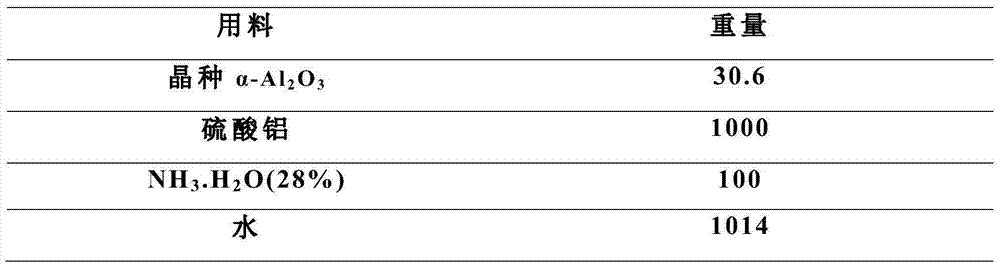

Preparation method of sapphire polishing solution

ActiveCN103881586AReduce the temperatureReduce processing costsPolishing compositions with abrasivesSalt waterNanocrystal

The invention discloses a preparation method of a sapphire polishing solution. The preparation method is characterized by comprising the following steps: (1) uniformly dispersing alpha-Al2O3 nano-crystals which have average particle size in the range of 100-300nm and are taken as crystal seeds in an aluminum salt water solution as a precursor solution; (2) preparing the precursor solution into spherical powder containing the crystal seeds of the alpha-Al2O3 nano-crystals as a precursor by virtue of a spray drying process; (3) sintering the precursor by controlling the temperature range within 900-1200 DEG C to obtain alpha-Al2O3 powder; (4) dispersing the alpha-Al2O3 powder into water, and adjusting the pH value and size of secondary particles to obtain the sapphire polishing solution. According to the preparation method disclosed by the invention, the obtained sapphire polishing solution has the advantages of small average particle size, narrow particle size distribution, good water dispersibility, wide and adjustable range of process parameters and capability of greatly improving the efficiency and the precision of sapphire polishing.

Owner:苏州柔陶新材料有限公司

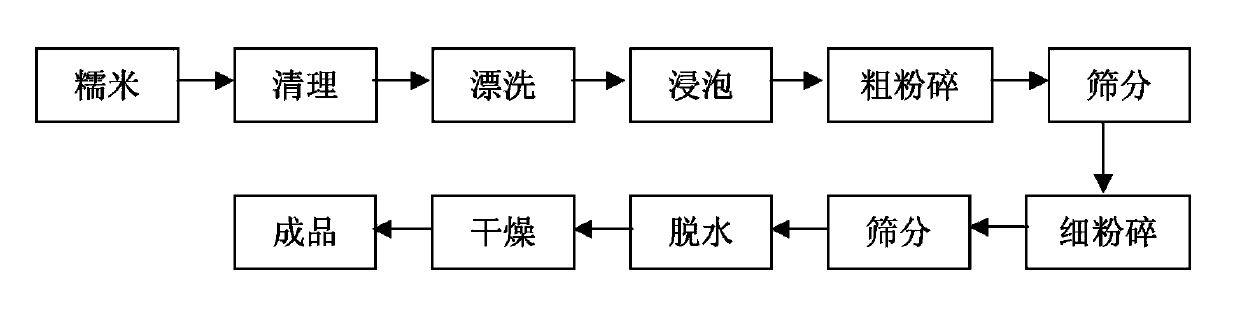

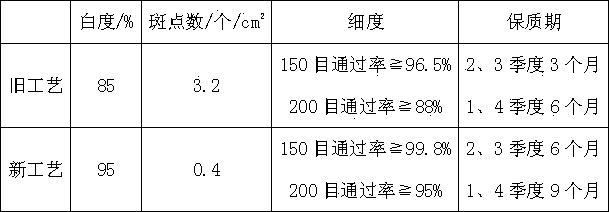

Method for producing water-grinding glutinous rice flour

The invention relates to a method for smashing glutinous rice, in particular to application of the smashing-screening coupling technology in the water-grinding glutinous rice flour production technology. The method for producing water-grinding glutinous rice flour comprises the steps that ash and impurities in rice are removed through a pretreatment process; coarse grinding is conducted on the soaked glutinous rice through a grinder and primary screening is conducted by a vibrating screen classifier; glutinous rice husks in glutinous rice milk are removed and 50-80-mesh milk is obtained; refined grinding is conducted through an ultra-fine grinder, secondary screening is conducted through the vibrating screen classifier, and ground glutinous rice milk particles are all over 100 meshes; the glutinous rice milk is dehydrated and dried and the finished product is obtained. The screening process is adopted for twice through the grinding technology and the method has the advantages that the technology is simple, cost is low, the prepared water-grinding glutinous rice flour is high in purity, low in impurity contents of fat, ash and the like, small in number of spots, high in whiteness and fineness and long in expiration date the mean grain size is in narrow distribution, the energy consumption is low, the production capacity is large and the like.

