Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Carbonic acid gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• CARBONIC ACID GAS (noun) The noun CARBONIC ACID GAS has 1 sense: 1. a heavy odorless colorless gas formed during respiration and by the decomposition of organic substances; absorbed from the air by plants in photosynthesis. Familiarity information: CARBONIC ACID GAS used as a noun is very rare.

Processing method for natural bamboo juice beverage

InactiveCN1927066AHighlight substantive featuresSignificant progressFood preparationCarbonic acid gasBamboo shoots

The invention relates to the preparative way of a functional beverage used bamboo as the main material. The technological processes go as follows: 1.package the fresh bamboo juice or bamboo shoot juice collected from the bamboo forest with clean and airlocked containers, transfer the juice to the frige during 2-6 hours, and store it at0-4DEG C. 2. collect the bamboo leaves and clean them thoroughly, dry them and deactivate enzyme in hot water(70-90DEG C) for 3-5min; take out of the leaves and dry them. 3. Crush the leaves and extract them with alcohol and water extracting method; concentrate the extraction 4.mix the bamboo juice or bamboo shoot juice with the bamboo leaves extractions; add pure water or spring water to the solution; homogenize the mixture, sterilize it and package it normally or package it with carbonic acid gas. Producers don't need to add any chemical conserving agent to keep its quality. The bamboo juice contains much rare trace elements, vitamins, and polysaccharides, which can not only activate human cells, promote the metabolism, regulate body's functional balance; it also has the effect of promoting the production of body fluid, mitigation, relieving cough and hematischesis.

Owner:邓天华

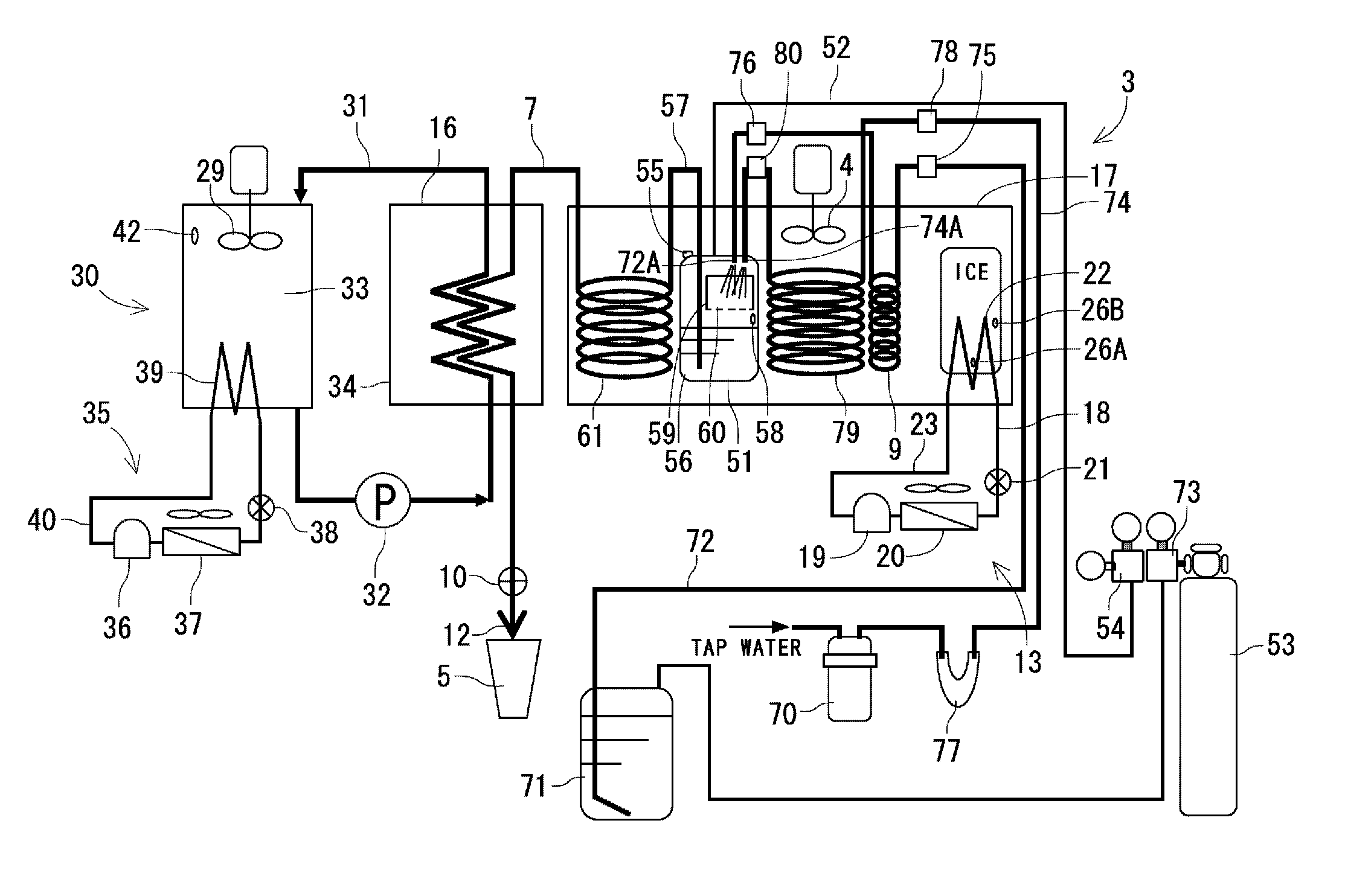

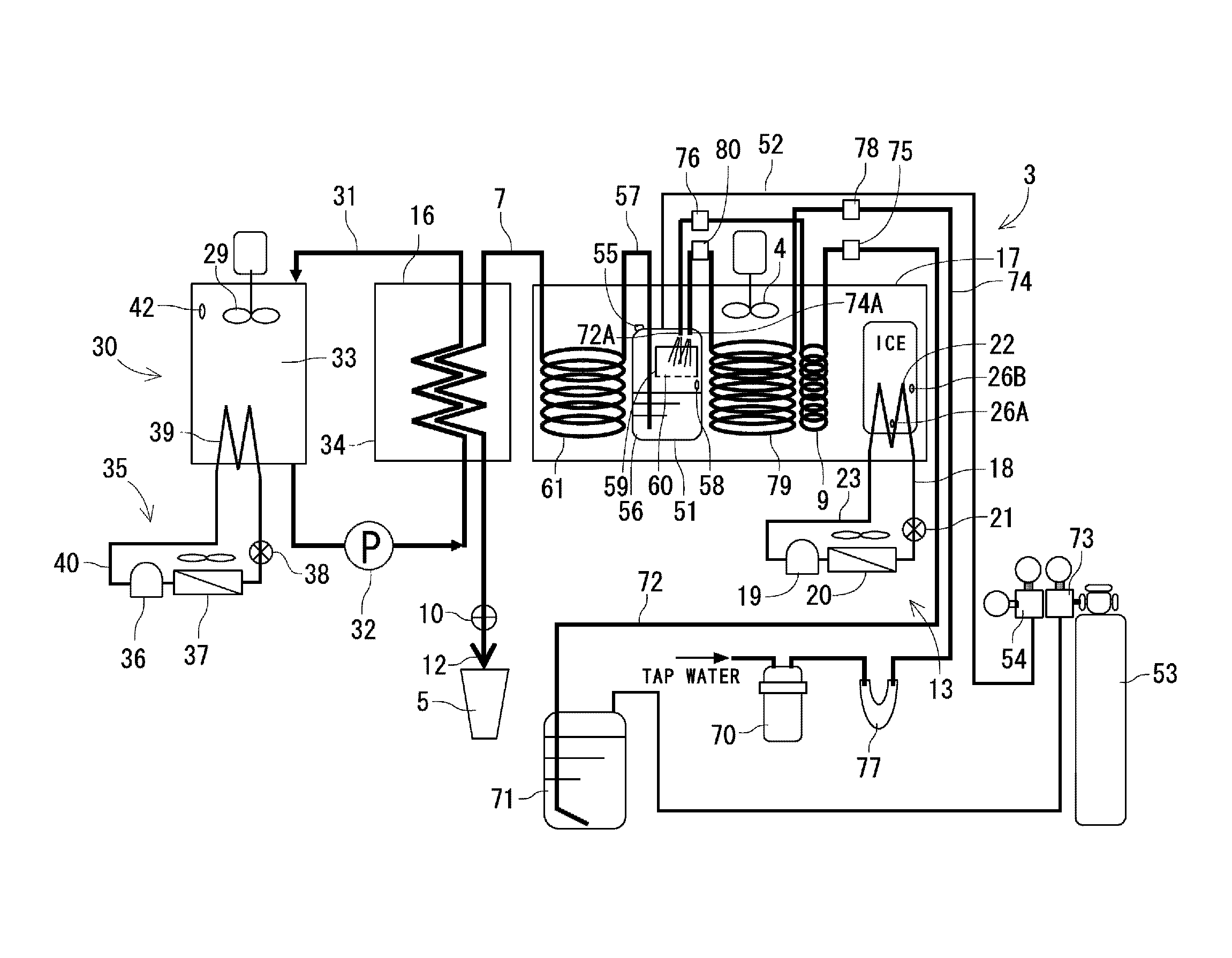

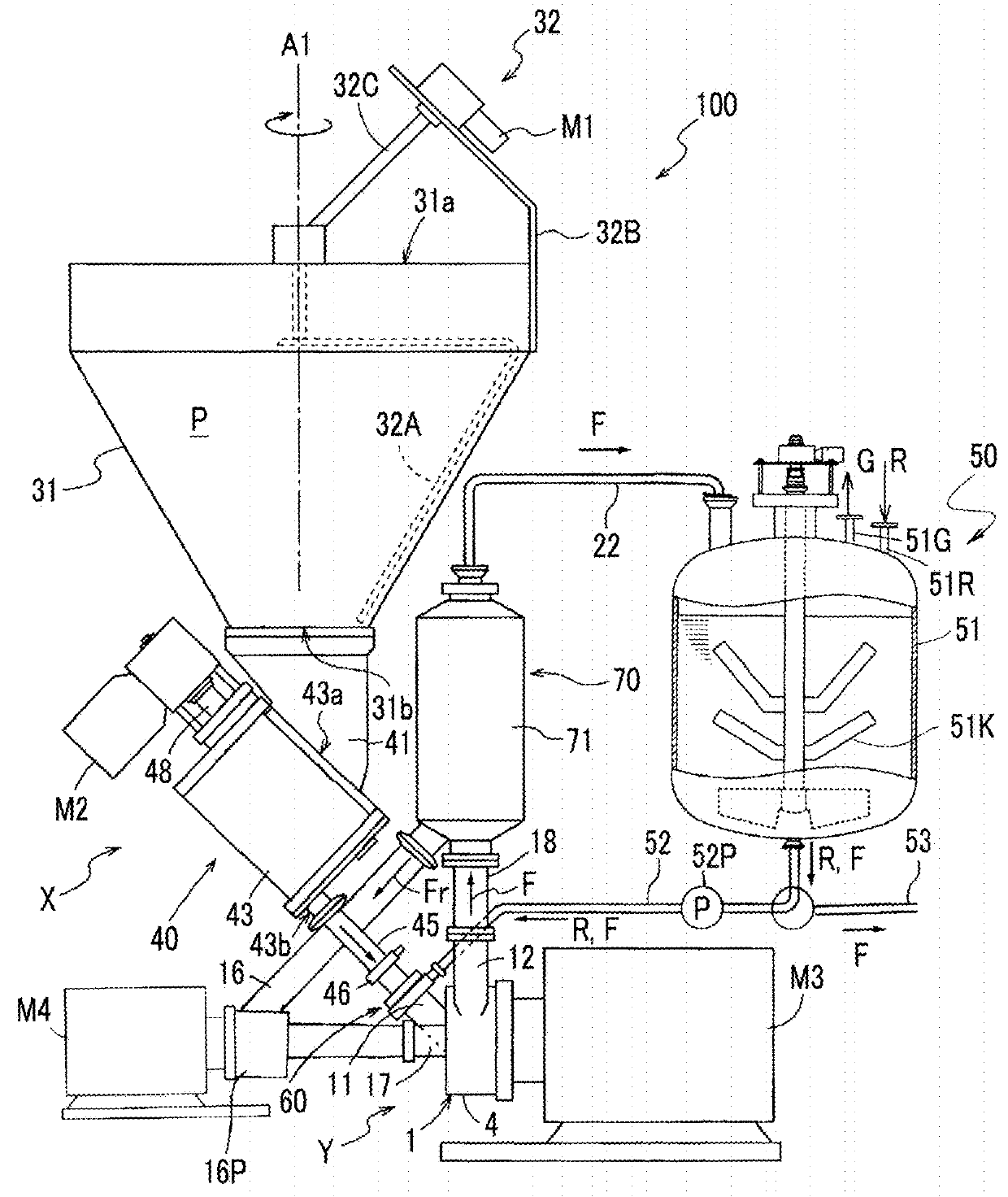

Beverage dispenser

InactiveUS20110042414A1Efficient preparationMade preciselyDomestic cooling apparatusLighting and heating apparatusEngineeringCarbonated drink

To provide a beverage dispenser capable of appropriately and smoothly supplying a carbonated beverage as a supercooled beverage. According to the present invention, there is disclosed a beverage dispenser including a carbonator 51 for manufacturing carbonated water; a beverage supply circuit 7 for supplying a carbonated beverage manufactured by the carbonator 51 to the outside; a heat exchanger 16 for supercooling; and a primary cooling device 13, the carbonator 51 mixes a carbonic acid gas supplied from a gas regulator 54 which supplies a pressurized carbonic acid gas, syrup and diluting water to manufacture the carbonated beverage, and the heat exchanger 16 for supercooling cools the carbonated beverage flowing through the beverage supply circuit 7 into a supercooled state at a temperature of a solidifying point or less to release the supercooled state in the outside.

Owner:THE COCA-COLA CO

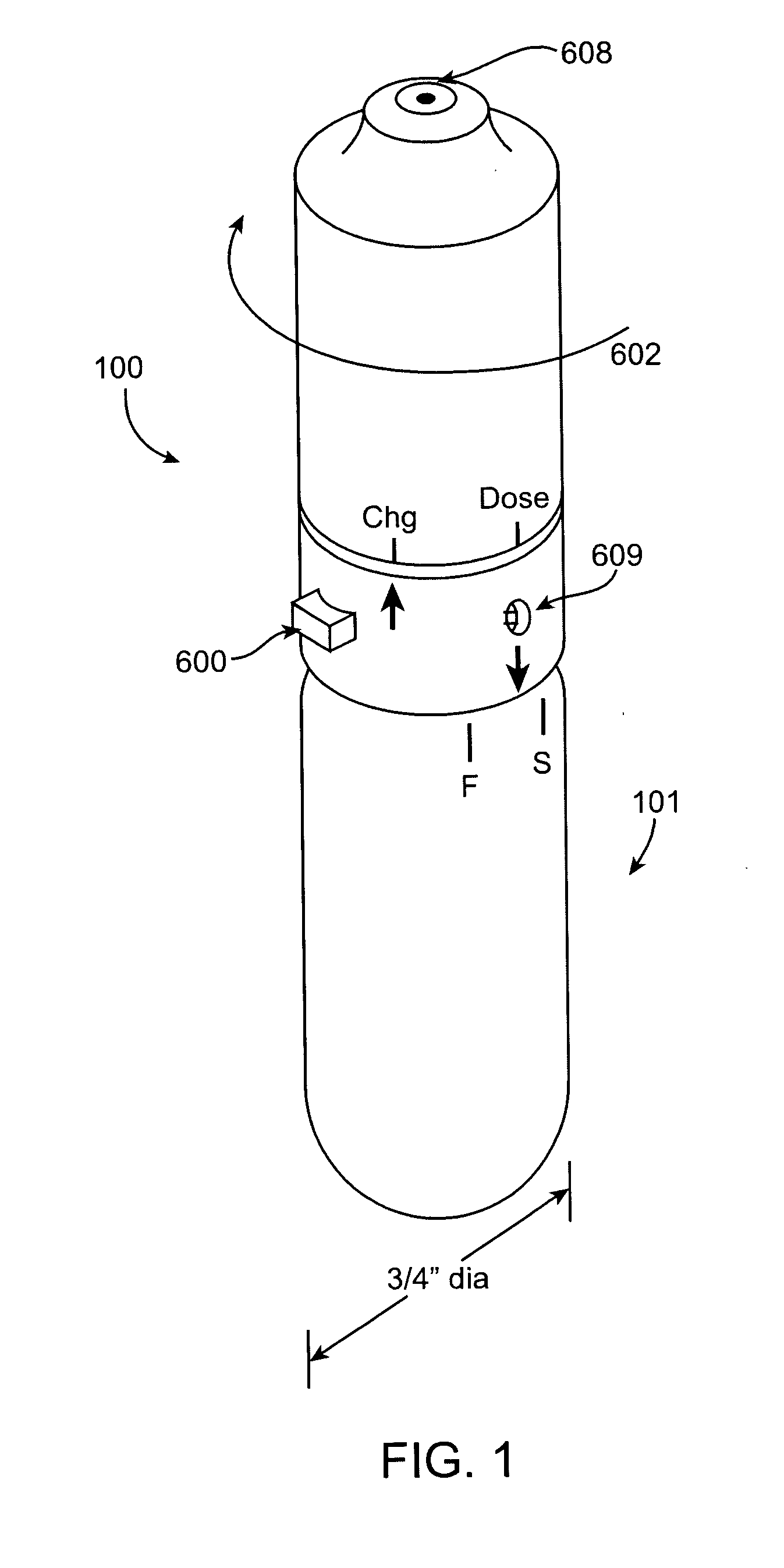

Methods and apparatus for the enhanced delivery of physiologic agents to tissue surfaces

InactiveUS20060172017A1Quick effectInterrupt and delay progressionBiocideInorganic active ingredientsNitric oxideNitrous oxide

Apparatus and methods deliver vasoconstrictive agents simultaneously with capnic gases. The capnic gases can enhance the effectiveness of the vasoconstrictive agent, lower the dosage of drug or concentration of agent necessary to achieve a therapeutic result, or both. Exemplary capnic gases include carbon dioxide, nitric oxide, nitrous oxide, and dilute acid gases.

Owner:CAPNIA INC

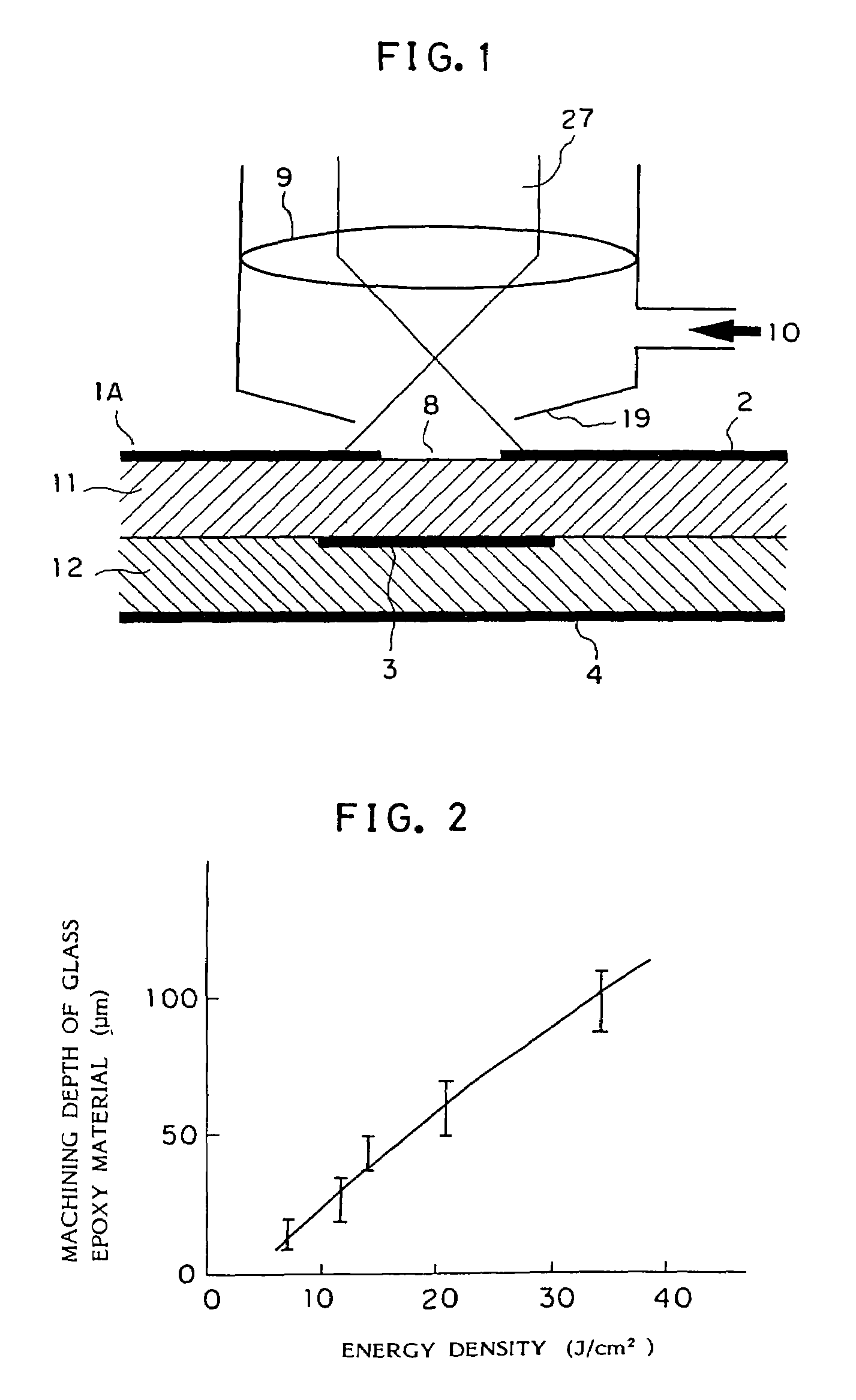

Laser beam machining method for wiring board, laser beam machining apparatus for wiring board, and carbonic acid gas laser oscillator for machining wiring board

InactiveUS6972392B2Improve productivityMethod implementationLaser beam welding apparatusEtching metal masksTime rangeLight beam

In a laser beam machining method for a wiring board, a machined portion of the wiring board is irradiated with a pulsed laser beam for a beam irradiation time ranging from about 10 to about 200 μs and with energy density of about 20 J / cm2 or more, thereby machining the wiring board, for example, drilling for a through-hole and a blind via hole, grooving, and cutting for an outside shape.

Owner:MITSUBISHI ELECTRIC CORP

Beverage dispenser

InactiveUS8485394B2Efficient preparationMade preciselyDomestic cooling apparatusLighting and heating apparatusEngineeringCarbonic acid gas

To provide a beverage dispenser capable of appropriately and smoothly supplying a carbonated beverage as a supercooled beverage. According to the present invention, there is disclosed a beverage dispenser including a carbonator 51 for manufacturing carbonated water; a beverage supply circuit 7 for supplying a carbonated beverage manufactured by the carbonator 51 to the outside; a heat exchanger 16 for supercooling; and a primary cooling device 13, the carbonator 51 mixes a carbonic acid gas supplied from a gas regulator 54 which supplies a pressurized carbonic acid gas, syrup and diluting water to manufacture the carbonated beverage, and the heat exchanger 16 for supercooling cools the carbonated beverage flowing through the beverage supply circuit 7 into a supercooled state at a temperature of a solidifying point or less to release the supercooled state in the outside.

Owner:THE COCA-COLA CO

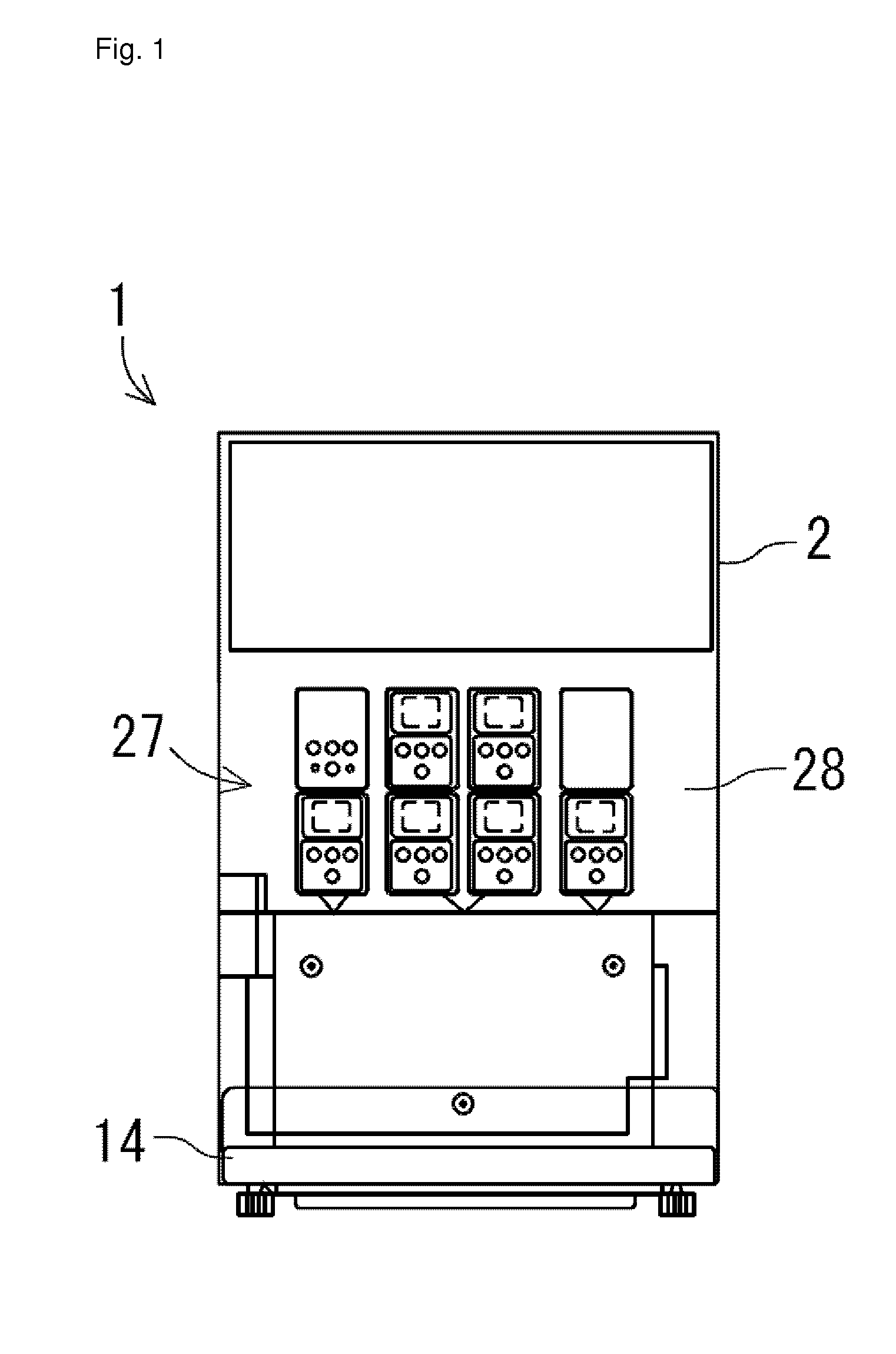

Automatic cocktail machine and method

InactiveUS20140335242A1High-quality and elegant and fashionable life styleEasy to operateLighting and heating apparatusWine preparationProcess engineeringCarbonic acid gas

Disclosed are an automatic cocktail machine and an automatic cocktail making method. Water, a carbonic acid gas cylinder and a plurality of cocktail materials are inputted. After a user's cocktail request is received, the cocktail request is compared with a list to determine the requested cocktail and read the cocktail recipe correspondingly. A bartending module is provided for adjusting and mixing water and the carbonic acid gas according to the cocktail recipe to form a carbonated water, and adjusted to a recipe temperature. An output module is provided for mixing an appropriate quantity of cocktail materials with the carbonic acid gas cylinder to output the cocktail. With this simple and convenient automatic cocktail machine, the users can get various cocktails quickly and enjoy different delicious cocktails.

