Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1969 results about "Melting tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A melting tank is a tank used by manufacturing companies to manufacture a variety of products.

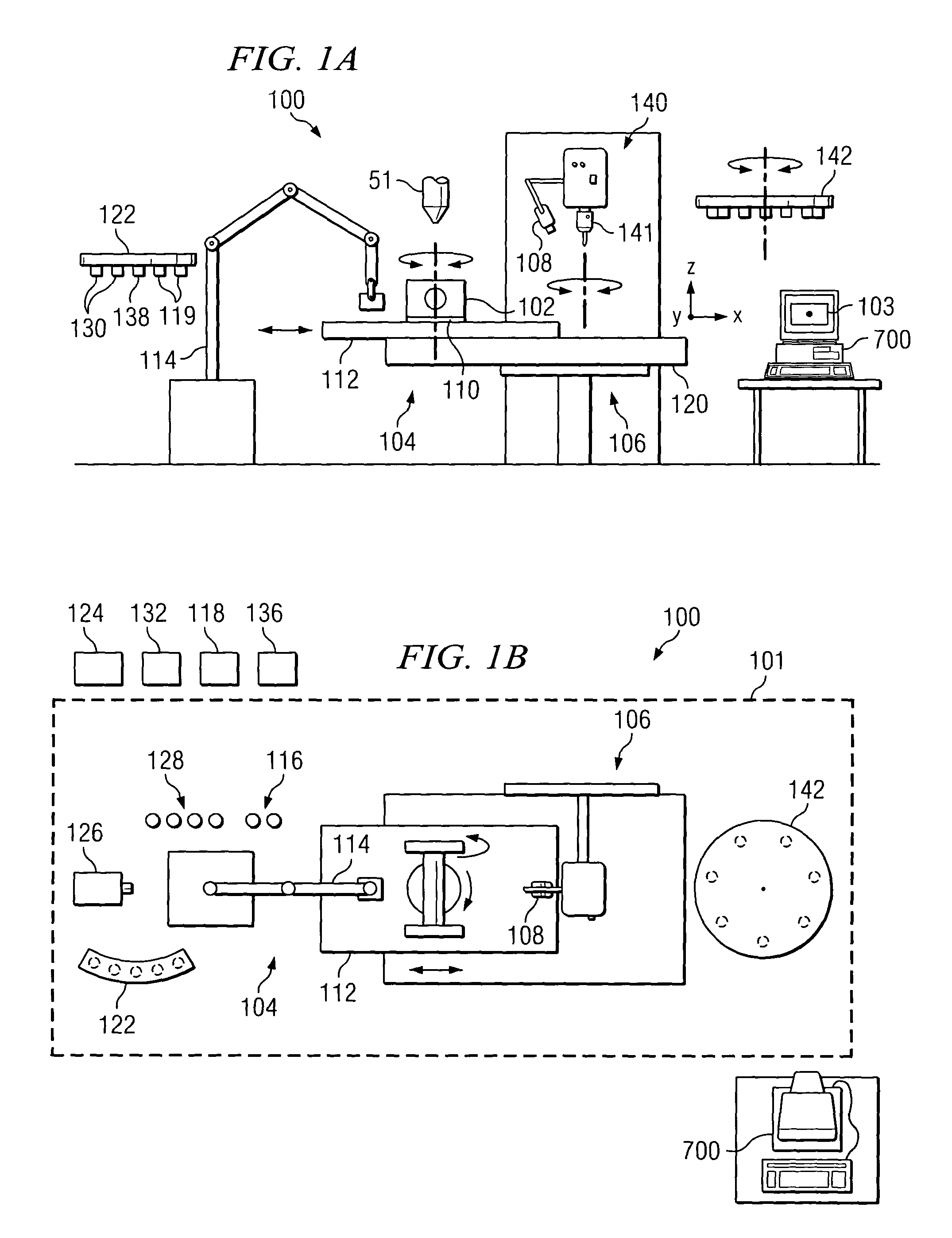