Owner:HENAN HUANGGUO GRAIN COMPANY

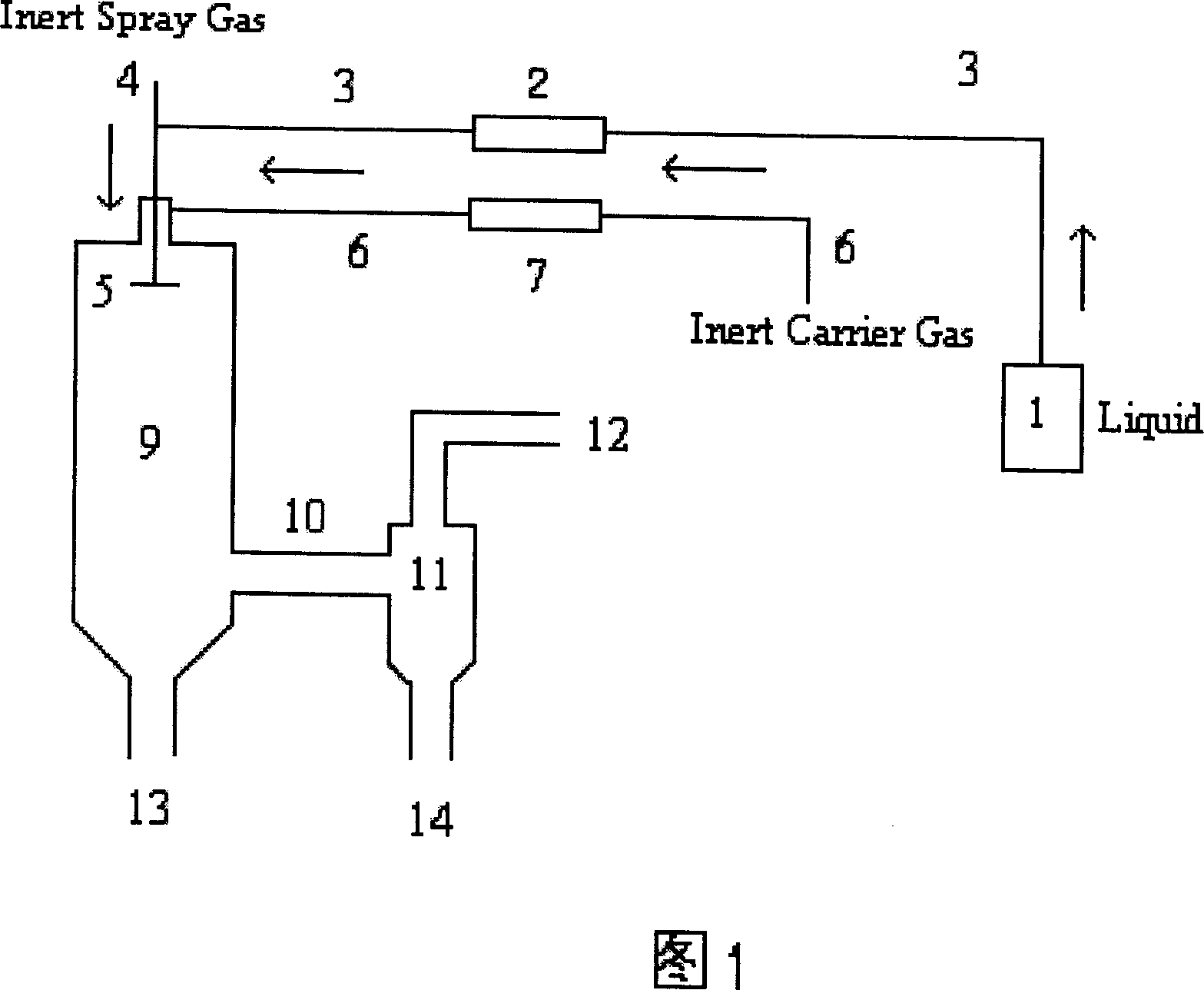

Iron/manganese catalyst used for Fischer Tropsch synthesis, its preparation method and application

ActiveCN1651138AHigh mechanical strengthReduce manufacturing costHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalManganese

An Fe / Mn catalyst for Fischer-Tropsch synthesis is prepared from Fe, Mn, Ni, alkali-earth metal, alkali metal and carrier proportionally through continuous coposition and spray drying. Its advantages are large specific surface area, high transform rate and high selectivity to hydrocarbon.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

