Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491 results about "Stub axle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stub axle or stud axle is either one of two front axles in a rear wheel drive vehicle, or one of the two rear axles in a front wheel drive vehicle. In a front wheel drive vehicle this axle is capable of angular movement about the kingpin for steering the vehicle.

Quad tracked vehicle

Owner:MGA ENTERTAINMENT

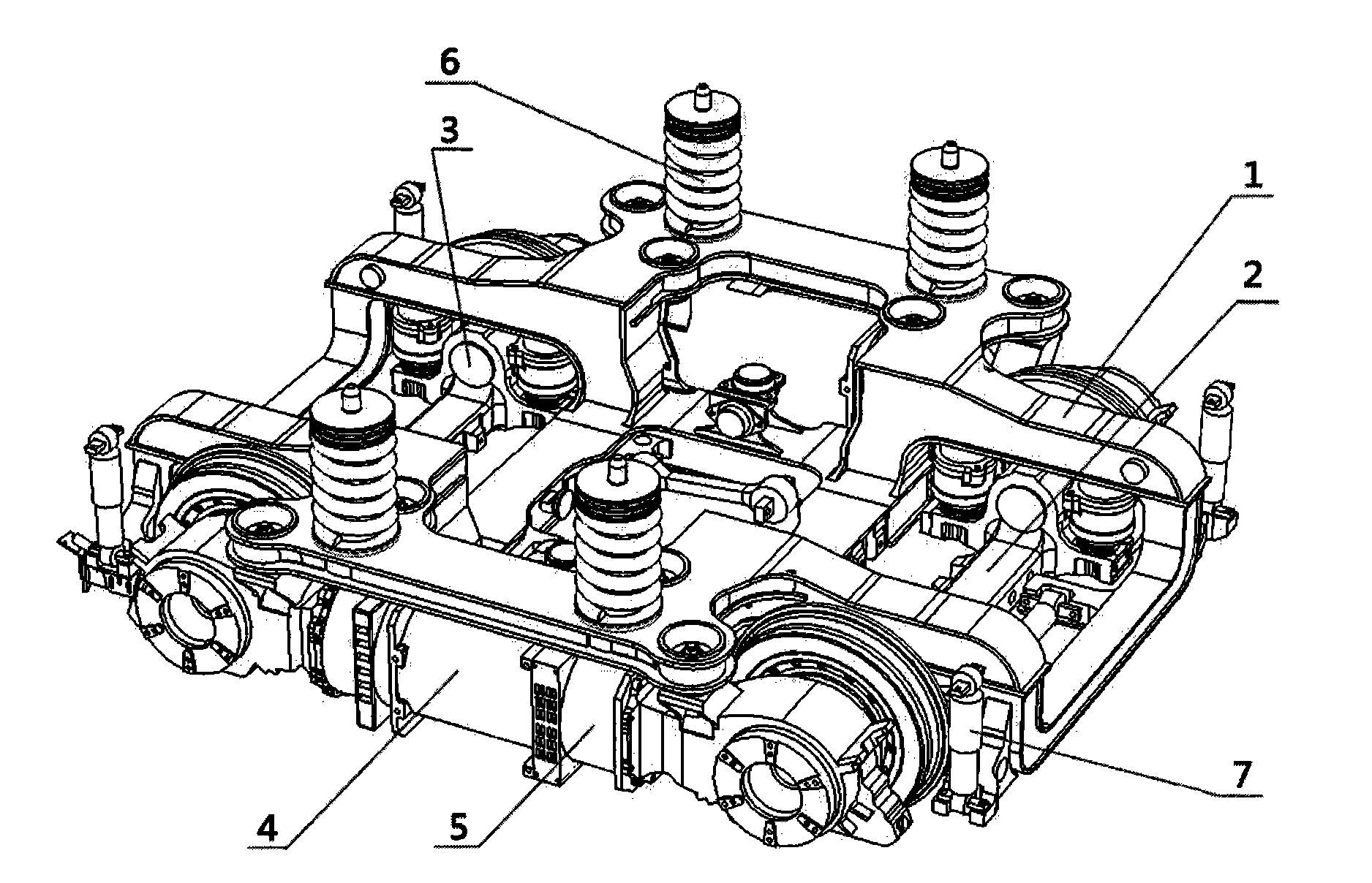

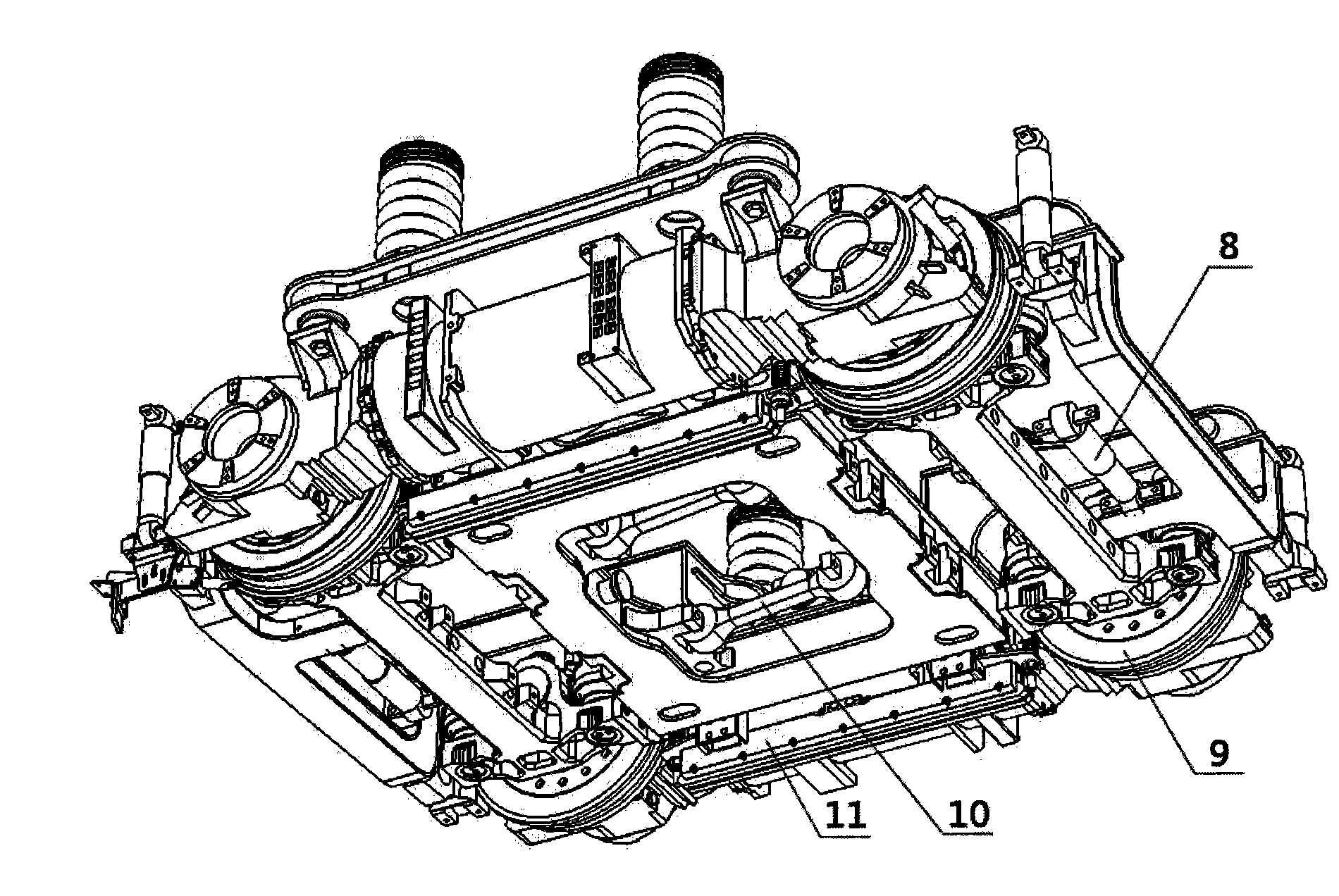

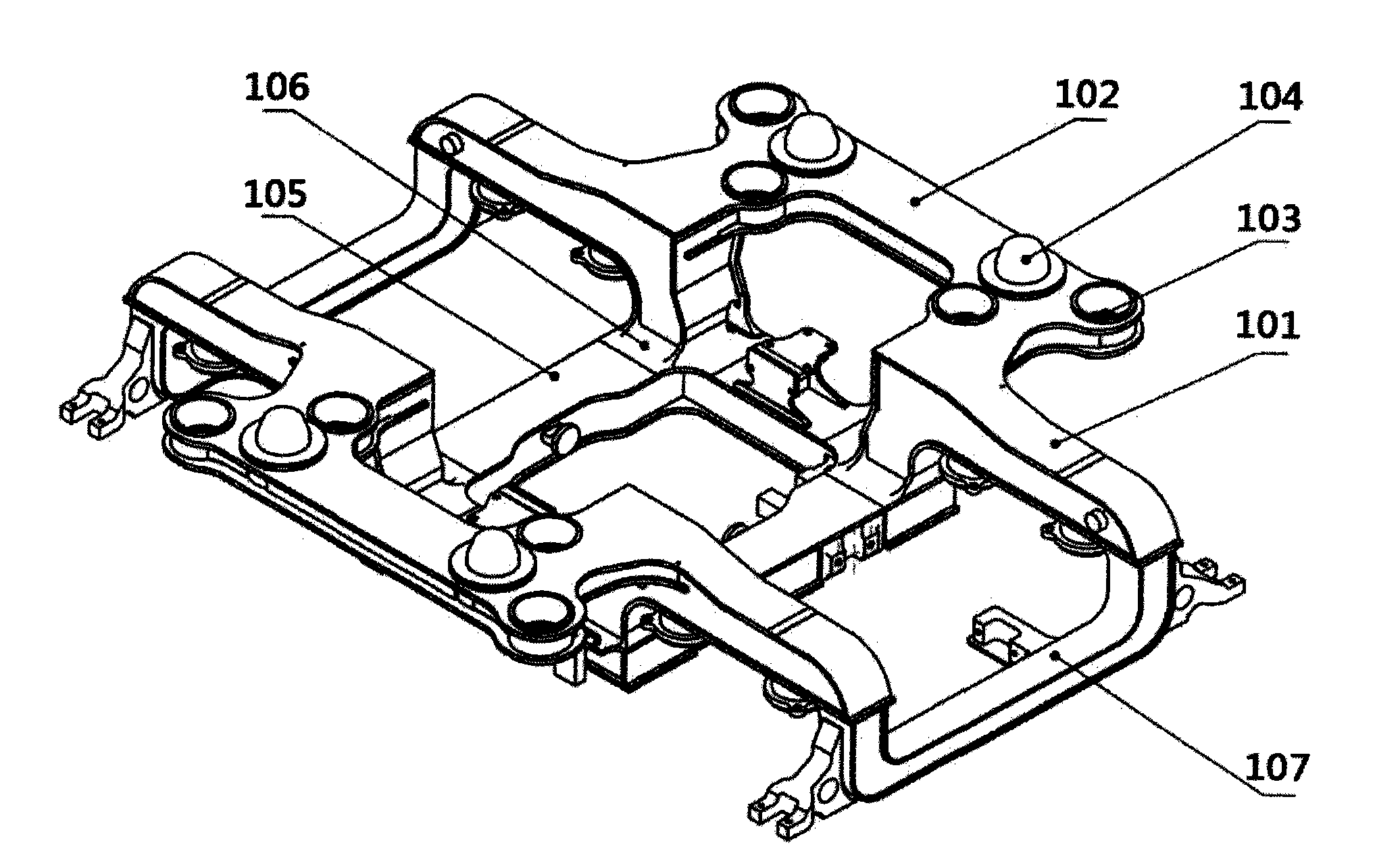

Power bogie with independent wheels for 100 percent low-floor light rail vehicles

The invention discloses a power bogie with independent wheels for 100 percent low-floor light rail vehicles. The power bogie with the independent wheels comprises a framework, an axle mechanism, primary springs, secondary springs, secondary vertical and transverse dampers, a double-pull rod traction mechanism, the longitudinal driving mechanism of an elastically frame-suspended motor and a hydraulic brake unit, wherein the side beams of the framework are cantilevers which protrude outward; two short shafts are supported by bearing units and connected with elastic wheels respectively; an axle consists of the two short shafts; two wheels on the same side of the bogie are fixed on a motor-driven shaft; a motor is coupled with two gear boxes; a brake system is integrated with a traction motor; the four secondary vertical dampers are arranged at the four corners of the framework; the secondary transverse dampers are arranged at the two ends of the framework; and a parallel double-pull rod traction system is arranged on the inner side of the framework. The requirement of 100 percent low floor on vehicle bodies is really realized by the high-strength welded framework, the independent wheel axle mechanism, the primary springs and the secondary springs which are rationally structured, the optimal secondary vertical and transverse dampers, the parallel double-pull rod traction device with internal traction, the longitudinal drive of the elastically frame-suspended motor, and the hydraulic brake unit which is integrated with the traction motor.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

