Biomass heat- and solar-energy multistage cooling, heating and power combined supply system

A technology of combined cooling, heating and power supply and solar energy, applied in the field of energy and the environment, can solve the problems that conventional power generation cycles cannot effectively utilize low-temperature heat energy, and achieve the effects of improving continuous energy supply capacity, improving heat exchange efficiency, and simplifying heat exchange equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

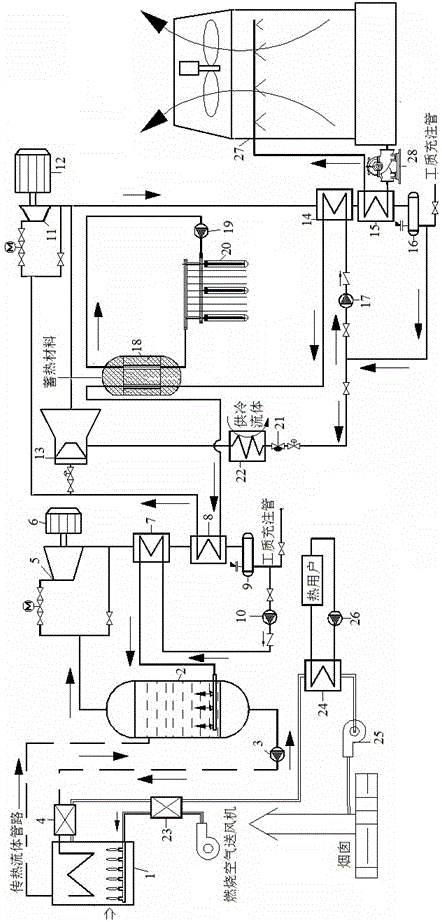

[0035] Example 1: A multi-stage combined cooling, heating and power supply system of biomass thermal energy and solar energy, including a heat transfer fluid circulation loop, a power generation loop, a combined cooling and power supply loop, a solar circulation loop, a biomass combustion furnace exhaust pipe, a power supply Hot water circuit, cooling water circuit;

[0036] The heat transfer fluid circulation circuit is composed of biomass combustion furnace 1, direct contact evaporator 2, heat transfer fluid circulation pump I3, heat transfer fluid smoke exhaust heat exchanger 4 and the pipes connecting them; heat transfer fluid circulation pump I3 The pipeline is connected between the direct contact evaporator 2 heat transfer fluid outlet and the heat transfer fluid smoke exhaust heat exchanger 4 inlet, and the heat transfer fluid smoke exhaust heat exchanger 4 outlet is connected to the biomass combustion furnace 1 heat transfer fluid inlet through the pipeline , the outle...

Embodiment 2

[0043] Embodiment 2: A multi-stage combined cooling, heating and power supply system of biomass thermal energy and solar energy, including a heat transfer fluid circulation loop, a power generation loop, a combined cooling and power supply loop, a solar circulation loop, a biomass combustion furnace exhaust pipe, a power supply Hot water circuit, cooling water circuit;

[0044] The heat transfer fluid circulation circuit is composed of biomass combustion furnace 1, direct contact evaporator 2, heat transfer fluid circulation pump I3, heat transfer fluid smoke exhaust heat exchanger 4 and the pipes connecting them; heat transfer fluid circulation pump I3 The pipeline is connected between the direct contact evaporator 2 heat transfer fluid outlet and the heat transfer fluid smoke exhaust heat exchanger 4 inlet, and the heat transfer fluid smoke exhaust heat exchanger 4 outlet is connected to the biomass combustion furnace 1 heat transfer fluid inlet through the pipeline , the ou...

Embodiment 3

[0052] Embodiment 3: A multi-stage combined cooling, heating and power supply system of biomass thermal energy and solar energy, including a heat transfer fluid circulation loop, a power generation loop, a combined cooling and power supply loop, a solar circulation loop, a biomass combustion furnace exhaust pipe, a power supply Hot water circuit, cooling water circuit;

[0053] The heat transfer fluid circulation circuit is composed of biomass combustion furnace 1, direct contact evaporator 2, heat transfer fluid circulation pump I3, heat transfer fluid smoke exhaust heat exchanger 4 and the pipes connecting them; heat transfer fluid circulation pump I3 The pipeline is connected between the direct contact evaporator 2 heat transfer fluid outlet and the heat transfer fluid smoke exhaust heat exchanger 4 inlet, and the heat transfer fluid smoke exhaust heat exchanger 4 outlet is connected to the biomass combustion furnace 1 heat transfer fluid inlet through the pipeline , the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com