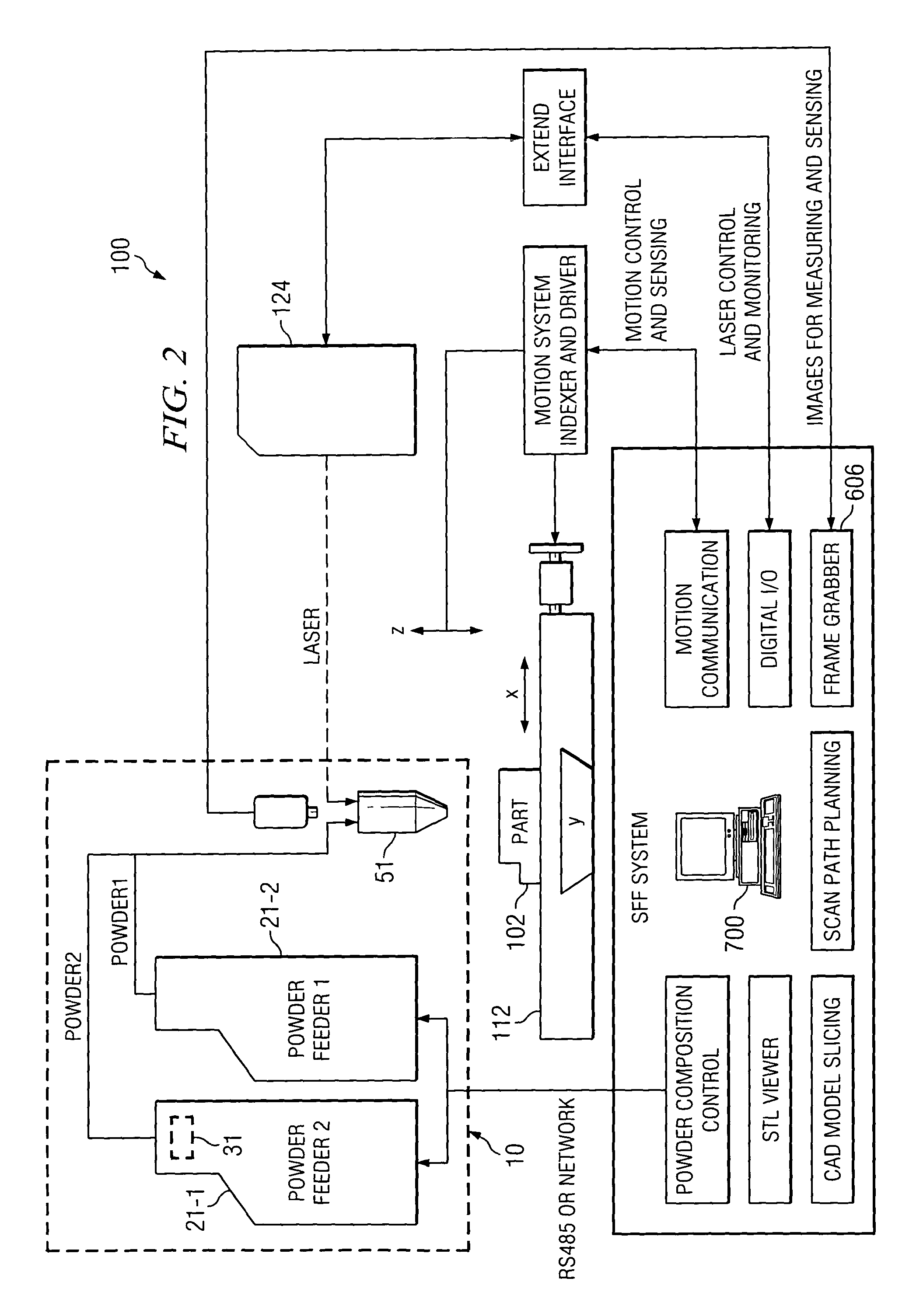

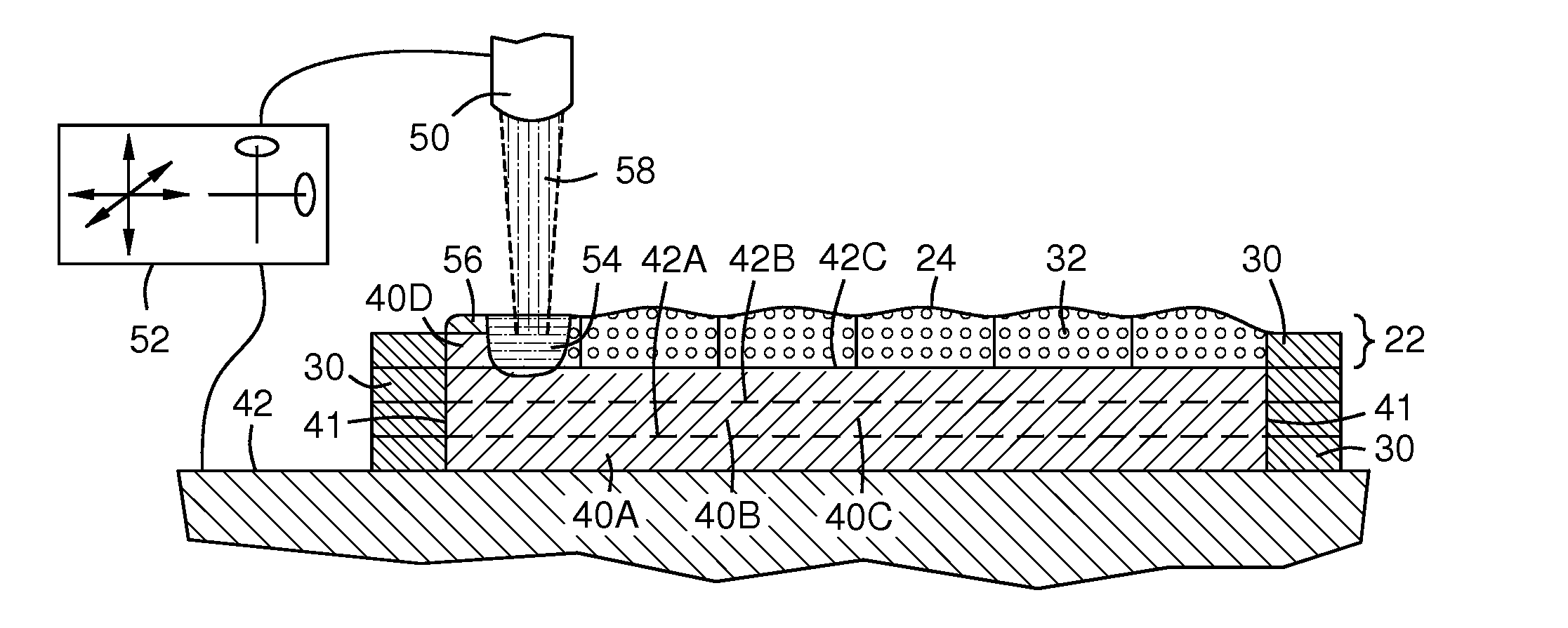

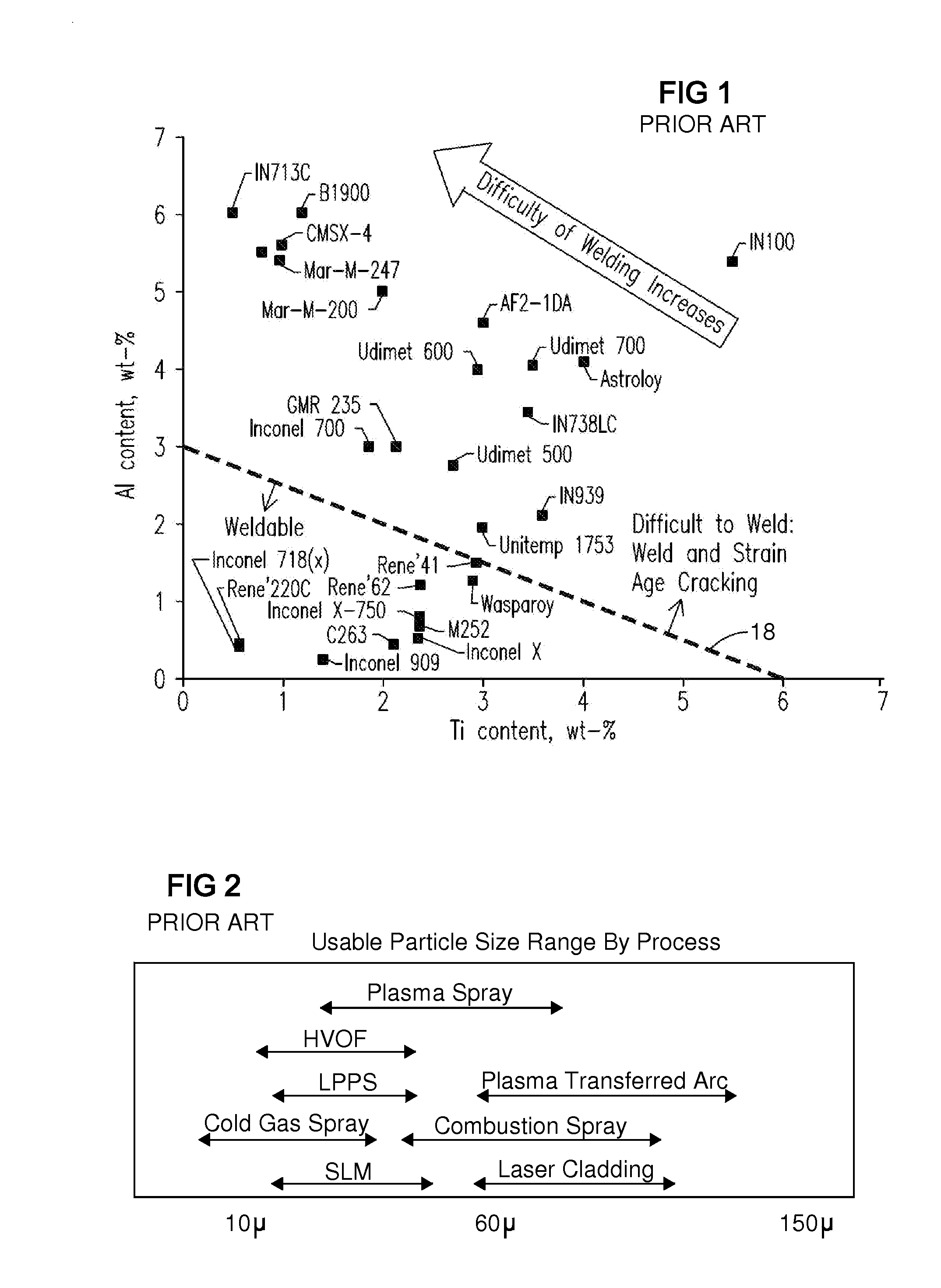

Systems and methods for additive manufacturing and repair of metal components

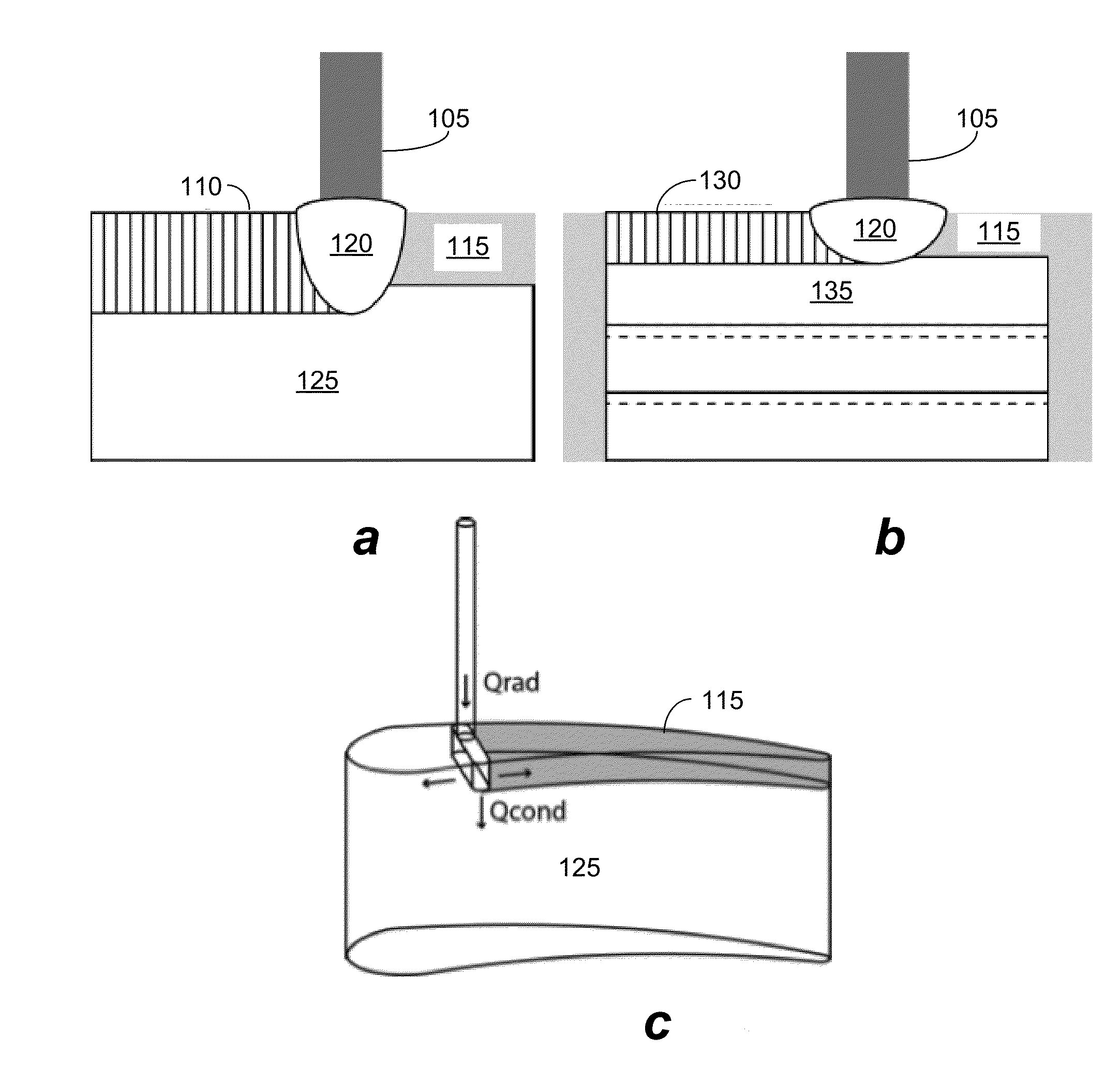

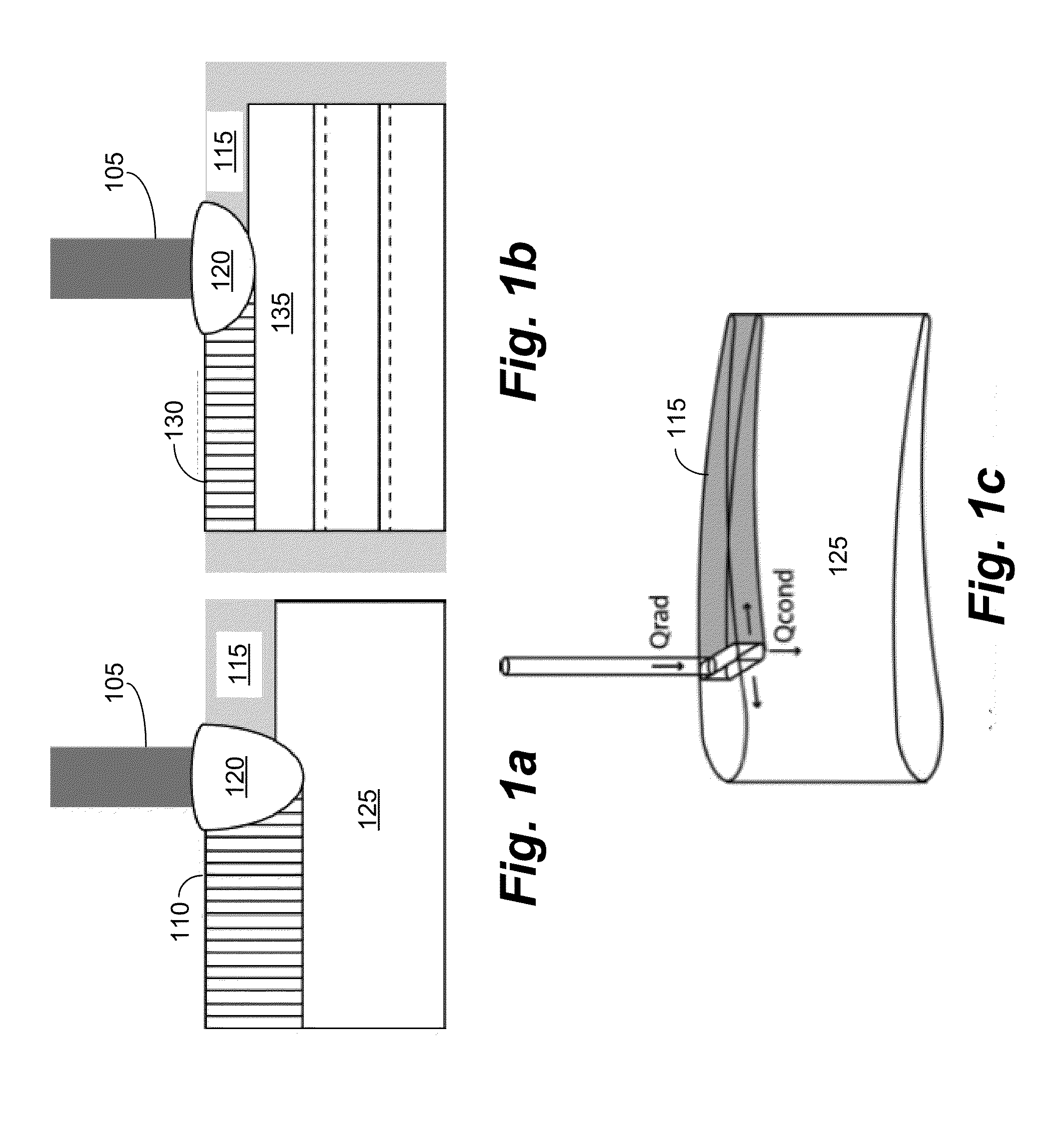