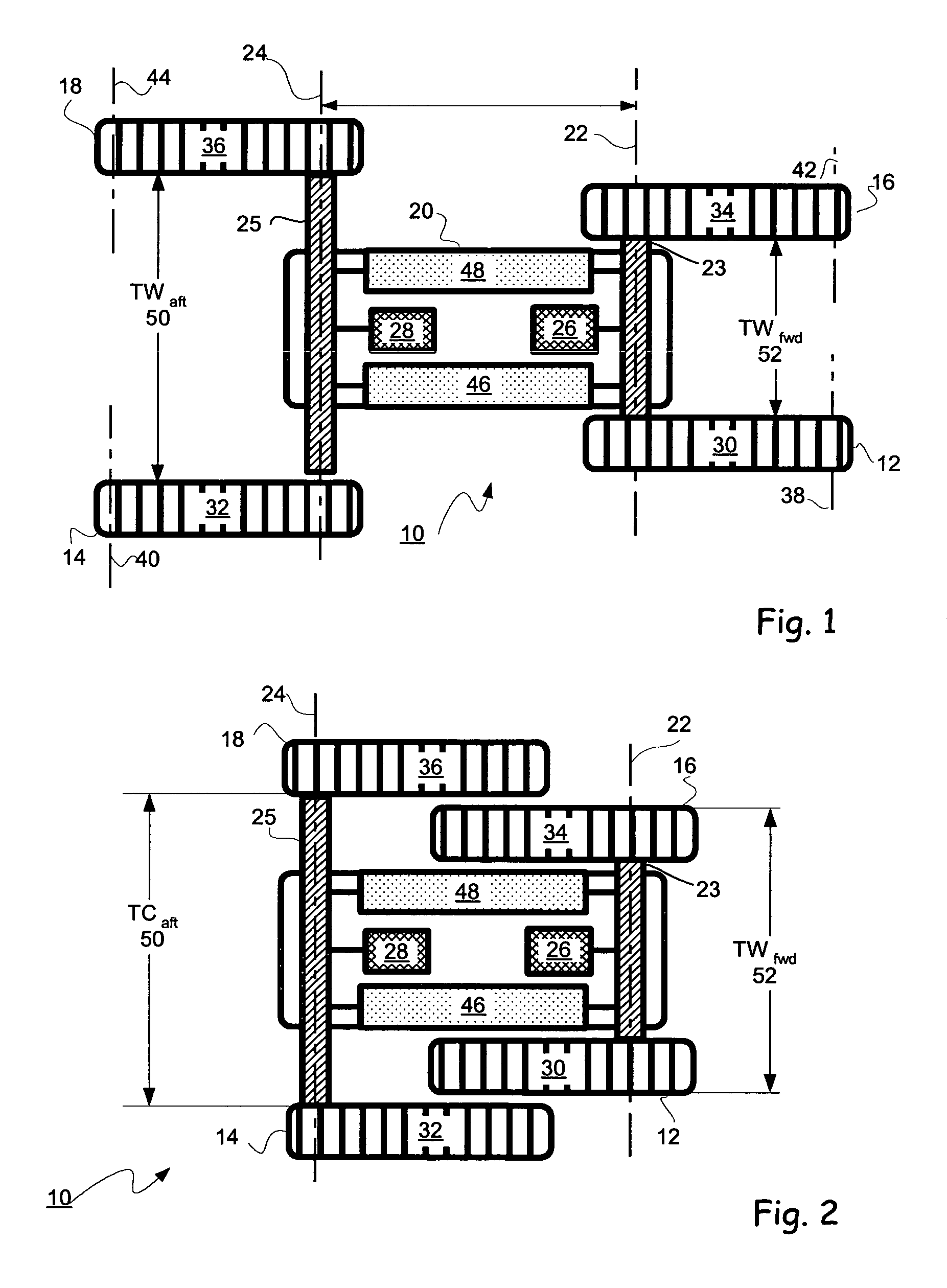

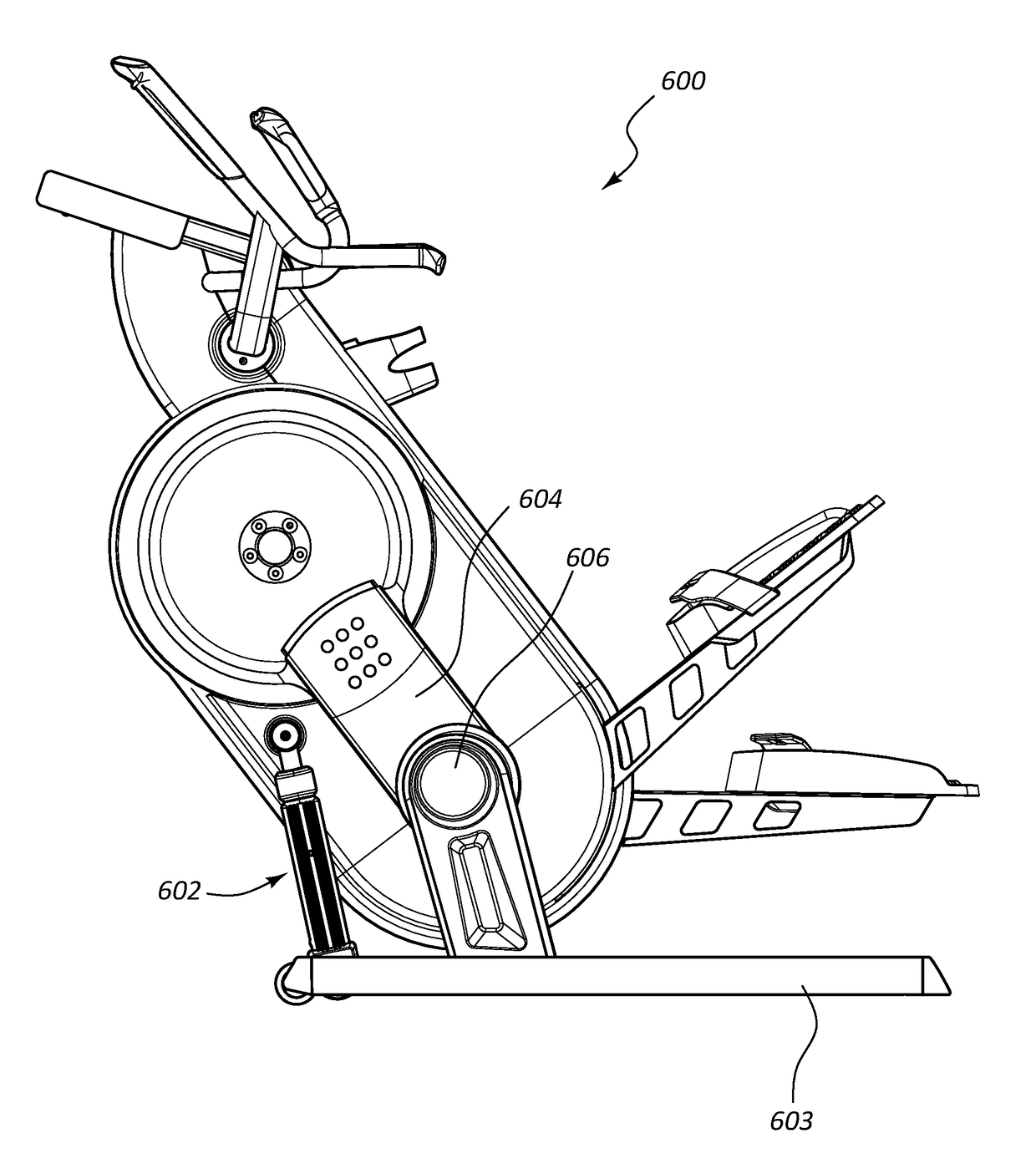

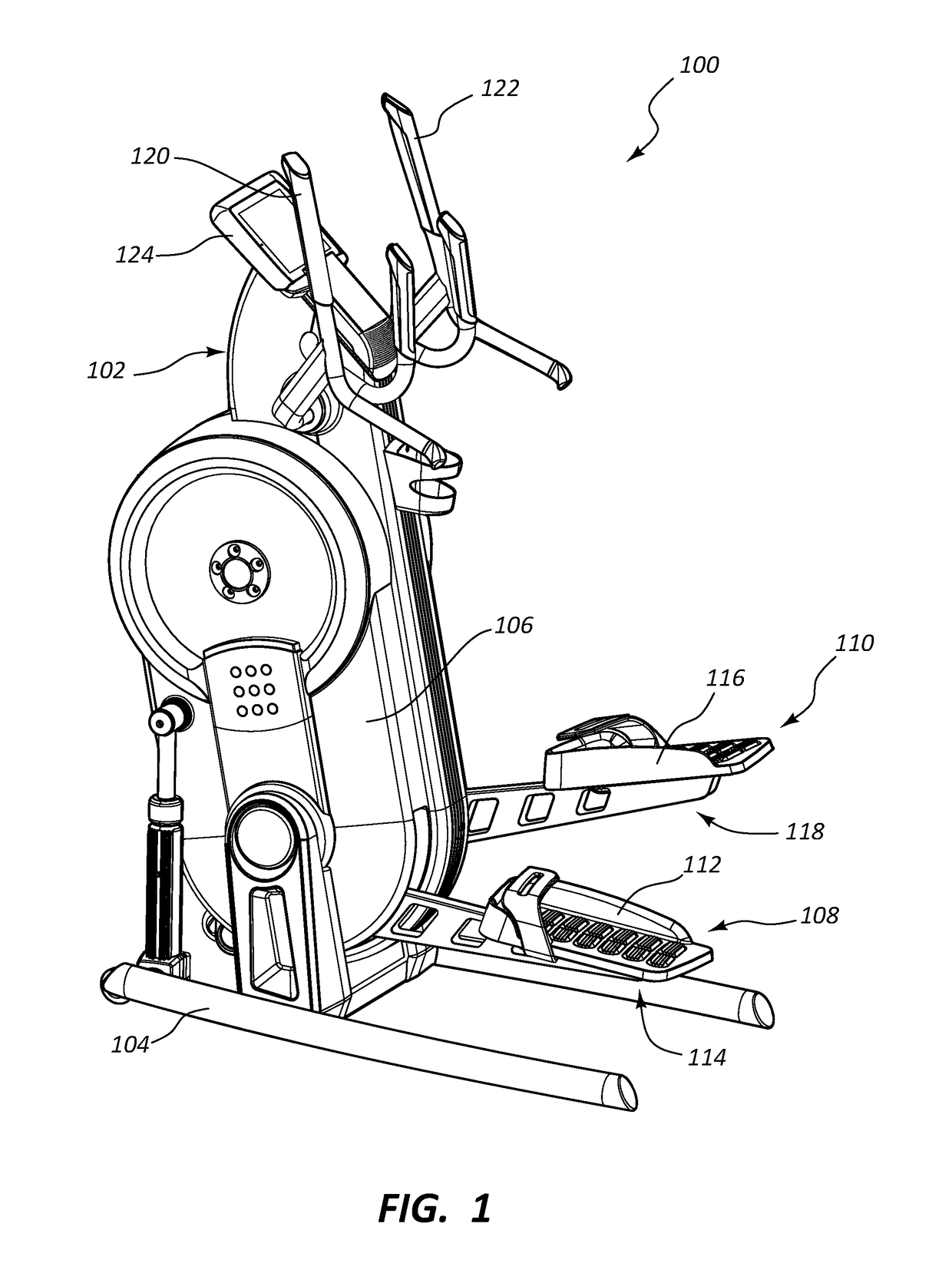

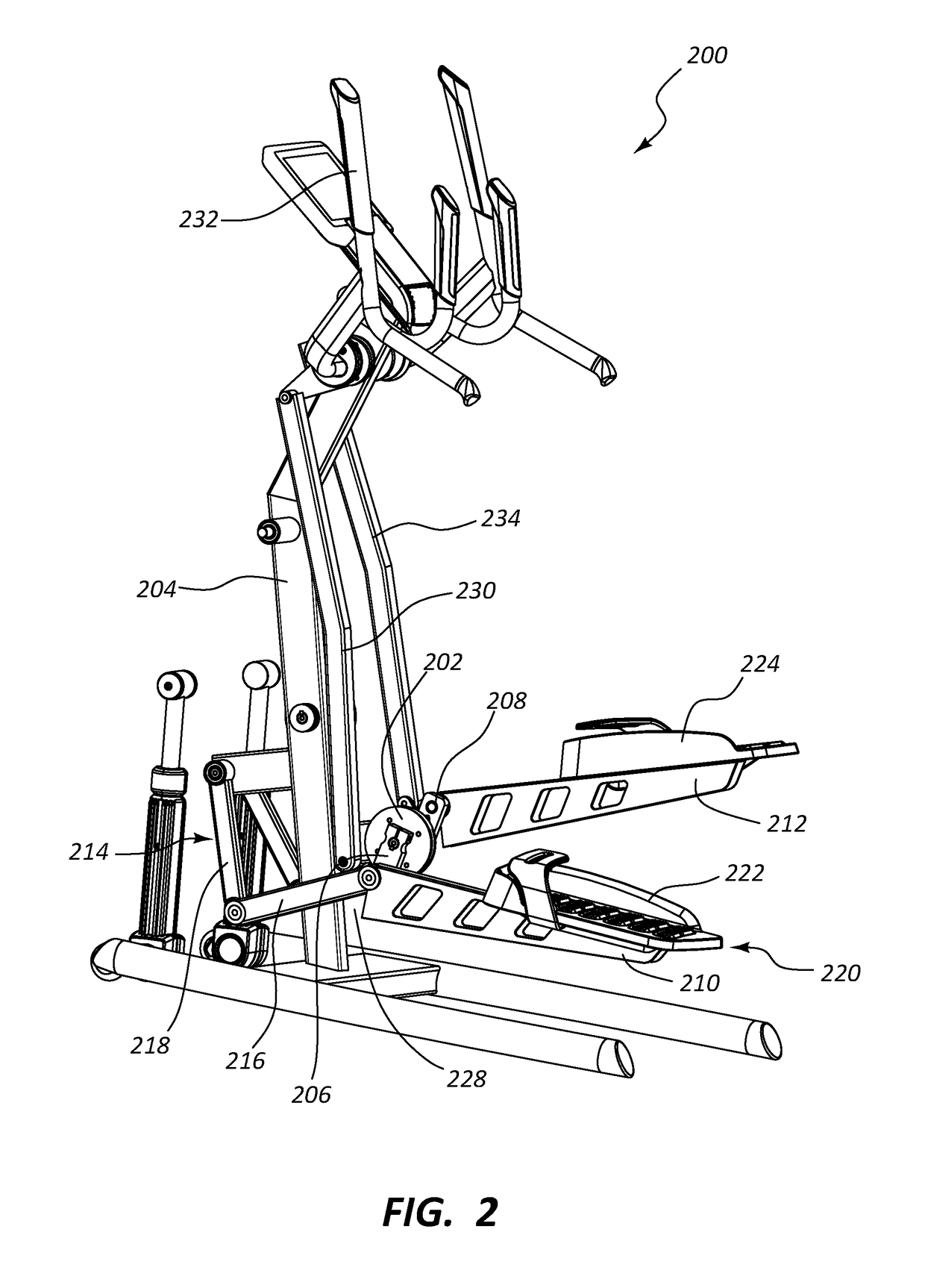

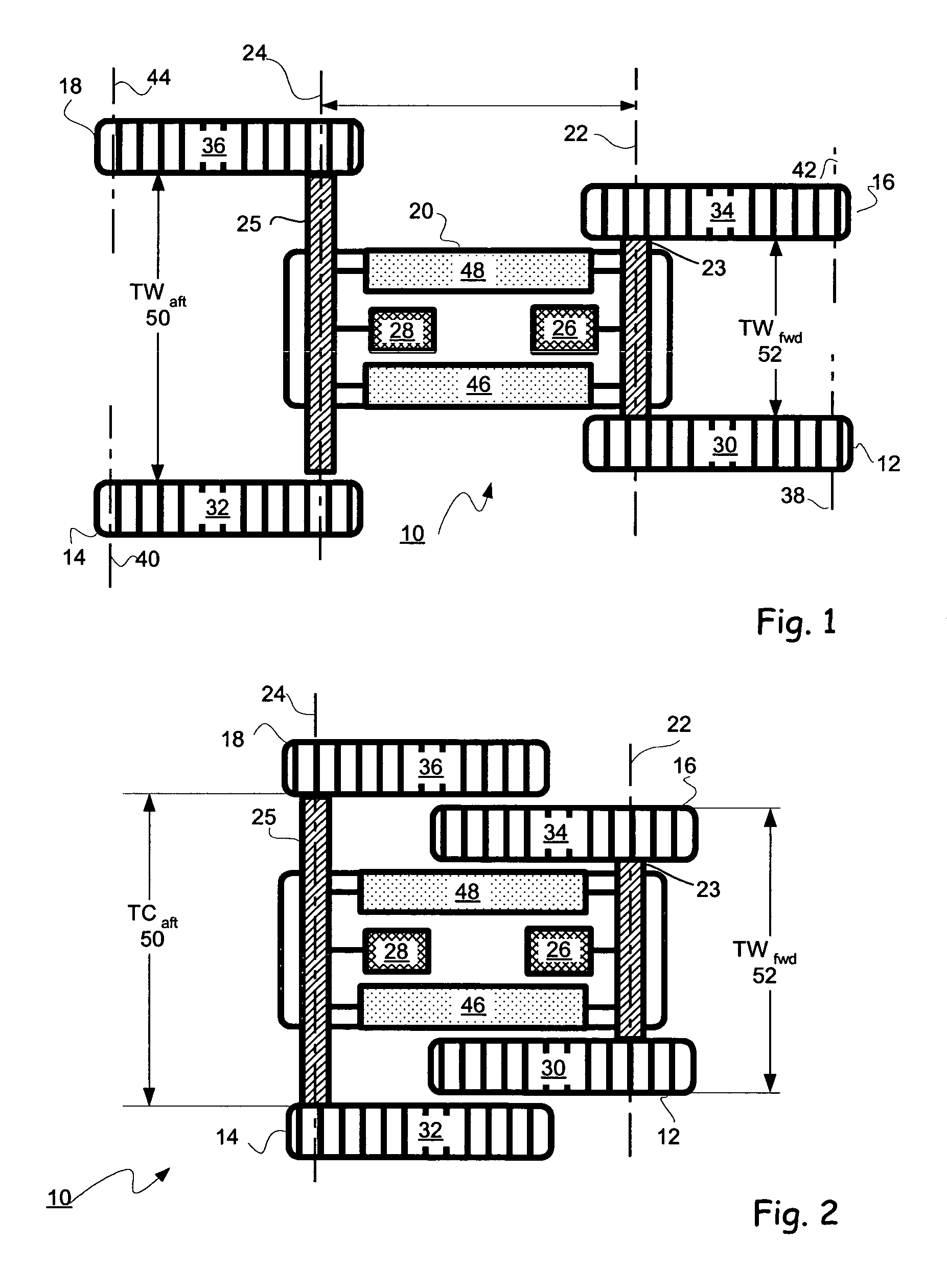

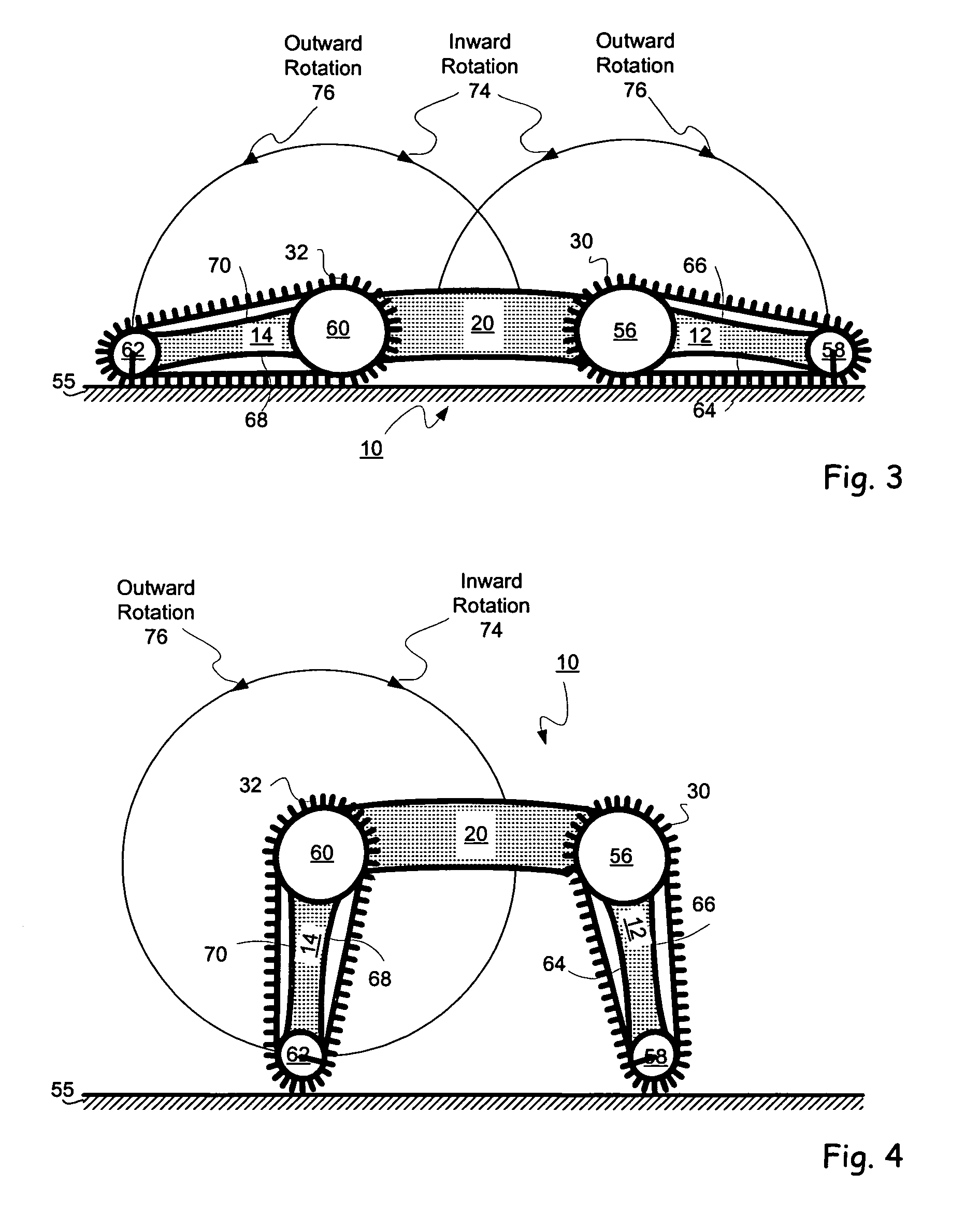

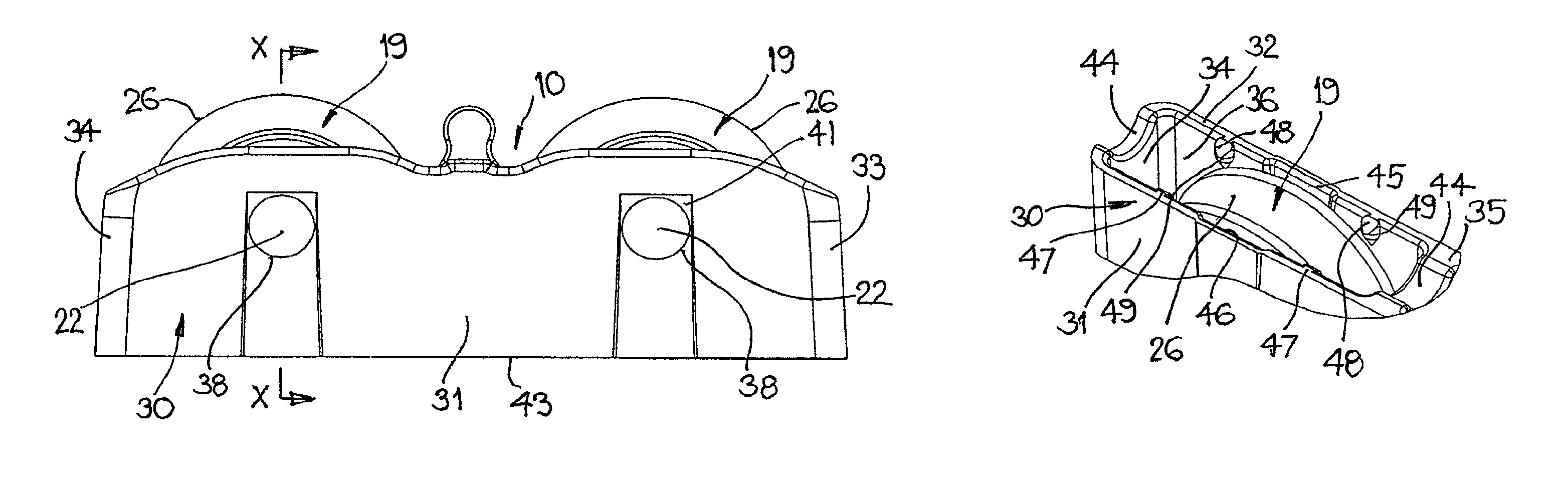

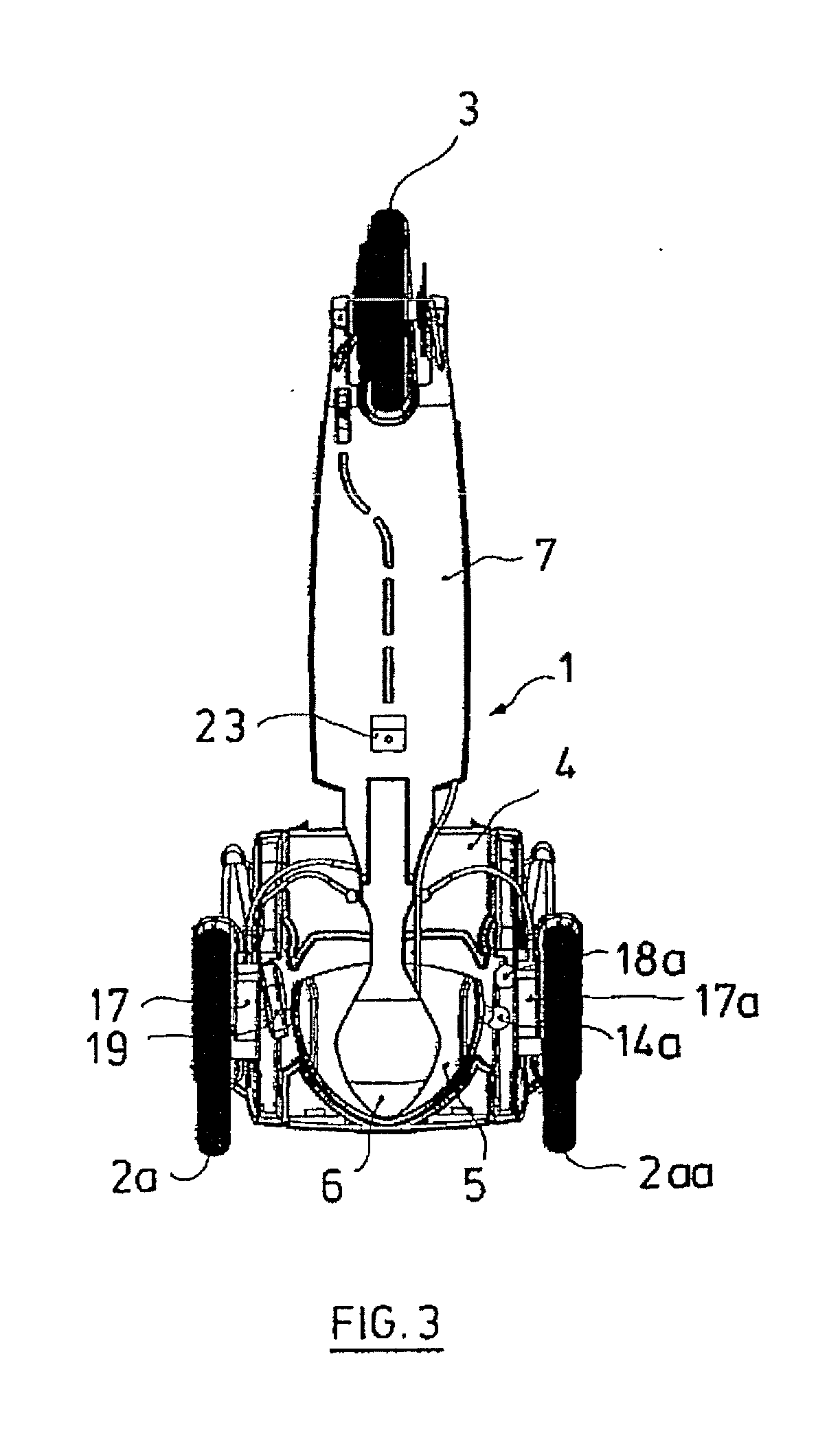

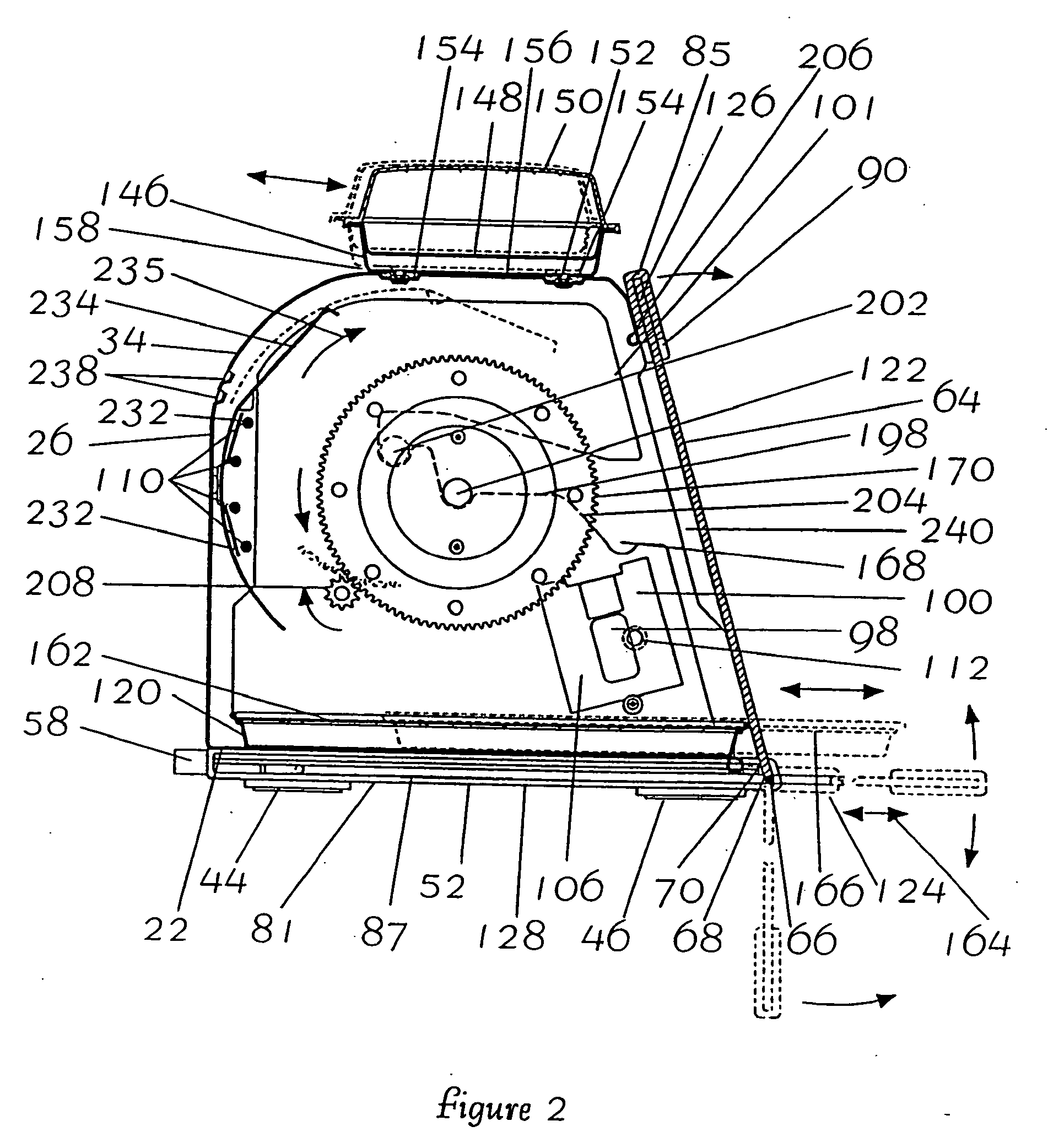

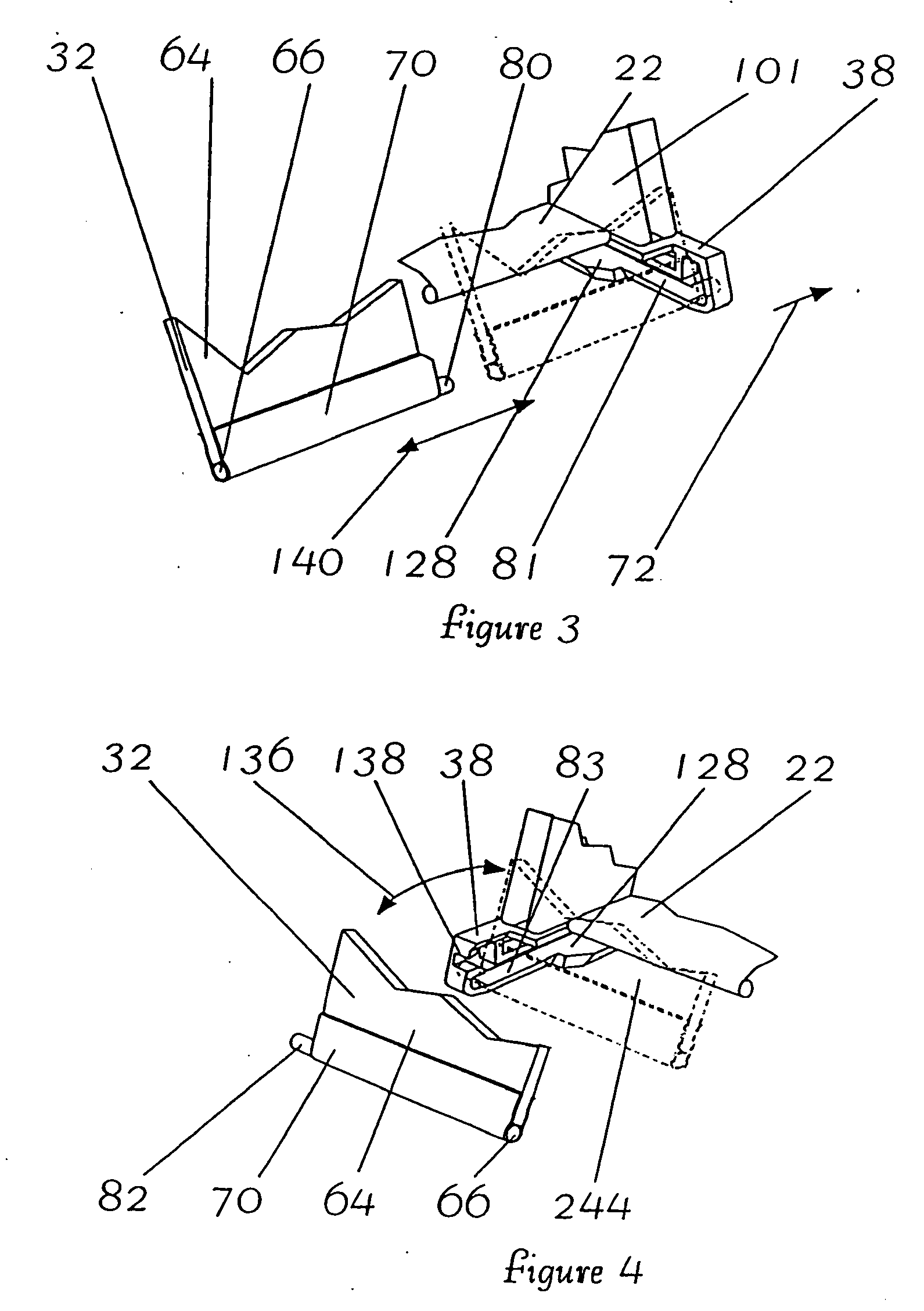

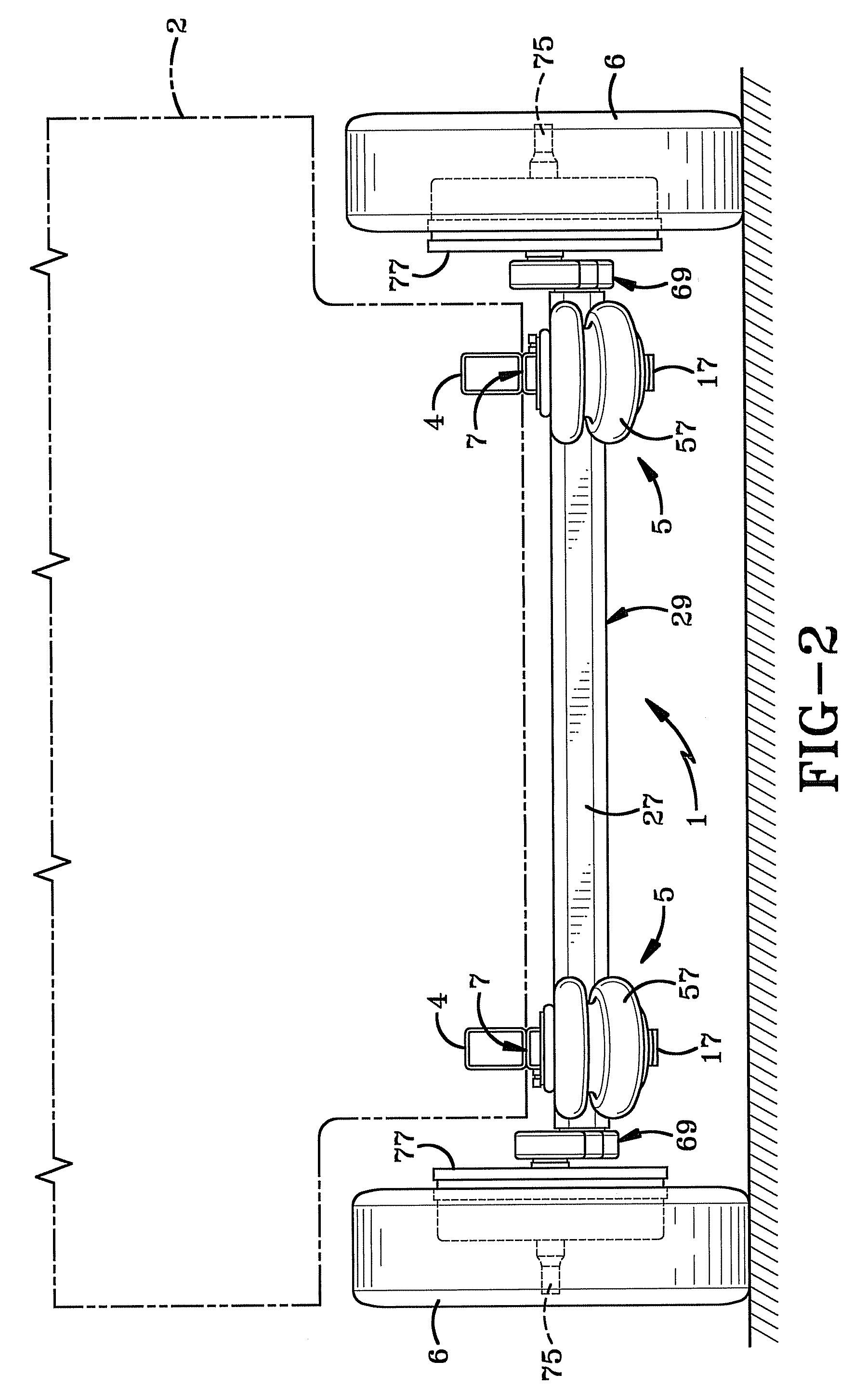

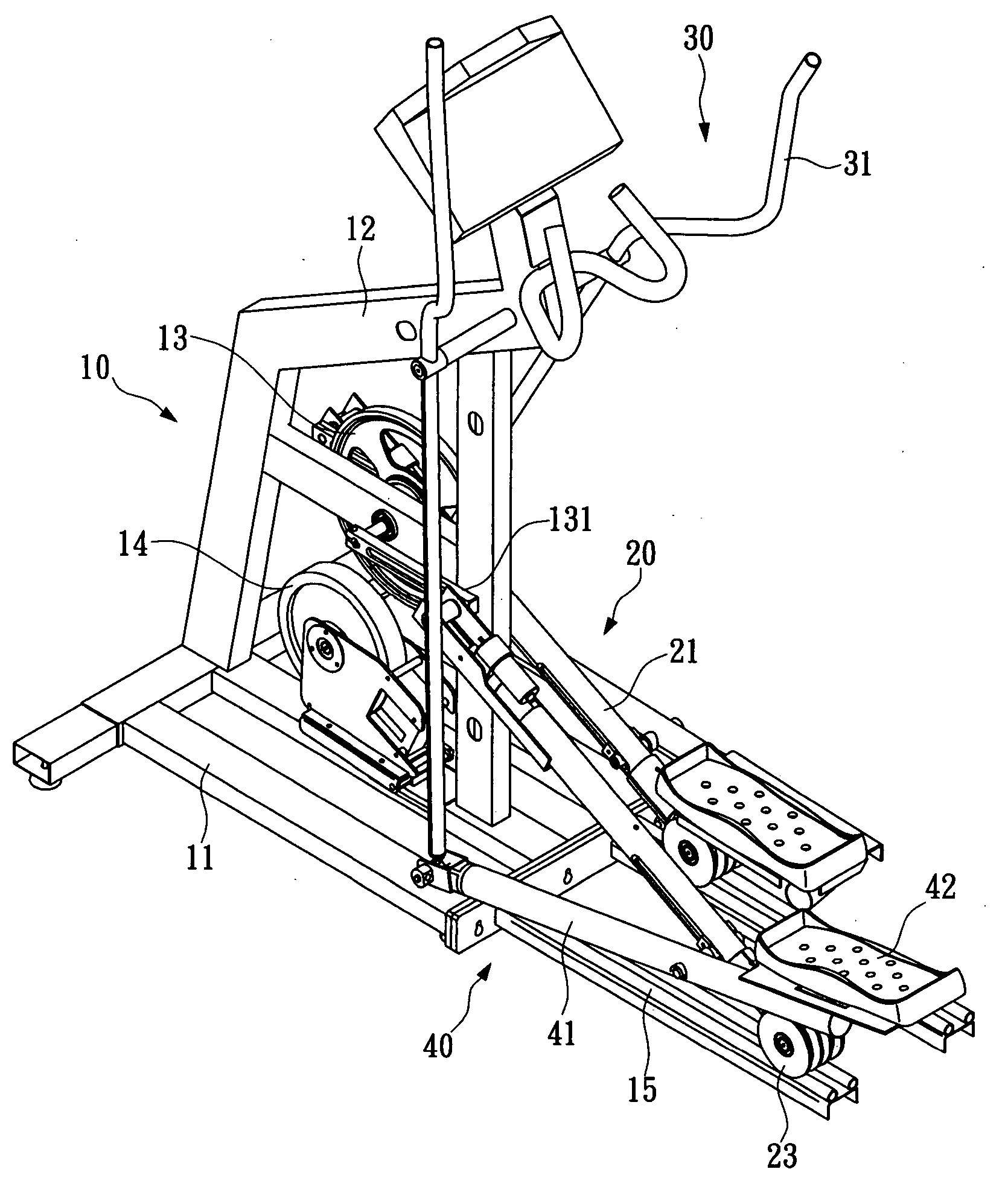

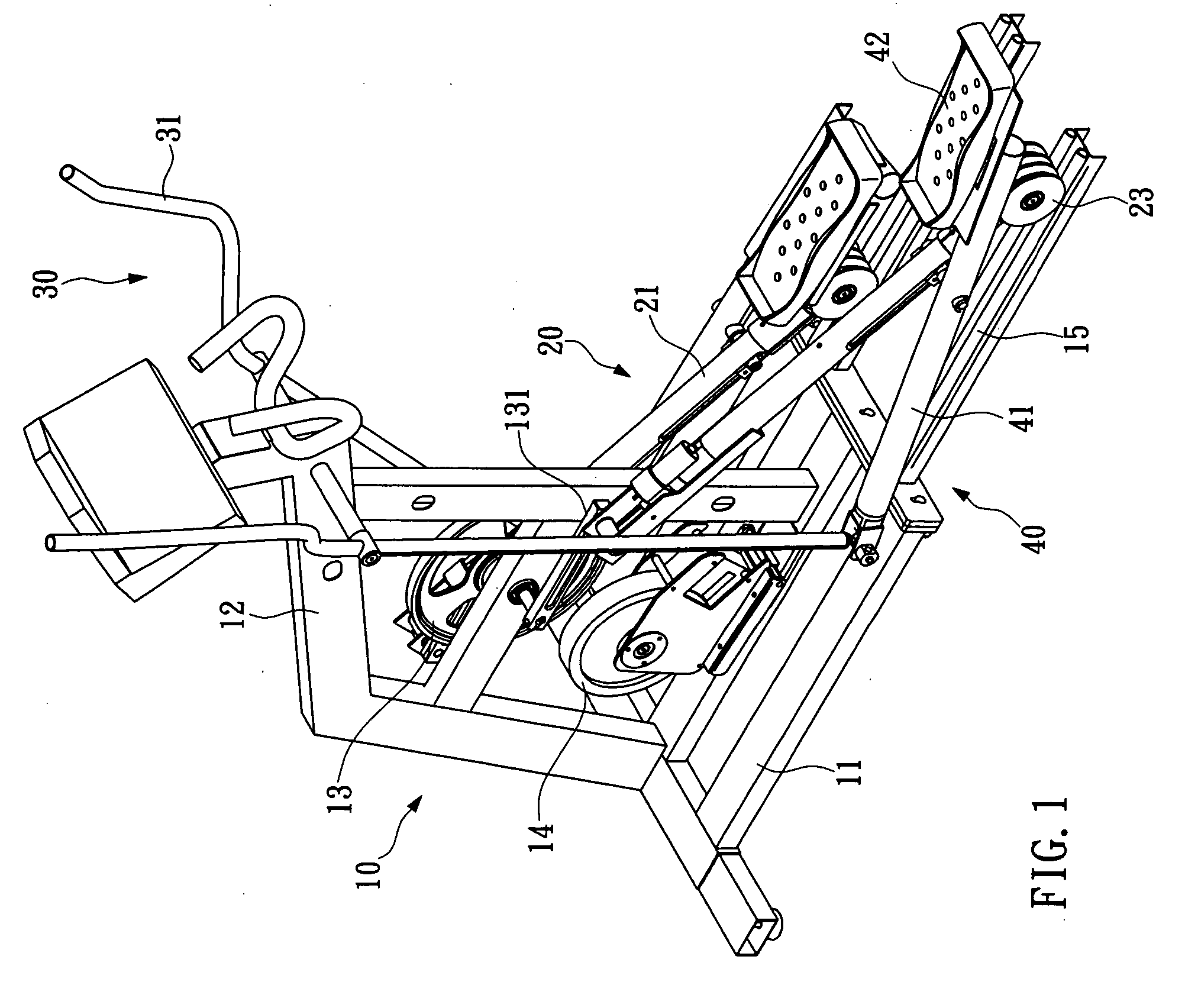

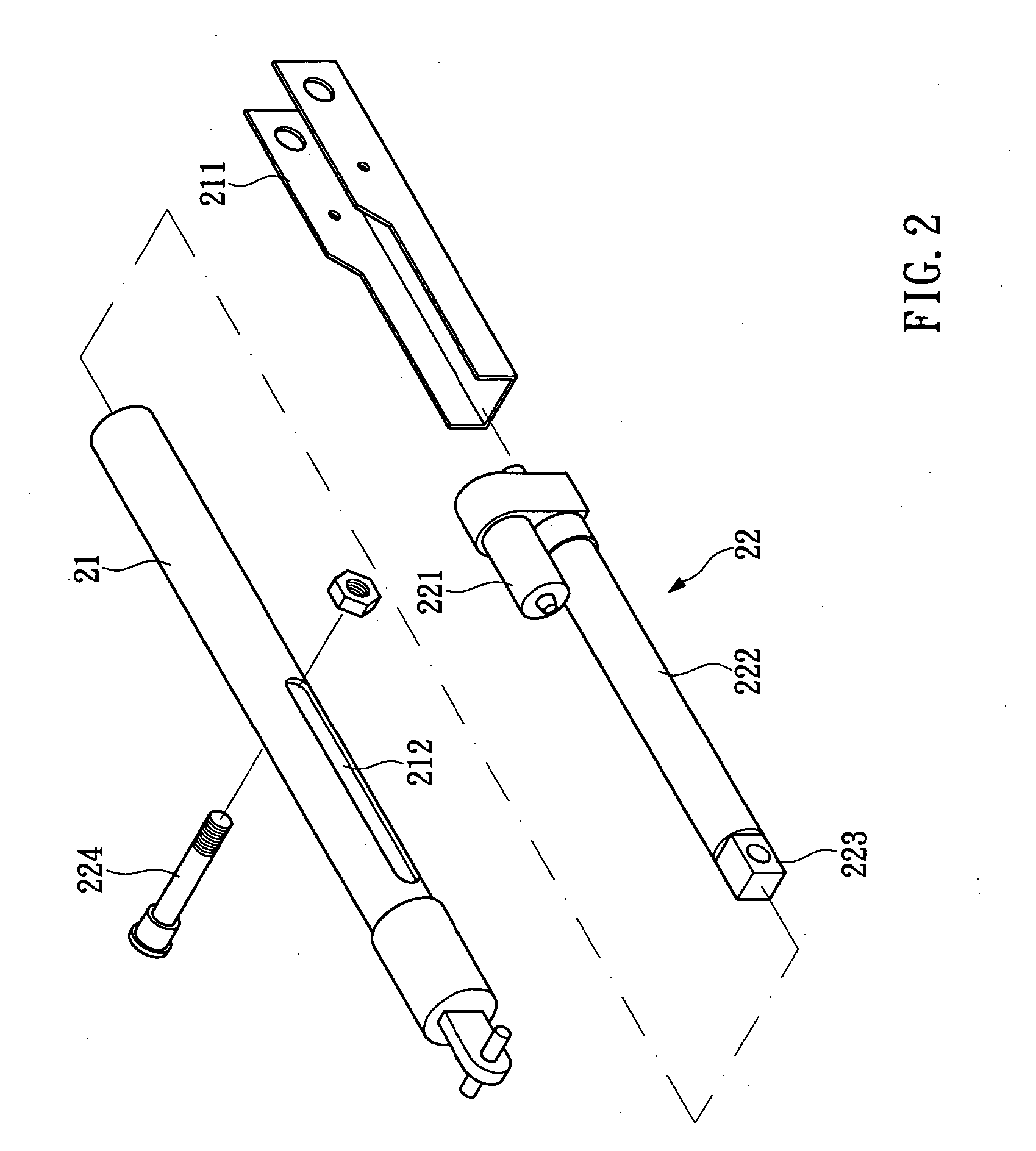

Pedal path of a stepping machine

A vertical stepping machine includes a frame, a crank wheel connected to the frame, a crank wheel connected to the frame, a pedal beam having a first end and a second end, wherein the first end is in mechanical communication with the crank wheel, a pedal connected to the second end of the pedal beam, a linkage assembly connected to the frame and to the pedal beam, an arm support rotatably connected to the frame, an arm linkage connecting the arm support to the linkage assembly, and a rotary resistance mechanism positioned above the crank wheel when the vertical stepping machine is in an upright orientation. The pedal beam moves in an elliptical path when the crank wheel rotates and the elliptical path has a vertical major axis and a horizontal minor axis when the vertical stepping machine is in an upright position.