Owner:HUANG HSIANG CHI

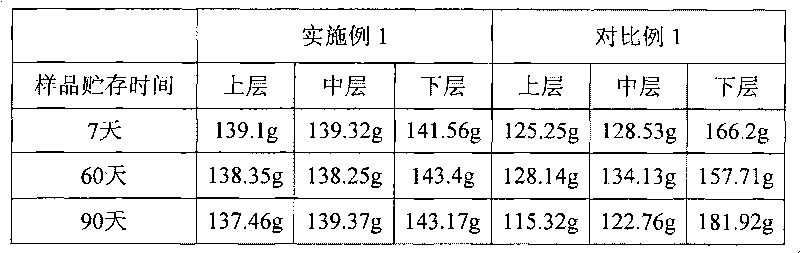

Carbonic acid gas-containing foaming liquid dairy product and method for producing same

The invention provides a carbonic acid gas-containing foaming liquid dairy product and a method for producing the same, wherein the foaming liquid dairy product contains 0.15 to 1 percent of lactoprotein and 1.5 to 3.5 percent of grease substances, and each kilogram of the foaming liquid dairy product contains 0.5 to 1 grams of CO2 gas. The selected raw materials are mixed in a ratio to obtain mixed concentrated solution, and the concentrated solution is sterilized and then mixed with CO2-containing acid liquor to form the carbonic acid gas-containing foaming liquid dairy product, and the product has good foam forming property and persistent foaming property and can be preserved for 6 months.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

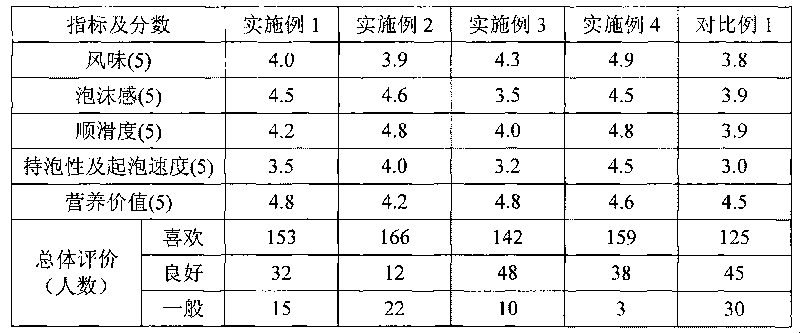

Device and process for separating carbonic acid gas by indirect burning of biomass

InactiveCN101289185AExtensive social benefitsBroad industrial application prospectsHydrogenCarbon compoundsOxygenCarbonic acid gas

The invention relates to a device used for indirectly burning biomass to separate carbon dioxide and a method which is a burning way of the biomass and a biomass burning process based on a cycle oxygen carrier. The device consists of a circulating fluidized bed, a cyclone separator and a fluidized bed, which is formed into a circulation loop; the method is characterized in that oxidation reaction happens to metal and air in the circulating fluidized bed to generate a metallic oxide which enters the fluidized bed after being separated by the cyclone separator; gasification reaction happens to the biomass in the fluidized bed and the carbon dioxide or water vapour; reduction reaction happens to fuel gas generated from the gasification reaction and the metal oxide to generate the metal, the carbon dioxide and the water vapour, wherein, the carbon dioxide and the water vapour are discharged from an air outlet of the fluidized bed and condensed to obtain pure carbon dioxide and the metal reduced returns to the circulating fluidized bed for carrying out oxidation reaction with the air to complete the regeneration process of the metallic oxide. The carbon dioxide can be separated from combustion products without extra energy consumption.

Owner:SOUTHEAST UNIV

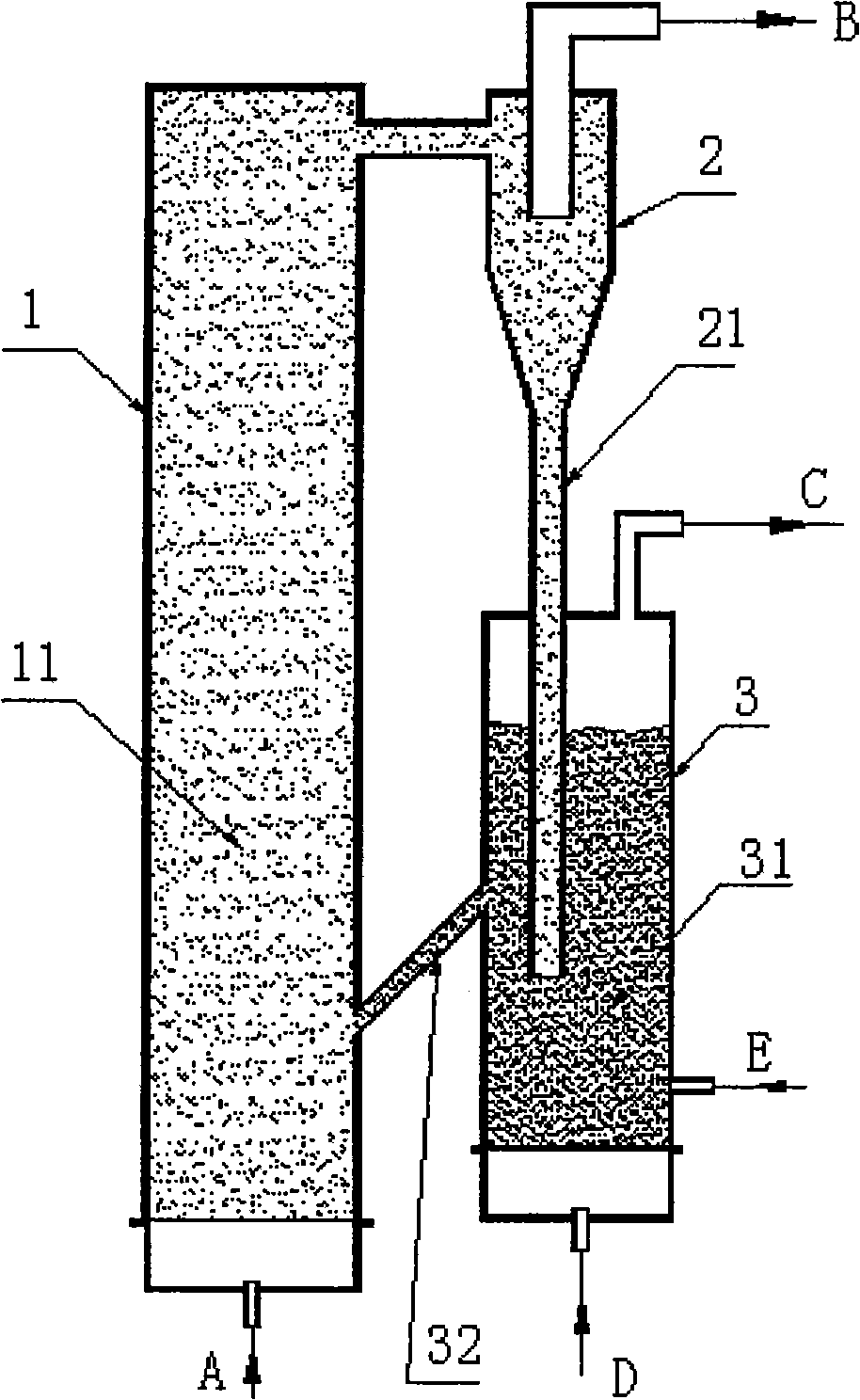

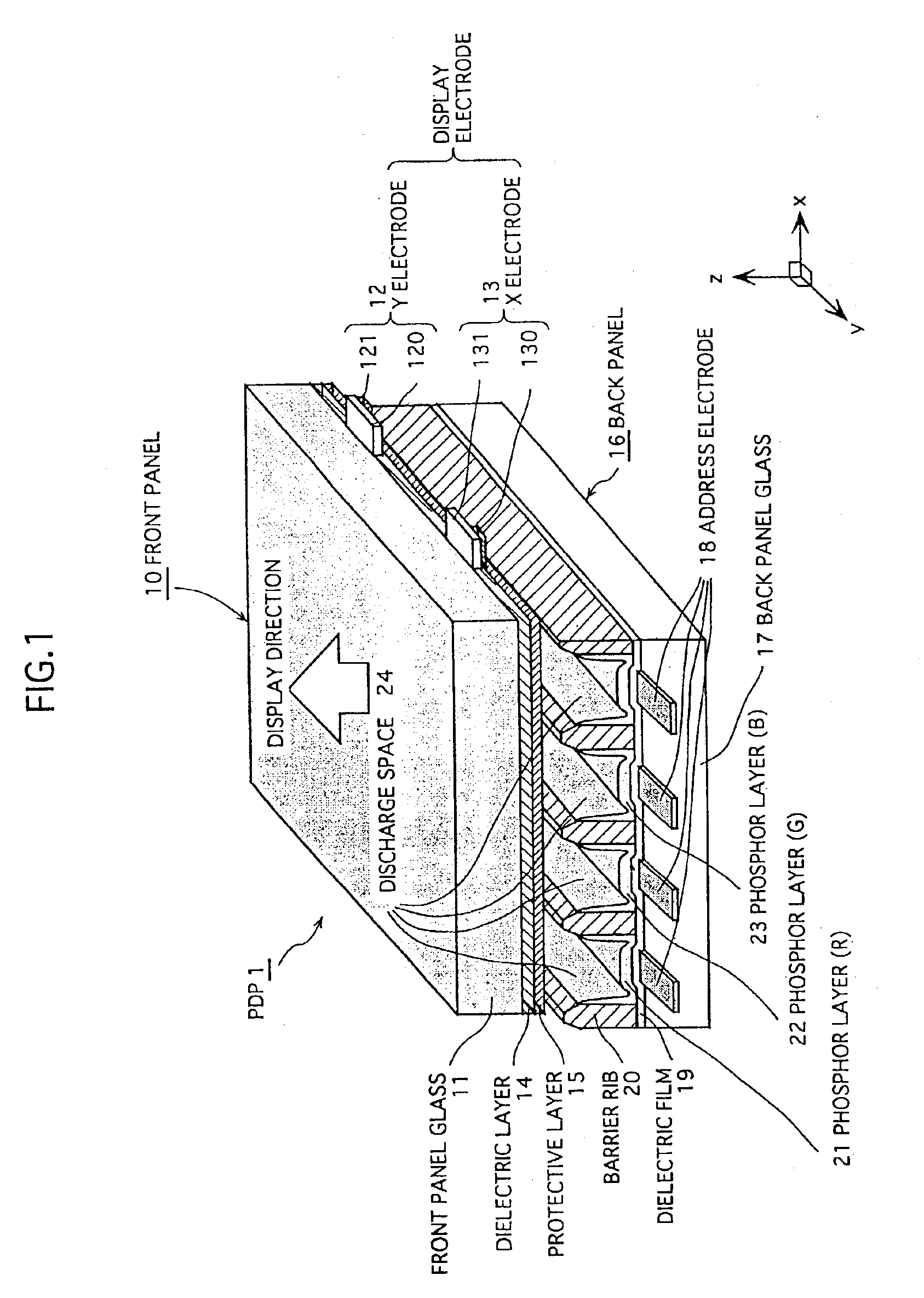

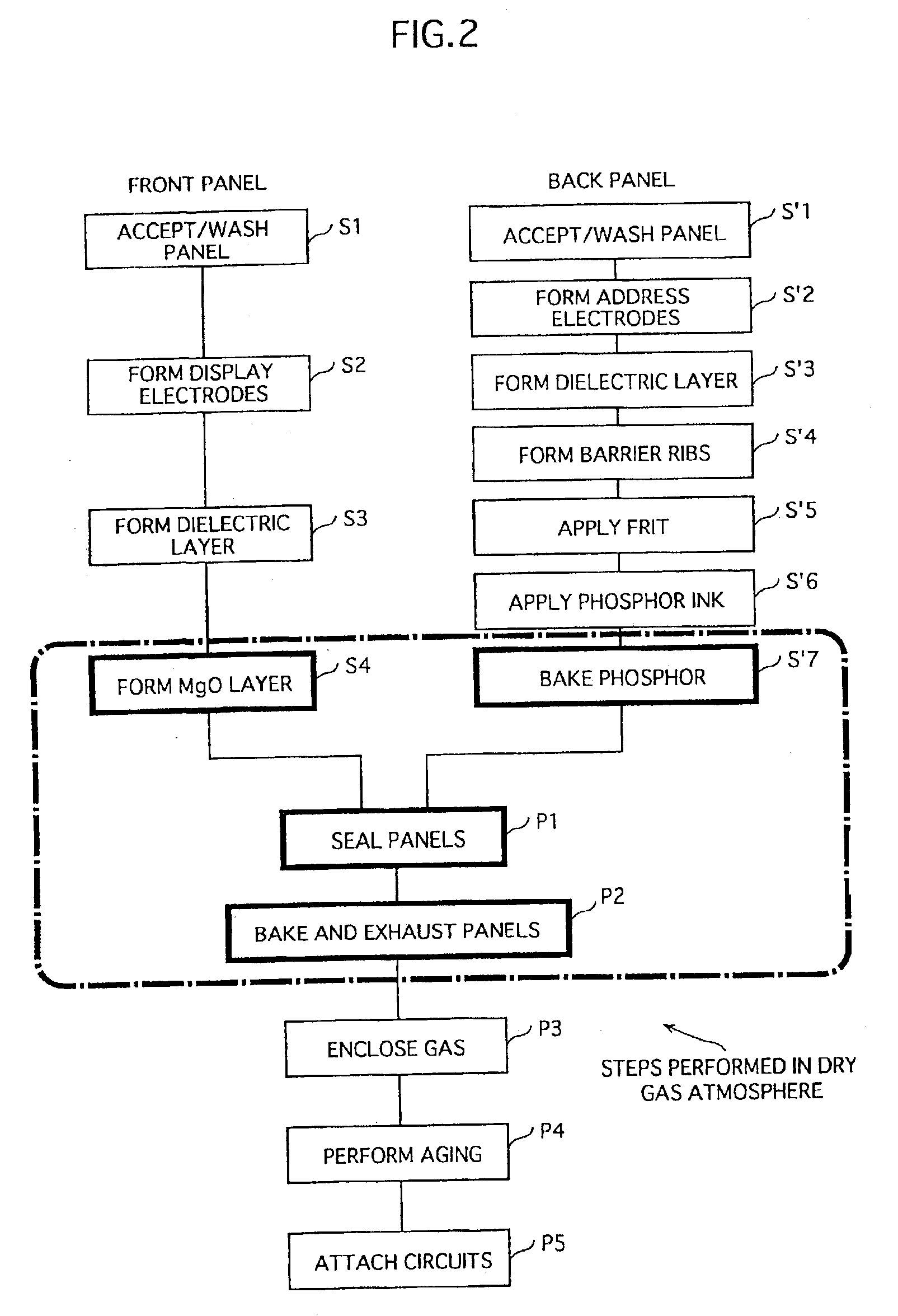

Production method for plasma display panel

InactiveUS7070471B2Quality improvementImprove the display effectAlternating current plasma display panelsTube contructional detailsPhosphorManufactured apparatus

A manufacturing apparatus for a PDP includes a unit for forming a protective layer protecting a dielectric layer on a first plate, a unit for baking a phosphor layer applied on a second plate, a unit for sealing the first and second plates arranged so that the protective layer faces the phosphor layer, and a unit for baking the first and second plates while exhausting a space between them. The four units are placed in one or more closed chamber. When the apparatus is driven, spaces in and between the closed chambers each contain a gas atmosphere with vapor partial pressure of 10 mPa or lower, or with a pressure of 1 Pa or lower, where the protective layer and the phosphor layer exhibit less water-absorbing property, preventing degradation of the PDP performances. The protective layer does not contact with atmospheric carbonic acid gas, preventing alteration thereof.

