Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

437 results about "Biomass burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

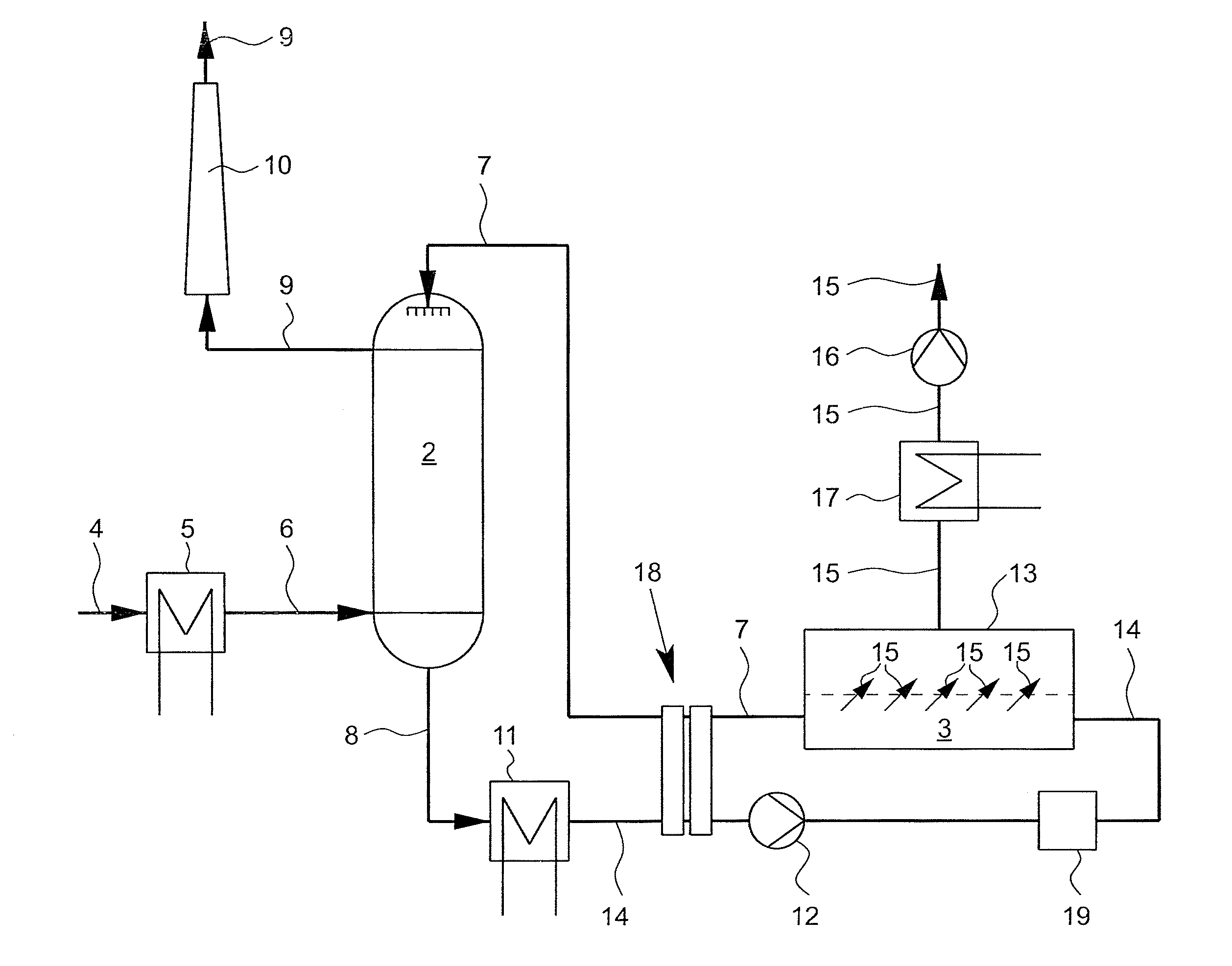

Method of converting energy

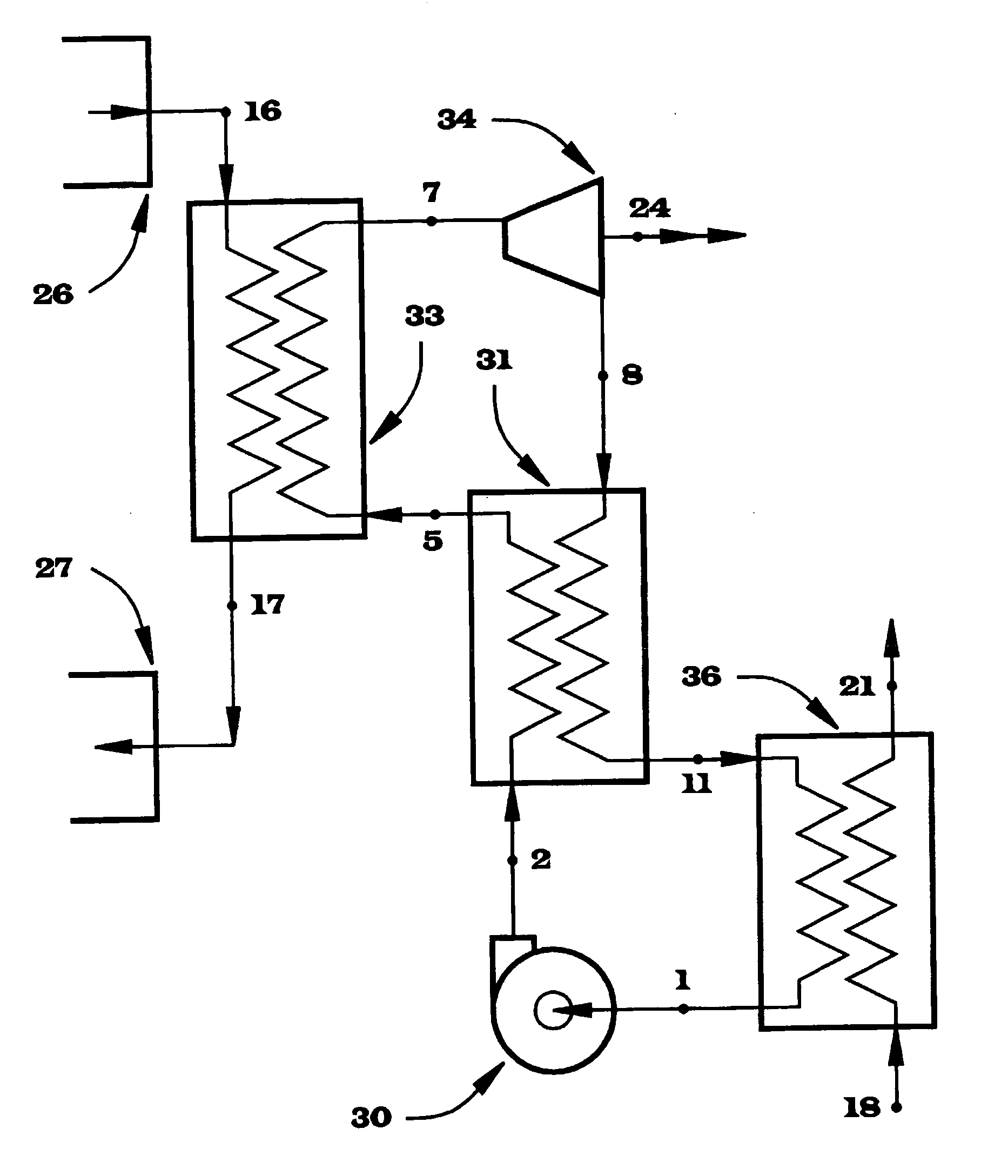

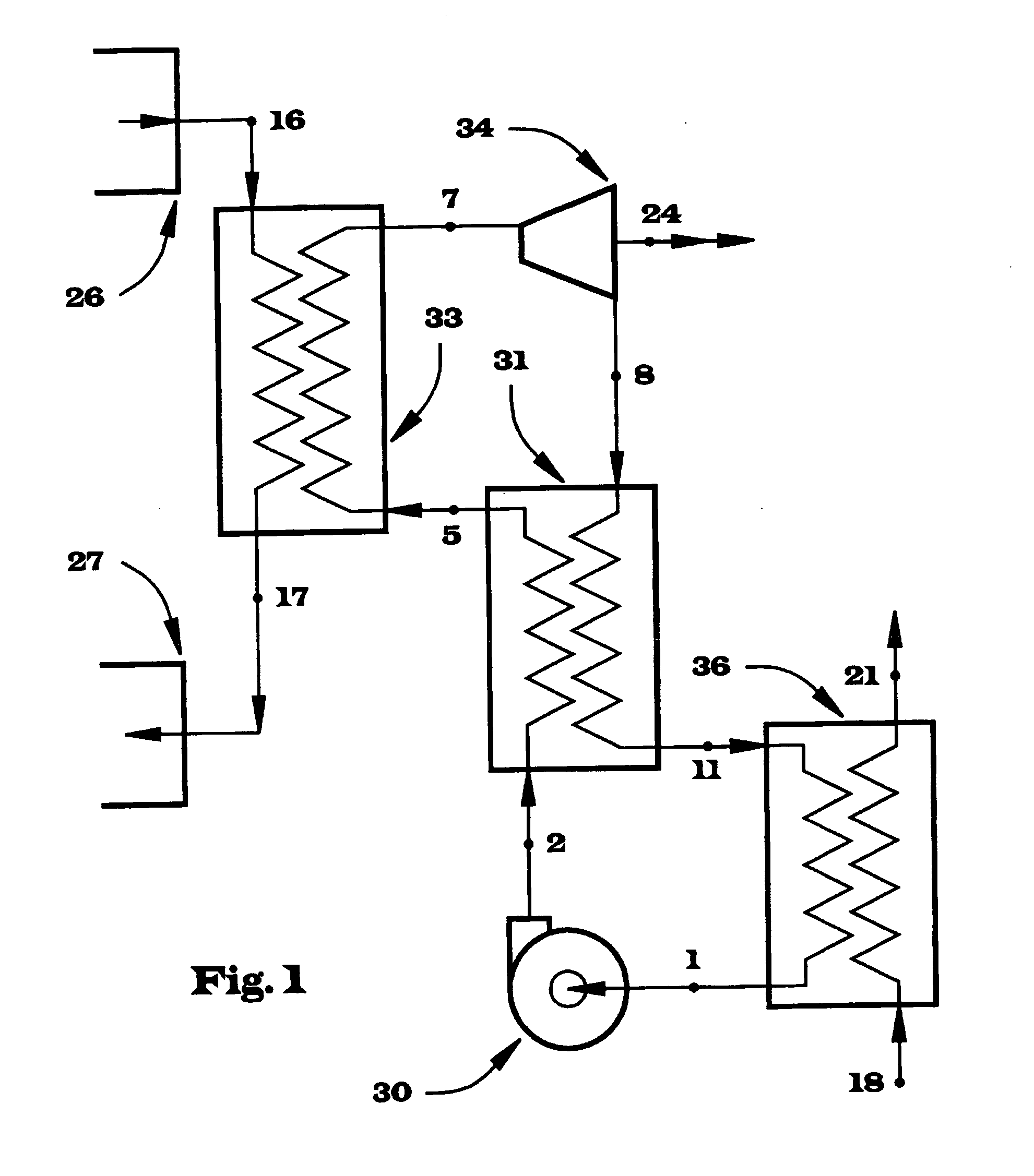

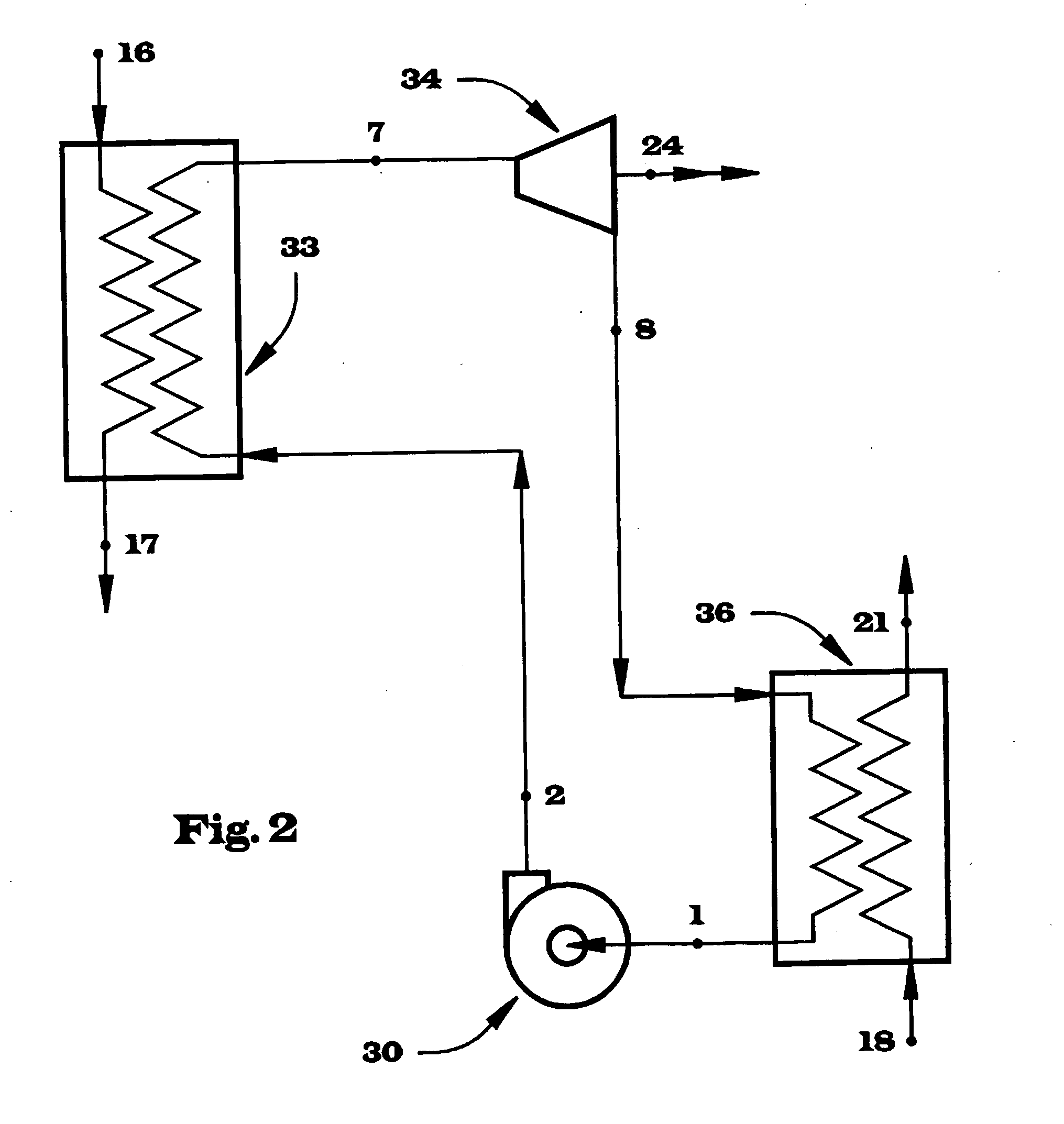

The invention provides a method of converting heat energy to a more usable form using a multi-component working fluid mixture that contains ammonia and water. The working fluid is operated in a thermodynamic cycle that includes liquid compression (30), vaporization (33), expansion through a turbine (34) and condensing (36). The multi-component fluid varies in temperature during phase change allowing for the use of counter-flow heat exchangers for the heater (33), cooler (36), recuperator and pre-heater (32). Significant recuperation is possible due to the temperature change during phase change. A pre-heater (32) can be applied to ensure only single-phase vapour exists within the heater. The invention can be used in conjunction with a biomass combustor or with waste flue gas from an existing industrial process. The coolant exits at a temperature sufficient to allow use in external heating applications or to minimize the size of external heat rejection equipment