Owner:IFIT INC

Conveyor roller assembly, conveyor roller insert and axle for conveyor roller

Owner:SST CONVEYOR COMPONENTS INC

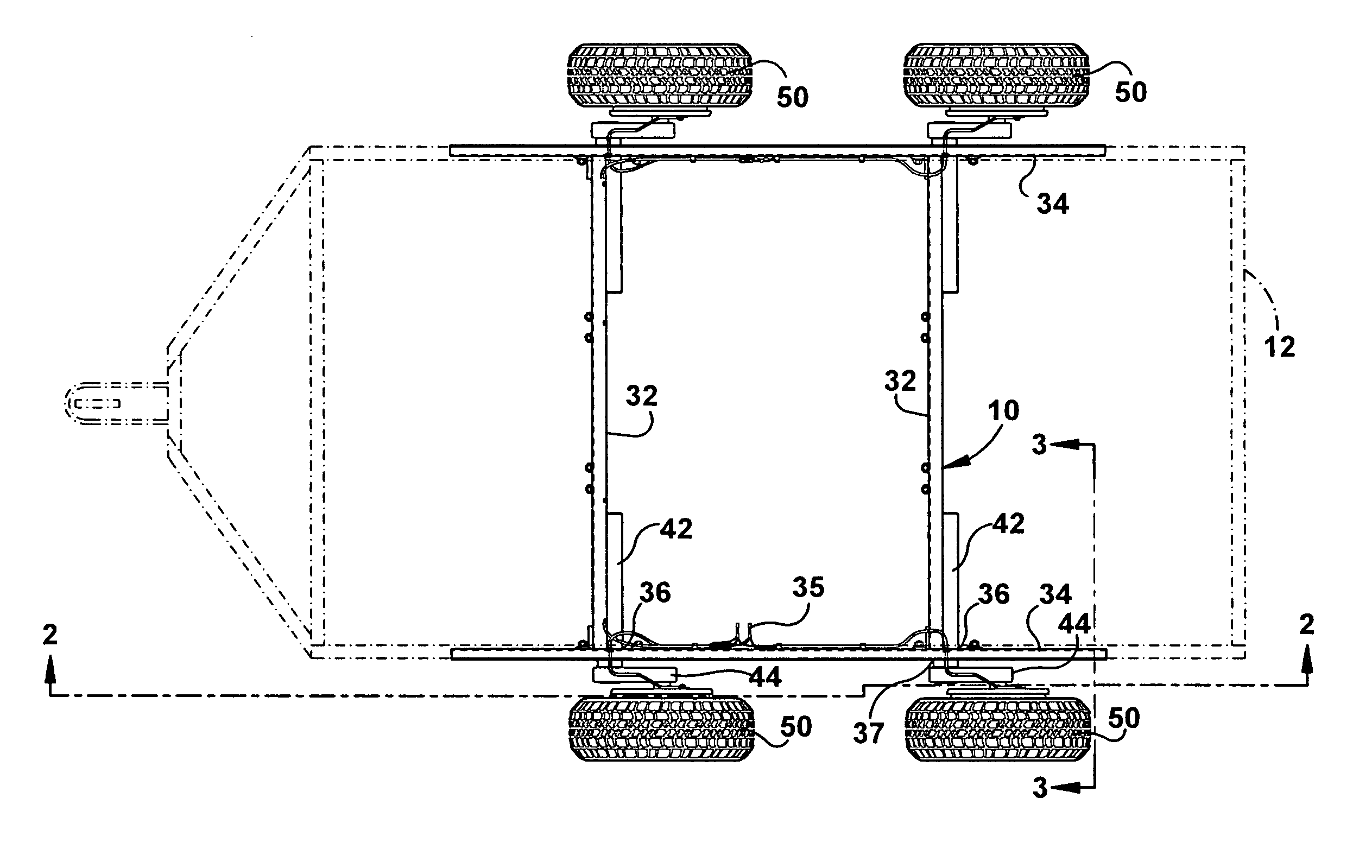

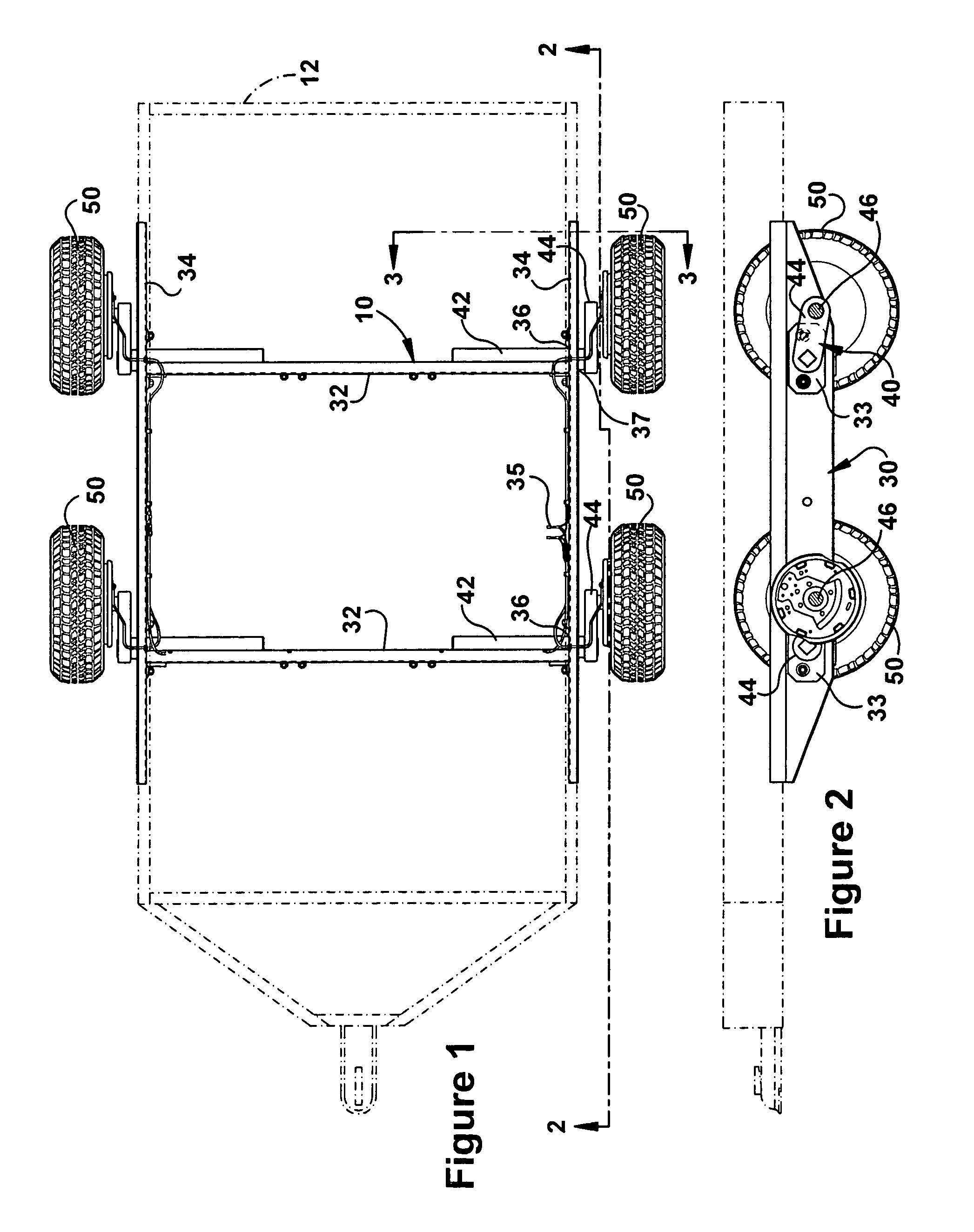

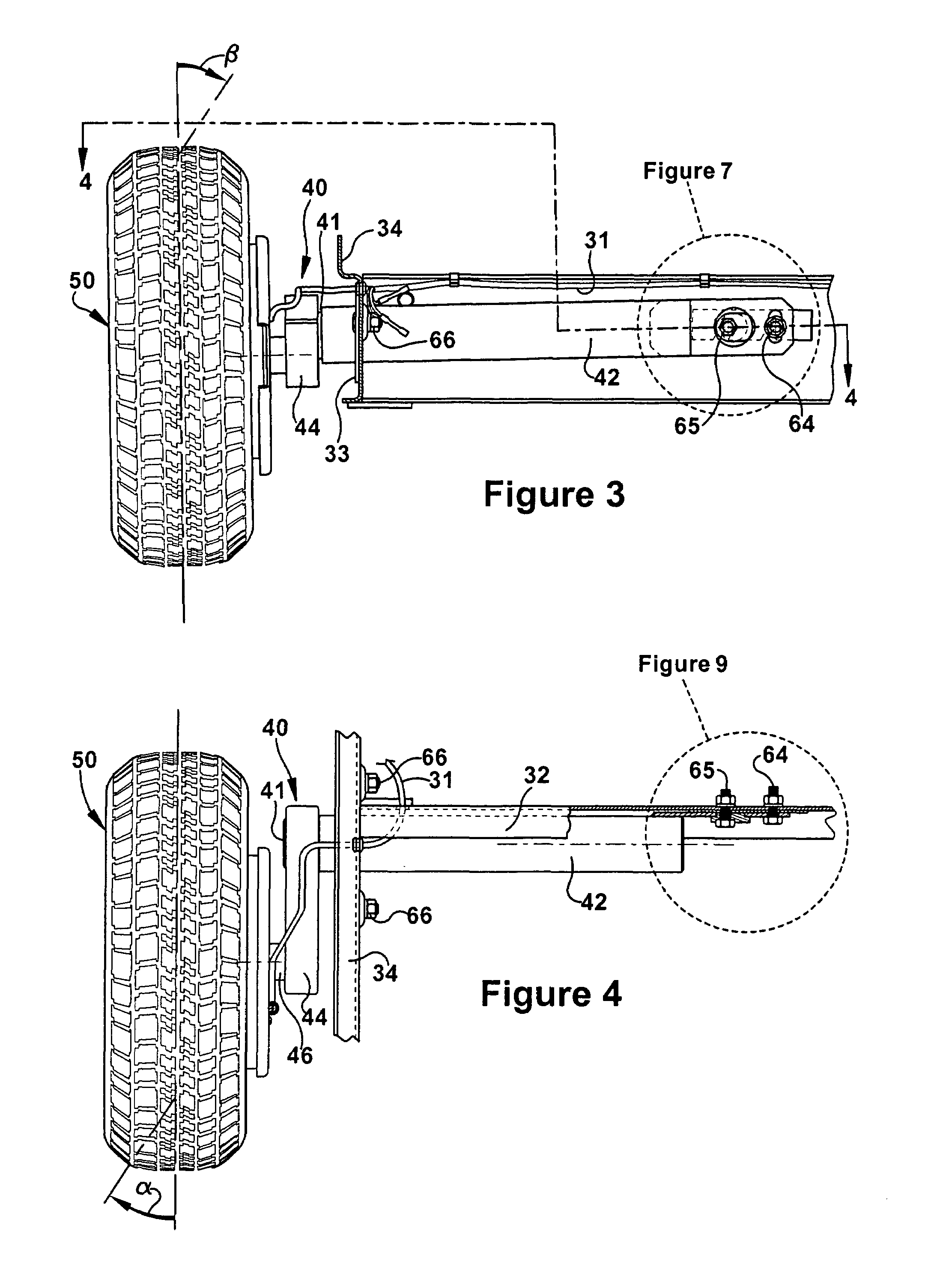

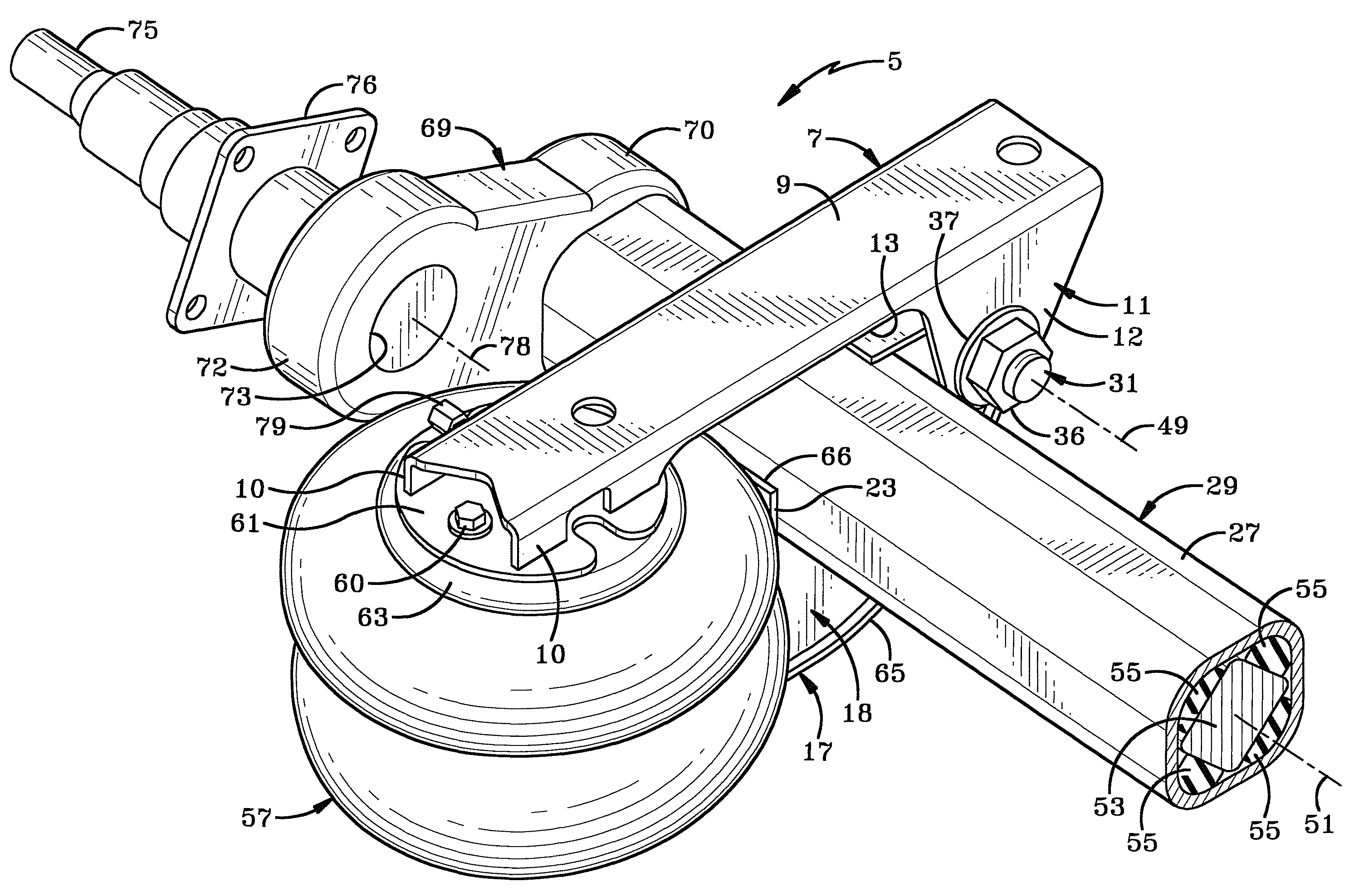

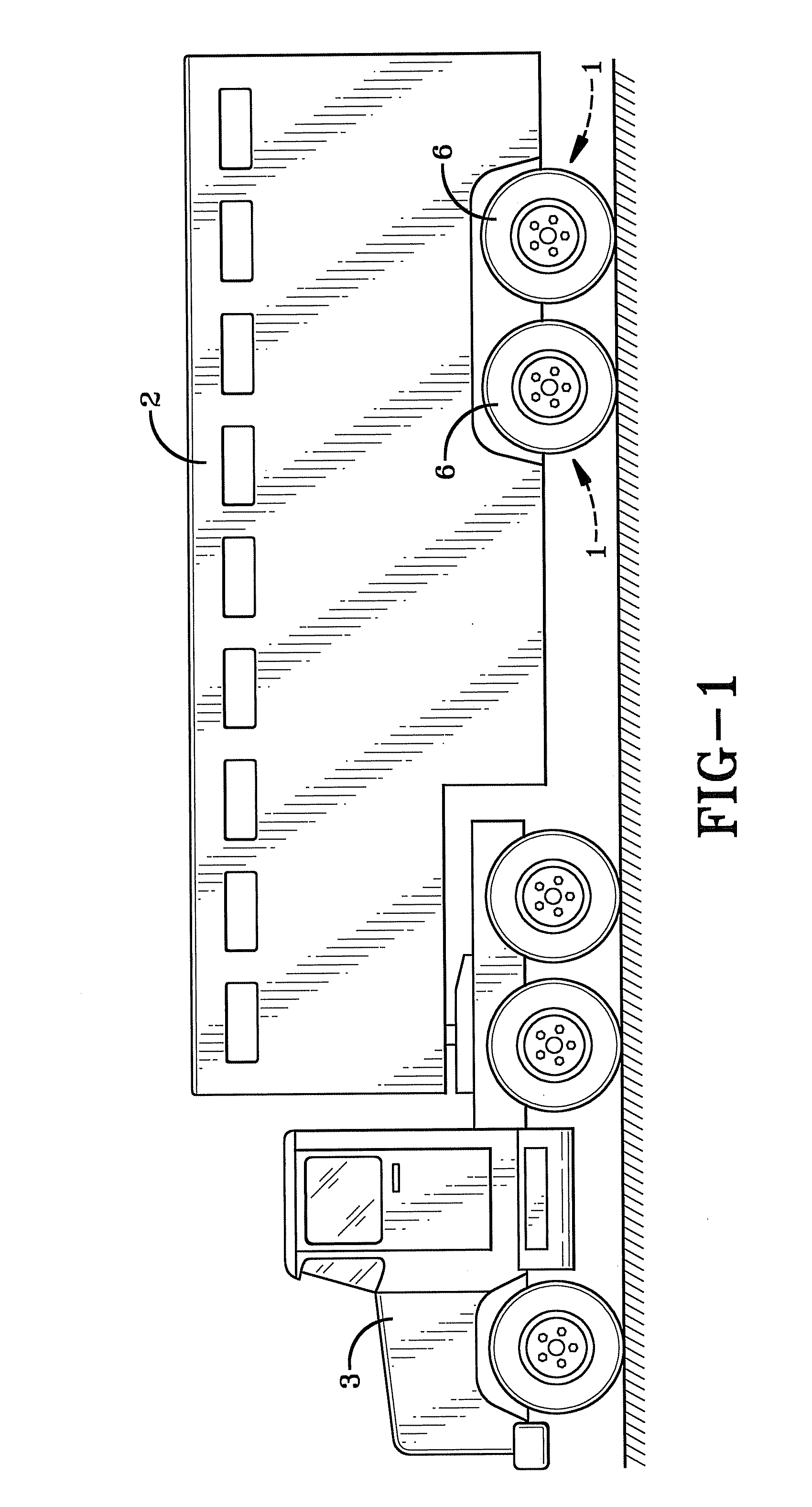

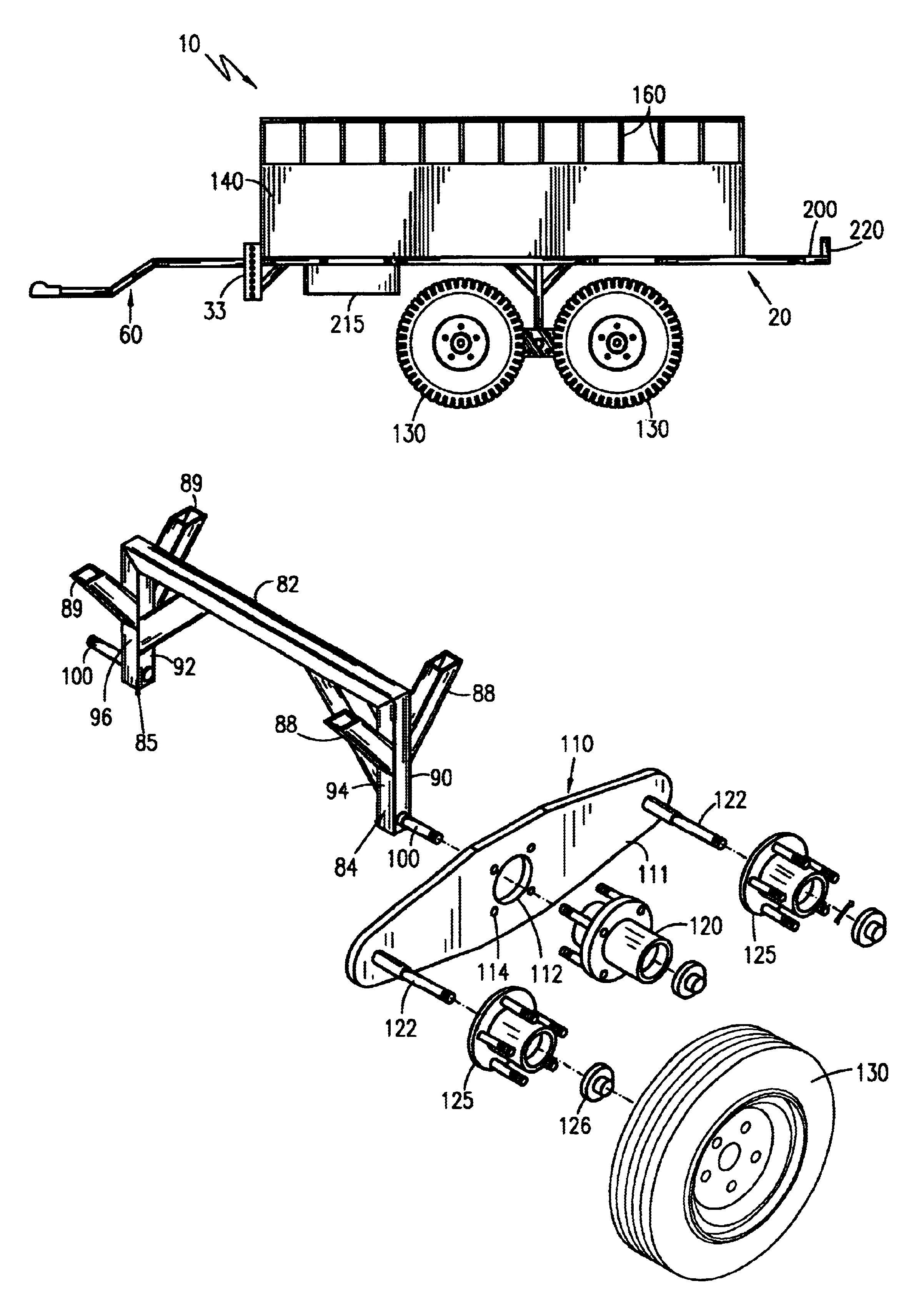

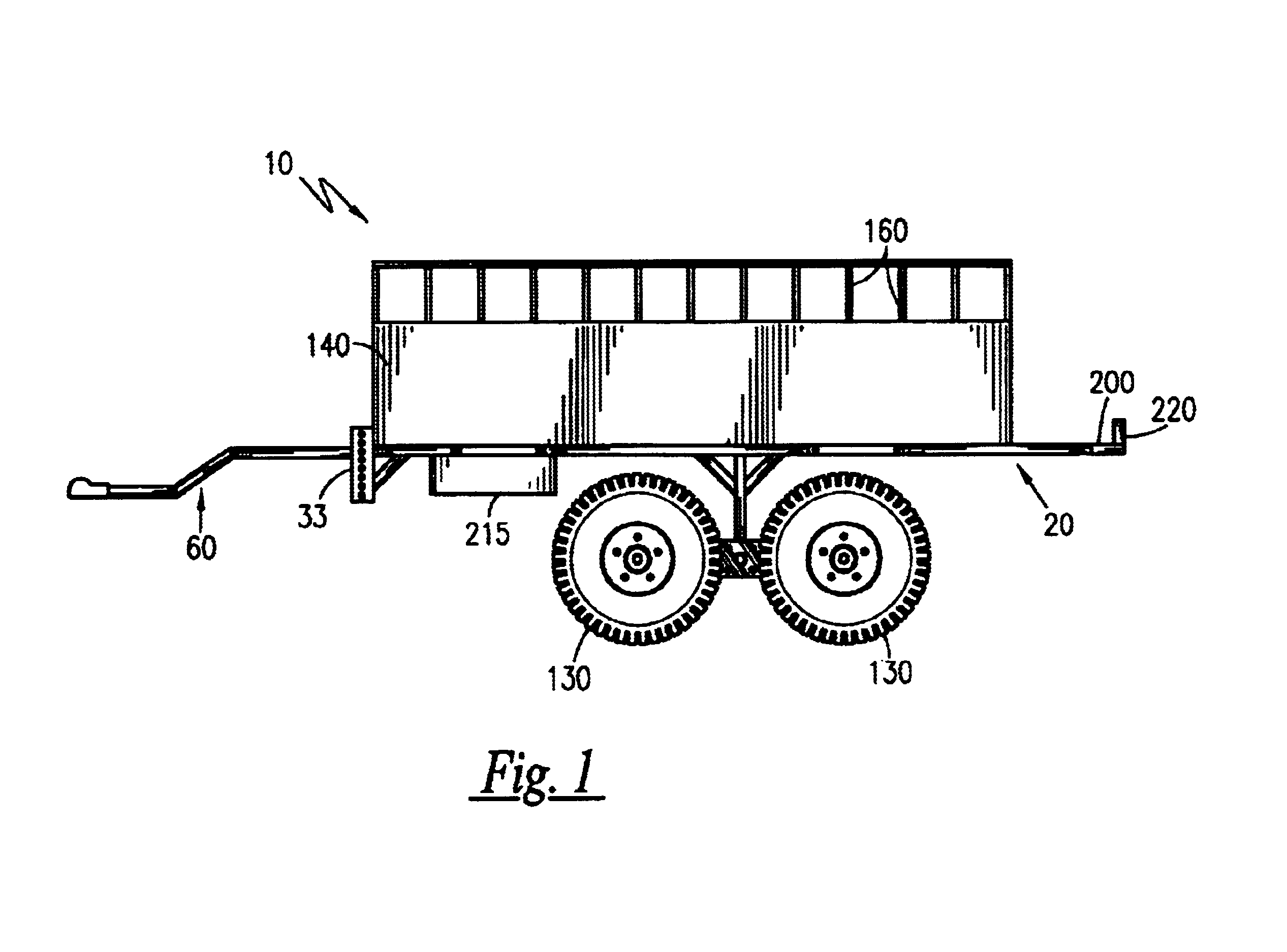

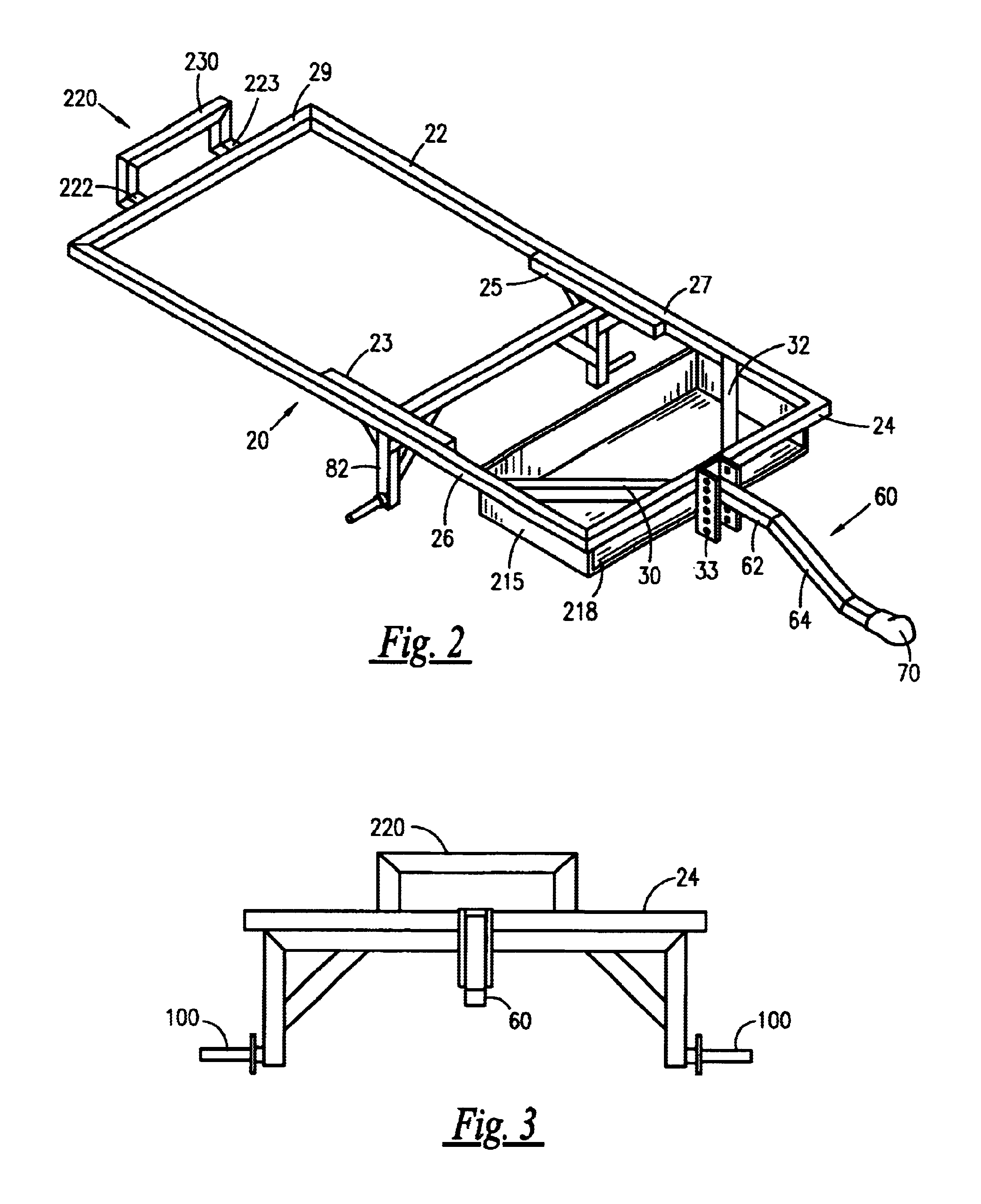

Trailer sub-frame assembly

A sub-frame assembly for use with a vehicle having wheels such as a trailer is provided. The sub-frame assembly comprises two or more frame members, one or more cross members, and two or more stub torsion axle assemblies. Each of the stub torsion axle assemblies have a torsion arm, a spindle extending from the torsion arm for mounting one of the wheels, and a distal end extending from the stub torsion axle assembly for mounting to the frame assembly. The frame assembly may further comprise one or more shim plates for reception between the cross member and the distal end of the stub torsion axle assembly for allowing adjustment of the toe angle of the wheel assembly. In addition, the stub torsion axle assembly may be rotatably mounted to the cross member whereby the camber angle of the wheel assembly may be adjusted.

Owner:DEXTER AXLE CO

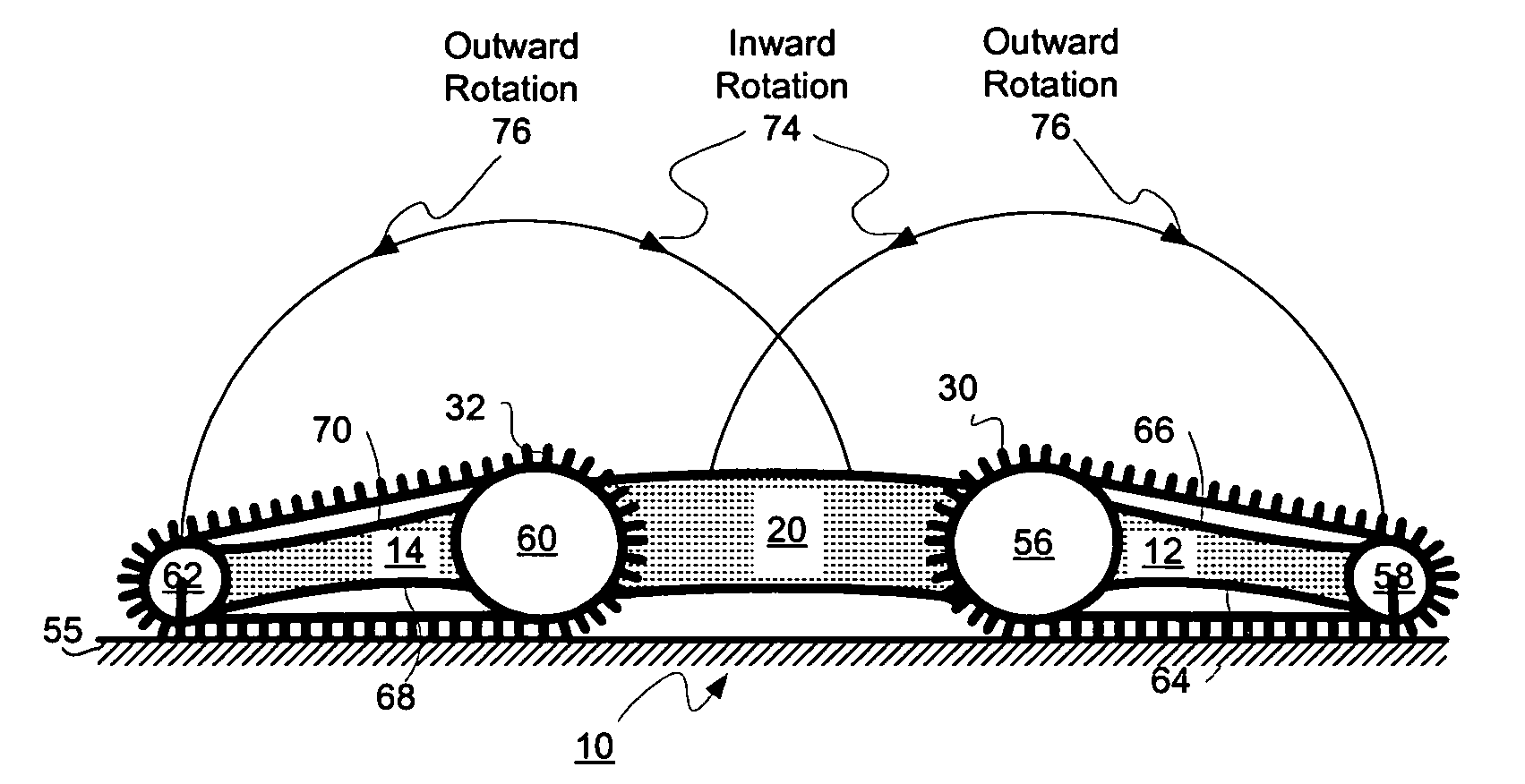

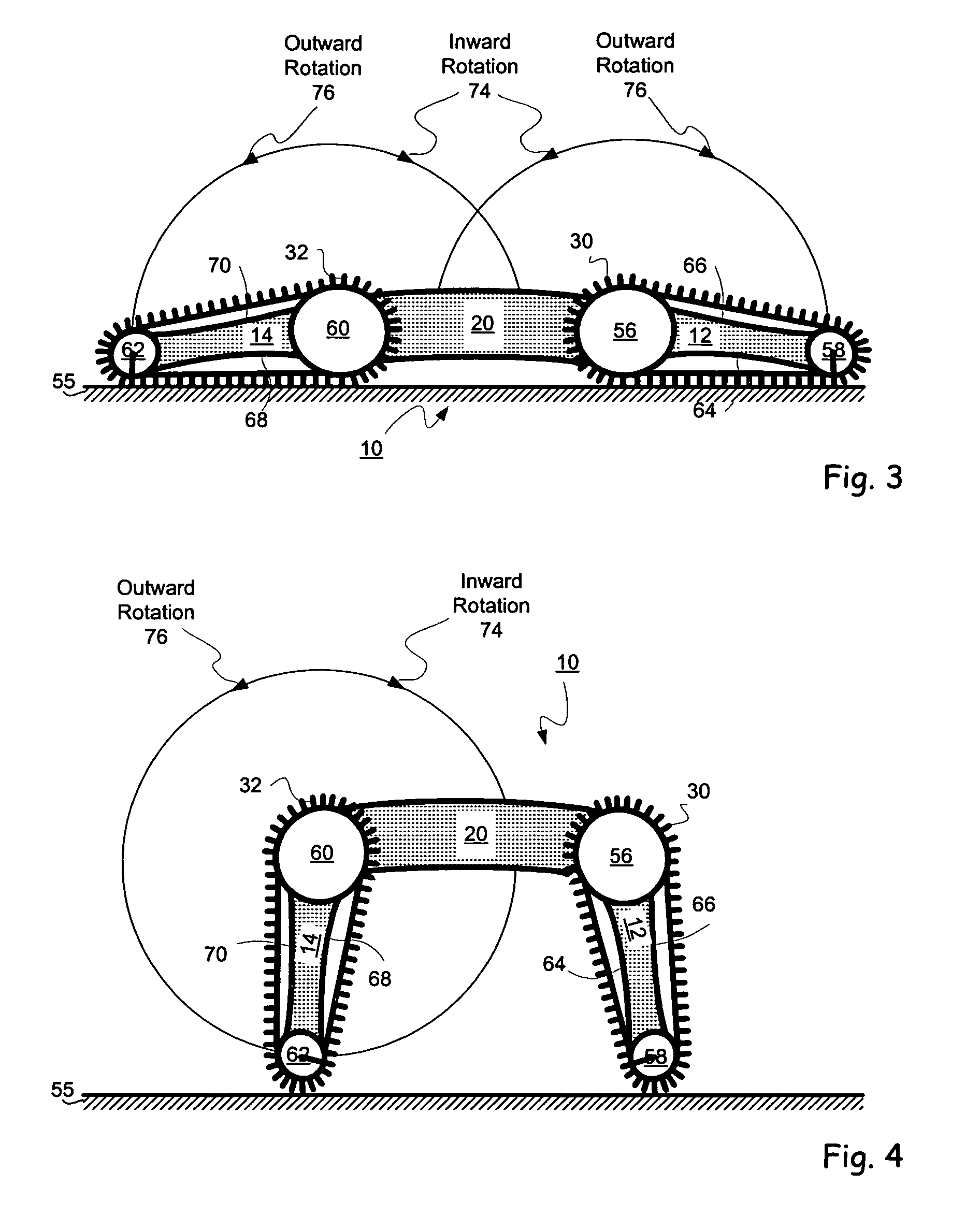

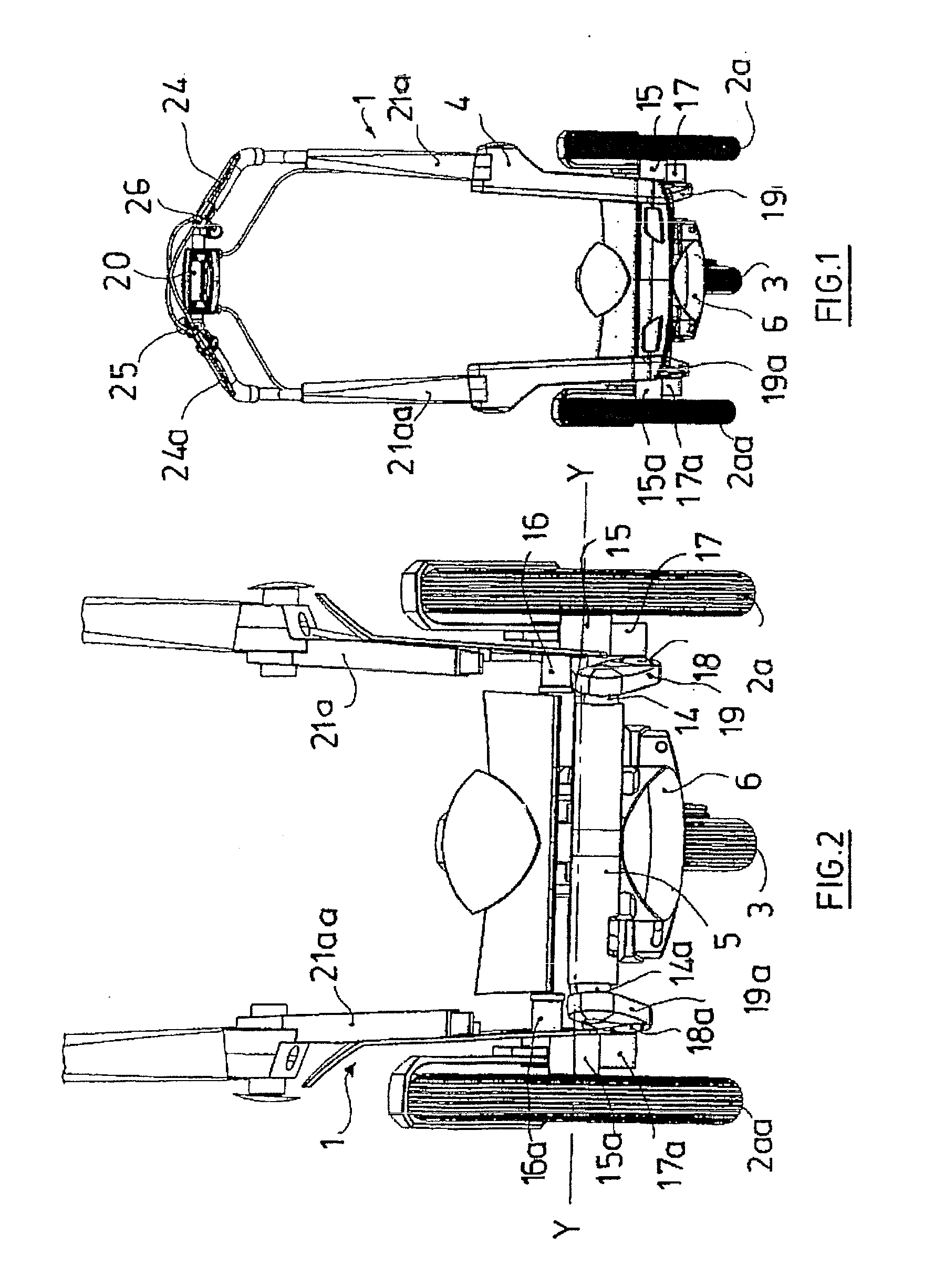

Quad tracked vehicle

Owner:MGA ENTERTAINMENT

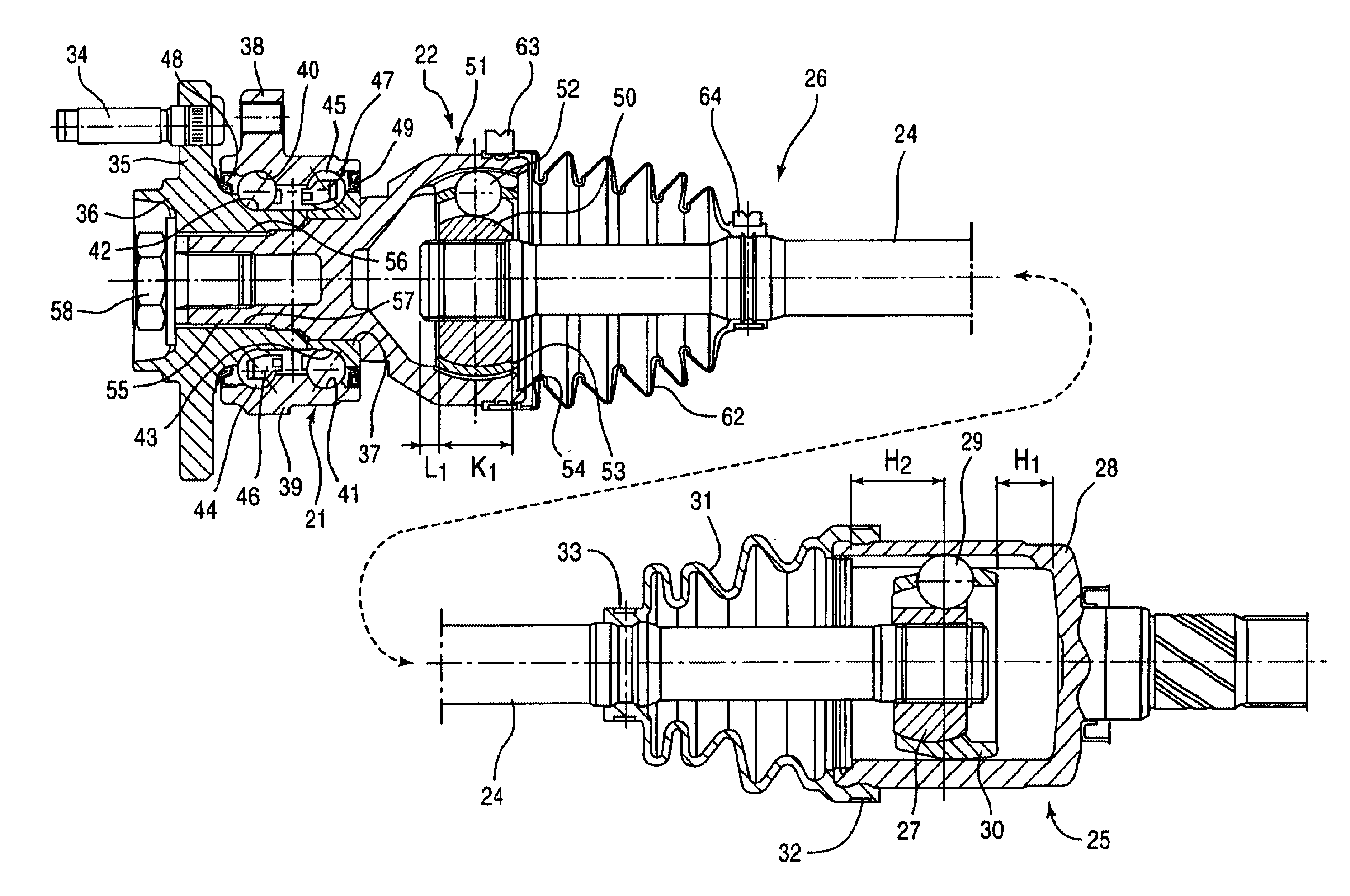

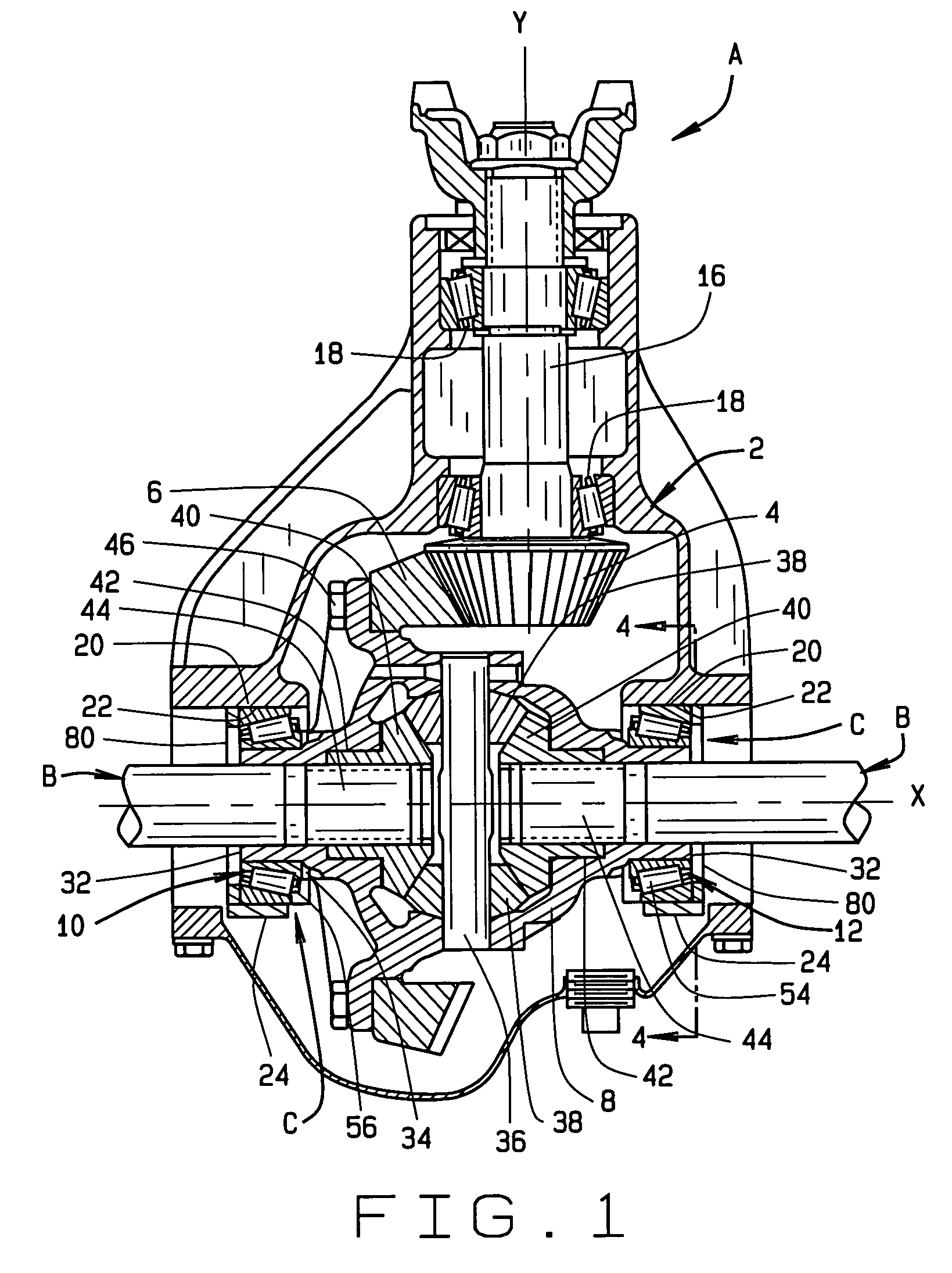

Drive wheel bearing assembly

In a drive wheel bearing assembly, a fixed type constant velocity universal joint is coupled to a wheel bearing, mounted to one end of an intermediate shaft, and a sliding type constant velocity universal joint, is coupled to a differential, mounted to the other end portion of the intermediate shaft. One end portion of a stub shaft is connected to an inner joint ring of the constant velocity universal joint via torque transmission portions; one end portion of the intermediate shaft is connected to the other end portion of the stub shaft via torque transmission portions. A threaded portion is formed on an outer diameter portion of either the intermediate or stub shaft; a nut member threadedly engages the threaded portion; and a keeper ring is fitted into annular grooves formed on the outer diameter portion of the intermediate shaft or the stub shaft and an inner diameter portion of the nut member allowing the nut member to rotate, but not move axially.

Owner:NTN CORP

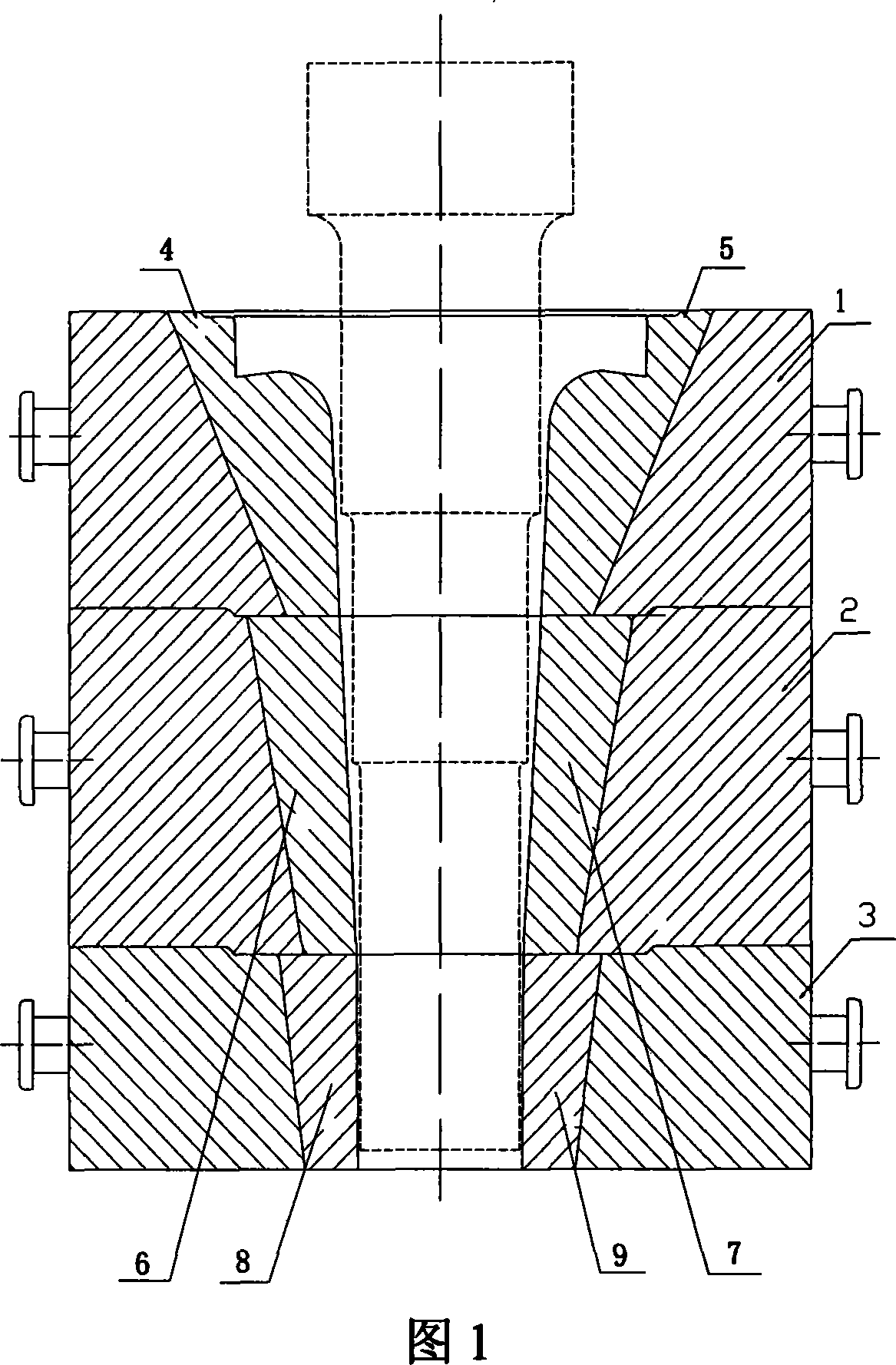

Fabrication technology of big flange stub axle type components

InactiveCN101116891AImprove forgeabilitySave raw materialsForging/hammering/pressing machinesEngine componentsStub axleLarge size

The invention relates to a processing technique for large flange short-axle type parts. The invention is characterized in that: the processing technique comprises the processing procedures of refining, forging, heat treating, detecting, and machining. The forging processing procedure is that: firstly a preformed stock is forged by free forging on a large-size hydraulic machine, and secondly, the preformed stock is placed in the die to be vertically upset forged into a die-forging part the dimension of which is approximate to that of a finish product. The invention overcomes the drawbacks that the large water press can only freely form by large-size forging piece, and can save raw materials and shorten cold processing time. The invention has the most advantage that the processing technique improves forging ability of the large flange arranged at the end of large flange short-axle parts.