Owner:PANASONIC CORP

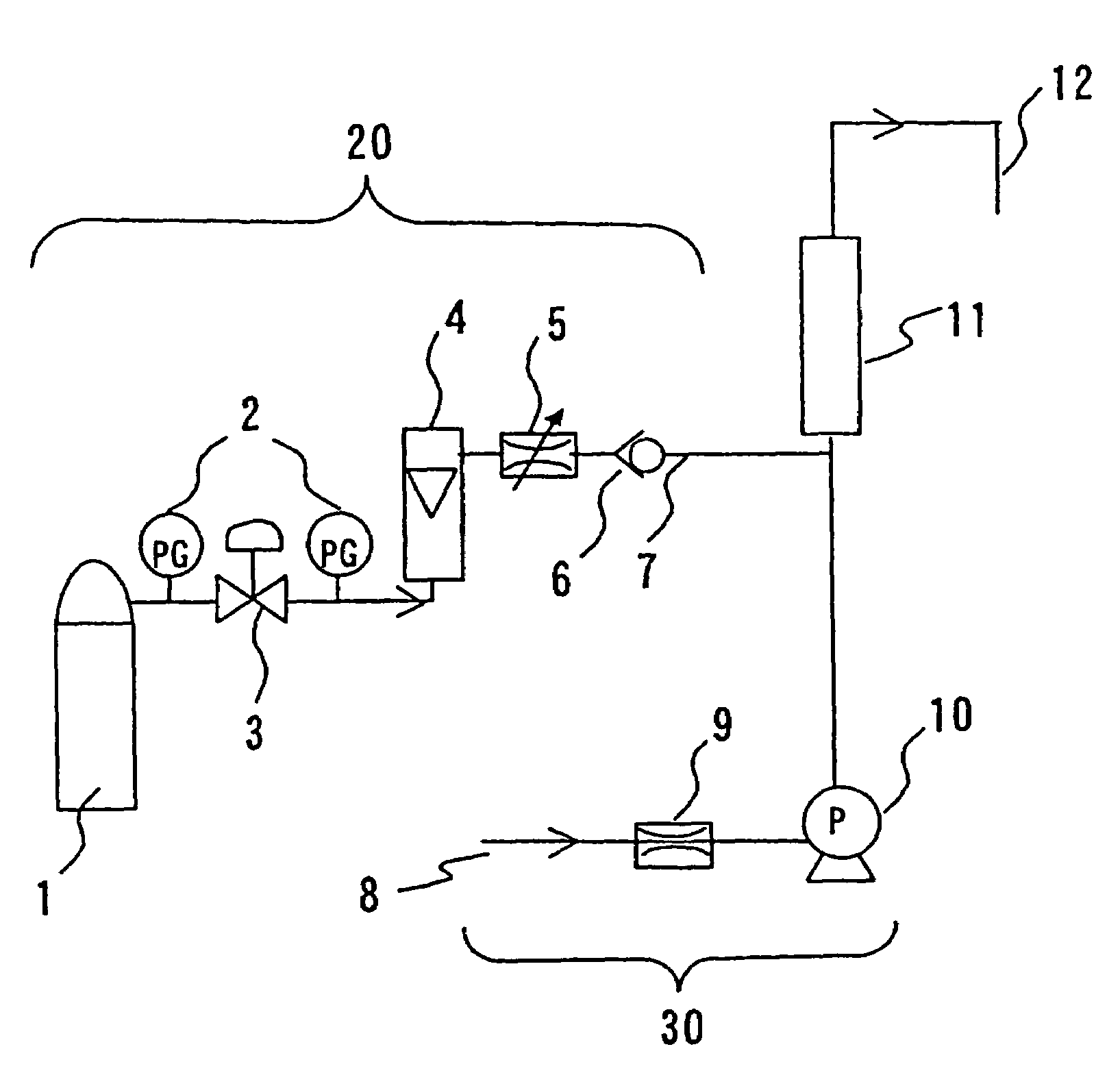

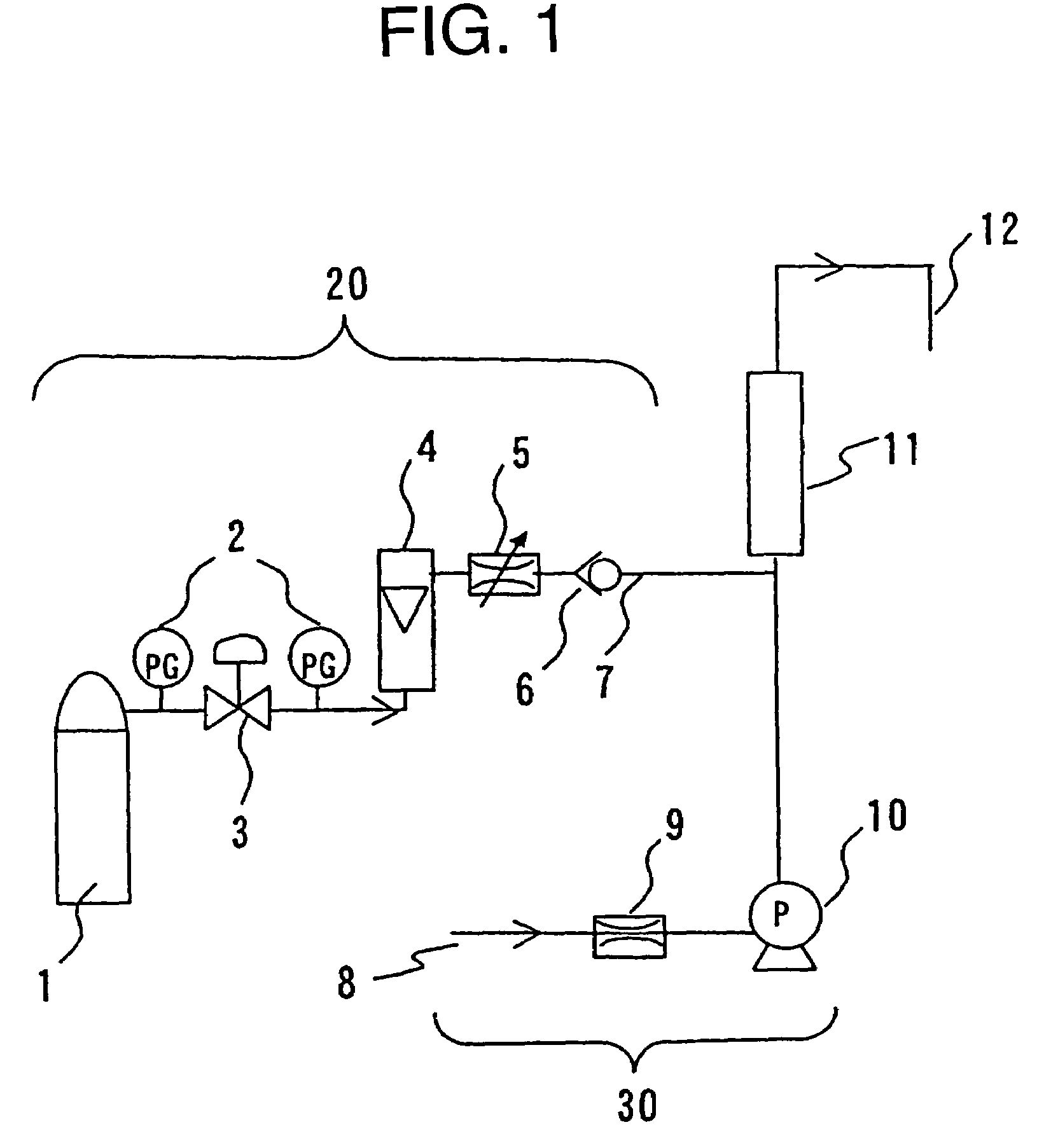

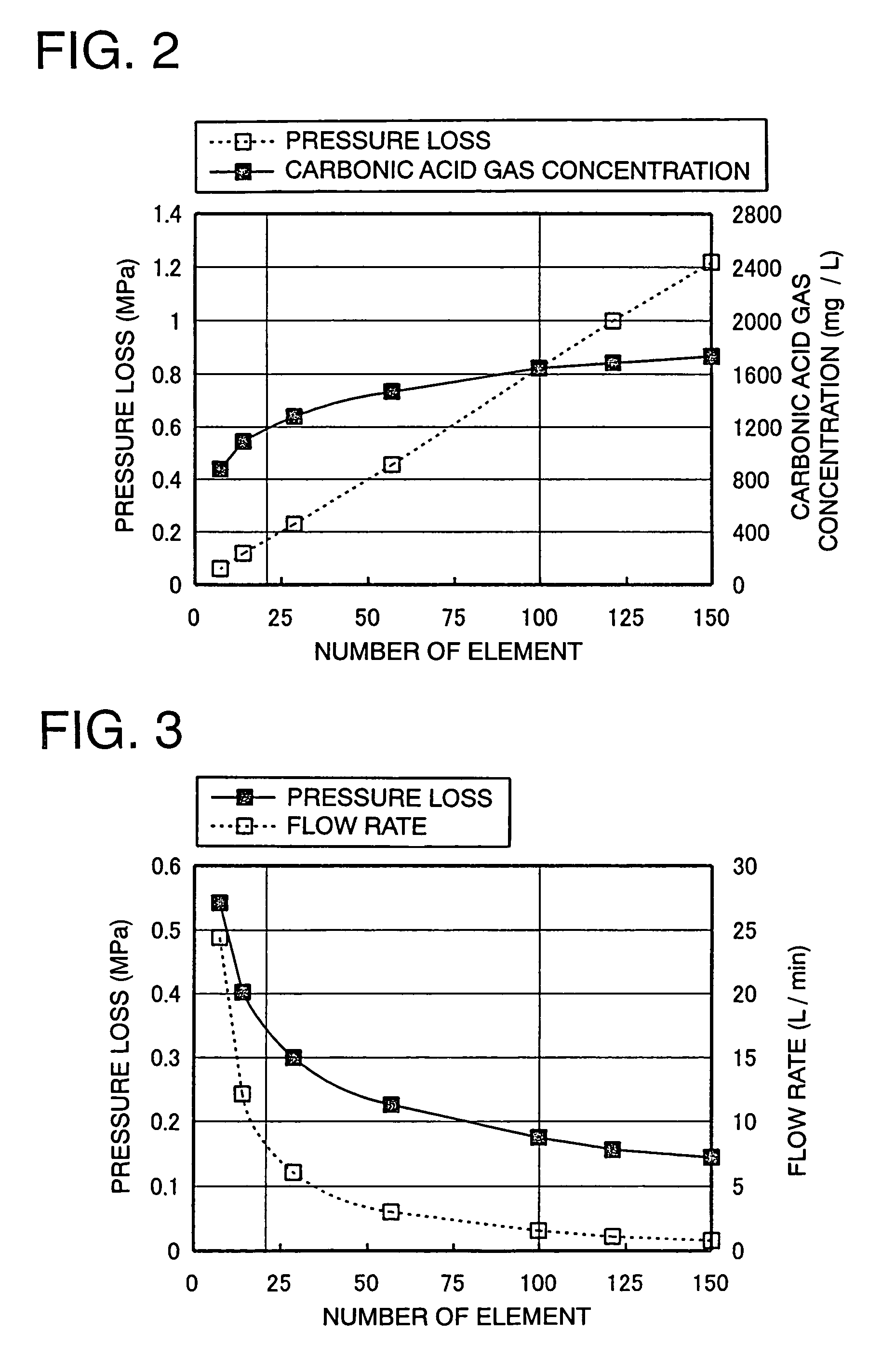

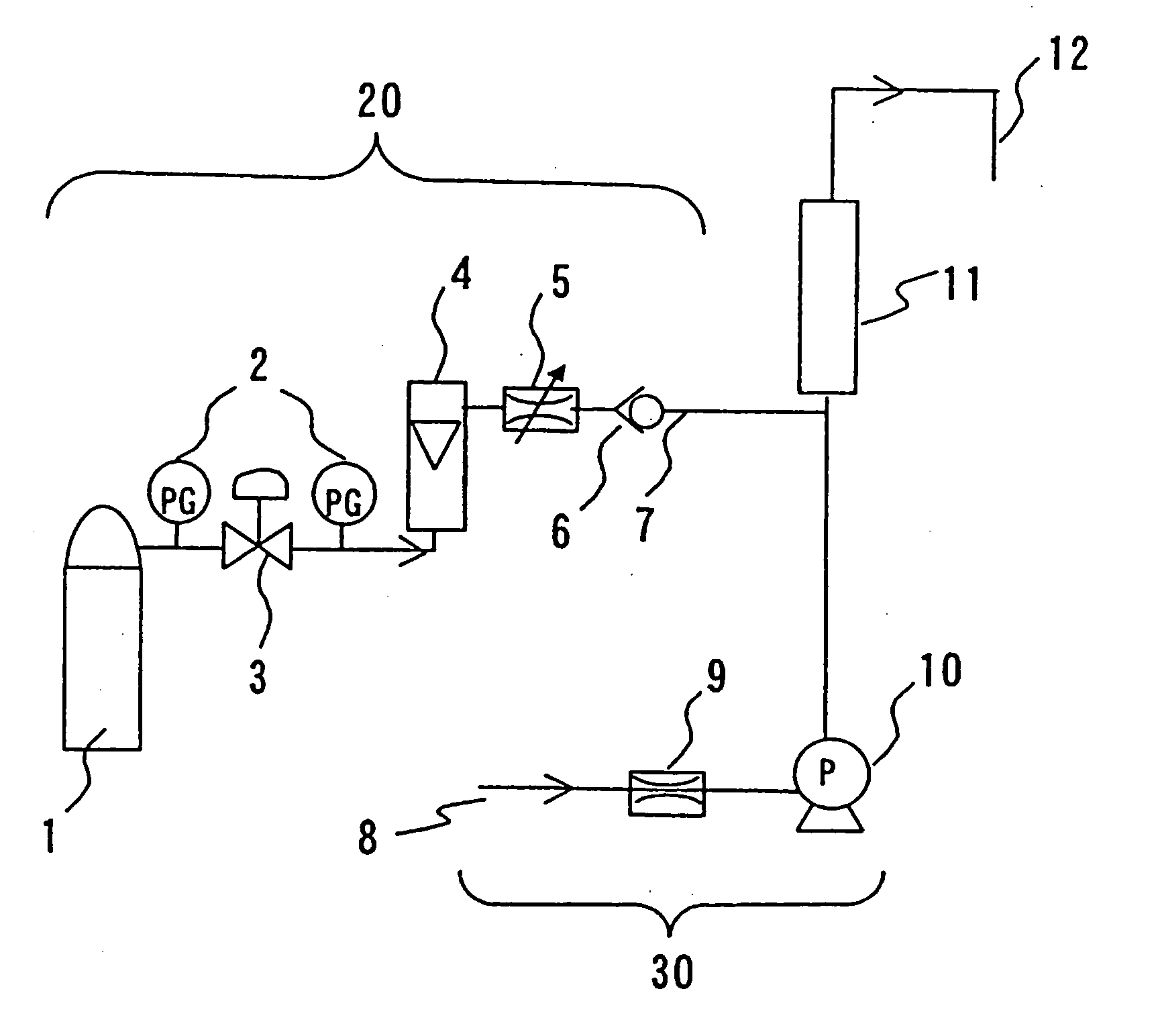

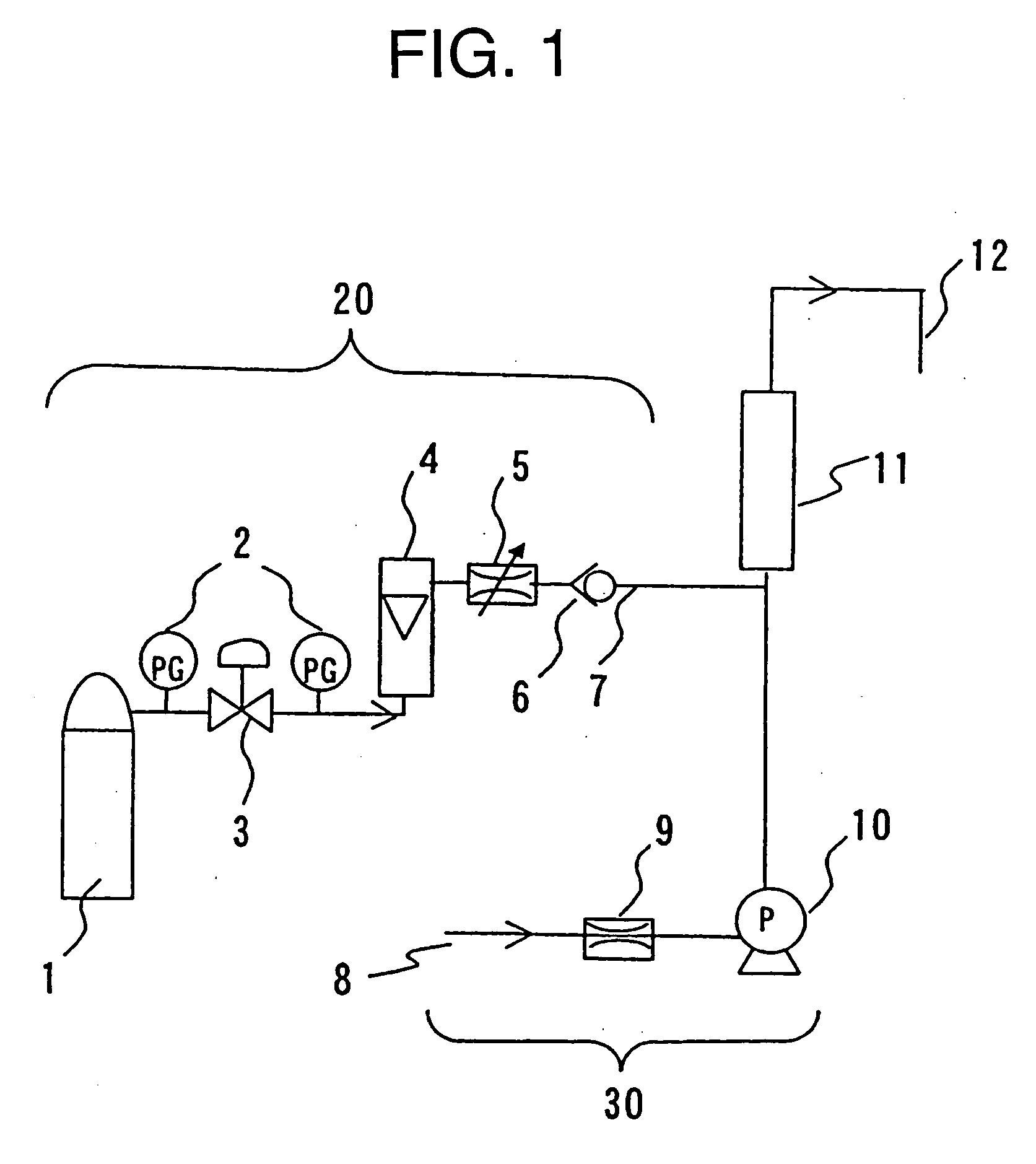

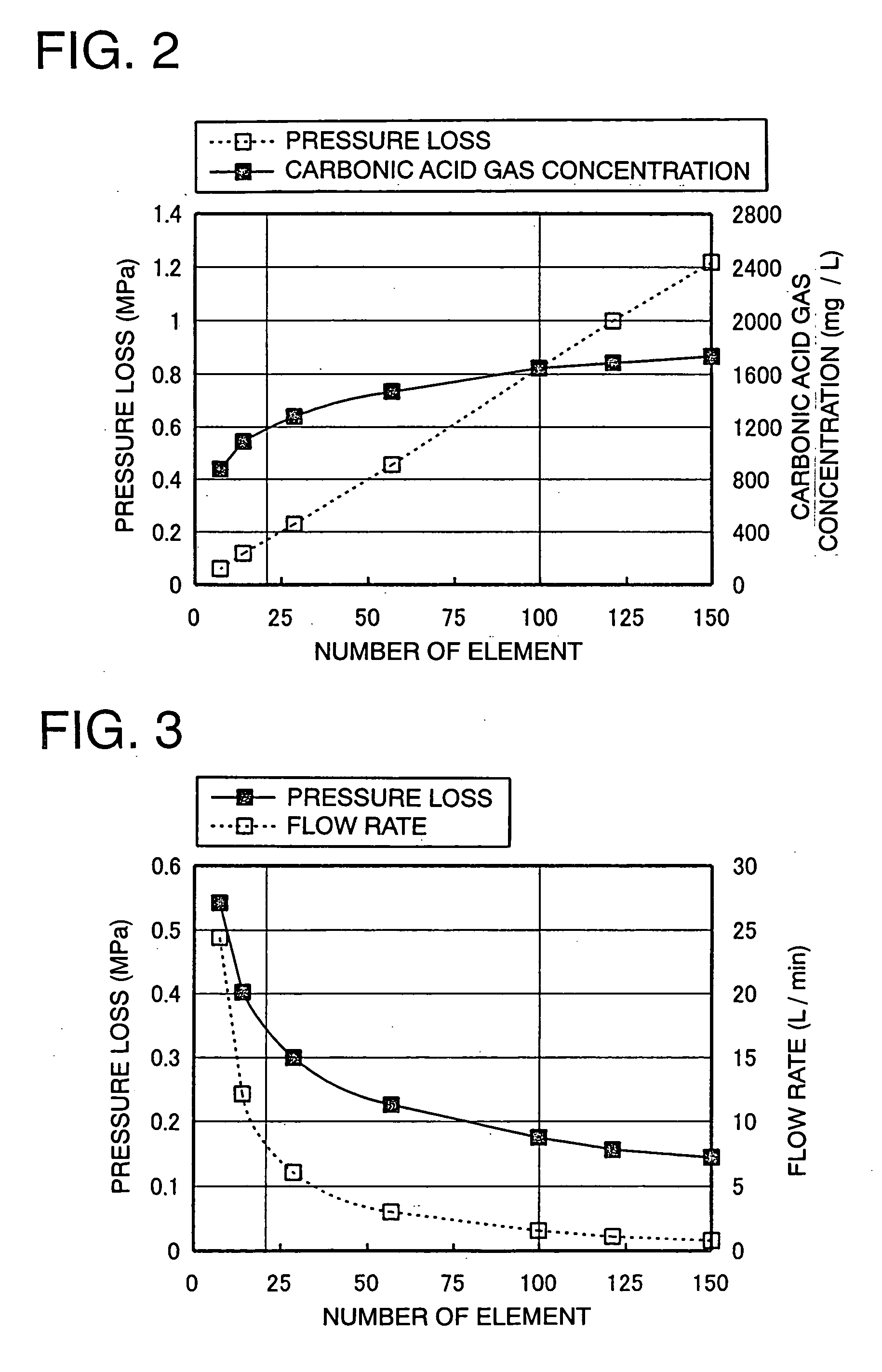

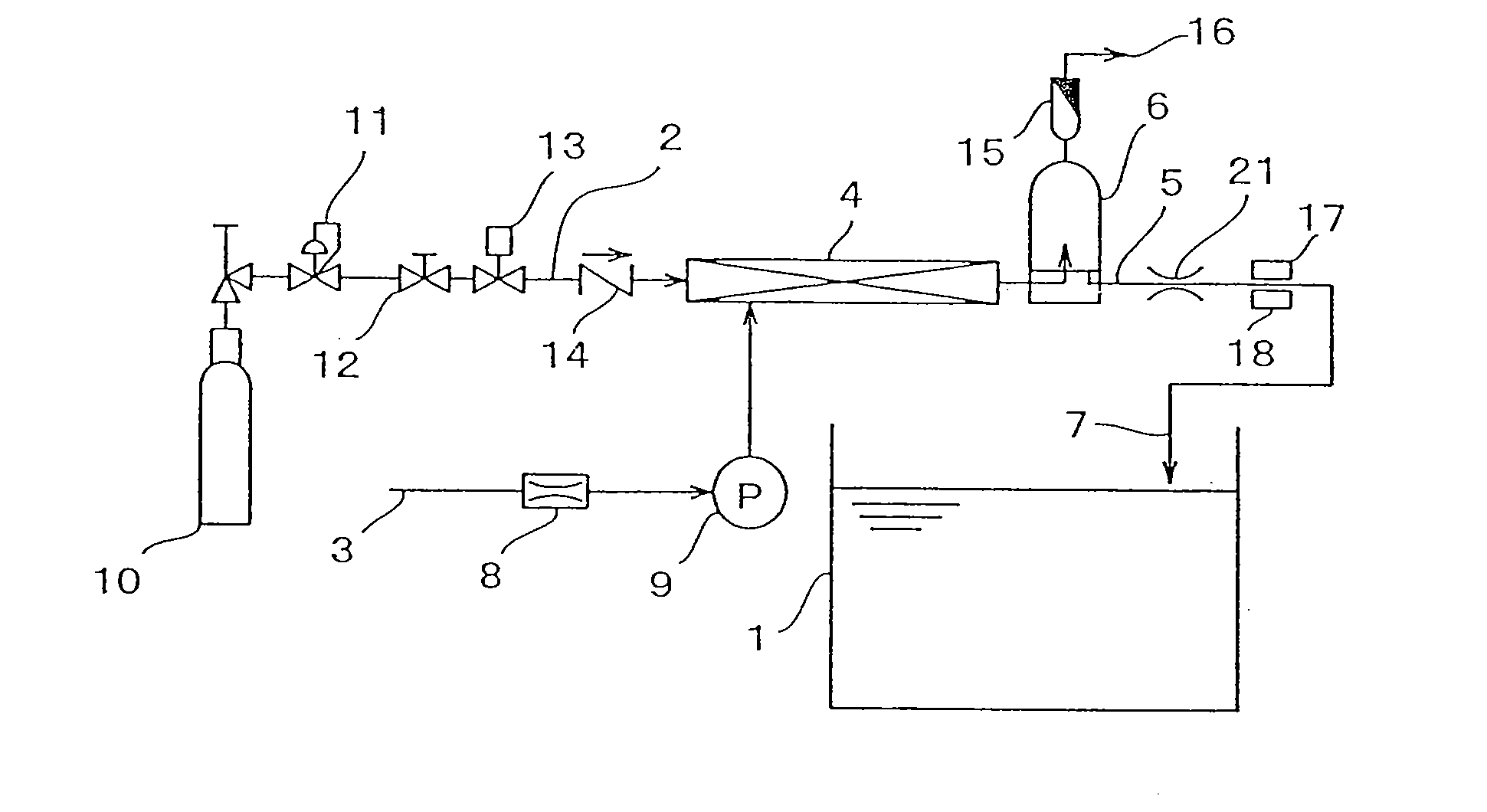

Equipment and process for the production of carbonated water

InactiveUS7374156B2Short timeIncrease pressureLiquid degasificationFlow mixersHigh concentrationStatic mixer

A process for producing carbonated water having a high concentration, inexpensively and easily, involves using a static mixer having 20 to 100 elements so as to provide a value Re×N of 100,000 to 2,000,000, in with Re represents a Reynolds number, when a mixture of water and carbonic acid gas flow in the static mixer.

Owner:MITSUBISHI RAYON CO LTD

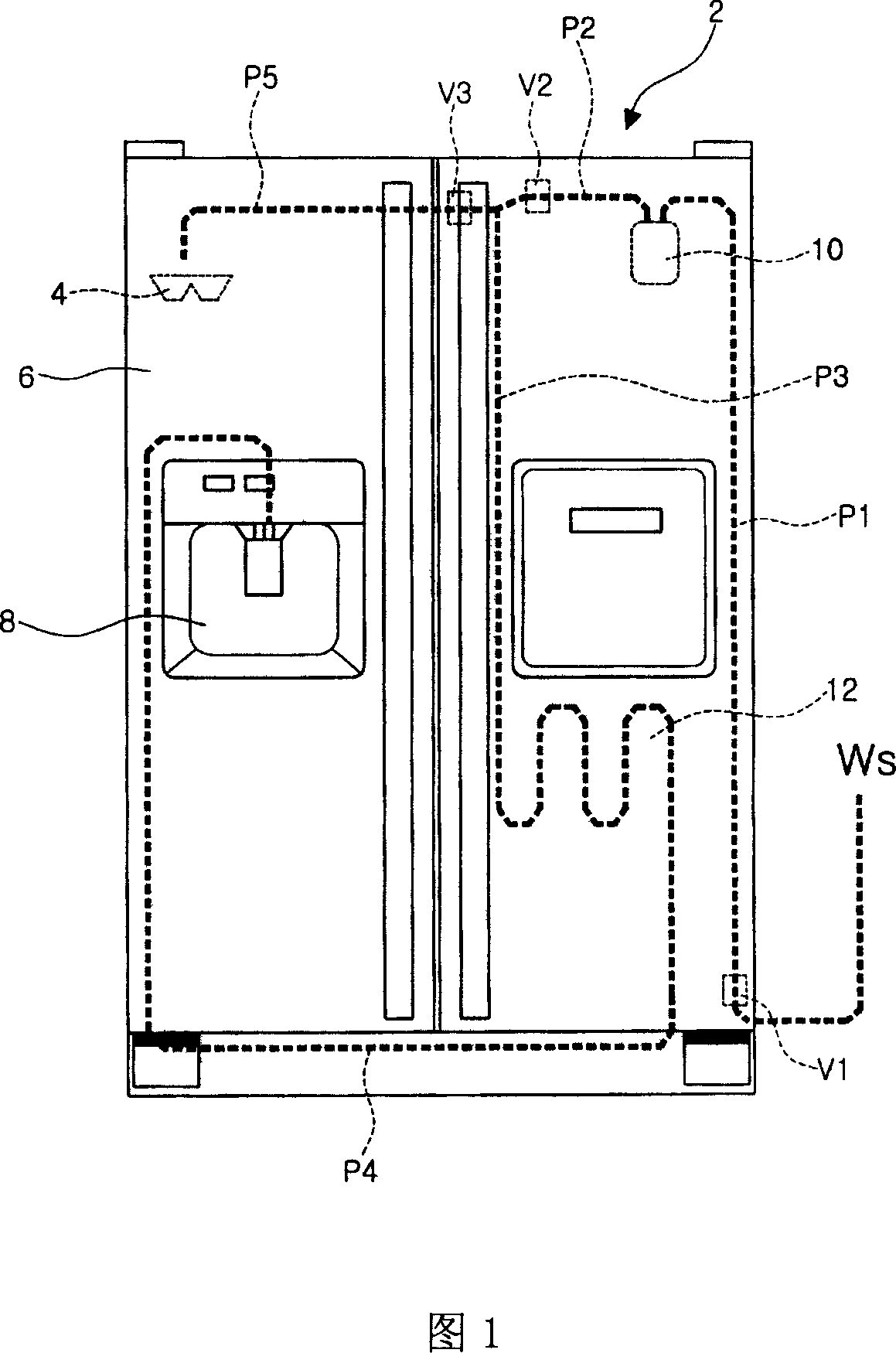

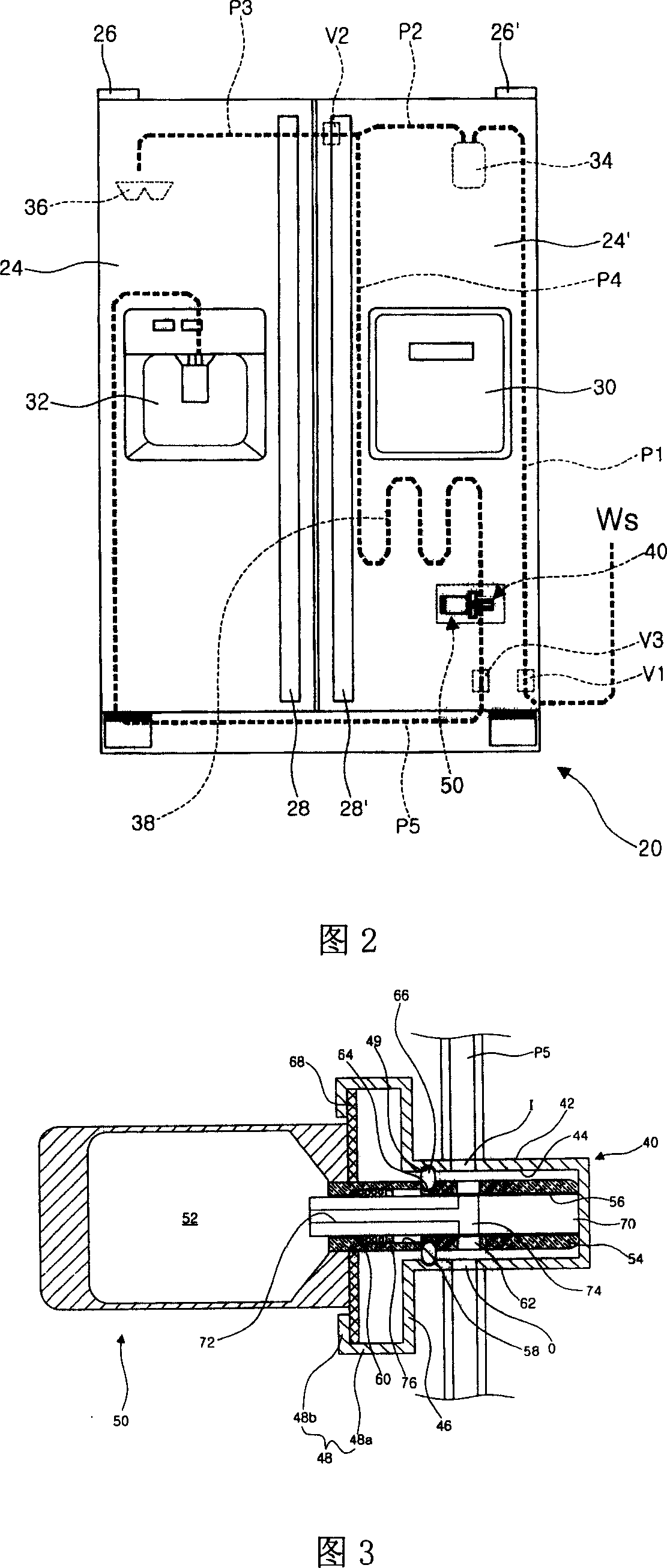

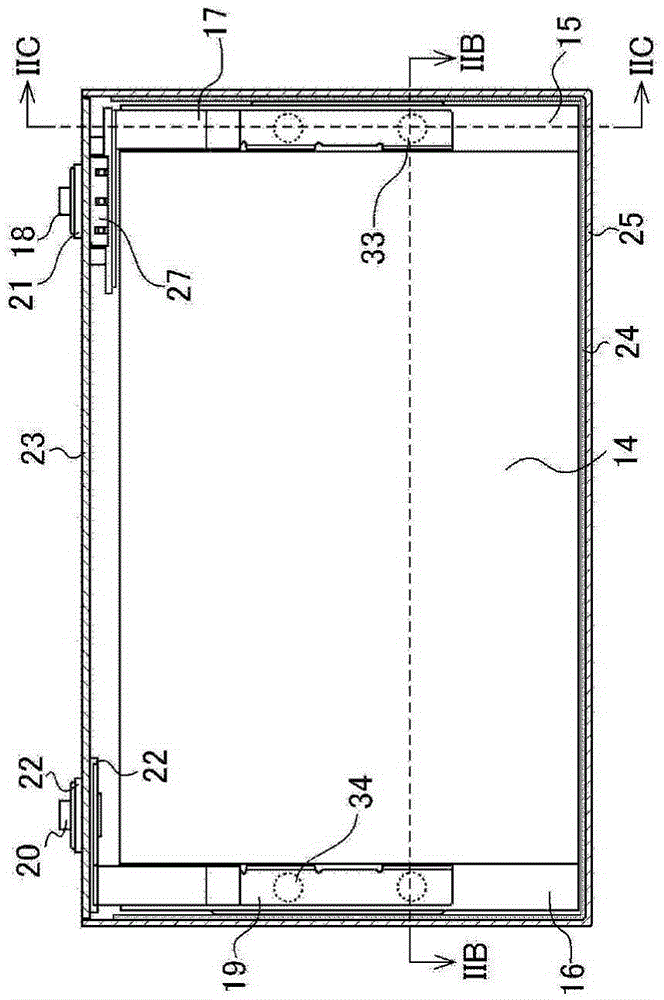

Electric refrigerator

InactiveCN101071019AImprove solubilityLighting and heating apparatusIce productionSolubilityWater source

The invention involves a refrigerator, the invention include filters for the water supply from outside sources into the refrigerator to internal water filter; its water supply source connected with the side of a supply pipe connection, connect the other side of the supply section 2; the adoption of two suppliers of water, and cooling water storage tanks; can be used to connect users from drinking water from the water dispenser and the water supply of 5; also include the provision in section 5 of supply, and water tanks nearby location, the additives used to add to flow through No. 5 in the water supply of the additive me. The rear tank additives me set up, the outflow of water distributor to add additives, can be provided to users of different flavor of drinking water; carbonate gas additive is to be set up by the additive me from the cold water, improve the solubility of the additive.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Method for processing fish of red flesh

InactiveUS20050048188A1Same palatabilityFreeze fastMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsAmbient airMixed gas

A method for processing a fish of red flesh includes a packing step of cutting a fish in such a shape as would fit immediate use by consumers, piling the cut fish orderly on a tray and stowing the cut fish on the tray into a pack, a vacuumizing step of filling the pack during the packing step with a vacuum atmosphere, a gas-filling step of filling the pack immediately after completion of the vacuumizing step with a mixed gas of carbonic acid gas and oxygen gas without exposing the interior of the pack to the ambient air, thereby exposing the fish to the mixed gas, a pack-sealing step of tightly closing the pack filled with the carabonic acid and the oxygen gas, and a freezing step of quickly freezing the fish contained in the pack and transforming the fish into a frozen fish.