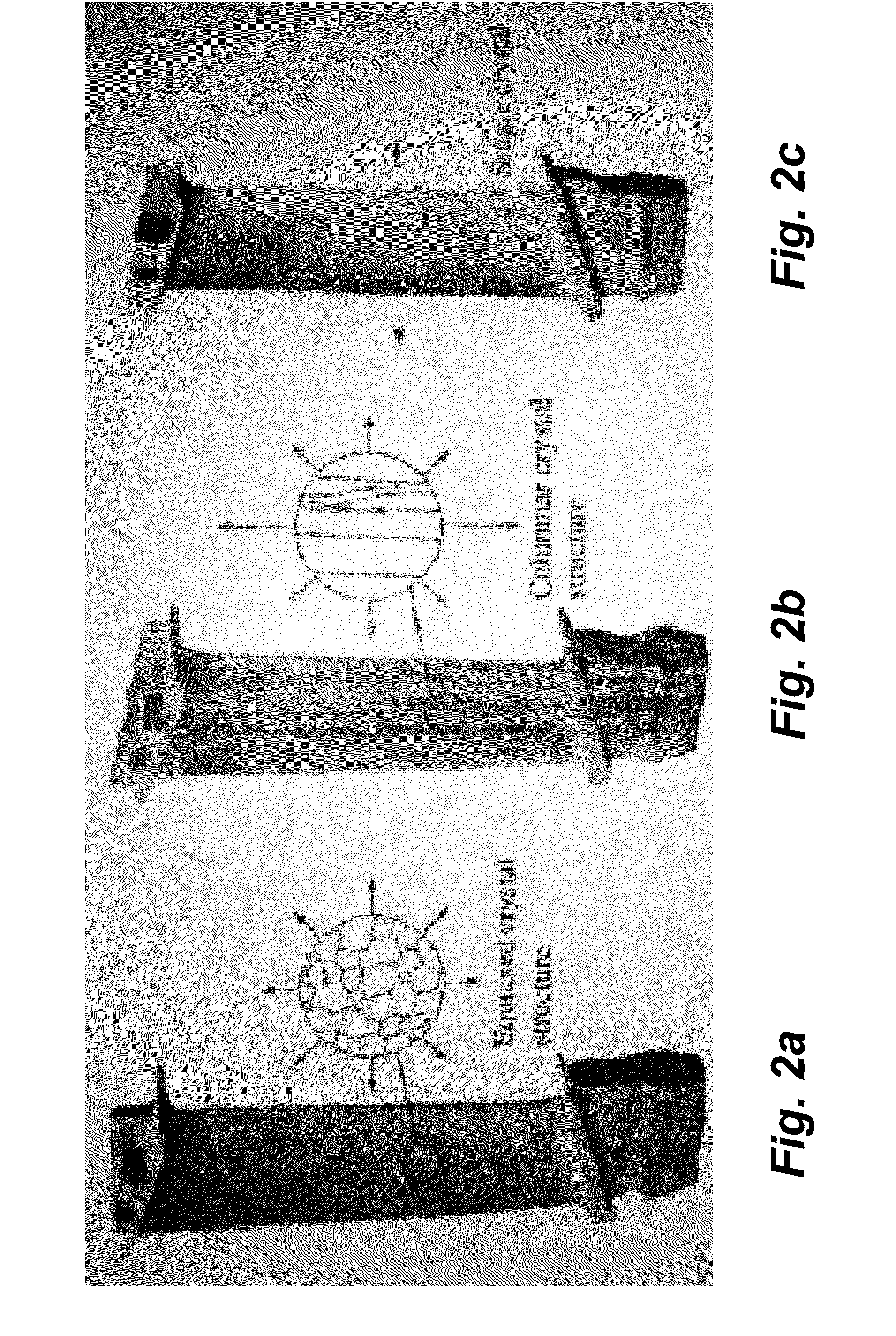

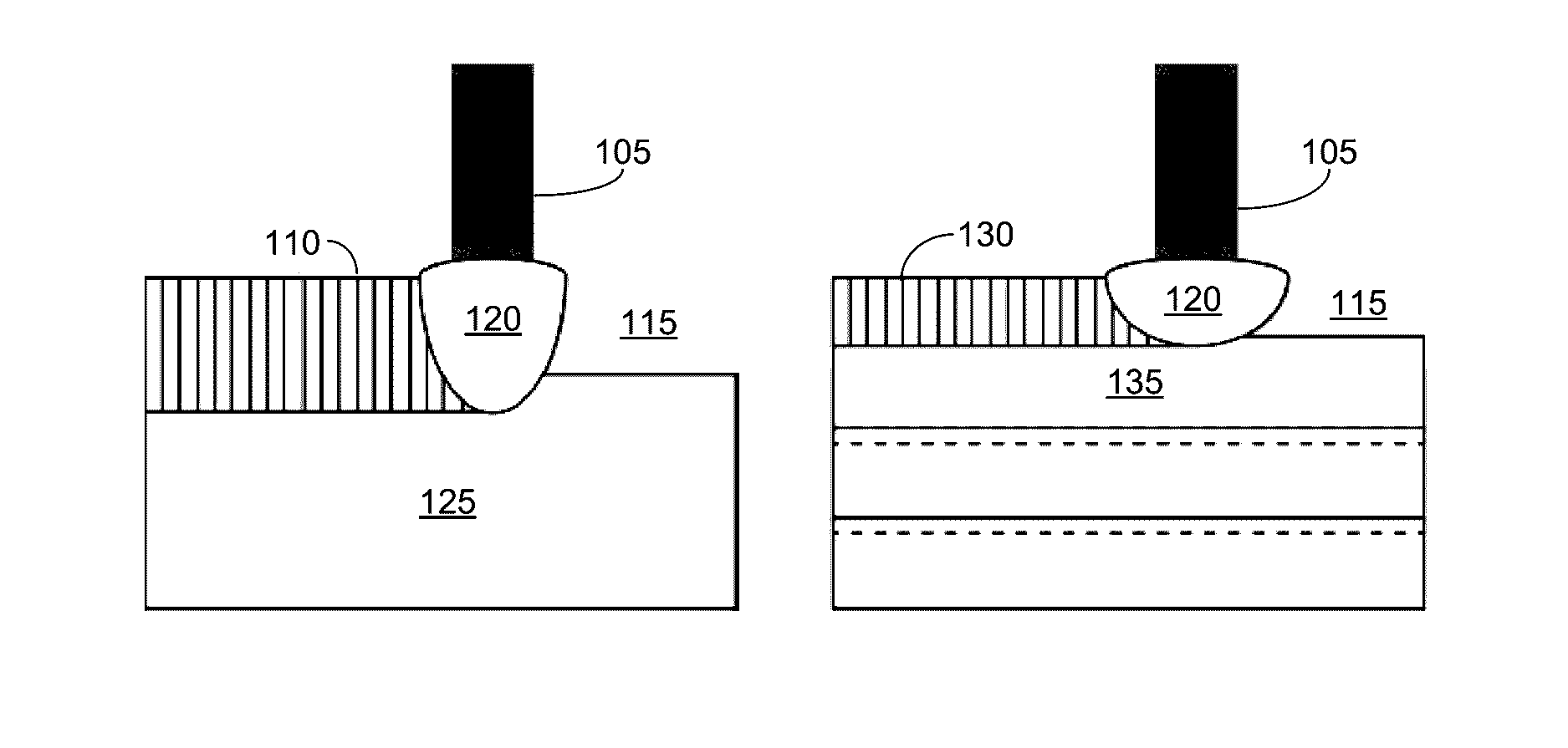

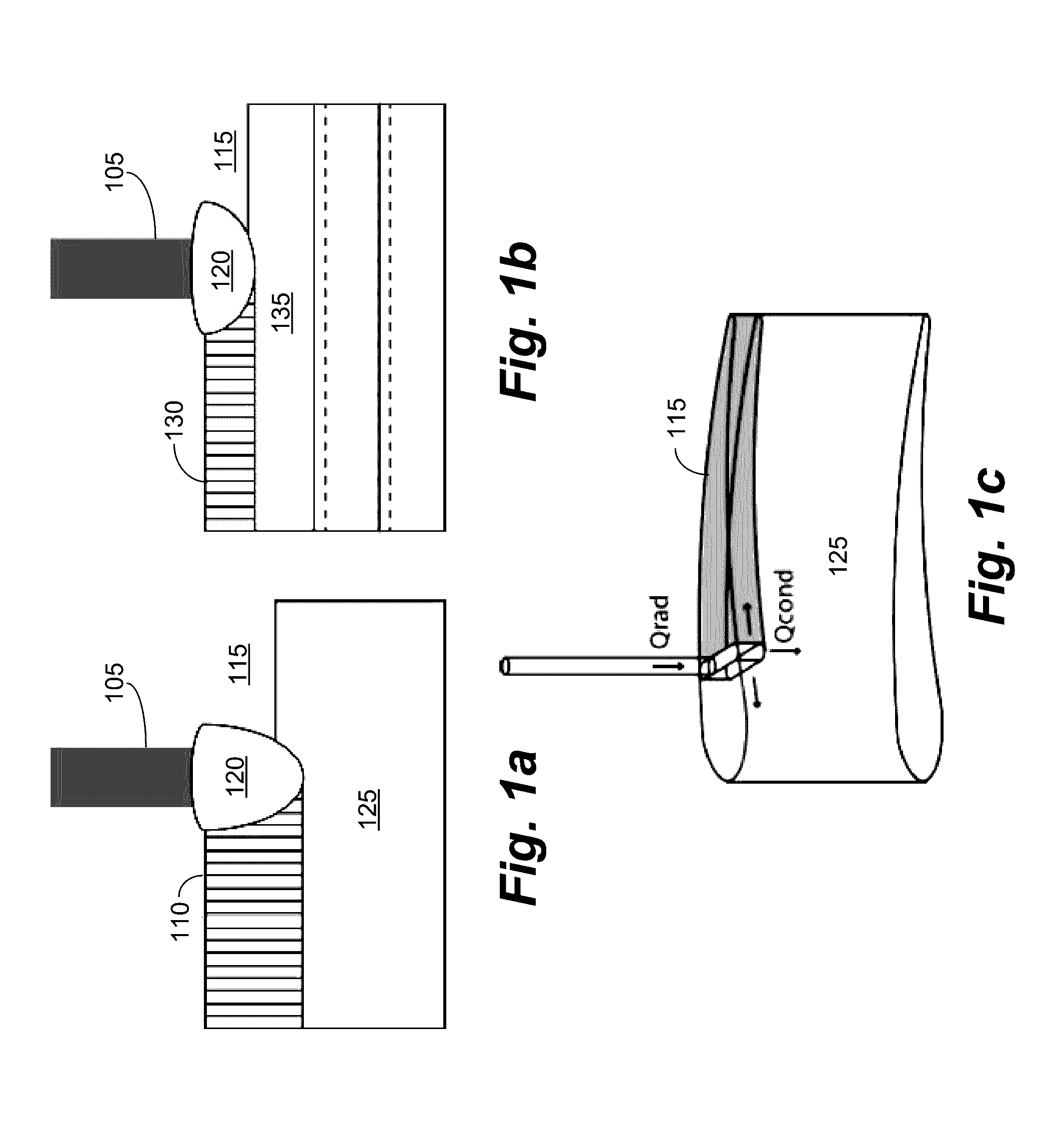

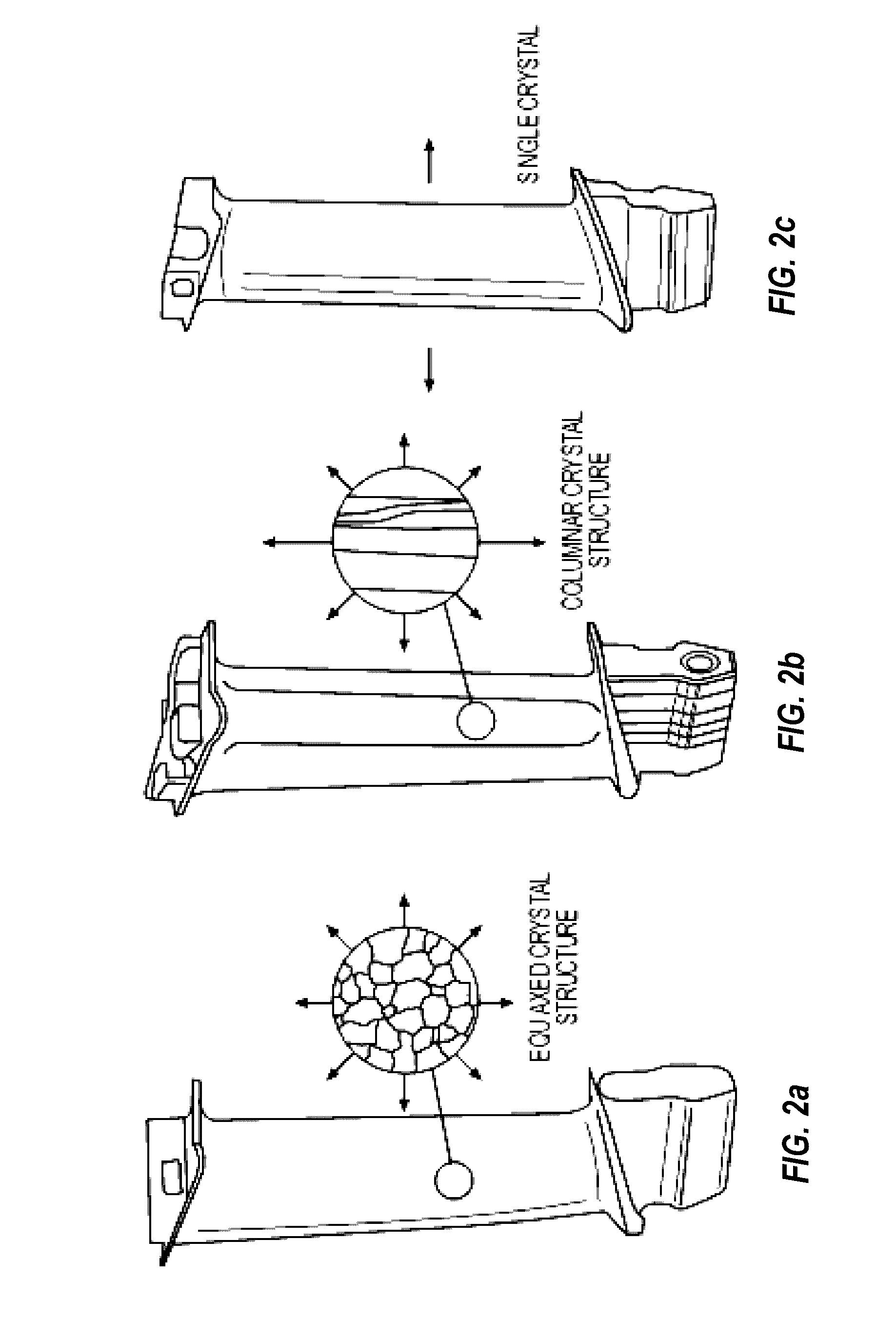

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

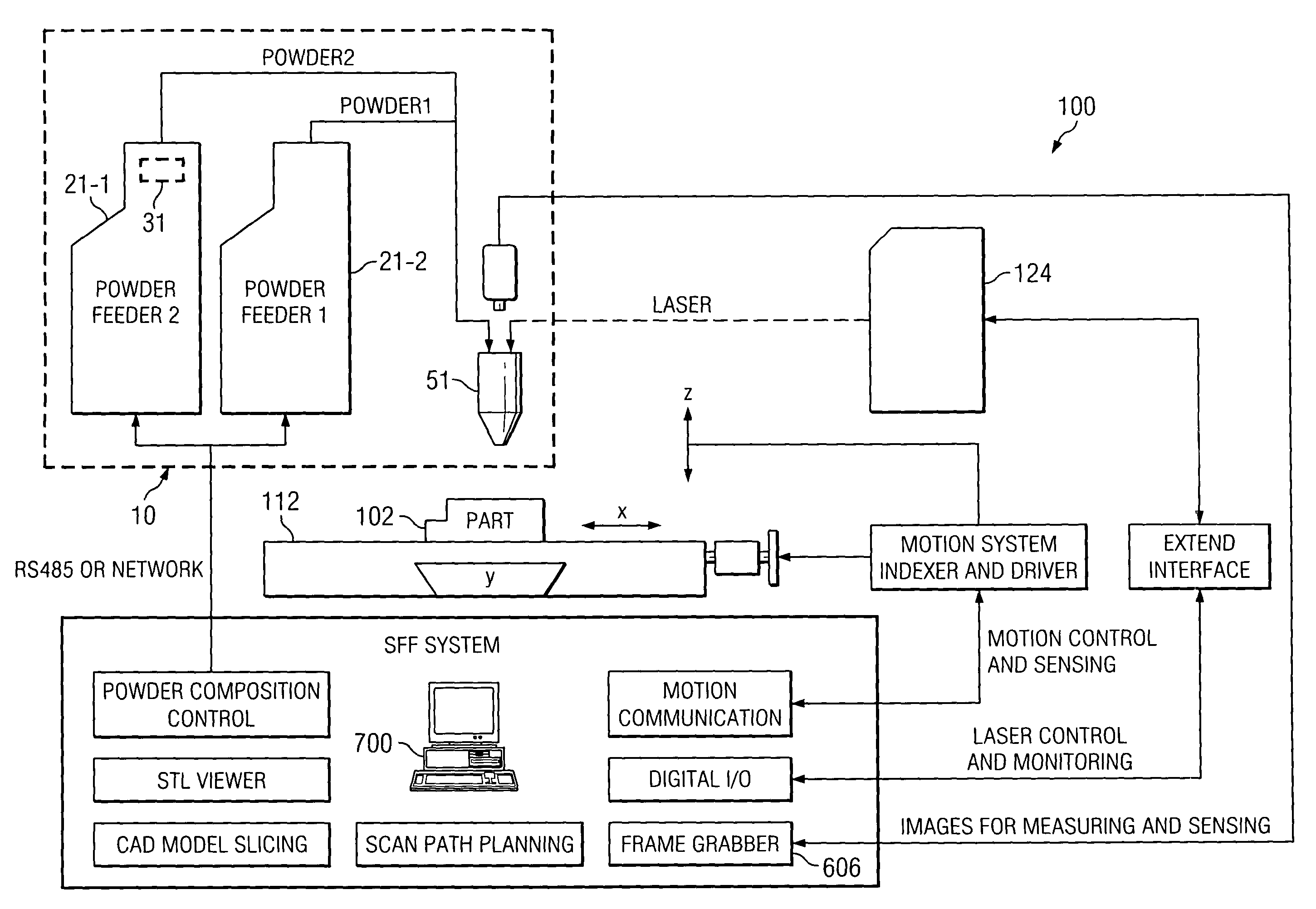

System and method for controlling the size of the molten pool in laser-based additive manufacturing

InactiveUS6995334B1High geometric accuracyEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser Nozzle

According to one embodiment of the invention, a method for controlling the size of the molten pool in a laser based additive manufacturing process includes coaxially aligning an imaging device with a laser nozzle and imaging a molten pool, created by a laser, on a substrate with the imaging device. The method further includes comparing at least one characteristic of the molten pool with a respective characteristic of a target molten pool, and adjusting, in substantially real-time, a laser power of the laser based on the comparison in order to correlate the characteristic of the molten pool with the respective characteristic of the target molten pool.

