Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

323results about How to "Increase the calorific value of combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

Halogen-free synergistic flame-retardant silica aerogel preparation method

InactiveCN106244172AAvoid the problem of increased calorific value of combustionIncrease the calorific value of combustionSilicaSolventThermal insulation

The invention discloses a halogen-free synergistic flame-retardant silica aerogel preparation method, which comprises: S1, mixing a halogen-free flame retardant agent, an inorganic synergist and a first solvent, and carrying out ball milling dispersing to obtain a suspension A; S2, uniformly mixing a silicon source and water, adding an acidic aqueous solution, uniformly mixing to obtain a silicic acid sol, adding the suspension A obtained in the S1 to the silicic acid sol, uniformly mixing, adjusting the pH value to 5-6, adding a drying control chemical additive, stirring, heating, carrying out thermal insulation, and crushing to obtain a sol B; and S3, taking the sol B obtained in the S2, carrying out solvent exchange, modifying with a silane coupling agent, and drying to obtain the halogen-free synergistic flame-retardant silica aerogel. According to the present invention, the halogen-free synergistic flame-retardant silica aerogel has advantages of good flame-retardant property, low combustion heat value, low density, good hydrophobicity, large specific surface area, simple operation, and low production cost.

Owner:ECONANO TECH LTD BEIJING

Solid alcohol fuel and its preparing method

InactiveCN1944603AEasy to igniteIncrease the calorific value of combustionSolid fuelsAlcohol fuelParaffin wax

The present invention discloses one kind of solid alcohol fuel, which is prepared with industrial alcohol 90.73 wt%, stearic acid 4.76 wt%, NaOH 0.62 wt%, paraffin 1.30 wt% and distilled water 2.59 wt%, and through two steps at temperature of 70deg.C. The solid alcohol fuel has easy ignition, high heat value, no black smoke and bad smell produced during burning and other features. Especially, it can burn stably in anoxic condition, so that it is suitable for use in plateau and upland.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

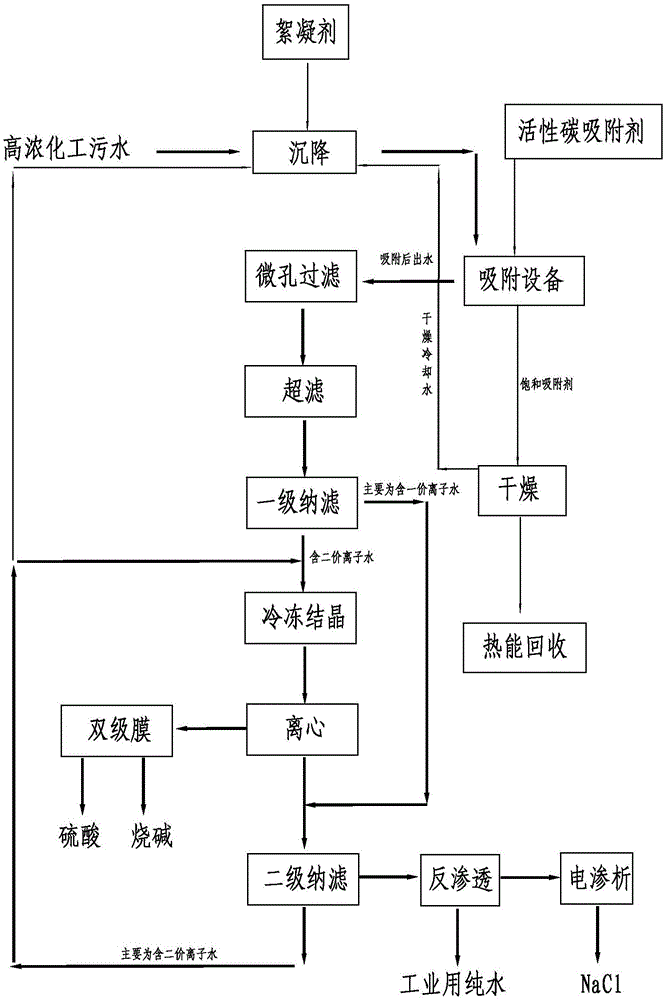

Comprehensive treatment process of waste water high in concentration and high in salinity

ActiveCN105016530AEasy to getEasy to operateMultistage water/sewage treatmentAlkali metal chloridesFiltrationReverse osmosis

The invention relates to a comprehensive treatment process of waste water high in concentration and high in salinity. The process comprises the steps of centralizing the waste water, adding organic flocculant, and sedimentating large particle impurities and a large proportion of suspended matters and floating objects; adding activated carbon absorbent for absorbing organic matters; conducting filtration, removing granular impurities, colloidal substances and suspended matters in water, and then separating monovalent ions and divalent ions in the waste water through first-grade nanofiltration; making water containing the monovalent ions to be subjected to reverse osmosis, and obtaining pure water which can be used as industrial water; making concentrated water to be subjected to electrodialysis for concentrating monovalent salt, and obtaining NaCl accessory substances; making water containing the divalent ions to be subjected to freezing crystallization, conducting the centrifugation, making crystal body sections to be subjected to two-stage membrane electrodialysis, obtaining acid-alkali products, and making a water layer to be subjected to nanofiltration treatment; making the saturated absorbent which absorbs the organic matters to be subjected to dewatering and drying, and conducting the recycling. According to the comprehensive treatment process of the waste water high in concentration and high in salinity, the cost is low, the organic matters and inorganic salt in the waste water can be removed simultaneously and then utilized, energy is saved, and the environment is protected.

Owner:沧州绿源水处理有限公司

Alcohol base liquid fuel

The composition of alcohol base liquid fuel includes 50 portions of 99.9% methyl alcohol and 10 portions of 95% butyl alcohol as main burning agent, 10 portions of 98% ethyl alcohol as dispersing agent, 10 portions of industrial glycerine as solidifying agent, 1.5 portions of potassium permanganate as oxygenation agent, 0.8 portion of isobutyl alcohol as cosolvent, 0.5 portion of nonane, 0.5 portion of cyclohexane, 1 portion of n-octane, 1 portion of ethane as boiling point and flashing point regulating agent, 1.2 portions of triethanolamine as anticorrosive and carbon deposition resisting agent, 2.5 portions of rose essence and 1 portion of lavender oil as small-regulating agent and 10 portions of combustion promotor. Said invention also provides its preparation method.