Owner:天津市天重江天重工有限公司

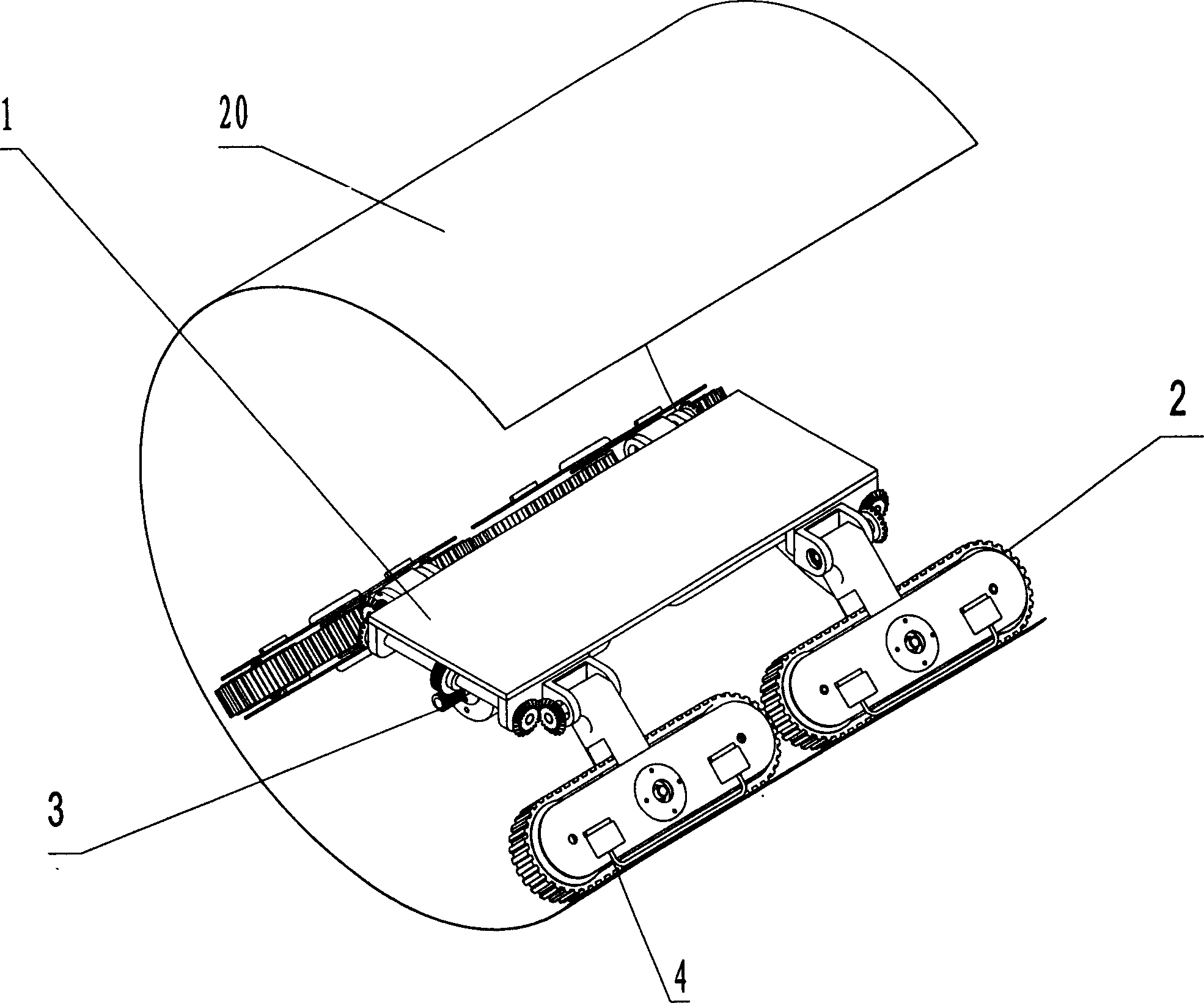

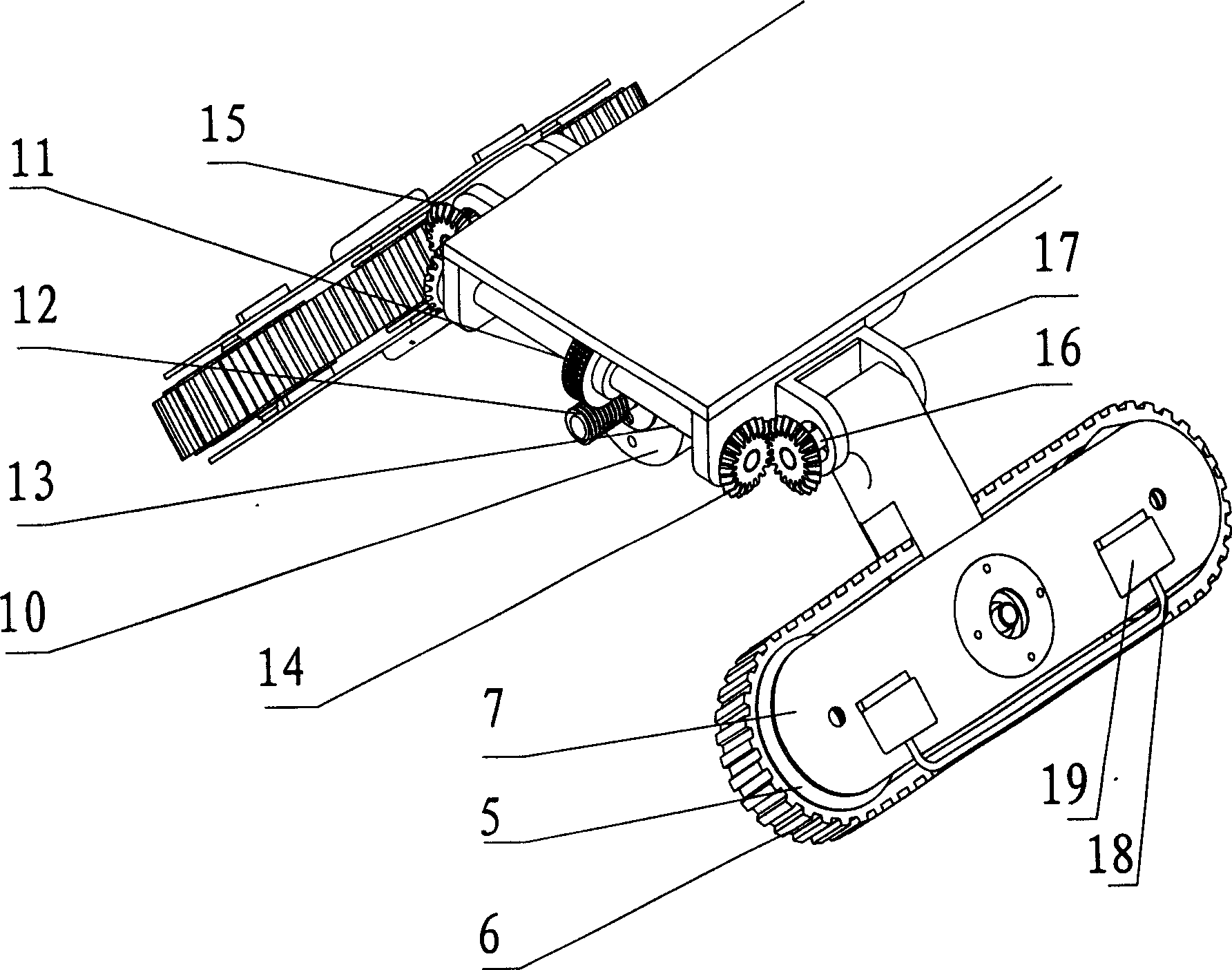

Moving mechanism of robot in pipe with self position changing four caterpillar feet

InactiveCN1456467AAutomatically adjust contact positionIncrease flexibilityEndless track vehiclesManipulatorTransverse axisStub axle

An autonomously changing walking mechanism of the robot with 4 caterpillar legs for walking in pipeline with variable diameter is composed of main body, caterpillar leg, transverse swinging unit, and pipe diameter measuring unit. Said caterpillar leg consists of caterpillar wheels, caterpillar belt and its supporter, bearing axle and swinging arm. Said transverse swinging unit comprises motor, worm couple, transverse axle, two pairs of bevel gears, swinging axle and supporter. Its advantages are simple structure, high power, automatic regulation, and smooth walking in pipeline.

Owner:DONGHUA UNIV

Variable-tilt-angle stepless loading type biaxial rotary oscillation ball-block friction-abrasion test machine

InactiveCN102661903AReliable transmissionCompact structureInvestigating abrasion/wear resistanceReliable transmissionBall screw

The invention relates to a variable-tilt-angle stepless loading type biaxial rotary oscillation ball-block friction-abrasion test machine, comprising a loading component, a biaxial rotary oscillation component and a driving component, wherein the loading component is a stepless loading type loading mechanism, is driven by a servo motor and a ball screw, and transmits a loading force to a clamping piece of a sample block through a buffering spring, so that the sample block supplies a load to a coupling sample ball, and stepless loading is realized; the driving component drives a crank with a sliding groove and a rocker to move through an asynchronous motor; the rocker is linked with a short shaft at one end of the biaxial rotary oscillation component, which is provided with an oscillation framework with a shaft; the biaxial rotary oscillation component is fixedly connected on a bottom engine base through a left bearing plate and a right bearing plate of a rack; and a sample ball shaft in the oscillation framework with the shaft does biaxial rotary oscillation with adjustable tilt angle and frequency with two shafts, which are vertical with each other, through a two-step conical gear transmission mechanism below the sample ball shaft. The variable-tilt-angle stepless loading type biaxial rotary oscillation ball-block friction-abrasion test machine provided by the invention has the advantages of adjustable tile angle and frequency, accurate and controllable loading, reliable transmission and stable movement, and can entirely simulate friction and abrasion of a ball-three quarter block biaxial rotary oscillation working condition.

Owner:SHANGHAI UNIV

Roller support assemblies

ActiveUS7962998B2Easy to assembleMinimize and prevent damageCurtain accessoriesCastorsStub axleEngineering

Owner:ANTHONY INNOVATIONS

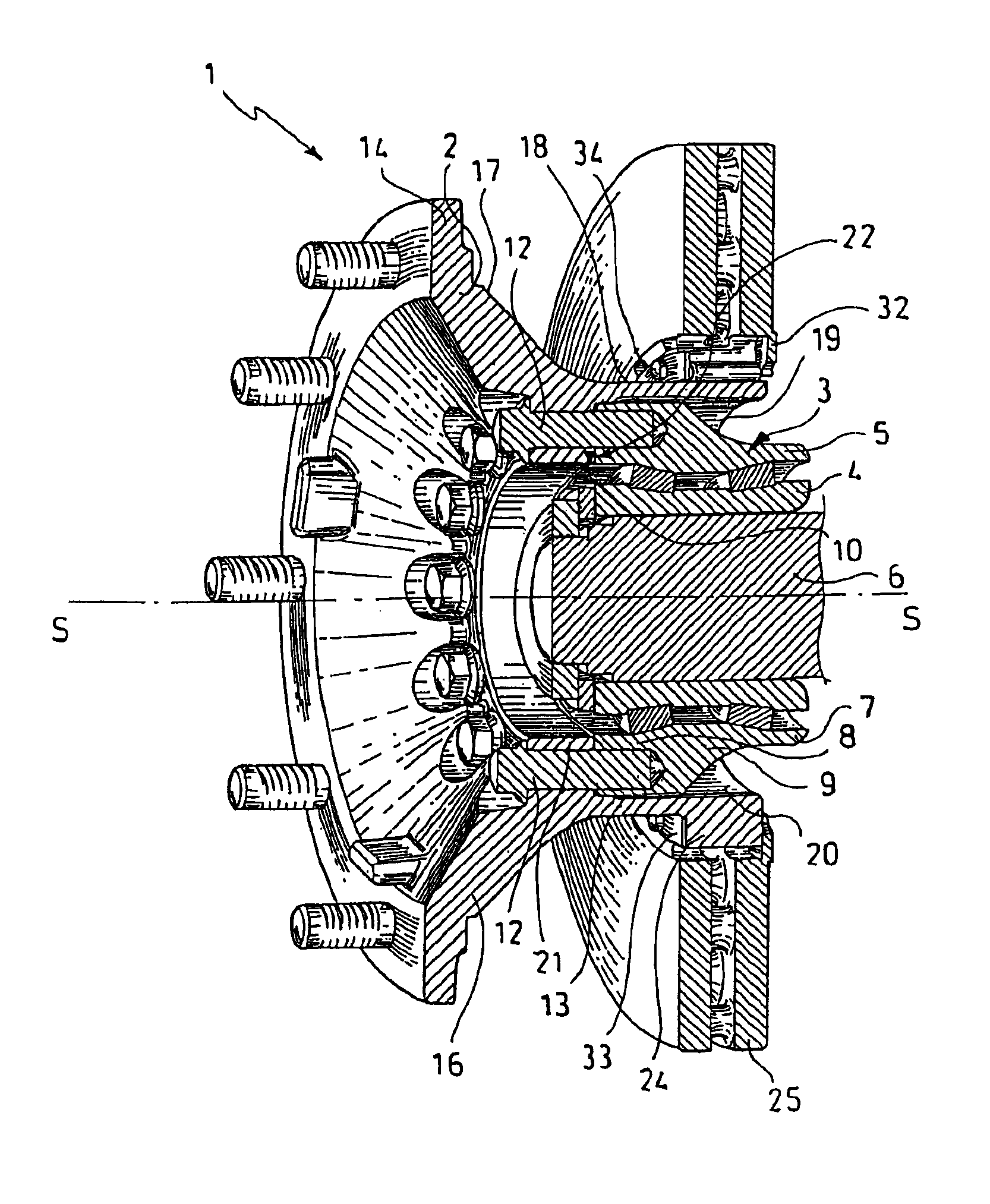

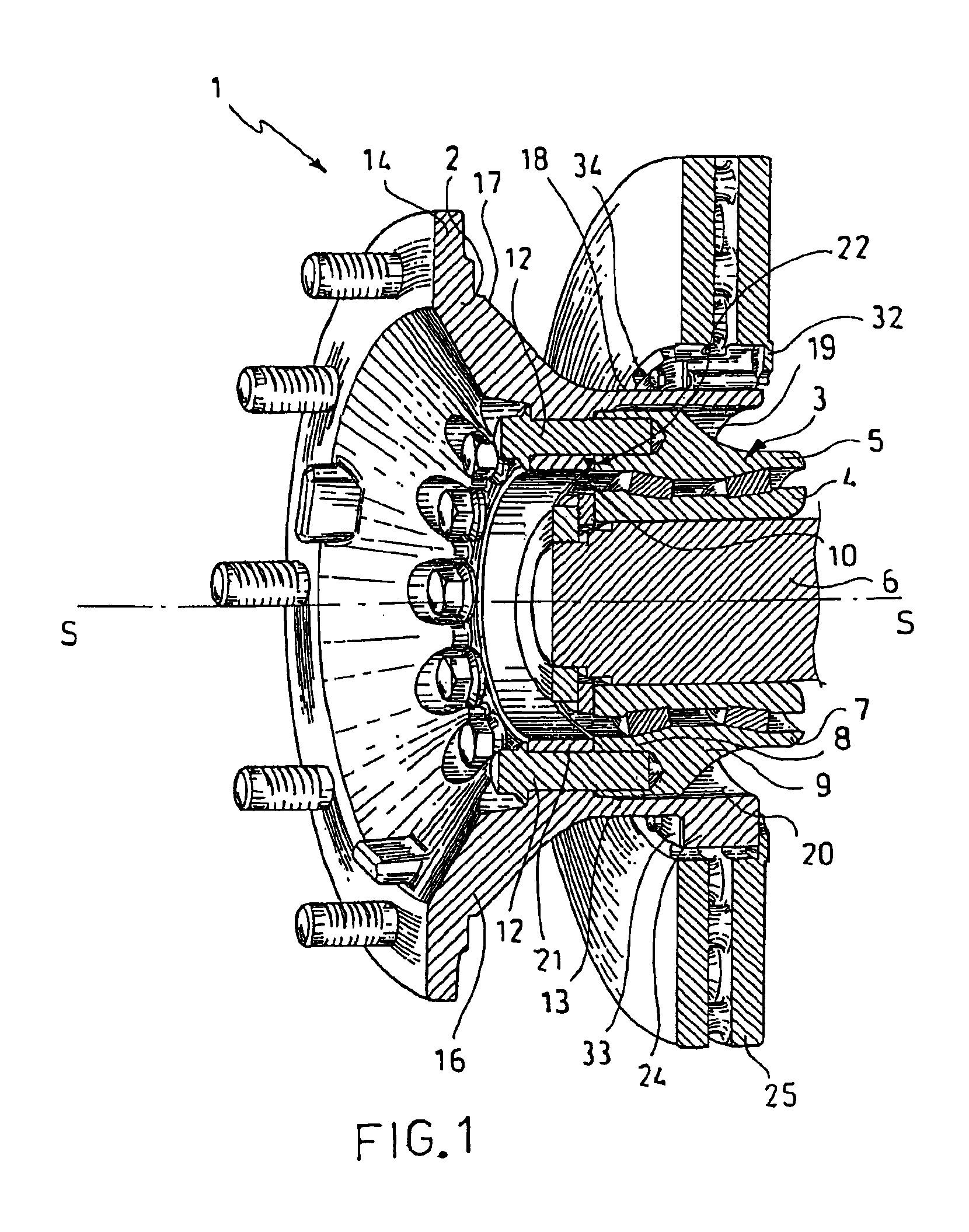

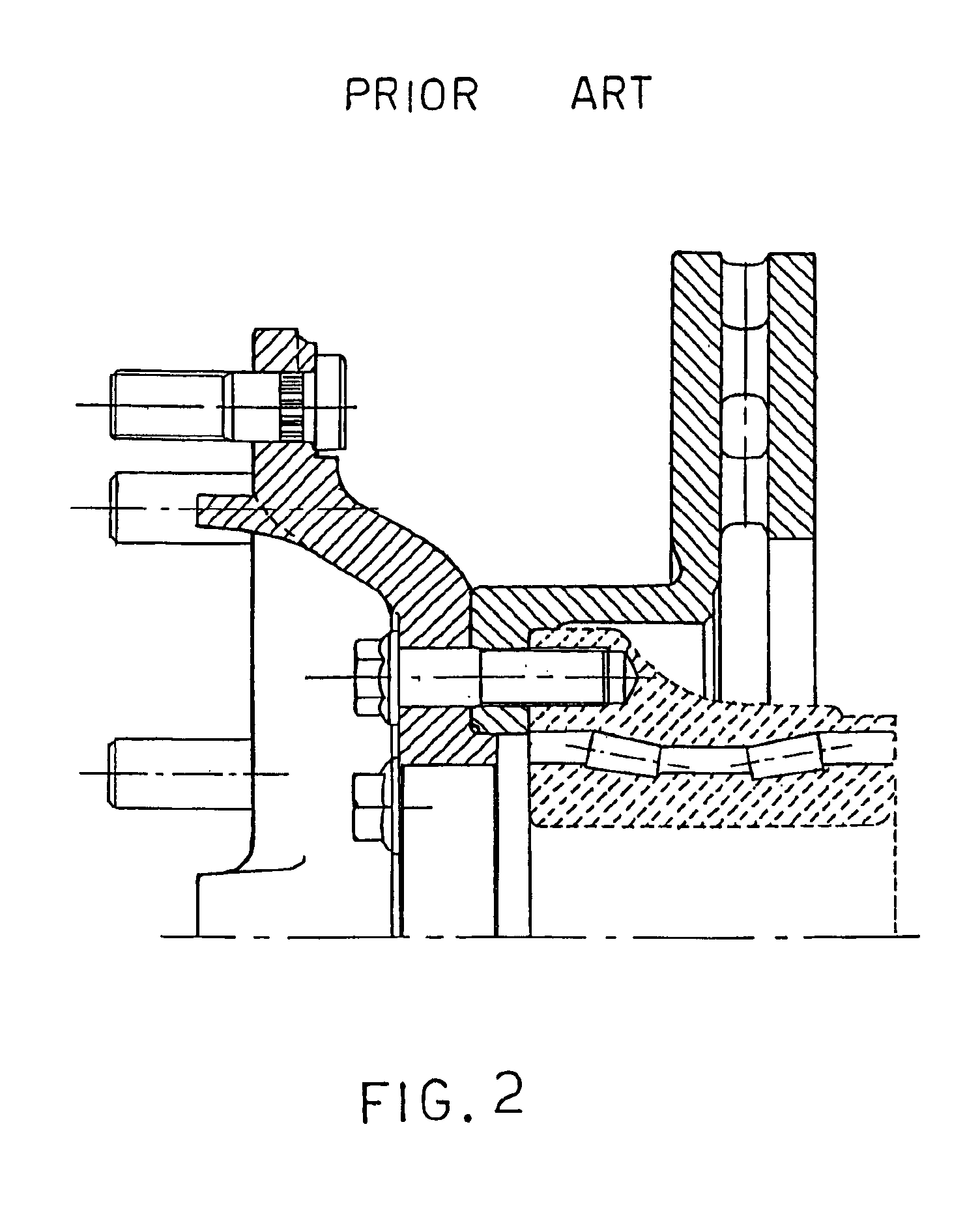

Wheel support for vehicles with disk brakes

InactiveUS6880682B2Safe and easy replacementEven by forceAxially engaging brakesHubsStub axleEngineering

A wheel support for providing a connection, rotatable about an axis (S), between a wheel of a vehicle which can be braked by a disk brake and the stub axle (6) of the vehicle comprises a bell (24) suitable for supporting a braking band (25) and a connection flange (14) for the connection of the vehicle wheel. The bell (24) and the connection flange (14) are formed integrally, constituting a single body (2) which can be connected rotatably and releasably to the stub axle (6) of the vehicle.

Owner:FRENI BREMBO SPA

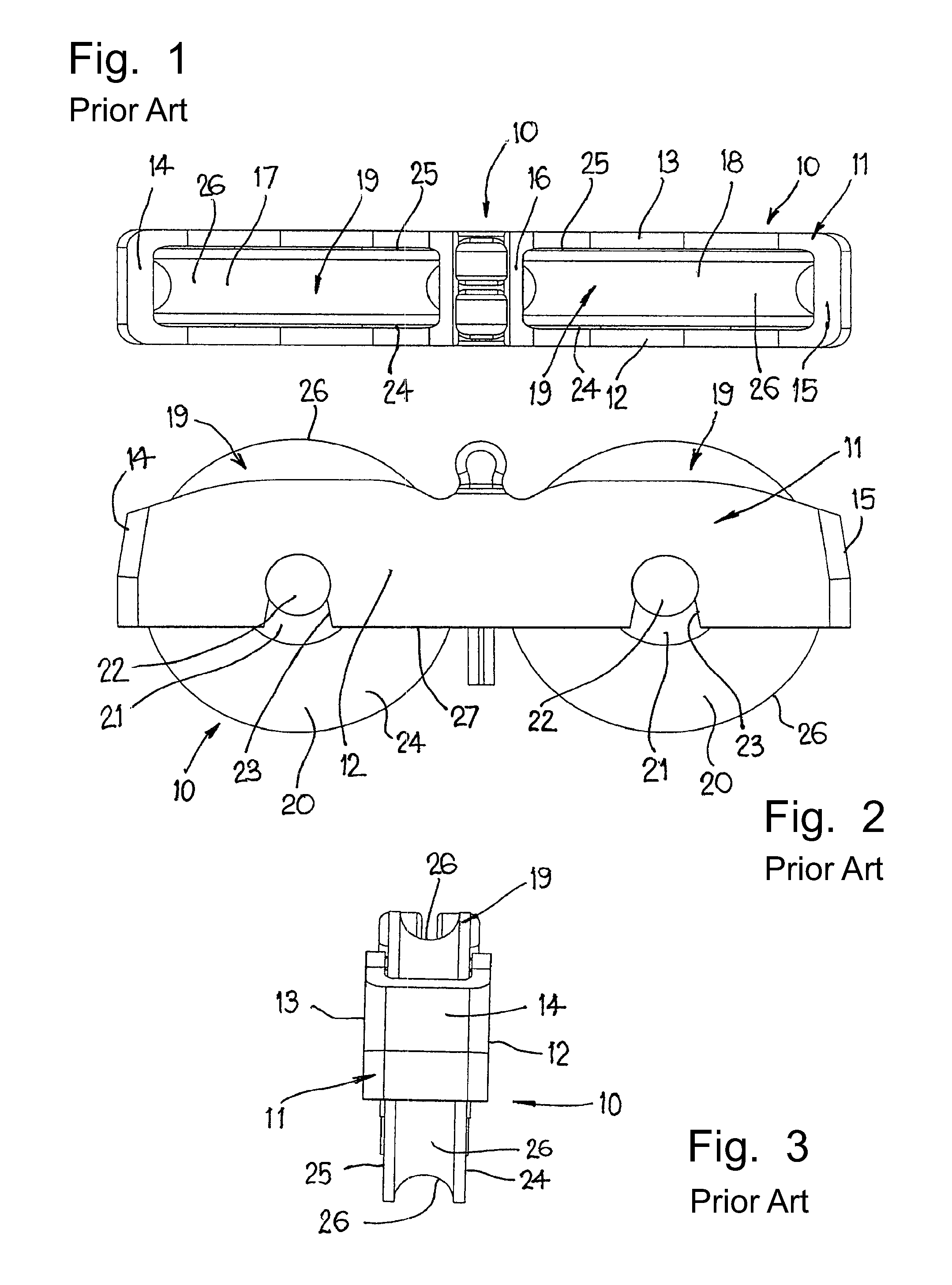

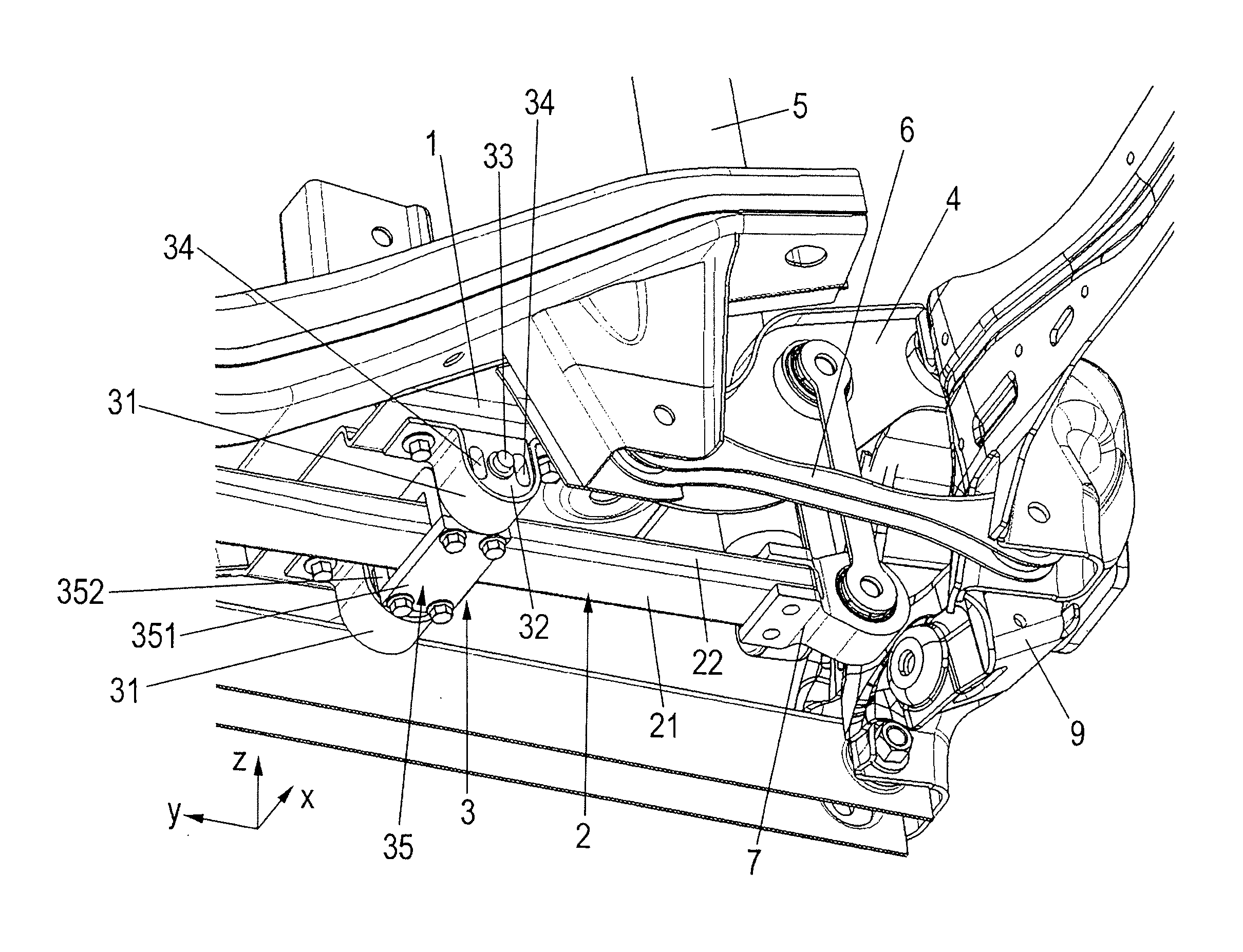

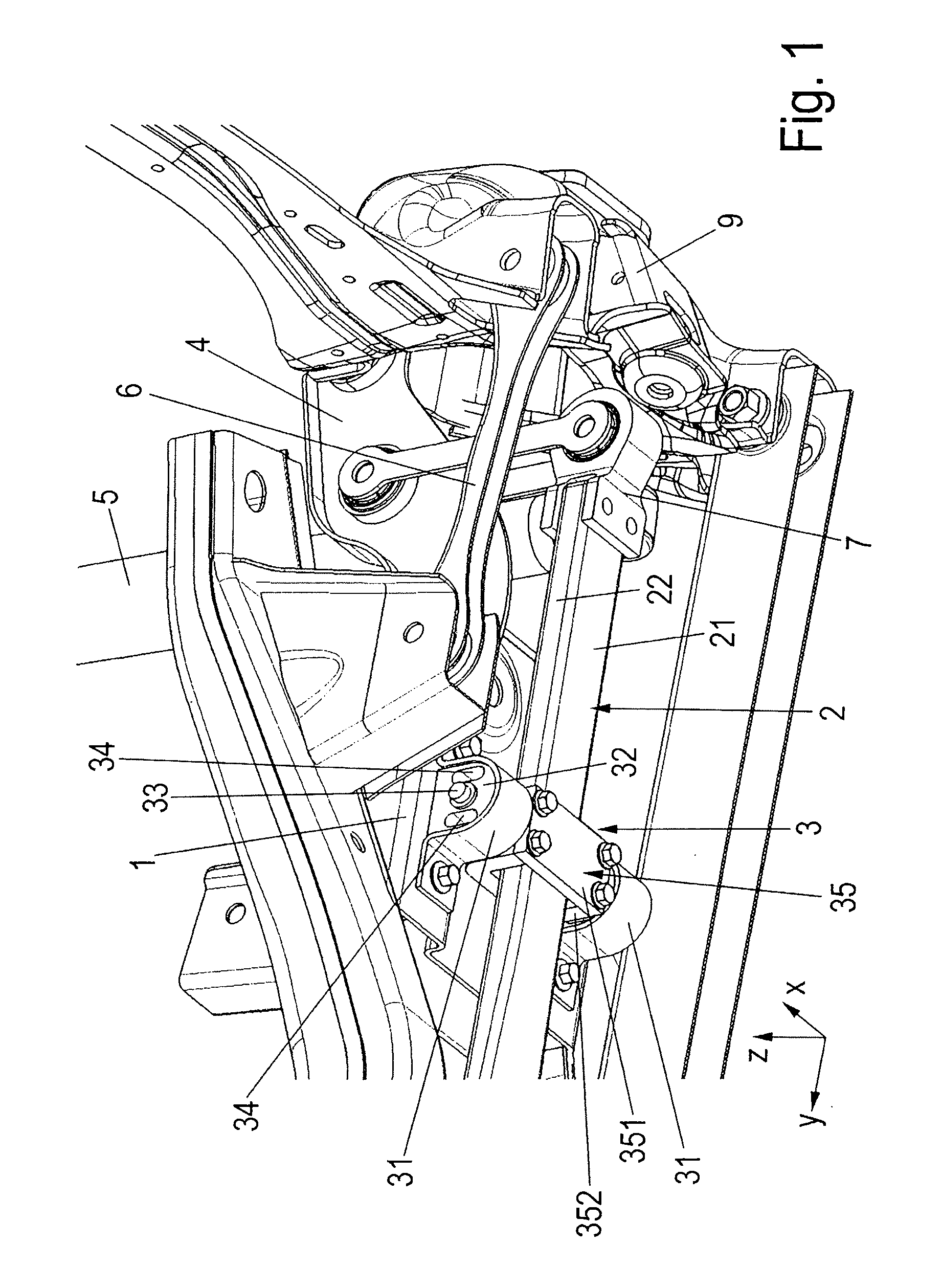

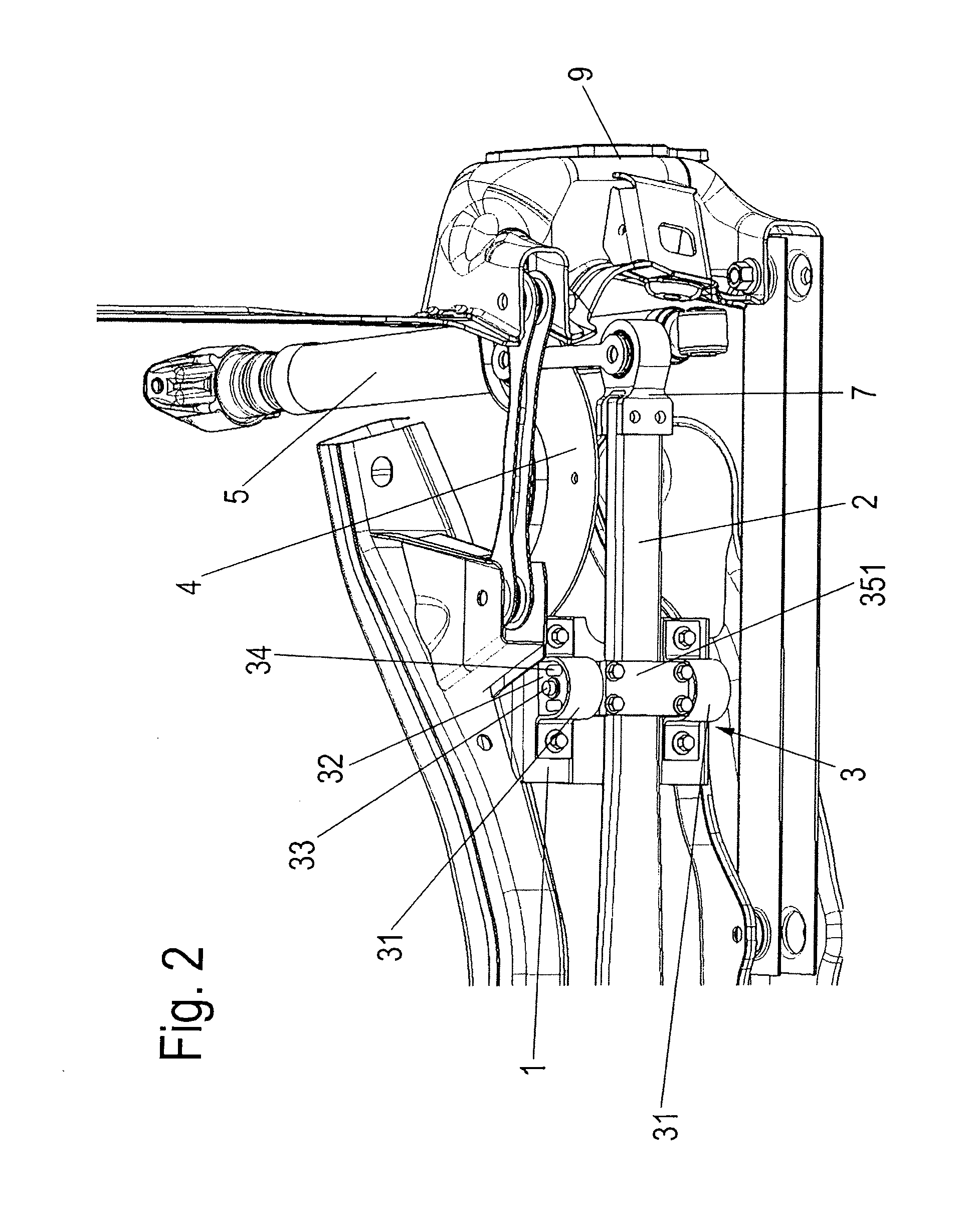

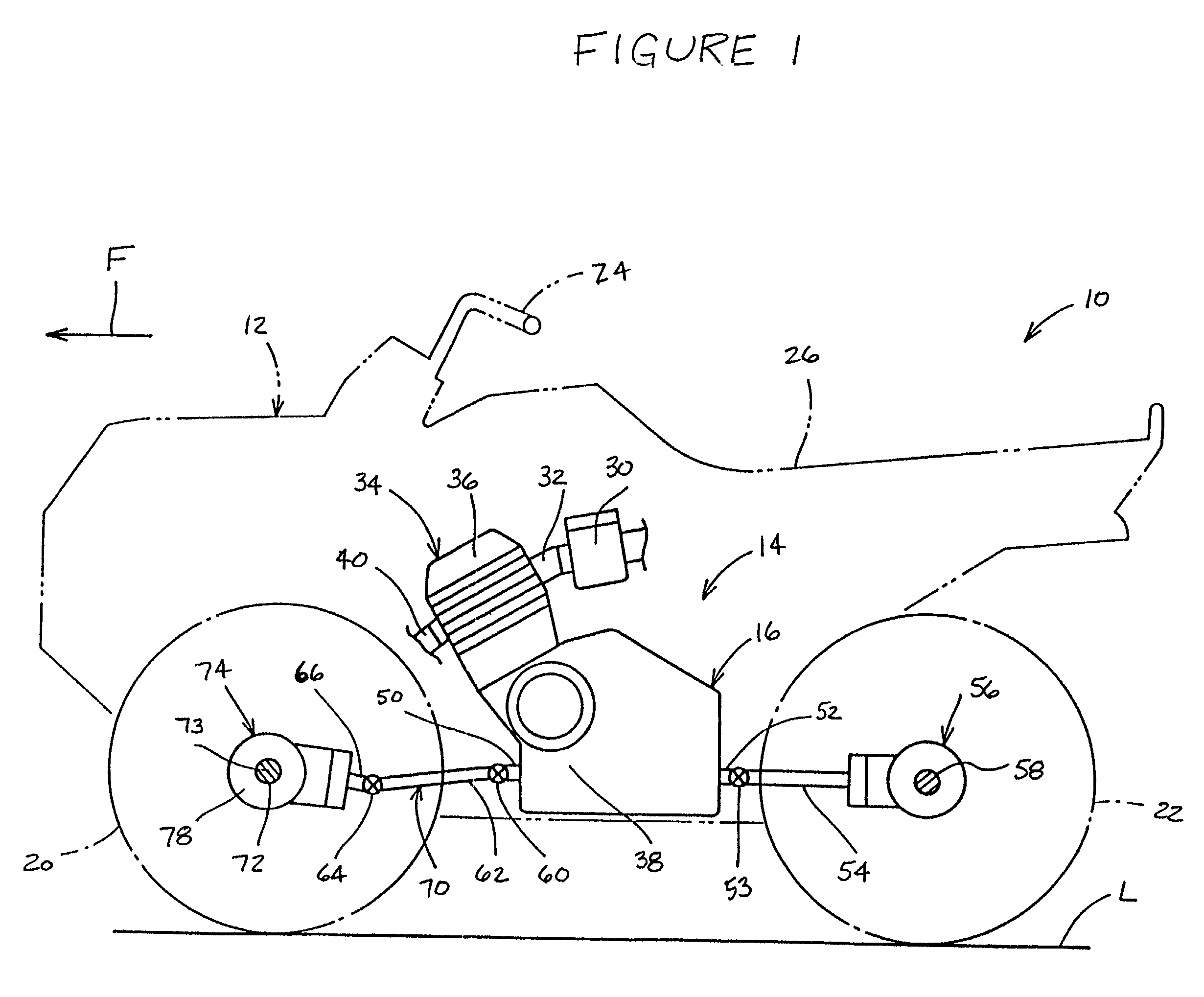

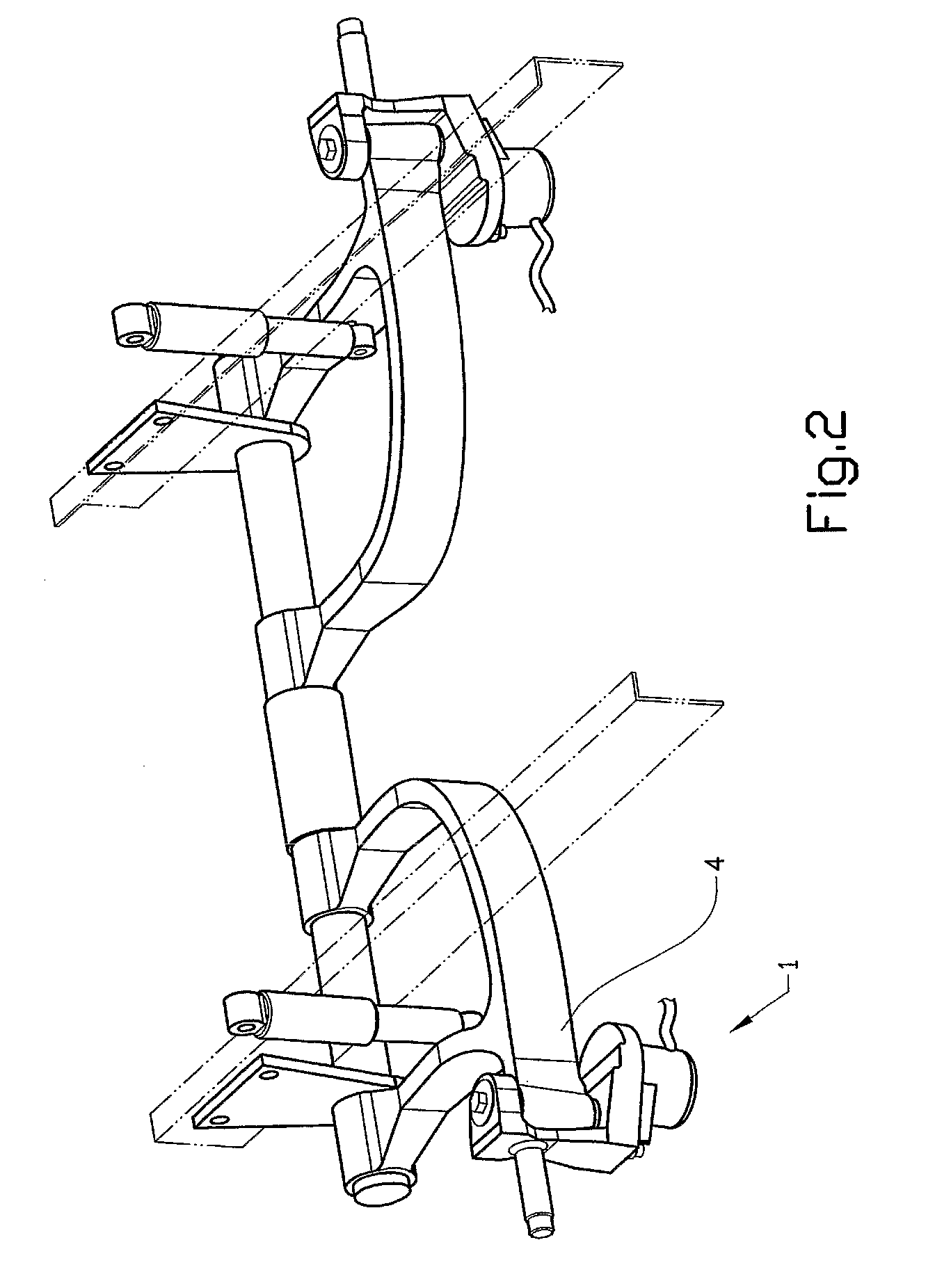

Wheel suspension of a motor vehicle

ActiveUS20120098229A1Reduce distanceInterconnection systemsResilient suspensionsTransverse axisStub axle

