Device and process for separating carbonic acid gas by indirect burning of biomass

A carbon dioxide and biomass technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost and low separation efficiency, and achieve a wide range of social benefits and industrial application prospects.

Inactive Publication Date: 2008-10-22

SOUTHEAST UNIV

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. Separation and purification of carbon dioxide by molecular membrane separation method, the separation efficiency is low and the cost is high

2. Removing carbon dioxide through biological photosynthesis and finding high-efficiency biological algae for large-scale removal of carbon dioxide still need technological breakthroughs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

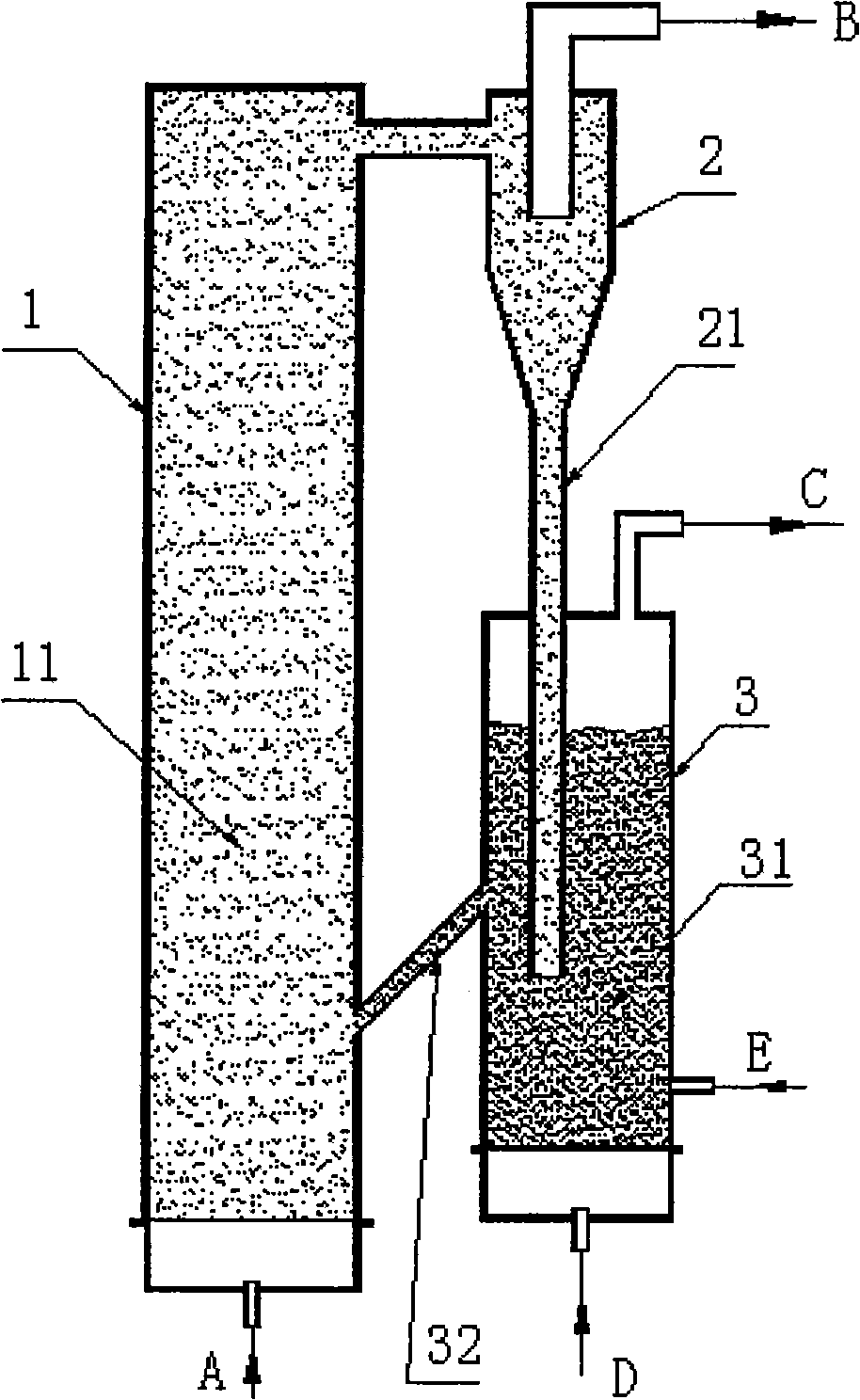

The invention relates to a device used for indirectly burning biomass to separate carbon dioxide and a method which is a burning way of the biomass and a biomass burning process based on a cycle oxygen carrier. The device consists of a circulating fluidized bed, a cyclone separator and a fluidized bed, which is formed into a circulation loop; the method is characterized in that oxidation reaction happens to metal and air in the circulating fluidized bed to generate a metallic oxide which enters the fluidized bed after being separated by the cyclone separator; gasification reaction happens to the biomass in the fluidized bed and the carbon dioxide or water vapour; reduction reaction happens to fuel gas generated from the gasification reaction and the metal oxide to generate the metal, the carbon dioxide and the water vapour, wherein, the carbon dioxide and the water vapour are discharged from an air outlet of the fluidized bed and condensed to obtain pure carbon dioxide and the metal reduced returns to the circulating fluidized bed for carrying out oxidation reaction with the air to complete the regeneration process of the metallic oxide. The carbon dioxide can be separated from combustion products without extra energy consumption.

Description

A device and method for separating carbon dioxide by indirect combustion of biomass technical field The invention relates to a combustion method of biomass, specifically a device and a method for realizing a biomass combustion process based on a circulating oxygen carrier and separating carbon dioxide during the biomass combustion process. Background technique Carbon dioxide is the most influential greenhouse gas among many potential greenhouse gases. How to reduce carbon dioxide emission has become one of the main contents of human sustainable development in the future. The conventional combustion technology is the direct contact combustion of biomass and air, and the carbon dioxide in the generated flue gas only accounts for 10-15%. The subsequent treatment (concentration and purification) of carbon dioxide is too costly, and the following methods are usually used: 1. Separation and purification of carbon dioxide by molecular membrane separation method, the separation e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B31/20C01B3/32C01B32/50

Inventor 沈来宏吴家桦肖军

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com