Owner:TIANJIN HONGBO ENVIRONMENT PROTECTION FUEL NEW ENERGY SOURCE

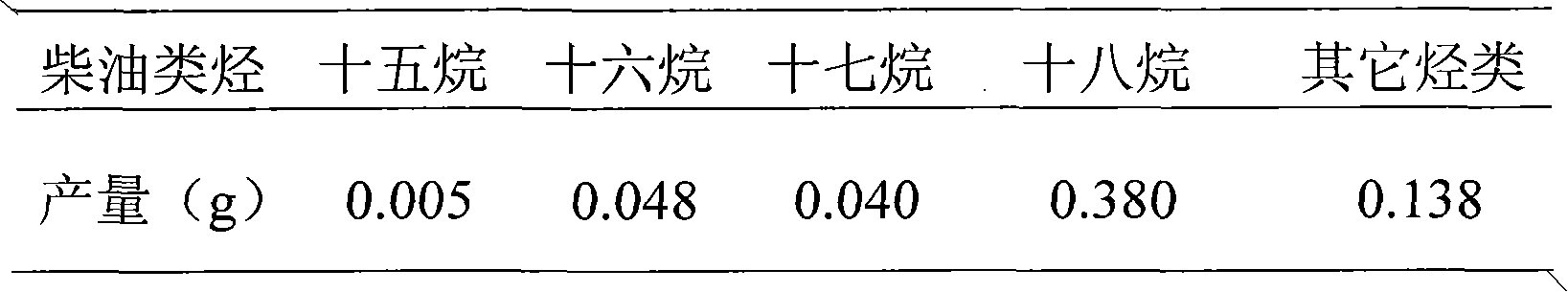

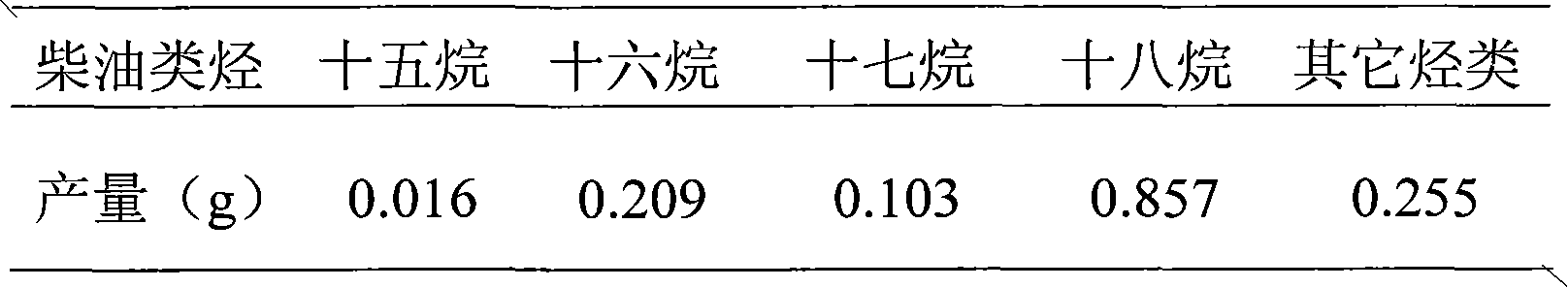

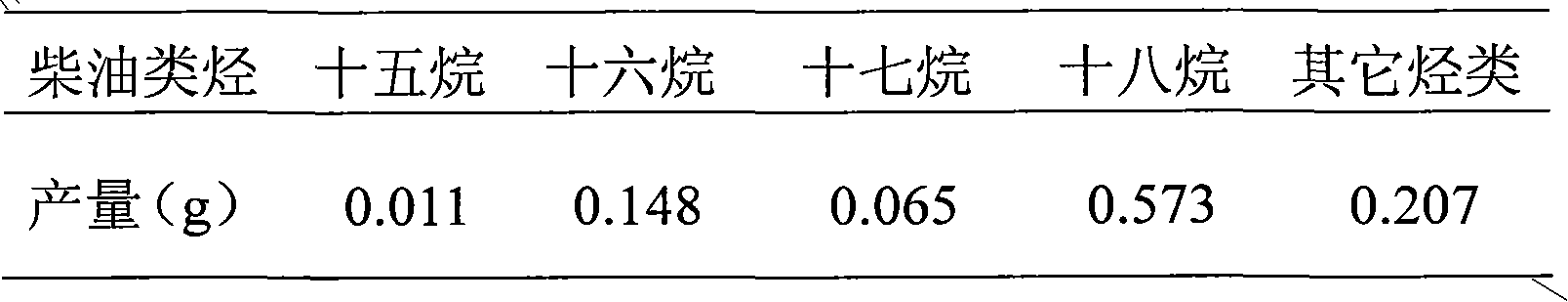

Method for preparing diesel hydrocarbons from vegetable fat through catalytic hydrogenation and deoxygenation

InactiveCN101899318AReduce manufacturing costConducive to large-scale industrialization promotionBiofuelsLiquid hydrocarbon mixture productionAlkaneHydrogen

The invention discloses a method for preparing diesel hydrocarbons from vegetable fat through catalytic hydrogenation and deoxygenation, is a method for preparing alkane with a high calorific value from vegetable fat through catalytic hydrogenation and deoxygenation, and adopts a one-pot method reaction process, comprising the following steps: adding a molybdenum carbide catalyst, vegetable fact and solvent in a reactor, filling hydrogen in the reactor, stirring and heating, reacting for 3-10h with the reaction pressure of 1-10MPa and the reaction temperature of 250-350 DEG C, stopping reaction, cooling to room temperature, filtering and separating the catalyst out to obtain the diesel hydrocarbons with alkane at a high calorific value. By adopting the technical scheme in the invention, the method has low production cost and high product combustion value, is favor of large-scale industrialized popularization and is a clean and regenerative diesel alternative fuel.

Owner:ZHEJIANG UNIV

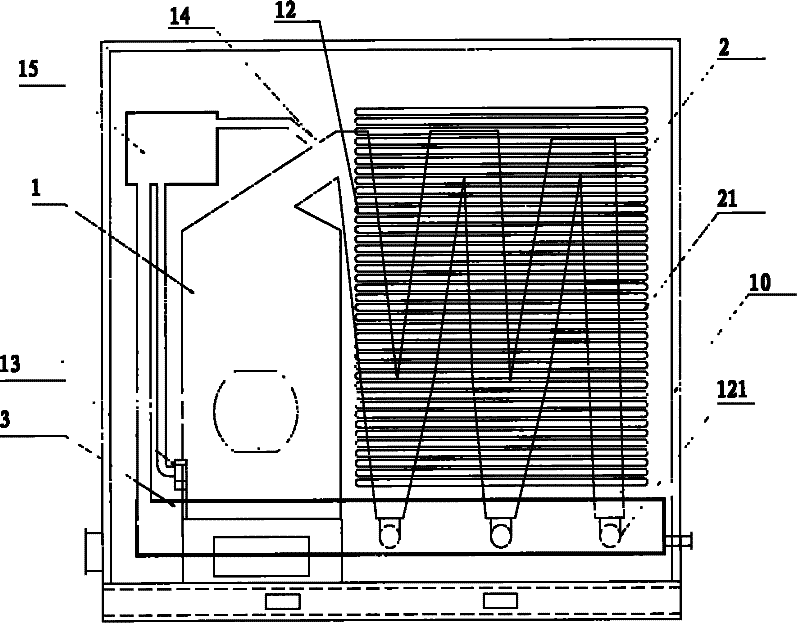

Heating device

InactiveCN101701747BImprove sedimentation removal effectEnvironmental protectionStationary conduit assembliesEnvironmental resistanceCombustion

The invention relates to a heating device which comprises a heating furnace and at least one heat exchange compression box connected with the heating furnace. The heating device is characterized in that an air inlet pipe and an exhaust pipe are arranged in the heat exchange compression box, one end of the air inlet pipe is connected with the heating furnace, the other end is communicated with theexhaust pipe through at least three rows of S-shaped and at least three layers of S-shaped heat exchange pipes, the air inlet pipe is continuously bent like V, a dust collection chamber is arranged at the tail end of the lower part of each V-shaped bending part, and a water circulation cooling system is arranged in the dust collection chambers and the heating furnace. The heating device can effectively settle dust in the air, avoid pipelines from being blocked by the dust, improve the combustion heat value, prolong the service life of the device and realize the significant effects of environmental protection and energy conservation.

Owner:童书开

Water resistance vegetable composite oil phase

The invention relates to a water resistance vegetable composite oil phase which comprises the following components in percent by mass: 5-30 percent of hydrogenated vegetable fatty acid, 5-20 percent of vegetable wax, 20-50 percent of vegetable oil foot, 5-20 percent of vegetable oil and fat, 20-50 percent of decompressed cerate and 0.5-3 percent of surfactant. The water resistance vegetable composite oil phase is prepared by adopting the following steps of: firstly, heating various components in a single melting tank to the temperature of 75-85 DEG C and melting; and sequentially pumping the components into a reaction kettle through an oil pump according to the proportion requirement after weighted through an electronic scale, stirring, raising the temperature to 105-110 DEG C, starting a vacuum pump for dewatering, filtering, forming and packaging. The invention overcomes the defect of water resistance of the modified ammonium nitrate fuel oil explosive and extruded explosives, and provides a high-quality and low-cost water resistance vegetable composite oil phase used for the modified ammonium nitrate fuel oil explosive and extruded explosives; and the explosives produced by using the composite oil phase have excellent water resistance, and especially the extruded explosives really have excellent water resistance.

Owner:谢斌

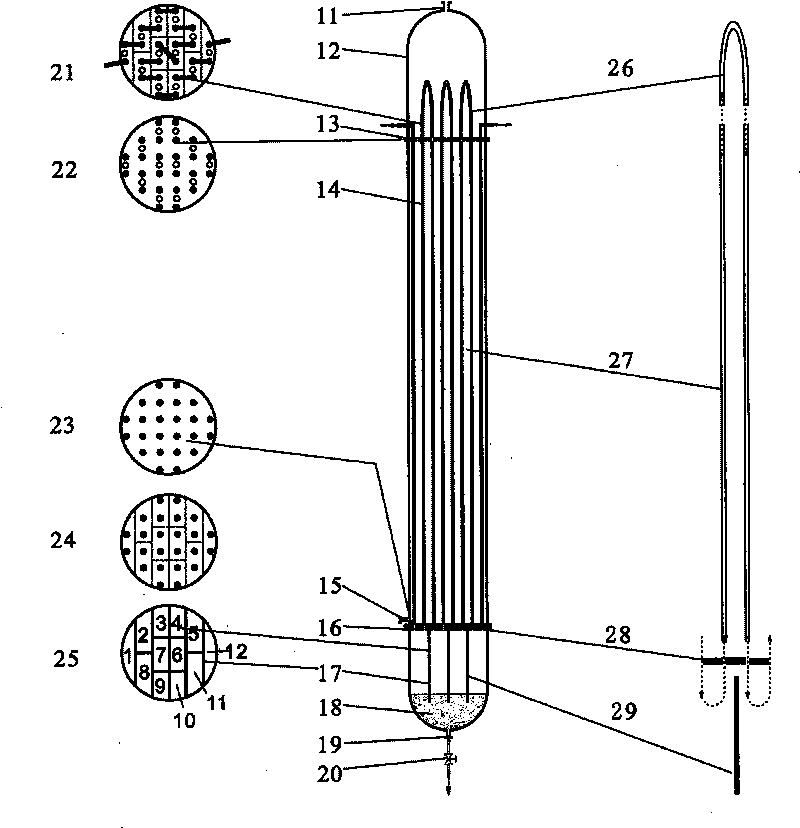

Method for largely, industrially and synthetically treating and using plant stem leafs and device thereof