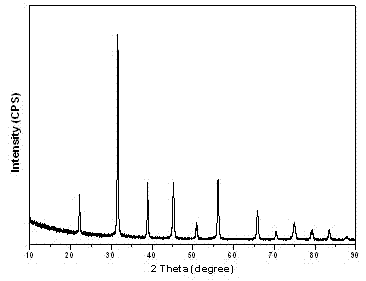

Preparation method of tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal

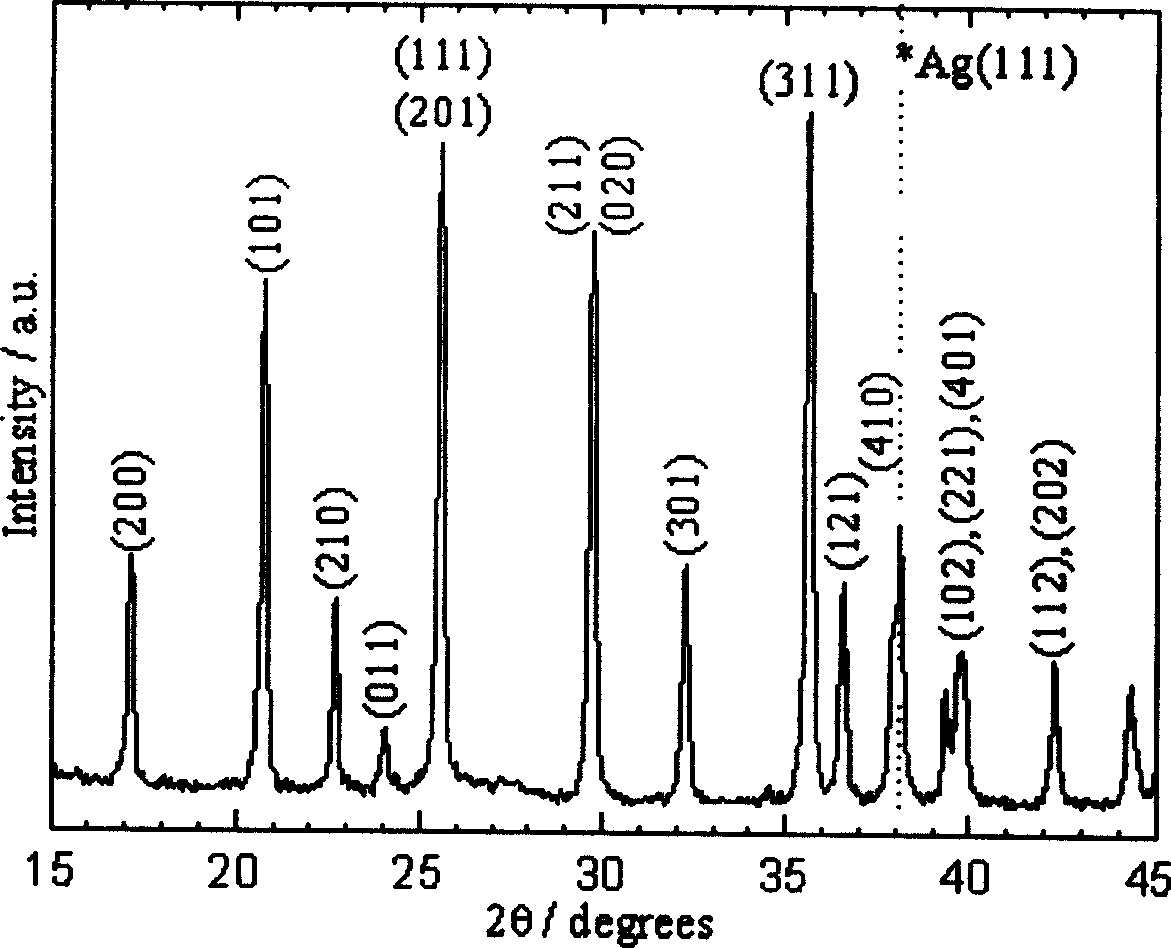

ActiveCN102887705AEasy purityA simple solvothermal method prepared high-purityBarium titanatePotassium hydroxide

The invention discloses a preparation method of a tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal. The preparation method comprises the following steps of: using barium acetate and tetrabutyl titanate as raw materials, adding deionized water, adding potassium hydroxide of an appropriate amount to promote crystallization, and carrying out hydrothermal reaction at the temperature of 110-240 DEG C so as to prepare the tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal. The preparation method is simple in technical process, easy in control, low in cost and easy in scale production. The prepared product is high in purity, good in crystallinity, good in dispersivity and narrow in particle size distribution. The product has wide application prospects in the fields of microelectronic devices, high-capacity capacitors, sensors, storage materials, piezoelectric ceramics, filters and the like.

Owner:ZHEJIANG UNIV

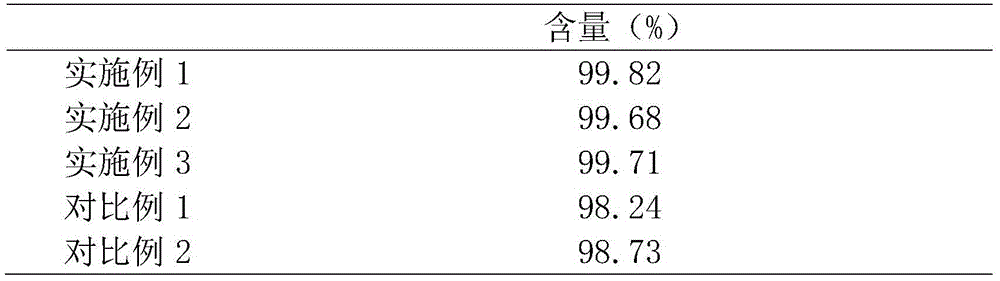

Method for extracting and separating shikimic acid from fructus anisi stellati

ActiveCN105601498ANarrow particle distributionImprove uniformityCarboxylic compound separation/purificationDesalinationElution

The invention discloses a method for extracting and separating shikimic acid from fructus anisi stellati. The method particularly comprises the following steps of 1 pretreatment, wherein an extract obtained by extracting the fructus anisi stellati is added to pure water with the weight equal to that of the extract, the materials are put into a high-speed dispersing and emulsifying machine to be treated, and a high-speed dispersed and emulsified mixture is obtained; 2 column chromatography, wherein the high-speed dispersed and emulsified mixture obtained in the first step passes through an anion resin column to enable the shikimic acid to be exchanged and adsorbed, elution is conducted with a sodium hydroxide solution, and eluent is obtained; 3 desalination, wherein the eluent obtained in the second step passes through a cationic resin column for desalination, and sodium salt is removed; 4 crystallization, wherein the desalinated eluent is concentrated and then added into acetone to enable the shikimic acid to be precipitated and crystallized, and then recrystallization is conducted with acetone.

Owner:GUANGXI WANSHAN SPICE

Iron/manganese catalyst used for Fischer Tropsch synthesis, its preparation method and application

ActiveCN1297343CNarrow particle distributionLarge specific surface areaHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPtru catalyst

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing carbon coated lithium ferrous phosphate composite material including metal conductive agent

InactiveCN1291508CImprove electronic conductivityImprove protectionElectrode manufacturing processesPhosphateHYDROSOL

This invention relates to a preparation method for LiFe PO4 / M / C compound positive material, the precursor of Li-Fe-PO4-M is synthesized with Li salt, Fe compound, phosphate, silver salt and organic acid as the raw materials by the sol-coagel method. Then the precursor mixed with pyrogenic-decomposed in inert atmosphere to get LiFePO4 / M / C compound positive material.

