High-activity carbon-supported platinum catalyst for low-platinum-loading proton exchange membrane fuel cell and preparation method thereof

A proton exchange membrane, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of wide particle size distribution of Pt particles, complex reduction and purification processes, acceptable battery power density, etc. The effect of increased density and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

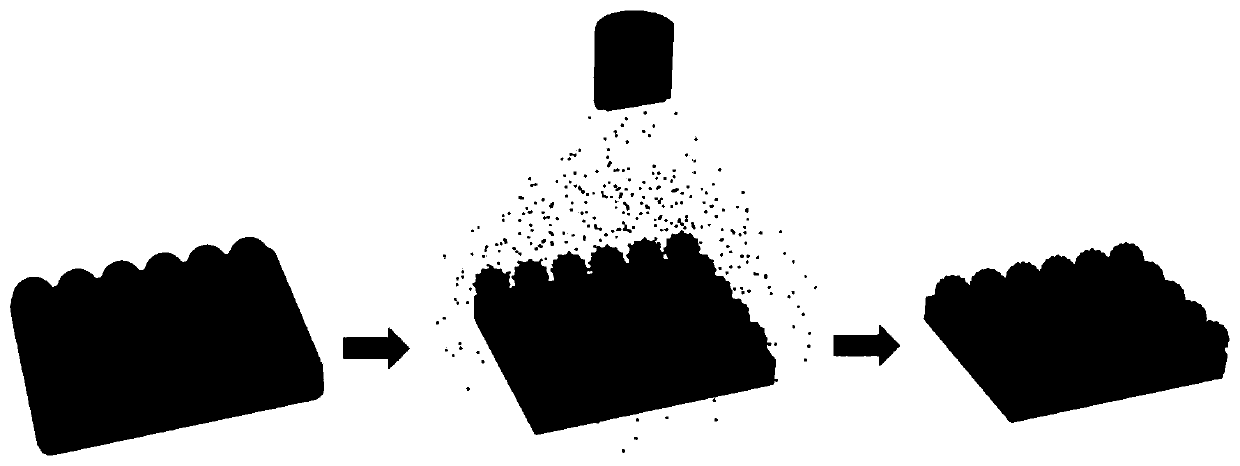

[0032] A method for preparing a highly active carbon-supported platinum-type catalyst for a proton exchange membrane fuel cell with a low platinum loading capacity, comprising the following preparation method:

[0033] (1) Purified carbon powder;

[0034] (2) Preparation of carbon ink:

[0035] Mix carbon powder, isopropanol, deionized water and zirconia and ball mill it;

[0036] (3) Preparation of ultra-thin carbon powder layer:

[0037] Add the carbon ink into a flat-bottomed vessel filled with deionized water, spread the carbon particles evenly on the water surface, and form an ultra-thin carbon powder layer after drying;

[0038] (4) Preparation of highly active carbon-supported platinum catalyst:

[0039] Using ultra-thin carbon powder layer as substrate, platinum was sputtered by magnetic sputtering to prepare highly active carbon-supported platinum catalyst.

[0040] Further, the method of described step (1) purifying carbon powder is: carbon powder is added to H ...