ActiveCN101724659AAchieve purificationRealize continuous productionPreparation by oxidation reactionsBio-organic fraction processingMarshSlag

The invention discloses a method for synthetically treating and using plant stem leafs and straws in large scale and a device thereof. The method comprises the steps of: taking the plant stem leafs and straws as raw materials; and generating marsh gas, marsh slag and marsh liquid by means of microbial fermentation. The marsh gas is collected by the technology of the invention to be synthesized into fuel carbinol, or is purified and liquefied to be used as fuel for a vehicle to replace the natural gas; and the marsh slag and the marsh liquid are taken as fertilizer to be returned to the soil to maintain the ecological balance of the soil.

Owner:张永北

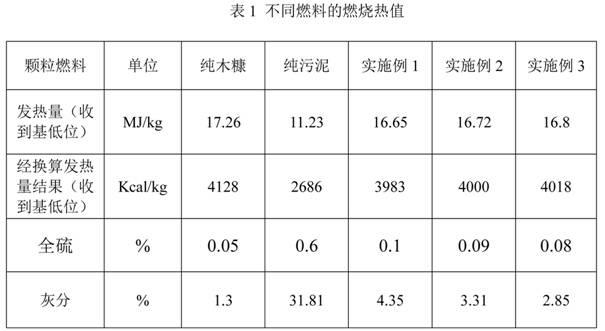

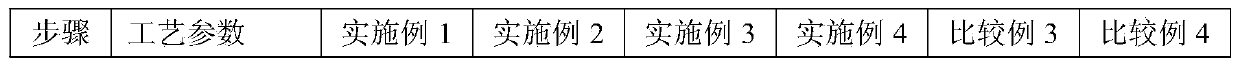

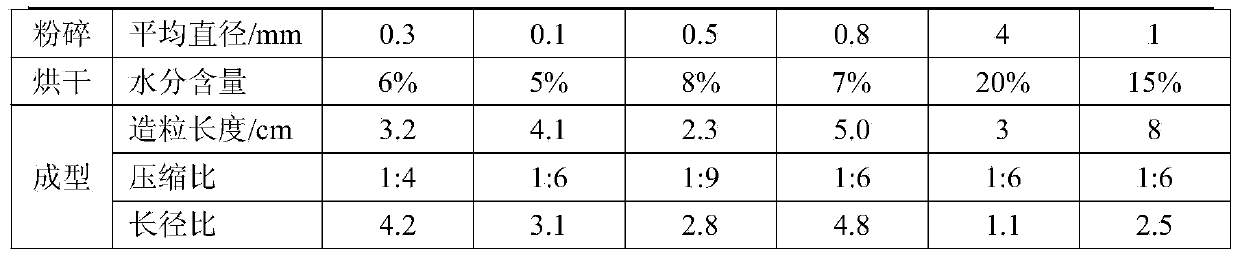

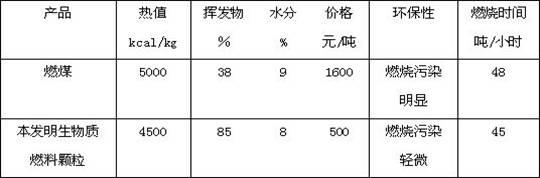

Environment-friendly biomass granular fuel and preparation method thereof

The invention discloses an environment-friendly biomass granular fuel, which comprises the following components in part by weight: 80-85 parts of sawdust, 5-10 parts of sludge and 0.1-1 part of illegally recycled waste cooking oil. A preparation method of the environment-friendly biomass granular fuel comprises the following steps: drying the sawdust and the sludge, adding the illegally recycled waste cooking oil to the sawdust and the sludge, agitating the mixture uniformly, and processing the mixture into cylindrical grains under conditions of a high temperature and a high pressure. By using the biomass granular fuel provided by the invention, the production cost is decreased; the energy consumption is decreased; the combustion heat value is high; the combustion time is long; the wear of a machine is reduced; the environment is protected effectively; the fuel problem is solved; simultaneously, the health is also protected; the biomass granular fuel is environment-friendly; the cost is decreased; after the biomass granular fuel is combusted, waste residues can be returned to the nature to be used as a fertilizer, and also can be used as a raw material of an environment-friendly brick; and the resource utilization and the harmless treatment of waste materials such as the sludge, the illegally recycled waste cooking oil and the like are achieved.

Owner:曹其宽

Composite biomass granular fuel and its processing technology

ActiveCN103224823AImprove combustion qualityIncrease the calorific value of combustionBiofuelsSolid fuelsPeanut hullBiomass burning

The invention discloses a composite biomass granular fuel and its processing technology. The formula of the composite biomass granular fuel comprises the following components: by weight, 15-20% of peanut shell, 15-20% of wood chip, 40-50% of rice husk, 8-12% of grease, 6-10% of a gangue powder and 0.5-1% of calcium oxide. The processing technology comprises the following steps: crushing peanut shell, rice husk and wood chip into powders according to the above proportions of the formula, adding grease, gangue powder and calcium oxide, uniformly mixing, compressing, screening, and packaging to prepare the biomass granular fuel. The composite biomass granular fuel prepared in the invention has high fuel value, is not easy to form slag, and can be widely applied in various biomass combustion apparatuses.

Owner:襄阳广盛木业有限公司

Biomass wood sawdust pellet fuel and preparation method thereof

ActiveCN103992835AExtended burn timeImproved thermal efficiency and combustion rateBiofuelsSolid fuelsThermal efficiencySawdust

The invention discloses a biomass wood sawdust pellet fuel and a preparation method thereof. The biomass wood sawdust pellet fuel contains the ingredients in parts by weight: 5-15 parts of pine wood sawdust and 60-100 parts of hard miscellaneous wood sawdust, wherein the hard miscellaneous wood sawdust contains two or more of toothed oak wood sawdust, olive ash wood sawdust, ash wood sawdust, birch wood sawdust, elm wood sawdust, jujube wood sawdust and oak wood sawdust. The biomass wood sawdust pellet fuel has the advantages that the combustion time is prolonged and the calorific value of combustion, combustion rate and thermal efficiency are remarkably increased while the requirements on energy saving and environmental friendliness are met.

Owner:联合优发生物质能源徐州有限公司

Biomass fuel particle and preparation method thereof

The invention discloses a biomass fuel particle. 70-80 percent by weight of biomass fuel raw material, 5-20 percent by weight of palm meal and 5-20 percent by weight of chemical mud alcohol-precipitation substance which are used as raw materials are uniformly mixed and are compressed into square or cylindrical biomass fuel particle by using a special press block complete machine. The biomass fuel particle has the advantages of smoothness in surface, tight texture, low breaking rate, remarkably-improved production efficiency and less wear on a mechanical die.

Owner:天津市施乐德科技有限公司

Emulsification diesel fuel additive, emulsification diesel fuel using the same and preparation method thereof

InactiveCN101058747AGood miscibilityImprove stabilityRefining by water treatmentEmulsionAnti oxidant

The invention discloses an emulsion diesel additive and emulsion diesel and making method, wherein the emulsion diesel additive is composed of anti-oxidant, metal passivator and cetane number modifier; the emulsion diesel contains 30-100g water, 3-40g lipophilic emulsifier, 0. 5-20g hydrophilic emulsifier and 0. 1-10g emulsion diesel additive. The invention is compatible with emulsion diesel with high stable, which can be reserved for a long time.