Owner:YOSHIO ARAI

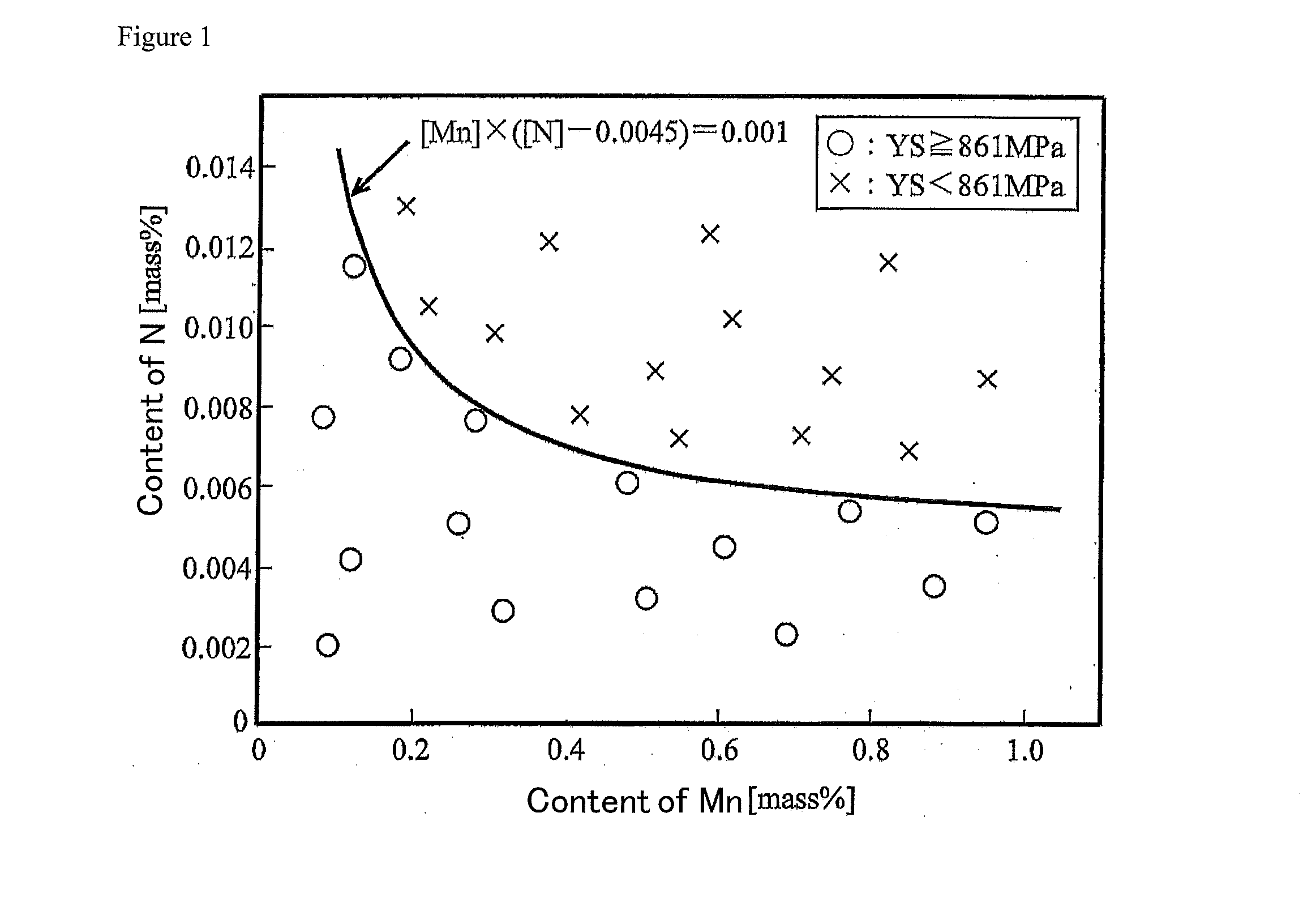

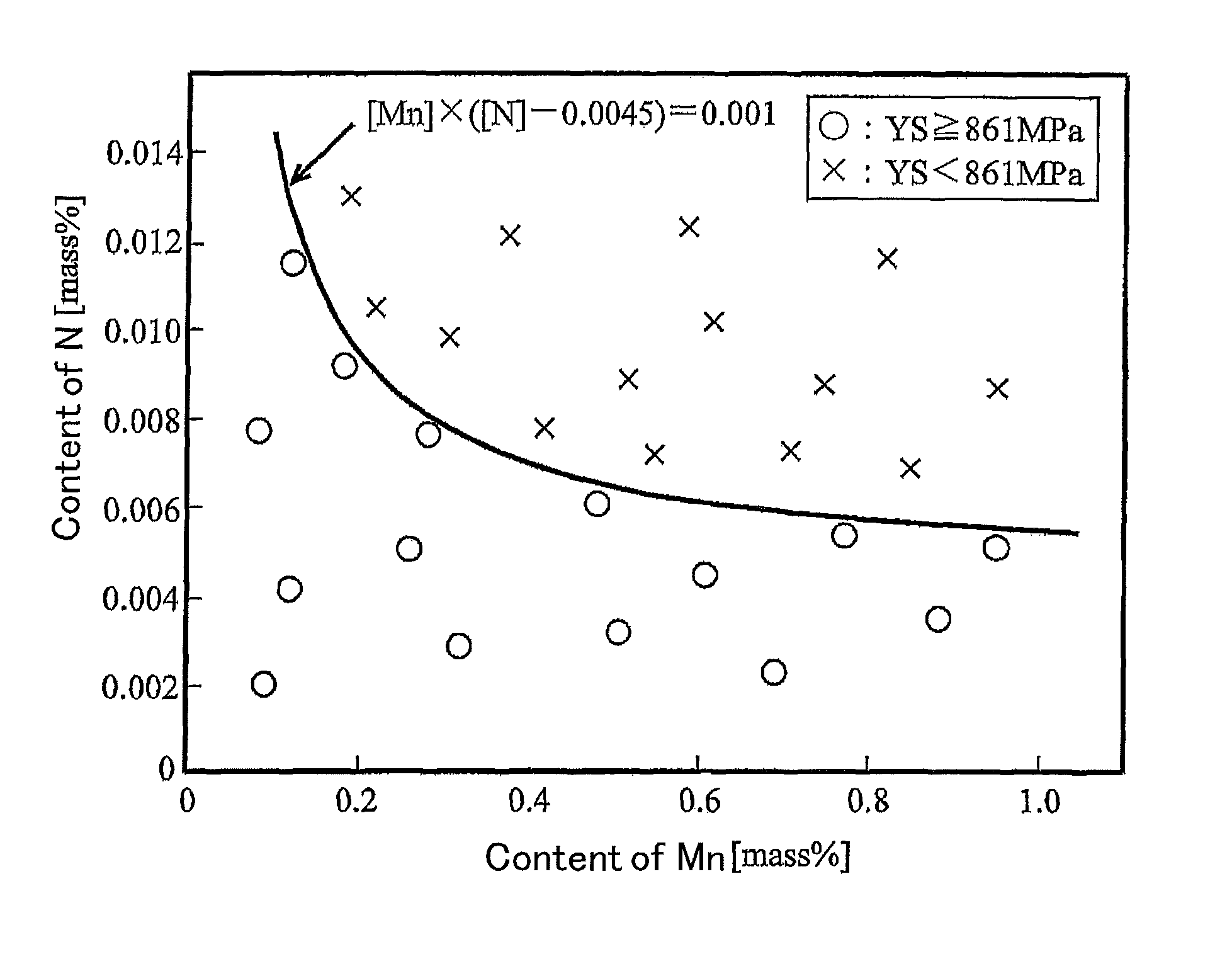

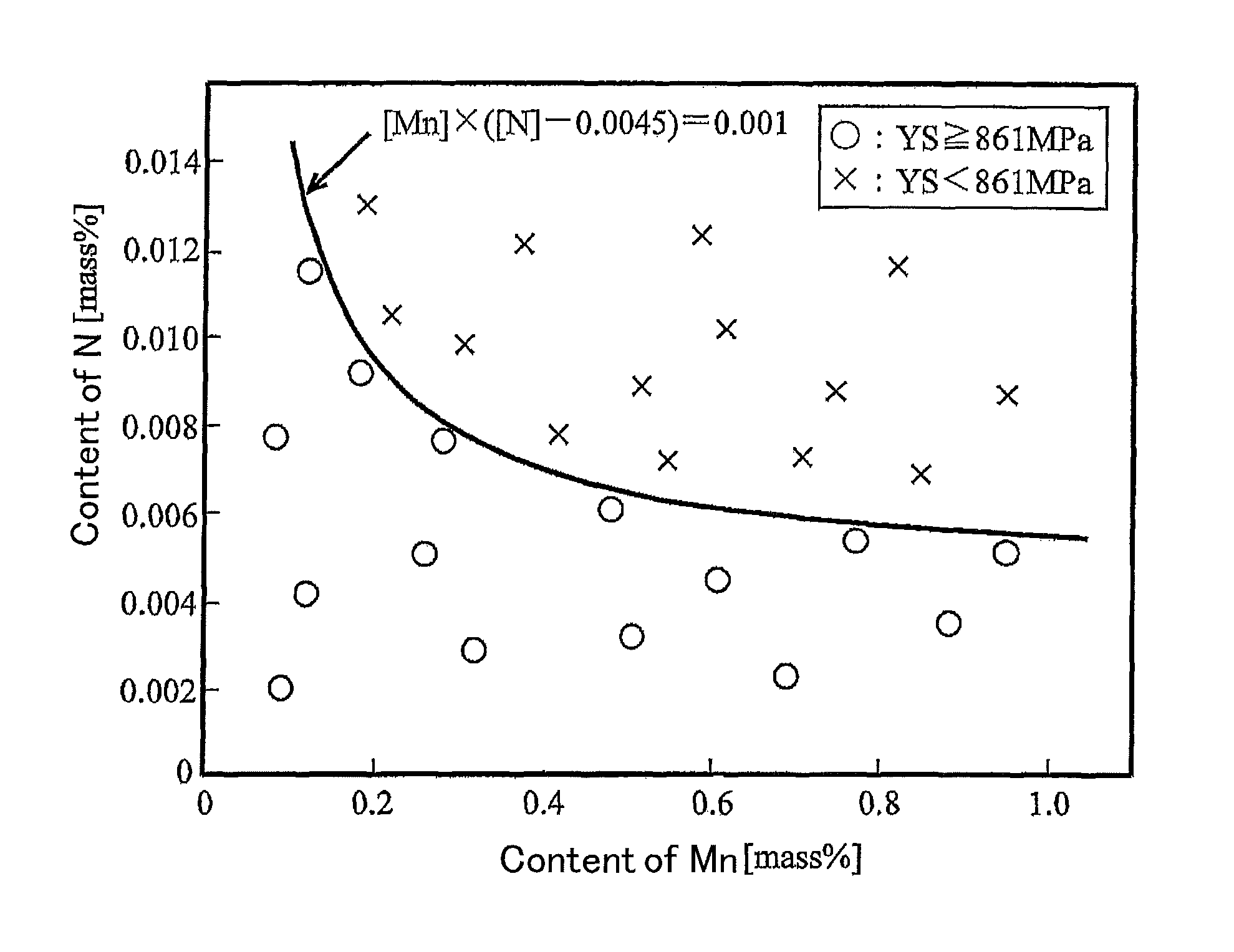

High-strength stainless steel pipe excellent in sulfide stress cracking resistance and high-temperature carbonic-acid gas corrosion resistance

ActiveUS20110226378A1High strengthImprove corrosion resistanceRigid pipesMicro structureMetal microstructure

The problem to be solved is the provision of a high-strength stainless steel pipe having a sufficient corrosion resistance in a high-temperature carbonic acid gas environment and having an excellent sulfide stress cracking resistance at normal temperature.A high-strength stainless steel pipe consist of by mass %, C: 0.05% or less, Si: 1.0% or less, P: 0.05% or less, S: less than 0.002%, Cr: more than 16% and 18% or less, Mo: more than 2% and 3% or less, Cu: 1% to 3.5%, Ni: 3% or more and less than 5%, Al: 0.001% to 0.1% and O: 0.01% or less, Mn: 1% or less and N: 0.05% or less, and Mn and N in the above ranges satisfy formula (1), and the balance being Fe and impurities; and the metal micro-structure of the stainless steel pipe mainly includes a martensitic phase and comprises 10 to 40% of a ferritic phase by volume fraction and 10% or less of a retained γ-phase by volume fraction.[Mn]×([N]−0.0045)≦0.001 (1)wherein the symbols of elements in formula (1) respectively represent the contents (unit: mass %) of the elements in the steel.

Owner:NIPPON STEEL CORP

Preparation method of lithium carbonate

ActiveCN103449481ASimple and excellent method for preparing lithium carbonateAvoid transportLithium carbonates/bicarbonatesLithium chlorideLithium carbonate

The invention relates to a preparation method of lithium carbonate. The method comprises the following steps: mixing ammonia and carbon dioxide gas (carbonic acid gas) with a water solution containing lithium chloride to carry out carbonation reactions, and then recovering the generated solid through a solid / liquid separation method. The invention also relates to a preparation method of high purity lithium carbonate. The preparation method of lithium carbonate is capable of reducing transportation cost, and improving the purity of lithium carbonate through a simple washing operation.

Owner:NITTETABU MINING CORP +1

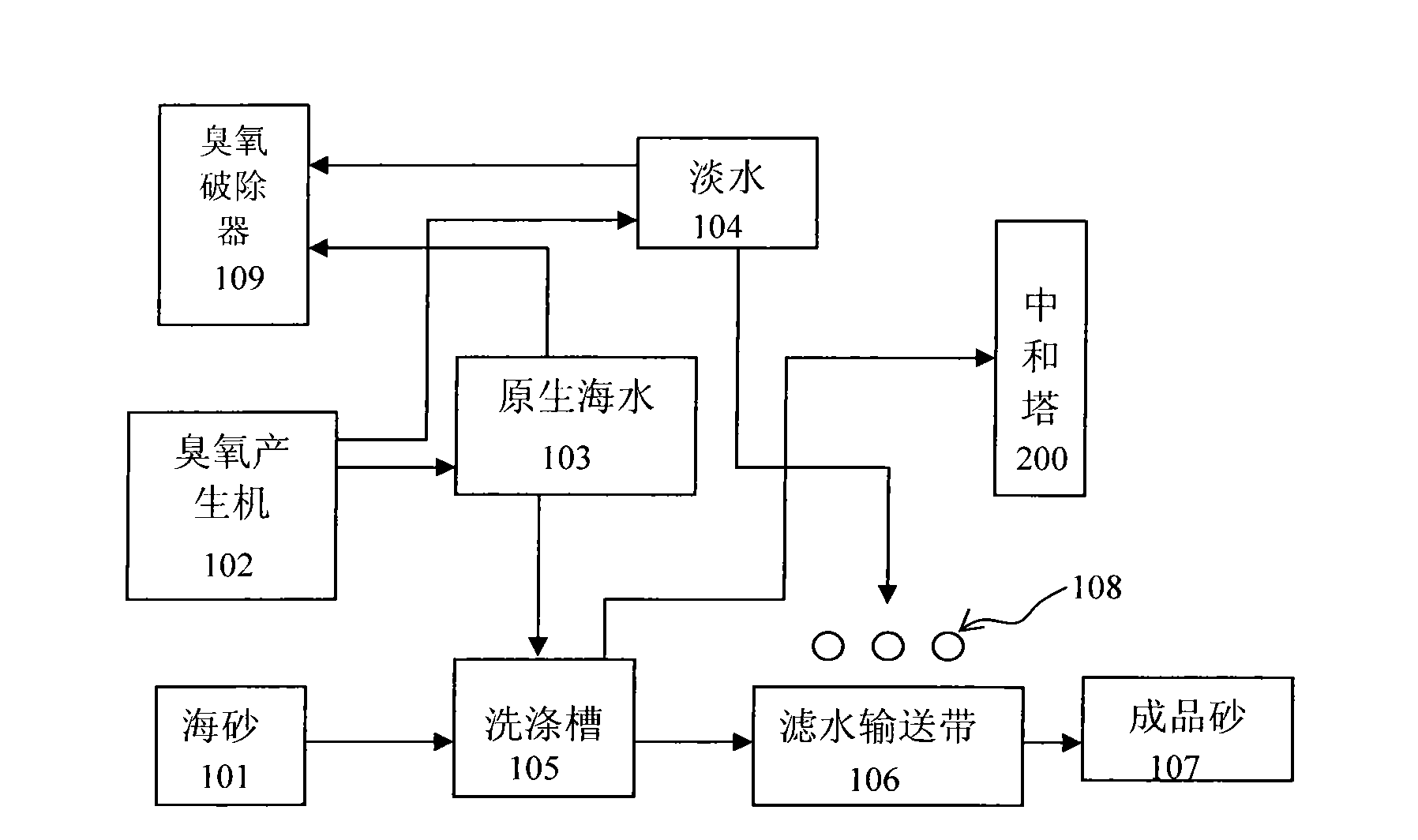

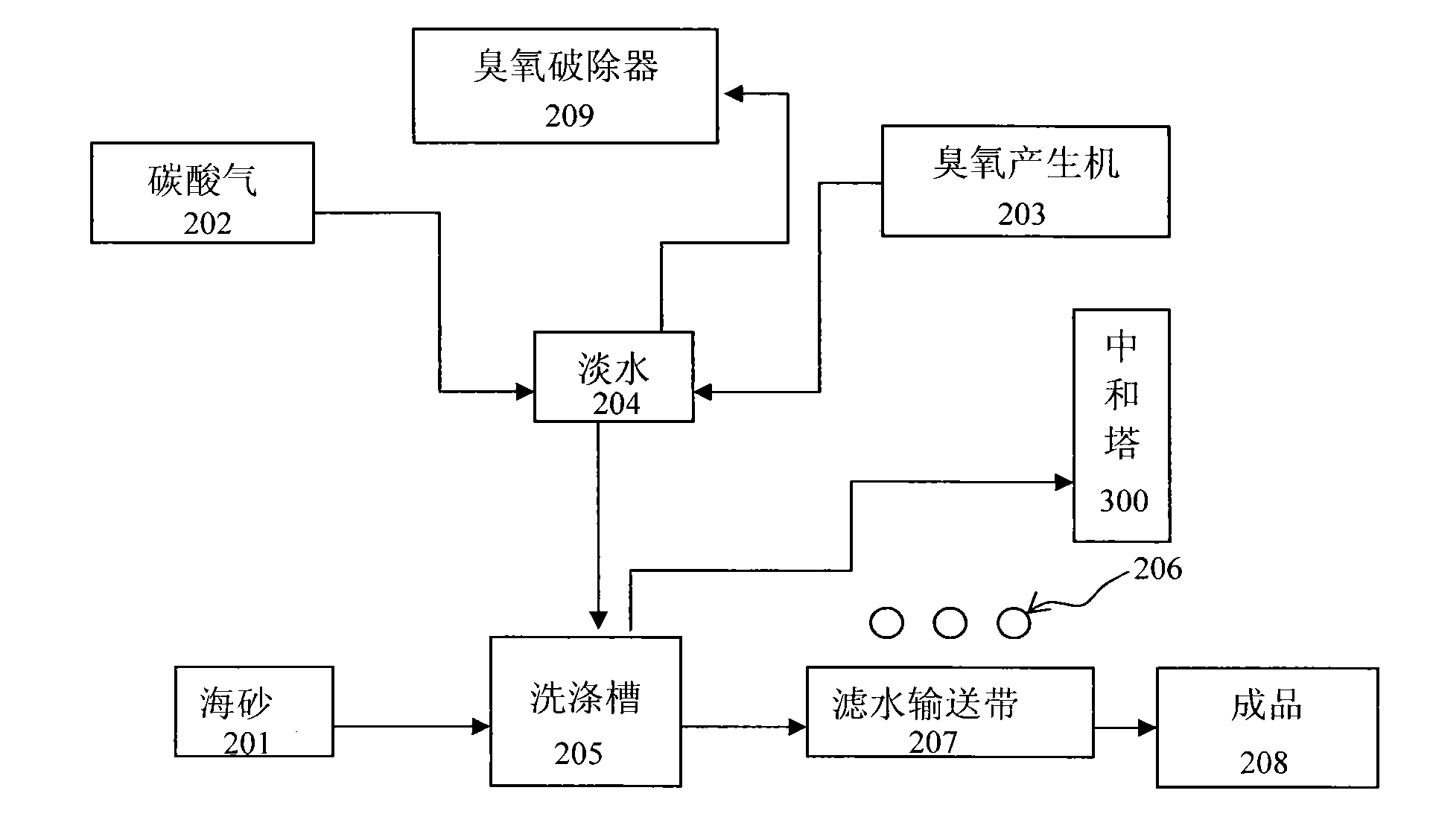

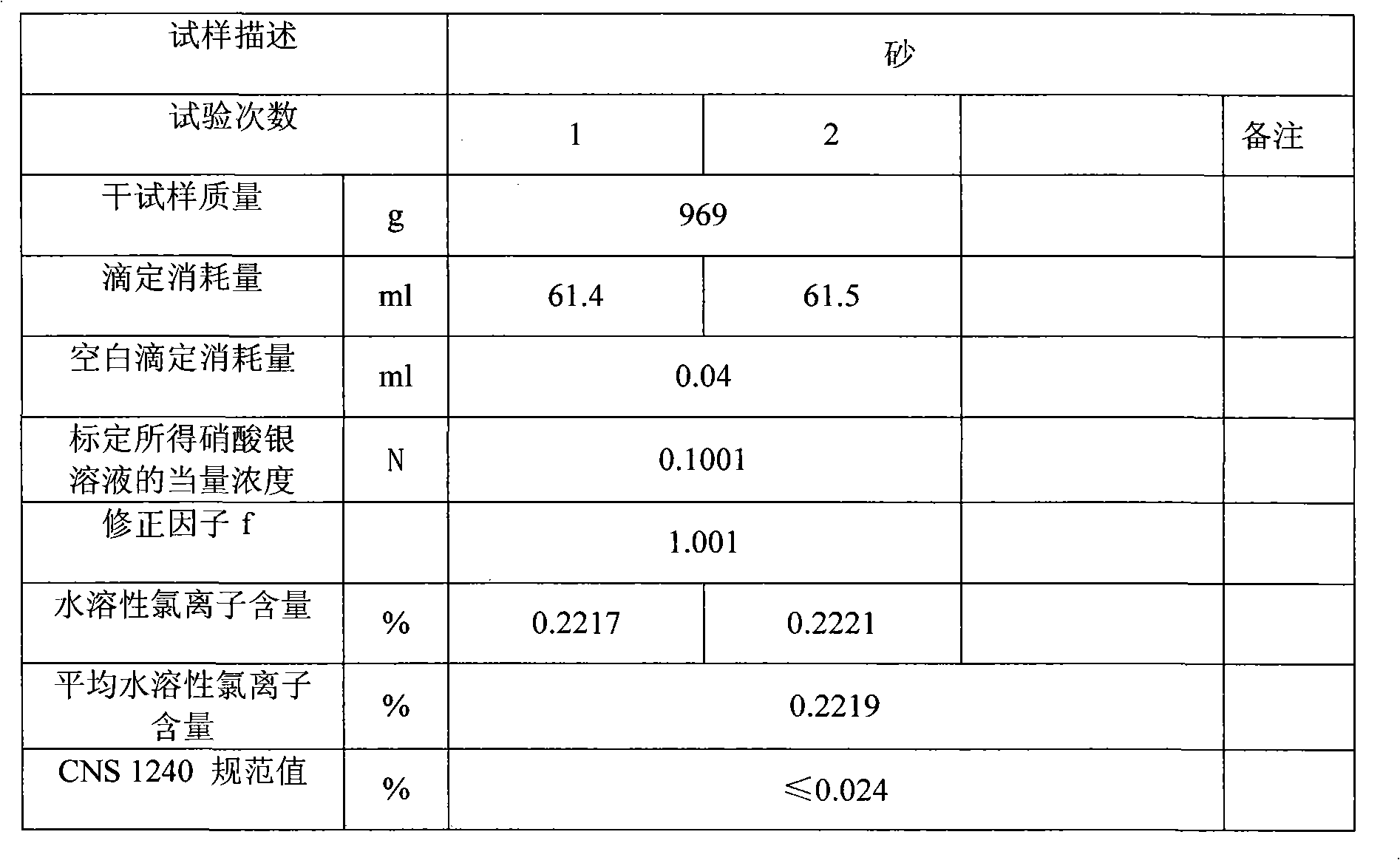

Method for supercritically washing sea sand, river sand and hill sand

InactiveCN101537414AOvercome physical propertiesReduce viscosityCleaning using liquidsHigh concentrationHazardous substance

The invention discloses a method for supercritically washing sea sand, river sand and hill sand, which mainly applies two-phase coexistence washing water formed by mixing gaseous ozone, carbonic acid gas and liquid water, overcomes the capillary phenomenon caused by physical characteristics viscosity and surface tension of water, and generates supercritical washing to remove substances on the surface of the sea sand which are harmful to cement, reinforcing steel bar and the like, such as chloride, sulfate, organic substances, algae and the like. The ozone as a strong oxidizing agent plays a role in decomposing the organic substances, so when high-concentration ozone water is used as washing water, the ozone water has high efficiency and low cost in removing harmful ions of the sea sand or the river sand, and has the characteristic of no harmful substance residue; and the washed sea sand does not have odor, and has low content of ash, and can become high quality sand for construction and engineering.