Owner:ZHEJIANG UNIV

Method of producing a catalyst for ethylene homo-and co-polymerization

InactiveUS7045478B2High bulk densityHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlcoholTitanium

The present invention relates to a catalyst for homo-polymerization or co-polymerization of ethylene, or more particularly to a solid complex titanium catalyst for homo-polymerization or co-polymerization of ethylene. The catalyst may be produced by preparing a magnesium solution by contact-reacting a magnesium halide compound with an alcohol. Reacting the solution with an ester compound and a boron compound. Then reacting the solution with a mixture of a titanium compound and a silicon compound.

Owner:SAMSUNG GENERAL CHEMICALS CO. LTD

Process of precipitation for spheric manganese carbonate and the products produced thereby

ActiveUS8211397B2High bulk densityImprove life characteristicsTwo-part coupling devicesIron compoundsSpherical morphologySpinel

Disclosed herein are a manganese carbonate useful as a material for spinel-type LiMn2O4, having a spherical morphology, and a method of preparing the same. The spheric manganese carbonate has a high packing density and shows superior lifetime characteristics, leading to spinel-type LiMn2O4 resistant to structural changes and having superior lifetime characteristics.

Owner:SK ON CO LTD

Hollowed wampee sauce and preparation method thereof

ActiveCN105639599ANarrow particle distributionImprove uniformityFood ingredient functionsEmulsionHigh pressure

The invention discloses a hollowed wampee sauce and a preparation method thereof. The method comprises the following steps: 1) selecting a raw material and treating; 2) performing high-speed dispersion emulsifying treatment: crushing hollowed wampee fruit obtained from step 1) with a beater, then adding pure water of the same weight, putting in a high-speed dispersion emulsifier to give a high-speed dispersion emulsion; 3) performing pressurized extraction: putting the emulsion treated in step 2) in a high pressure tank, pressurizing to 4kg / cm<2>, so that the pressure is uniform, and maintaining for 10-15min, then restoring to normal pressure in 1-3s, and obtaining a pulp extract mixture; 4) pickling: adding salt into the pulp extract mixture obtained from step 3) to be sealed in a container 3-4 months, 5) adding ingredients for pickling: taking out the pickled material obtained from step 4), adding the ingredients and mixing well, then adding to the sealed container to be pickled for 1-2 months; 6) subpackaging and sterilizing to obtain a finished product.

