Technique for preparing mixed fuel of hydrogen and dimethyl ether from methanol

A technology of mixed fuel and process method, which is applied in the field of chemical industry, can solve the problems of high energy consumption, distilled water and reaction-generated water are not effectively used, and achieve the effects of high combustion calorific value, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

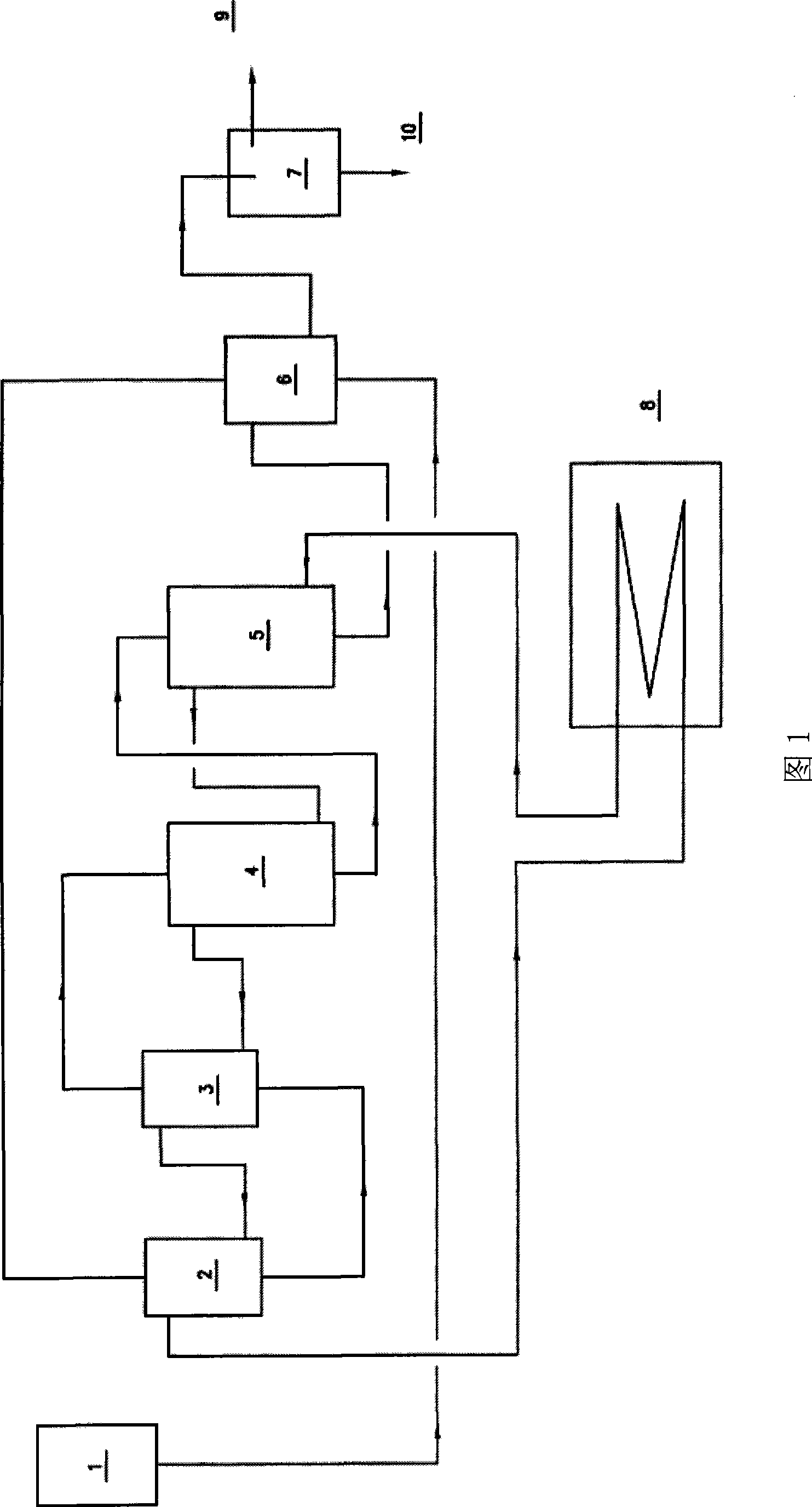

[0027] The flow chart of the process flow chart of methanol hydrogen production and dimethyl ether mixed fuel in this embodiment is shown in Fig. 1 . The specific process method of the present embodiment is as follows: methanol is mixed with water or the condensate obtained by the reaction, pure water is used when starting the process, the condensate obtained by the reaction is used after the reaction is started, and the amount of methanol in the reaction raw materials is controlled to be 64kg / h, The amount of water is 6.4 kg / h pure water. The mixed raw material is preheated to 90°C by the heat exchanger 6, sent to the vaporizer 2 for vaporization, and the vaporization temperature is 150°C, and the vaporized mixed raw material is heated to 190°C in the superheater 3, and then sent to the methanol steam reforming reactor The catalytic reforming reaction is carried out within 4, the reaction pressure is 0.2MPa, the temperature is 240°C, and the catalyst used in the reaction is C...

Embodiment 2

[0030] The flow chart of the process flow chart of methanol hydrogen and dimethyl ether mixed fuel in this embodiment is shown in Figure 1. When the process is started, the thermal load furnace 8 is used for heat supply. After the reaction is stable, the heat supply of the thermal load furnace 8 is gradually reduced. The heat transfer oil in the shell side of the device provides the heat generated by the methanol dehydration reaction to the vaporization, superheating and reforming reaction devices. The specific method of this embodiment is as follows: methanol is mixed with water or the condensate obtained by the reaction, pure water is used when starting the process, and the condensate obtained by the reaction is used after the reaction is started, the amount of methanol in the reaction raw materials is controlled to be 64kg / h, water The amount is 3.2kg / h. The mixed raw material is preheated to 80°C by the heat exchanger 6, and sent to the vaporizer 2 for vaporization at a va...

Embodiment 3

[0032] The process flow diagram of the process method of methanol hydrogen production and dimethyl ether mixed fuel in this embodiment is shown in Figure 1. When starting up, the thermal load furnace is used for heating. After the reaction is stable, the heat supply of the thermal load furnace is gradually reduced. The heat transfer oil provides the heat generated by the methanol dehydration reaction to the vaporization, superheating and reforming reaction devices. The specific method of this embodiment is as follows: methanol is mixed with water or the condensate obtained by the reaction, pure water is used when starting the process, and the condensate obtained by the reaction is used after the reaction is started, the amount of methanol in the reaction raw material is controlled to be 80kg / h, water The amount is 16kg / h. The mixed raw material is preheated to 90°C by the heat exchanger 6, sent to the vaporizer 2 for vaporization, and the vaporization temperature is 200°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com