A wheel suspension of a motor vehicle includes a transverse leaf spring arranged along a transverse axis of the motor vehicle. The transverse leaf spring is connected via two bearings with a body of the vehicle and is connected in an articulated manner at its two mutually opposite ends with a stub axle or suspension arm. The bearings are arranged such that the transverse leaf spring is stiffly fixed in a direction of a vertical axis of the vehicle and is movable in a translatory manner in a direction of the transverse axis of the vehicle and is rotationally movable around an axis that is parallel to a longitudinal axis of the vehicle.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

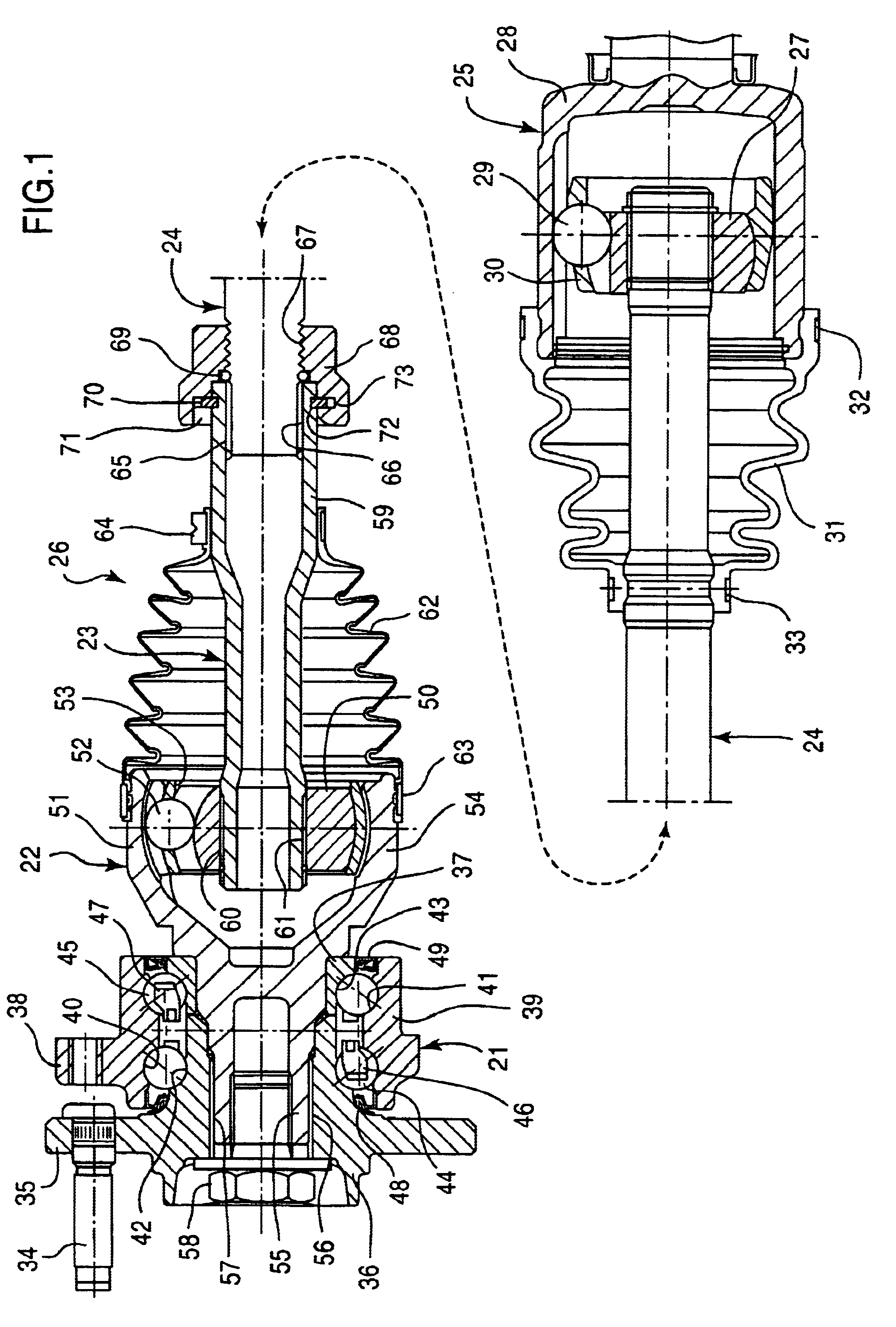

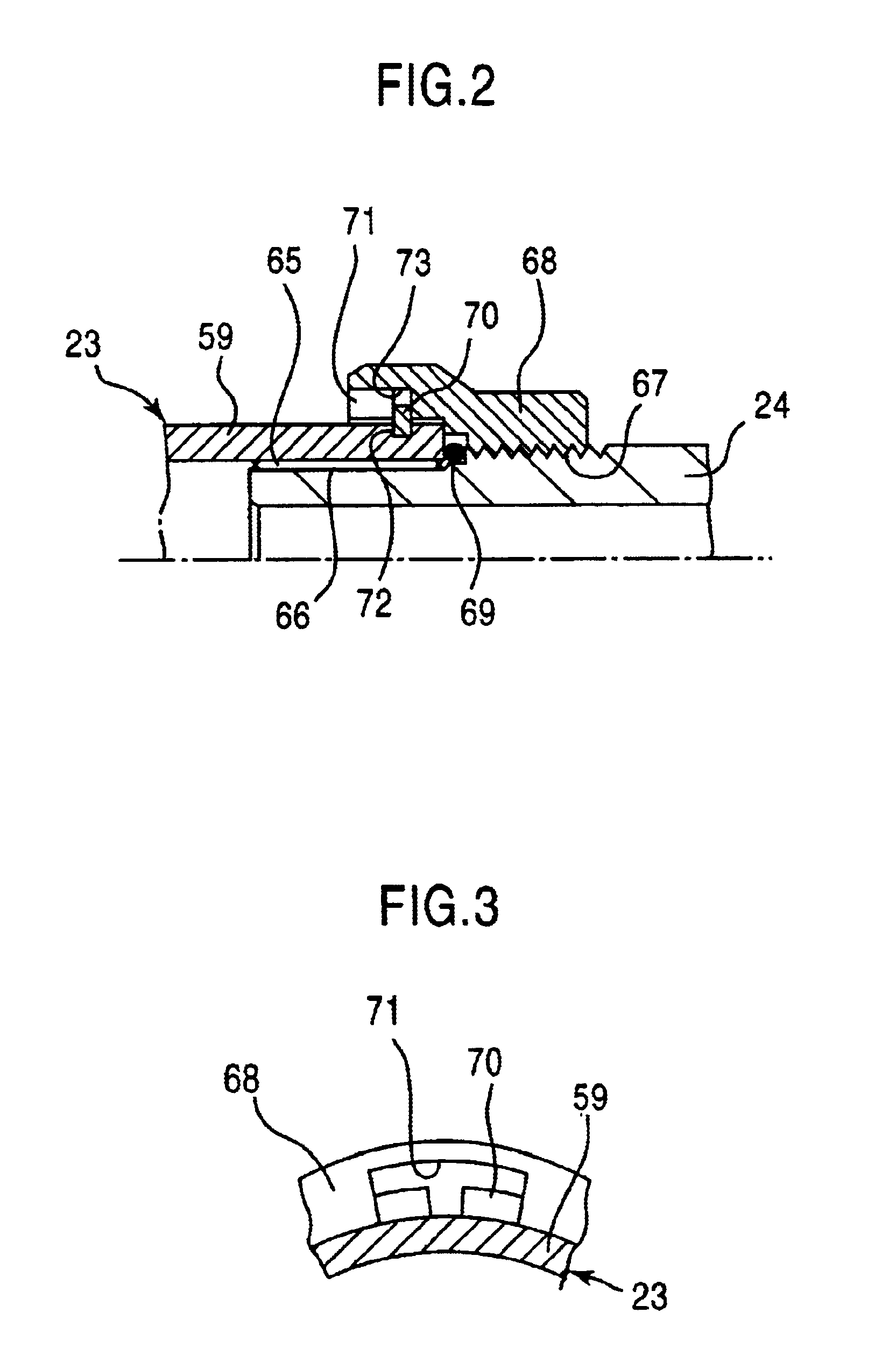

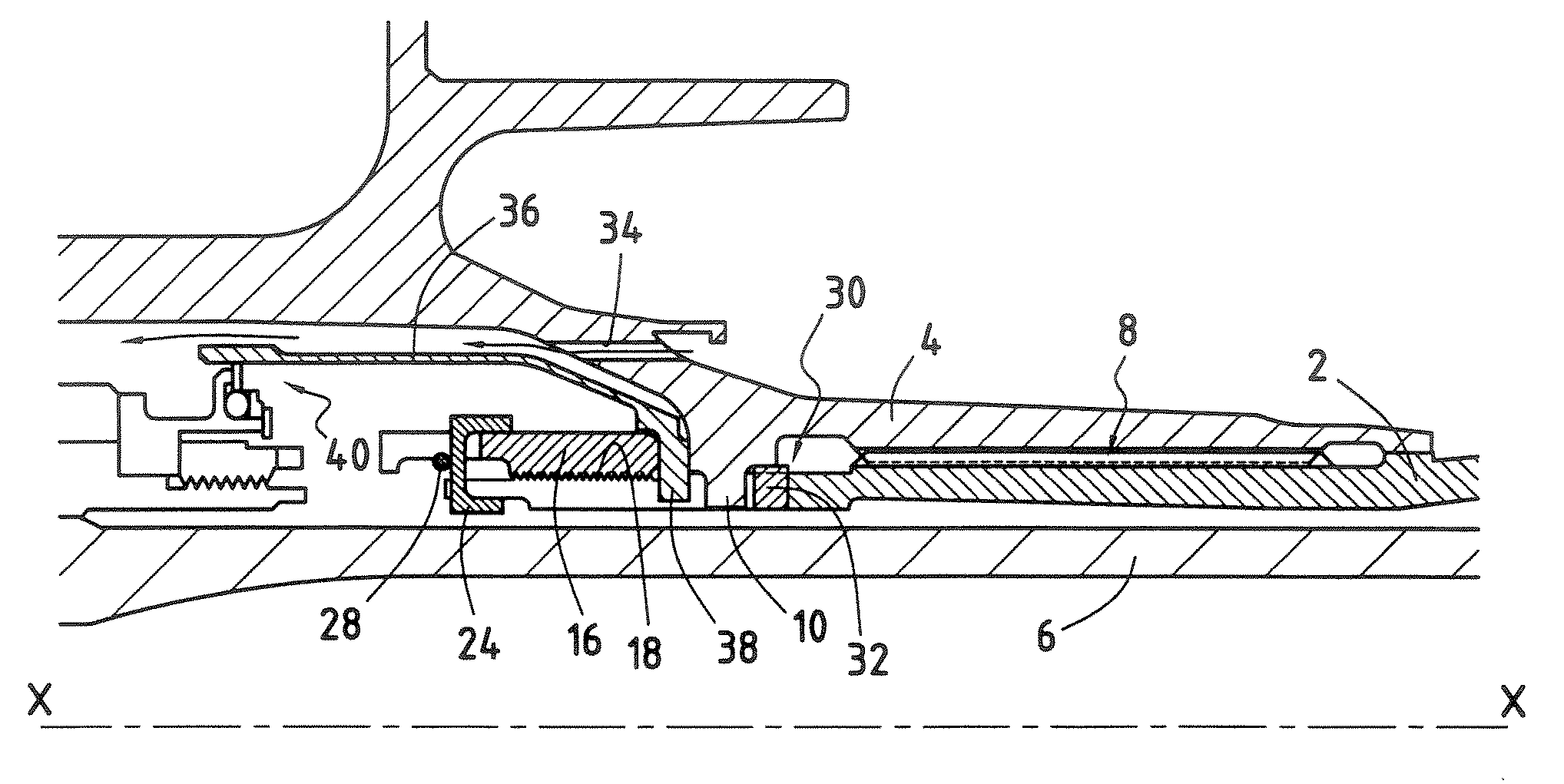

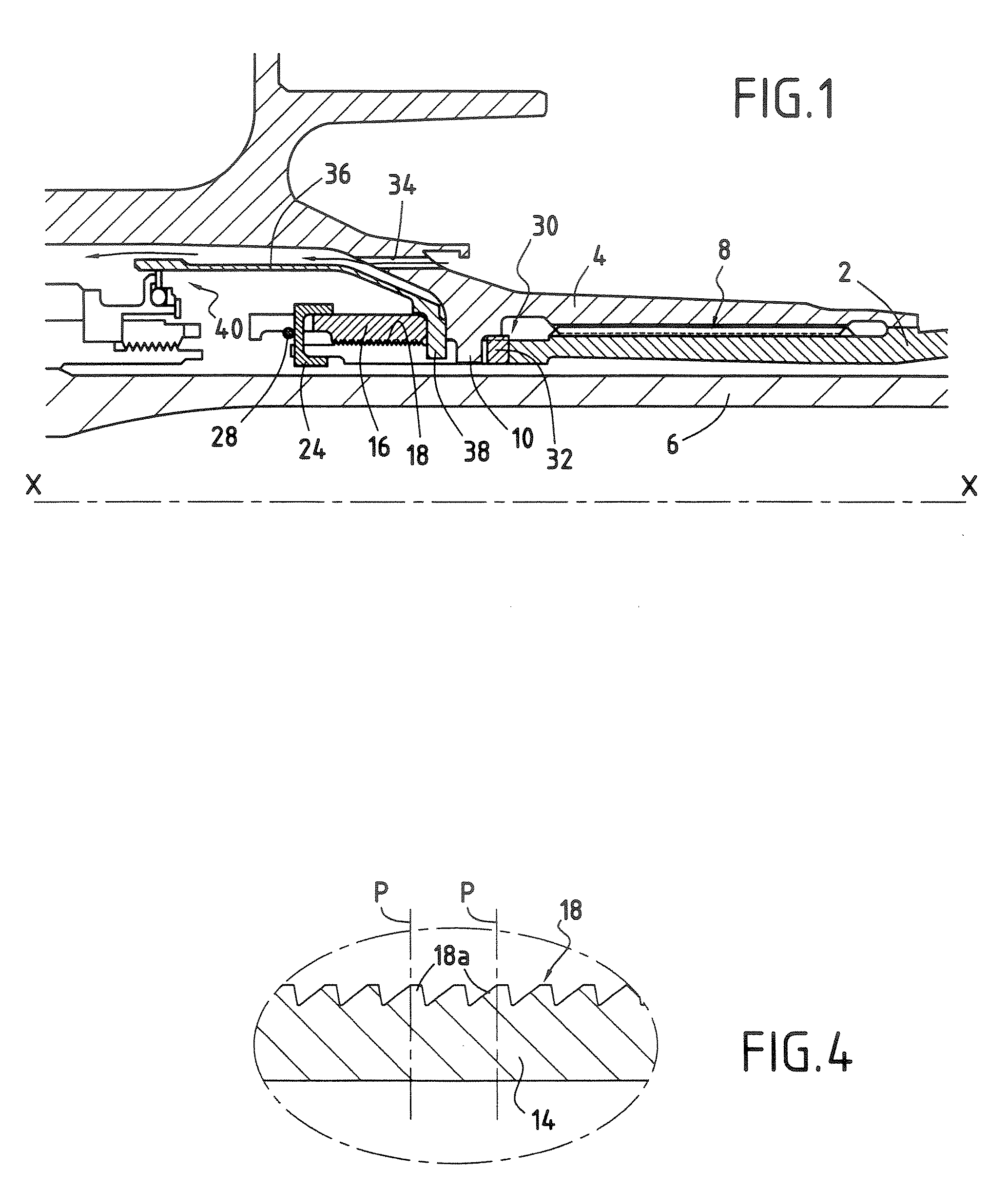

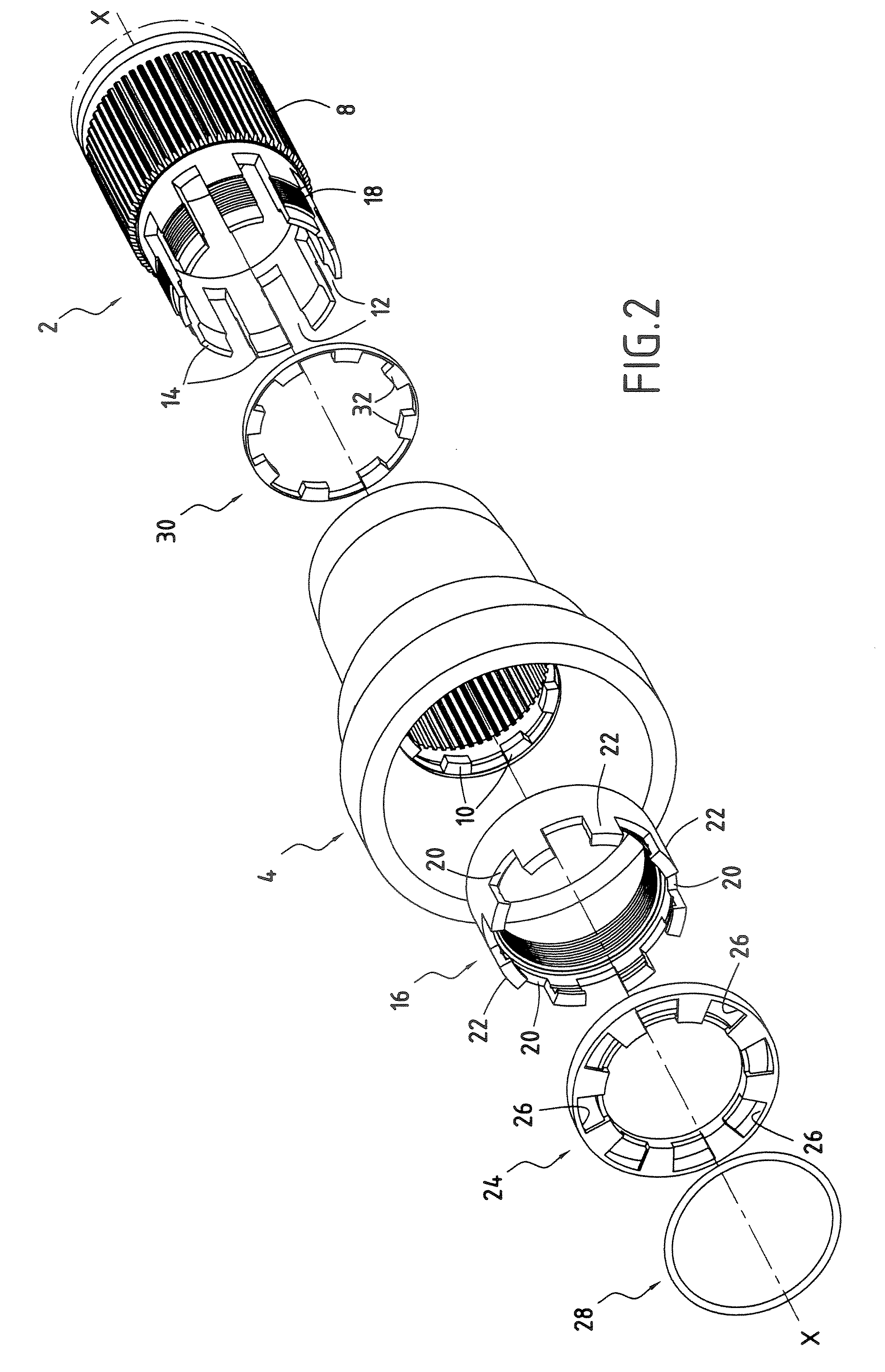

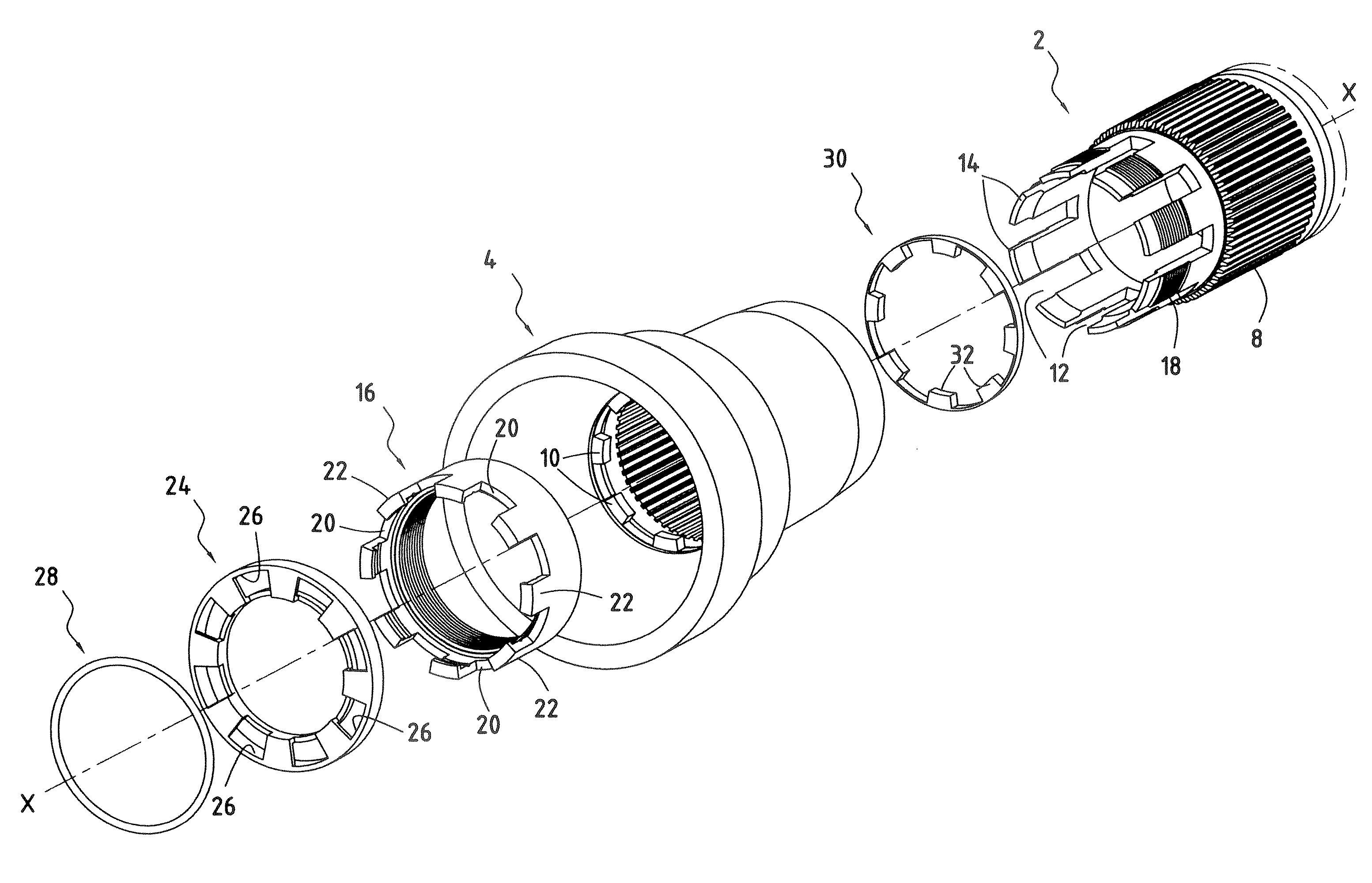

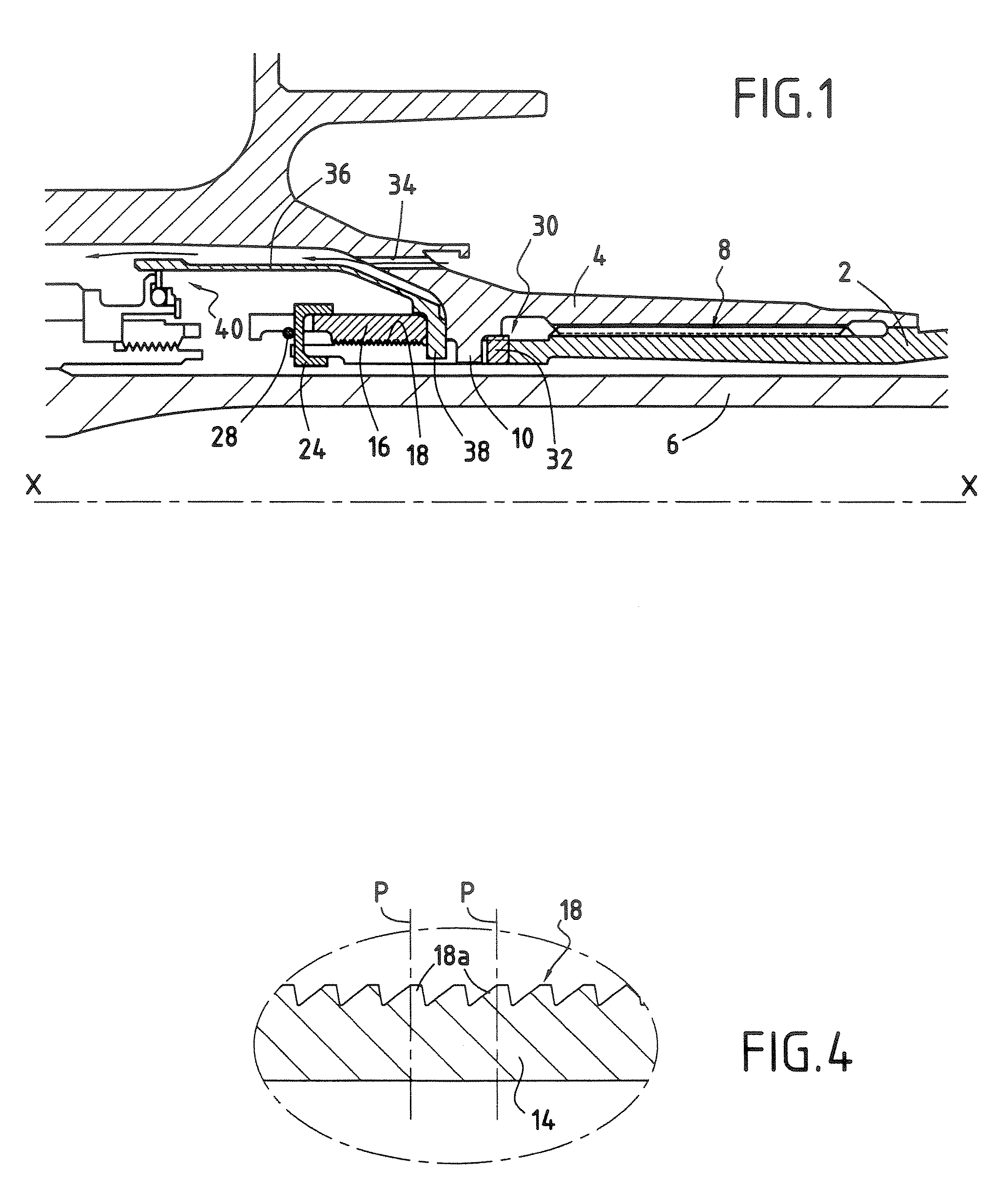

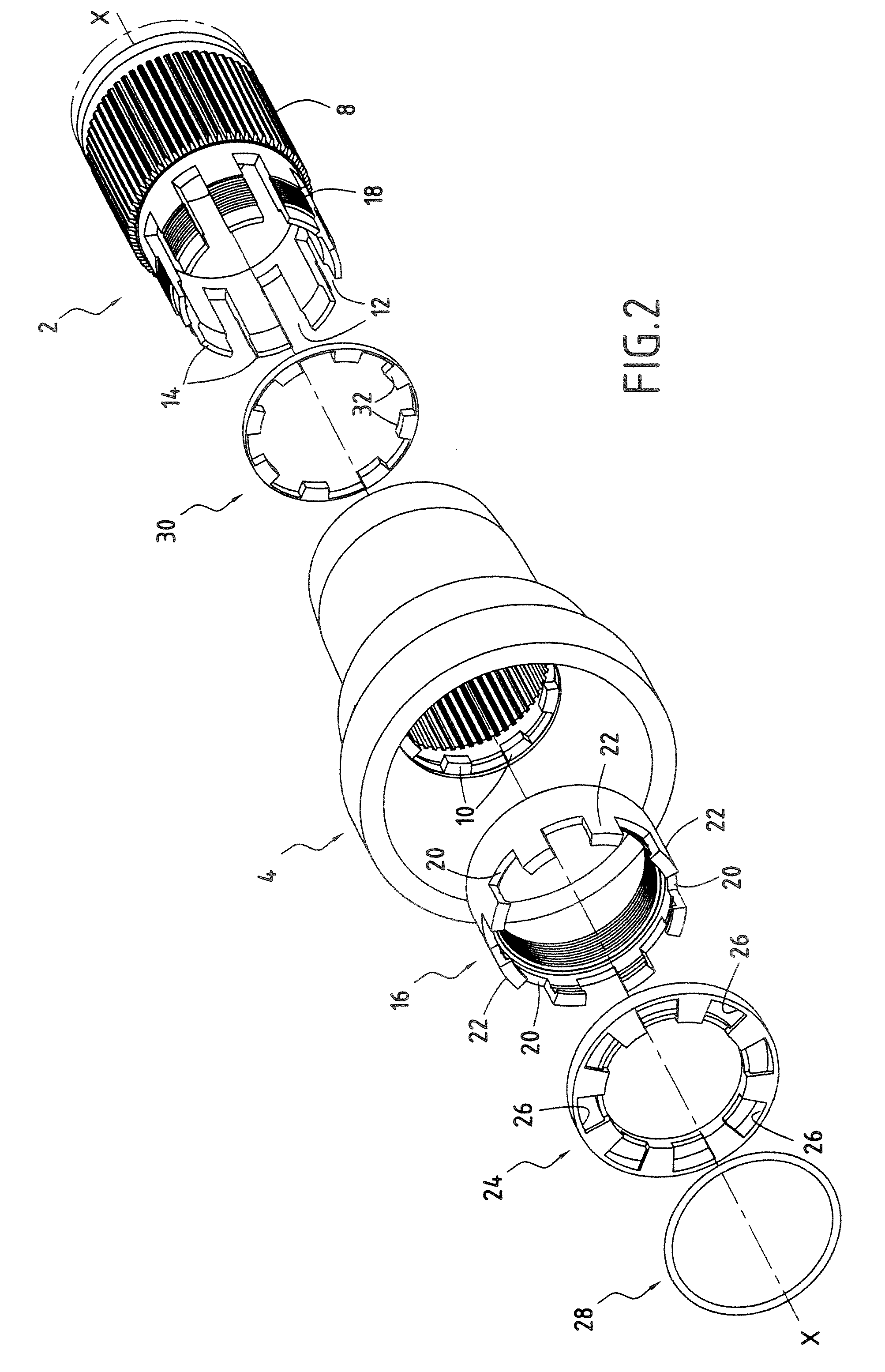

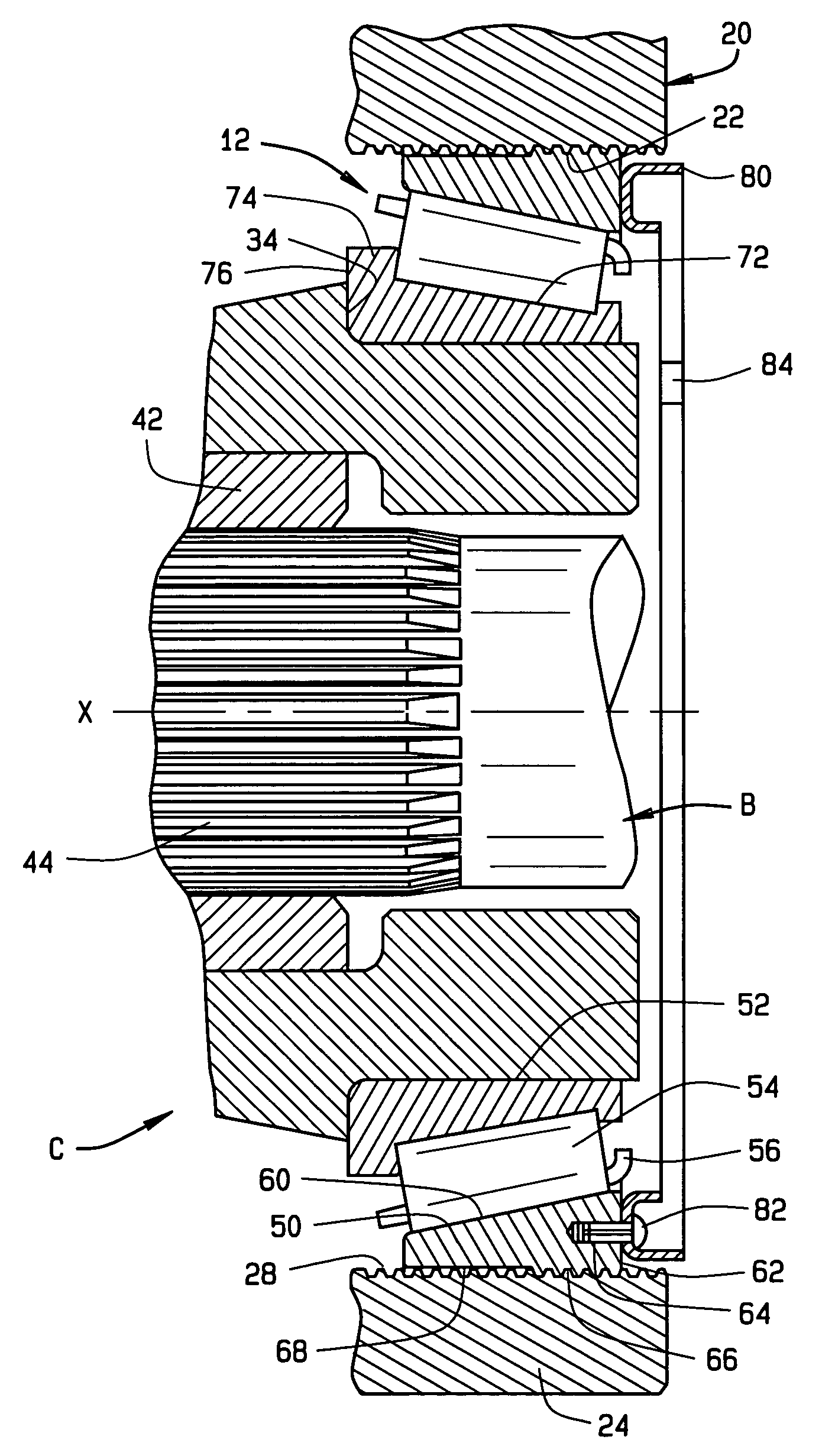

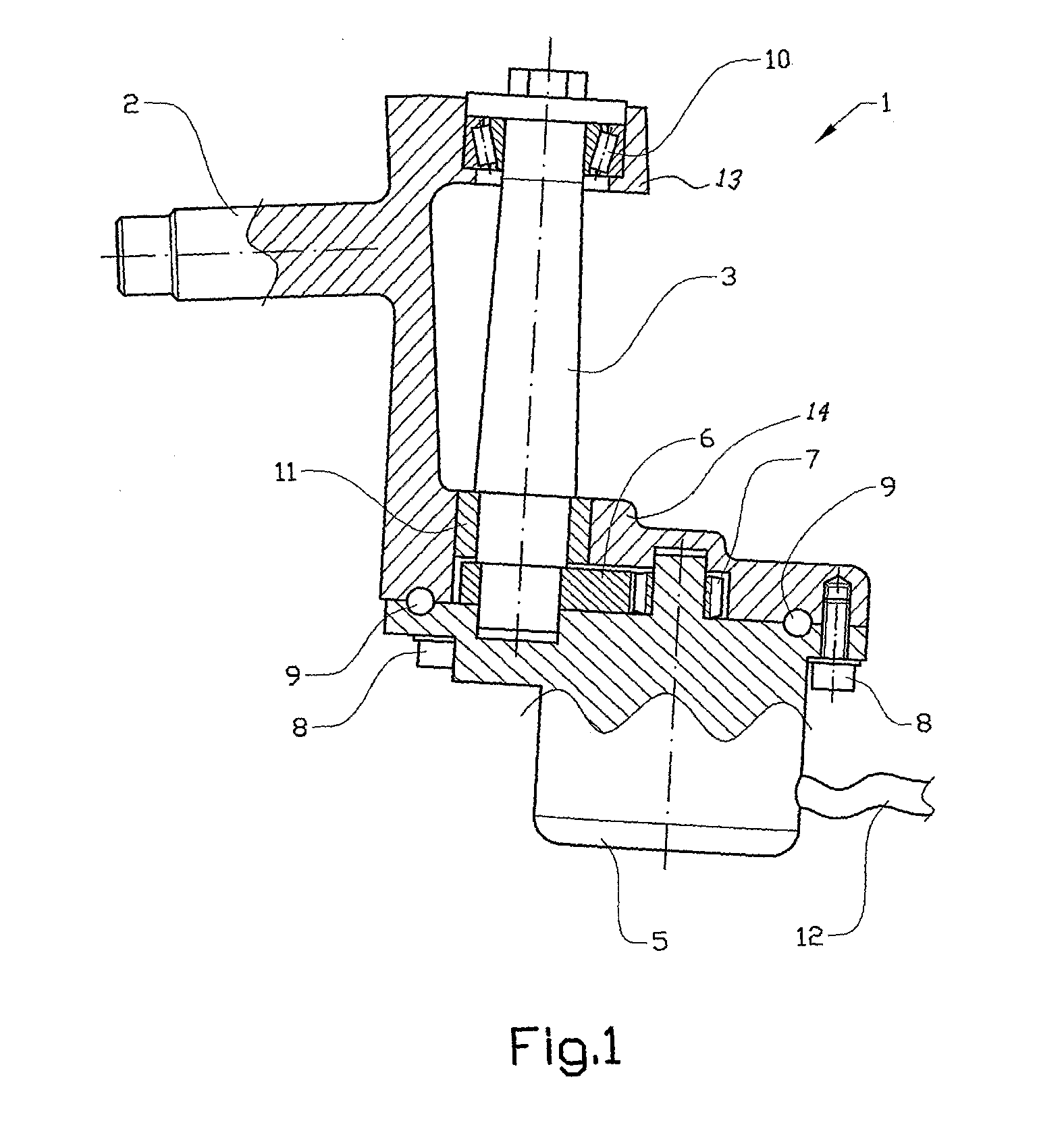

Radially-compact assembly between a turbine shaft and a stub axle of a turbomachine compressor shaft