Owner:江苏大墩子银杏生物科技有限公司

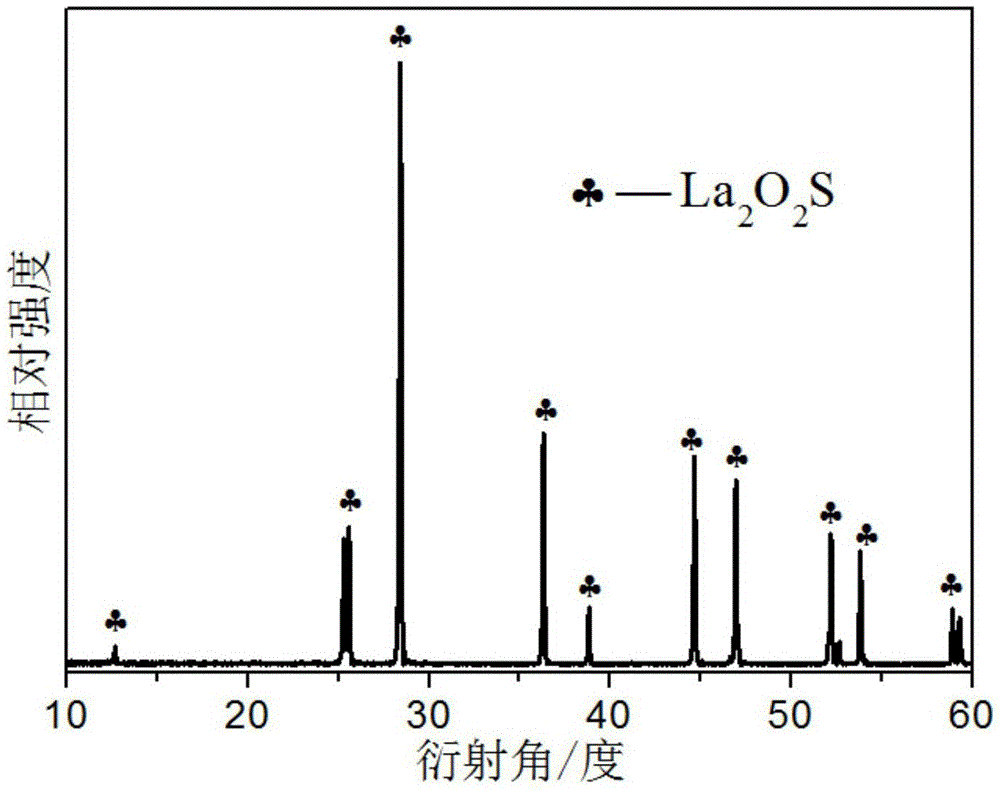

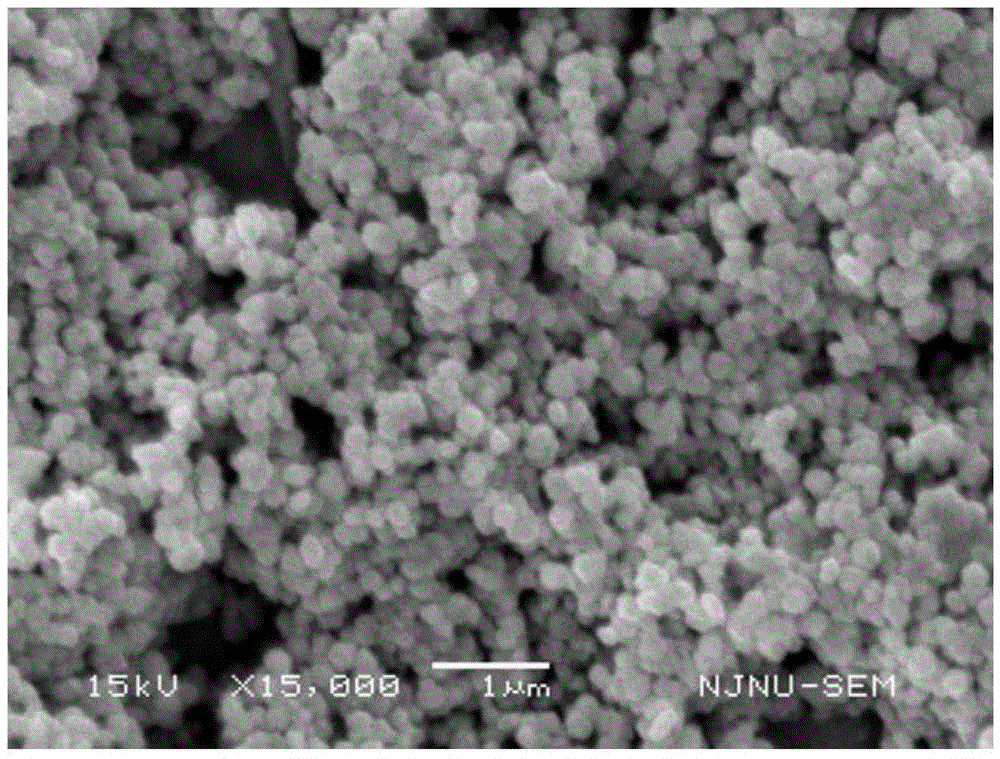

Zn reinforced rare earth sulfur oxide up-conversion luminescent material and preparation method thereof

ActiveCN105602564ALean structureLow phonon energyLuminescent compositionsLuminous intensityRare earth

The invention provides a Zn reinforced rare earth sulfur oxide up-conversion luminescent material and a preparation method thereof. The chemical formula of the material is (Ln1-x-y-zYbxREyZnz)2O2S, wherein the x is greater than or equal to 0.04 and is smaller than or equal to 0.2, the y is greater than or equal to 0.005 and is smaller than or equal to 0.02, the z greater than or equal to 0.005 and is smaller than or equal to 0.02, the Ln is one of La, Y and Gd, and the RE is one of Er, Ho, Tm, Pr, Eu and Tb. The luminous intensity of the material is greatly improved and is improved by 50%-120%. The preparation method of the material adopts a precipitator return-titration method to obtain rare earth oxide raw materials and then adopts a gas sulfidization method, the reaction conditions are simple and easy to control, the method can well keep the morphology and particle size of rare earth oxides, most of the rare earth sulfur oxide up-conversion luminescent materials prepared by means of the method are spherical, uniform in particle size and relatively smaller in particle size distribution range, and D90 is equal to 0.2-0.5 microns.

Owner:防城港市唐氏食品有限公司

Preparation method of water-in-oil type nanometer emulsion

InactiveCN105771714ASmall particle sizeNarrow particle distributionTransportation and packagingMixing methodsRoom temperatureOil phase

The invention discloses a preparation method of a water-in-oil type nanometer emulsion. The preparation method comprises the following steps: preparing and generating a water-in-oil type emulsion by utilizing T-type and Y-type furcated combination channels; in a dispersion phase containing an oil or water component, diluting the water-in-oil type emulsion through adding a nonionic polymer surfactant, simultaneously stirring for more than 5 minutes at a certain stirring speed and dropwise adding a certain volume of water at the same stirring speed; controlling the temperature of the water-in-oil type emulsion to be 5-60 DEG C under the action of stirring and keeping the temperature for 3-6 minutes; adding a solution containing an aqueous solution and a hydrophilic surfactant component in the water-in-oil type emulsion, wherein the volume ratio of an oil phase to a water phase is not less than 7:3, and the ratio of the total mass of the surfactant to the mass of the water phase is 0.3-1.0; then enabling the temperature of the whole system to reach a room temperature under stirring so as to prepare the stable water-in-oil type nanometer emulsion. A low-energy emulsification method coupling the component and the temperature overcomes the defect of limited applicability of a conventional low-energy emulsification method and has the advantages of being wider in applicability, low in energy consumption and low in cost.

Owner:SOUTHEAST UNIV

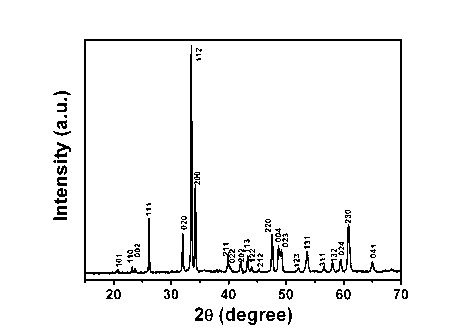

Preparing process of double-perovskite Y2MNCoO6 dielectric ceramic

The invention provides a preparing process of double-perovskite Y2MnCoO6 dielectric ceramic, relates to a ceramic preparing process and aims at solving the defects existing in the traditional preparing process of Y2MnCoO6 dielectric ceramic that the process is heavy and complicated, the finished product is poor in condition and the like. The invention provides a sol-gel method, comprising the steps of: mixing and dissolving ingredients, adding corresponding catalyst or complexing agent, drying, pyrolyzing, grinding, prefiring, and firing to prepare Y2MnCoO6 dielectric ceramic. The obtained Y2MnCoO6 dielectric ceramic can be widely applied to the field of ceramic things.