Owner:汤奇岳

Cola ginger chocolate coated and hung on cold drink

The invention relates to cola ginger chocolate coated and hung on cold drink. The cola ginger chocolate coated and hung on the cold drink consists of the following raw materials in part by weight: 270 to 310 parts of white sugar, 160 to 200 parts of milk powder, 80 to 120 parts of cocoa powder, 40 to 60 parts of cola ginger powder, 360 to 400 parts of oil and fat, a proper amount of vanillin, 1 to 4 parts of lecithin and 1 to 3 parts of polyglycerol polyricinoleate, wherein the cola ginger powder is the combination of cola nut powder and ginger powder. The cola ginger chocolate is provided with cola nut and ginger on the basis of the original formula of the common coating and hanging chocolate, so that the cola ginger chocolate has the taste of cola ginger, does not contain carbonic acid gas, and can meet the requirements of customers who like drinking cola beverages, but worry about that carbonated beverages are bad for teeth. The cola nut and the ginger are added into the cola ginger chocolate, so that the product categories are enriched and market gap is filled on the premise of not influencing the forming of the chocolate coating.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

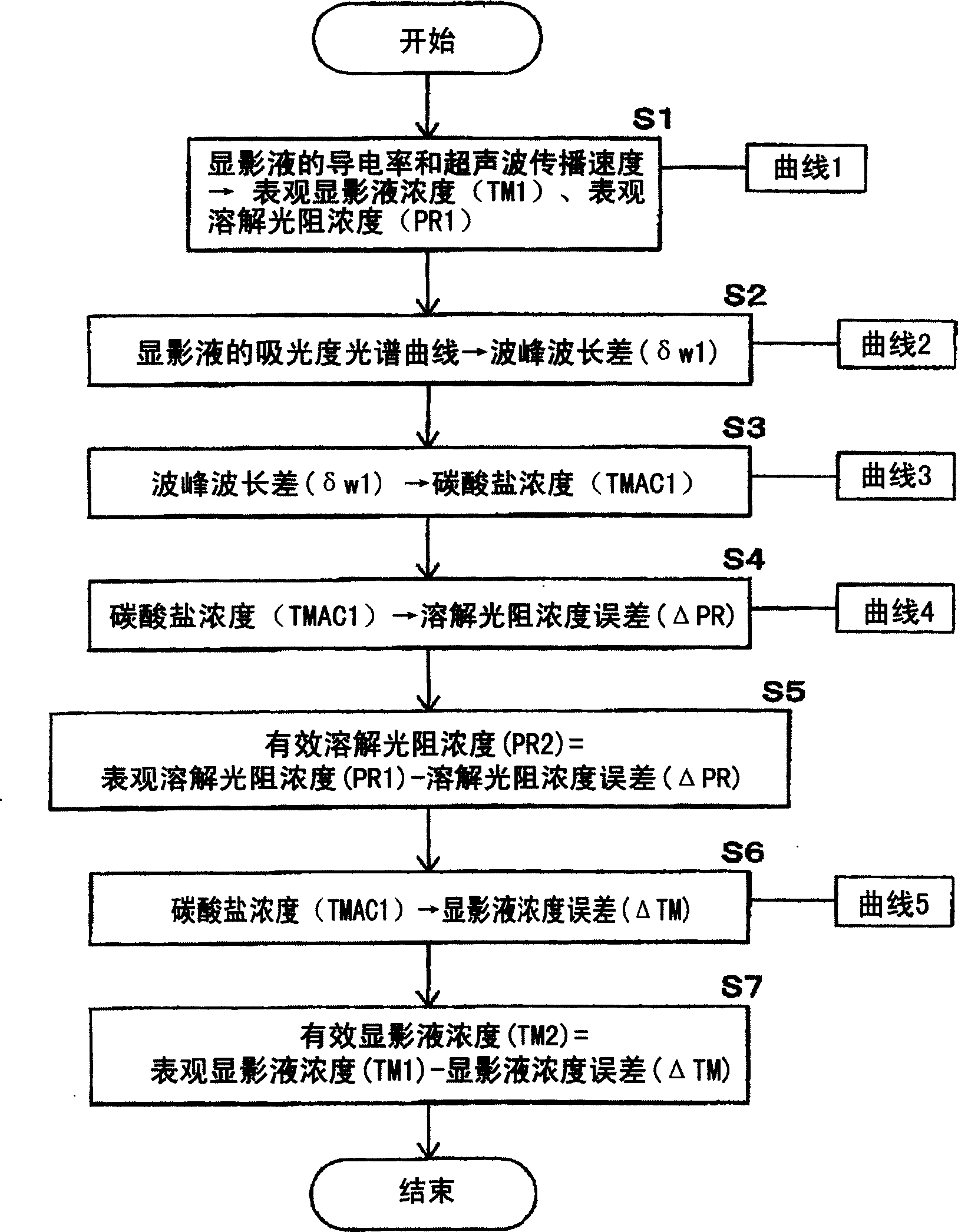

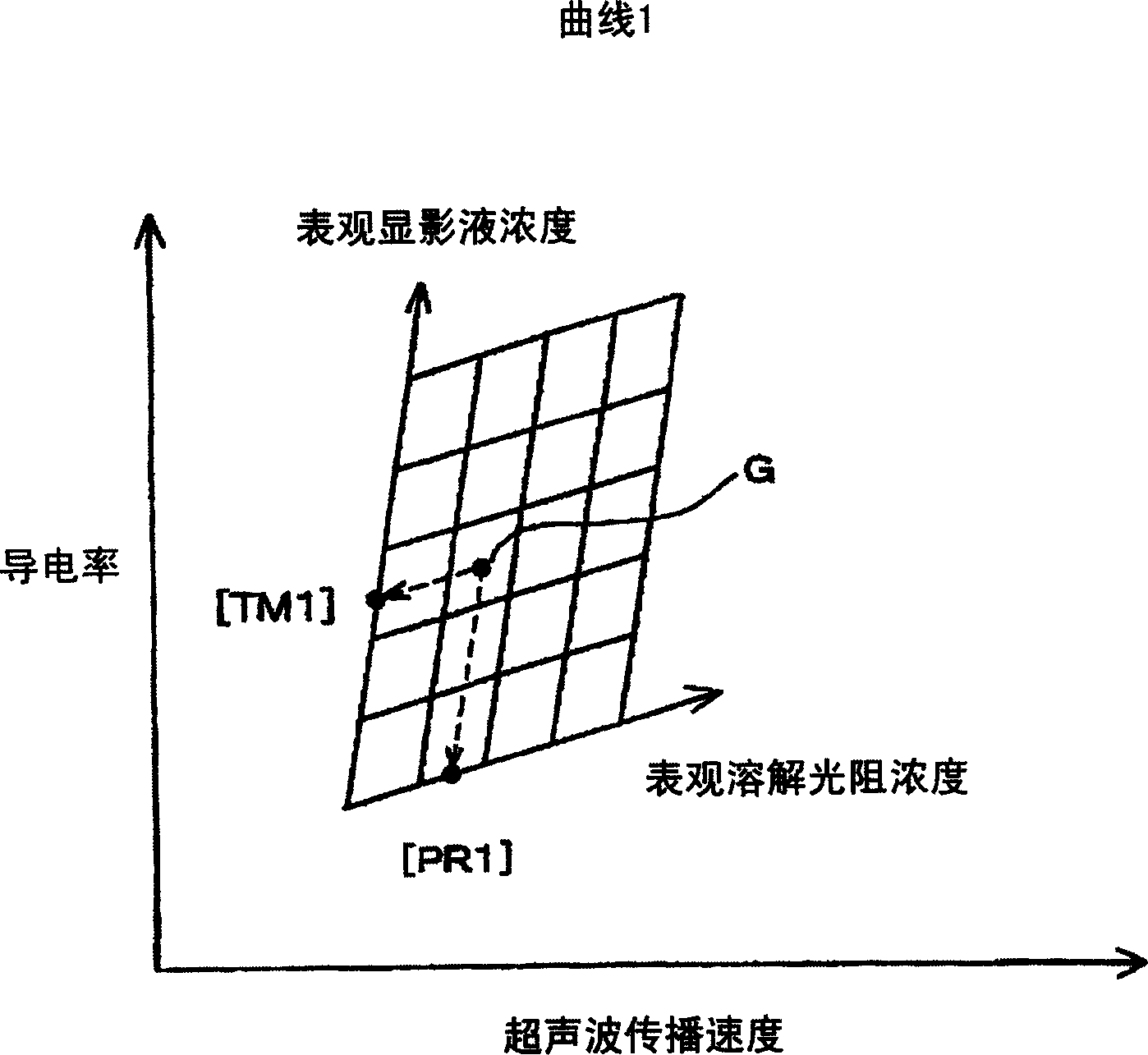

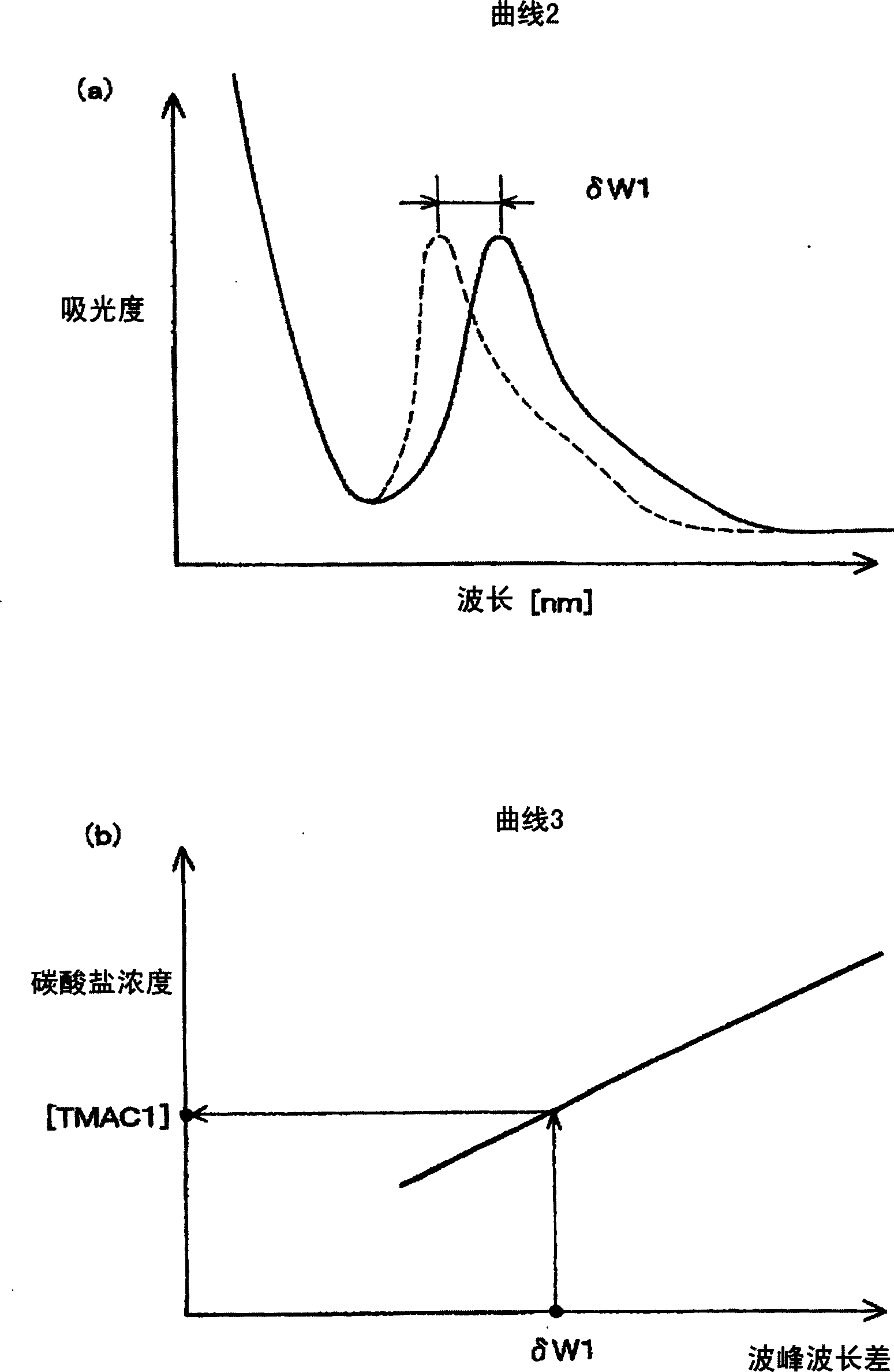

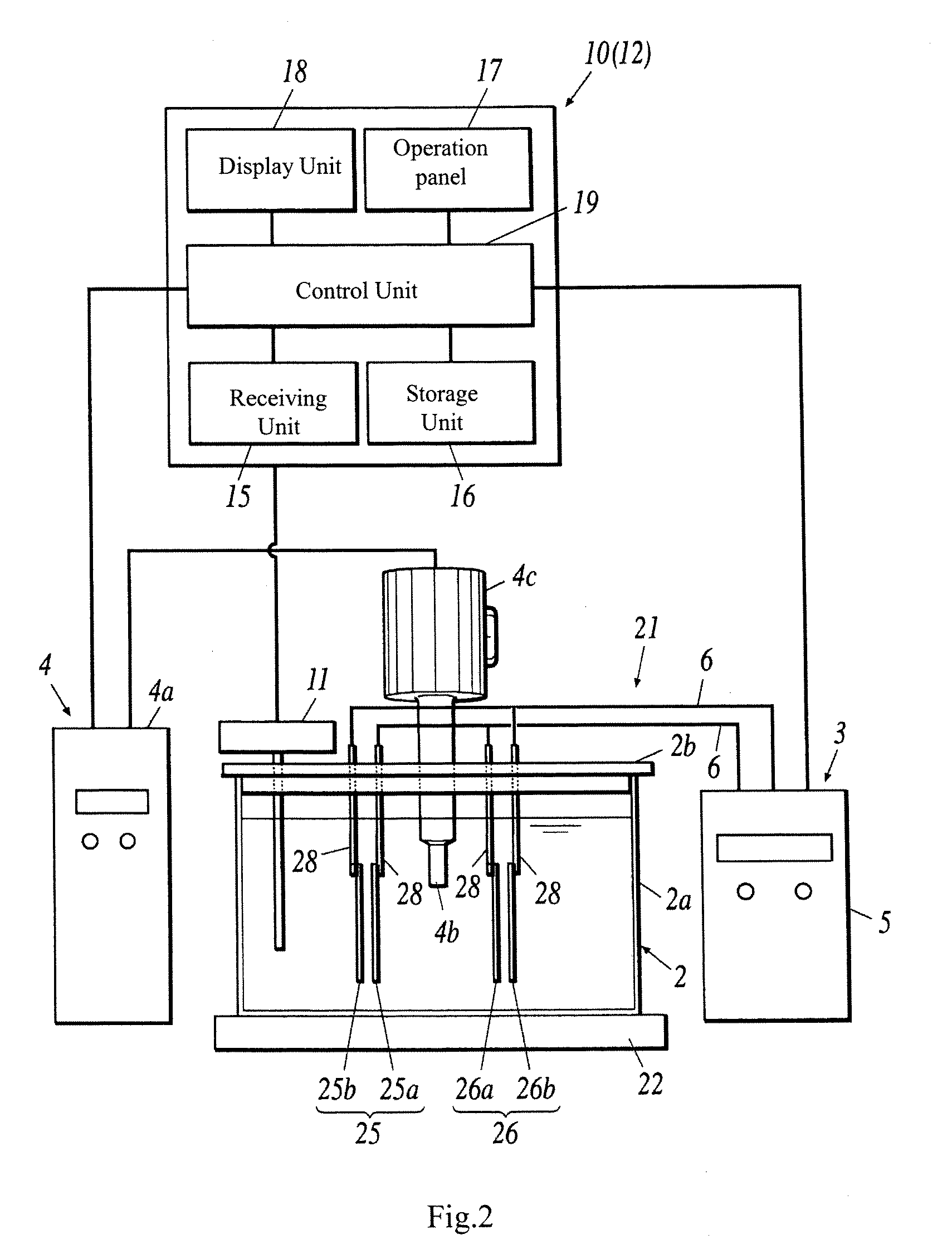

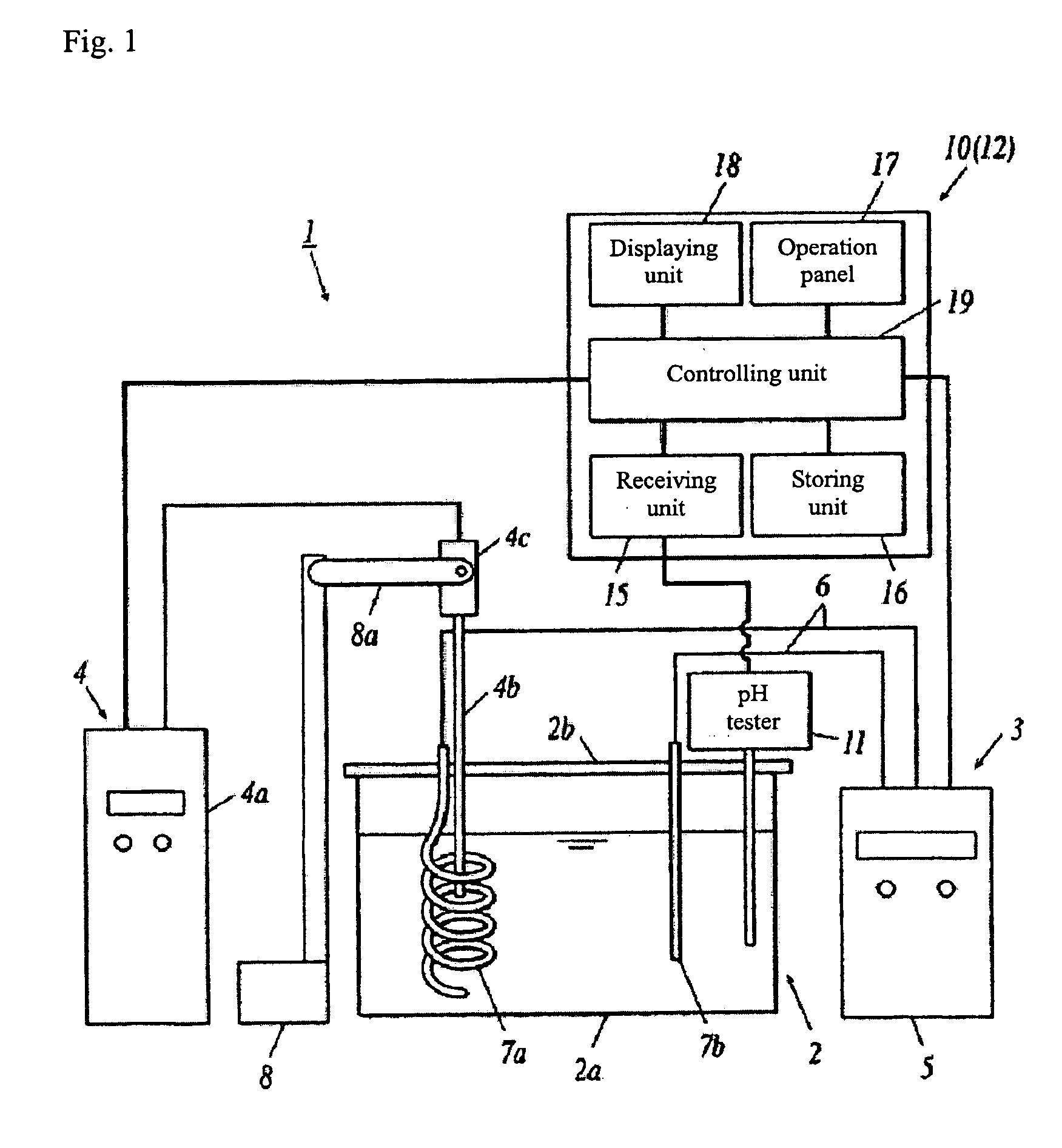

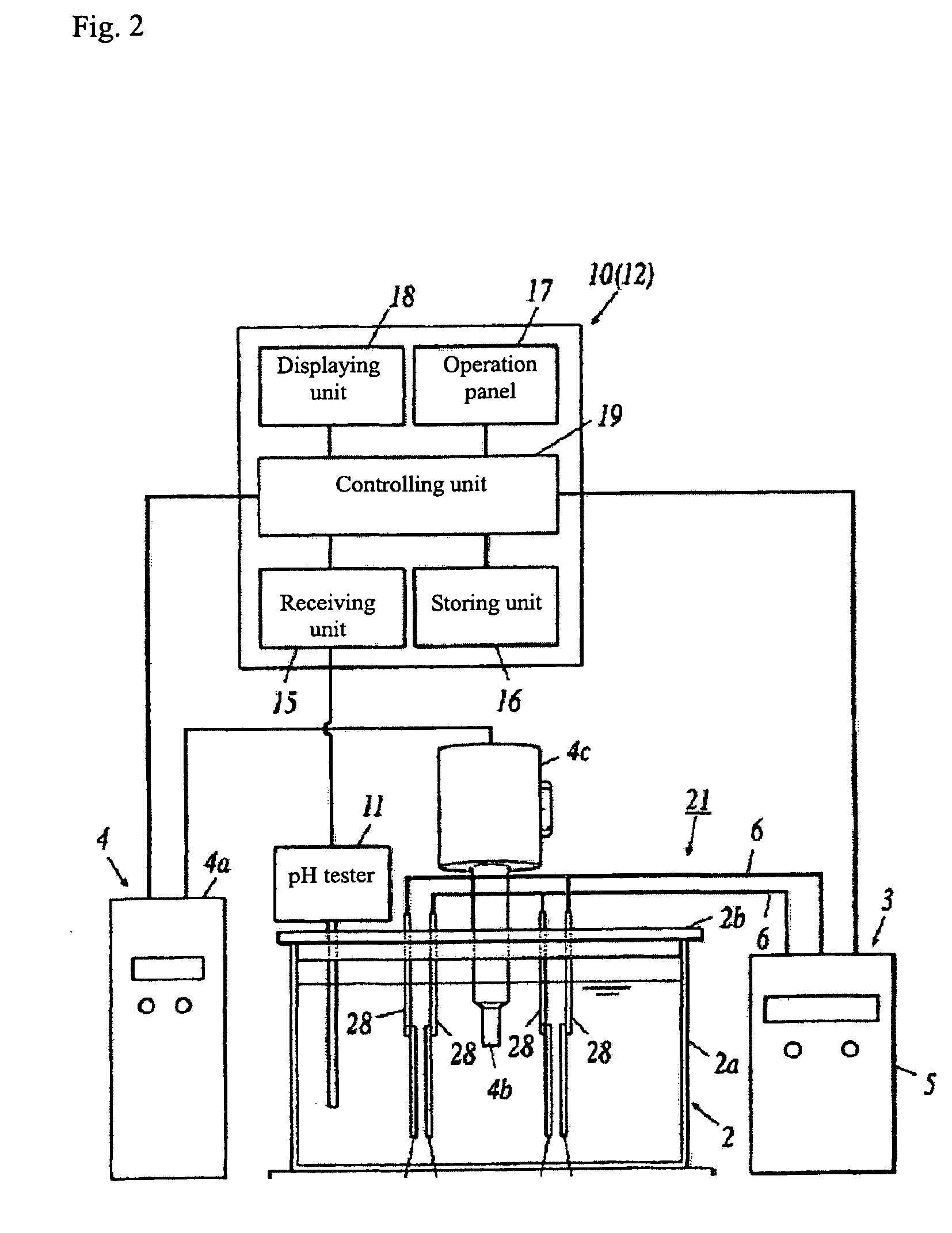

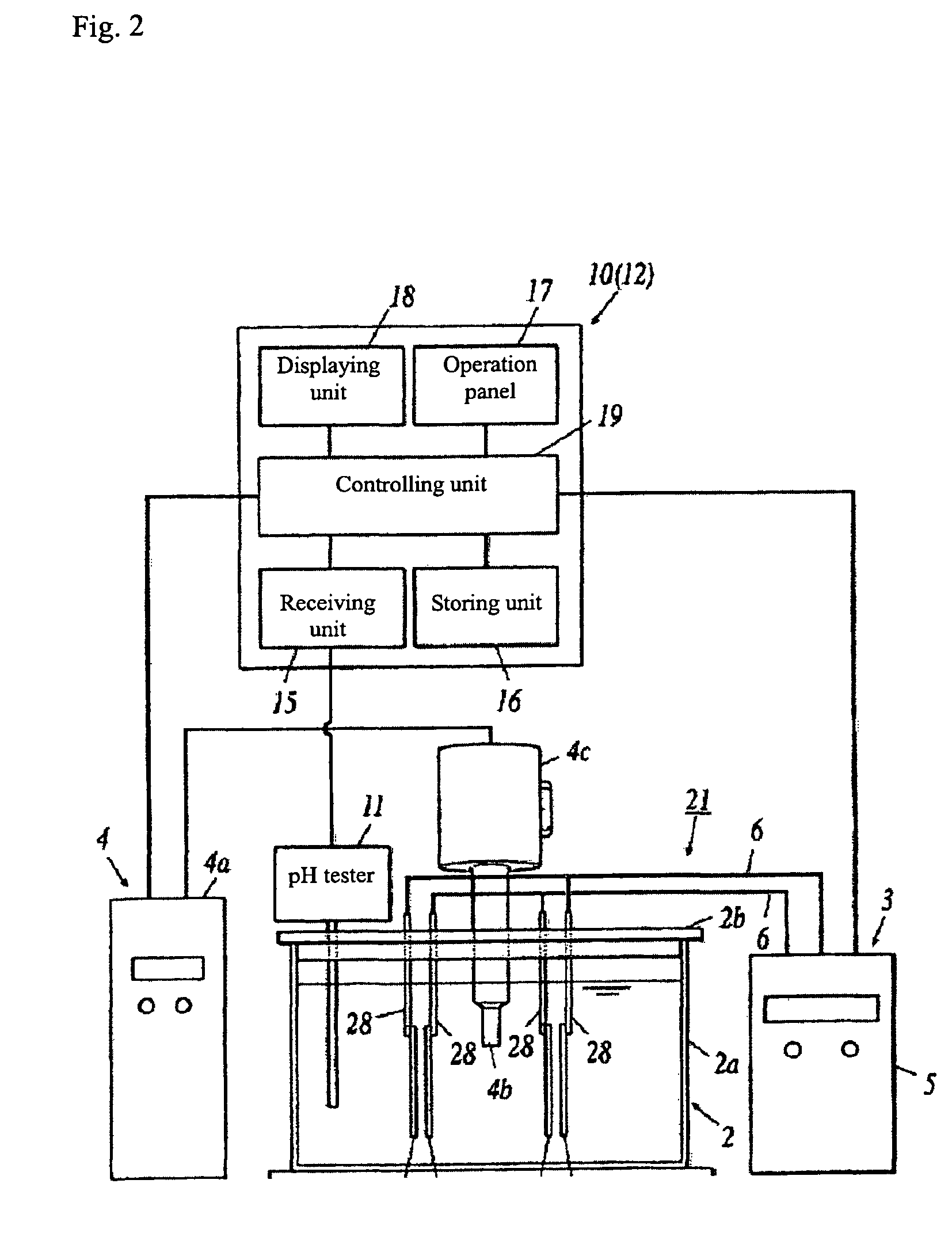

The management method and device of working solution level

InactiveCN1664706APrecise managementHigh precisionSemiconductor/solid-state device manufacturingPhotosensitive material processingResistLength wave

The invention provides a method and an appararutus for controlling a developer for photoresist by which practical effective developer concentration and effective dissolved resist concentration can be obtained accurately in real-time while considering effects of carbonate concentration. An apparent developer concentration (TM1) and an apparent dissolved resist concentration (PR1) are calculated from the correlation between conductivity and ultrasonic propagation rate of the developer. Carbonate concentration (TMAC1) is calculated from the peak wavelength difference ([delta]wl) obtained by spectral analysis for the absorbent of the developer and by using the correlation between the peak wavelength difference and the carbonate concentration of the developer. Effective dissolved resist concentration (PR2) and effective developer concentration (TM2) are calculated from the obtained carbonate concentration (TMAC1) while considering effects of the carbonate concentration on the dissolved resist concentration and on the developer concentration obtained, the effects which are preliminarily obtained by an experiment of blowing carbonic acid gas.

