The management method and device of working solution level

A management method and developer technology, applied in optics, photography, opto-mechanical equipment, etc., can solve the problem that carbonate is not taken into account and cannot completely eliminate the influence of carbon dioxide, and achieve the maintenance of developing sensitivity, precise management and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

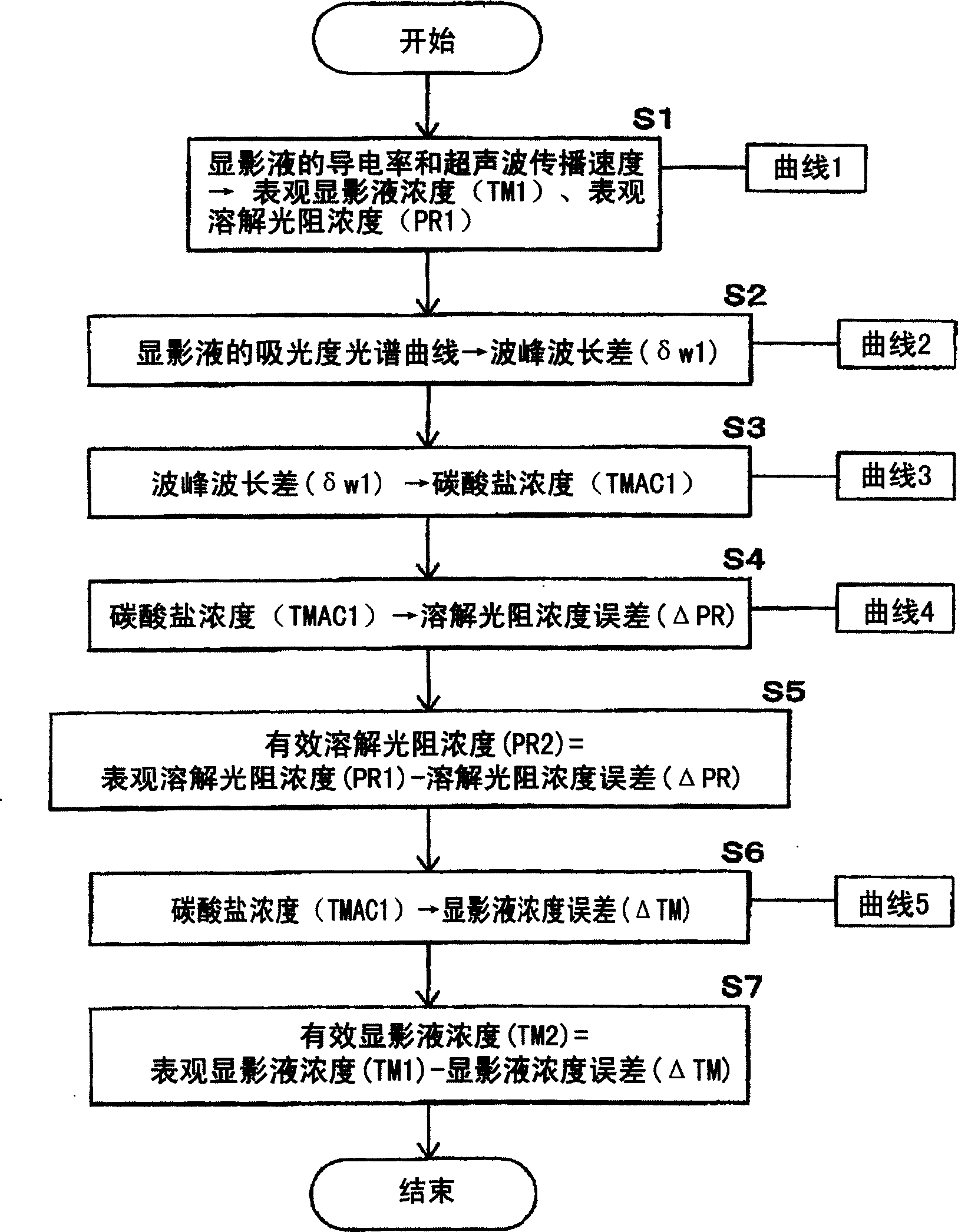

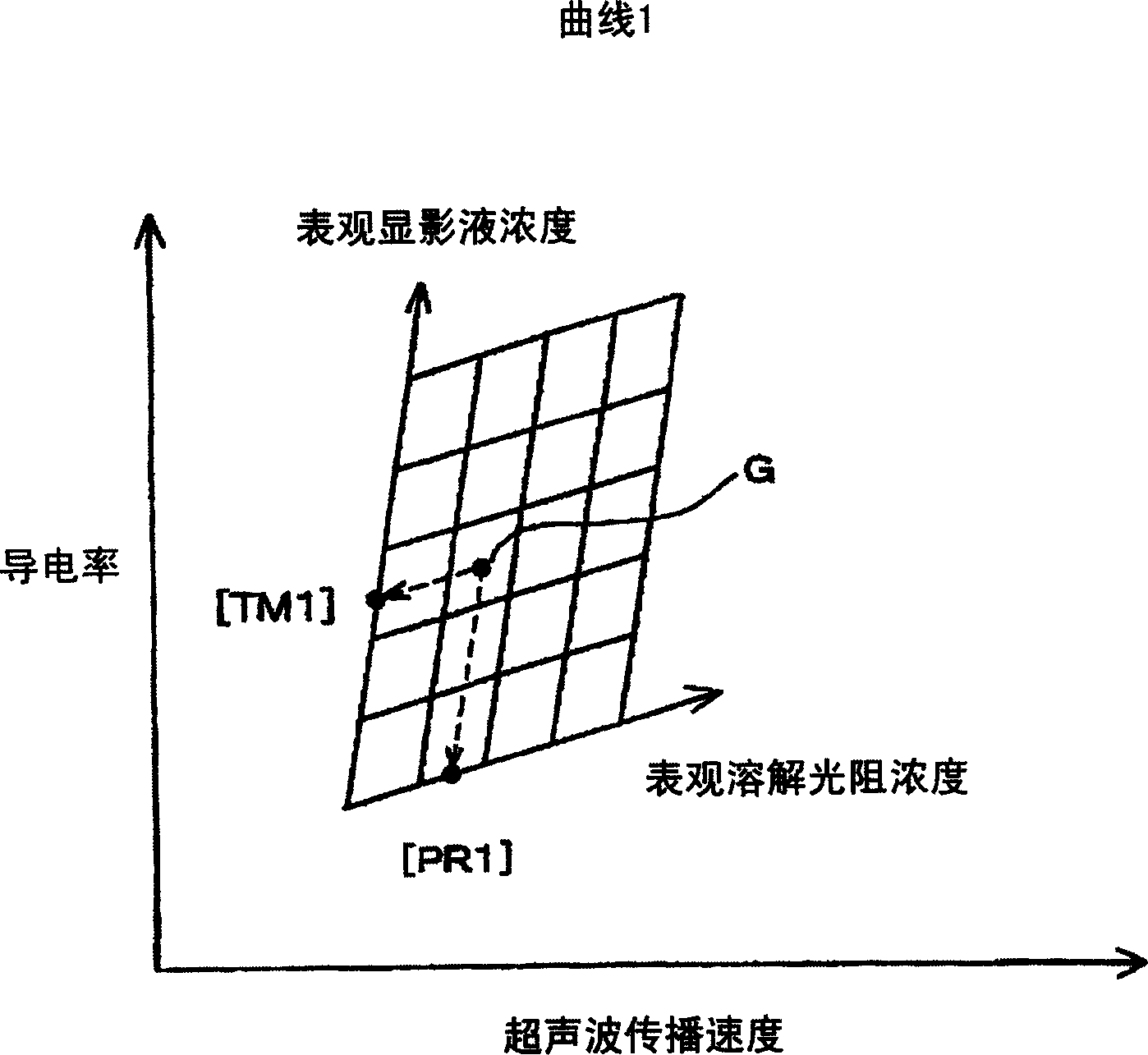

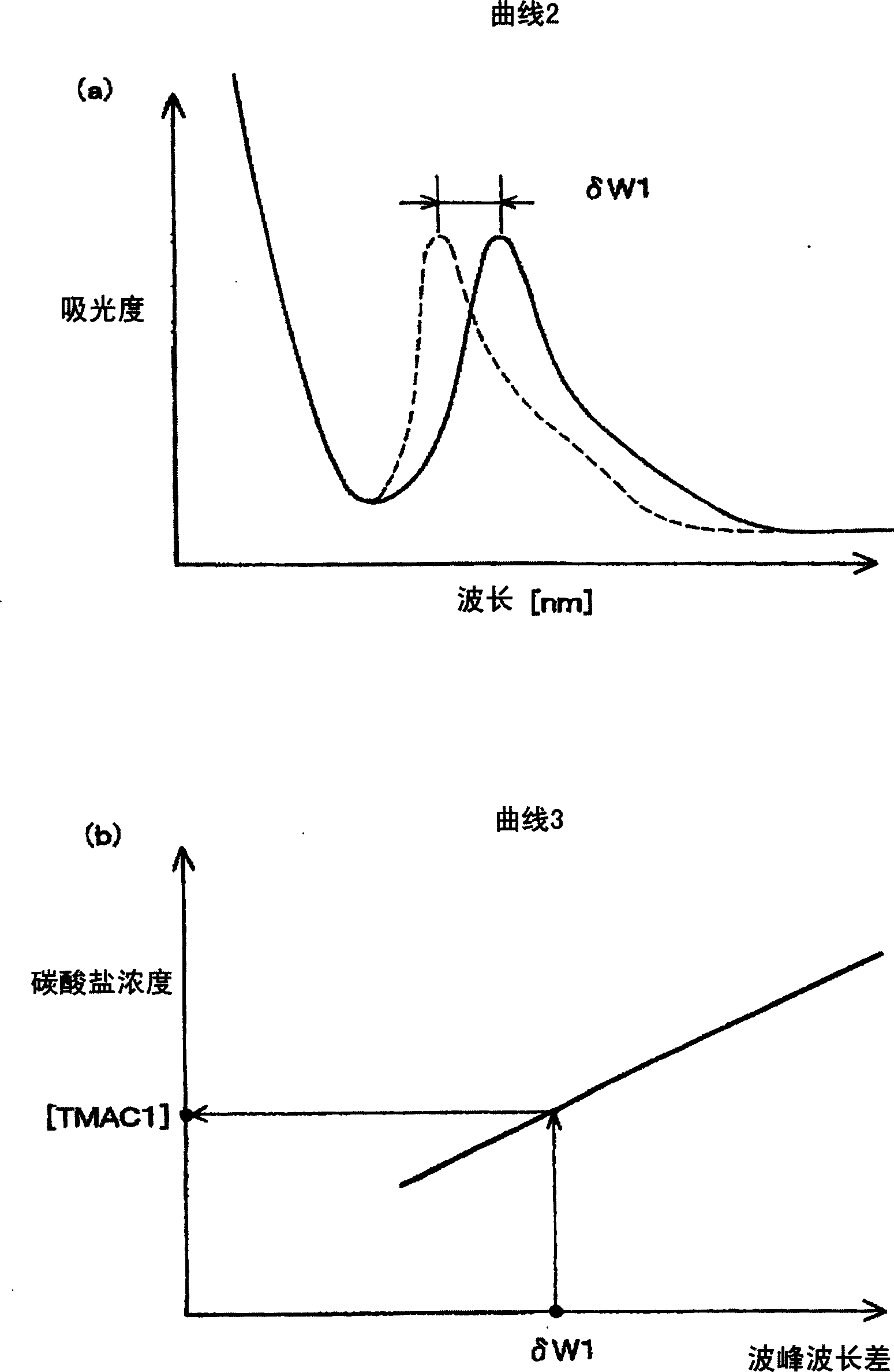

[0040] figure 1 It is a flowchart showing the processing procedure of an example of the photoresist developer management method of the present invention; figure 2 , image 3 (a), image 3 (b), Figure 4 , and FIG. 5 are graphs showing Curve 1, Curve 2, Curve 3, Curve 4, and Curve 5 used in the photoresist developer management method of the present invention, respectively.

[0041] The photoresist developer management method of the present invention is a method for concentration management of a photoresist (photosensitive organic resin) developer used in a liquid crystal substrate manufacturing process, a printed circuit board manufacturing