Embodiment 1

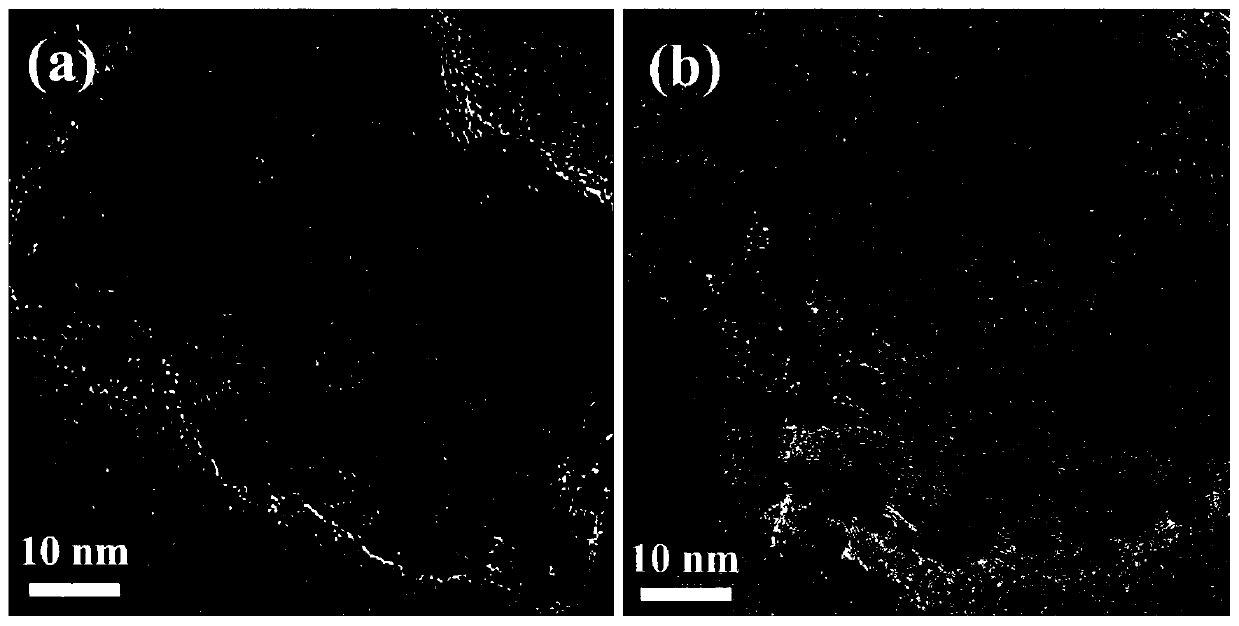

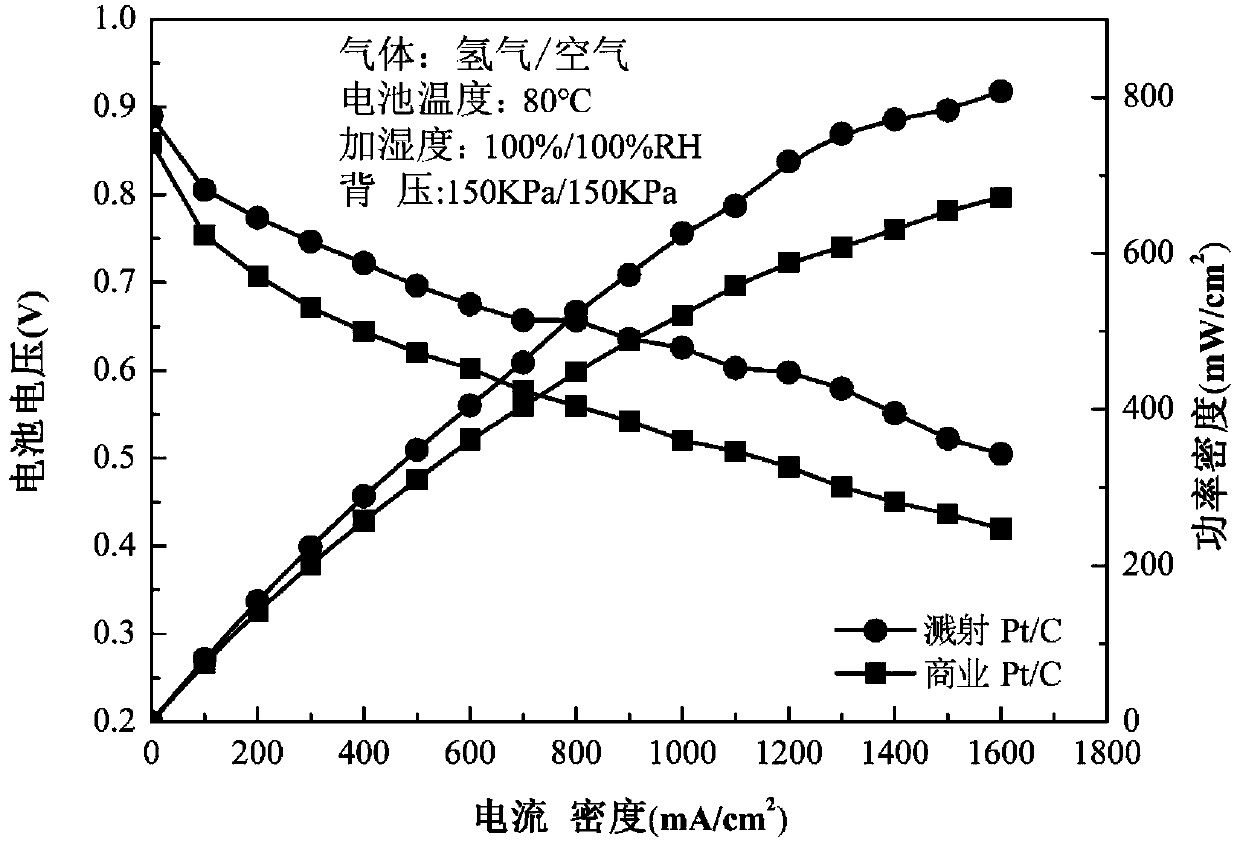

[0049] Highly active carbon-supported platinum catalyst

[0050] The preparation method is as follows:

[0051] (1) Purified carbon powder:

[0052] Add toner (Vulcan XC-72) to H 2 o 2 It can be obtained by ultrasonic cleaning in a mixed solution of concentrated sulfuric acid, where H 2 o 2 Concentration is 30wt.%, concentrated sulfuric acid concentration is 98wt.%, H 2 o 2 The mass ratio to concentrated sulfuric acid is 3:1.

[0053] (2) Preparation of carbon ink:

[0054] Mix 0.15 g of carbon powder, 3.35 g of isopropanol, 4 g of deionized water, and 9 g of zirconia balls, put them into a ball mill jar, and take them out after 1.5 hours of ball milling.

[0055] (3) Preparation of ultra-thin carbon powder layer preparation:

[0056] Slowly drop the carbon ink into a petri dish filled with deionized water, so that the carbon particles spread evenly on the water surface to form an ultra-thin toner layer, and place it in a vacuum drying oven at 100°C for 6 hours. The u...

Embodiment 2

[0060] Highly active carbon-supported platinum catalyst

[0061] The preparation method is as follows:

[0062] (1) Purified carbon powder:

[0063] Add toner (Vulcan XC-72) to H 2 o 2 It can be obtained by ultrasonic cleaning in a mixed solution of concentrated sulfuric acid, where H 2 o 2 Concentration is 30wt.%, concentrated sulfuric acid concentration is 98wt.%, H 2 o 2 The mass ratio to concentrated sulfuric acid is 3:1.

[0064] (2) Preparation of carbon ink:

[0065] Mix 0.15 g of carbon powder, 2.25 g of isopropanol, 3 g of deionized water, and 7.5 g of zirconia balls, put them into a ball mill jar, and take them out after 1.5 hours of ball milling.

[0066] (3) Preparation of ultra-thin carbon powder layer preparation:

[0067] Slowly drop the carbon ink into a petri dish filled with deionized water, so that the carbon particles spread evenly on the water surface to form an ultra-thin toner layer, and place it in a vacuum drying oven at 100°C for 6 hours. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com