Owner:SOUTHERN METHODIST UNIVERSITY

Solid freeform fabrication system and method

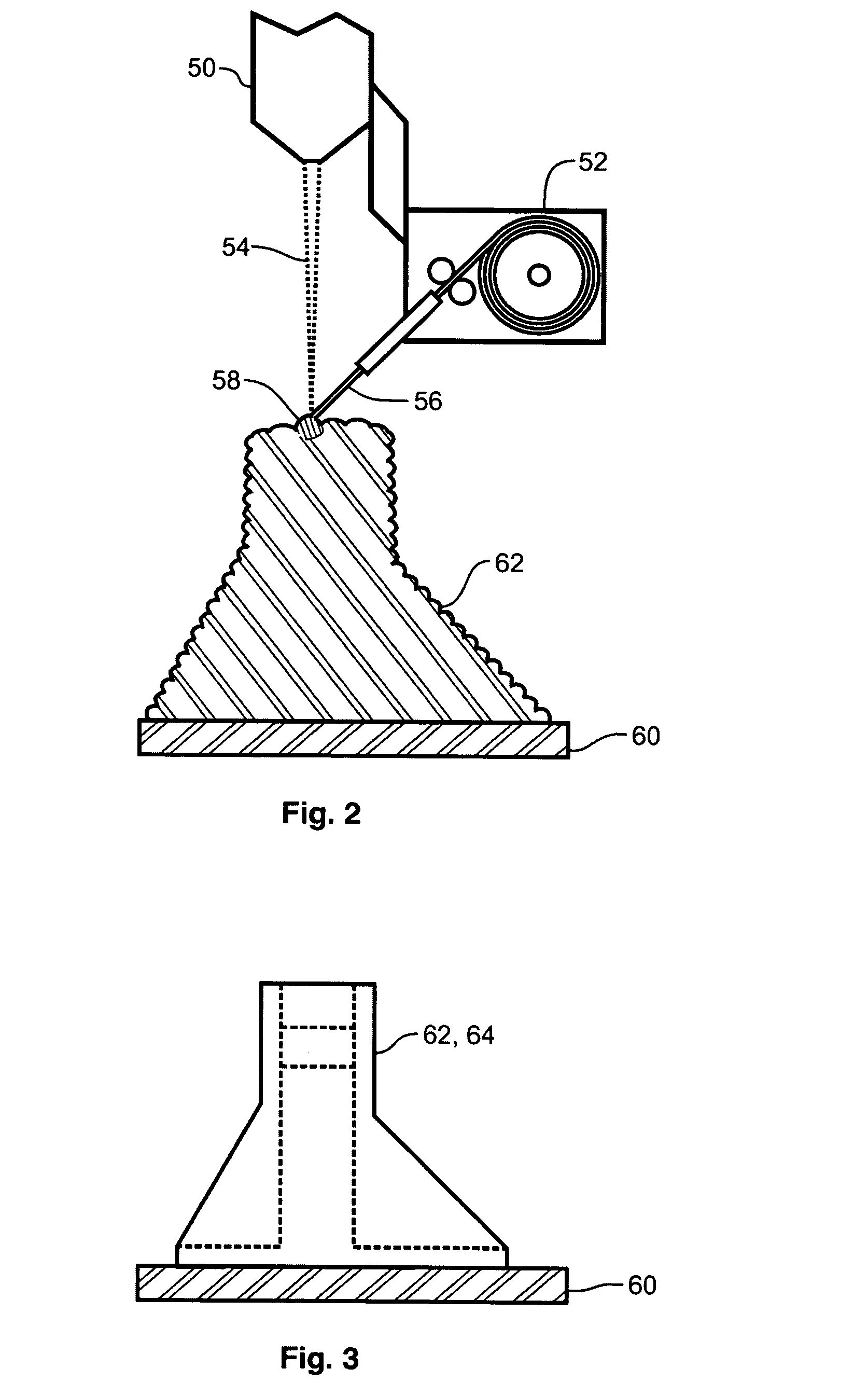

A system and method of solid freeform work piece fabrication through layered deposition of feedstock material on a mold structure. An energy beam and feedstock are fed to a feed point adjacent to a mold structure, thereby forming a molten puddle. The feed point is moved relative to the mold structure, thereby advancing the molten puddle of presently fed feedstock and rapidly solidifying previously fed feedstock. The feed point is sequentially advanced within a predetermined geometric volume containing at least a portion of the mold structure, thereby sequentially fusing the feedstock, by action of the advancing molten puddle, into a near net shape work piece built-up upon the mold structure.

Owner:HENN DAVID S

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Developer/rinse formulation to prevent image collapse in resist

An apparatus and method are provided for developing photoresist patterns on electronic component substrates such as semiconductor wafers. The method and apparatus use a specially defined developer composition in sequence with a specially defined rinse composition to develop an exposed photoresist pattern and then to rinse the developed pattern. Both the developer composition and rinse composition contain an anionic surfactant and, when the solutions are used in sequence, have been found to provide a resist pattern which avoids pattern collapse even when small features such as line widths less than 150 nm with aspect ratios of greater than about 3 are formed. It is preferred to use a puddle developing and puddle rinsing process to develop and rinse the exposed wafer. Preferred anionic surfactants are ammonium perfluoroalkyl sulfonate and ammonium perfluoroalkyl carboxylate.