ActiveUS20070212226A1Mitigate such drawbackEasy to operateEngine manufacturePump componentsStub axleEngineering

The invention relates to an assembly between a turbine shaft and a stub axle of a turbomachine compressor shaft, the assembly comprising a substantially cylindrical compressor shaft stub axle, a substantially cylindrical turbine shaft disposed coaxially inside the compressor shaft stub axle, means for transmitting torque between the turbine shaft and the compressor shaft stub axle, and clamping means for clamping a downstream end of the turbine shaft to the compressor shaft stub axle. The compressor shaft stub axle has a plurality of teeth extending radially from its inside surface, and the turbine shaft is provided at its downstream end with a plurality of axial slots, the teeth of the stub axle co-operating with the slots of the turbine shaft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Radially-compact assembly between a turbine shaft and a stub axle of a turbomachine compressor shaft

ActiveUS7811052B2Mitigate such drawbackEasy to operateEngine manufactureEngine fuctionsStub axleEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

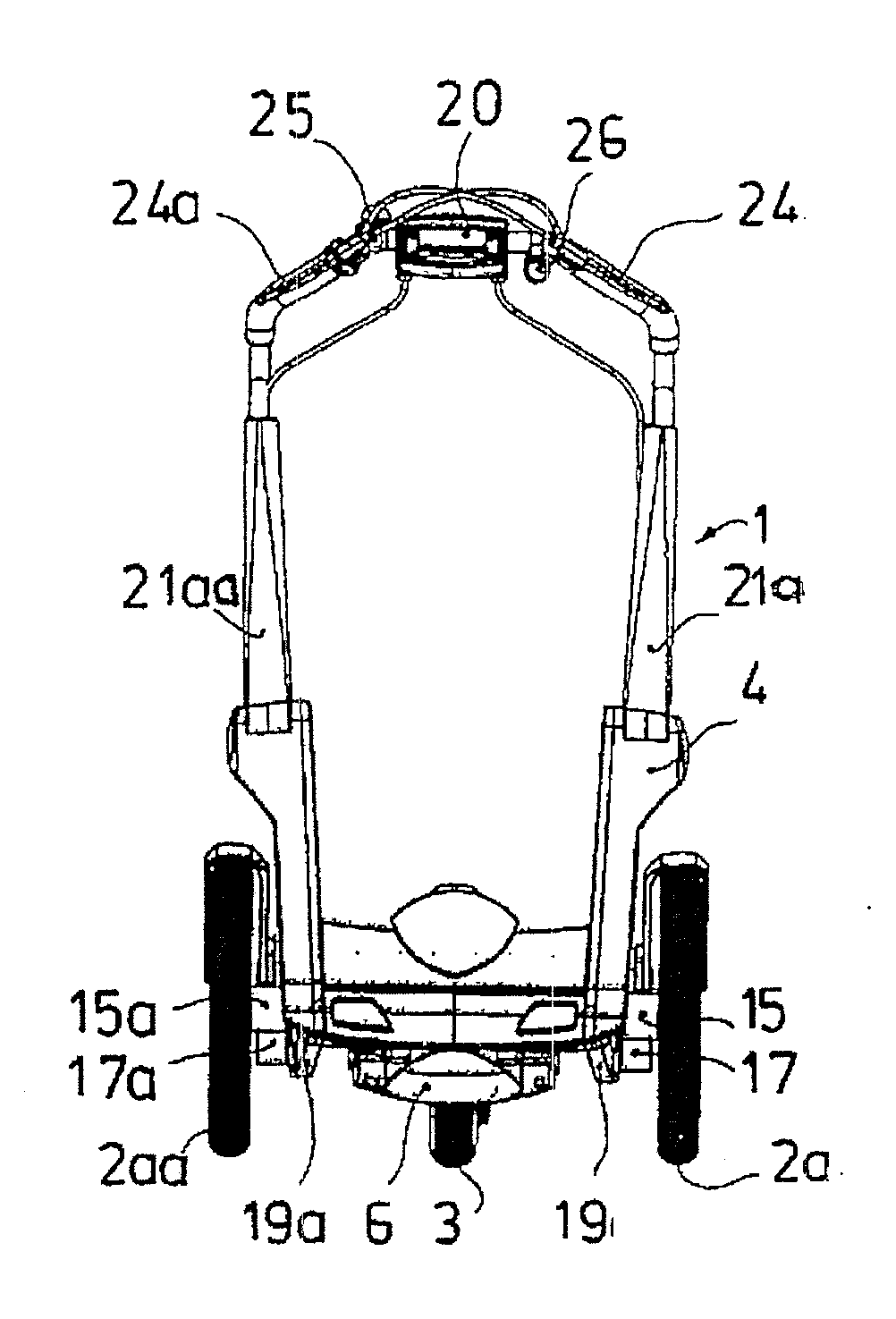

Load and/or transport cart

InactiveUS20130153322A1Optimization rangeSmall sizePassenger cyclesCarriage/perambulator accessoriesSteering angleStub axle

A load and transport cart includes, under a loading platform, a triangular steering plate and, therebelow, a front part of a footboard, wherein the steering plate has a bore, an annular-segment shaped groove, an elongated hole and two opposing first ball heads. The first ball heads each lie in an articulated manner in a respective bearing at one end of a respective steering lever and, at the other end of each lever is a bearing for a respective further ball head of a respective triangular swinging fork on a stub axle of which a respective front wheel is rotatably mounted, wherein each of the swinging forks is rotatably mounted on the loading platform via pivot pins, and wherein the steering axis is located in front of an imaginary axis and can be deflected to the left or right by the steering angle of 45°.

Owner:CONSTIN HANS PETER

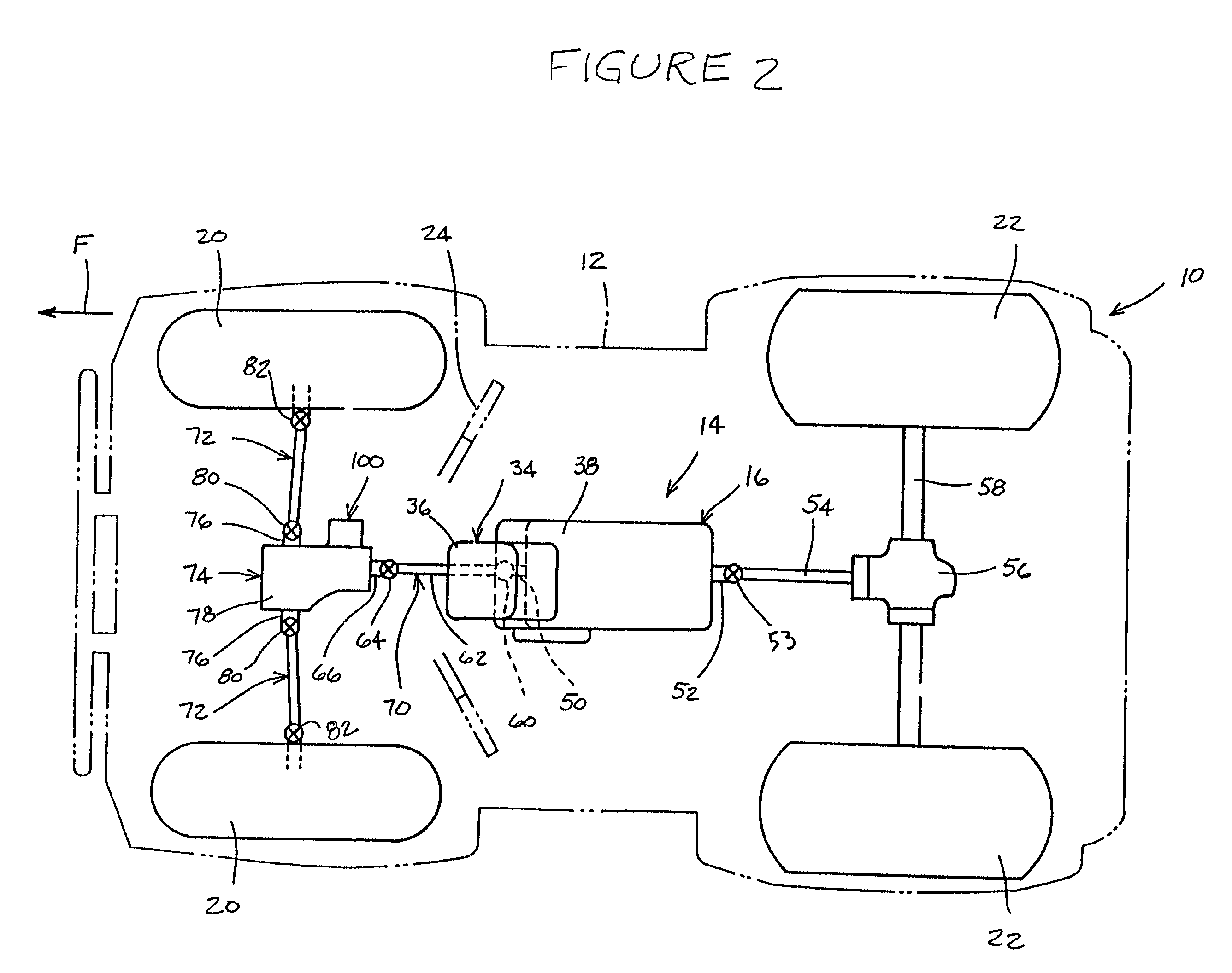

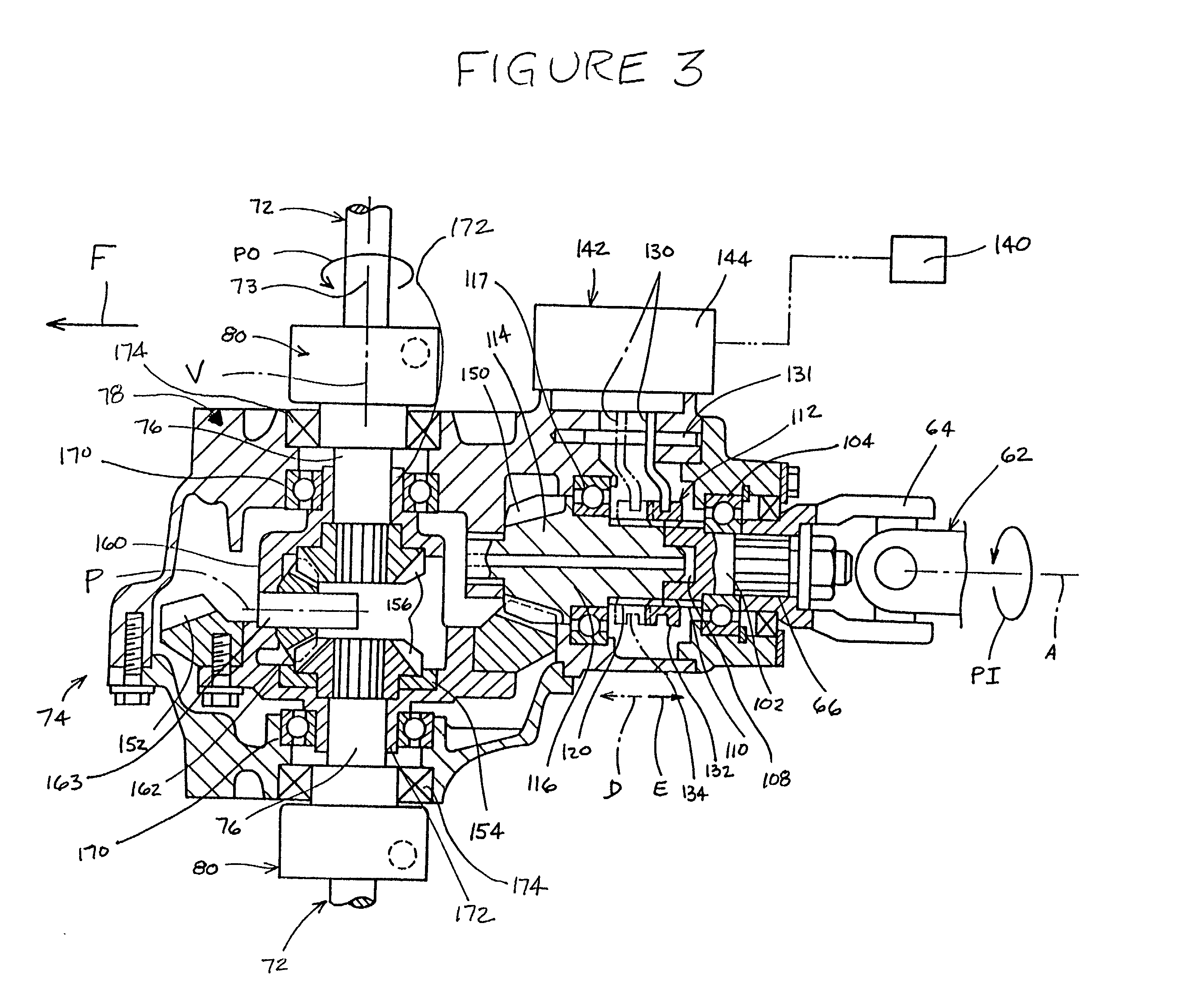

Selective four wheel drive transmission for all-terrain vehicle

An all-terrain vehicle has a selectively engageable four wheel drive system. The system has dedicated rear wheel drive and selectively engageable front wheel drive. The front wheel drive is engaged within the differential housing. A differential input shaft extends into the differential housing. A stub shaft is journaled for rotation within the housing. A sleeve slides relative to the two shafts and couples the two through a coupling configuration. The coupling configuration results from the externally splined ends of the two shafts and the internally splined surface of the sleeve. The positioning of the sleeve is controlled by a shift fork. The shift fork is moved by an actuator in response to a signal produced by a control unit. A switch allows an operator to instruct the control unit when to engage and disengage the front wheel drive system.

Owner:YAMAHA MOTOR CO LTD

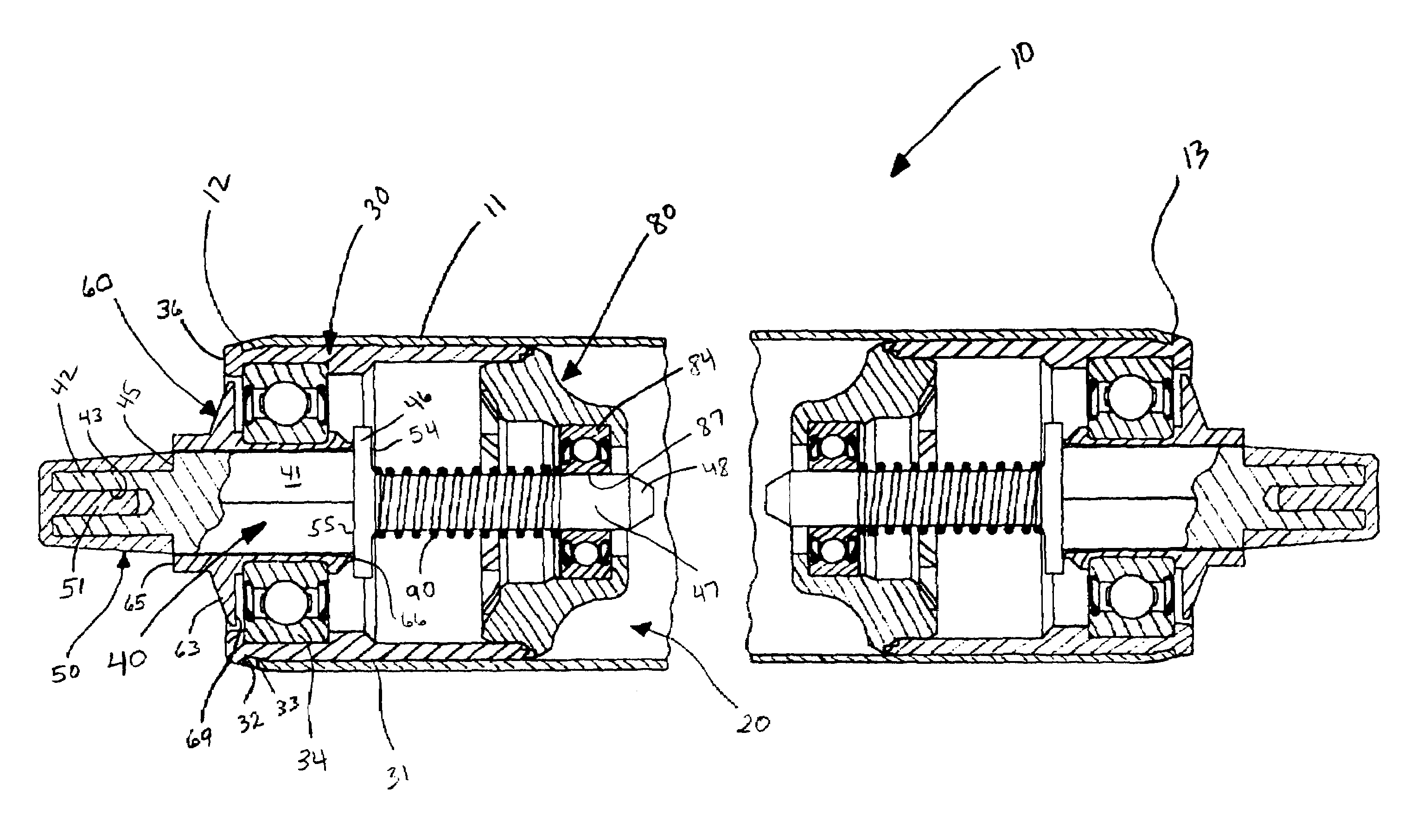

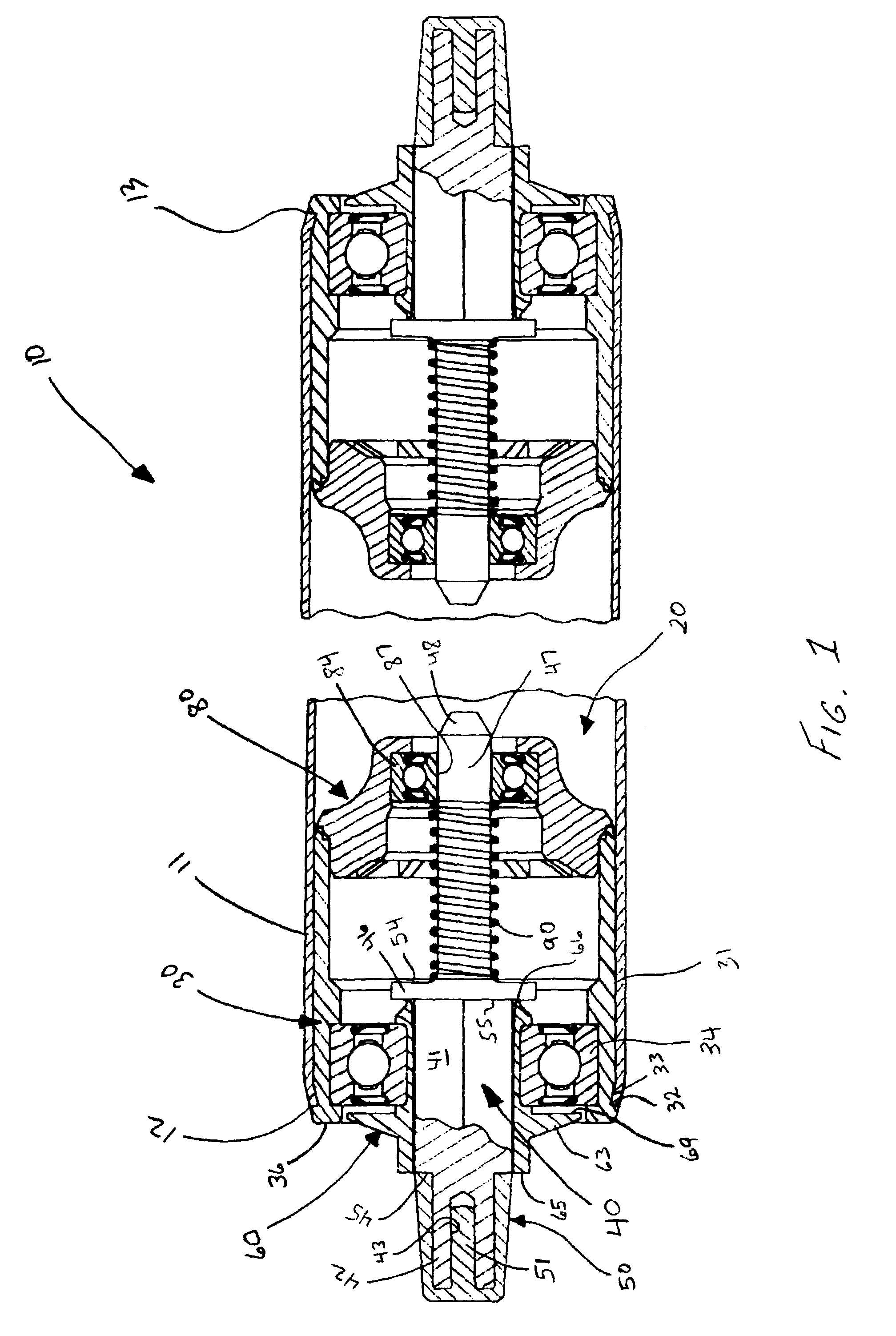

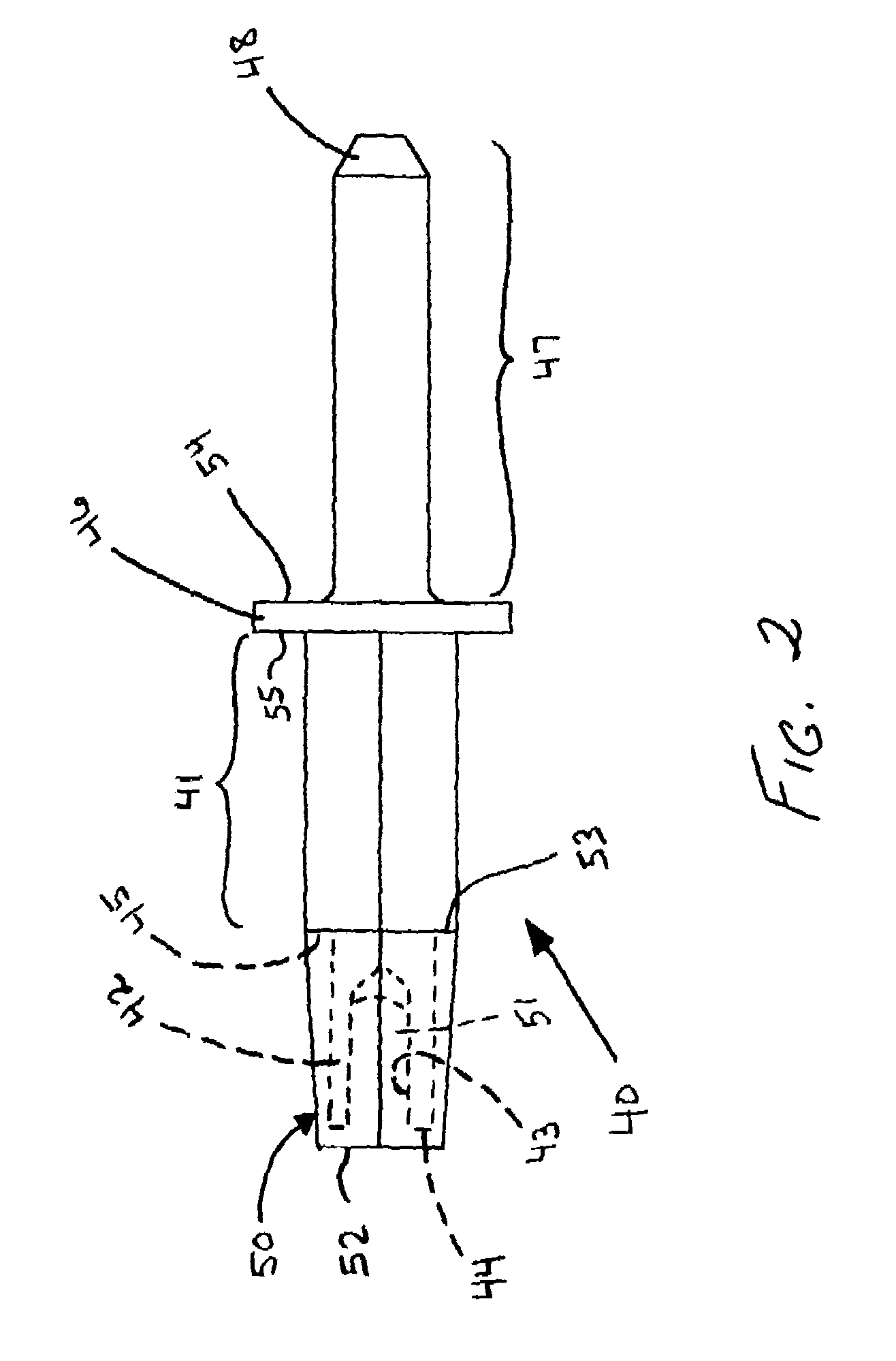

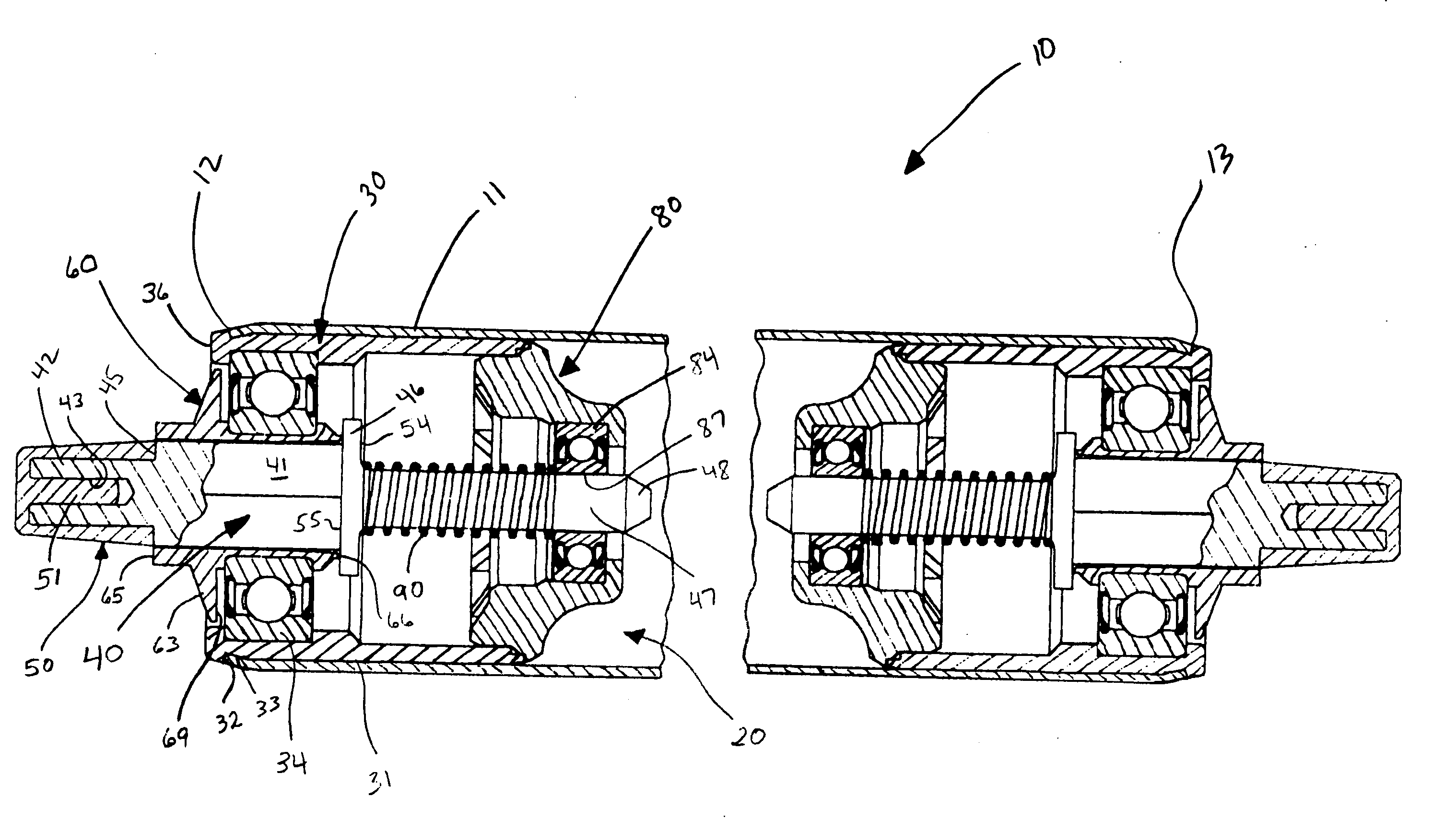

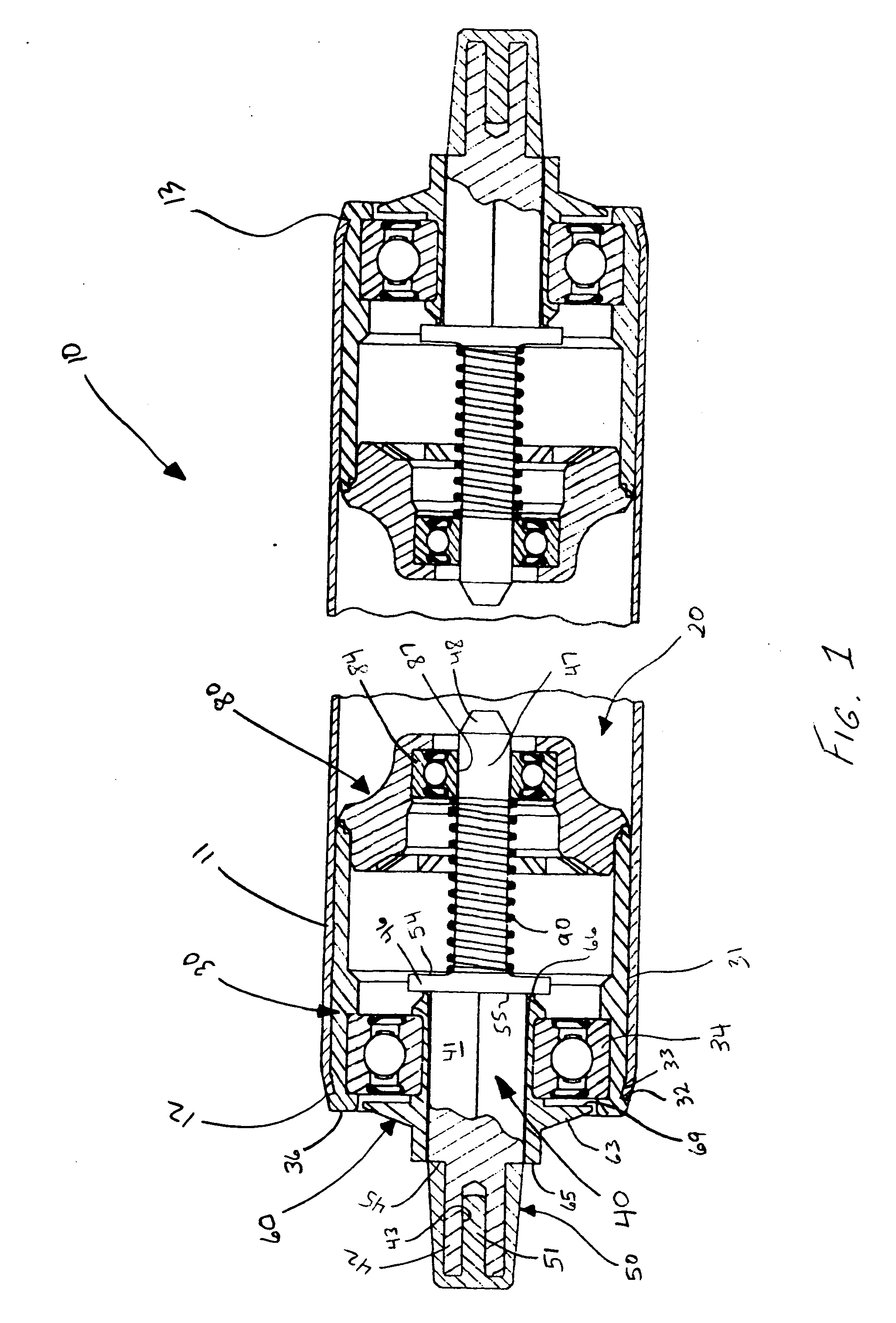

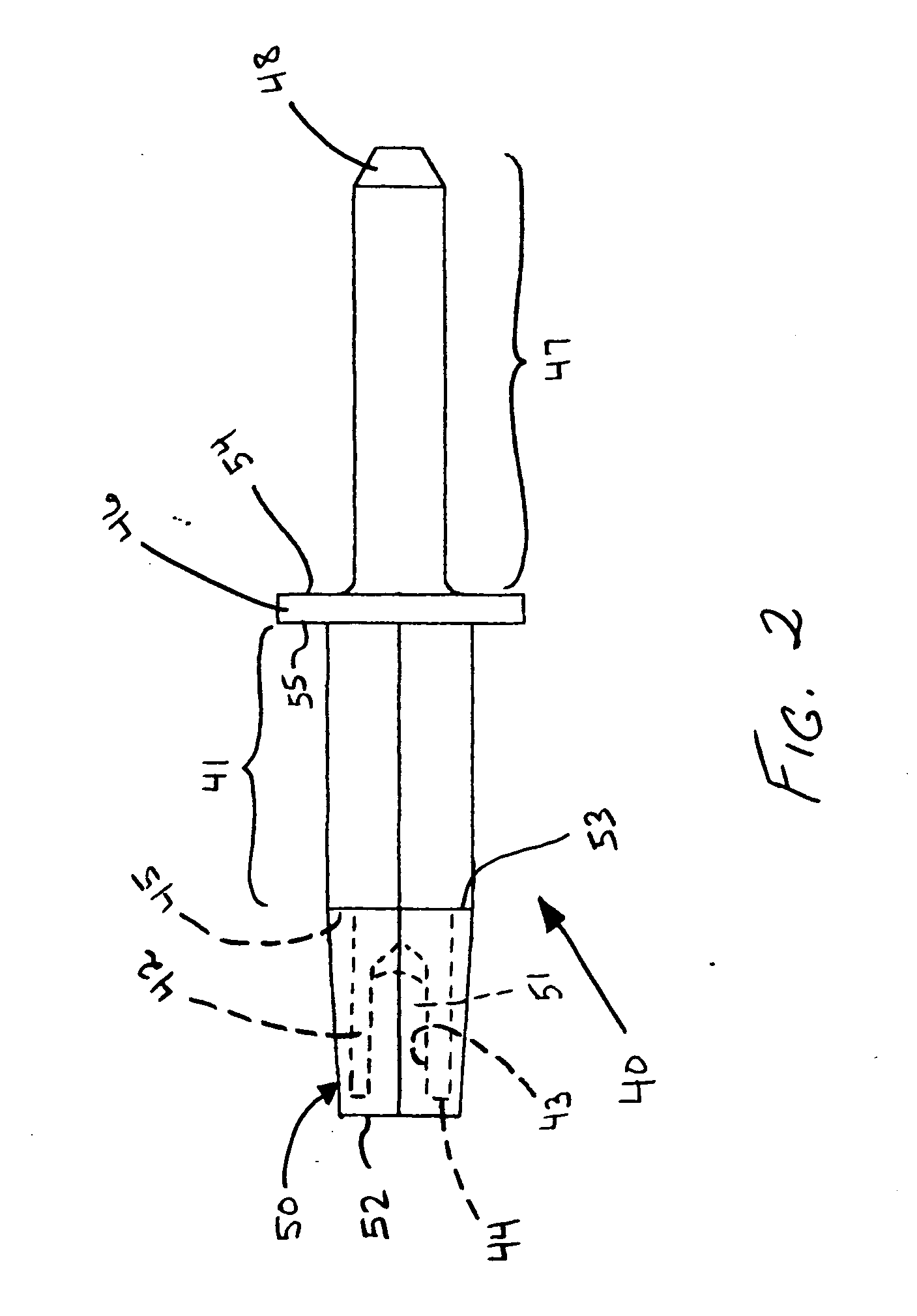

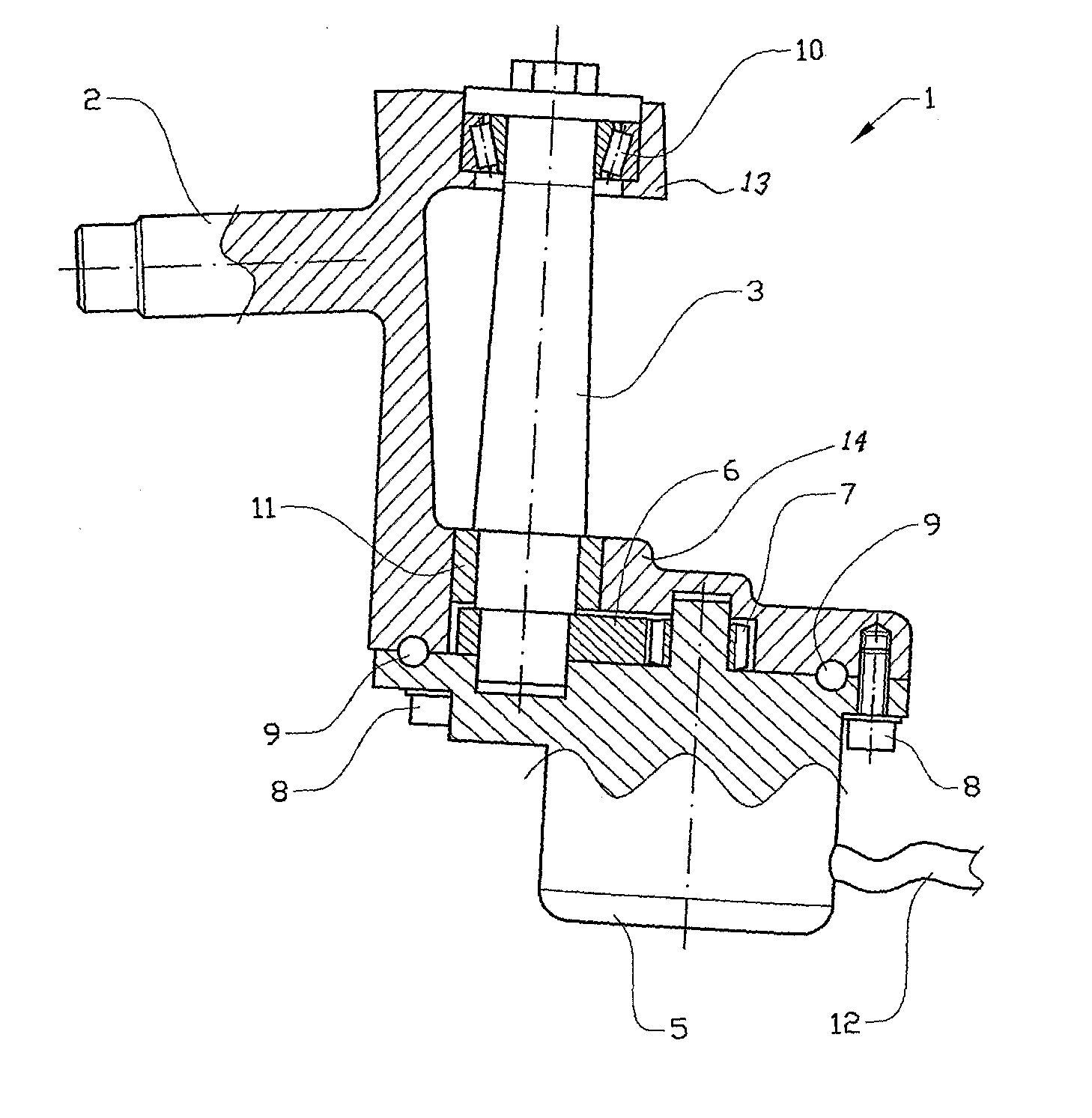

Conveyor roller assembly, conveyor roller insert and axle for conveyor roller

A roller insert for a conveyor roller tube including a cartridge having inner and outer ends and configured to be inserted into an end of a conveyor roller tube; a stub axle positioned within the cartridge, the stub axle including an elongate body portion, a cylindrical tip portion extending away from the body portion, and an end cap having distal and proximal ends and a hardness less than that of the tip portion, the end cap threadingly secured on the cylindrical tip portion; and at least one bearing mounted within the cartridge and supporting the axle such that the cartridge is rotatable with respect to the axle and the axle is slidable with respect to the bearing; wherein the axle is biased outwardly from the cartridge such that the end cap projects outwardly from the cartridge outer end. A conveyor roller and an axle for a conveyor roller are also provided.