Owner:西村 保二 +1

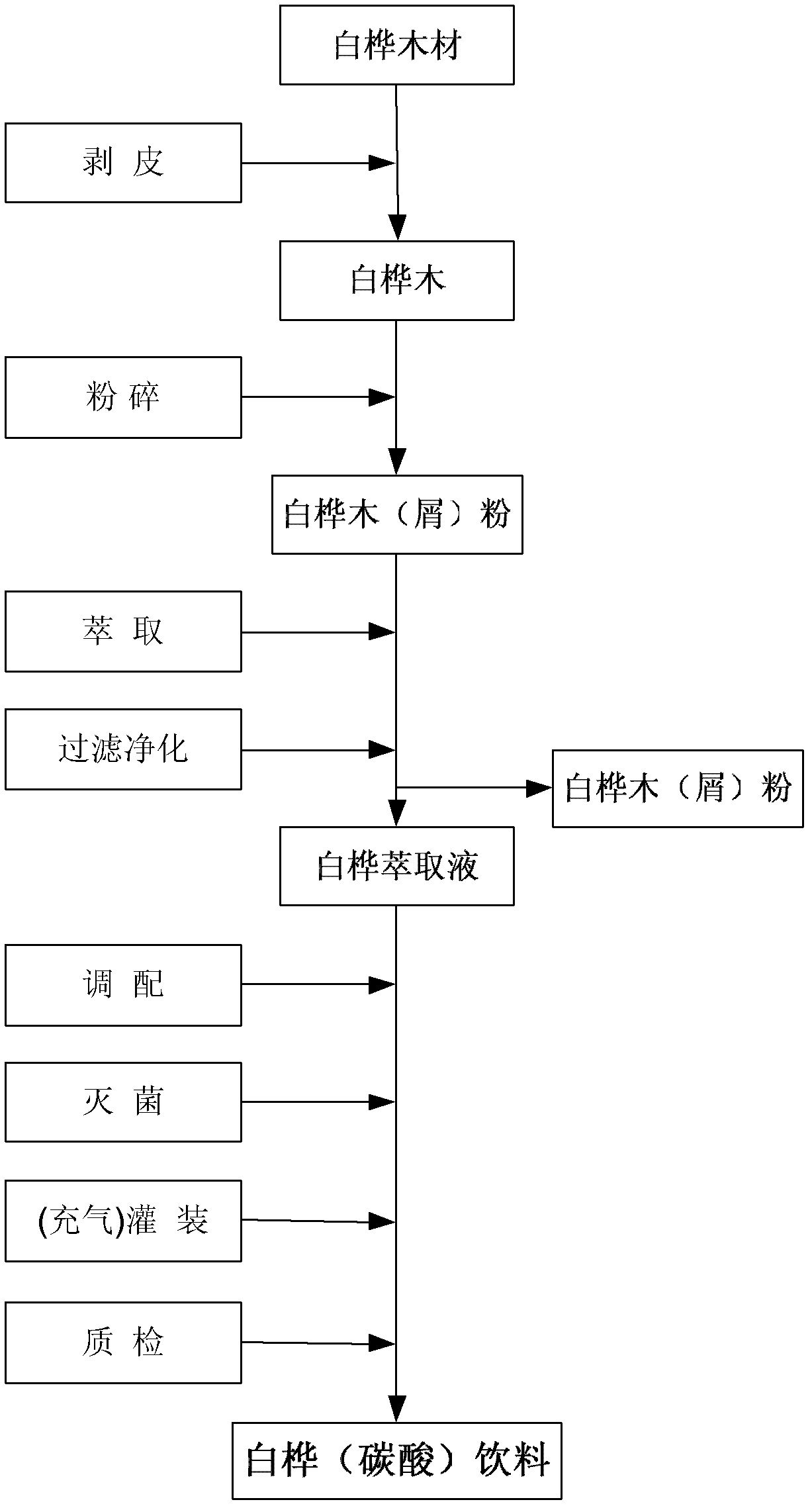

White birch (carbonic acid) beverage and preparation process thereof

InactiveCN102599598AStrong natural birch flavorPure tasteFood preparationAmino acidCarbonic acid gas

The invention relates to a white birch (carbonic acid) beverage and a preparation process thereof. The white birch (carbonic acid) beverage is characterized by comprising 1 to 99 percent by weight of white birch extraction liquid, 0.01 to 10 percent by weight of sweetening agent, 0 to 0.5 percent by weight of acid, 0 to 0.1 percent by weight of edible essence, 0.005 to 0.01 percent by weight of sodium benzoate or potassium sorbate and the rest of drinking purified water. The preparation process comprises the following steps of: (1) peeling of white birch lumber; (2) smashing of the white birch; (3) preparation of white birch extraction liquid; (4) preparation of white birch beverage; (5) sterilization; and (6) (inflation) filling. The white birch (carbonic acid) beverage is characterized in that white birch lumber (scrap) extraction liquid is adopted as a main raw material, so that a strong natural flavor of white birch is realized, taste is pure, and the stability is good; and the white birch (carbonic acid) beverage is rich in soluble sugar, amino acid, vitamins, minerals, aromatic substances and the like, and is a natural beverage which is beneficial to all ages.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

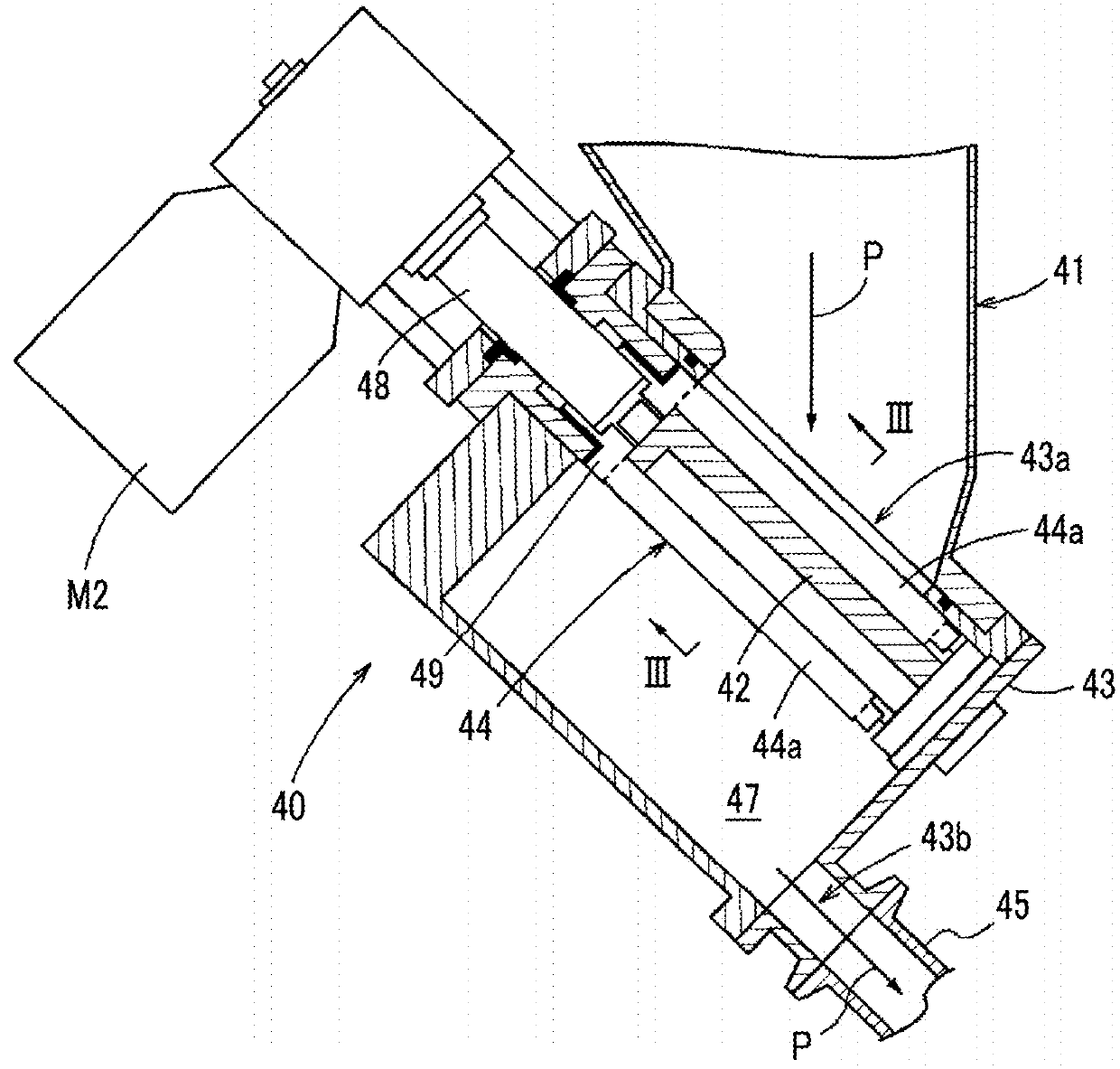

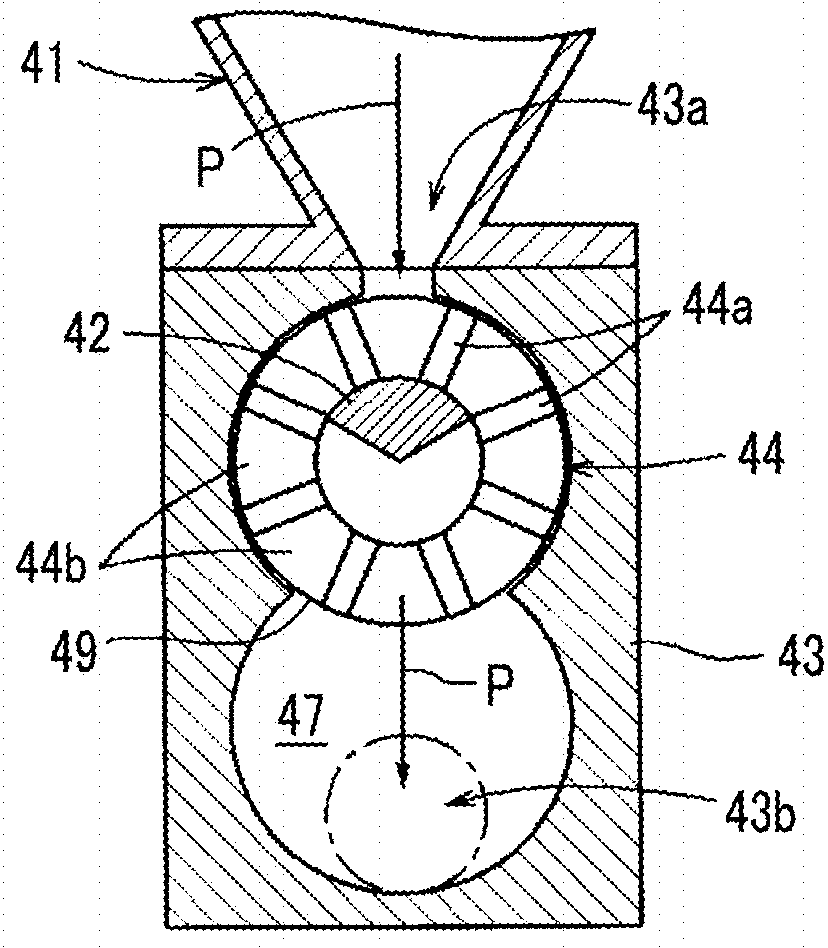

Method for manufacturing slurry for positive electrode of nonaqueous electrolyte secondary battery and slurry for positive electrode of nonaqueous electrolyte secondary battery

ActiveUS20180183047A1Reliably deaerateShorten production timePositive electrodesElectrode collector coatingEngineeringSlurry

Owner:NIHON SPINDLE MFG CO LTD +1

Method for processing fish of red flesh

InactiveCN1582681ALong storage timeMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsEngineeringZoology

A method for processing a fish of red flesh includes a packing step of cutting a fish in such a shape as would fit immediate use by consumers, piling the cut fish orderly on a tray and stowing the cut fish on the tray into a pack, a vacuumizing step of filling the pack during the packing step with a vacuum atmosphere, a gas-filling step of filling the pack immediately after completion of the vacuumizing step with a mixed gas of carbonic acid gas and oxygen gas without exposing the interior of the pack to the ambient air, thereby exposing the fish to the mixed gas, a pack-sealing step of tightly closing the pack filled with the carabonic acid and the oxygen gas, and a freezing step of quickly freezing the fish contained in the pack and transforming the fish into a frozen fish.

Owner:HARUMI SUISAN

Process for producing solution having carbon dioxide dissolved therein, apparatus therefor and carbonated water

The oxalic acid aqueous solution filled in an electrolytic tank is electrolyzed with an electrolyzer to produce carbonic acid gas, while ultrasonic wave from an ultrasonic generator is applied to the produced carbonic acid gas bubbles, to form micro bubbles, which is dissolved in said oxalic acid aqueous solution, so as to easily produce carbonic acid gas solution with micro carbonic acid gas bubbles dissolved at a low cost; said carbonic acid gas solution can substitute carbonated spring.

Owner:OMSI

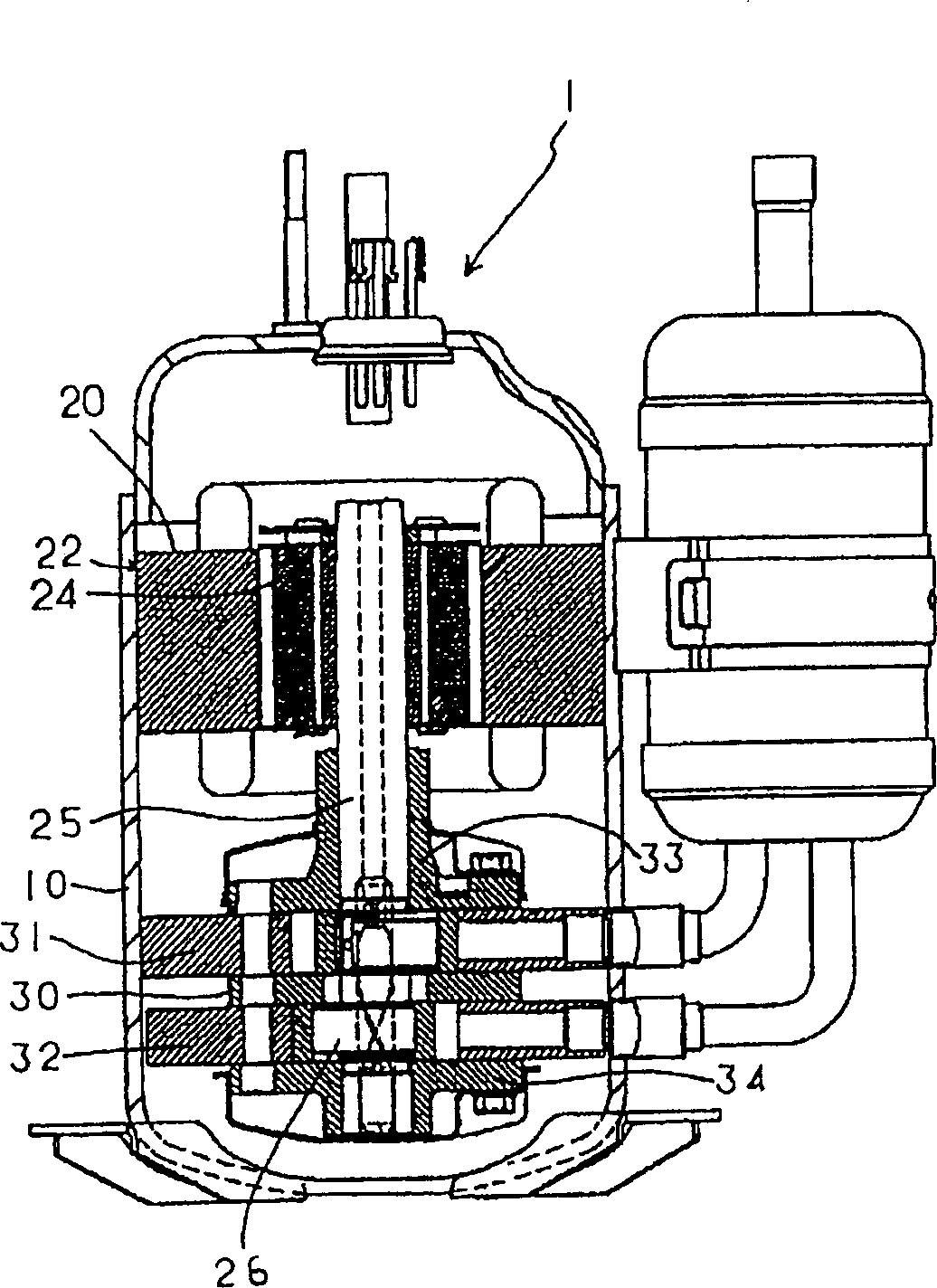

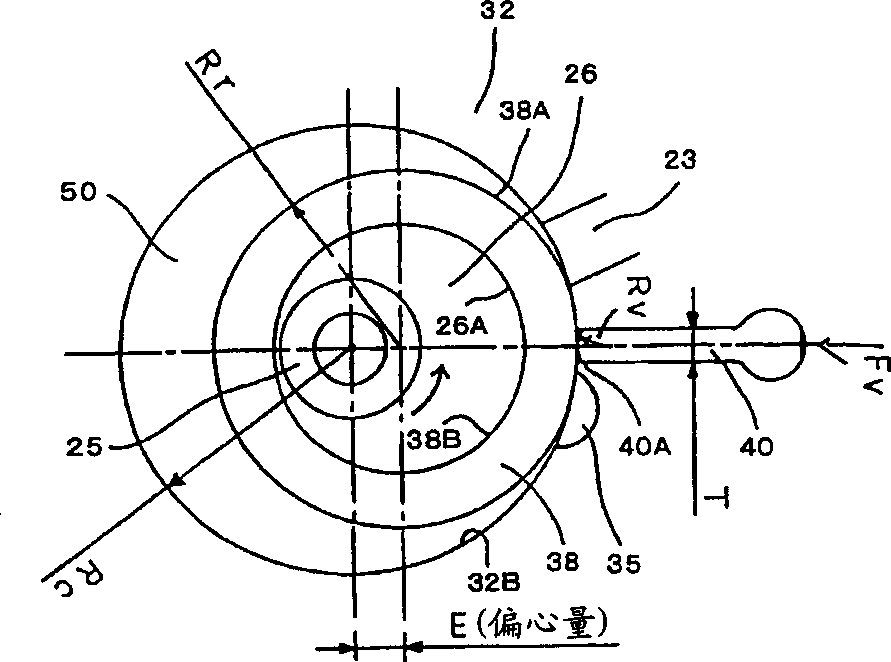

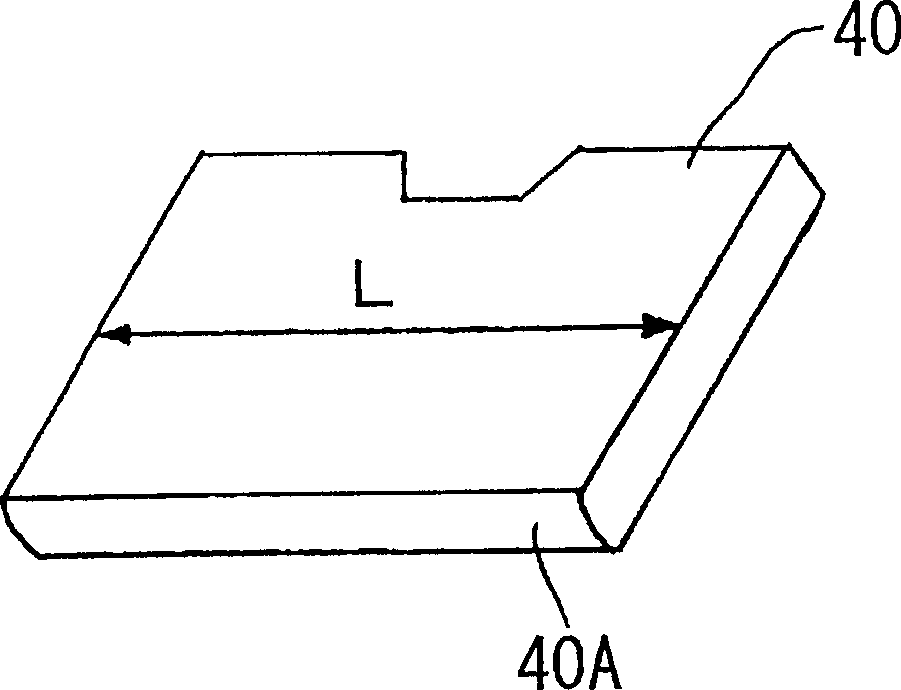

Rotary compressor

InactiveCN1370930AAvoid abnormal wearImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsAlcoholEngineering

A rotary compressor which uses carbonic acid gas as the refrigerant, polyalkylene glycol as a lubricant, or polyalfa olefin or mineral oil as a base oil. The compressor includes a roller and a vane whose radius of curvature (Rv) (cm) at a sliding contact portion with respect to said roller can be represented by the following Expression (1): <DF NUM="Expression (1)">T < Rv < Rr < / DF> where T is the thickness (cm) of the vane, and Rr is the radius of curvature (cm) of the outer periphery of the roller which slidingly comes into contact with the vane. <IMAGE>