Owner:HENAN UNIV OF SCI & TECH

High-activity carbon-supported platinum catalyst for low-platinum-loading proton exchange membrane fuel cell and preparation method thereof

InactiveCN110993974ANothing producedHigh purityMaterial nanotechnologyCell electrodesActivated carbonPtru catalyst

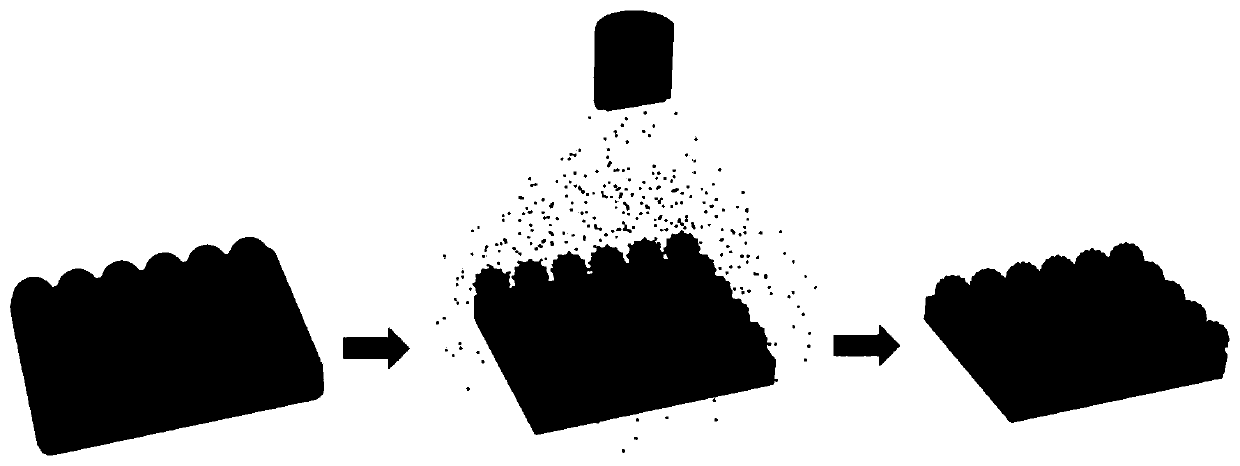

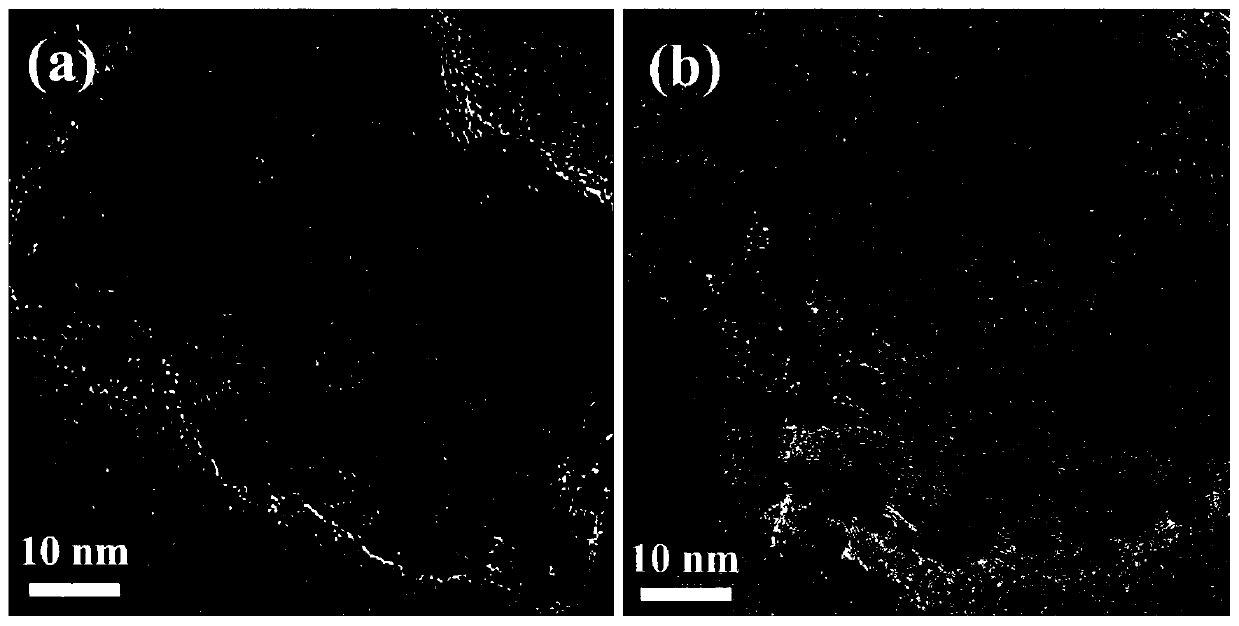

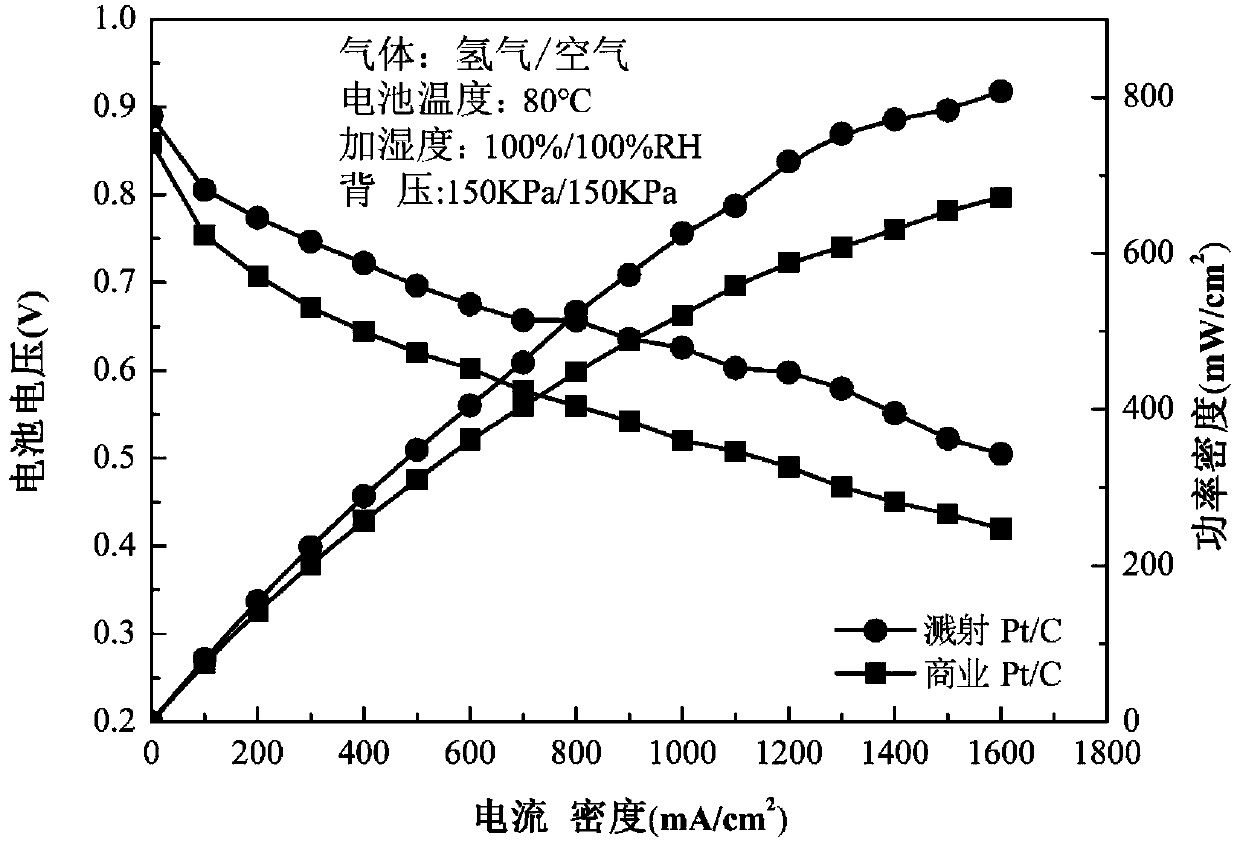

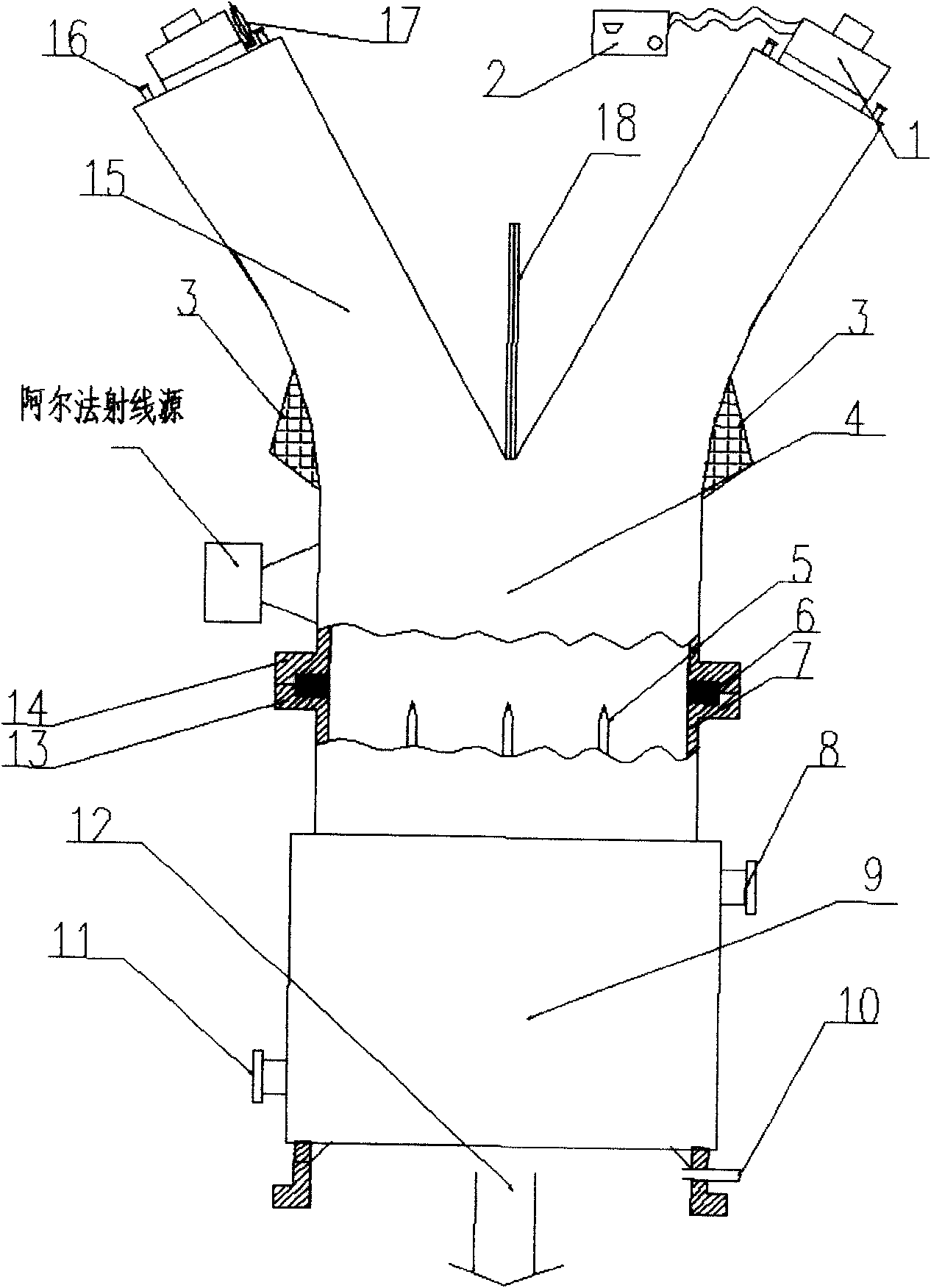

The invention discloses a high-activity carbon-supported platinum catalyst for low-platinum-loading proton exchange membrane fuel cell and a preparation method thereof. The method comprises the following steps: (1) purifying carbon powder; (2) preparing carbon ink, namely mixing carbon powder, isopropanol, deionized water and zirconium oxide balls, and performing ball milling to obtain the carbonink; (3) preparing an ultrathin carbon powder layer, namely dripping carbon ink into a flat-bottom vessel filled with deionized water, uniformly spreading the carbon particles on the water surface, and performing drying to form the ultrathin carbon powder layer; and (4) preparing the high-activity carbon-supported platinum catalyst, namely preparing the high-activity carbon-supported platinum catalyst by taking the ultrathin carbon powder layer as a substrate and sputtering platinum through magnetron sputtering. The Pt average particle size of the prepared high-activity carbon-supported platinum catalyst is 3 nm, distribution is uniform, the particle size range is 2.5-3.5 nm, and the size distribution range is narrow. The carbon-supported platinum catalyst can be applied to a cathode catalyst layer of a proton exchange membrane fuel cell, and compared with commercial Pt / C, the power density of the cell is greatly improved.

Owner:WUHAN UNIV OF TECH

Process and device for preparing nano-powder by utilizing ultrasonic static electricity