Owner:SMITH & WESSON

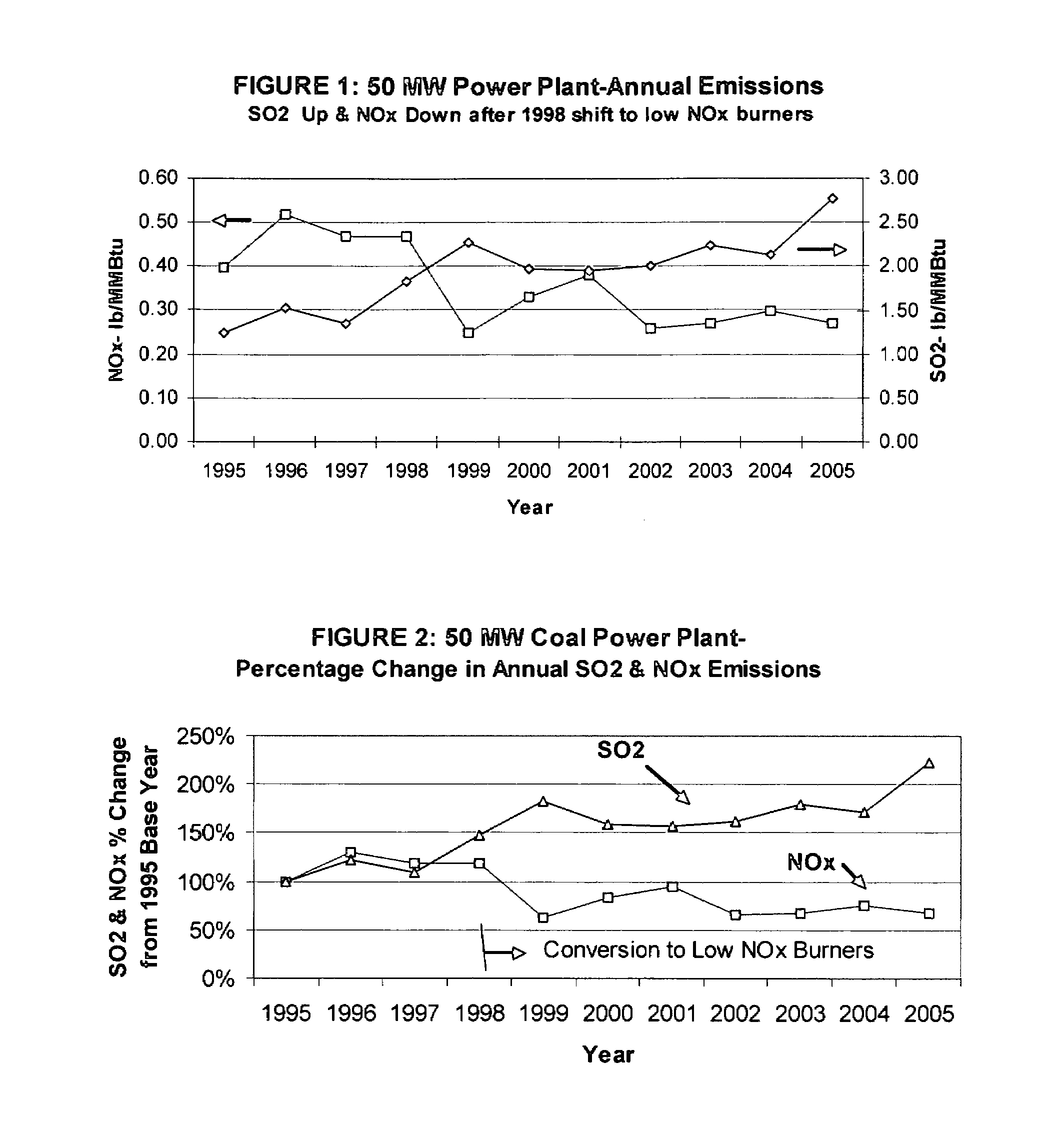

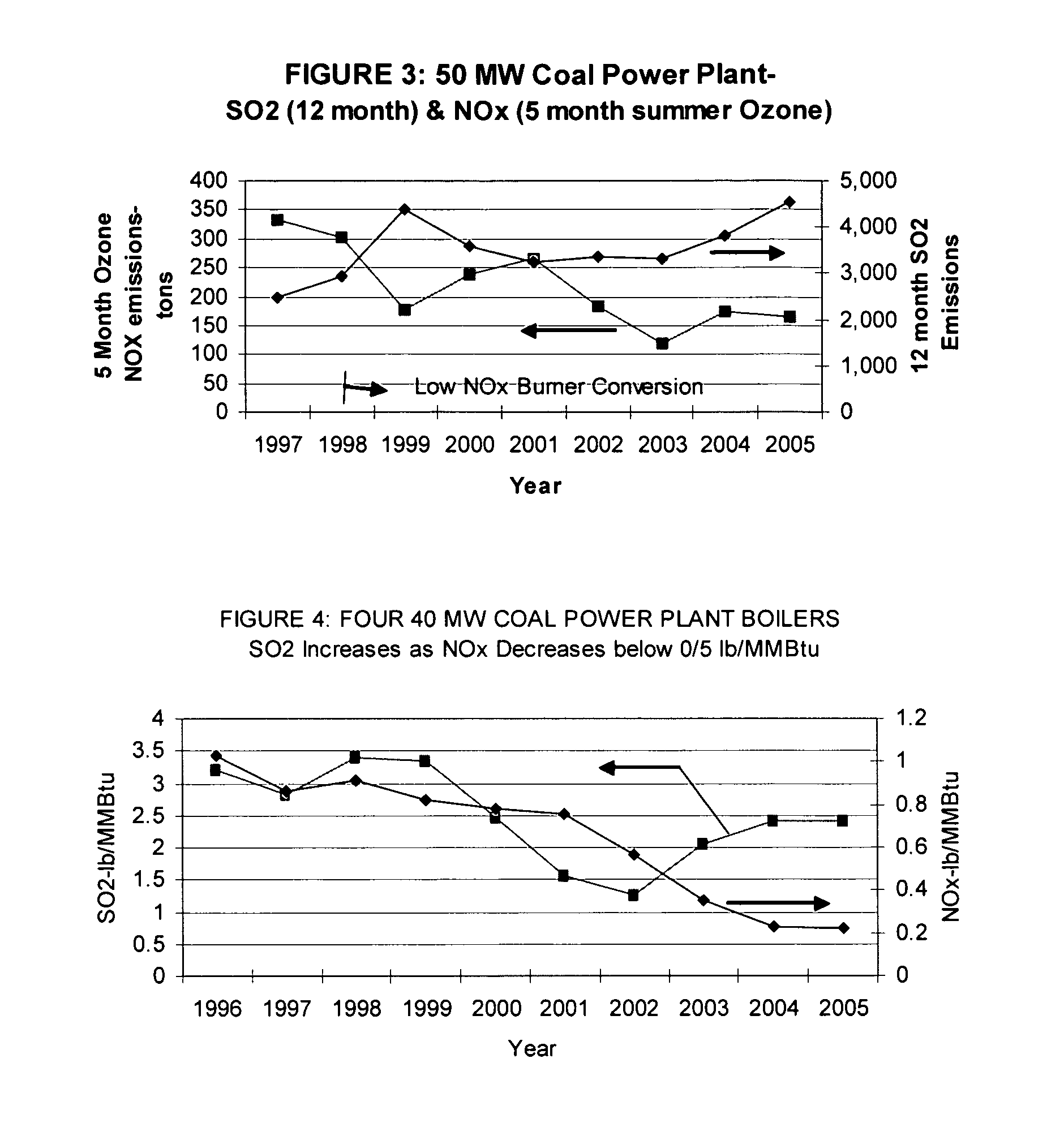

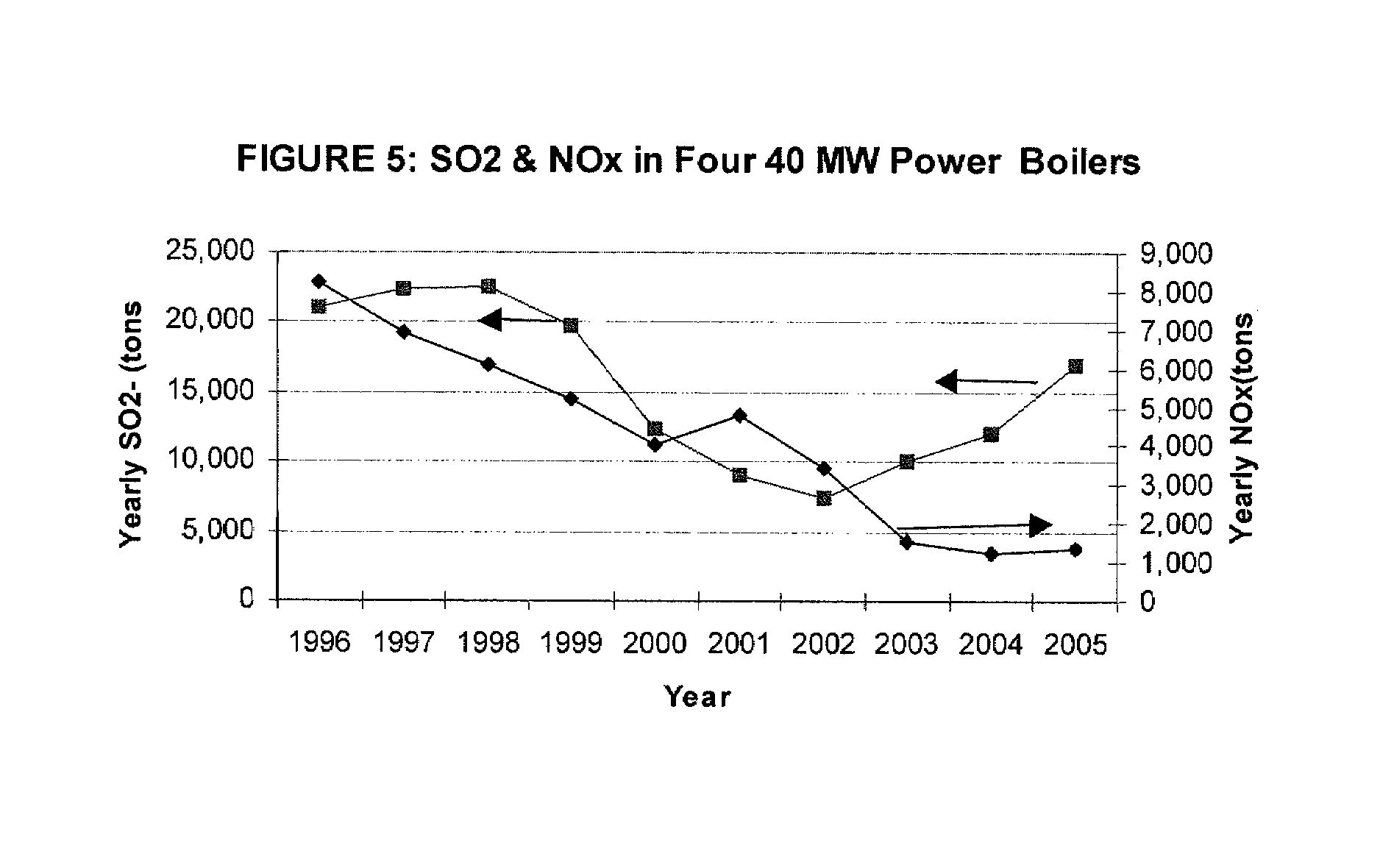

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

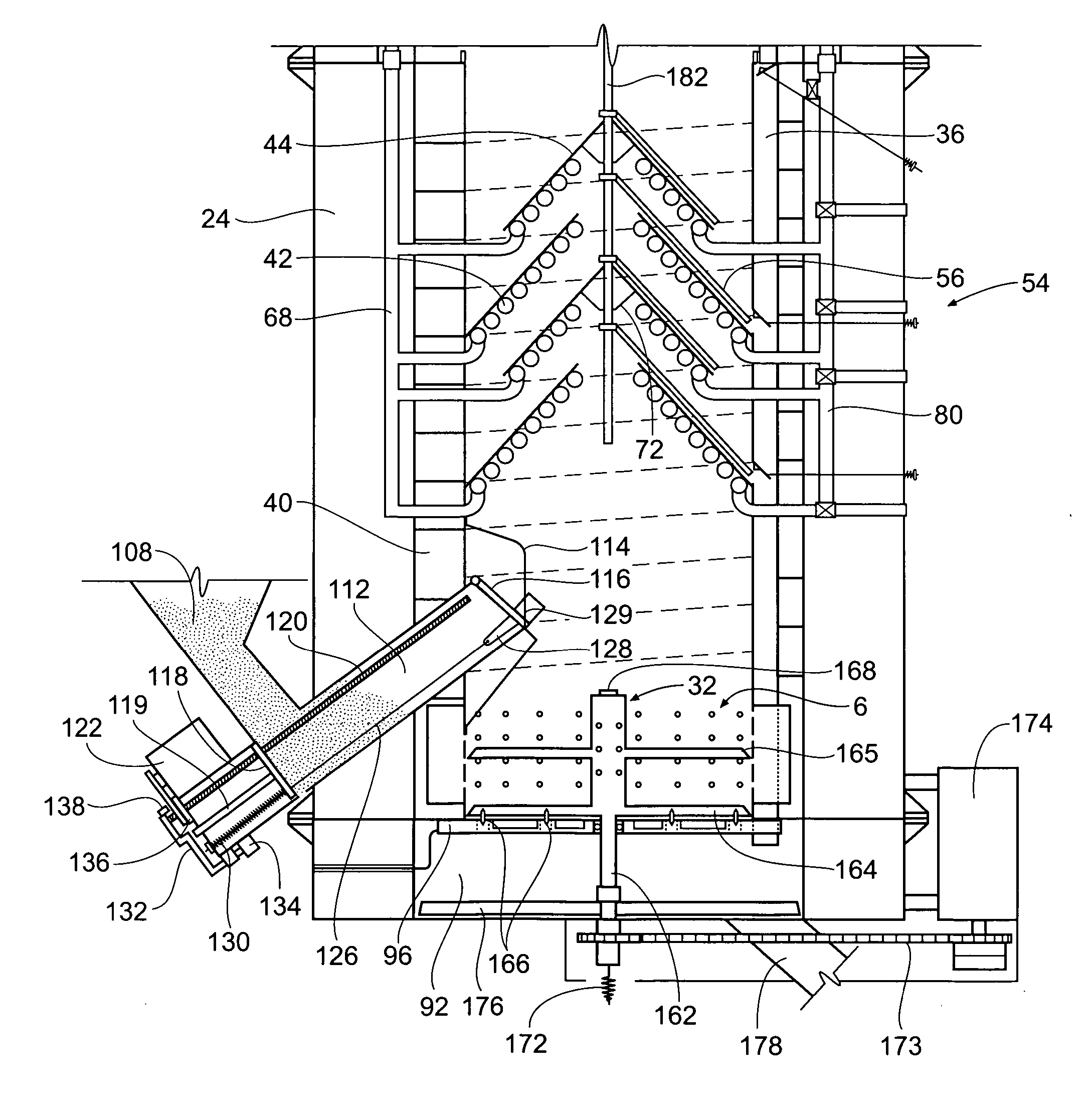

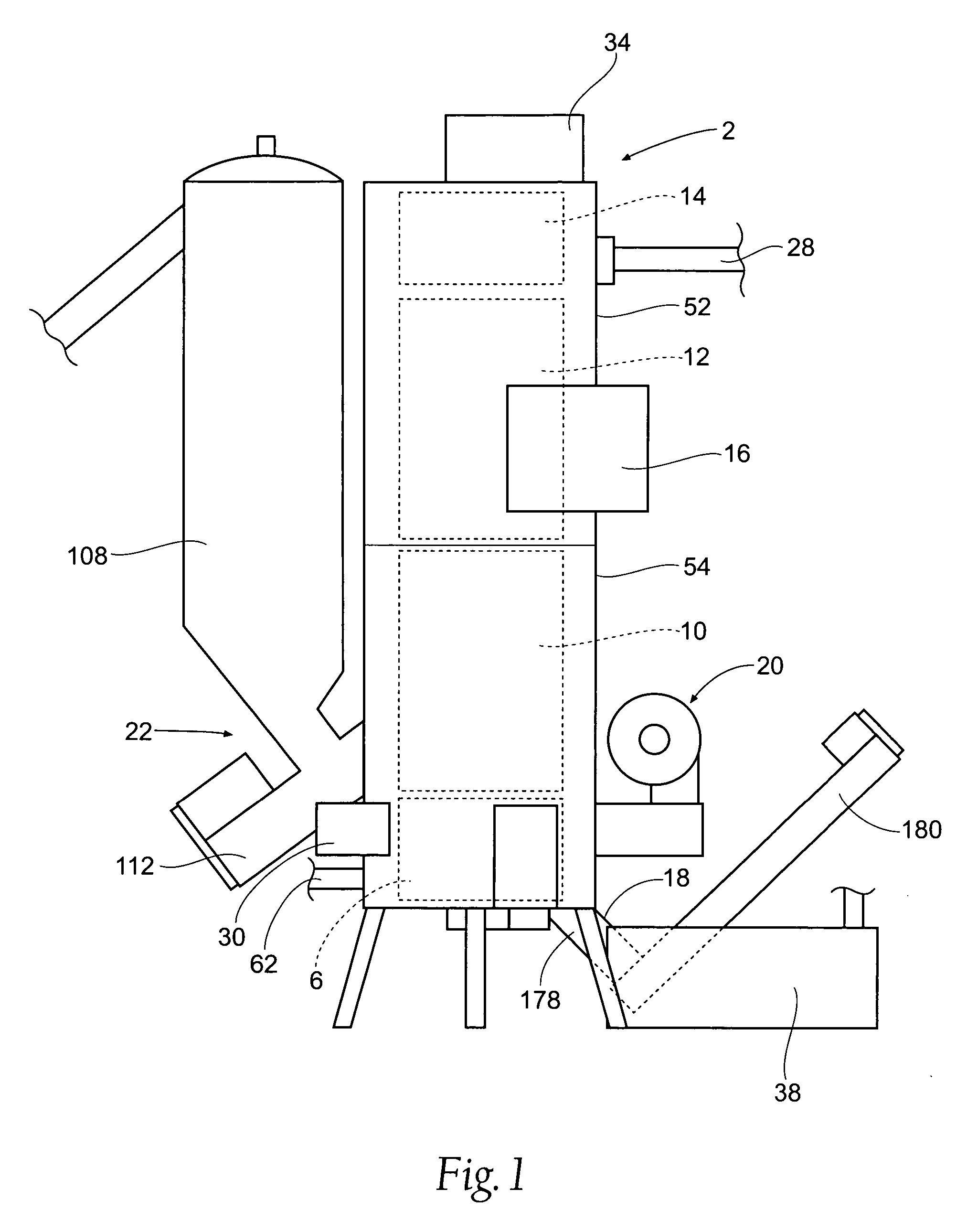

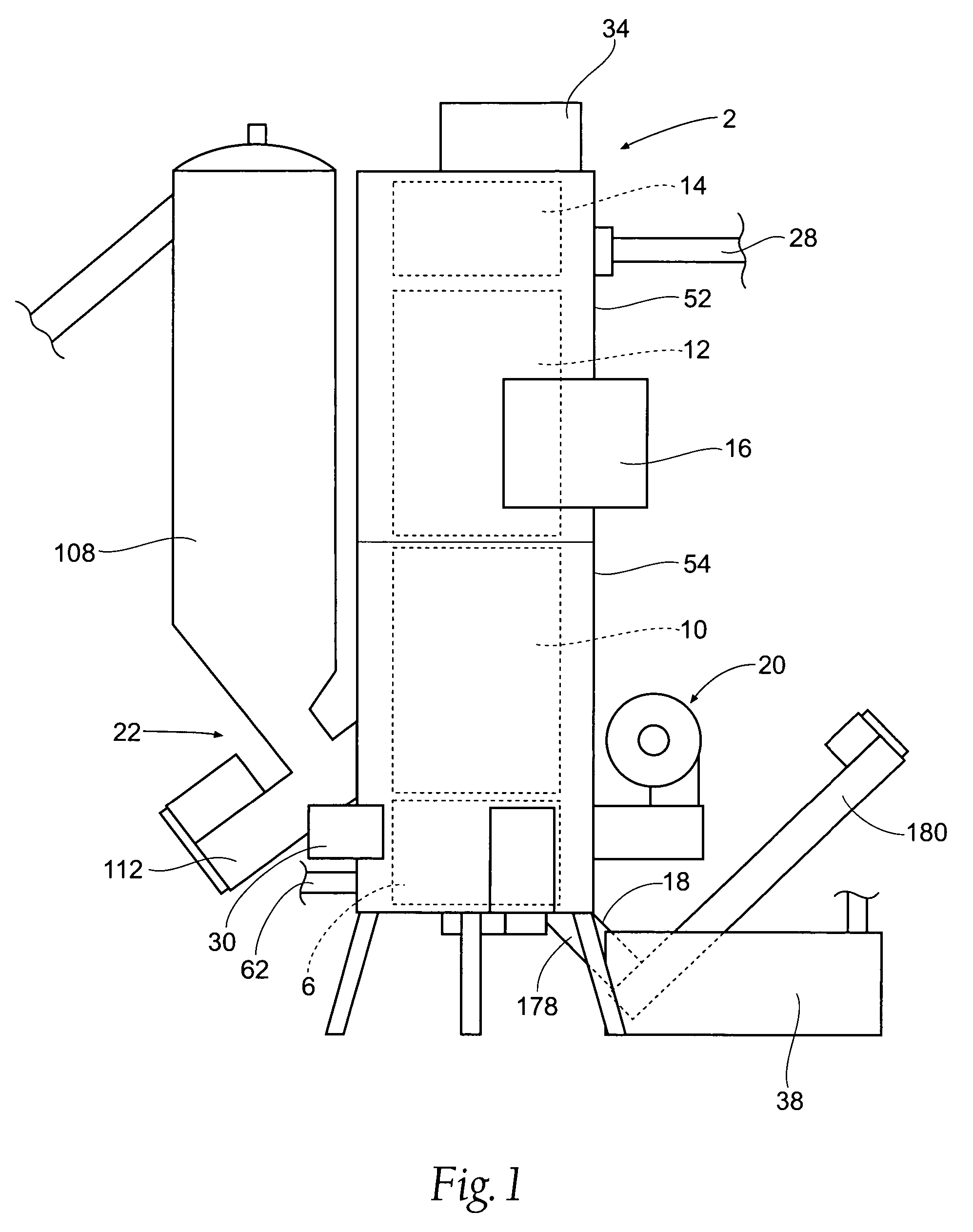

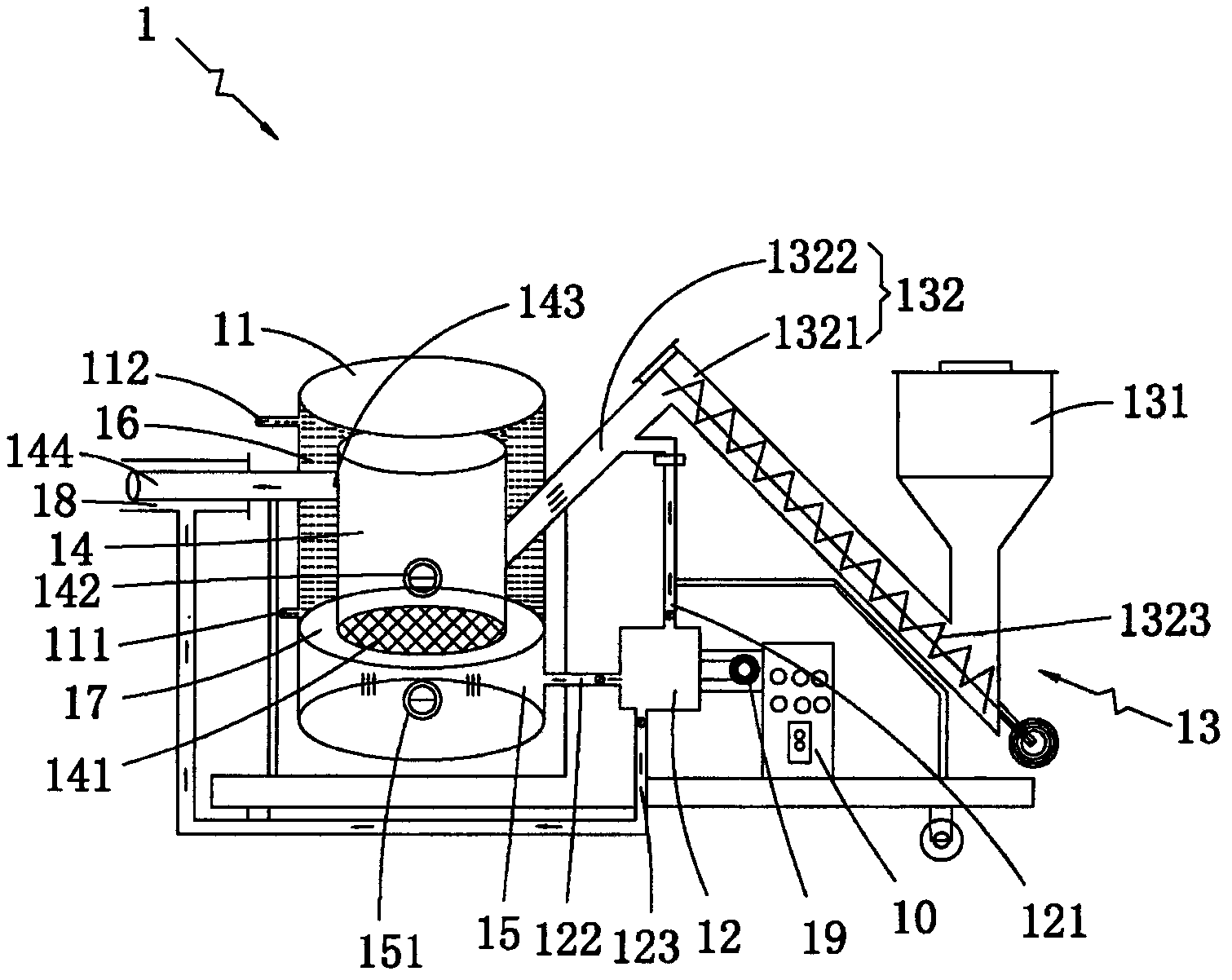

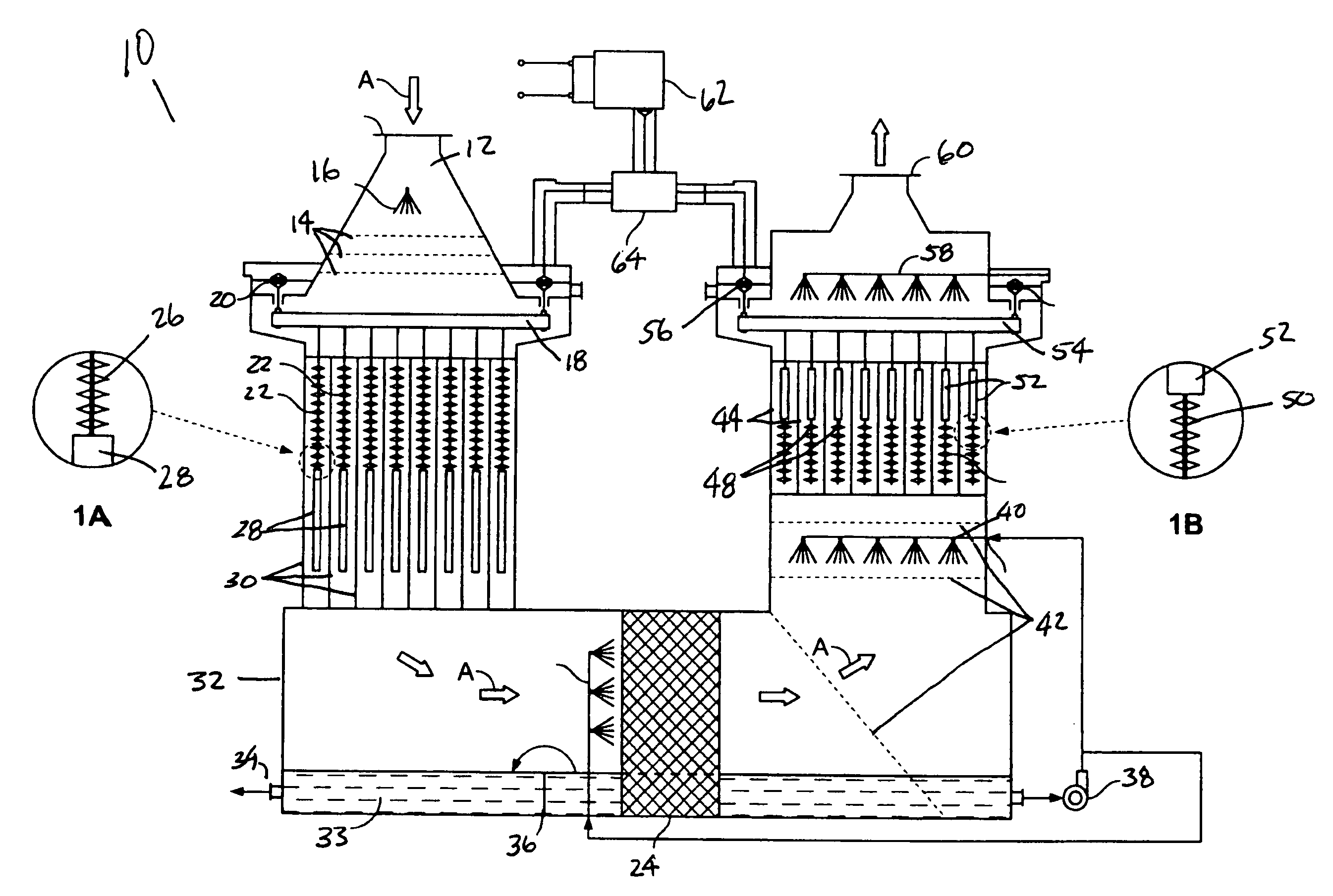

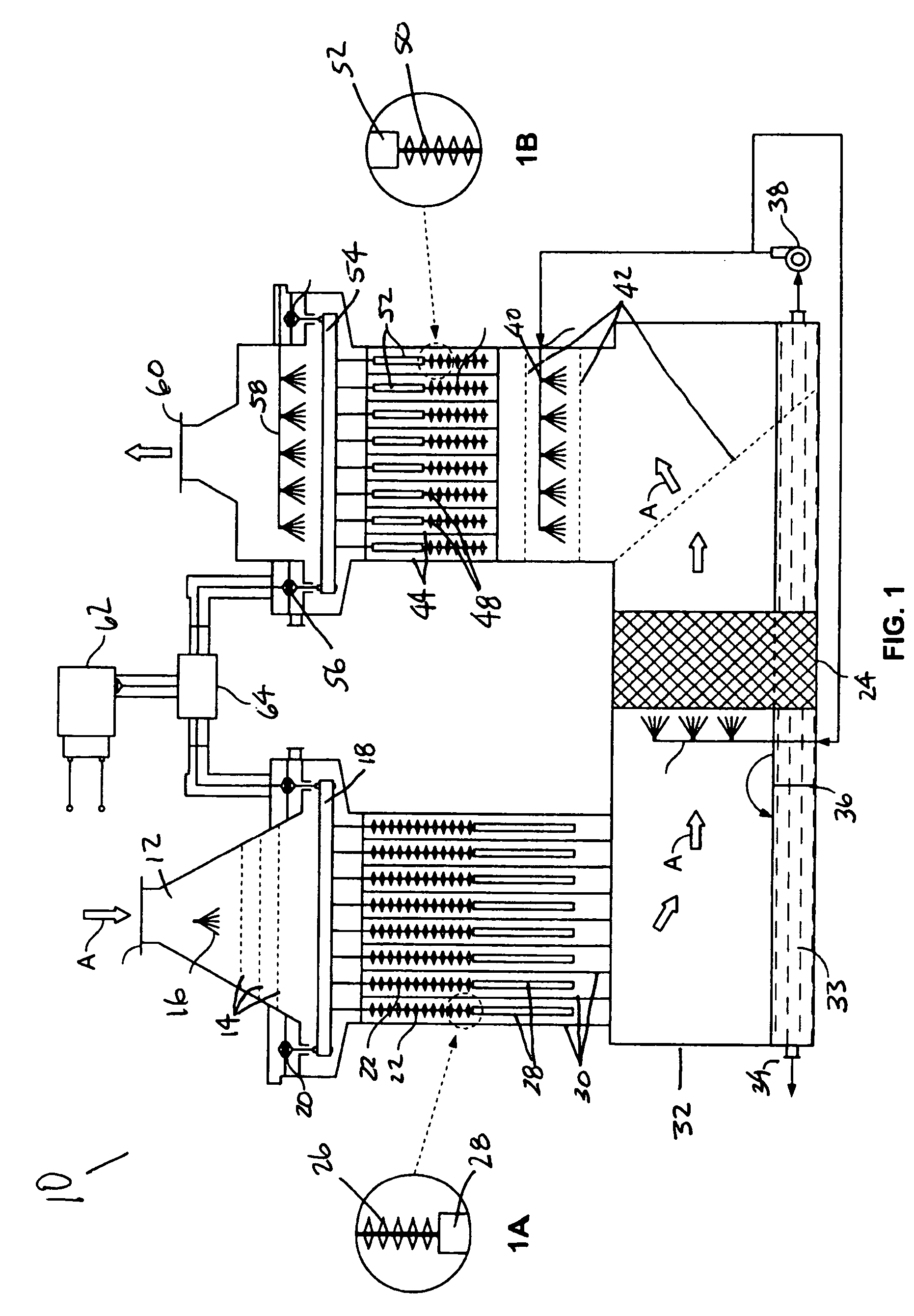

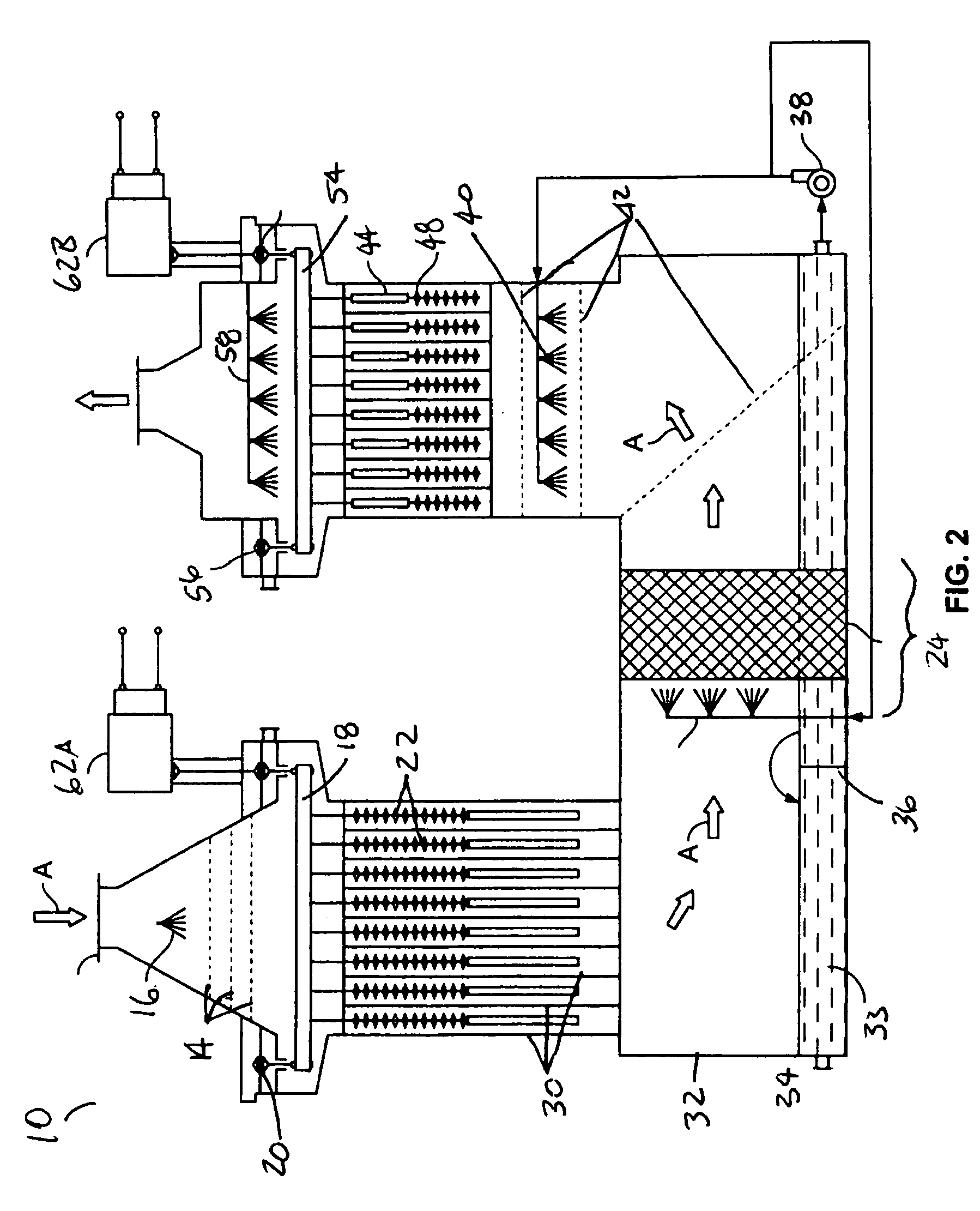

Granular biomass burning heating system

InactiveUS20070137538A1Improve unit efficiencyReduce lag timeAir supply regulationStirring devicesInformation controlProcess engineering

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

Tobacco leaf baking equipment

InactiveCN105520185AShort cycleSimple structureTobacco preparationBiomass combustionProcess engineering