Owner:刘同元

Fireworks and crackers blasting-agent composition

The invention discloses a fireworks and crackers blasting-agent composition. Agents in the fireworks and crackers blasting-agent composition include, by weight, 40%-60% of potassium perchlorate, 15%-30% of potassium acid phthalate, 10%-20% of a metal-filled multi-walled carbon nanotube, 5%-10% of metal oxide and 3%-5% of black powder, the multi-walled carbon nanotube is filled with one or more combinations of metals of aluminum, silver, iron, nickel, potassium, magnesium, lithium, sodium and the like, and the metal oxide is one or more combinations of ferroferric oxide, iron sesquioxide, copper oxide, manganese oxide, zinc oxide, cobalt oxide and aluminum oxide. The fireworks and crackers blasting composition agents free from metal powder are obviously improved in security coefficient, the explosion dynamics of the agents is high, burning rate of bright points is high, shelf life is long and blasting effect is good.

Owner:WANZAI JIANKUN CHEM

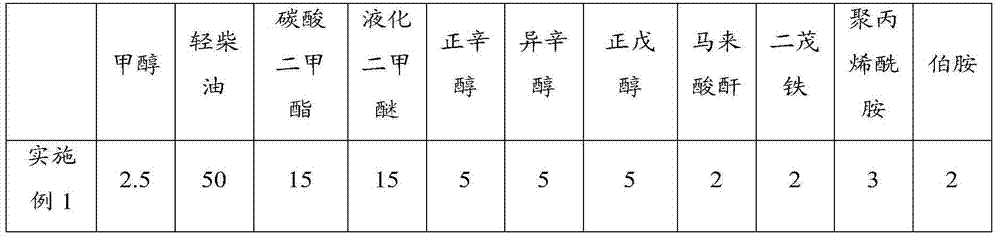

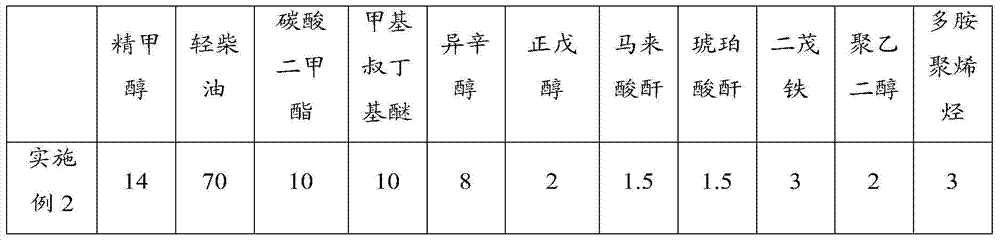

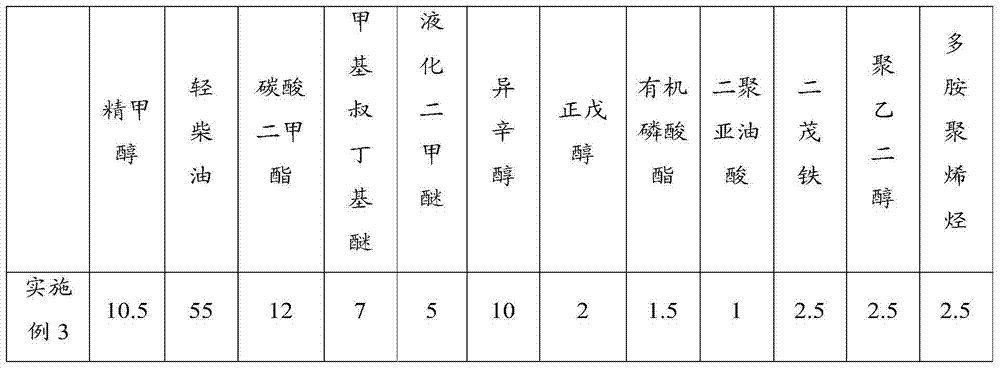

Methanol-diesel oil additive and preparation method thereof

InactiveCN104745243AImprove economyStrong social benefitsLiquid carbonaceous fuelsAlcoholMethyl carbonate

The invention provides a methanol-diesel oil additive and a preparation method thereof. The methanol-diesel oil additive is mainly prepared from the following raw materials in parts by mass: 2.5-14 parts of methanol, 50-70 parts of light diesel oil, 10-15 parts of dimethyl carbonate, 10-15 parts of ether, 10-15 parts of alcohol, 2-3 parts of a preservative, 2-3 parts of a cosolvent, 2-3 parts of an antioxidant and 2-3 parts of a dispersant, wherein the ether contains 2-5 carbon atoms and the alcohol contains 5-9 carbon atoms. The preparation method comprises the following steps: mixing and stirring the methanol and the cosolvent and fully dissolving so as to obtain modified methanol; uniformly stirring and mixing the modified methanol with the light diesel oil and dimethyl carbonate so as to obtain a mixture; and sequentially adding the ether, the alcohol, the preservative, the antioxidant and the dispersant to the mixture, and uniformly mixing and stirring so as to obtain the methanol-diesel oil additive. According to the embodiment disclosed by the invention, the methanol-diesel oil additive has the effects of being environment-friendly, good in intersolubility with diesel oil, enough in power, not changing a car and capable of keeping the original structure of the car, and the like.

Owner:张东宁

Preparation method of biomass particle carbon

InactiveCN107365615ABurn completelyImprove combustion efficiencyBiofuelsSolid fuelsCarbonizationSulfide

The invention relates to the technical field of biomass fuel and aims at providing a preparation method of biomass particle carbon with a high calorific value and a low clinkering rate. The preparation method of the biomass particle carbon is characterized by comprising the following steps of: raw material pretreatment, extrusion forming and carbonization refining, wherein the carbonization refining is to heat a biomass particle after the extrusion forming under an air isolated condition, carbonize the biomass particle and remove impurities such as sulfide in the biomass particle; the biomass particle carbon comprises the following raw materials in parts by weight: 20-30 parts of crop straw, 10-20 parts of bagasse, 30-40 parts of bamboo scrap, 80-90 parts of wood chip, 4-5 parts of flame accelerator, and 3-4 parts of anti-slagging agent. The biomass particle carbon prepared by the method has the high calorific value and the low clinkering rate.

Owner:黄山市巨龙生物能源科技有限公司

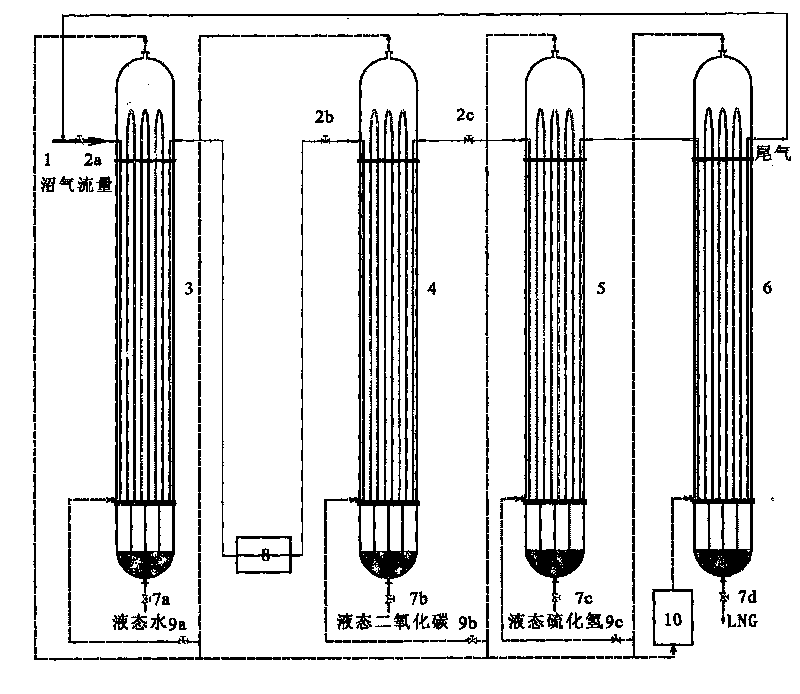

Technique for preparing mixed fuel of hydrogen and dimethyl ether from methanol

InactiveCN101362973AIncrease the calorific value of combustionLow costGaseous fuelsHeat carrierMixed fuel

The invention discloses a technical method for producing mixed fuel of hydrogen and dimethyl ether by using methanol, and belongs to the field of chemical engineering. The technical method couples the methanol-steam reforming reaction and the methanol dehydration reaction in a technology through the control of the proportion of the using amounts of methanol and water which enter a methanol-steam reforming reactor and the proportion of the using amounts of catalysts for the methanol-steam reforming reaction and the methanol dehydration reaction, the heat which is released by the methanol dehydration reaction is provided for the gasification, the overheating and the methanol-steam reforming reaction through a heat carrier of the shell side of a device, water which is generated by the methanol dehydration reaction is utilized in the methanol-steam reforming catalytic reaction after the cooling and the condensation, thereby effectively utilizing the heat which is released by the dehydration reaction, saving a heat supply energy source which is arranged outside a system, effectively utilizing the water which is generated by the dehydration reaction and reducing the consumption of purified water; at the same time, the invention provides a high heating value novel clean mixed fuel, the cost is low, and the mixed fuel can replace liquefied petroleum gas or high-pollution water gas which is used in small and medium-sized enterprises for supplying the heat.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