process, a semiconductor substrate manufacturing process, etc., Although the absorbance of the developing solution is also measured, unlike the prior art, the dissolved photoresist concentration is not detected from the measured absorbance, but the peak wavelength is obtained from its spectral analysis, and the carbon contained in the de...

Embodiment 2

[0064] Figure 6 It is a flowchart showing the processing procedure of another example of the method for managing a developing solution for photoresist of the present invention.

[0065] In this management approach, the figure 1 In the shown comparison, only step S11 is different, and subsequent steps S12 to S18 are the same as figure 1 Steps S1 to S7 are the same. That is, this management method is characterized in that, in performing figure 1 Before the treatment, remove the air bubbles of the developer that is to be managed.

[0066] The air bubbles are contained in the developer due to gas-liquid mixing that occurs when the developer is released into nitrogen gas under nitrogen scrubbing, or mixed with air (containing oxygen, nitrogen, carbon dioxide, etc.) when nitrogen scrubbing is insufficient. Although the bubbles have no influence on the sensitivity of the developer, they have an influence on the measurement of the conductivity, ultrasonic velocity, and absorbance...

Embodiment 3

[0068] Figure 7 It is a pipeline system diagram showing the overall structure of the developing solution management device for photoresist of the present invention.

[0069] The developer solution management device 10 for photoresist is a device that embodies the management method of the present invention, and has a measurement unit 6 including a conductivity meter (CI) 1 for measuring the conductivity of the developer solution, and a Calculate the apparent developer concentration (TM1) and apparent dissolved photoresist concentration (PR1) based on the relationship between the electrical conductivity of the developer and the ultrasonic propagation velocity with an ultrasonic velocity meter (US) 2 for measuring the ultrasonic velocity; and Equipped with: an absorbance photometer 3 (UV-Abs) used to measure the absorbance, and the carbonate concentration is calculated for the correlation between the peak wavelength difference (δw1) obtained from the spectral analysis of the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com