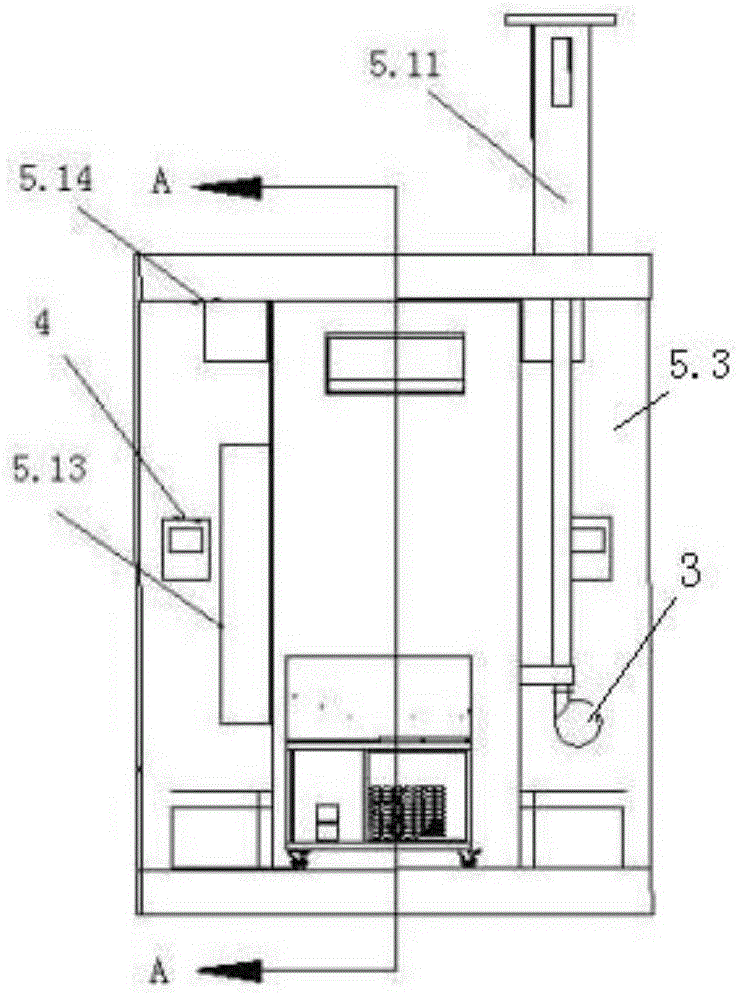

The invention aims to provide tobacco leaf baking equipment. The tobacco leaf baking equipment comprises a heating apparatus, a humidity discharging apparatus and a controller, wherein the heating apparatus comprises a biomass combustion furnace, a heat exchanger connected with an exhaust gas outlet pipe of the biomass combustion furnace, a circulating fan used for conveying hot air, and a feeding apparatus used for feeding to the biomass combustion furnace; the feeding apparatus comprises a hopper and a helical conveying part for conveying the material in the outlet of the hopper to the material inlet of the biomass combustion furnace; the humidity discharging apparatus comprises a humidity discharging opening and a humidity discharging window formed in the humidity discharging opening; and an oxygen supplying device, the circulating fan and the helical conveying part in the biomass combustion furnace are all connected with the controller. By adoption of the technical scheme, the tobacco leaf baking equipment has the advantages as follows: the overall tobacco leaf baking equipment is simple in structure; due to the integrated design of the heating apparatus, the humidity discharging apparatus and the controller, the tobacco leaf baking equipment is high in practicability; and the biomass combustion furnace is adopted for providing heat energy, so that the tobacco leaf baking equipment is green and environment friendly.

Owner:CHANGSHA XINDI ELECTRONICS TECH

Non-to-minimally fractionalized biomass-fueled renewable energy

InactiveUS20130328322A1Simpler and more practical and economically viable conversionIncrease costSolid waste disposalBiofuelsForms of energyOrganic Rankine cycle