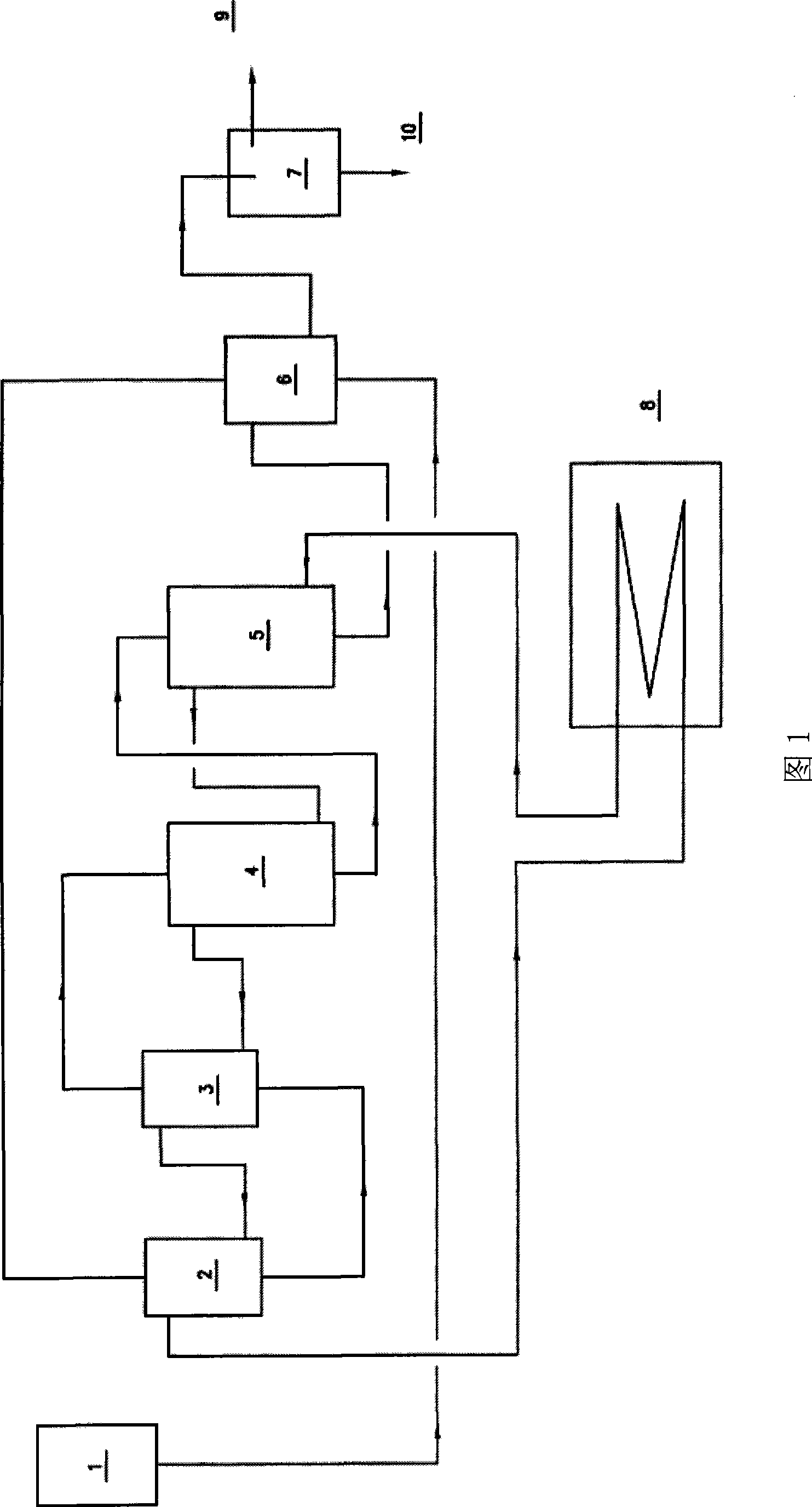

Process for full-particle-size sorting and enriching kerogen from oil shale

ActiveCN104263397AImprove oil yieldIncrease the calorific value of combustionLiquid hydrocarbon mixture productionWet separationKerogenCombustion

The invention relates to a process for full-particle-size sorting and enriching kerogen from oil shale. The process comprises the following steps: crushing oil shale raw ores till the particle size is less than 50-80mm; sieving and grading the crushed product by using a 0.5mm sieve; carrying out gravity separation on +0.5mm oversize material to obtain massive kerogen-enriched products and massive low-kerogen products; recovering magnetic separation media from undersize material; carrying out floating separation on tailings generated after recovery of magnetic separation media and sieved -0.5mm undersize material, wherein fine particle kerogen-enriched products are obtained after floating foam products generated by floating separation are filtered and dehydrated; concentrating and dehydrating the tailings obtained after floating separation to produce fine-particle low-kerogen products, wherein the filtered and dehydrated filtrate and concentrated and dehydrated overflow become circulating water. By sorting full-particle-size oil shale, kerogen in massive and fine-particle oil shale is effectively enriched, so that the oil yield of the massive oil shale and the combustion heat value of the fine-particle oil shale are improved and the problem of environmental pollution is effectively reduced. The process is simple in process and wide in practicality.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

