Method for largely, industrially and synthetically treating and using plant stem leafs and device thereof

A technology for comprehensive treatment of plant stems and leaves, applied in biochemical equipment and methods, chemical instruments and methods, biomass post-processing, etc. Cost, effect of vast resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

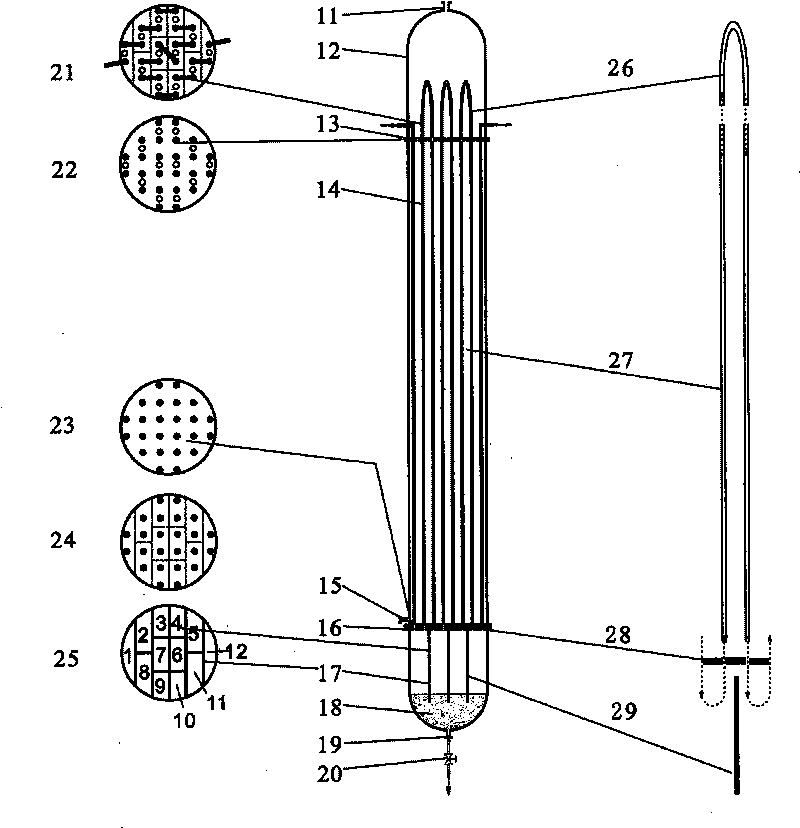

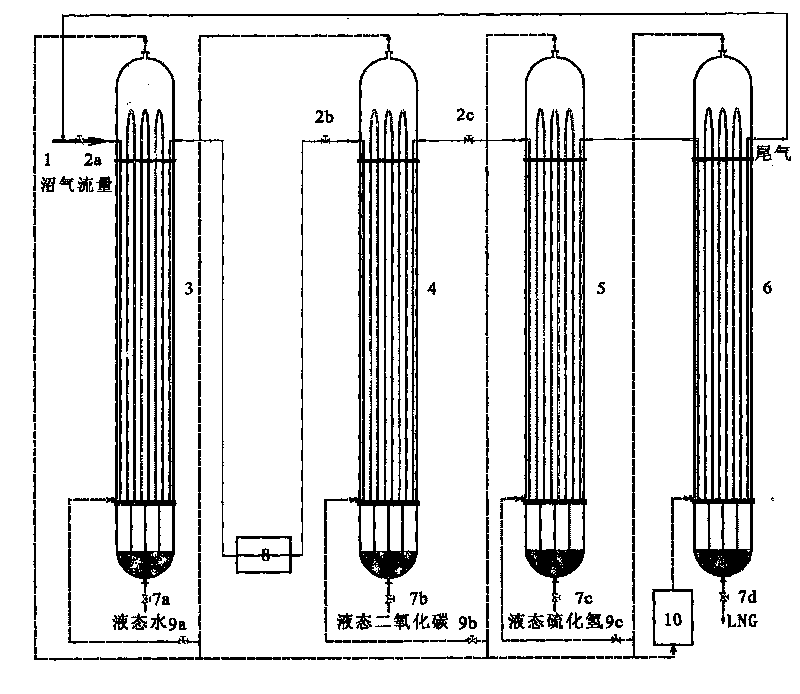

[0067] The present invention will be further described below with reference to the accompanying drawings, and the described embodiments are only used to help those skilled in the art understand the present invention, rather than to limit the scope of application of the present invention.

[0068] Taking a 1,000-mu rubber plantation on a farm in Hainan as an example, biogas fermentation bags are used to build biogas production sites in units of 10 to 50 mu, and biogas storage tanks are built in units of 1,000 mu. During the deciduous season in winter, rubber fallen leaves are collected on a per 10 mu basis for use in biogas production. Crush the concentrated rubber fallen leaves, mix the raw materials according to the ratio of fallen leaves:cow dung=7:3, pour lime water, adjust the pH value to about 7, put them into mesh bags, stack them in biogas bags, seal them, and anaerobic fermentation . After a week of fermentation, the biogas bags started to produce gas. Gas production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com