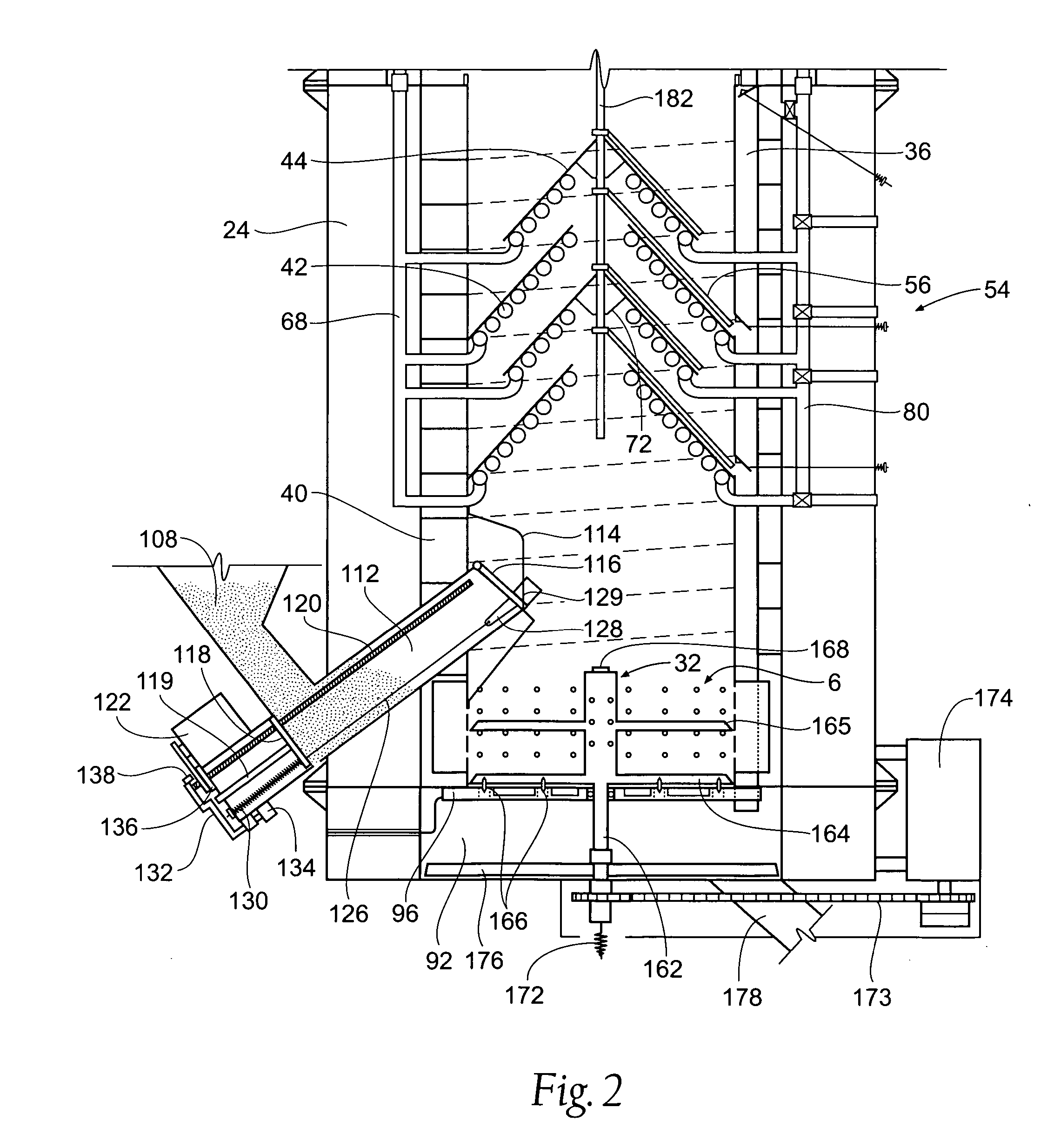

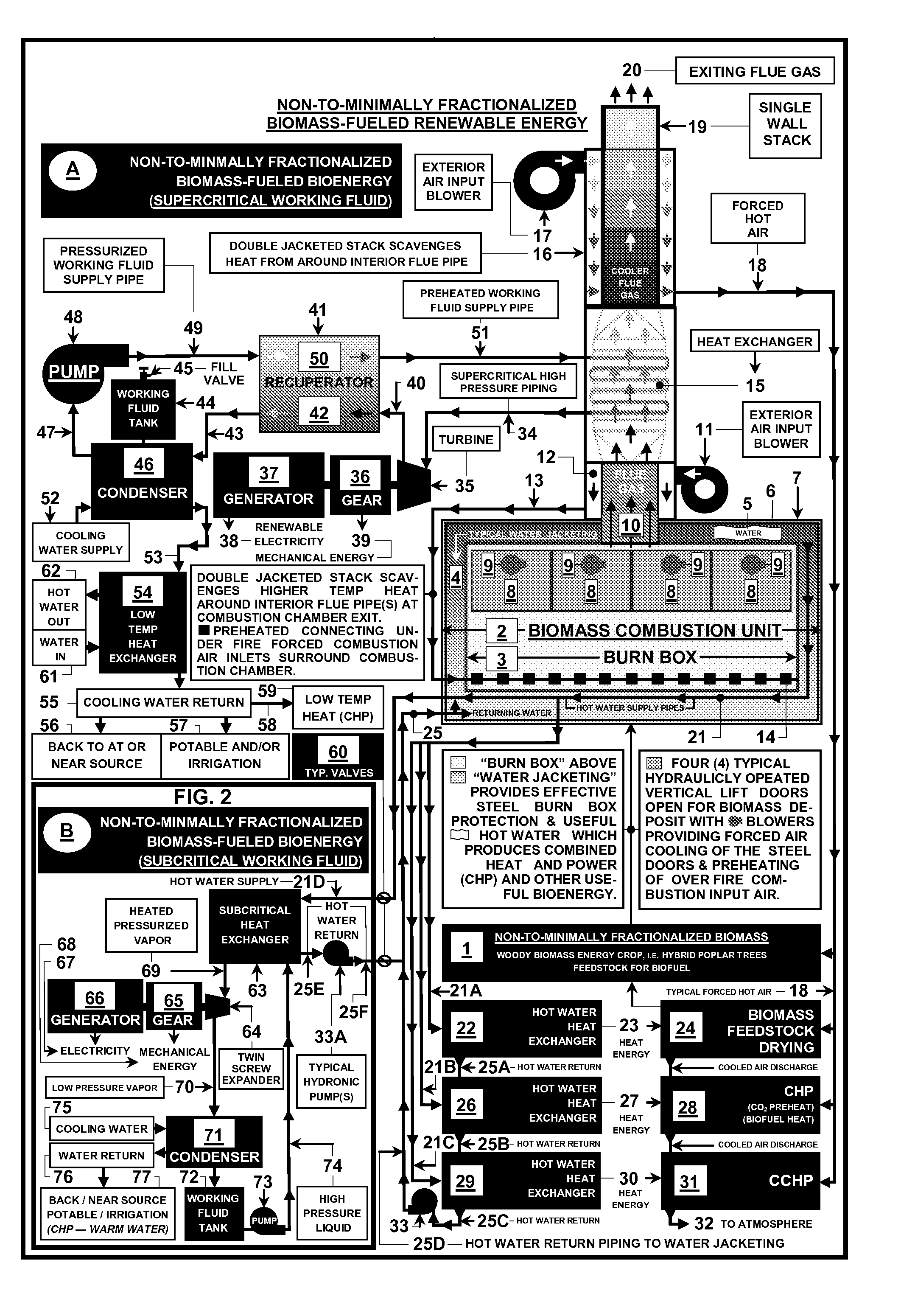

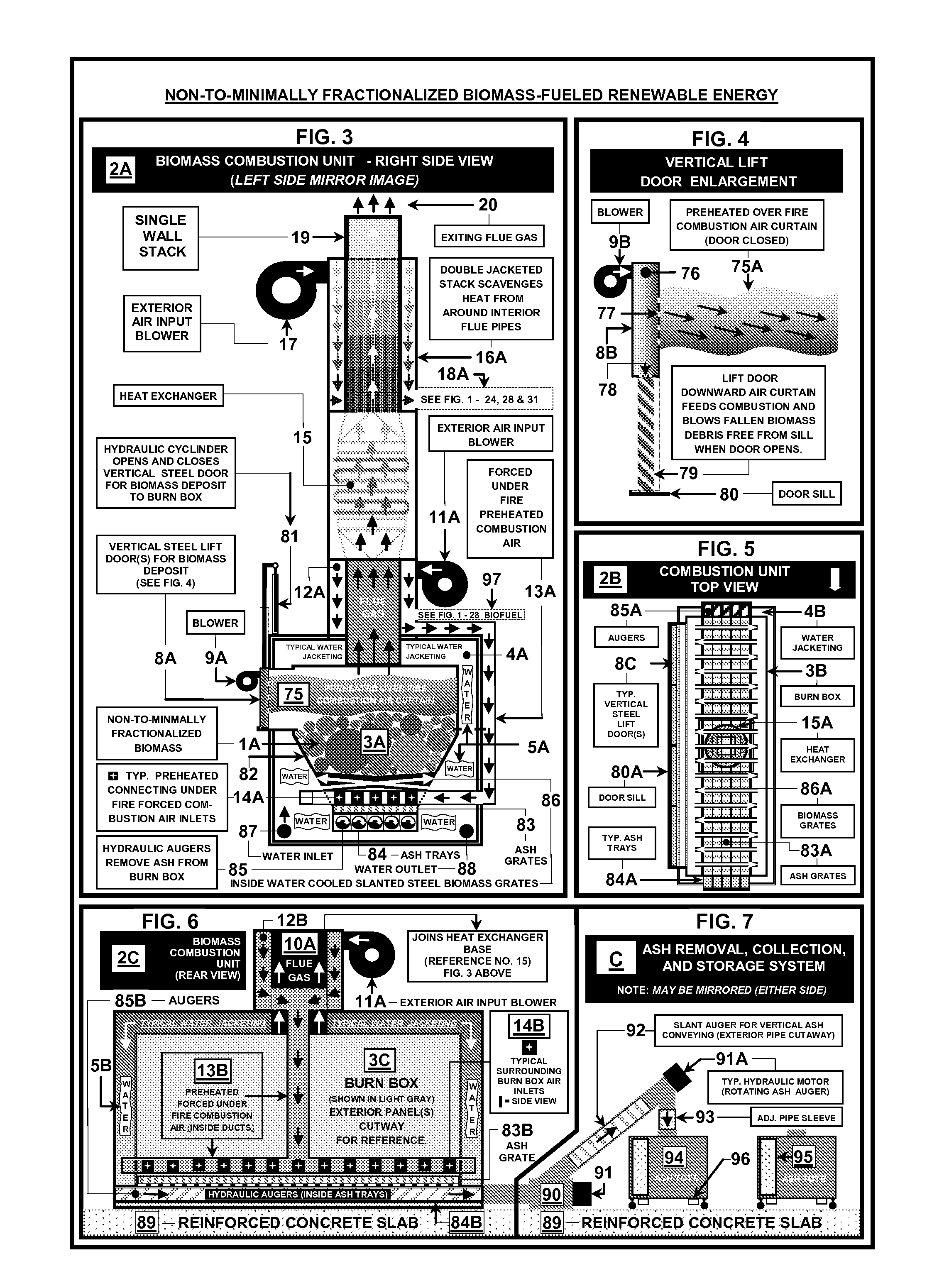

A novel Biomass Combustion Unit apparatus purposefully designed to be uniquely fueled with Non-To-Minimally Fractionalized Biomass for the intentional production of heat for conversion to a multiplicity of useful energy forms. More particularly, said apparatus provides useful heat for: (i) Power Generation, (ii) Heating Applications, (iii) Cogeneration or Combined Heat and Power (CHP), (iv) Trigeneration or Combined Cooling, Heat, and Power (CCHP), (v) Mechanical Energy and (vi) Facilitating the production of Biofuels. Additionally, methods and systems are presented wherein the abovementioned forms of energy deploy organic and inorganic working fluids, in both Subcritical and Supercritical Power Generation Cycles, via Organic Rankine Cycle and a modified Rankine Cycles, respectively. Further, Woody Biomass Energy Crops and Biofuel components are presented as well.

Owner:JULIAN MARVIN DUANE

Granular biomass burning heating system

InactiveUS7621227B2Minimize back burningImprove unit efficiencyAir supply regulationStirring devicesCombustionThree stage

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

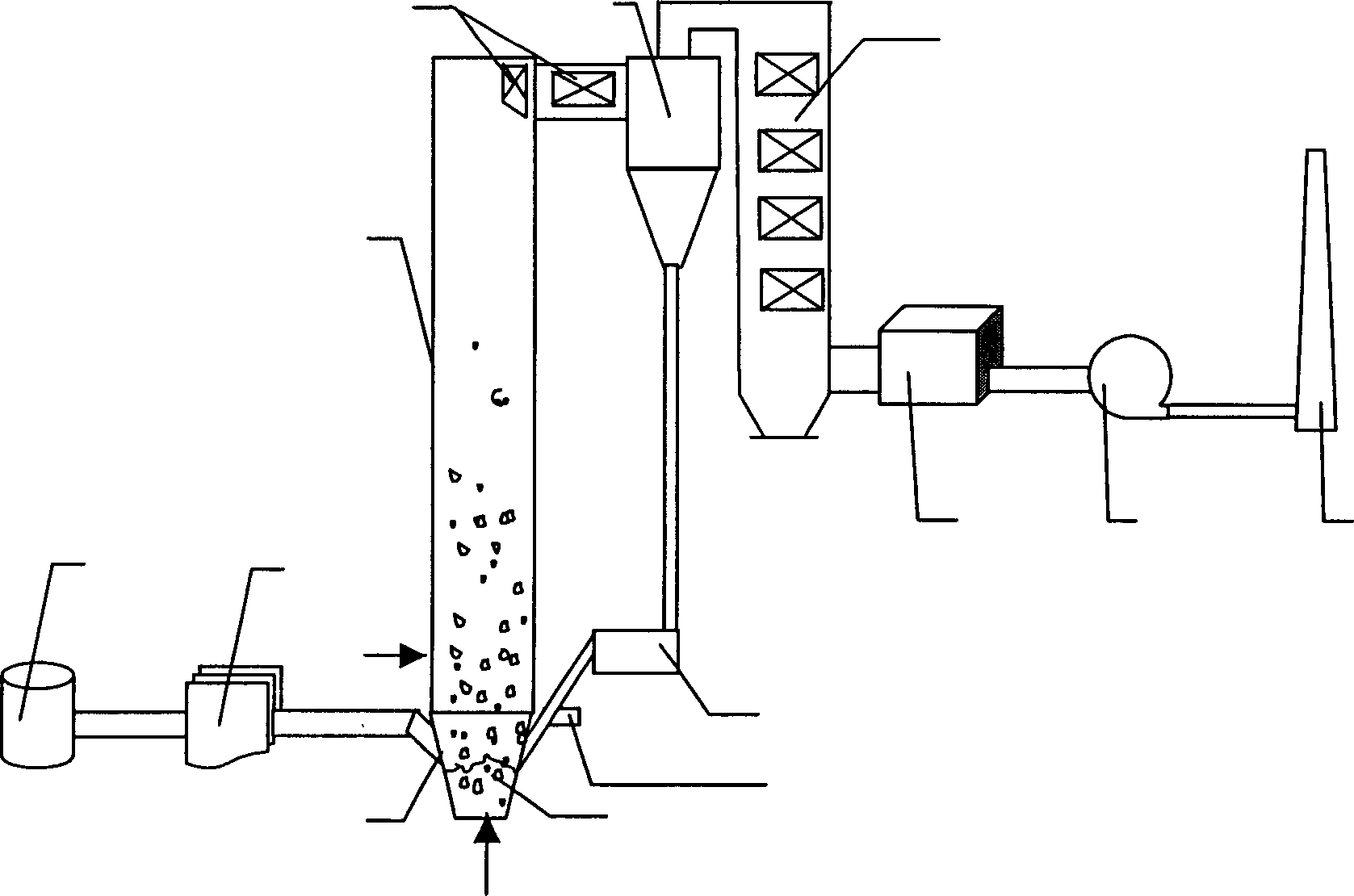

Circulating fluidized bed combustion device with biomass fuel and combustion method thereof

ActiveCN1804460AGuaranteed combustion spaceReduced risk of increased incomplete combustion lossesFluidized bed combustionIncinerator apparatusBiological materialsBiomass burning

The invention relates to a cycle fluid bed burning device and relative method which uses biological material as fuel. Said device comprises a furnace, a furnace outlet and a horizontal gas flue. Wherein, the horizontal gas flue has a heated surface, a cyclone separator with middle temperature connected with its back; the upper end of cyclone separator is connected to the tail gas flue, the dust cleaner, the wind guide device, and the chimney; the lower end of cyclone separator is connected to the cycle circuit and the furnace dense-phase area; the circle circuit is connected with bed material and additive feeding inlet to apply the additive which can solve the problem of alkali metal; the biological fuel via the parallel feeding inlets at the front of furnace, the breaking pretreatment is blown by the wind into the section-variable dense-phase area of furnace; and the straw should be first broken into 10cm. The invention has wider raw material and high burning efficiency while it can solve the problem of alkali metal.