Owner:SANYO ELECTRIC CO LTD

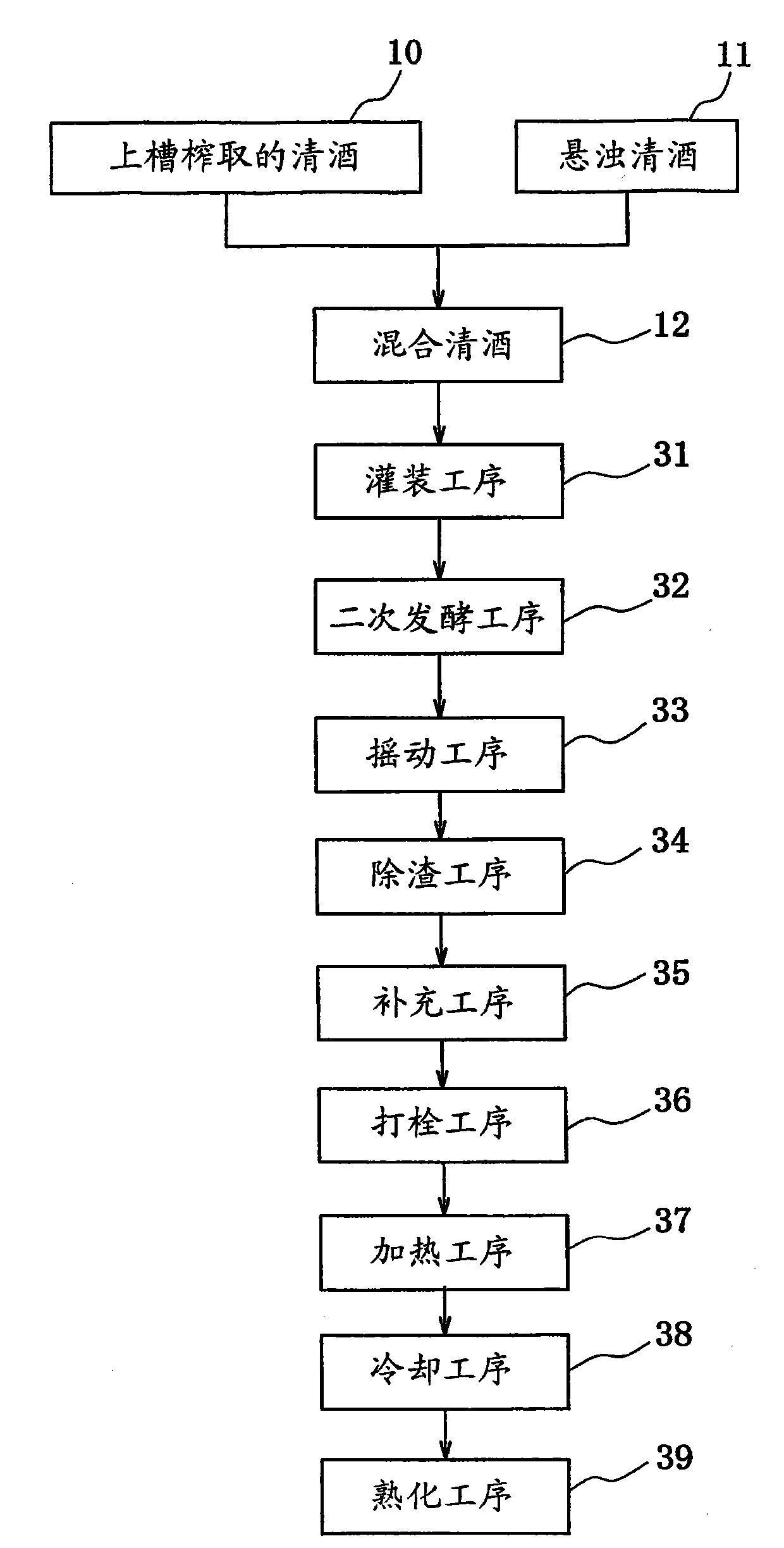

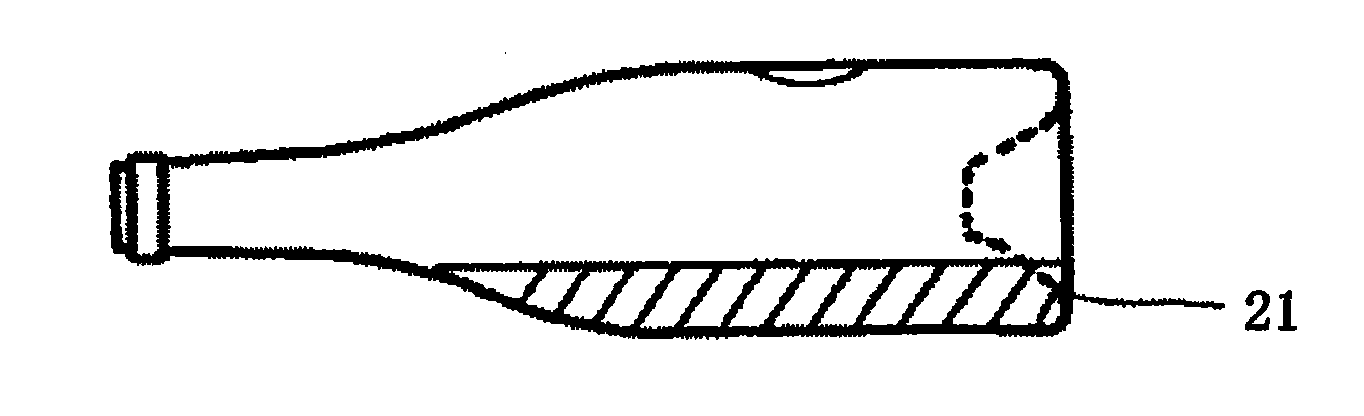

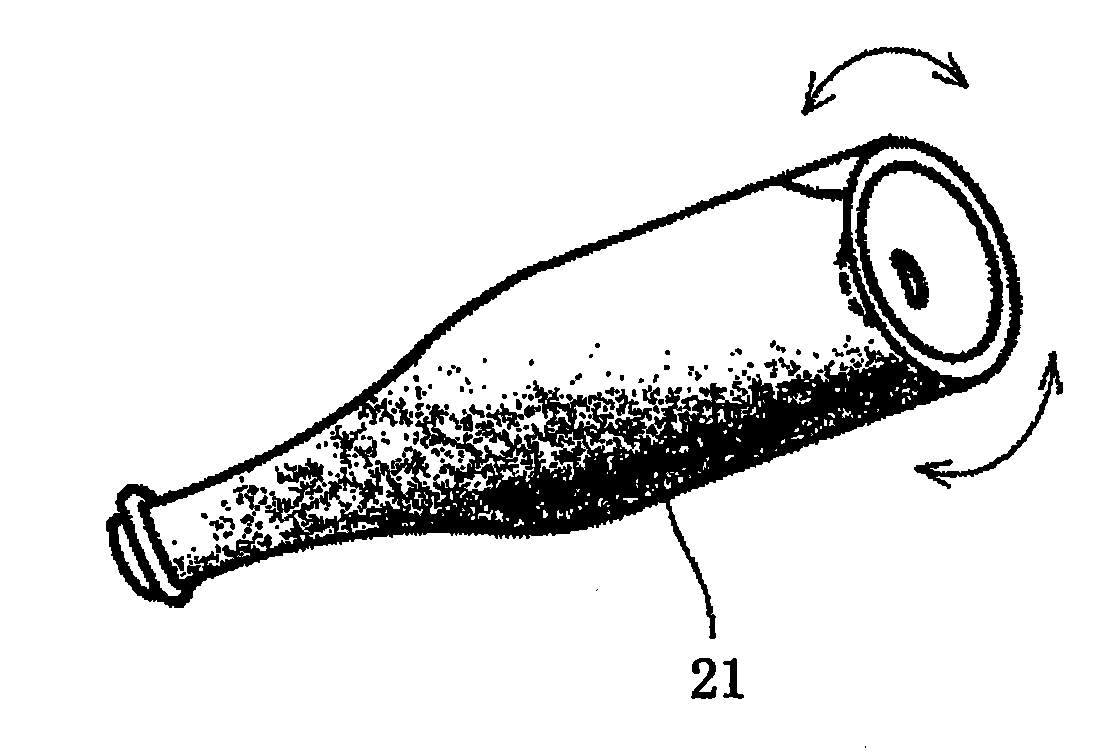

Sparkling sake and method of producing the same

It is intended to provide a sparkling sake of the in-bottle fermentation type produced by blending a sake obtained by filtering a sake mash with an unrefined sake obtained by roughly screening a moromi mash containing yeasts and having a fermentation activity and then generating carbon dioxide gas in a closed container filled with the thus obtained sake blend, which has champagne-like bubbles with a fine texture and a smooth feeling and shows little cloudiness and a refreshing taste. The above object is achieved by a method characterized in that rice and rice koji are used as the starting materials, the carbon dioxide gas contained in the above-described container is the carbon dioxide gas having been generated substantially by the secondary fermentation, and the content of the carbon dioxide gas is 3.0 GV or more.

Owner:NAGAI SAKE

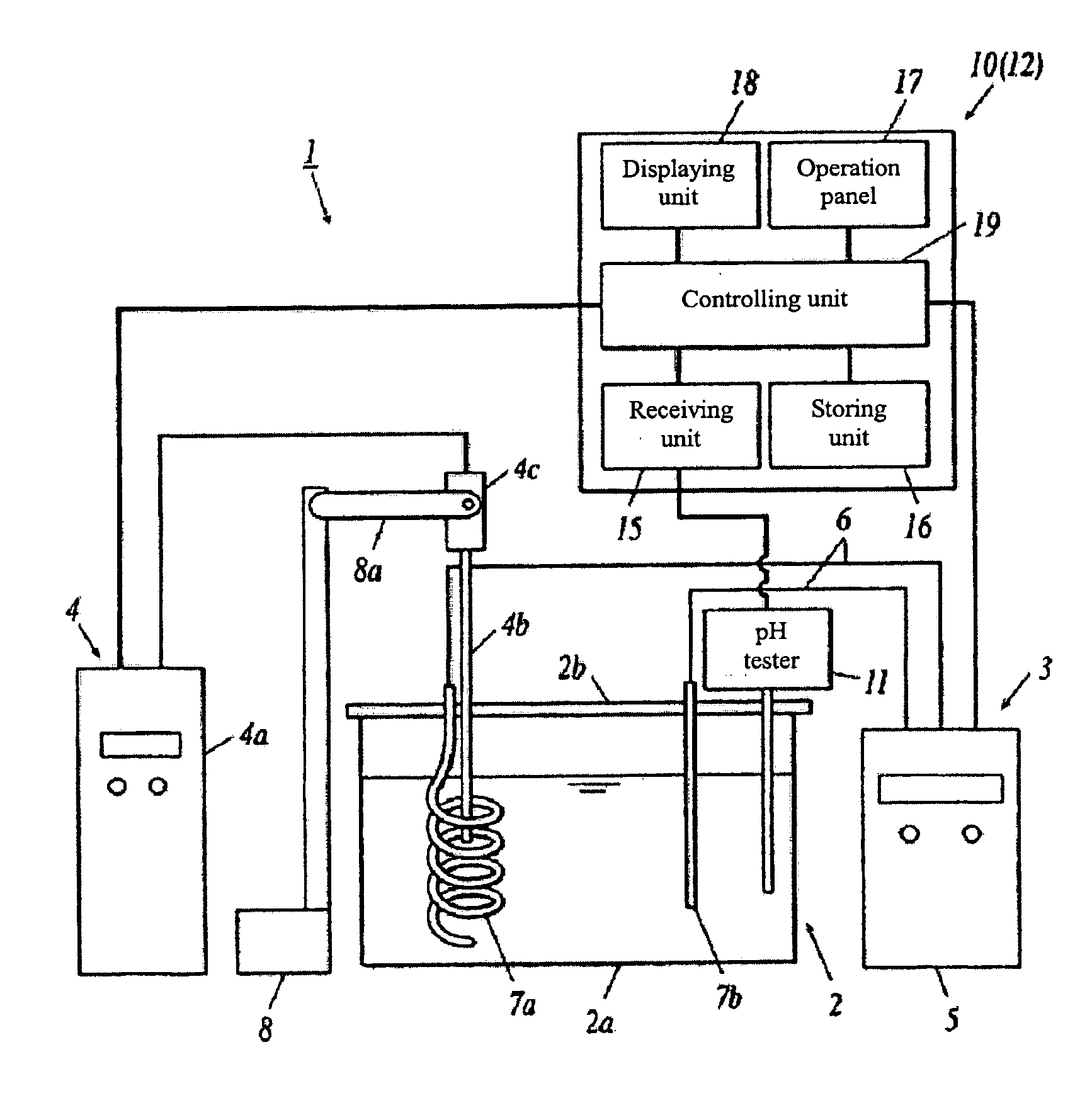

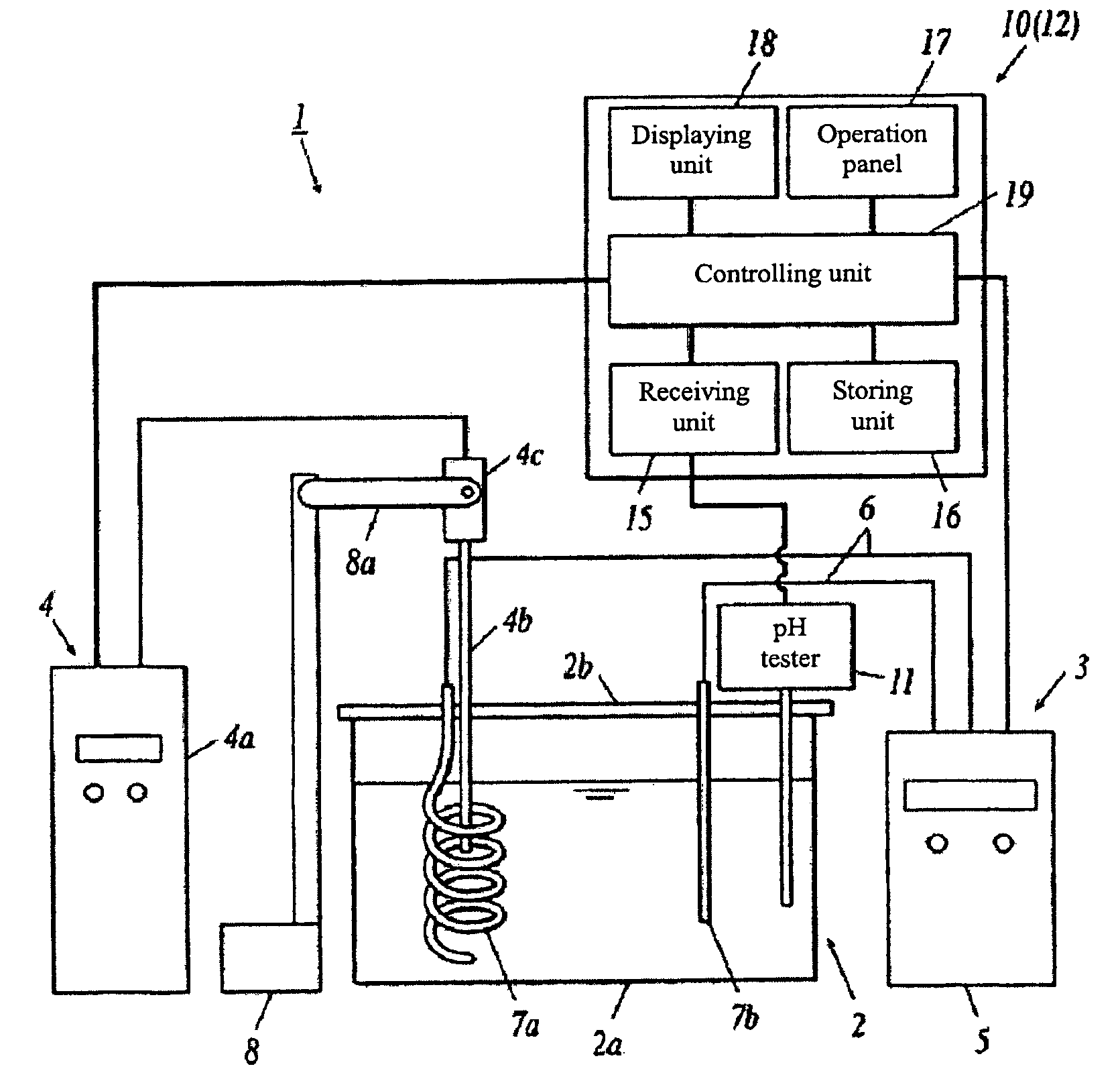

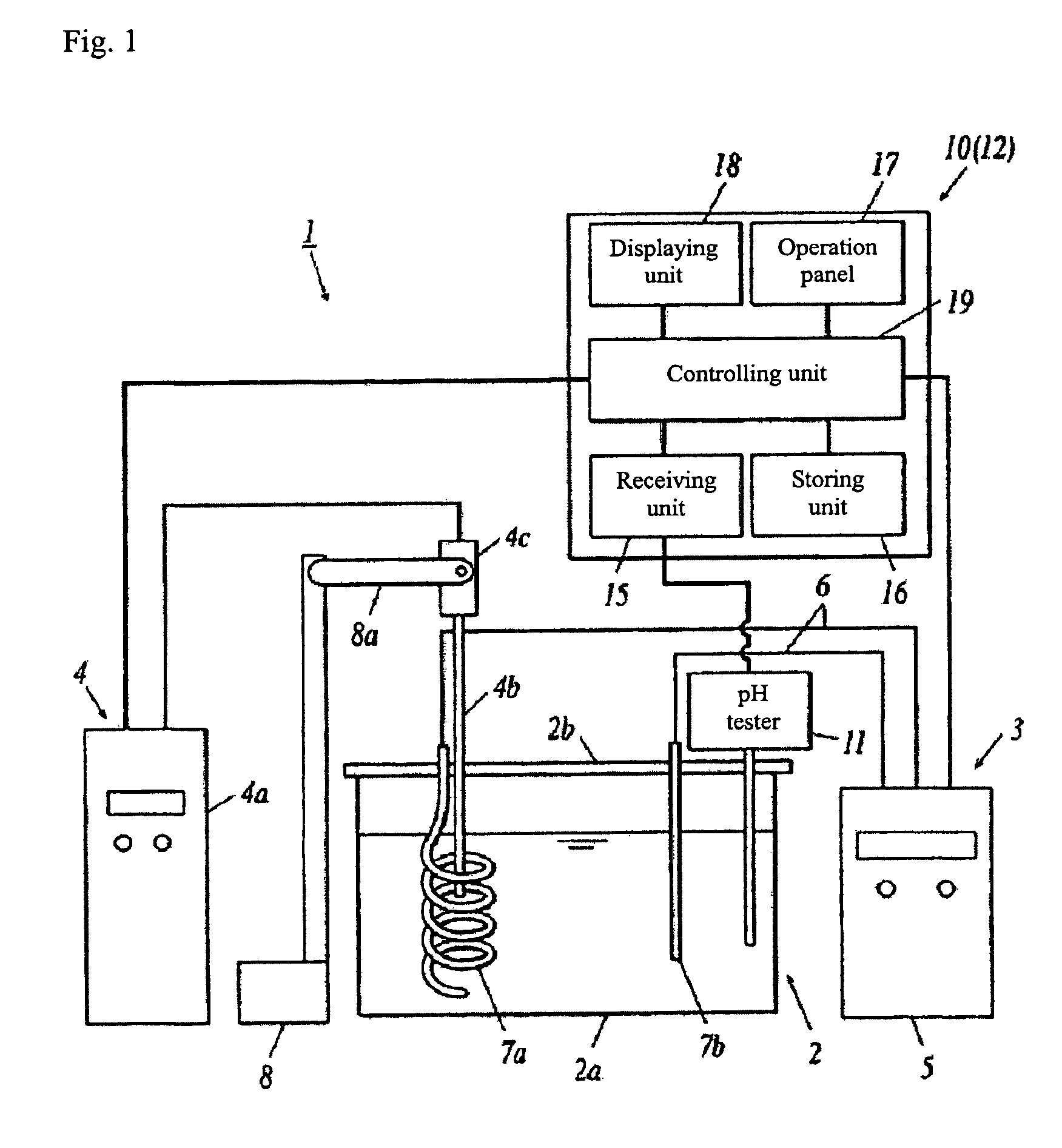

Process for Producing Carbon Dioxide Solution, Production Apparatus, And Carbonated Water

InactiveUS20090175960A1Low costFriendlyCarbon compoundsInorganic active ingredientsCarboxylic acidAqueous solution

A first aqueous solution filled in an electrolytic cell (2) is electrolyzed by applying DC voltage between the electrodes 7a and 7b in said electrolytic cell 2, to form an oxidation field short of electrons in said aqueous solution; and then, a second aqueous solution with carboxylic acid dissolved in it is mixed into the first aqueous solution in oxidation field state, so that the first aqueous solution in oxidation field state obtains electrons and is deoxidized, and the carboxylic acid is oxidized, to produce carbonic acid gas in said aqueous solution. Therefore, the present invention can be used to produce carbonic acid gas solution at a low cost easily.

Owner:OMSI

High-strength stainless steel pipe excellent in sulfide stress cracking resistance and high-temperature carbonic-acid gas corrosion resistance

The problem to be solved is the provision of a high-strength stainless steel pipe having a sufficient corrosion resistance in a high-temperature carbonic acid gas environment and having an excellent sulfide stress cracking resistance at normal temperature. A high-strength stainless steel pipe consist of, by mass %, C: 0.05% or less, Si: 1.0% or less, P: 0.05% or less, S: less than 0.002%, Cr: more than 16% and 18% or less, Mo: more than 2% and 3% or less, Cu: 1% to 3.5%, Ni: 3% or more and less than 5%, Al: 0.001% to 0.1% and O: 0.01% or less, Mn: 1% or less and N: 0.05% or less, and Mn and N in the above ranges satisfy formula (1), and the balance being Fe and impurities; and the metal micro-structure of the stainless steel pipe mainly includes a martensitic phase and comprises 10 to 40% of a ferritic phase by volume fraction and 10% or less of a retained γ-phase by volume fraction.[Mn]×([N]−0.0045)≦0.001 (1)wherein the symbols of elements in formula (1) respectively represent the contents (unit: mass %) of the elements in the steel.

Owner:NIPPON STEEL CORP

Equipment and process for the production of carbonated water

InactiveUS20060202363A1Short timeIncrease pressureLiquid degasificationFlow mixersHigh concentrationEnvironmental engineering

It relates to equipment and a process for producing carbonated water of a high-concentration inexpensively and easily. Since the equipment for producing the carbonated water and the process for producing the carbonated water using a static mixer having 20 to 100 elements realize production of the carbonated water of the high-concentration inexpensively and easily, they can be applied particularly effectively for so-called one pass production process. Moreover, the carbonated water of a higher concentration can be produced further effectively by providing a value Re×N of 100,000 to 2,000,000, wherein N is a number of elements of the static mixer and Re is a Reynolds number when a mixture of water and a carbonic acid gas flow in the static mixer.

Owner:MITSUBISHI RAYON CO LTD

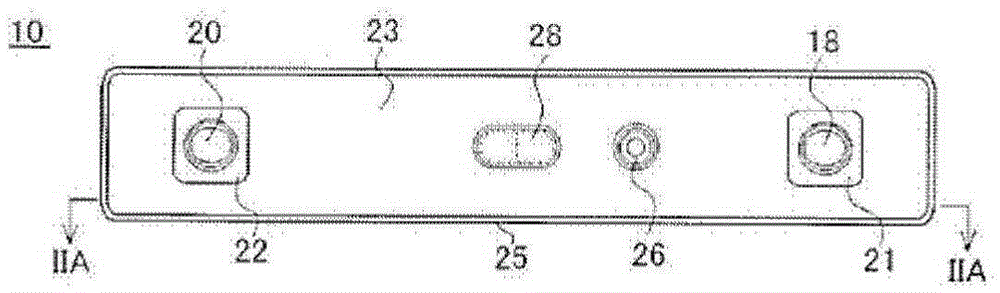

Non-aqueous electrolyte secondary cell

ActiveCN105324882APromote circulationImprove securityCell seperators/membranes/diaphragms/spacersCell electrodesLithium carbonatePressure response

The present invention ensures the operation of a pressure response-type current shutoff mechanism that makes it easy for carbonic acid gas generated by the breakdown of lithium carbonate in a positive electrode mixture layer to circulate to the outside of a flat winding electrode, and quickly raises the pressure inside a battery before the temperature inside the battery rises to the point of causing a failure, such as smoke, fire or explosion. A non-aqueous electrolyte secondary battery (10) of one embodiment of the present invention has a pressure response type current shutoff mechanism, and has insulating tape (11b) attached in the width direction of a positive electrode mixture layer (11a) at a position facing a separator (13) and on top of the positive electrode mixture layer (11a) at the winding start end and / or winding finish end of a positive electrode sheet (11) in a flat winding electrode (14).

Owner:SANYO ELECTRIC CO LTD

Process for producing carbon dioxide solution, production apparatus, and carbonated water

InactiveUS8273236B2Good effectPromote increaseCarbon compoundsInorganic active ingredientsCarboxylic acidAqueous solution

A first aqueous solution filled in an electrolytic cell (2) is electrolyzed by applying DC voltage between the electrodes 7a and 7b in said electrolytic cell 2, to form an oxidation field short of electrons in said aqueous solution; and then, a second aqueous solution with carboxylic acid dissolved in it is mixed into the first aqueous solution in oxidation field state, so that the first aqueous solution in oxidation field state obtains electrons and is deoxidized, and the carboxylic acid is oxidized, to produce carbonic acid gas in said aqueous solution. Therefore, the present invention can be used to produce carbonic acid gas solution at a low cost easily.