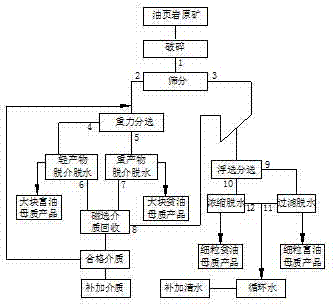

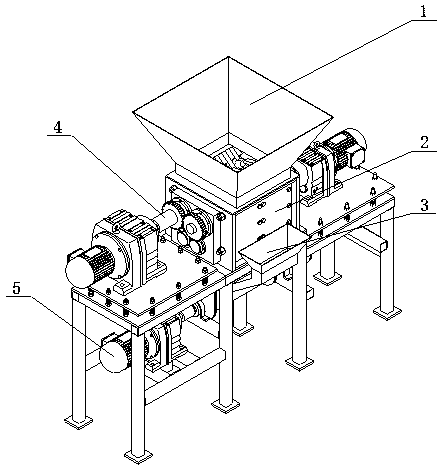

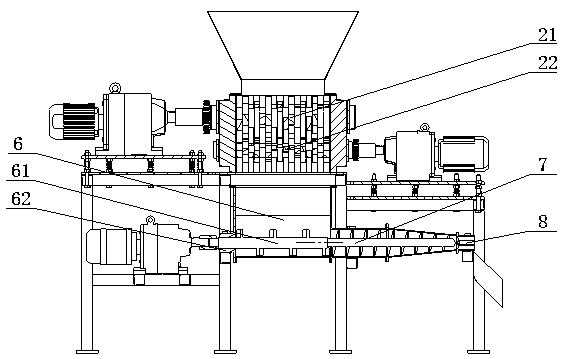

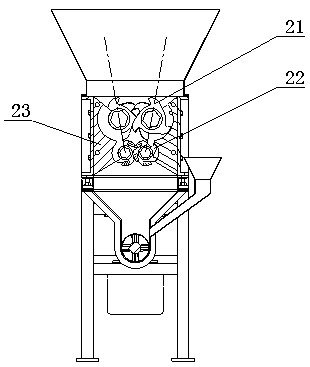

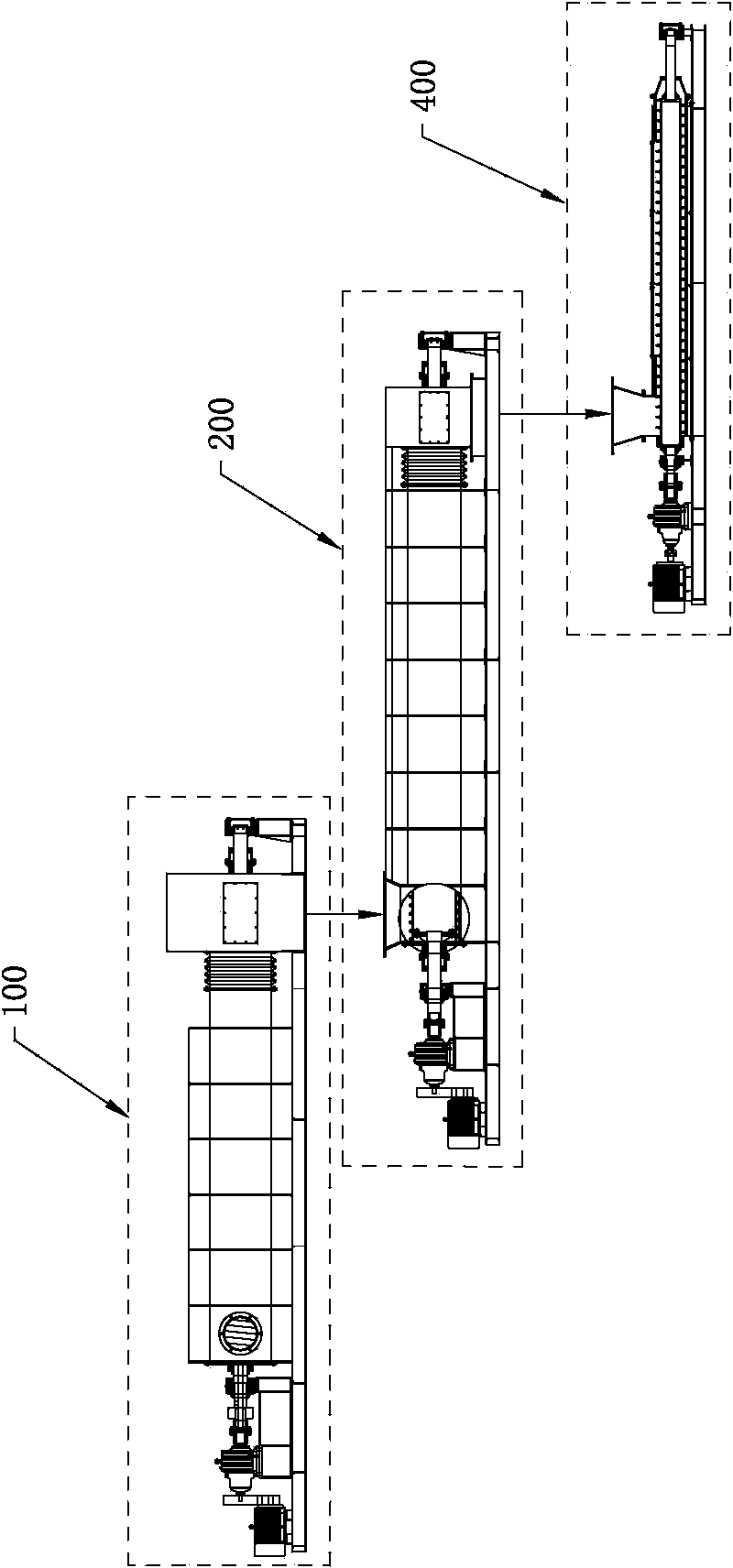

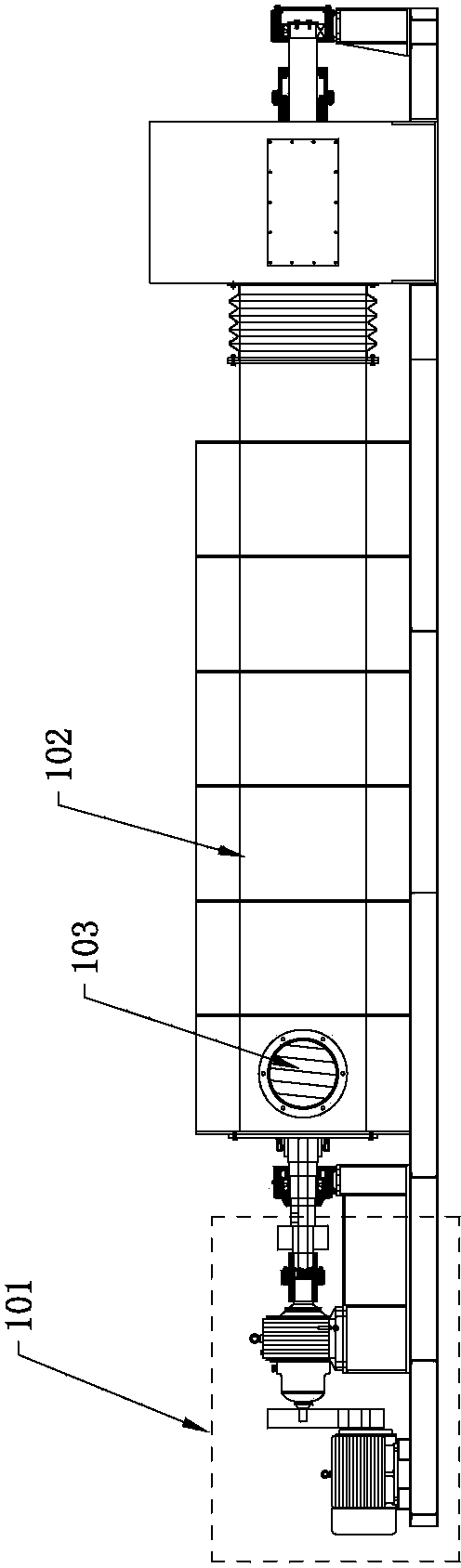

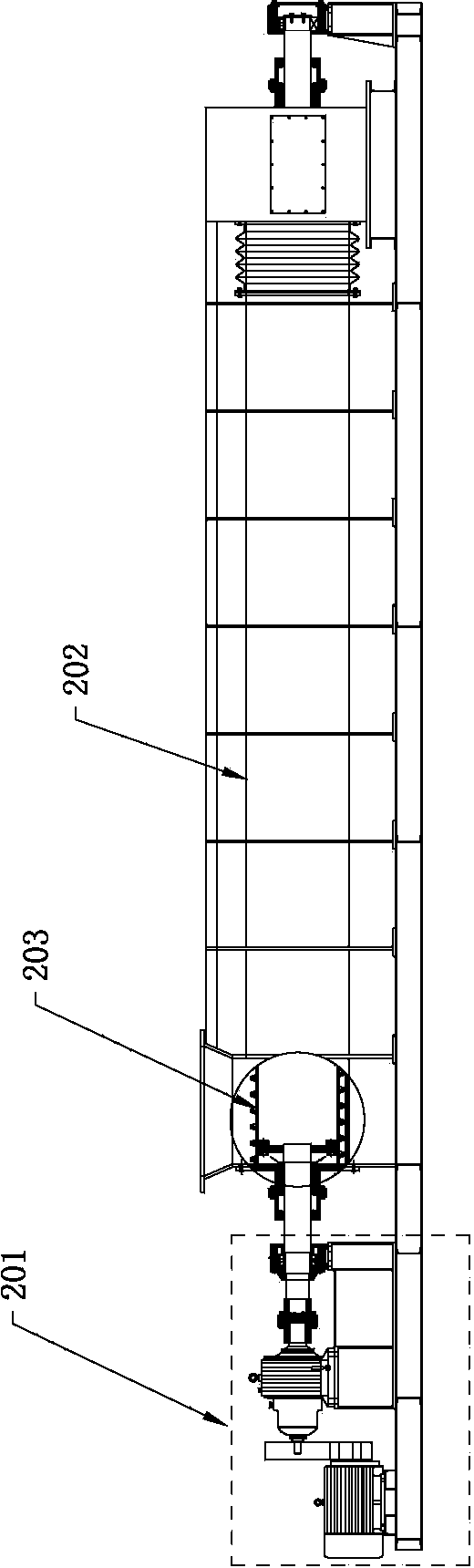

RDF production equipment and RDF preparation method

InactiveCN109022095AEvenly dispersedIncrease the calorific value of combustionTransportation and packagingBiofuelsRefuse-derived fuelCombustion

The invention discloses RDF (refuse derived fuel) production equipment. The equipment includes a crushing box internally equipped with a crushing mechanism, the top of the crushing box is equipped with a feed inlet, the bottom of the crushing box is equipped with a crushing discharge port, and a mixing box communicated with the crushing discharge port is disposed under the bottom of the crushing box. The box wall of the mixing box is equipped with an additive feed inlet, the mixing box is internally equipped with a stirring shaft, one end of the stirring shaft extends out of the box wall of the mixing box and is in power connection with a stirring motor, and the other end of the stirring shaft is connected to a screw conveying extrusion moulding machine. The screw conveying extrusion moulding machine includes a shell communicated with the mixing box and a screw conveying shaft coaxially connected to the stirring shaft. The equipment also includes a heating device for heating the mixingbox or the shell of the screw conveying extrusion moulding machine. The invention also provides an RDF preparation method using the RDF preparation equipment. The equipment and method provided by theinvention can increase the combustion heat of refuse derived fuel, have no need for an adhesive, are beneficial to environmental protection and are convenient for storage and transportation.