InactiveCN101623616AGood monodispersityReduce reunionGranulation by liquid drop formationChemical/physical/physico-chemical nozzle-type rreactorsEngineeringPollution

The invention provides a process and a device for preparing nano-powder by utilizing ultrasonic static electricity. The process and the device combine the advantages of ultrasonic atomization and static atomization and skillfully overcome the disadvantages of the two. The process mainly comprises the following steps that: raw material is heated to be in a liquid state through a heating furnace, degassed through a degassing device and then conveyed to an atomizer through a pipeline; the raw material in the atomizer is first precharged via a precharging device and then is guided into a nozzle of a piezoelectric-type ultrasonic atomization system through a flow-guiding pipe in order to be atomized; the obtained material is accelerated through a primary acceleration-ring group, enters an inductive charging ring, and is charged and atomized again; the atomized raw material is accelerated through a secondary acceleration-ring group, joined and mixed through a Y-shaped pipe; mixed compounded fog drops are irradiated with an alpha ray source to remove surface charge; the charge-removed fog drops pass through a flow-guiding device (a resistance-wire heating pipe is arranged in the flow-guiding device to perform corresponding thermal decomposition on the fog drops needing thermal decomposition), enter a condenser, are condensed into solid powder; and the solid power leaves the atomizer and then enters a collection device in order to be collected. Therefore, the nano-powder with product stability, high performance, narrow particle distribution, uniform particle distribution, good monodispersity, little agglomeration, high purity and good sphericity can be prepared by utilizing equipment which is simple, low in cost, free from pollution, easy to control and suitable for large-scale continuous industrial production.

