Biomass wood sawdust pellet fuel and preparation method thereof

A pellet fuel and biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of biomass pellet fuel, such as low calorific value, low combustion rate and thermal efficiency, distinguishing identification and compound compatibility, short fuel burning time, etc. Reach the effect of reducing the addition of binding medium, prolonging the burning time and increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Biomass particle fuel is prepared according to the following steps:

[0038] (1) Mixing and crushing:

[0039] Select each described raw material component by the composition of table 1, formula ratio: pine sawdust 5kg and oak sawdust 10kg, ash sawdust 5kg, ash sawdust 10kg, birch sawdust 15kg, elm sawdust 5kg, jujube sawdust 10kg and oak sawdust 5kg ; Mixed and pulverized to obtain wood chips with a diameter of 0.05-2mm.

[0040] (2) Drying: Send the mixed and pulverized sawdust particles into a drum oven for drying. The temperature in the front section is about 160-250°C, and the temperature in the rear end gradually decreases, so that the moisture content of the wood chips will be 5-8 %;

[0041] (3) Transit inspection: the dried sawdust particles are sent to the storage room for moisture content inspection to ensure that the moisture content of the sawdust particles is 5-8%. If it is too dry, it needs to be mixed with sawdust with high humidity; if the humidity i...

Embodiment 2

[0044] The implementation process of this embodiment is basically the same as that of Example 1, and its formula ratio and process control parameters are shown in Table 1 and Table 2.

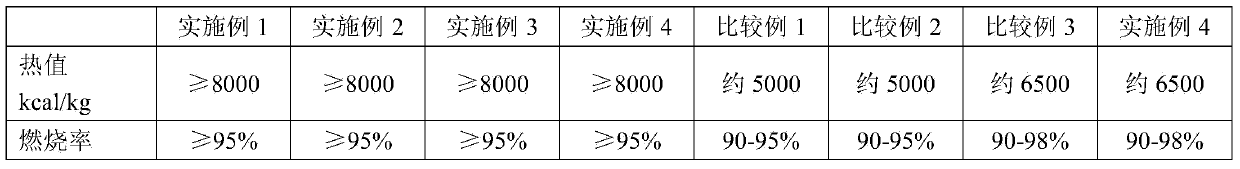

[0045] Table 1 formula ratio

[0046] components Example 1 Example 2 Example 3 Example 4 Comparative example 3 Comparative example 4 Pine sawdust 5 10 15 12 5 12 Oak sawdust 10 — — 20 10 20 Ash sawdust 5 90 5 10 5 10 Ash sawdust 10 — 90 5 10 5 birch sawdust 15 — — 5 15 5 Elm sawdust 5 — — 25 5 25 Jujube sawdust 10 — — 15 10 15 oak chips 5 5 — 20 5 20 CaO 0.5 1 0.6 — 0.5 —

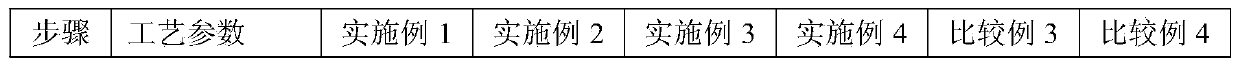

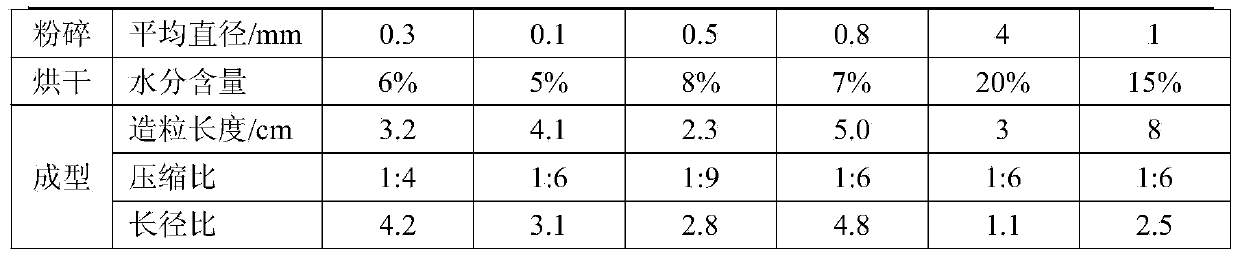

[0047] Table 2 Process parameters

[0048]

[0049]

Embodiment 3

[0051] The implementation process of this embodiment is basically the same as that of Example 1, and its formula ratio and process control parameters are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com