Sparkling sake and method of producing the same

A foaming and sake technology, applied in biochemical equipment and methods, wine preparation, alcoholic beverage preparation, etc., can solve the problems of insufficient clarification, turbid wine color, rough wine taste, etc., and maintain a refreshing taste , Less suspension, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

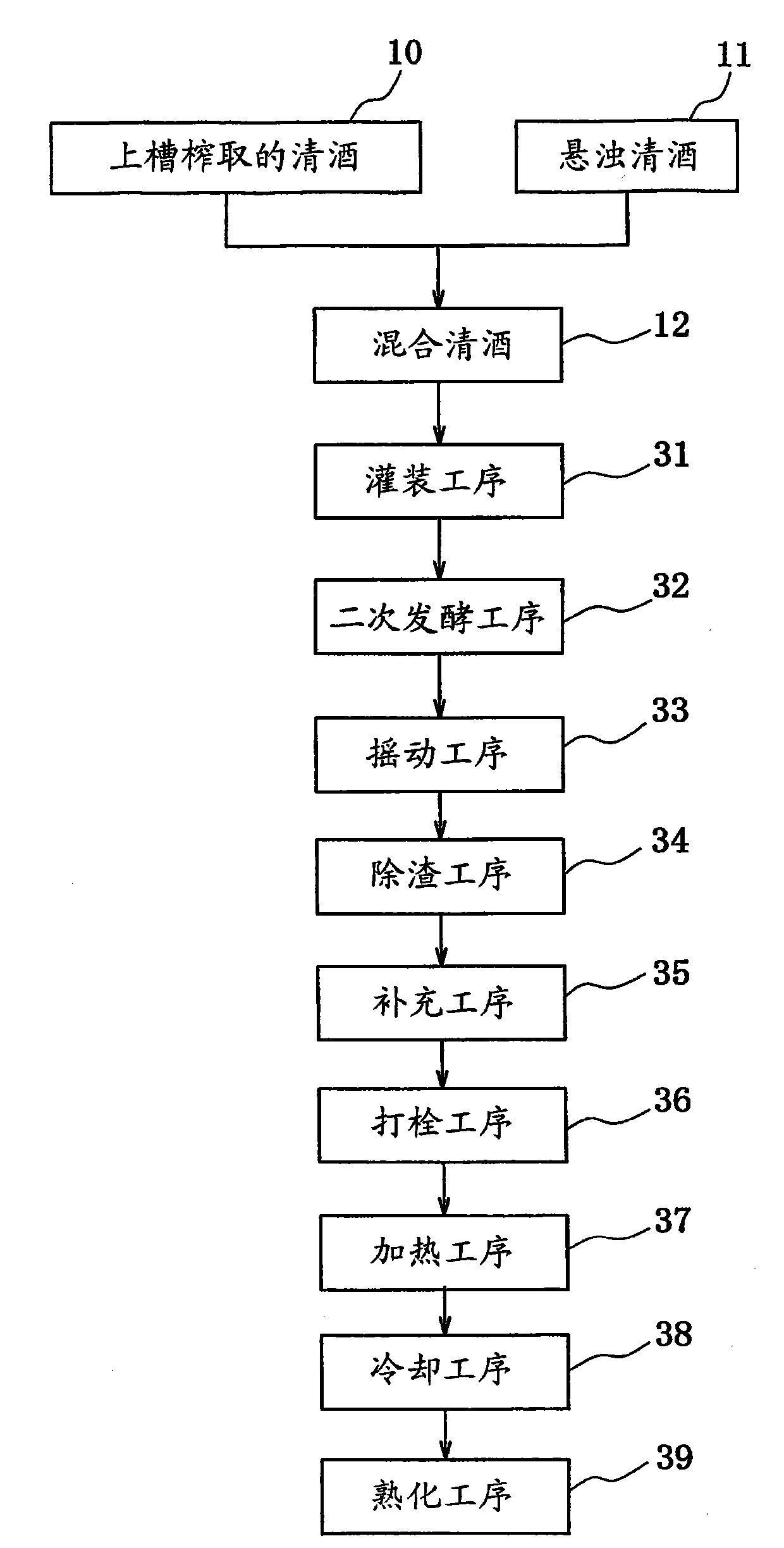

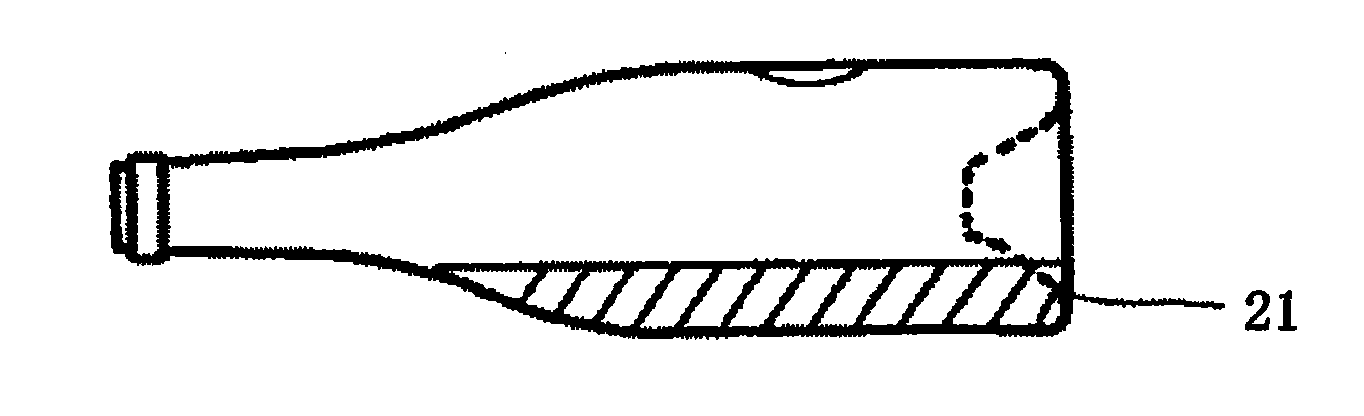

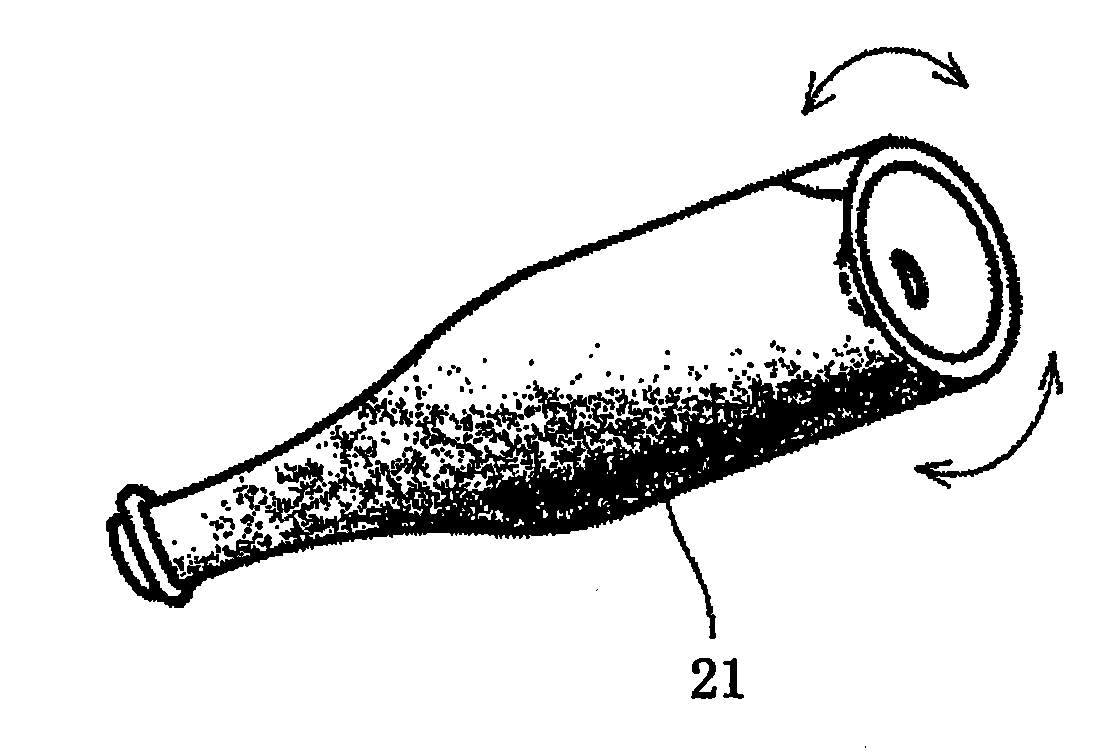

[0076] In Example 1, such as figure 1 As shown, the following steps are carried out sequentially: a mixing step of mixing sake 10 (sake degree: -20 to -3) squeezed through the upper tank and sake mash (sake degree: -35 To -10) The obtained suspended sake 11 is mixed together according to the ratio of 1:15 to 19:1; filling process 31, the mixed sake 12 is filled into a commercially available container and sealed; secondary fermentation In step 32, the mixed sake in the container is fermented to generate carbon dioxide gas; in the shaking step 33, the bottom of the container is rotated and shaken while the mouth of the container is turned downward, so that the dregs 21 deposited inside the container are accumulated At the mouth of the container; deslagging process 34, after the dross 21 has accumulated in the mouth of the container, the mouth of the container is cooled, thereby reducing the internal pressure of the container to weaken the container The ejection pressure of the ...

Embodiment 2

[0079] In Example 2, after the container of the sample liquor of Example 1 was unsealed, the sparkling sake in the container was transferred to another container, and the sparkling sake having the value (3.171 GV) of the carbon dioxide gas content shown in Table 1 was obtained. A sample of sparkling sake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com