Owner:李洋

Illicium verum liquor and making method thereof

ActiveCN105602796ANarrow particle distributionImprove uniformityDigestive systemAlcoholic beverage preparationBiotechnologyIllicium verum

The invention discloses a making method of an illicium verum liquor. The making method includes the following steps that 1, raw materials are selected and processed: fresh or dried illicium verum fruits are selected, fruits with diseases and pests, decayed fruits, rotten fruits and immature fruits are removed, and cleaning is performed; 2, high-speed dispersing emulsification processing is performed: the illicium verum fruits are smashed, the same weight of pure water is added, the fruits are put in a high-speed dispersing emulsification machine for processing to obtain a high-speed dispersed emulsified material; 3, steam explosion processing is performed: the high-speed dispersed emulsified material obtained the step 2 is put into a steam explosion tank to be processed, wherein the explosion pressure is 3.0-3.5 Mpa, and the holding time is kept to 150-200 s; 4, fermentation is performed: the material obtained in the step 3 is transferred to a fermentation tank, high-activity yeast liquid is added, and fermentation is performed at the fermentation temperature of 20-25 DEG C for 15-20 days; 5, mixing and aging are performed: the fermented illicium verum liquid is transferred to another tank, is subjected to standing, clarification and filtration and is transferred to an aging tank, and the aging is performed for 10-15 days; 6, blending, filtering, filling and sterilization are performed to obtain a finished product.

Owner:GUANGXI WANSHAN SPICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com