Owner:CHONGQING UNIV OF TECH

Garbage thermal cracking machine

ActiveCN103450913AImprove recycling ratesIncrease the calorific value of combustionSolid waste disposalSpecial form destructive distillationInsulation layerThermal insulation

A garbage thermal cracking machine comprises a feed device and further comprises a preheating device, a high temperature cracking device and a controller. A first driving device of the preheating device is in drive connection with a first screw, the first screw is arranged inside a first material cylinder in a rotatable and penetrating mode, and a first heating layer and a first thermal insulation layer are arranged on the inner wall of the first material cylinder. A second driving device of the high temperature cracking device is in drive connection with a second screw, the second screw is arranged in a second material cylinder in a rotatable and penetrating mode, a second heating layer and a second thermal insulation layer are arranged on the inner wall of the second material cylinder, the second thermal insulation layer is arranged between the inner wall of the second material cylinder and the second heating layer, a cracking area is formed between the second screw and the second heating layer, and the first driving device, the second driving device, the first heating layer and the second heating layer are electrically connected with the controller. The garbage thermal cracking machine has the advantages of being high in sealing performance, good in effect of heating materials, environmentally friendly, free of emission, ceaseless in work, high in work efficiency and the like.

Owner:GAOZHOU ZHONGLIANG MACHINERY MFG

Smokeless moxibustion and preparation method thereof

InactiveCN101628036AIncrease the calorific value of combustionRegulate spleen and stomachAntibacterial agentsDevices for heating/cooling reflex pointsAlginic acidMugwort

The invention discloses a smokeless moxibustion comprising the following materials of effective ingredients by weight percent: 83.2-85.8 percent of mugwort leaf, 2.8-4 percent of nard, 1.8-2 percent of angelica root, 1.8-2 percent of asarum, 1.8-2 percent of notopterygium root, 1.8-2 percent of costus root, 1.8-2 percent of cumin, 1.8-2 percent of clove and 0.6-0.8 percent of alginic acid, wherein the above components have a total content of 100 percent. The method comprises the following steps: placing the mugwort leaf in a crucible and adding rice vinegar for carbonization treatment to make carbonized mugwort leaf grain; fully mixing the weighted nard, angelica root, asarum, notopterygium root, costus root, cumin and clove, frying the mixture for a moment and grinding to make mixed powder; soaking sodium alginate with warm water and diluting to 50g / L to make sodium alginate solution; mixing and stirring the mugwort leaf grain, mixed powder and sodium alginate solution, tamping, shaping, and finally drying in the shade to make the product.