Owner:ZHEJIANG UNIV +1

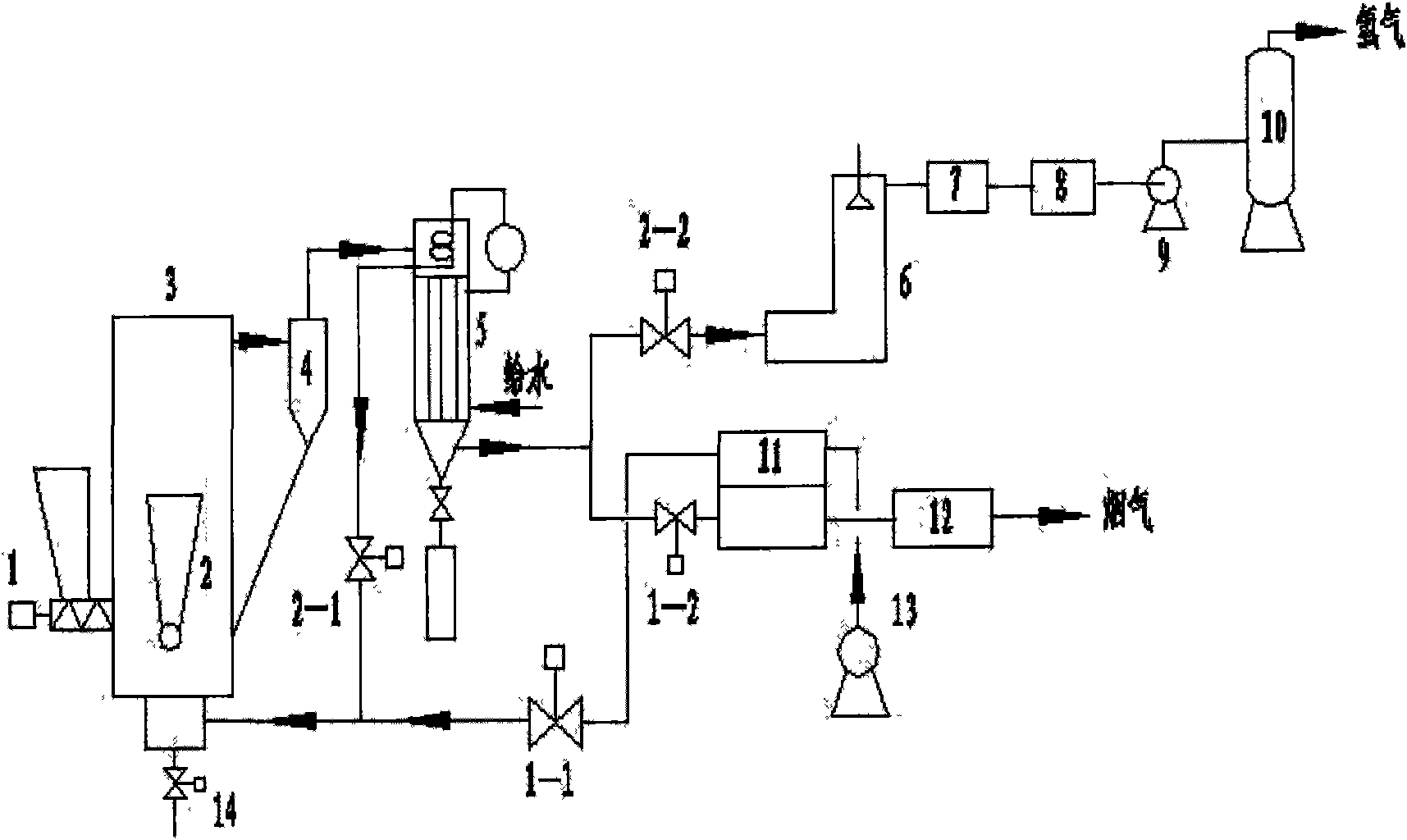

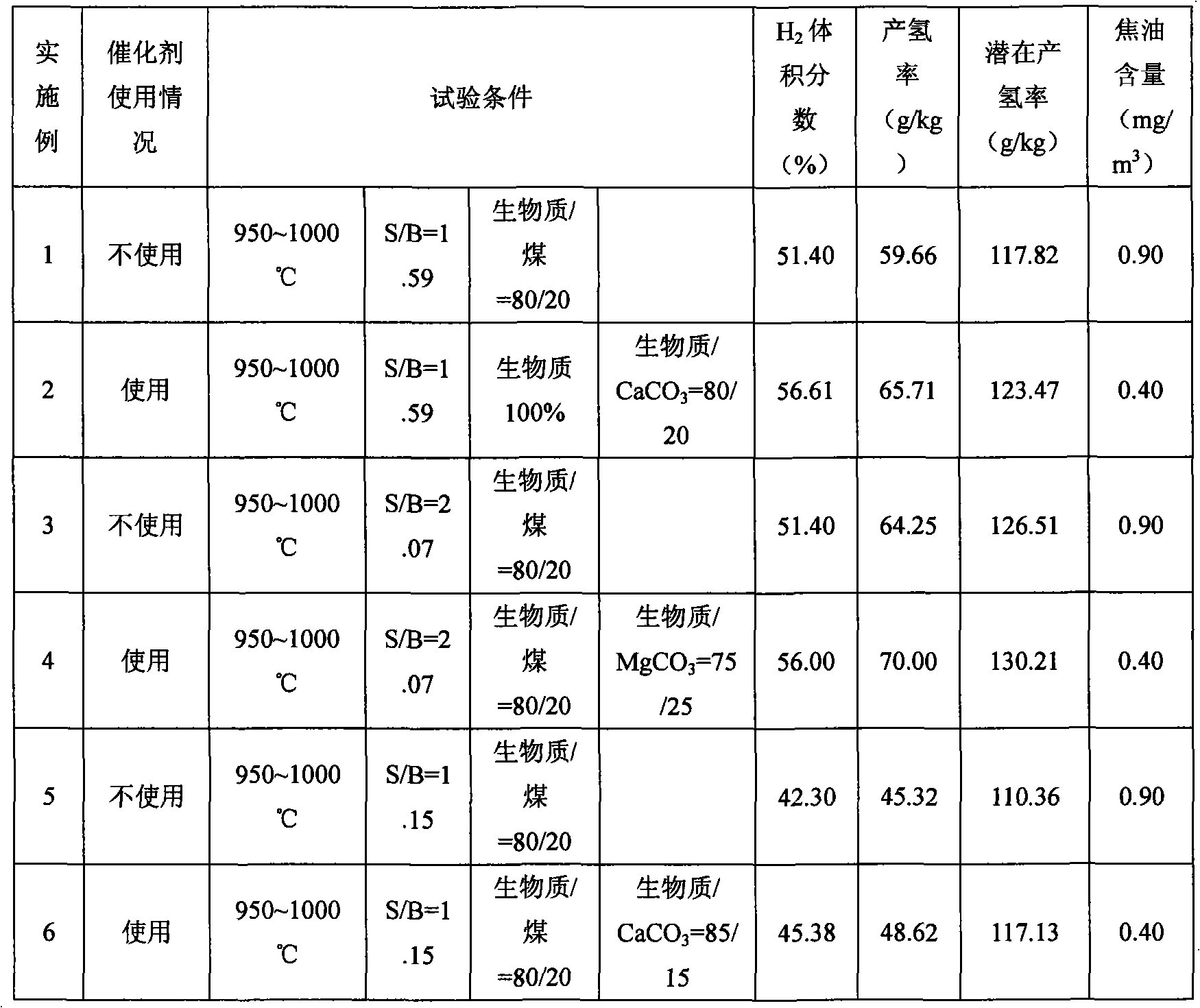

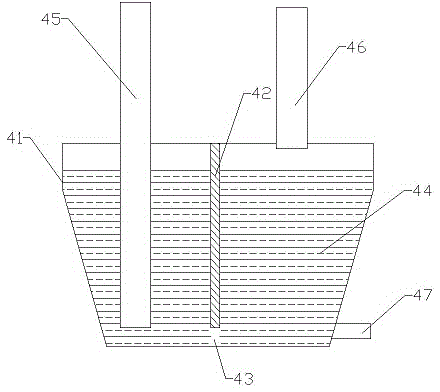

Method and device for producing hydrogen through biomass gasification by using single fluidized bed and two-step method

InactiveCN101570315AQuality improvementLess investmentHydrogen separationEnergy inputWater vaporVariable pressure

The invention belongs to the field of energy. Biomass is used as a raw material, and is added with catalyst calcium carbonate / magnesium carbonate of a carbonate system to react in a fluidized bed; a biomass gasification process is divided into two processes, namely a biomass burning process and a biomass pyrolysis and gasification process, and the two processes work alternately in turn, wherein the burning process comprises that catalyst calcium carbonate / magnesium carbonate granules are added into the fluidized bed, simultaneously air is supplied to the fluidized bed, the air supply to the furnace is stopped when the temperature of the bed layer is raised to a predetermined temperature, and the burning process is finished; then the biomass burning process turns to the gasification process, namely vapor and biomass are supplied to the fluidized bed to obtain hydrogen-rich gas with extremely low tar content; and after the hydrogen-rich gas is washed and purified by coal gas, the hydrogen-rich gas is converted into H2 and CO2 in a CO conversion device, then the gas is desulfurized and compressed, and the H2 is extracted from the gas in a variable pressure adsorption device. The method achieves that the gasification and burning two processes and the cyclic regeneration of a catalyst are finished in the same fluidized bed gasification furnace, the investment is saved, and the running cost is low.

Owner:JIANGSU UNIV

Biomass heat- and solar-energy multistage cooling, heating and power combined supply system

ActiveCN104154677AImprove heat transfer performanceReach the evaporation standardFrom solar energyMachines/enginesThermal energyLiquid storage tank

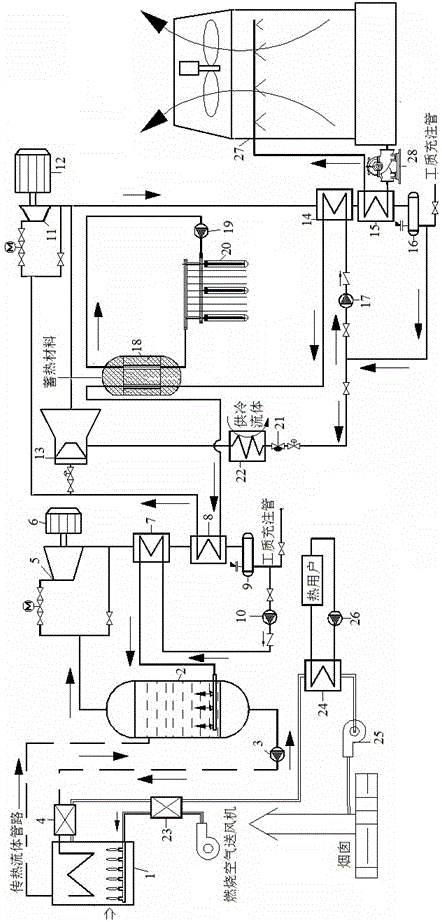

The invention provides a biomass heat- and solar-energy multistage cooling, heating and power combined supply system and belongs to the technical field of energy resource and environment. The biomass heat- and solar-energy multistage cooing, heating and power combined supply system comprises a heat transfer fluid circulation loop, a power generation loop, a cooling and power combined supply loop, a solar energy circulation loop, a biomass burning furnace smoke discharge pipeline, a heat and hot water supply loop and a cooling water loop, wherein the power generation loop is composed of a direct-contact type evaporator, a first turbine, a first heat regenerator, a condensation evaporator, a first liquid storage tank and a first working medium pressurizing pump, and the solar energy circulation loop comprises a heat storage and exchange device, a second heat transfer fluid circulation pump and a solar heat accumulation heater. The biomass heat- and solar-energy multistage cooling, heating and power combined supply system is high in heat exchange efficiency, gradient utilization of heat is realized, energy utilization efficiency is high, cooling, heat and power can be continuously and stably output, the direct-contact type evaporator is simple in structure and the like; output load of a biomass burning furnace and output load of the heat storage and exchange device can be adjusted according to needs of heat users for cooling load, heat supply load and power supply load.

Owner:KUNMING UNIV OF SCI & TECH

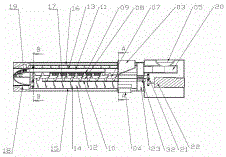

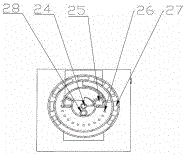

Biomass burning machine provided with tubular furnace hearth

InactiveCN104406158AQuick launchEasy to adjust dockingSolid fuel combustionAir/fuel supply for combustionSlagHearth

The invention relates to the technical field of biomass fuel burning, in particular to a biomass burning machine provided with a tubular furnace hearth. The biomass burning machine comprises a stock bin, a feeding mechanism, the tubular furnace hearth and a slag discharging and breaking device, and is characterized in that a detachable lengthened barrel (2) is arranged at the top of the stock bin, a stock bin cover (1) is mounted at the top end of the lengthened barrel (2) in a sleeving manner, and a hopper (4) is arranged in a barrel (3); the feeding mechanism comprises a feeding casing (6) and a feeding screw rod (7), the feeding casing (6) penetrates through a bellows (8) and is movably mounted at a bottom outlet of the hopper (4), and the feeding screw rod (7) is arranged in the feeding casing (6); and the slag discharging and breaking device comprises a slag discharging and breaking screw rod (9) provided with a hollow part as well as a chain wheel (10). The biomass burning machine provided with the tubular furnace hearth has the advantages of sufficient burning, low tail gas pollution, prevention of slag bonding and caking, wide biomass fuel adaptability, long service life, stable operation, low maintenance cost and the like.

Owner:YUNNAN HUAYI TECH

Slagging resistance method for mixed burning of biomass and sludge

InactiveCN103351094ARealize resource utilizationSolve the problem of easy slaggingSludge treatment by de-watering/drying/thickeningSolid fuelsResource utilizationSludge

The invention relates to a slagging resistance method for mixed burning of biomass and sludge. Sludge is added with flocculant for flocculation concentration, wherein weight ratio of the flocculant to the dry sludge is 1: (500-200). The concentrated sludge is added with a CaO tempering agent for dehydration treatment, wherein weight ratio of the CaO to dry sludge is 1: (100-10). The dehydrated sludge is dried and ground, and is then burnt after being mixed with biomass. Sludge discharged from a secondary sedimentation tank of a sewage treatment plant is added with aluminum, magnesium, calcium and other elements which contain biomass and function as resisting slagging in a burning process as conditioning agents to flocculate and dehydrate the sludge, and the sludge is directly burnt after being mixed with the biomass or burnt after being prepared and shaped into fuel, thus solving a problem of slagging in the biomass burning process. The method avoids direct addition of magnesium oxide, aluminum hydroxide, calcium oxide and other slagging-resistance additives, so as to avoid secondary pollution while saving resource; meanwhile, the method realizes resource utilization of the sludge, thus achieving two purposes.

Owner:TIANJIN UNIV

Device and process for separating carbonic acid gas by indirect burning of biomass

InactiveCN101289185AExtensive social benefitsBroad industrial application prospectsHydrogenCarbon compoundsOxygenCarbonic acid gas

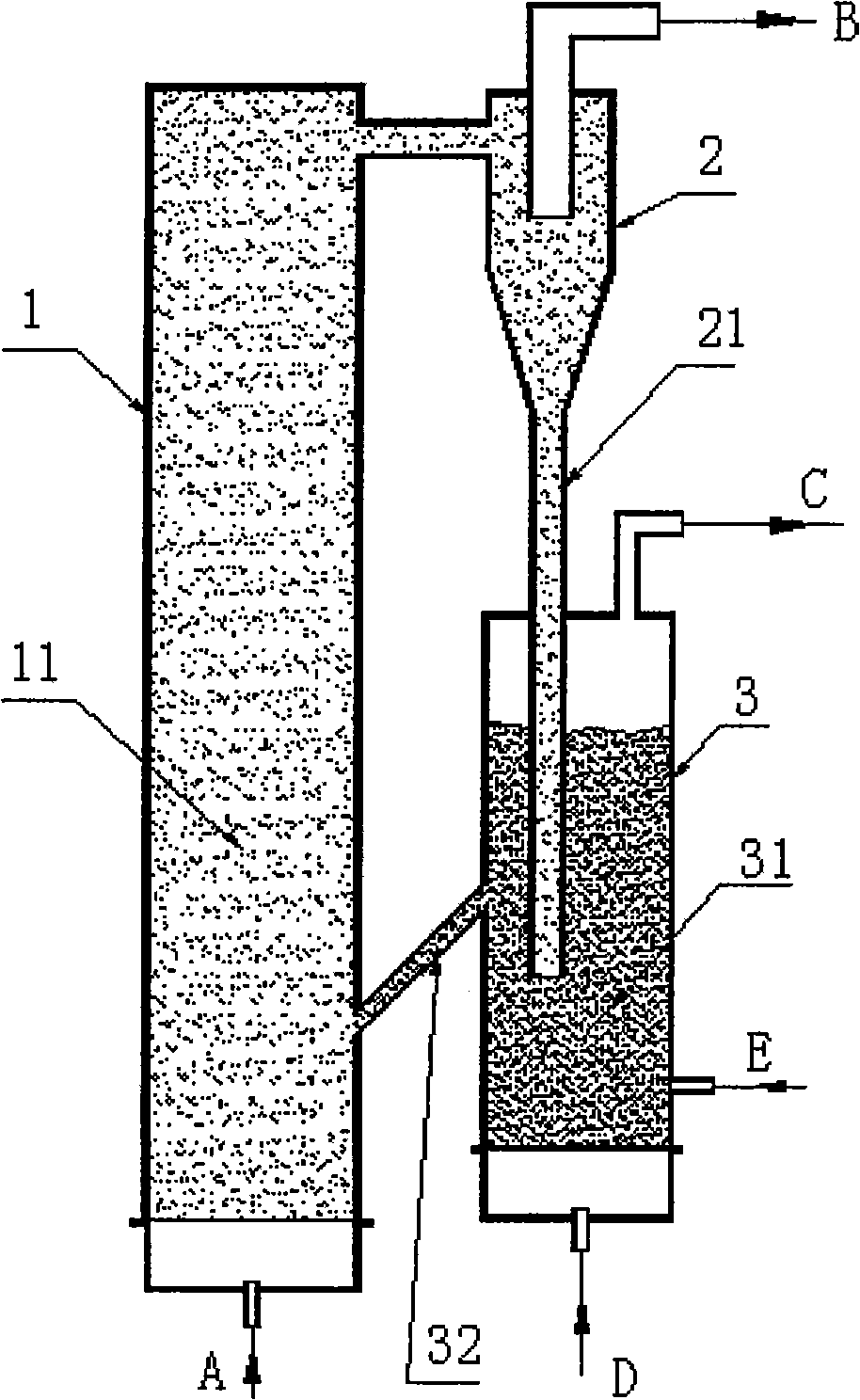

The invention relates to a device used for indirectly burning biomass to separate carbon dioxide and a method which is a burning way of the biomass and a biomass burning process based on a cycle oxygen carrier. The device consists of a circulating fluidized bed, a cyclone separator and a fluidized bed, which is formed into a circulation loop; the method is characterized in that oxidation reaction happens to metal and air in the circulating fluidized bed to generate a metallic oxide which enters the fluidized bed after being separated by the cyclone separator; gasification reaction happens to the biomass in the fluidized bed and the carbon dioxide or water vapour; reduction reaction happens to fuel gas generated from the gasification reaction and the metal oxide to generate the metal, the carbon dioxide and the water vapour, wherein, the carbon dioxide and the water vapour are discharged from an air outlet of the fluidized bed and condensed to obtain pure carbon dioxide and the metal reduced returns to the circulating fluidized bed for carrying out oxidation reaction with the air to complete the regeneration process of the metallic oxide. The carbon dioxide can be separated from combustion products without extra energy consumption.