Owner:SST CONVEYOR COMPONENTS INC

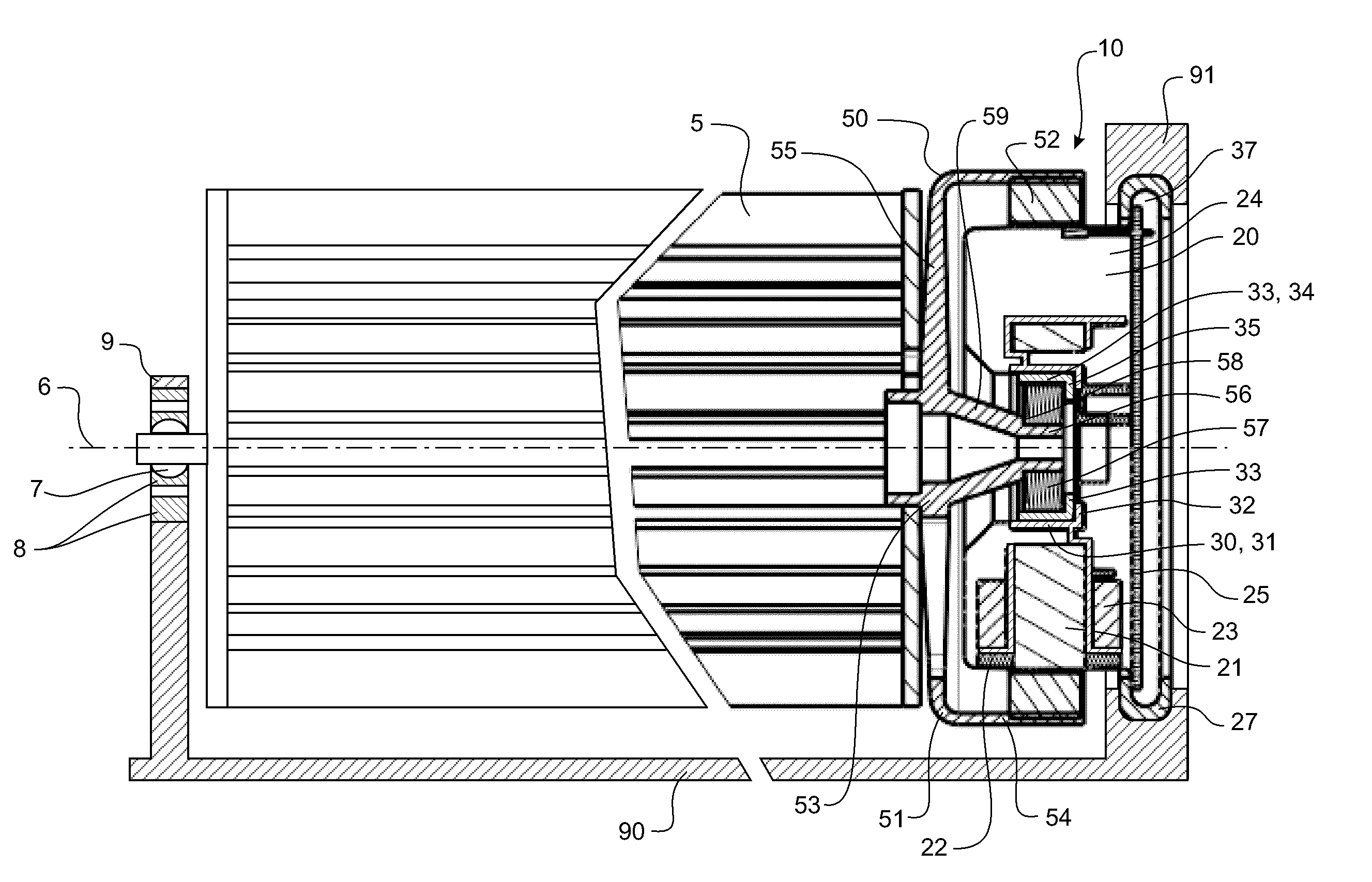

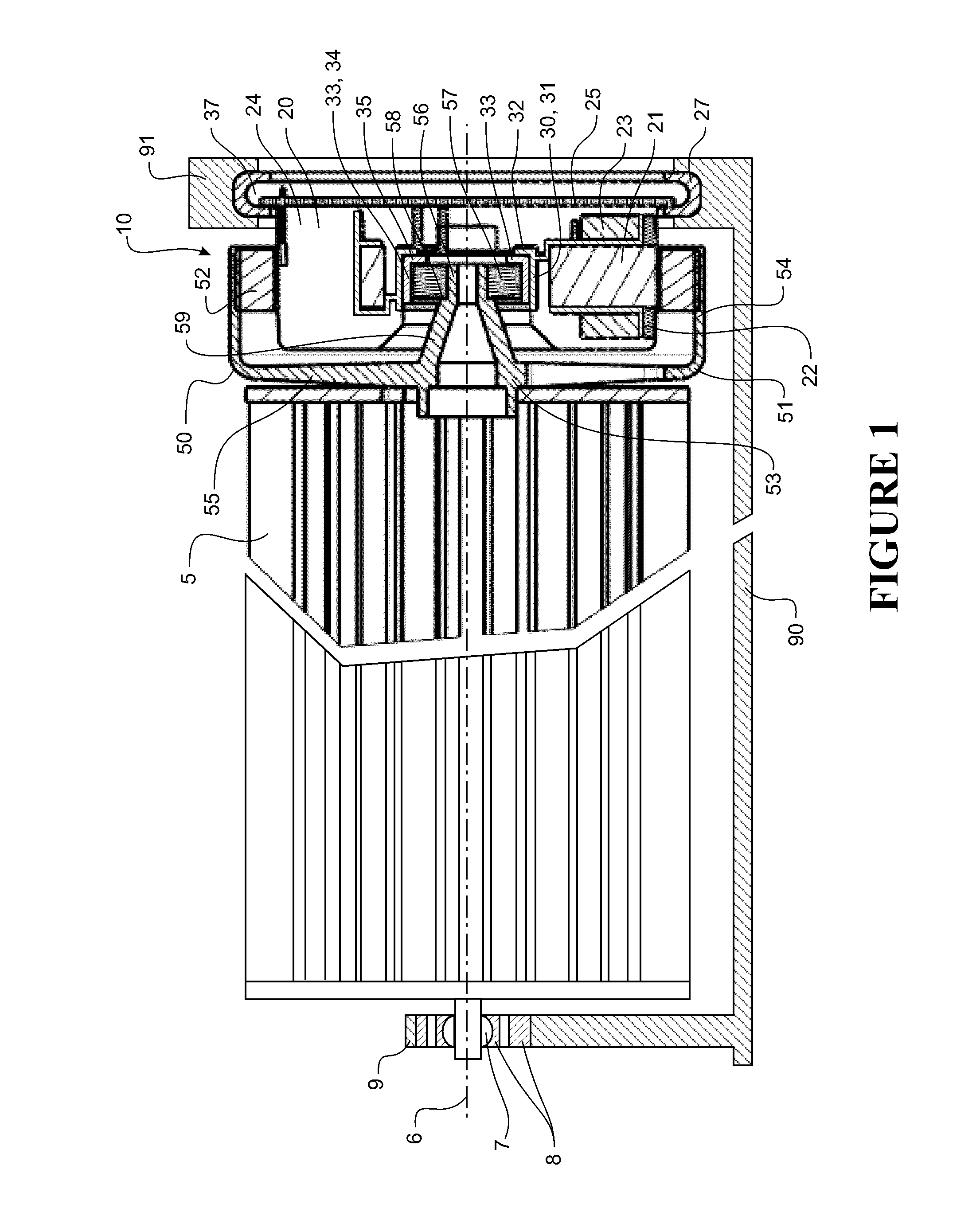

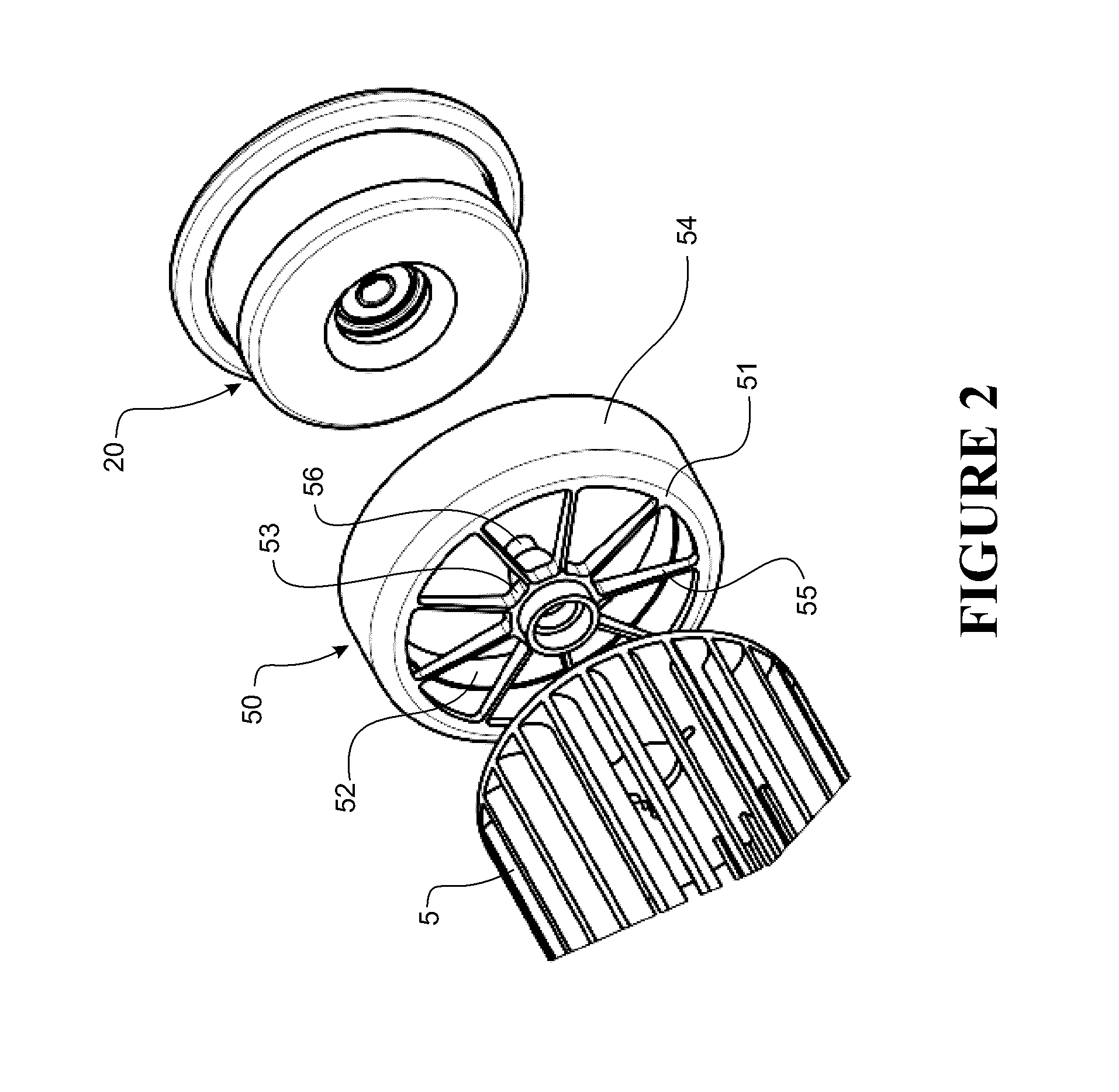

Motor

A BLDC motor for driving a cross flow fan in an air-conditioning application has an external rotor and an internal stator. The stator is a salient pole stator with insulated pole teeth and conductor coils. The inner diameter of the stator supports a single bearing. An electronic PCBA for control of the BLDC motor is optionally attached to the stator, all of which is encapsulated in a thermoset resin. The rotor comprises permanent magnet component(s) and a rotor frame. The rotor frame includes a stub axle that engages with the bearing element and features to provide torsional or rotational compliance between the rotor magnets and the fan. A level of compliance is provided between the bearing element and the stator to allow for angular misalignment between the rotational axis of the fan and the stator.

Owner:FISHER & PAYKEL APPLIANCES LTD

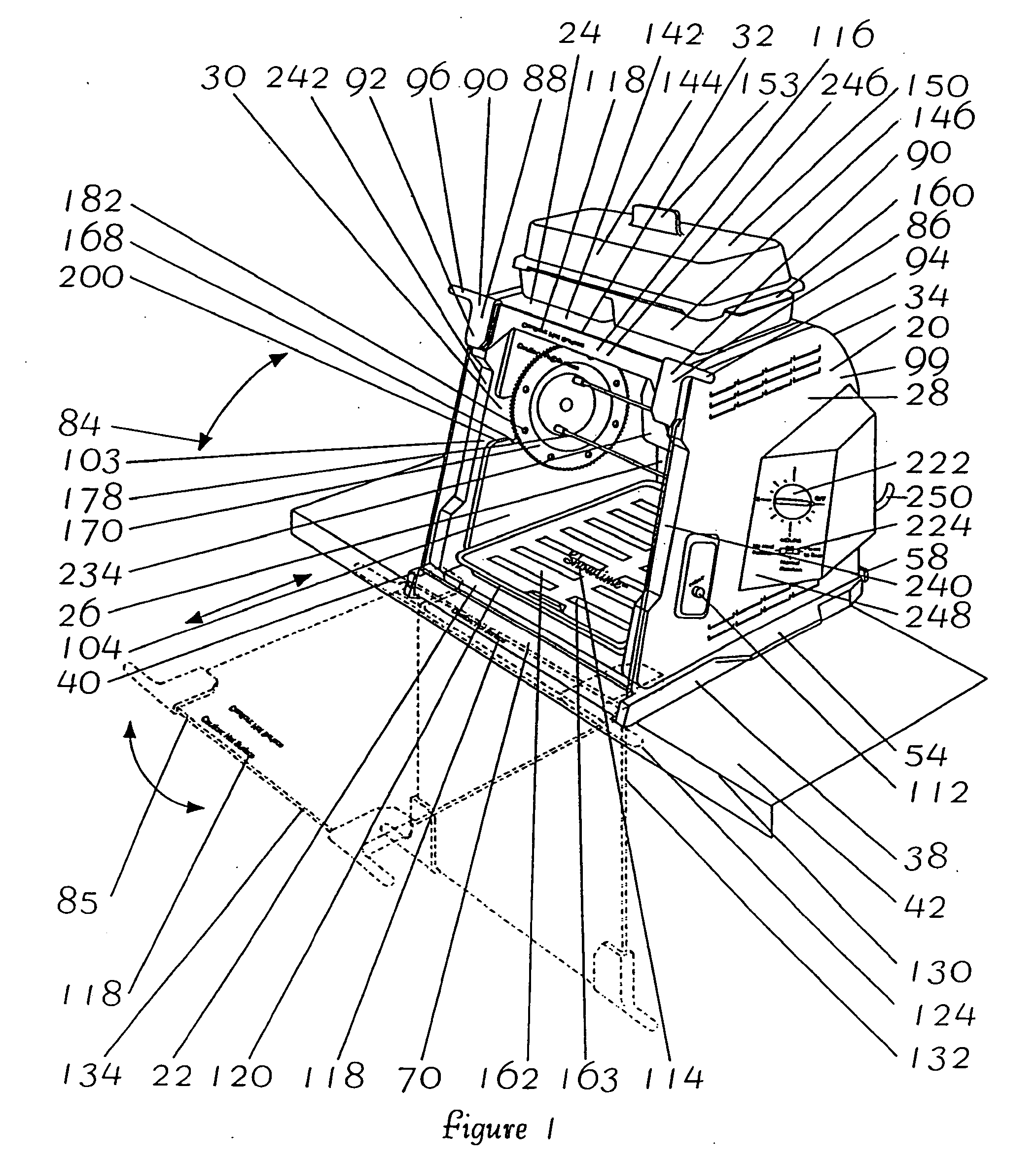

Spit assembly support base

InactiveUS20050284306A1Easy to insertEasy to removeMeat processingFood shapingCircular coneStub axle

A support base for supporting the spit assembly of a rotisserie oven. The support base includes a substantially circular-shaped member having a periphery and an indented portion defined therein. The indented portion has a frustum-conical shape and extends downwardly into the substantially circular-shaped member, and the substantially circular-shaped member has an opening for receiving the stub axle of a spit assembly defined therein.

Owner:RONCO HLDG

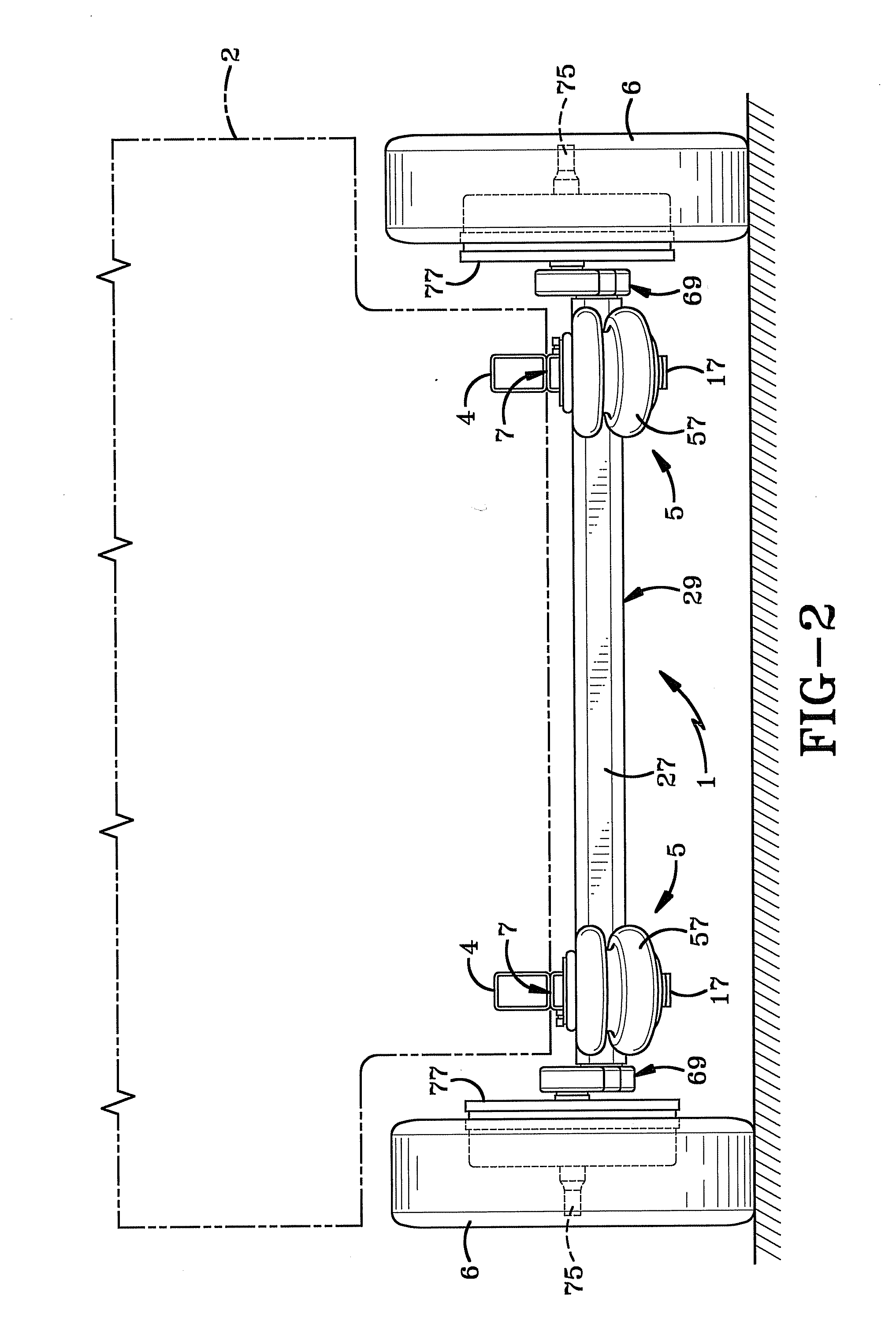

Suspension assembly

A vehicle suspension system includes a pair of suspension assemblies mounted on a pair of spaced vehicle frame members for supporting a vehicle body on the vehicle wheels. A torsion axle extends between the pair of suspension assemblies and terminates in a pair of stub shafts. The axle is mounted on a pair of spaced frame brackets attached to the vehicle frame. An air spring extends between the vehicle frame and an outer end of a support arm pivotally mounted on each end of the torsion axle. The stub shafts are supported within an outer tube of the torsion axle by a plurality of elastomeric members. One end of each stub shaft is connected to a spindle arm which has a spindle extending from an opposite end of the arm. The length of the air spring support arm and the distances between the pivot axis of the support arm and the axis of the spindle and torsion axle are chosen so that the surface of the air spring is always out of contact with the mounting bracket and has a portion inboard between the axis of the spindle and axis of the torsion axle.

Owner:TRANSPORTATION TECH

Bearing arrangement for a vehicle differential

A vehicle differential includes a housing having bearing seats and a carrier provided with stub shafts which project into the bearing seats. The carrier is supported in the housing on two single row tapered roller bearings which allow the carrier to rotate, but confine it radially and axially. The housing also contains a beveled pinion which meshes with a beveled ring gear that is attached to the carrier. The two bearings are mounted in opposition and each includes a cup that is located in the bearing seat for that bearing, a cone that fits around the stub axle that projects into that bearing seat, and tapered rollers located between the cup and cone. Each bearing seat contains an internal thread and the bearing cup which fits into the seat has an external thread that engages the internal thread. Each cup also carries a locking ring which is engaged by an adjustment tool to turn the cup, but is later deformed into the housing to secure the cup against rotation. By rotating the cups in their bearing seats, one can adjust the setting of the bearings and the mesh setting of the pinion and ring gear.

Owner:THE TIMKEN CO

Vehicle, method and steering system for vehicle

InactiveUS20060266574A1Easy to adaptEasy to installSteering linkagesFluid steeringStub axlePower unit

A vehicle, method and steering system for a vehicle in which the steering system includes a stub axle articulated on a king pin. The king pin is configured to be fixed to an element spring suspension-mounted in the vehicle. The steering system includes at least one power unit fixed to the stub axle, and the power unit transmits a torque to the king pin.

Owner:VOLVO LASTVAGNAR AB

Suspension assembly

ActiveUS20090278329A1Easy rideImprove stabilitySpringsInterconnection systemsVehicle frameAir spring

A vehicle suspension system includes a pair of suspension assemblies mounted on a pair of spaced vehicle frame members for supporting a vehicle body on the vehicle wheels. A torsion axle extends between the pair of suspension assemblies and terminates in a pair of stub shafts. The axle is mounted on a pair of spaced frame brackets attached to the vehicle frame. An air spring extends between the vehicle frame and an outer end of a support arm pivotally mounted on each end of the torsion axle. The stub shafts are supported within an outer tube of the torsion axle by a plurality of elastomeric members. One end of each stub shaft is connected to a spindle arm which has a spindle extending from an opposite end of the arm. The length of the air spring support arm and the distances between the pivot axis of the support arm and the axii of the spindle and torsion axle are chosen so that the surface of the air spring is always out of contact with the mounting bracket and has a portion inboard between the axis of the spindle and axis of the torsion axle.

Owner:TRANSPORTATION TECH

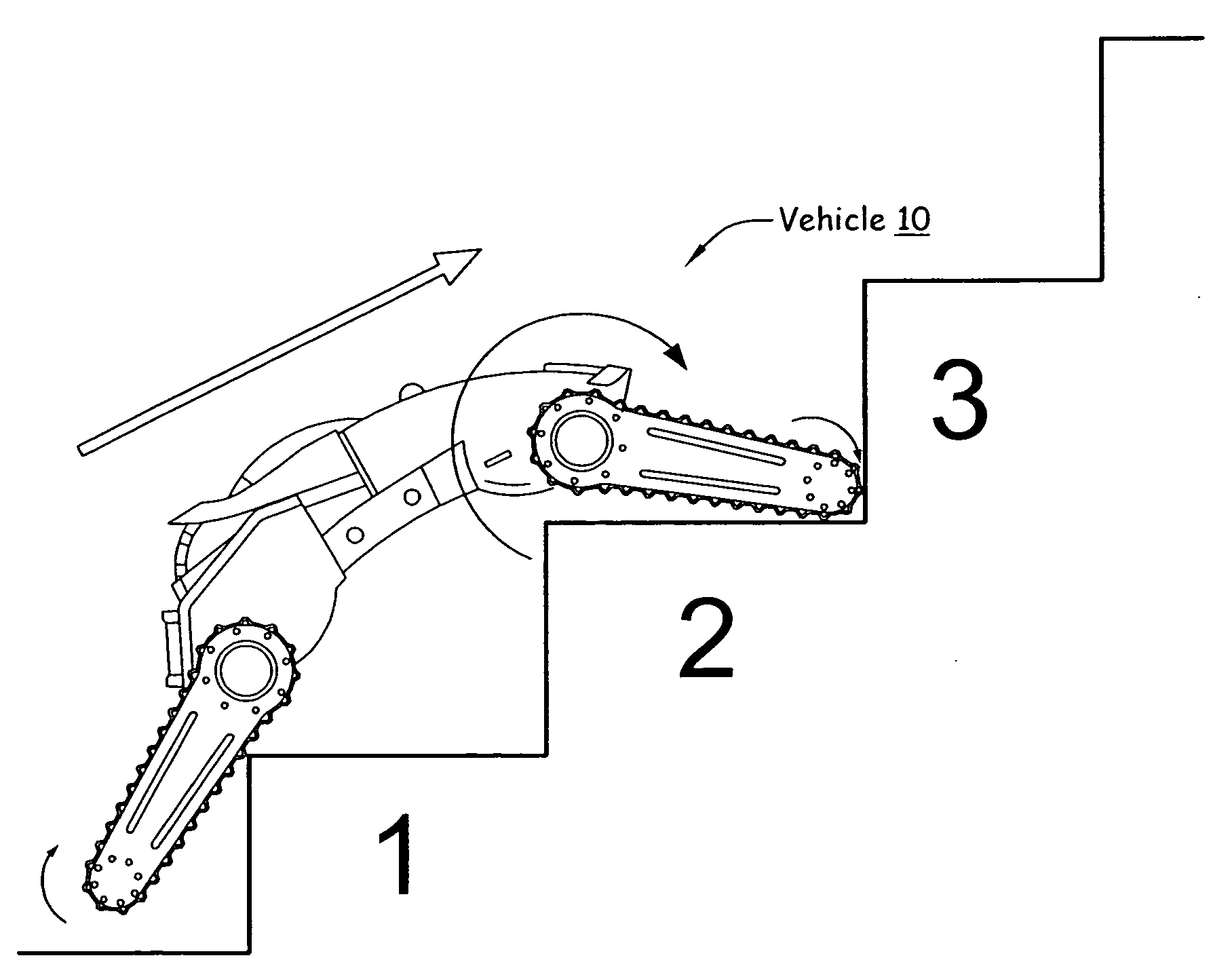

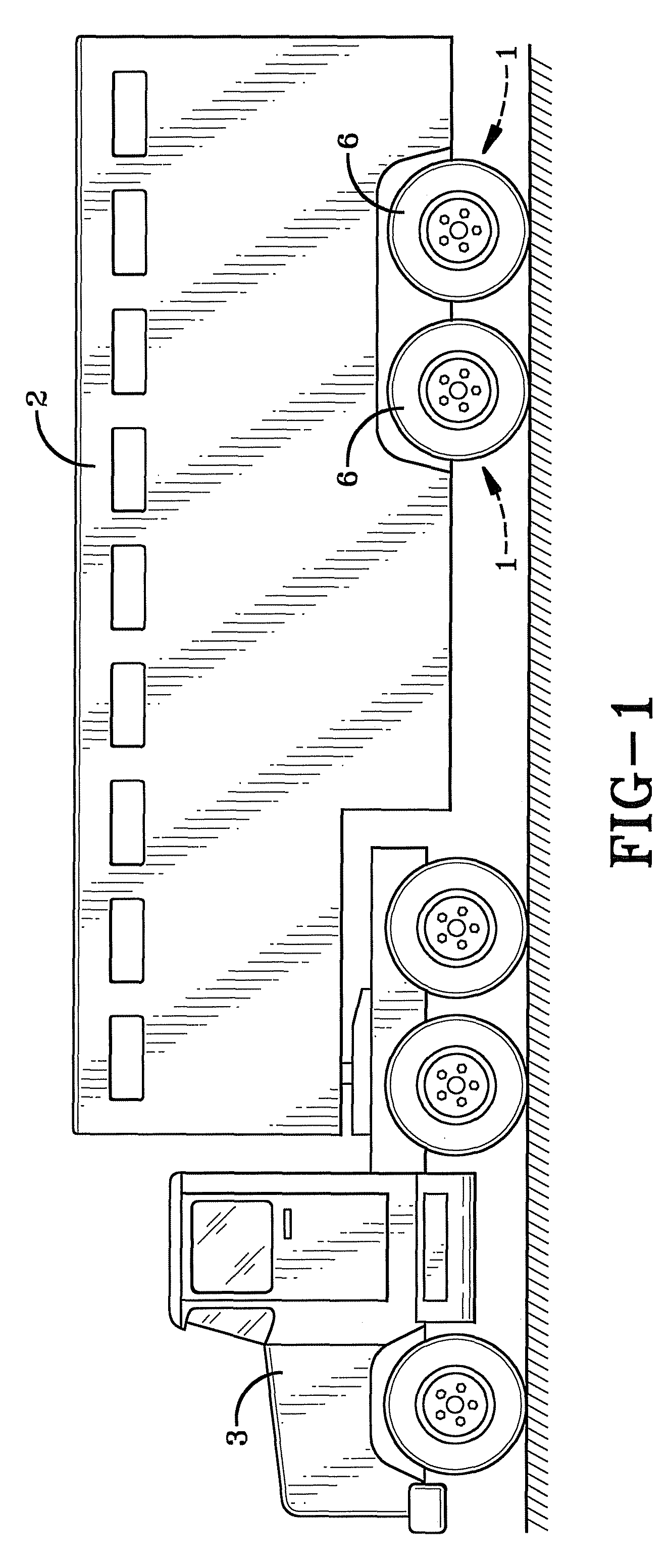

ATV trailer with fully-rotatable suspension

InactiveUS6923475B1Easy to operateProvide protectionTank vehiclesUnderstructuresWater storage tankStub axle

An ATV trailer with fully-rotatable suspension is provided. The ATV trailer is formed of frame members fabricated of square, metal tubing and welded together to form a framework of rails. A downwardly sloping tongue terminates into a ball hitch coupler being mountable to a hitch of a standard ATV. An I-suspension wheel assembly is provided which includes a wheel assembly bracket with a stub axle being adapted to mountably support an I-beam suspension apparatus. The I-beam suspension apparatus includes an I-member being fully rotatable 360° about the stub axle. Spindles are mounted to the I-member for mountably supporting standard ATV wheels. A metal box-like enclosure of walls forming a water-storage tank is mounted atop the frame members.