Owner:OMSI

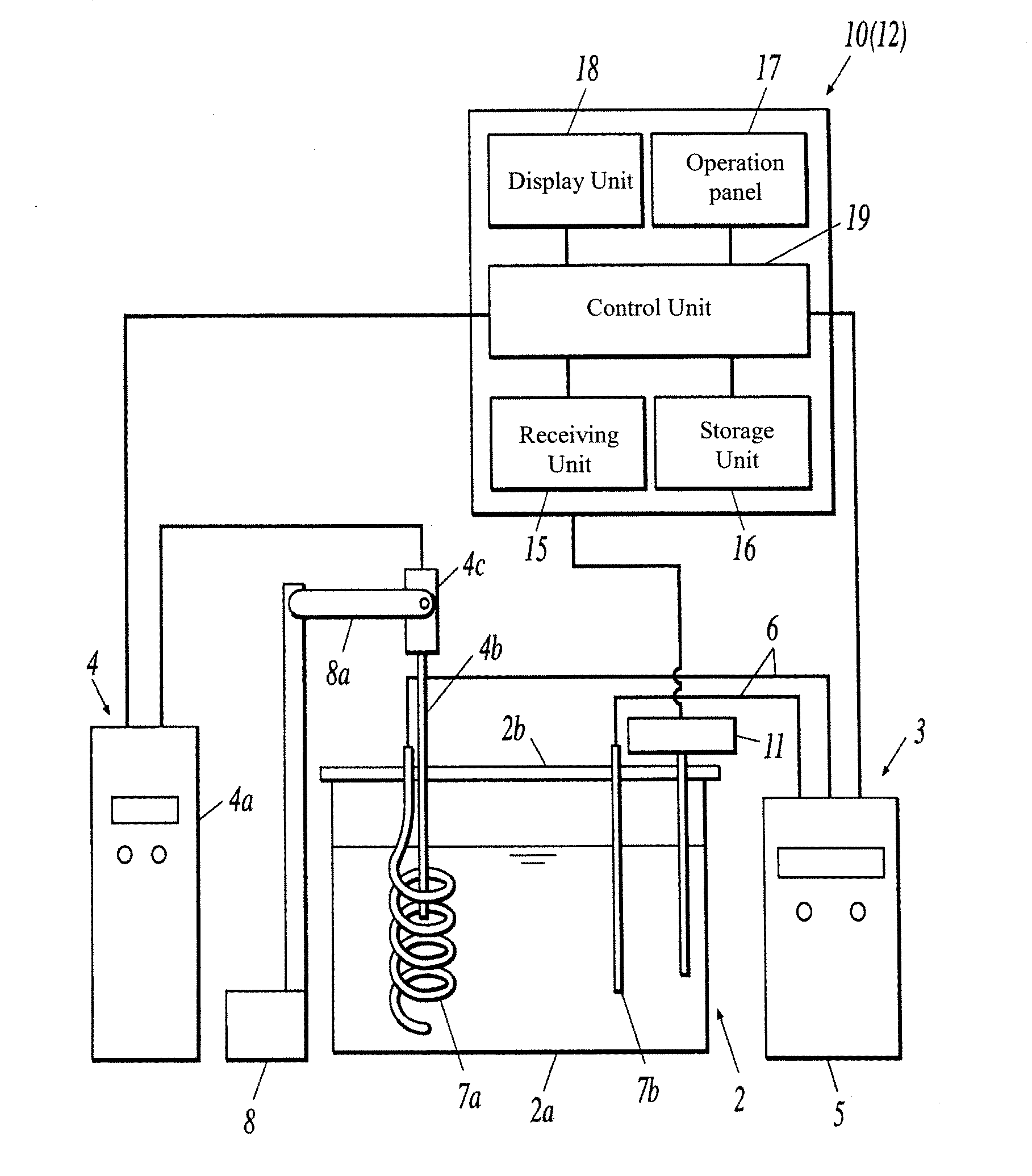

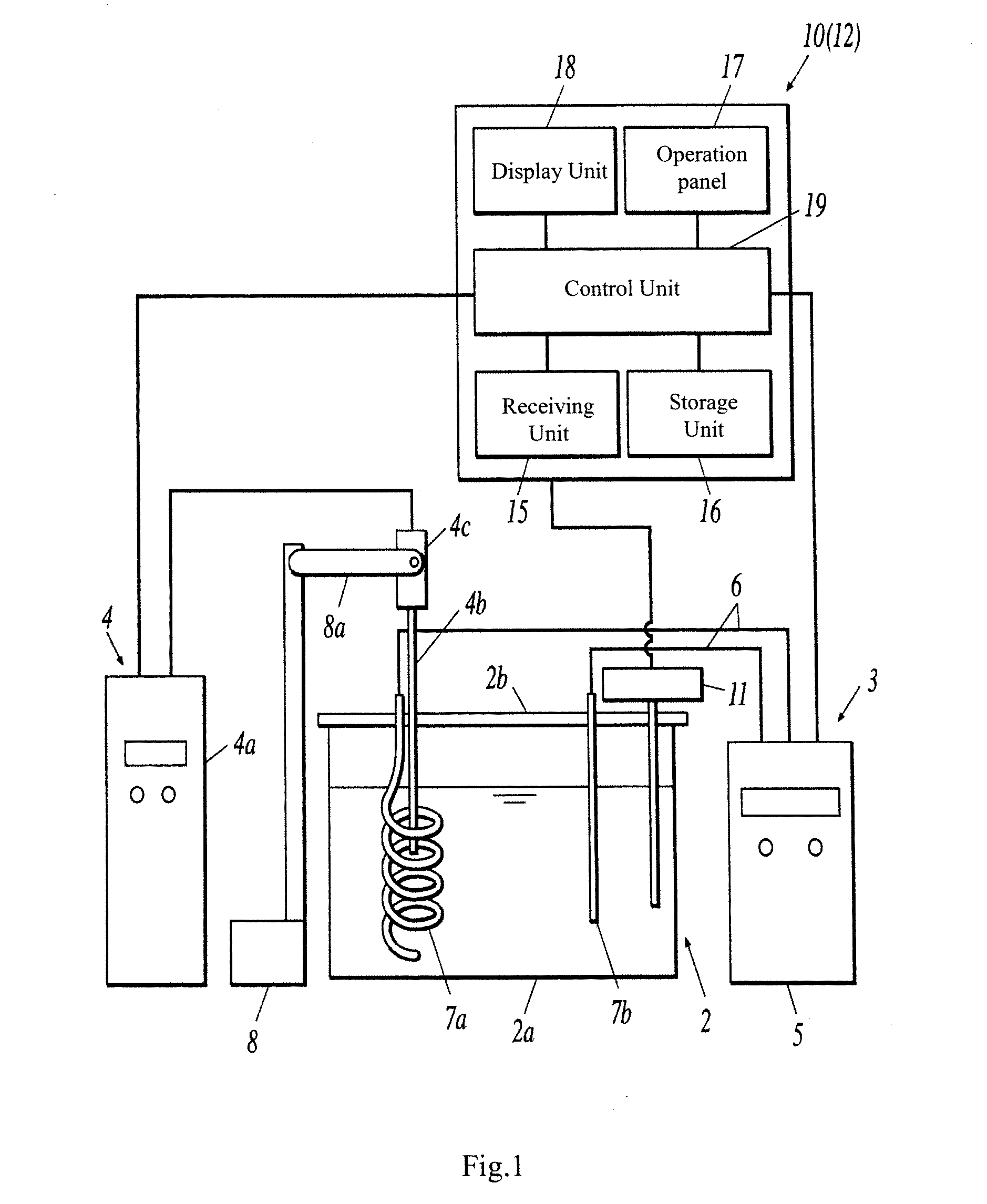

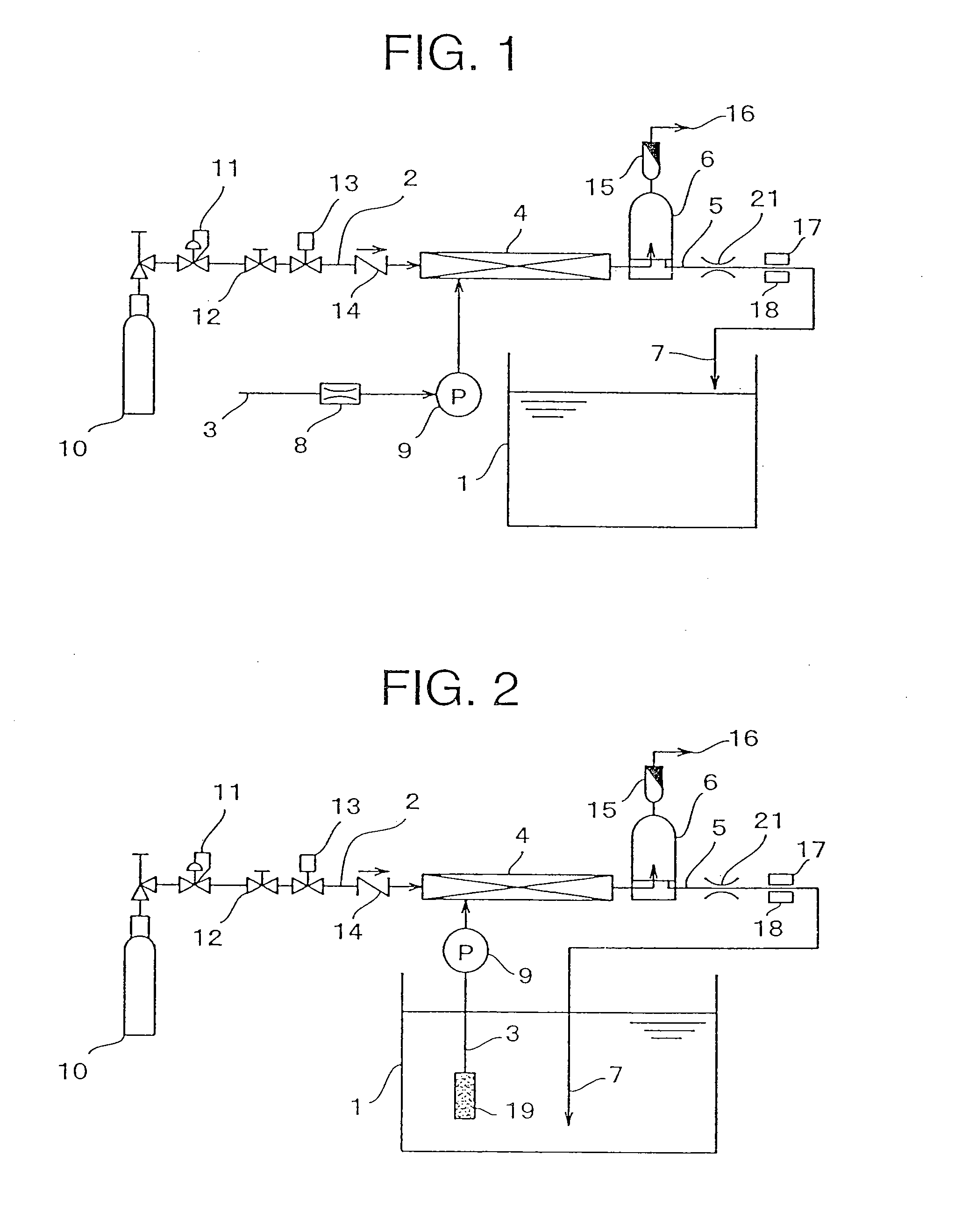

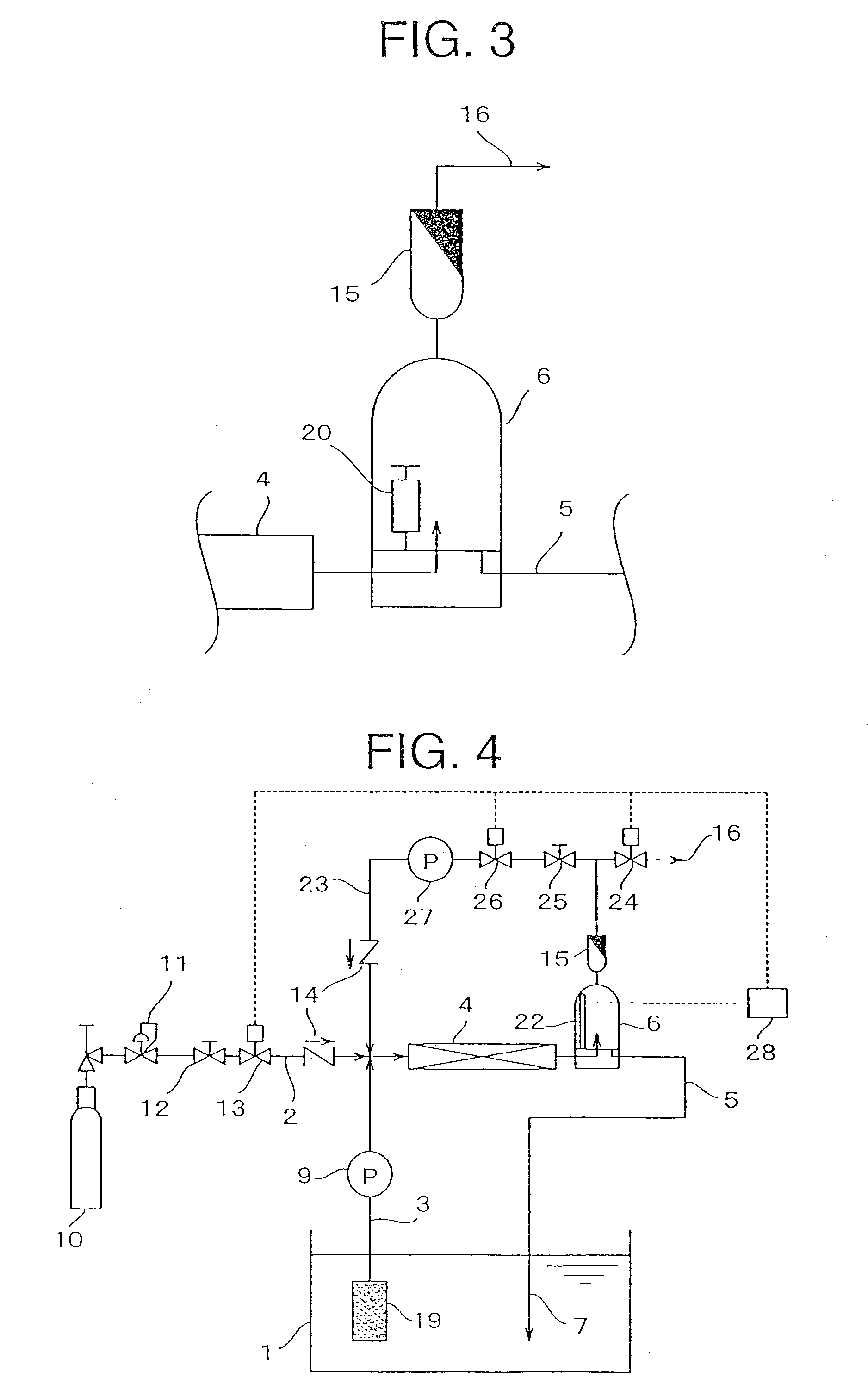

Carbonate spring producing system

InactiveUS20110123402A1Increase and decrease in bubble amountLevel controlLighting and heating apparatusVapor–liquid separatorControl valves

A carbonate spring producing system includes a gas-liquid separator (6) which is connected on the downstream side of a carbonic acid gas dissolver (4). A carbonic acid gas supply means (10) and hot water supply means are connected to the carbonic acid gas dissolver (4). A liquid lead-out pipe (5) is connected to the gas-liquid separator. Preferably an un-dissolved carbonic acid gas lead-out pipe (23) is connected on the upstream sides of the gas-liquid separator (6) and the carbonic acid gas dissolver (4). The un-dissolved carbonic acid gas lead-out pipe (23) includes a control valve (25), a compressor (27), and a liquid level detection means (22). The control valve (25) controls a flow rate of un-dissolved carbonic acid gas from the gas-liquid separator. The liquid level detection means (22) measures a liquid level of the gas-liquid separator. Control means (28) controls the flow rate of the supplied carbonic acid gas and the flow rate of the supplied un-dissolved carbonic acid gas based on the gas-liquid separator liquid level detected by the detection means (22). An amount of un-dissolved carbonic acid gas in the gas-liquid separator is always monitored, so that the un-dissolved carbonic acid gas in the hot water can securely be separated and removed by the gas-liquid separator, and the separated and removed un-dissolved carbonic acid gas can be redissolved.

Owner:MITSUBISHI RAYON CO LTD

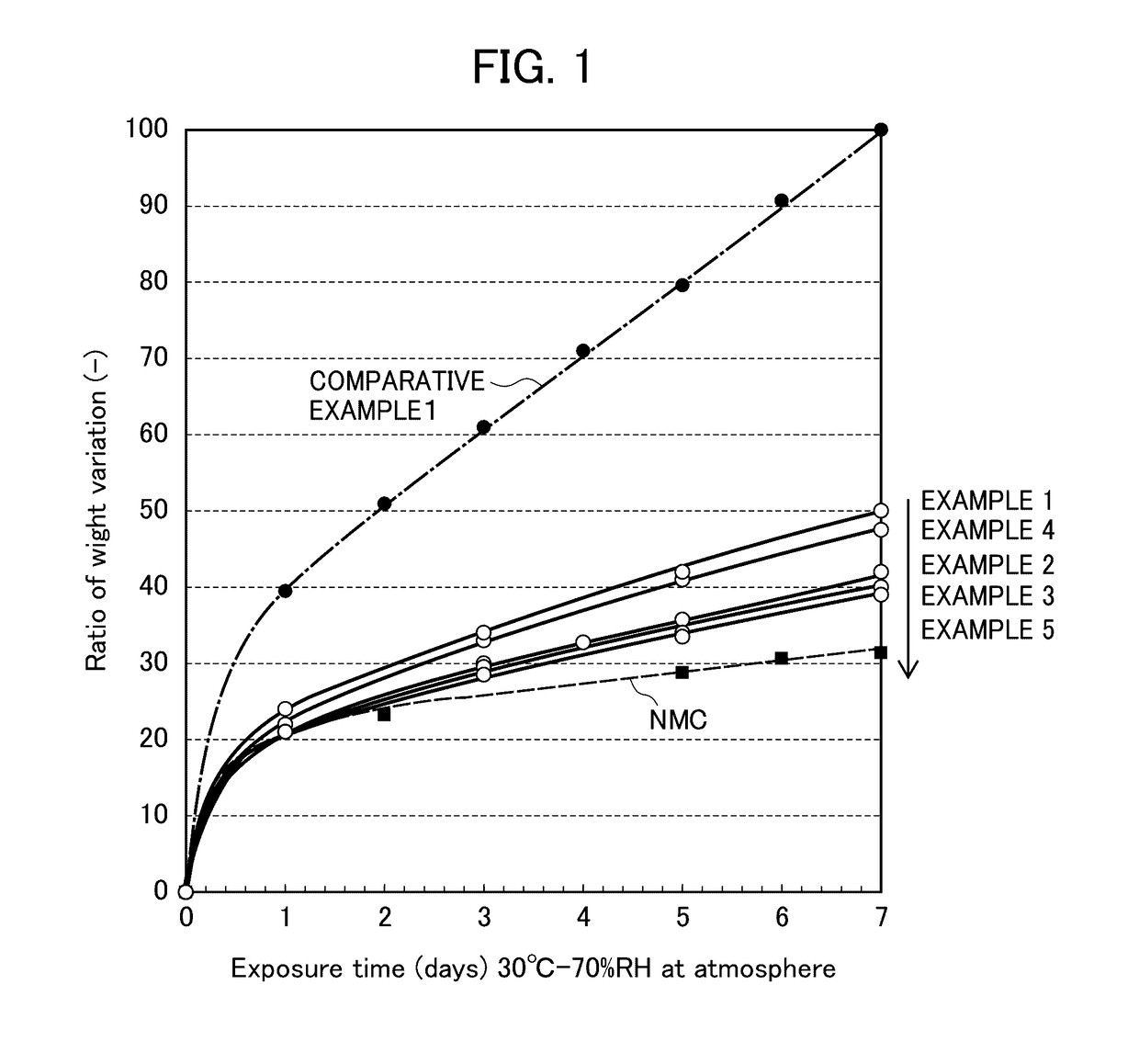

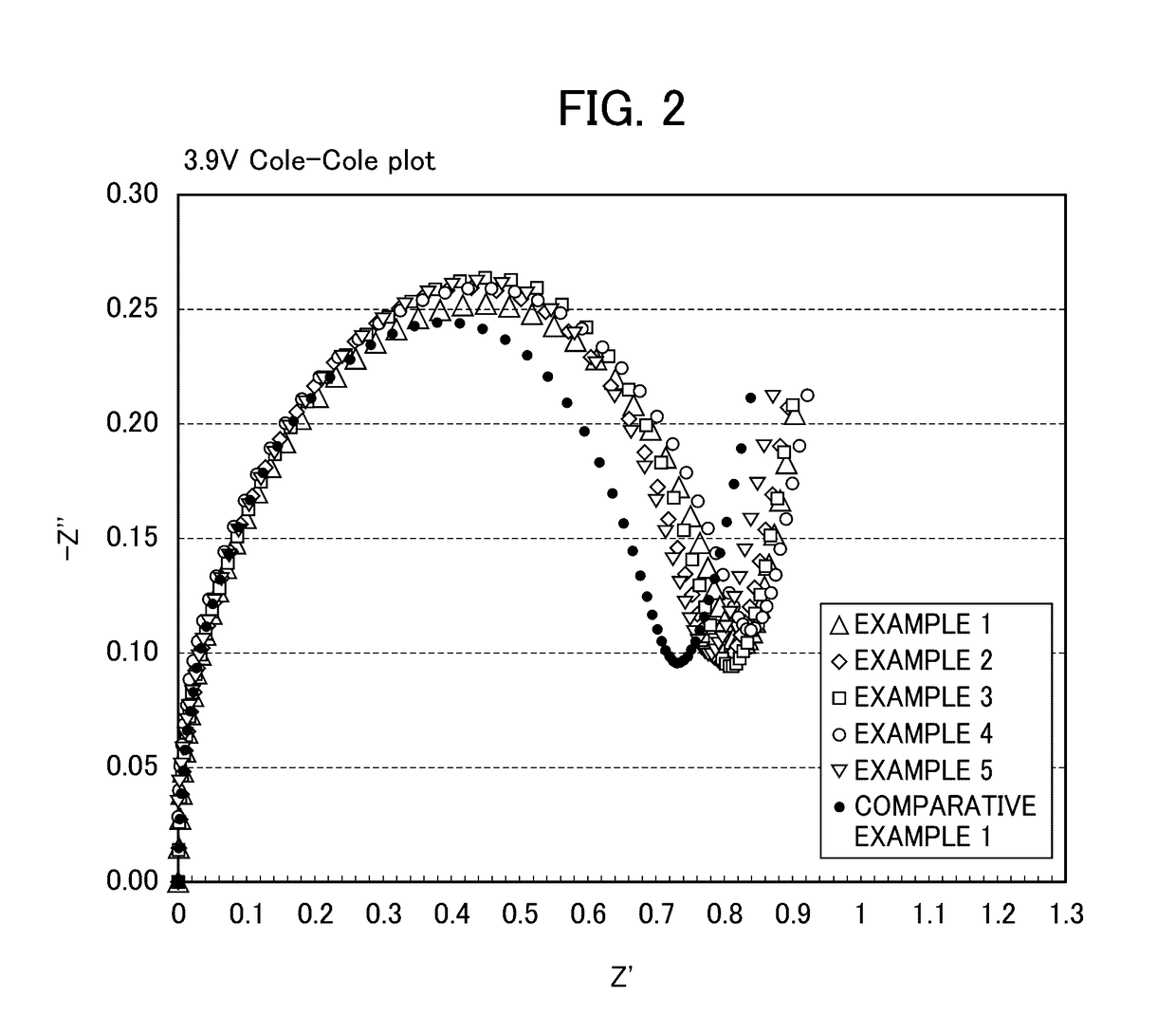

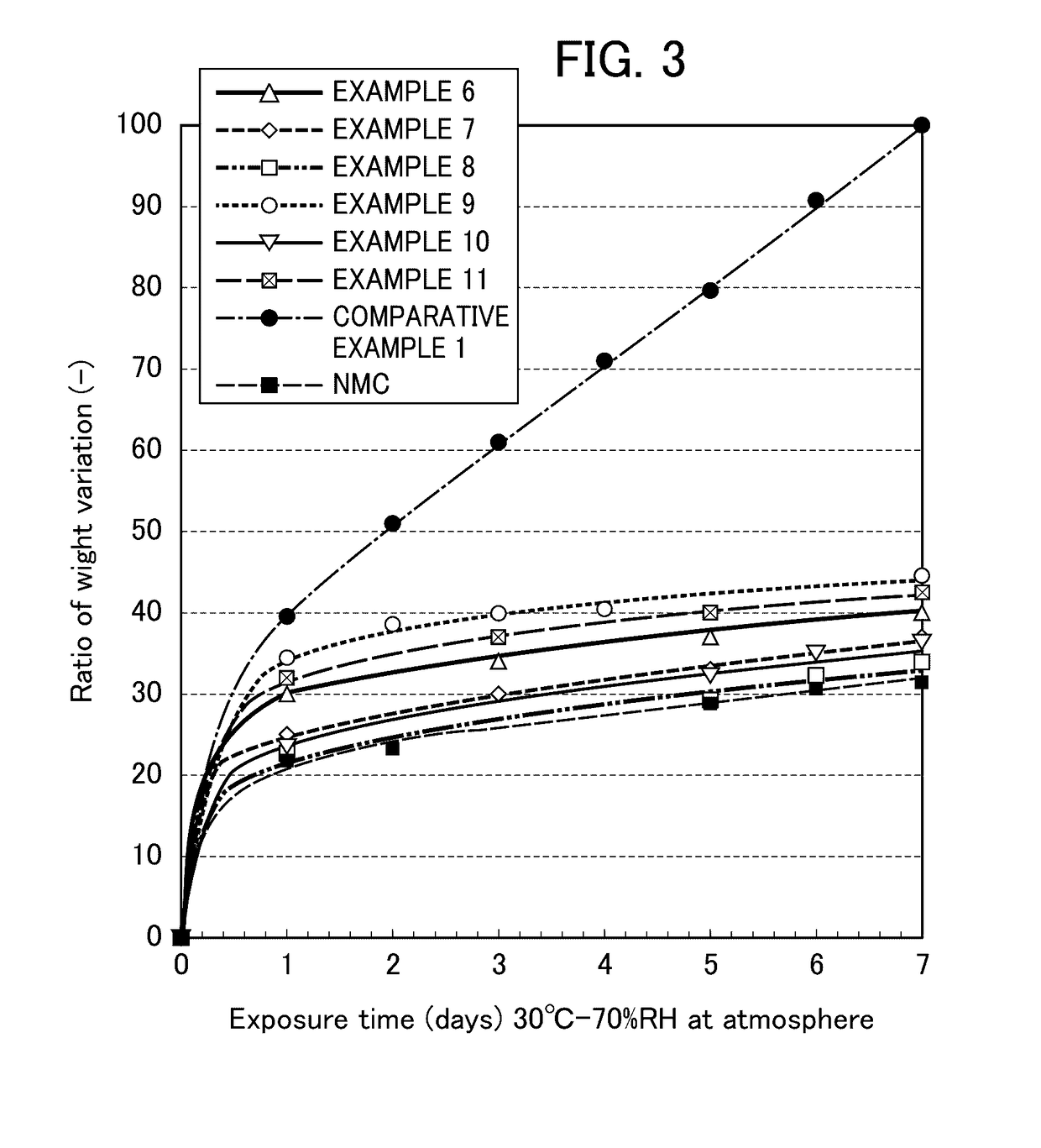

Coated lithium-nickel composite oxide particles and method for producing coated lithium-nickel composite oxide particles

ActiveUS20170117550A1Improve lithium ion conductivitySuppress generationPositive electrodesNickel compoundsEpoxyPolyolefin

Provided are excellent coated lithium-nickel composite oxide particles which are capable of suppressing the occurrence of impurities produced by absorbing water and carbonic acid gas as a result of the high environmental stability thereof, have strong adhesion properties, do not result in easy coating layer detachment, and also exhibit lithium ion conductivity. The surfaces of the lithium-nickel composite oxide particles are coated with a polymer or copolymer comprising one or more types selected from a group consisting of a modified polyolefin resin, a polyester resin, a polyphenol resin, a polyurethane resin, an epoxy resin, a silane-modified polyether resin, a silane-modified polyester resin, a silane-modified polyphenol resin, a silane-modified polyurethane resin, a silane-modified epoxy resin, and a silane-modified polyamide resin. As a result, the coated lithium-nickel composite oxide particles exhibit conductivity, and said compound is capable of suppressing the transmission of water and carbonic acid gas. Consequently, it is possible to provide coated lithium-nickel composite oxide particles for use in a lithium-ion battery positive electrode active material which is excellent for use in a lithium-ion battery.

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com