Owner:SOUTHEAST UNIV

Method for reducing slag in biomass combustion

ActiveUS20120312206A1Improve brittlenessReduce fouling rateSolid fuel pretreatmentSolid fuelsPtru catalystCapital equipment

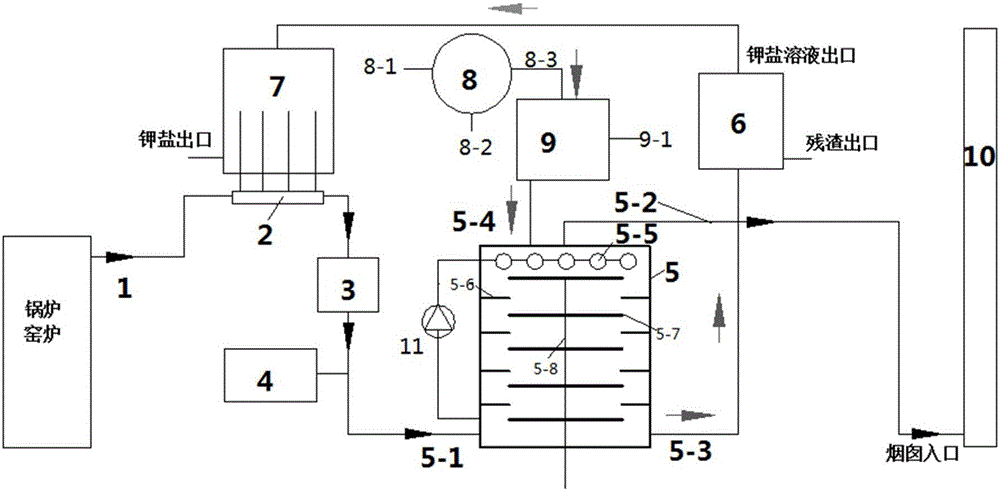

Biomass is quickly becoming an important feedstock for energy generation in power plants. Due to their composition and nature, certain biomass fuels contribute to slagging, fouling, and corrosion. This invention provides a novel method of reducing or suppressing slag deposition and / or cleaning deposited slag in energy production processes in which potassium-containing solid fuels are combusted. Besides acting as a slag suppressant, further advantages of this invention are that the additive has no detrimental side-effects on capital equipment, increases slag friability, decreases slag fouling rate, reduces heat transfer corrosion as well as increasing the lifetime of the selective catalytic reduction catalyst.

Owner:ECOLAB USA INC

Biomass-burning power generation device

The invention provides a biomass-burning power generation device and aims to solve the problem that biomass power generation is high in cost, serious in pollution and too narrow in available biomass material range. The technical scheme includes that the biomass-burning power generation device comprises a biomass burner (8), a temperature difference engine (17), a cooler (24), a circulating pump (25), a power generator (26) and a power control system (27), biomass fuel is burnt in the biomass burner (8) and releases high-temperature flame and gas to the temperature difference engine (17), low-temperature circulating liquid brings heat away from the temperature difference engine (17) to enable the temperature difference engine (17) to generate temperature difference so as to generate power output to drive the power generator (26) for power generation, and generated power is adjusted by the power control system and then output to the outside. The biomass-burning power generation device can be used for small-scale power generation of enterprises, institutions and the like, can be used for power generation of vehicular moving platforms, shipborne moving platforms, aircraft moving platforms and the like and can be used for distributed-type grid-connected power generation.

Owner:赵铭

Method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux

ActiveCN105771600AWell mixedAvoid secondary pollutionGas treatmentDispersed particle separationCombustionResource utilization

The invention relates to a method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux. The method comprises the steps that plant ash seriflux is adopted for independently or jointly oxidize and remove SO2, NOx, Hg, H2S, HCl and HF in tail gas of a combustion or chemical device; tail gas containing SO2, NOx, Hg, H2S, HCl and HF from a boiler or kiln or chemical device is cooled and enters a rotary absorption reactor; soluble or acid gas SO2, NO2, Hg2+, H2S, HCl and HF can be directly washed and absorbed by a solution, and indissolvable gas NO and Hg0 can be absorbed by a solution after being pre-oxidized or oxidized by an additive into NO2, HNO2, HNO3 and Hg2+. According to the method, resource utilization can be achieved for solid waste produced by biomass burning, multiple pollutants can be integrally removed, the purpose of dealing with waste by waste is achieved, secondary pollution is avoided in the whole removal process, and the market development and application prospect is wide.

Owner:刘杨先

Satellite remote sensing atmospheric ozone profile inversion algorithm

InactiveCN108760662AIncreased signal degrees of freedomIncrease vertical resolutionColor/spectral properties measurementsAtmospheric ozoneEarth surface

The invention discloses a satellite remote sensing atmospheric ozone profile inversion algorithm, which comprises: 1, carrying out radiation calibration and wavelength calibration by using an ozone monitoring instrument OMI; 2, carrying out radiation transmission model and weighting function calculation; and 3, inverting atmospheric ozone profile information based on an optimal estimation technology algorithm by using the radiation spectrum simulation value and the weighting function parameter calculated in the step 2 after the radiation calibration and the wavelength calibration of the ozonemonitoring instrument OMI are completed. According to the present invention, the algorithm is established by using the OMI ultraviolet radiation spectrum data and selecting the fitting wave bands UV-1and UV-2, and can invert the atmospheric ozone profile information from the earth surface to the 60 km atmosphere based on the optimal estimation technology, wherein the atmospheric ozone profile information comprises the total ozone column concentration, the troposphere ozone column concentration and the stratosphere ozone column concentration, such that the troposphere atmosphere ozone profileis accurately inverted; and the method can be used for analyzing the relationship between atmospheric ozone convective motion, exchange processes, biomass burning and human pollution, and tracking thetemporal and spatial transport of ozone.

Owner:UNIV OF SCI & TECH OF CHINA

Plant ash-based method for desulfurization, denitration and demercuration of double impact beds

InactiveCN104474879AImprove mass transfer efficiencyLow application costDispersed particle separationAir quality improvementCombustorSorbent

The invention relates to a plant ash-based method for desulfurization, denitration and demercuration of double impact beds. The method is characterized in that flue gas containing SO2, NOx and mercury from a burner is cooled by a flue-gas temperature regulator, and is sprayed into impact-bed reactors by laval spraying pipes; a plant ash type absorbing agent is sprayed into the impact-bed reactors by the laval spraying pipes which are coaxially and oppositely distributed; two strands of air flow oppositely impact in the reactors and realize absorption and removal of the SO2, the NOx and the mercury; the impact bed reactors are symmetrically distributed, and when the left impact bed reactor is regenerated, the flue gas from the burner is automatically switched and flows into the right impact bed reactor; the two impact bed reactors are mutually crossed for use and regeneration. The method has the advantages that biomass burning waste is utilized for the desulfurization, the denitration and the demercuration simultaneously, the purpose of using waste to treat waste can be achieved, and no secondary pollution is caused in the removing process, so that the invention relates to a flue-gas purifying method and device with wide application prospects.

Owner:JIANGSU UNIV

Side-Feed Forced-Air Biomass Burning Cookstove

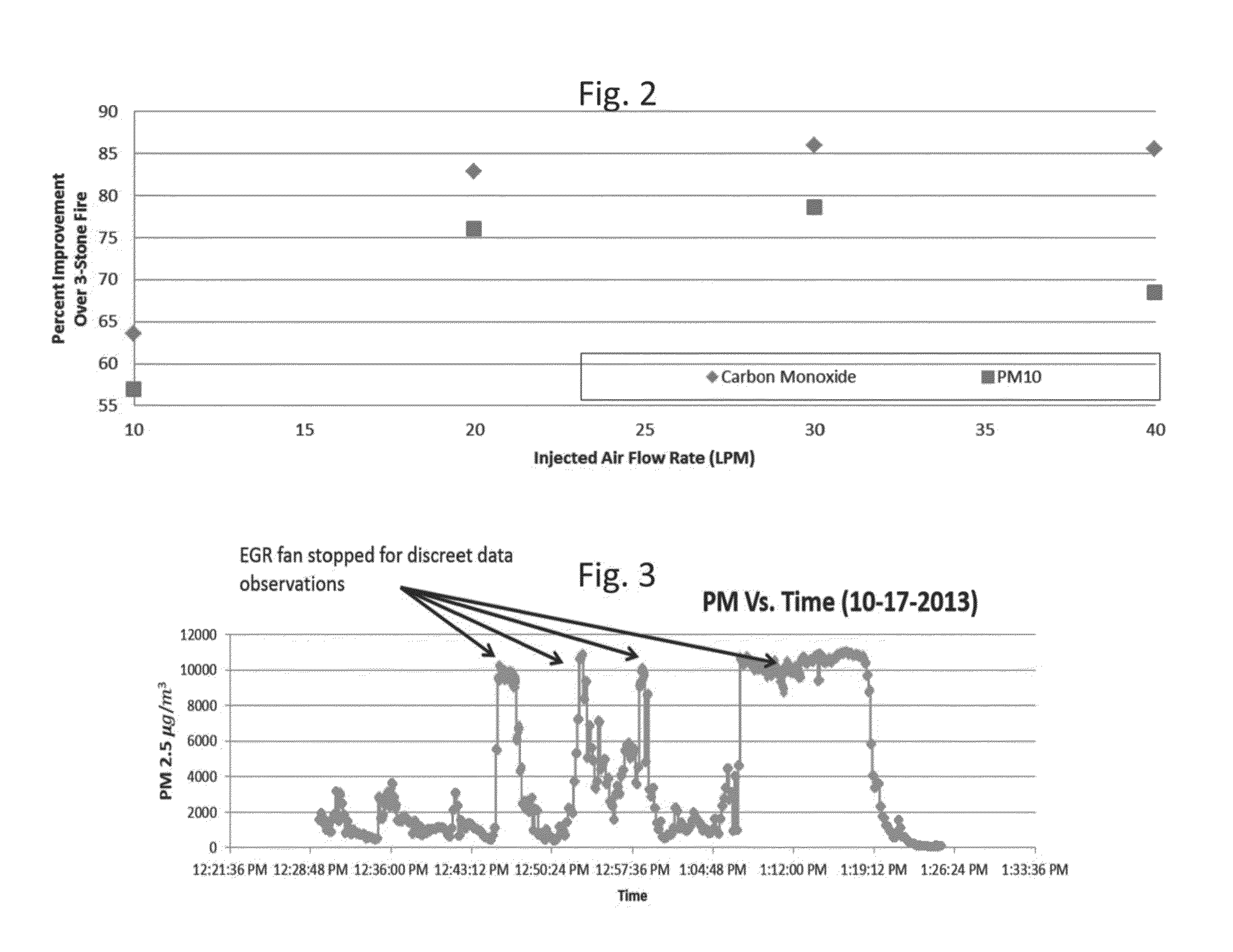

InactiveUS20160076774A1Emission reductionReduce particulate emissionsCombustion-air/flue-gas circulation for stovesCooking fumes removalParticulatesCombustion chamber

Disclosed herein are systems and devices that aid in reducing particulate emissions from biomass stoves, for example by the use of gases injected in or near the oxidation zone of a combustion chamber. Also disclosed are systems and devices providing electricity to a pump or blower that aids in injecting the gas and / or collecting exhaust gases. In some embodiments the device providing electricity is a thermoelectric generator that may also be used to power other devices. In many embodiments, the systems and devices inject a gas at or near the oxidation zone in the combustion chamber of a biomass stove. The gas injected into the zone may be fresh air, exhaust from combustion or combinations thereof. The gas can be forced into the to combustion chamber with the aid of a pump or blower that may also aid in drawing in exhaust gas.

Owner:COLORADO STATE UNIVERSITY +1

Biomass burning machine

InactiveCN103512024AImprove the combustion environmentLiquidSolid fuel combustionWater heatersCombustion chamberLiquid medium

The invention provides a biomass burning machine. Biomass is used for burning in the biomass burning machine. The biomass burning machine comprises a burning furnace, an air bellow and a feeding device connected to the burning furnace. A combustion chamber and a slag collection chamber are arranged in the burning furnace. The slag collection chamber is arranged below the combustion chamber. A space formed by the combustion chamber, the slag collection chamber and the inner wall of the burning furnace contains liquid mediums which are capable of conducting heat energy in the combustion chamber. Because the specific heat capacity of the liquid mediums is large, the liquid mediums can absorb the heat energy produced through burning of the biomass in the combustion chamber in a heat transmission mode, the burning environment of the biomass is improved, and the biomass burning machine is friendly to environment and reduces manpower and material resources. Moreover, the liquid mediums have fluidity, the liquid mediums absorbing the heat energy can be recycled after being cooled, and therefore the biomass burning machine has an energy-saving effect.

Owner:中山市兴和生物能源科技有限公司

Method and system for increasing the efficiency and environmental compatibility of combustion processes

InactiveUS20120318142A1Improve overall utilizationLow costGas treatmentUsing liquid separation agentCombustion systemFlue gas

A method and system for increasing the efficiency and environmental compatibility of combustion systems, preferably for heat recovery from a wet flue gas and / or for flue gas purification, especially of flue gas from the combustion of high water-content fuels, such as biomass, especially wood, and for reducing the volumetric flow of the flue gas and / or for recovery of water from the flue gas, wherein the flue gas is brought into contact with a measured quantity of concentrated hygroscopic in at least one absorber unit and the measured quantity of hygroscopic material is diluted and heated with absorption of water from the flue gas. Heated is extracted from the heated and diluted hygroscopic material after which it is concentrated in at least one separating unit by separation of water and the resulting measured quantity of concentrated hygroscopic material obtained is routed at least partially to the absorber unit.