Owner:王跃

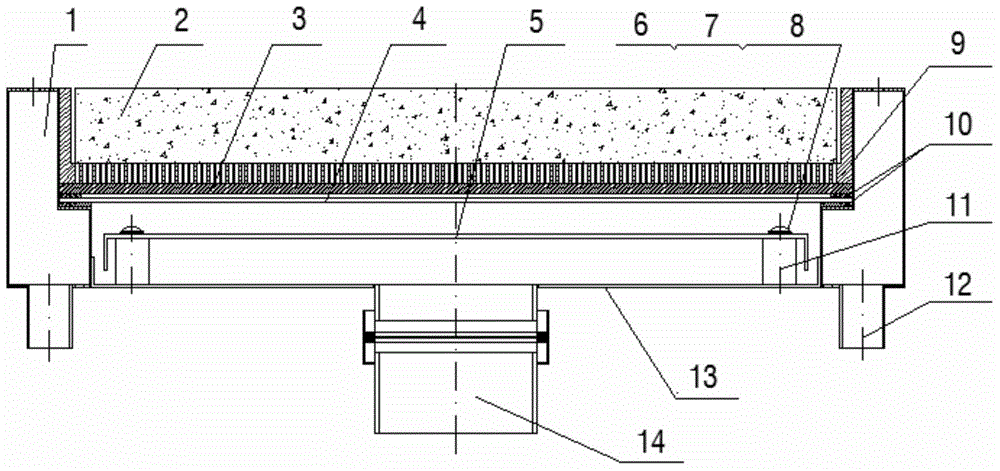

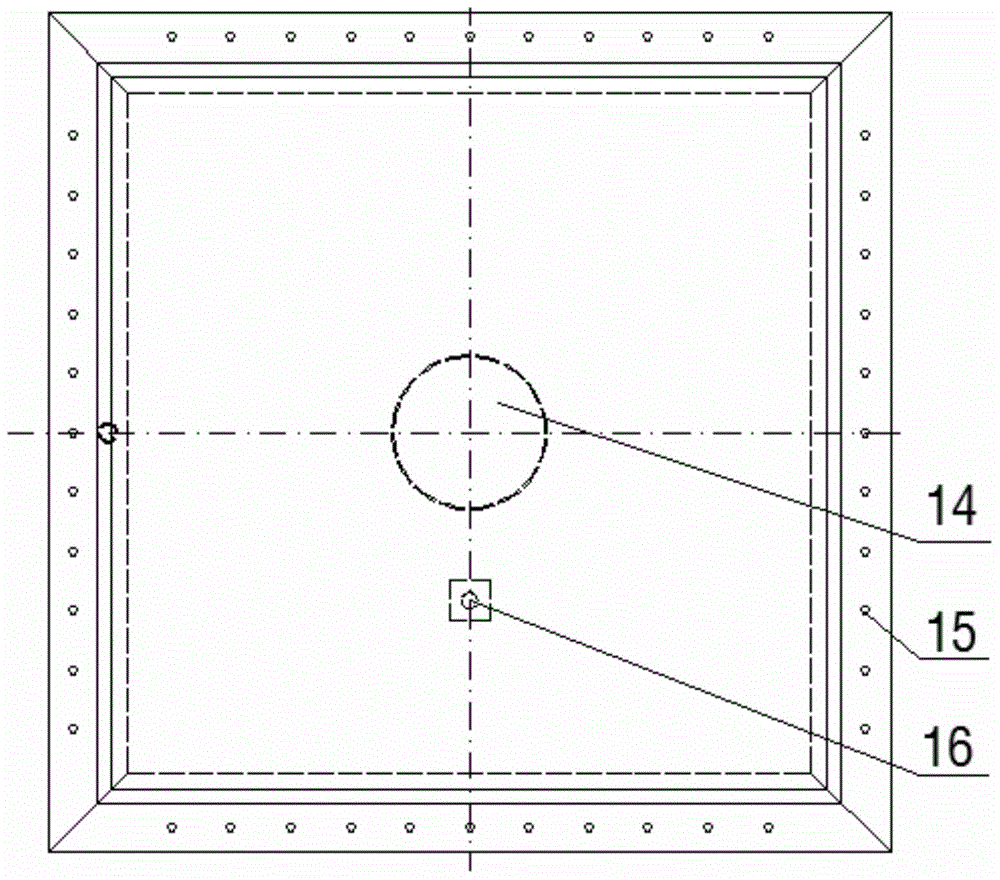

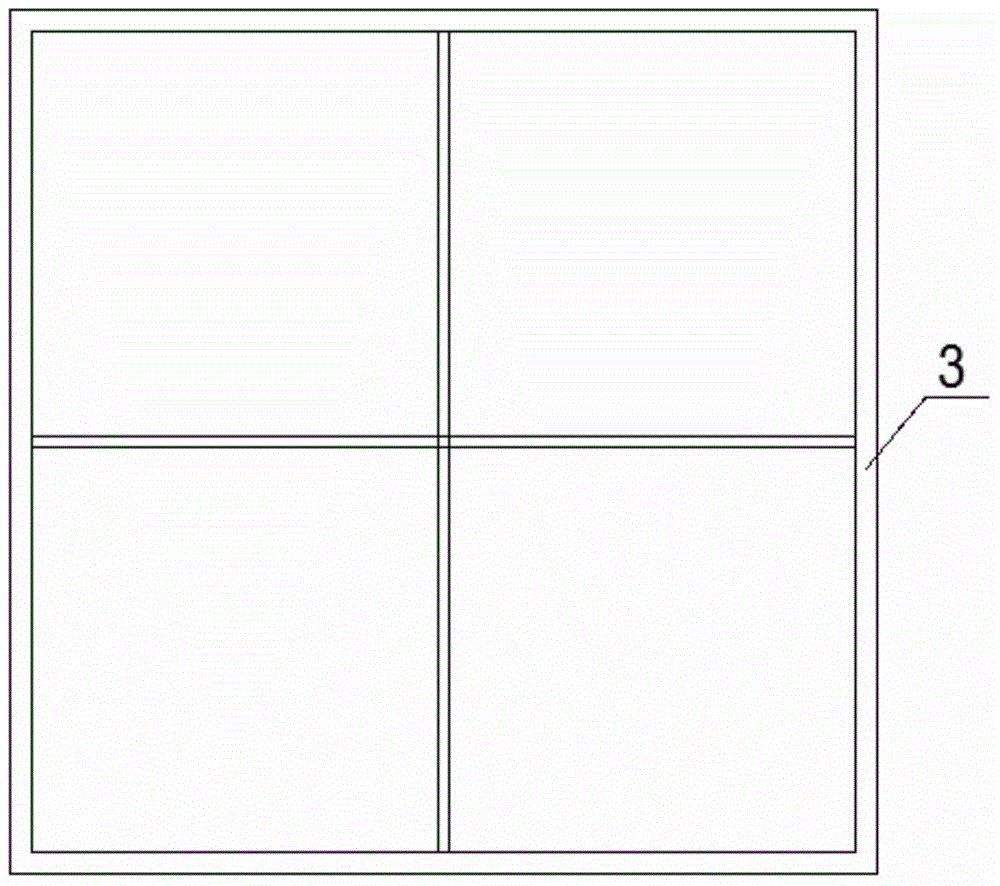

Monolayer multiporous foamed ceramic plate full-premix gas fuel burner

InactiveCN104879753AIncrease the calorific value of combustionReduce contentGaseous fuel burnerChemical industryCombustor

The invention relates to a monolayer multiporous foamed ceramic plate full-premix gas fuel burner. The monolayer multiporous foamed ceramic plate full-premix gas fuel burner comprises a burner shell composed of a cooling cavity and a shell bottom plate. A foamed ceramic plate, a honeycomb ceramic plate, a heat-resistant steel support, a top gas distribution plate, a bottom gas distribution plate and support posts are sequentially arranged from top to bottom in the cavity of the shell. Fuel and air are mixed and enter from a mixed gas inlet via a three-way pipe to sequentially pass the bottom gas distribution plate and the top gas distribution plate which are arranged at intervals, so that the mixed gas can be more uniformly distributed and burned in and on the surface of the foamed ceramic plate. The burner can be used on its own or by combining several burner units and can burn various gas fuels with heat variation range at 800-6000 kcal / m3. The burner is widely applicable to metallurgy, chemical industry, energy source, machinery and the like.

Owner:WUHAN UNIV OF SCI & TECH

Fuel instead of diesel oil, its preparation method and application

InactiveCN1948443ANo pollution in the processIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionNoise reduction

This invention discloses a fuel which substitutes diesel oil, the fuel contains methanol, diesel oil, additive for combustion, potentiator, the weight and shares ratio of used methanol, diesel oil, additive for combustion and potentiator are better selected as 50-95:5-10:0.2-1: 0.2-0.7. The fuel which substitutes diesel oil of this invention is optimized from what contain one or more kinds of what is selected from accessory ingredient such as: chaotropic agent, carbon reduction agent, limiting smoke agent, removing flavor agent, cleaner, noise reduction agent and antifreezer as so on..

Owner:张学义

Biofuel and method for preparing the same

The invention relates to the technical field of biofuel, in particular to biofuel and a method for preparing the same. Field mud, coal dust, saw dust powder, pine needles, algae, residue at dining tables and sludge of sewage treatment plants undergo rational matching design and are placed in a pulverizer to undergo smashing treatment, so that raw material ingredients in initial materials, the content of organic matter can meet the requirements of the biofuel, it is guaranteed that the biofuel suitable for combustion can be prepared; and the adding amount of the organic matter is low and the preparation cost of the biofuel is reduced. After the biofuel is smashed, potassium chlorate is added to be mixed with the biofuel, the fermentation treatment is performed in the oxygen-free environment at the temperature of 50-80 DEG C, the organic matter ingredients in the raw materials are converted, the combustion heat value of the biofuel is improved, the quality of the biofuel is improved, and the combustion heat value of a ton of biofuel is equivalent to the combustion heat value of 0.57-0.61 ton of standard coal.

Owner:广州明颂生物质成型燃料有限公司

Compounded oil phase for powder nitramon

InactiveCN101172915AImprove detonation sensitivityImprove combustion effectExplosivesDetonationLiquid fuel

The invention discloses a composite oil phase with nitromethane, in particular to the composite oil phase for powder type ammon explosives. The invention comprises the raw materials by weight proportions: 72 to 92 proportions of solid fuel oil, 5.0 to 20 proportions of liquid fuel oil, 2.0 to 5.0 proportions of nitromethane, and 1.0 to 3.0 proportions of condensation compounds of aromatic sulphonate and aldimine. The invention also discloses a preparation method thereof. The method comprises the steps as follow: the solid fuel oil is firstly melted, and liquid fuel oil, condensation compound of organic acid salt aldehydes and nitromethane are added in turn for being mixed fully, and then the mixture is cooled and packed. The invention is characterized in that the burning thermal value is high; the viscosity is small; and the dispersion on the surface of powder type ammonium nitrate grain to form a moisture proof anti-blocking water resistance oil membrane is easy, thus the detonation Sensitivity and the detonation energy of the powder type ammon explosives are improved. The utility model used for the powder type ammon explosives has the advantages that the oil phase with the nitromethane is simple and reliable, has low cost and facilitates the industrialization production and utilization.

Owner:ANHUI UNIV OF SCI & TECH +1

Modified alcohol-base environment-protection fuel and preparation method thereof

InactiveCN102174337ANo pollution in the processReduce surface tensionLiquid carbonaceous fuelsSocial benefitsCombustion

The invention provides a modified alcohol-base environment-protection fuel and a preparation method thereof. The fuel is prepared by taking methanol or ethanol with low-carbon alcohol, or mixed alcohol, or C1-C8 mixed alcohol recovered in the industry and the mixture of the methanol, the ethanol, the mixed alcohol and the C1-C8 mixed alcohol as a main fuel and matching with auxiliary additives, such as active solution, solvent, oil or vegetable oil or animal oil, aldehyde preventing agent and modifier and the like. The fuel has stable combustion and high thermal efficiency, can be applied to the industries of catering, industries and kilns and the like, and can replace the diesel oil, thus lowering the dependent of society on the petroleum products; and the fuel has good energy-saving and emission-reduction effects, and has good economic benefit, environment-protection benefit and social benefit.

Owner:吉林市富源化工厂

Environment-friendly biomass particle fuel and processing method

The invention relates to the technical field of biomass fuel and specifically relates to environment-friendly biomass particle fuel and a processing method. The particle fuel is prepared from the following raw materials in parts by weight: 45 to 65 parts of woodwork waste mixture, 10 to 20 parts of mulberry stalk, 5 to 15 parts of straw, 5 to 8 parts of tobacco stem, 3 to 5 parts of flame accelerator, 2 to 3 parts of anti-slagging agent and 1 to 2 parts of sulfur fixing agent. The invention further discloses the processing method of the particle fuel. The processing method comprises the steps of preparing the flame accelerator, the anti-slagging agent and the sulfur fixing agent according to selected parts by weight; mixing and smashing; drying: drying an obtained wood pellet mixture at high temperature; extrusion forming: sending the dried solid fuel into a granulator to be extruded and granulated and finally cooling to obtain the environment-friendly biomass particle fuel. The environment-friendly biomass particle fuel and the processing method disclosed by the invention have reliable performance, and the environment-friendly biomass particle fuel can meet the requirement of energy conservation and environmental friendliness and meanwhile has long combustion time and high combustion ratio.

Owner:云南省福仑木业有限公司

Civil liquid fuel and preparation method thereof

InactiveCN101875868AConvenient sourceSafe and reliable performanceLiquid carbonaceous fuelsLiquid fuelAmmonium nitrate

The invention relates to a civil liquid fuel and a preparation method thereof. The civil liquid fuel is prepared from the following raw materials by weight percent: 10%-35% of seawater or treated wastewater, 65%-90% of methanol, 0.2%-1% of xylene, 0.05%-0.1% of cyclohexane, 0.05%-0.5% of butyl acetate, 0.2%-1% of ammonium nitrate, 0.2%-1% of hydrogen peroxide with the mass concentration of 27% and 0.3%-1.5% of ethanol. The civil liquid fuel has simple preparation method, accessible raw materials, stable performance and safe transportation and use, have high heat value and can be completely burnt, do not generate pressure and do not explode; and the civil liquid fuel can be extinguished with water and be characterized by cleanliness, less emissions of production, environmental protection, safety and low cost. The invention can replace diesel and liquefied natural gas (LNG) and be suitable to be used in the diesel oil furnaces, boilers, liquefied gas furnaces and the like of various hotels, schools, factories, institutions and the like.

Owner:SHANGHAI YUANGUI ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com