Process for full-particle-size sorting and enriching kerogen from oil shale

A technology for oil shale and kerogen, which is applied in the field of oil shale full-grain fractionation and enrichment of kerogen, can solve the problem of reducing the purity and conversion utilization rate of oil shale reaction products, and affecting the economic benefits and social benefits of oil shale. efficiency, reduce oil shale and other issues, to achieve the effect of improving purity and conversion utilization, improving economic and social benefits, and improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

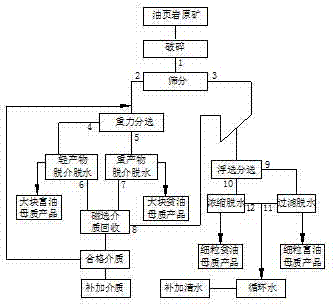

[0027] Such as figure 1 As shown, the oil shale full-grain separation and enrichment process of kerogen according to the present invention:

[0028] a. Use a roller crusher to selectively crush the oil shale raw ore to less than 50 mm to obtain the crushed product 1;

[0029] b. The crushed product 1 is screened and classified by a 0.5 mm linear vibrating sieve to obtain two grades of the above-sieve material with a particle size of -50+0.5 mm and the under-sieve material with a particle size of -0.5 mm;

[0030] c. -50+0.5 mm oversize material 2 enters the two-product heavy medium cyclone for gravity separation to obtain two products, light product 4 and heavy product 5, and the obtained two gravity-separated products enter the next step respectively;

[0031] d. The light product 4 obtained in step c enters the arc-shaped media removal sieve for light p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com