Owner:ALODYNE

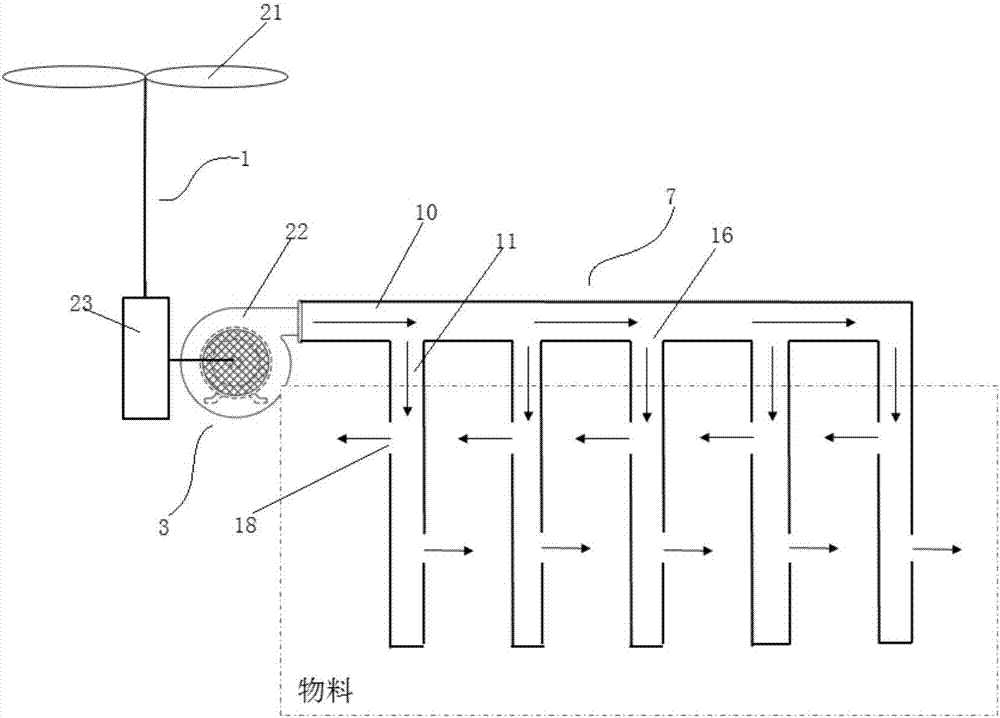

Blowing and sucking combined material drying system and control method thereof

ActiveCN107120927ADry thoroughlyImprove heat transfer efficiencyDrying gas arrangementsDrying machines with local agitationCombustionHeat stability

The invention discloses a blowing and sucking combined material drying system and a control method thereof. The blowing and sucking combined material drying system comprises an air pipe device, an air blowing part and an air sucking part, wherein air holes are formed in the air pipe device; the air blowing part is connected with the air pipe device and blows air to the air pipe device; and the air sucking device is connected with the air pipe device and performs air suction on the air pipe device. According to the blowing and sucking combined material drying system and the control method thereof, the biomass drying efficiency, combustion efficiency and heat stability are improved.

Owner:中科乡电(北京)环保科技有限公司

Wet electrostatic precipitator for treating oxidized biomass effluent

ActiveUS20060226373A1Material analysis using wave/particle radiationElectric discharge tubesParticulatesProcess engineering

An apparatus for removing particulate matter from a biomass combustion gas stream, the apparatus having a mist-producing element that mixes a gas stream entering the apparatus with liquid droplets; a Wet Electrostatic Precipitator (WESP) section that includes ionizing electrodes that electrically charge the particulate matter and the intermixed liquid droplets and collecting surfaces under the influence of an electrical field which attract and remove electrically-charged particulate matter and intermixed liquid droplets from the gas stream; and a scrubbing section that provides for additional scrubbing of the gas.

Owner:ZENVIRO TECH HLDG INC

Portable picnic biomass-burning warming furnace

InactiveCN102748780ALow costEasy to useDomestic stoves or rangesLighting and heating apparatusPicnicCombustor

The invention discloses a portable picnic biomass-burning warming furnace which comprises a furnace body and a furnace hearth. The furnace hearth is arranged in the furnace body, surrounded by the wall of the furnace hearth and communicated with a feeding hopper; the lower part of the furnace hearth is provided with a grate and an ash hopper, and the upper part is provided with a burner; the upper opening of the burner is provided with a burning basin; an air preheating and flowing cavity is formed between the shell of the furnace body and the wall of the furnace hearth; and a plurality of secondary air inlet holes are disposed on the shell of the furnace body. The portable picnic biomass-burning warming furnace does not need to be provided with a smoke pipe and a fan, is compact and portable, is easy to manufacture, simple in operation, and low in production and use cost, can burn various bulk biomass such as straw and tree branches which do not need to be fine processed on the spot fully without smoking, can be used for cooking and warming and is suitable for popularization.

Owner:沈桀

Heat transfer compounding integrated furnace for biomass burning

ActiveCN104879736ABurn evenlyOvercome the defects of insufficient combustionPilot flame ignitersSteam generation plantsFlue gasProcess engineering

The invention discloses a heat transfer compounding integrated furnace for biomass burning. The furnace comprises a steam boiler, a smoke vent of the steam boiler is sequentially communicated with a hot blast heater and a hot water furnace, the hot water furnace is communicated with a flue gas emission and flue gas waste heat recycling device, one fan is needed by whole equipment, therefore the production cost can be saved; furthermore, the smoke exhaust way of a traditional flue can be changed by the flue gas emission and flue gas waste heat recycling device, so that energy saving can be realized, and the dynamics of environmental protection can be improved; in addition, by adopting the scheme provided by the invention, the heat transfer compounding integrated furnace is novel in structure, convenient and quick to ignite, safe and convenient for fuel transportation and high in heat efficiency, and the production cost can be greatly reduced.

Owner:SHANDONG HAOBANG ENVIRONMENTAL PROTECTION TECH

Coal combustion product cements and related methods of production

Coal combustion product cement compositions produced using classes of relatively low-cost industrial by-products and low-value minerals. A variety of highly sustainable cements with low-environmental impact can be provided. Coal combustion by-products and other wastes produced on the large scale from the burning of coal or coal and biomass in coal-fired power stations with or without low-value minerals, processed minerals, and / or by-products of the mining, mineral processing, metal refining, petrochemical, fine chemical, pharmaceutical, agrochemical, biotechnology, food, feed and energy industries, as well as agricultural and municipal by-products, can be utilized to provide improved cements and cementitious materials that are more economic and environmentally friendly than traditional cements including Portland cement.

Owner:CALSTAR CEMENT

Method and device for producing syngas by combustion and gasification of double cylinders

ActiveCN101921625AEliminate heat transfer processHigh operating thermal efficiencyBulk chemical productionFixed-bed gasificationSyngasCombustible gas

The invention relates to a method and a device for producing syngas by combustion and gasification of double cylinders, which comprises a combustion furnace and a gasification furnace in a double-cylinder structure, as well as a matching indirect gasification device comprising a feeding system, a gas-solid separation system, a heat recovery utilization system and the like, wherein the combustion furnace constitutes an inner cylinder of the device, the gasification furnace is positioned in an annular space between an outer cylinder and the inner cylinder, and the reaction control of the gasification furnace can be implemented by zoning. The supply of materials is realized by a hopper, a feeder, a driving gear, a rotating disc and the like, and the materials in the hopper are sent onto the rotating disc in the gasification furnace via the feeder and respectively sent to feeding valve ports of the combustion furnace and the gasification furnace via the rotating disc, thereby realizing the distribution and the transportation of the materials. The invention provides an indirect gasification method with higher efficiency and a compact integrated device, and the device has high reliability and high utilization efficiency of energy, and can be used for directional gasification of coal or biomass, or be used as a matching device for producing combustible gas with high calorific value through combustion of the coal and the biomass.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Biomass burning fluidized bed boiler

ActiveCN102980177AEmission reductionImprove heat transfer performanceFluidized bed combustionApparatus for fluidised bed combustionCombustionFluidized bed

The invention discloses a biomass burning fluidized bed boiler which comprises a boiler wall, a primary air pipe, a secondary air pipe, an air distribution plate and an air distribution pipe, wherein the boiler wall is a heavy or semi-light boiler wall; and a water cooling pipe is arranged around a furnace. The biomass burning fluidized bed boiler also comprises a furnace, wherein a separation chamber is arranged on one side of the furnace; an inlet of the separation chamber is connected with a channel at an outlet of the furnace; an arc cover is arranged at the inlet of the separation chamber; a membrane water cooling wall is arranged on the side wall of the separation chamber; a smoke outlet is arranged in the center line direction of the arc cover; and a return feeder is arranged at the joint between a discharge port of the separation chamber and a return inlet of the furnace. The biomass burning fluidized bed boiler disclosed by the invention mainly solves the problem that because the particle size of the biomass material is not uniform and the humidity difference is large, sufficient combustion can not be realized at the outlet of the furnace in a short time; and a separator can separate smoke and the non-sufficiently burnt biomass material for further combustion.

Owner:XIANGTAN BOILER

Novel burner-type biomass burning machine adopting sleeves and moving grate

ActiveCN106090889ACompact designReduce volumeSolid fuel combustionLump/pulverulent fuel feeder/distributionThermal energySocial benefits

A novel burner-type biomass burning machine adopting sleeves and a moving grate mainly comprises a front reaction bin and a rear auxiliary control box, wherein the front reaction bin is divided by four layers of sleeves into a gasification bin, a gasified gas collecting and premixing bin, a fixed carbon burnout bed, a quaternary air distribution chamber and the like; fuel sufficiently reacts in all stages after entering the burning machine and before being discharged out of the burning machine in cooperation with the auger grate under the multistage air distribution function of a combustion air fan; the rear auxiliary control box comprises the combustion air fan, an air distribution header, a transmission motor, a comprehensive control system, an igniter and other auxiliary devices. The burning device adopts a relatively advanced and manure gasification combustion technique, reflects relatively greater industrial perspectiveness, is a novel biomass heat energy application technique which is clean, efficient, energy-saving, environment-friendly, stable in operation, simple and convenient to operate and wide in fuel adaptability, can be widely applied in clean heat energy equipment in distributive energy centers of new-type urbanization and regional industrial parks in China and can bring in remarkable economic and social benefits.

Owner:联合优发生物质能源徐州有限公司

Intelligently-controlled flue-cured tobacco biomass burning machine

PendingCN107420881AImprove roast qualityImprove securityTobacco preparationSolid fuel combustionBiomass burningCombustion chamber

The invention belongs to biomass burning machines and relates to an intelligently-controlled flue-cured tobacco biomass burning machine, in particular to a biomass particle burning machine structure technology applied to tobacco flue-curing chambers of large dense type flue-curing chambers and used for accurately controlling the burning state according to a tobacco flue-curing curve. When feeding of a bin of the intelligently-controlled flue-cured tobacco biomass burning machine is conducted, a top plate is taken off, biomass particle fuel is poured into the bin, a starting button on a lower burning machine control panel is pressed, an automatic feeding motor starts to work, fuel is sent into a burning chamber, an automatic ignition device works, fuel is ignited, a centrifugal fan is started, air is sent into the burning chamber for burning supporting, an automatic coke removing device works after certain time, and waste slag obtained after burning is output out of the burning chamber. The biomass burning machine and a tobacco dense flue-curing chamber control instrument are in interlocked control, automatic feeding and automatic coke removing of the burning machine are controlled according to the tobacco flue-curing curve, and accurate control over tobacco flue curing is achieved. Due to the height difference between an automatic feeding device and the bottom of the burning chamber, the backfire and backdraught phenomenon can be effectively prevented.

Owner:云南昆船电子设备有限公司

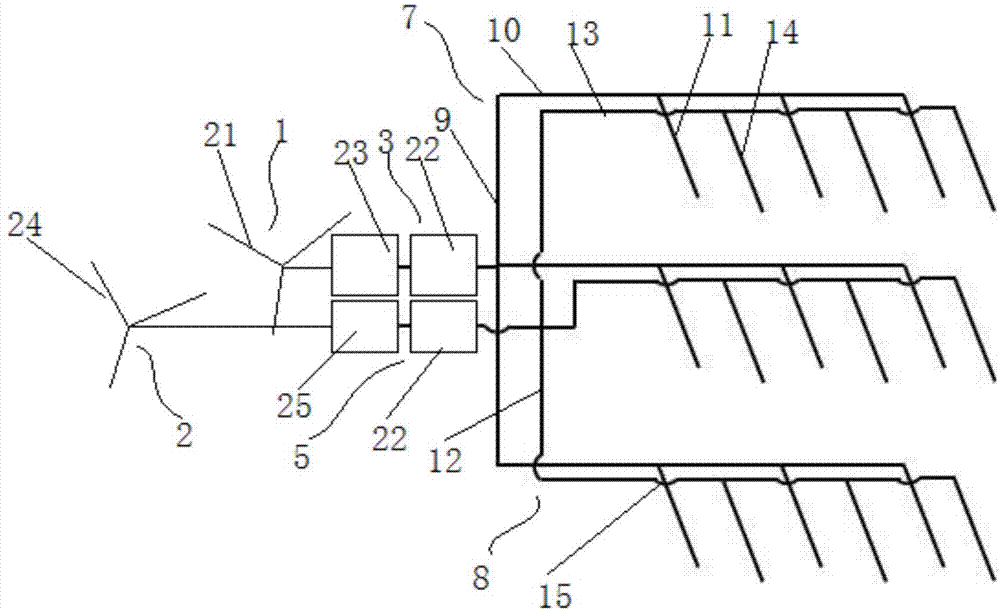

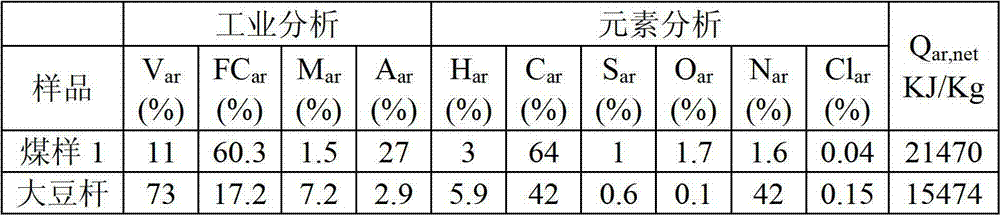

High-chlorine biomass and coal co-utilizing system with low-chlorine-corrosion and low-mercury discharge and method

ActiveCN102818248AEmission reductionReduce heat transfer areaCombustion processDispersed particle separationAir preheaterSingle substance

The invention discloses a high-chlorine biomass and coal co-utilizing system with low-chlorine-corrosion and low-mercury discharge and a method. The system comprises a coal-fired boiler system, wherein the coal-fired boiler system comprises a coal-fired boiler (1) with a boiler flue (11); the system is further provided with a biomass combustion furnace system; the combustion furnace system comprises a biomass combustion furnace (3) with a combustion furnace flue (7); an air pre-heater (4) with a cold air inlet (8), a hot air outlet and a pipeline (6) is arranged in the middle of the biomass combustion furnace flue; the smoke generated by the biomass combustion furnace flows to the air pre-heater (4) and is sent to the coal-fired boiler flue (11); a recycling flue (2) is arranged at the outer side of the biomass combustion furnace flue, wherein the inlet and the outlet of the recycling flue are arranged in the front and back sides of the air pre-heater; and the recycling flue is provided with a circulating fan (9). According to high-chlorine biomass and coal co-utilizing system with the low-chlorine-corrosion and the low-mercury discharge and the method, corrosion on high-temperature heating surface of coal powder furnace by CI (chlorine) released by biomass can be avoided; and meanwhile, the oxidation and granulation of mercury in the smoke can be accelerated by CI in the biomass, so that high temperature corrosion is avoided and the discharge of single substance of mercury is reduced.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com