Owner:MARTIN RICHARD K

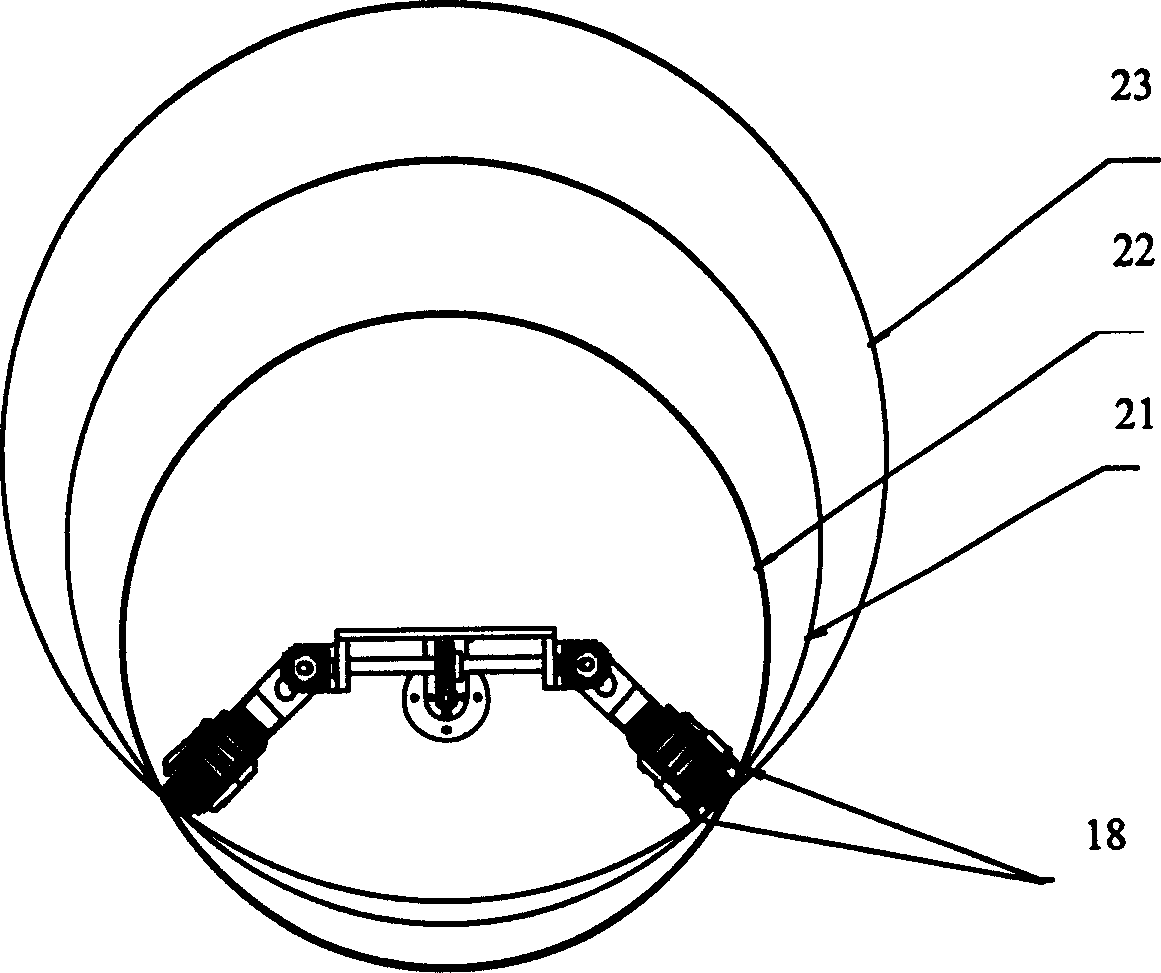

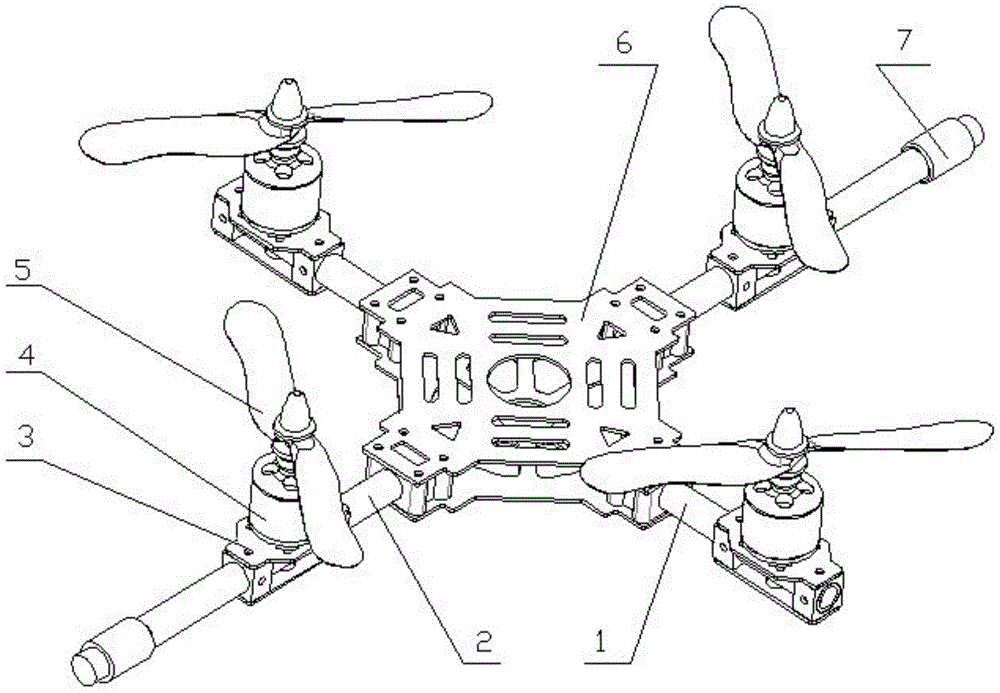

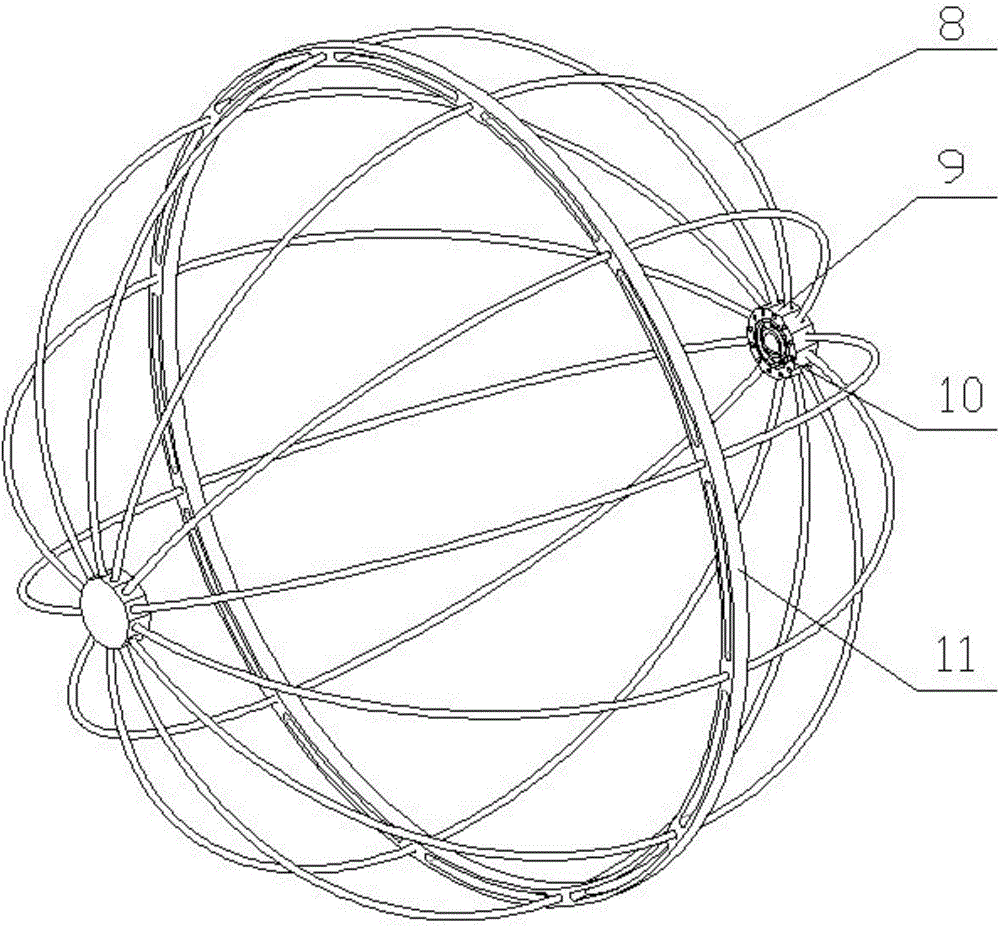

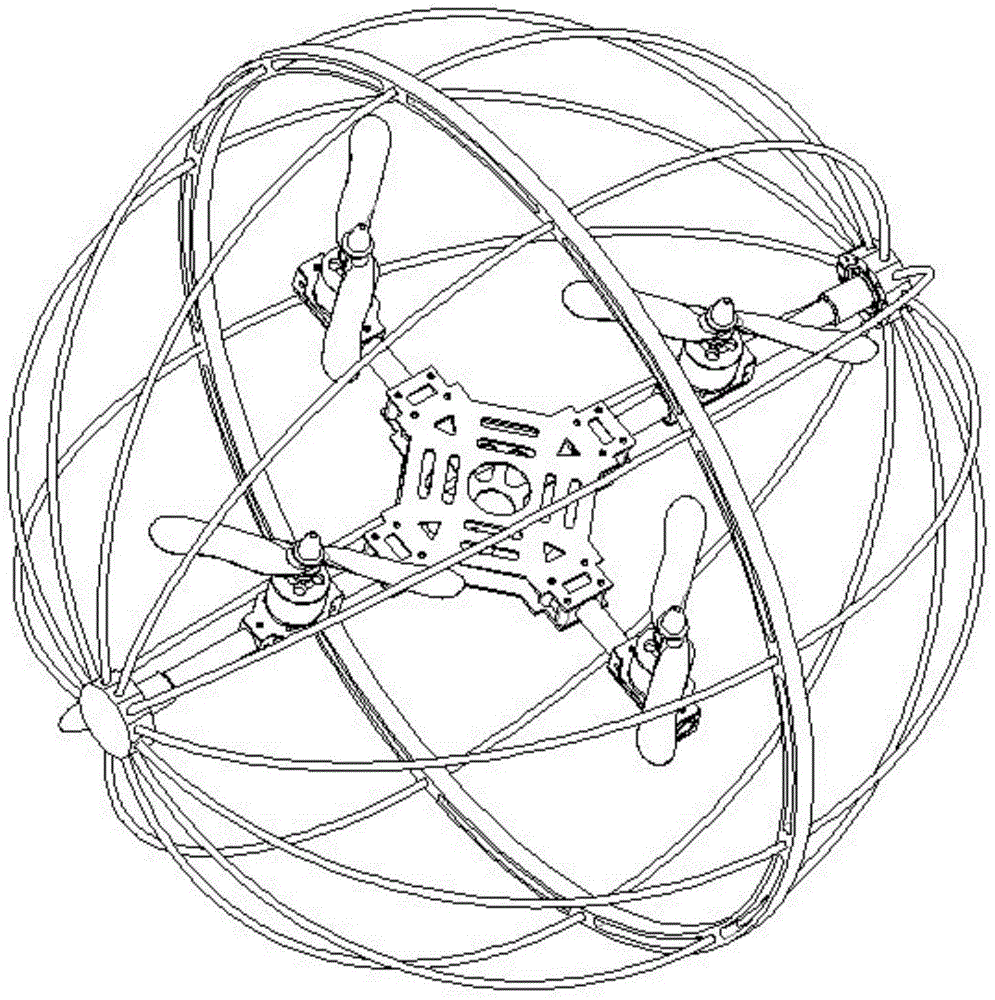

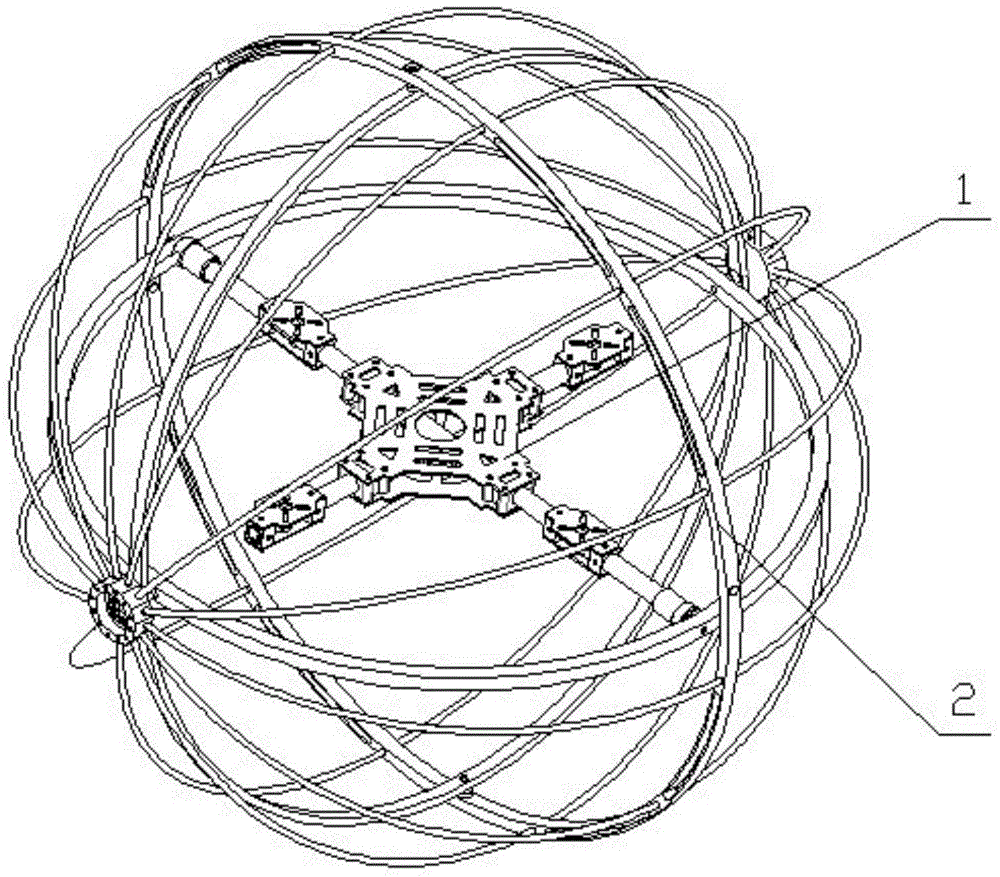

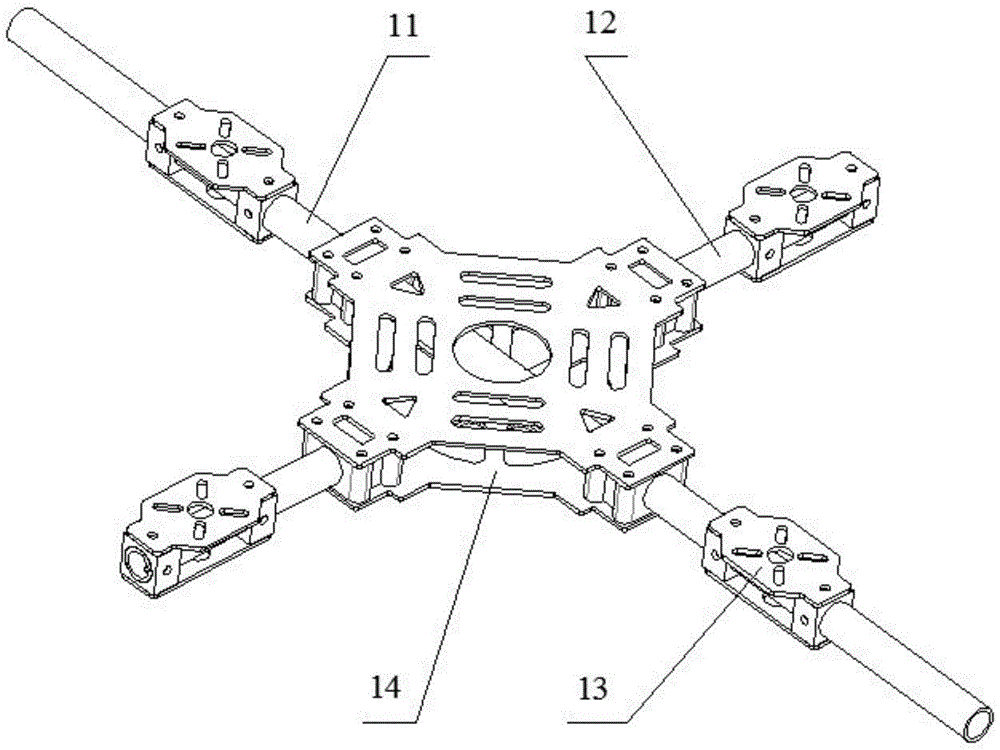

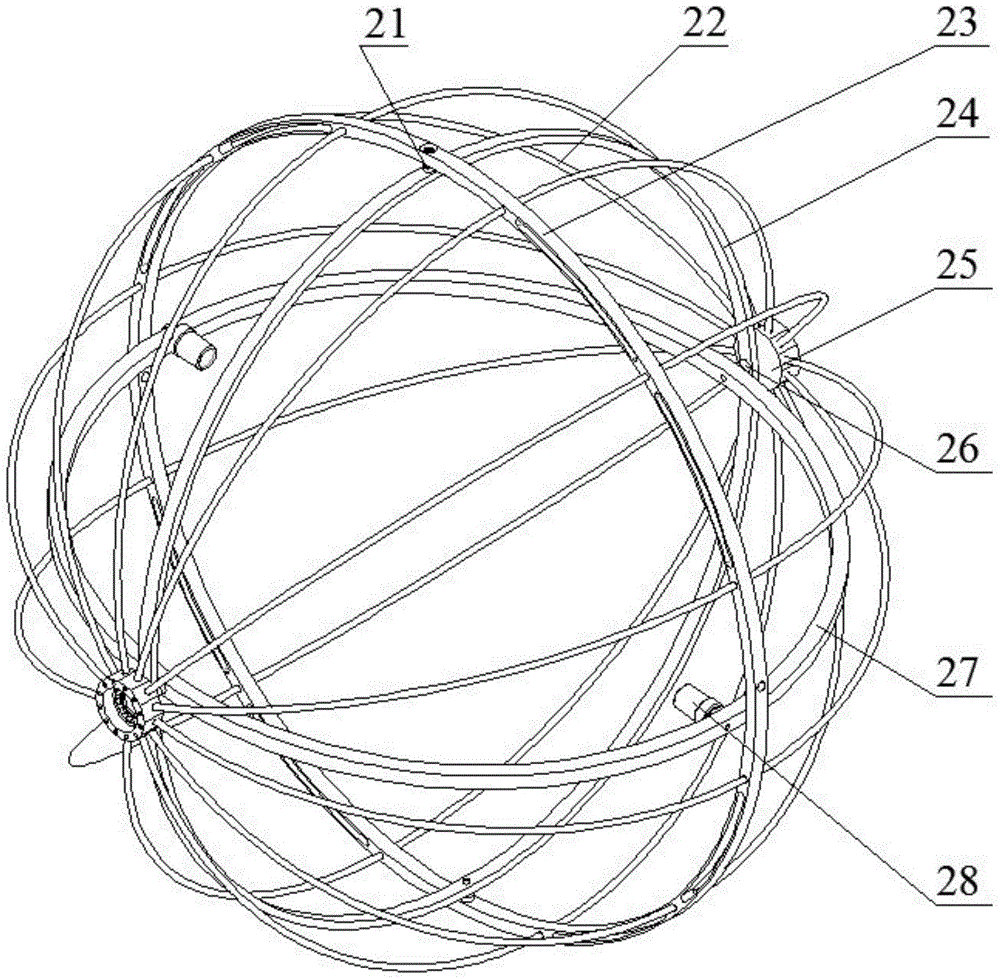

Spherical mechanism for quad-rotor amphibious robot

InactiveCN104786768ASimple structureFunctionalAircraft convertible vehiclesRotocraftStub axleQuad rotor

The invention discloses a spherical mechanism for a quad-rotor amphibious robot. The spherical mechanism is composed of a rotor wing mechanism and a spherical shell mechanism, wherein the rotor wing mechanism is composed of a long shaft, a short shaft, a base, four rotor wings and four motors, the spherical shell mechanism is composed of a flexible rod, two fixed bases and a rolling ring, the long shaft is perpendicular to the short shaft, the axis of the long shaft and the axis of the short shaft are located on the same plane, the four rotor wings and the motors are symmetrically installed on the long shaft and the short shaft, and a connecting shaft on the long shaft is connected with the fixed bases of the spherical shell mechanism to enable the rotor wing mechanism to rotate around the long shaft relative to the spherical shell mechanism. The rotor wing mechanism provides power for the robot, and the robot is made to fly in the air or roll on the ground by setting the rotating speed and direction of the four rotor wings. When the robot flies in the air, the spherical shell mechanism serves as a protecting device. When the robot rolls on the ground, the spherical shell mechanism serves as a protecting device and a rolling device. The spherical mechanism has the advantages of being simple in structure, practical, convenient to dismantle, convenient to maintain, low in cost and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Supporting and protection mechanism of four-rotor robot

InactiveCN104787325AReduce complexityExtended service lifeFuselagesRotocraftGyroscopeProtection mechanism

The invention discloses a supporting and protection mechanism of a four-rotor robot, which comprises a rotor supporting rack and a gyro protection mechanism, wherein the rotor supporting rack consists of a base, rotor and rotor driving motor fixing seats, and a long shaft and a short shaft which are used for mounting rotors and rotor driving devices; the gyro protection mechanism consists of a gyro mechanism and flexible levers; the gyro mechanism consists of an outer ring, a middle ring, two flexible lever fixing seats, an inner ring and shaft sleeves; the two ends of the long shaft of the rotor supporting rack are connected with the two shaft sleeves on the inner ring of the gyro protection mechanism to form a rotating shaft; and the rotor supporting rack freely rotates around the gyro protection mechanism. According to the supporting and protection mechanism, the robot can adapt to an unpredictable external environment, can effectively cope with an external emergency situation in a flying process, and can still keep an inherent state in case of collision. The supporting and protection mechanism is simple to manufacture, low in cost, good in adaptability and wide in application scope.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Elliptical exercise machine with adjustable exercising orbit

An elliptical exercise machine with adjustable exercising orbit substantially comprises a framework, an upright support disposed thereon, a flywheel disposed inside the upright support, a crank settled on the flywheel, at least two parallel rails arranged adjacent said framework, a wheel means comprising two wheel-shafts arranged on each side of said crank and each has a wheel which is coupled to said rail, a handle-shaft means comprising a pair of handle-shafts disposed on each side of the upright support with the top portions for users' handling, a running-pedal means comprising two pedals respectively coupled to two pedal-shafts which are linked to said handle-shafts for users' pedaling, a pair of adjust-devices on the wheel-shafts which are pivotally connected to the pedal-shafts for adjust the position of joints of pedal-shafts and wheel-shafts by moving axially along the wheel-shafts forwards and backwards. A user can modify the exercise model for training various muscle systems by operating said adjust-devices to lengthen or shorten the minor axle of the resultant elliptical exercising orbit to cause a non-uniform scale thereof.

Owner:CYCLING & HEALTH TECH IND R & D CENT

Shaft extension for use with outboard bearing designs

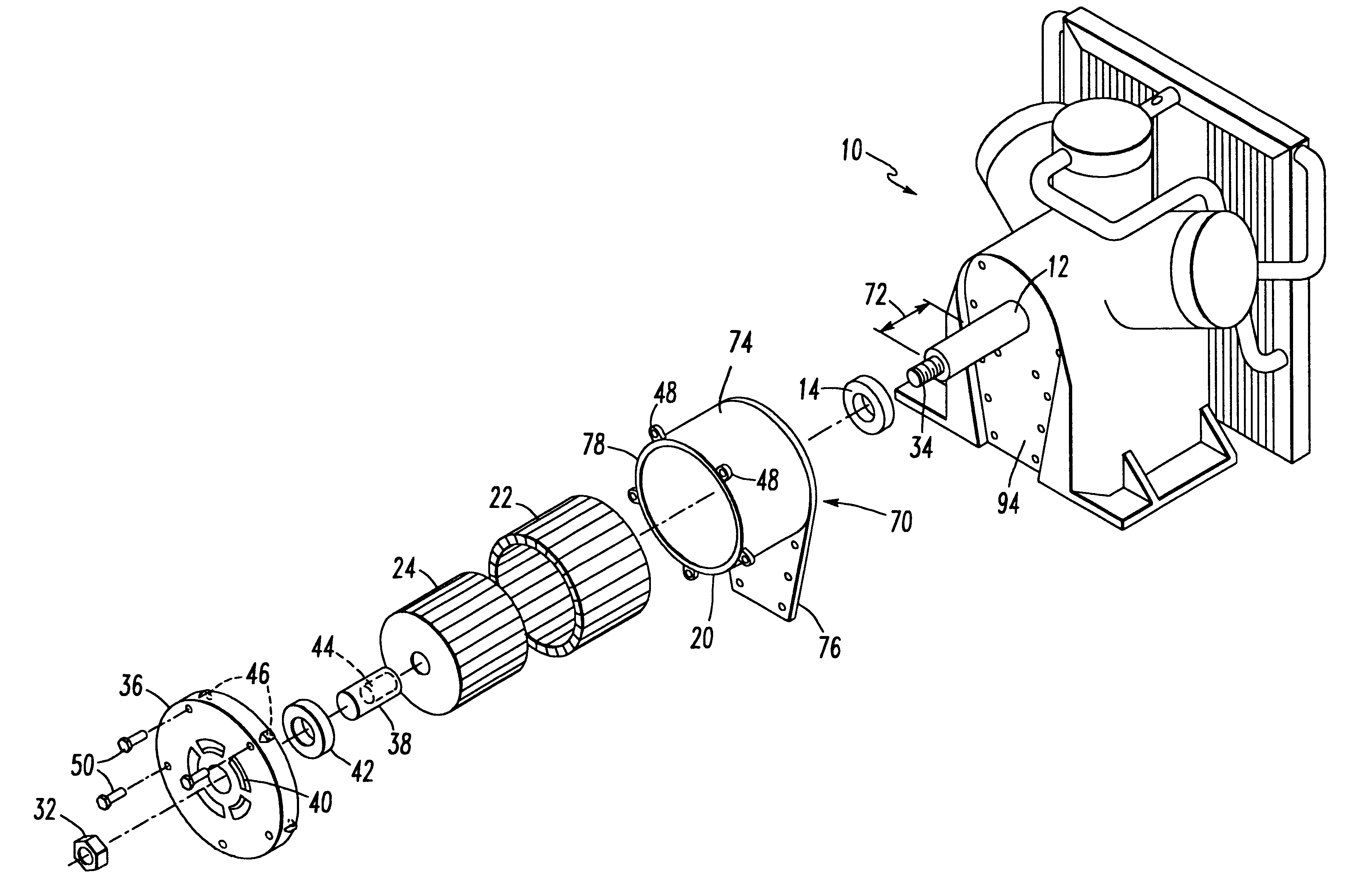

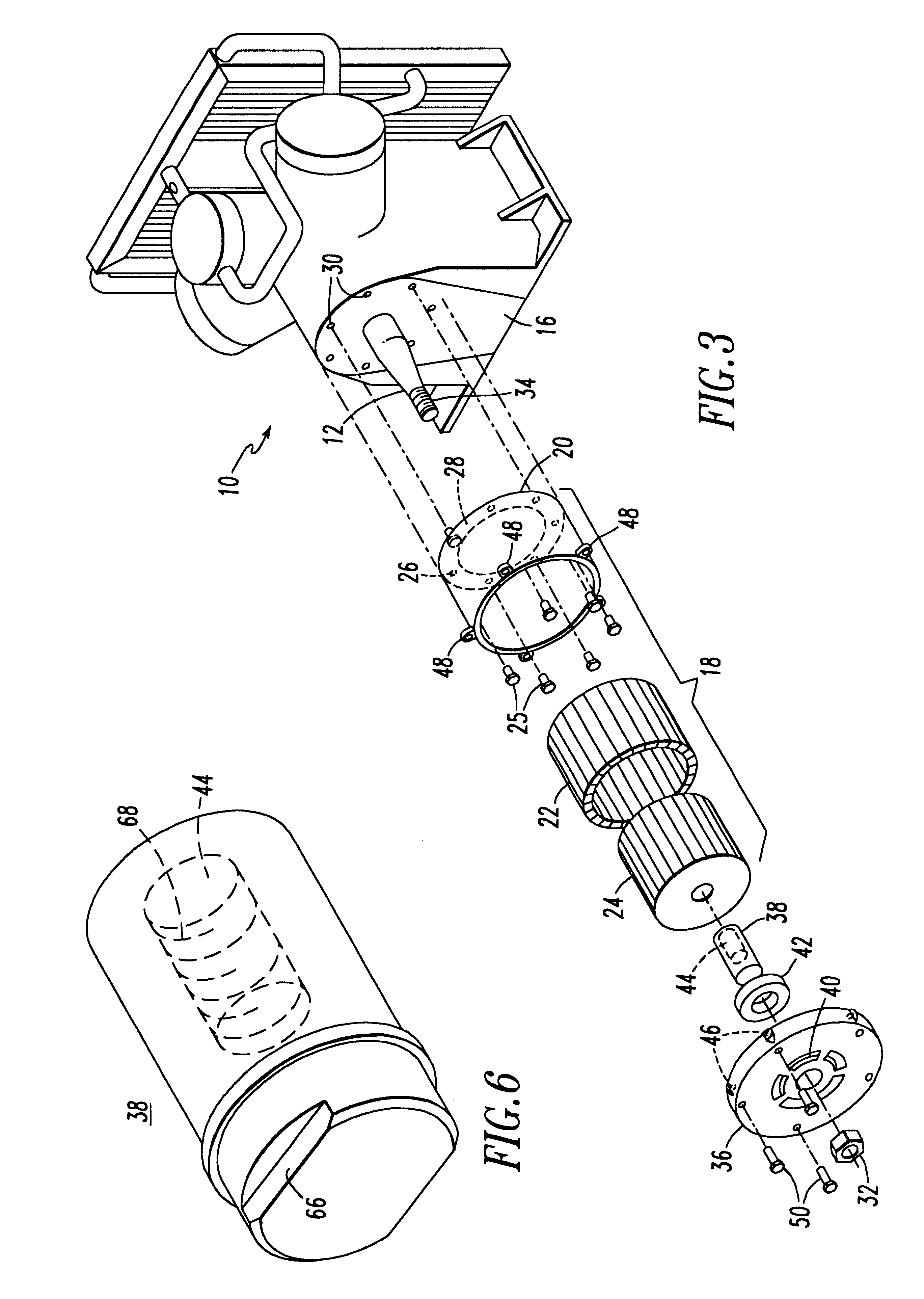

InactiveUS6419465B1Reduce failureLower performance requirementsPositive displacement pump componentsPiston pumpsStub axleAir compressor

A shaft extension for attachment to a crankshaft of an electric motor driven air compressor to axially extend the crankshaft for engagement with an outboard rotational bearing. The electric motor driven air compressor includes a bearing plate, an inboard rotational bearing mounted on the bearing plate, the crankshaft projecting through both of the inboard rotational bearing and the bearing plate and terminating in a distal end disposed exterior of the bearing plate. The air compressor also includes an electric motor, the electric motor having a stator frame, a stator fixedly mounted within the stator frame, and a rotor fixedly mounted to the crankshaft for rotation therewith and disposed interior of the stator. The air compressor further includes the outboard rotational bearing disposed axially outboard of the stator frame, the stator, and the rotor. The shaft extension includes an extension member having an extended major axis and a minor axis extending substantially transverse to the extended major axis and a connection mechanism for connecting the extension member to the distal end of the crankshaft.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

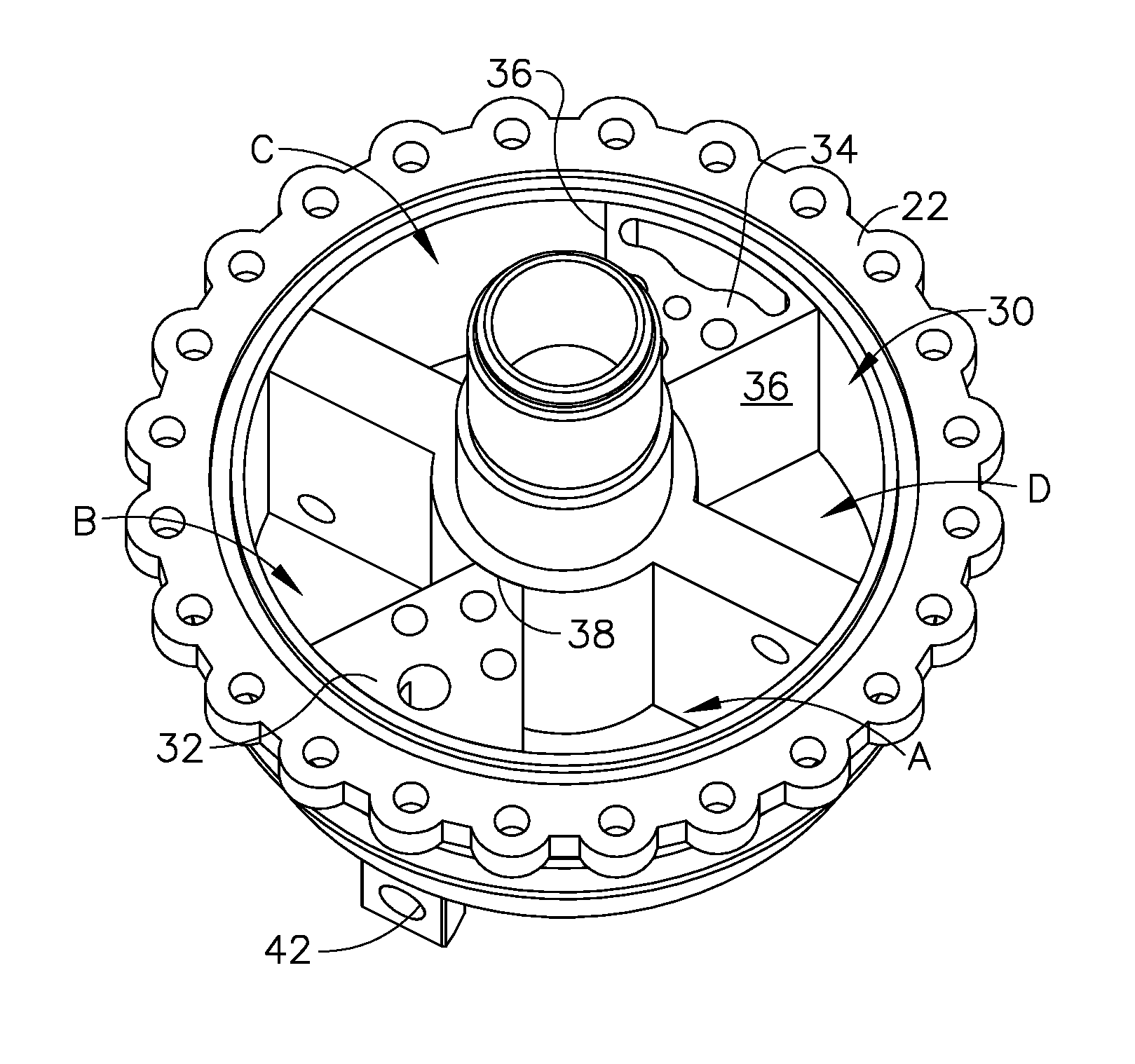

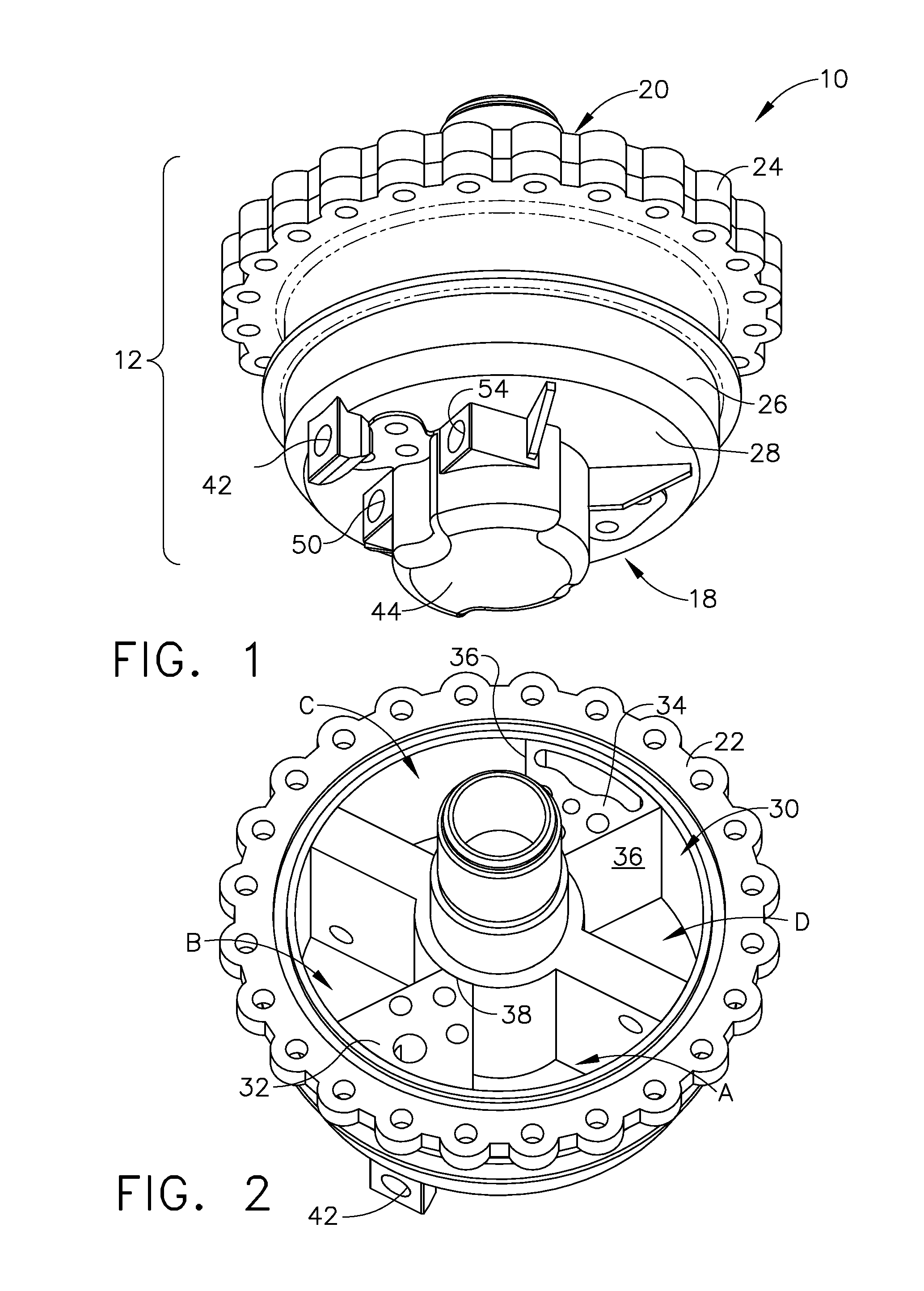

Rotary hydraulic actuator with hydraulically controlled position limits

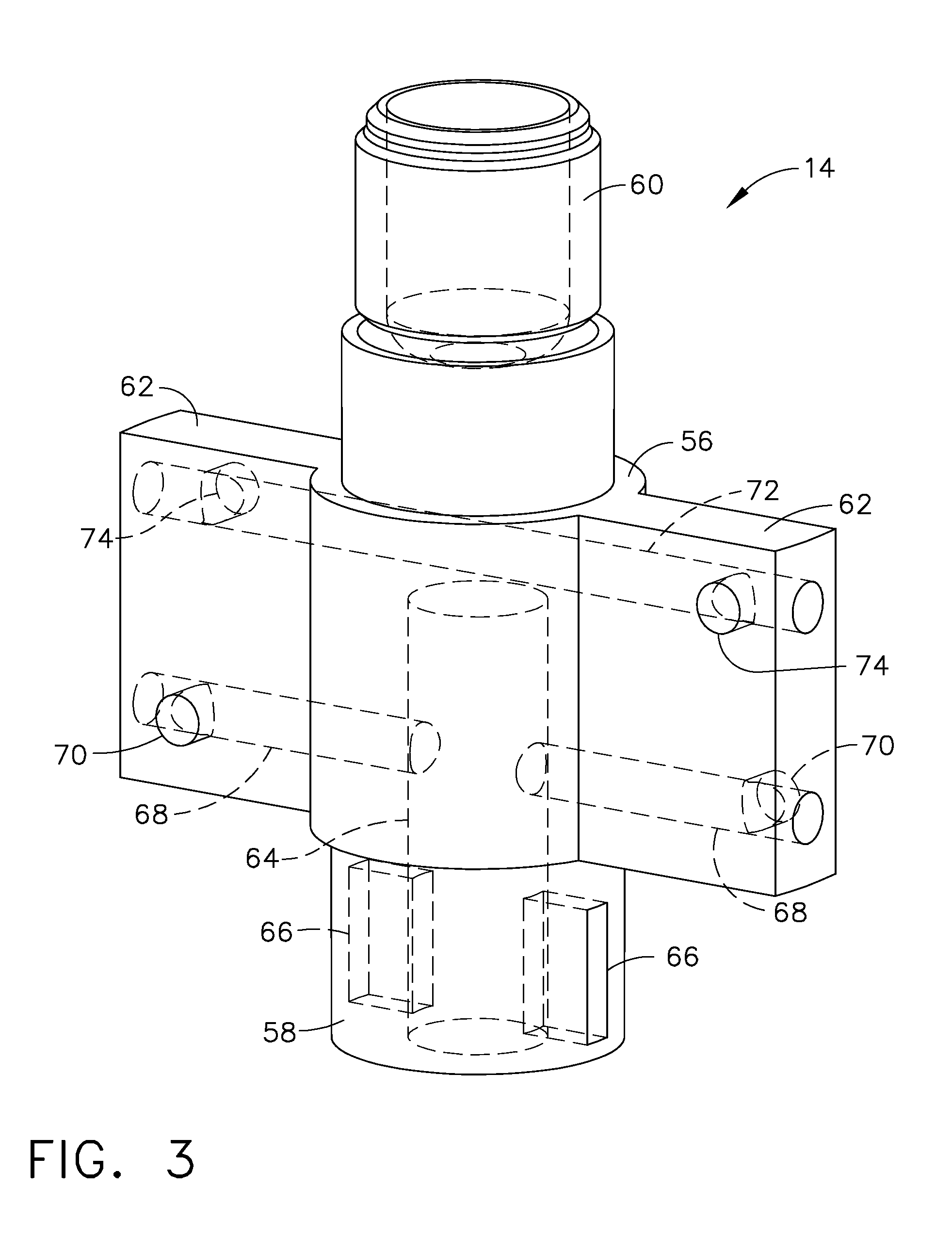

A rotary hydraulic actuator includes a housing defining a chamber, a first boss, and a port block with a bore communicating with the chamber. The port block includes rotor supply and drain ports communicating with the bore, and a stator port communicating with the chamber through a stator hole in the boss. A rotor mounted in the internal chamber includes: a body with a laterally-extending arm; a first stub shaft received in the bore, the first stub shaft including base slots passing laterally therethrough; a first rotor port disposed in the arm in communication with the internal chamber, and oriented in a tangential direction relative to an axis of rotation; and internal passages which interconnect the rotor base slots and the first rotor port. Passages in the port block communicate with the bore and interconnect the rotor supply and drain ports at a first angular position of the rotor.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com