Owner:IBM CORP

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

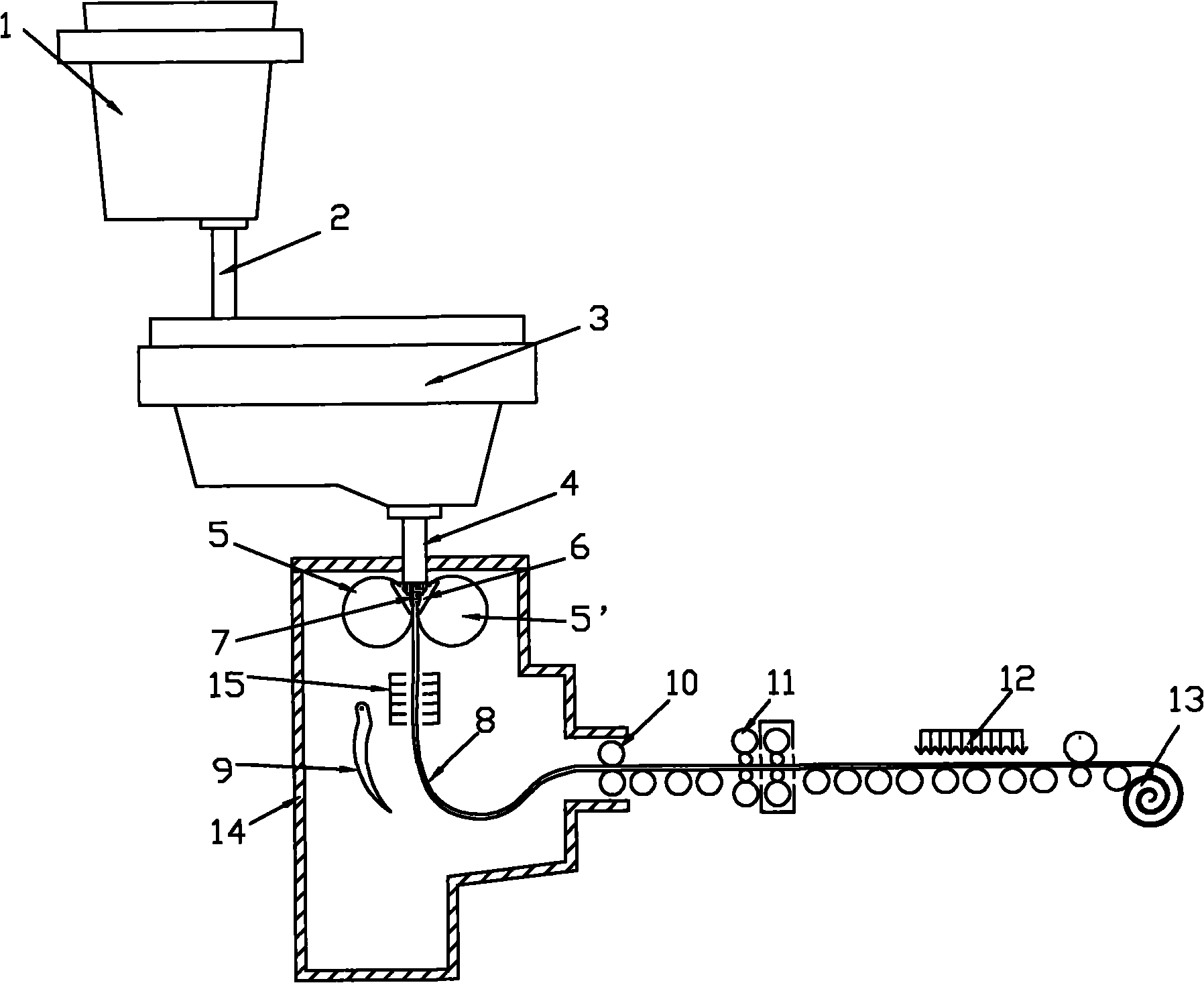

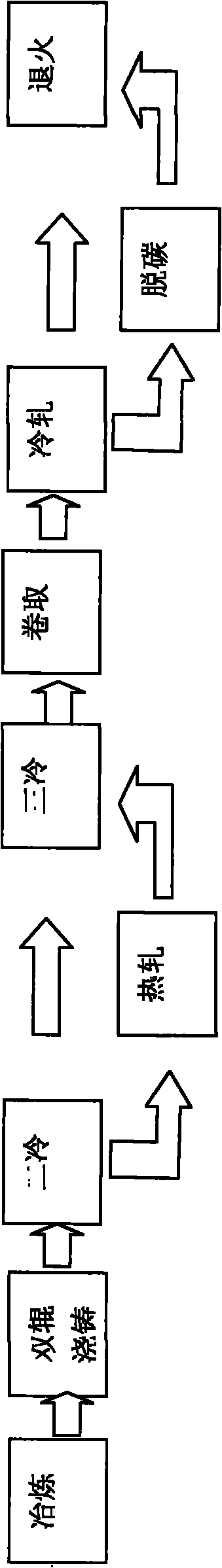

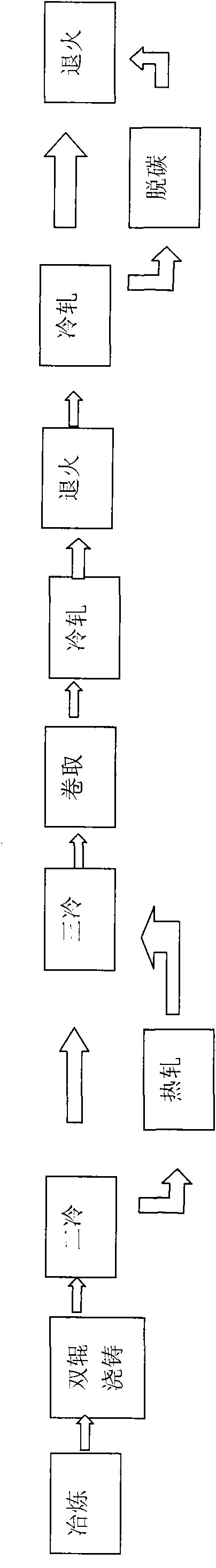

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

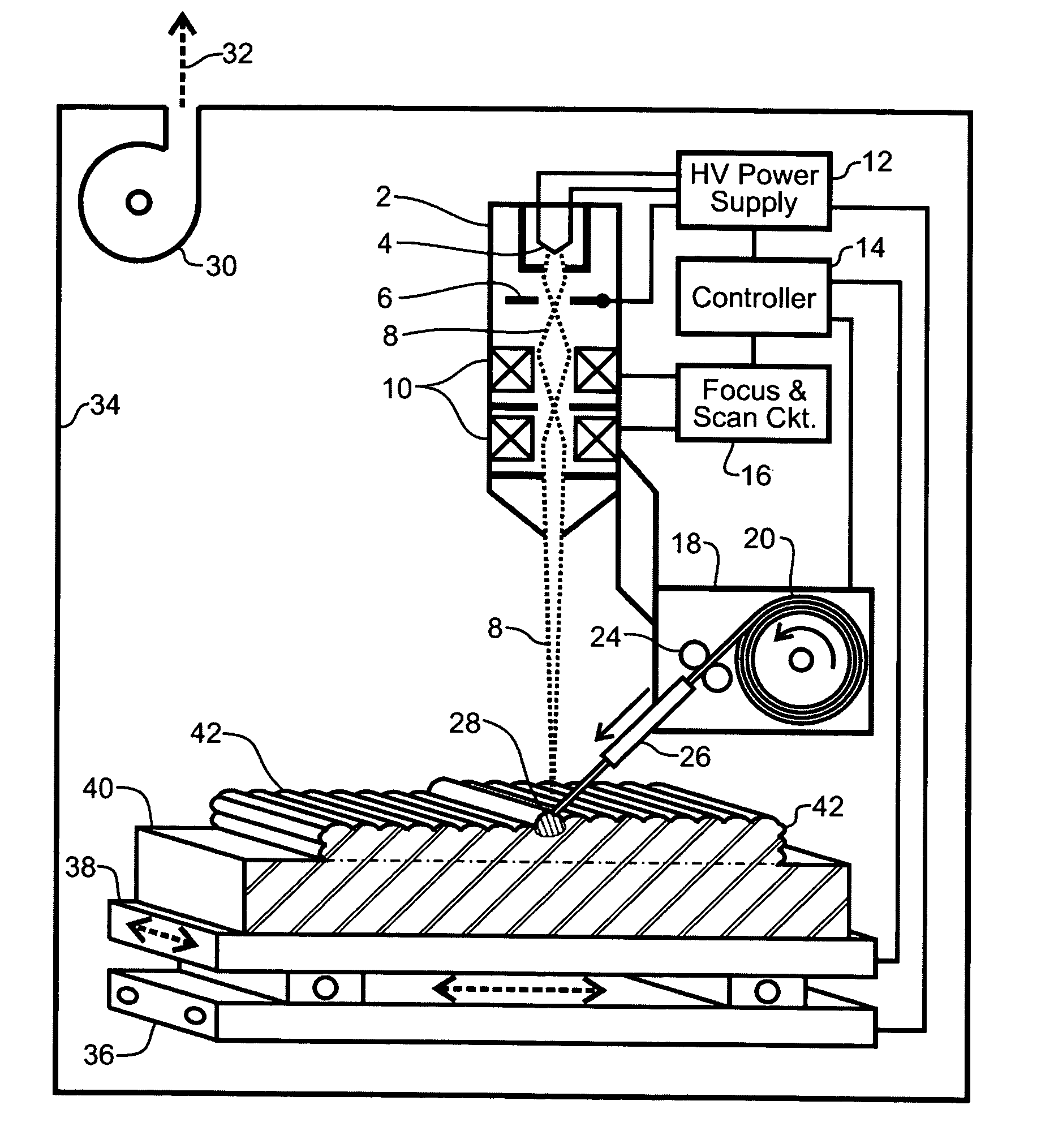

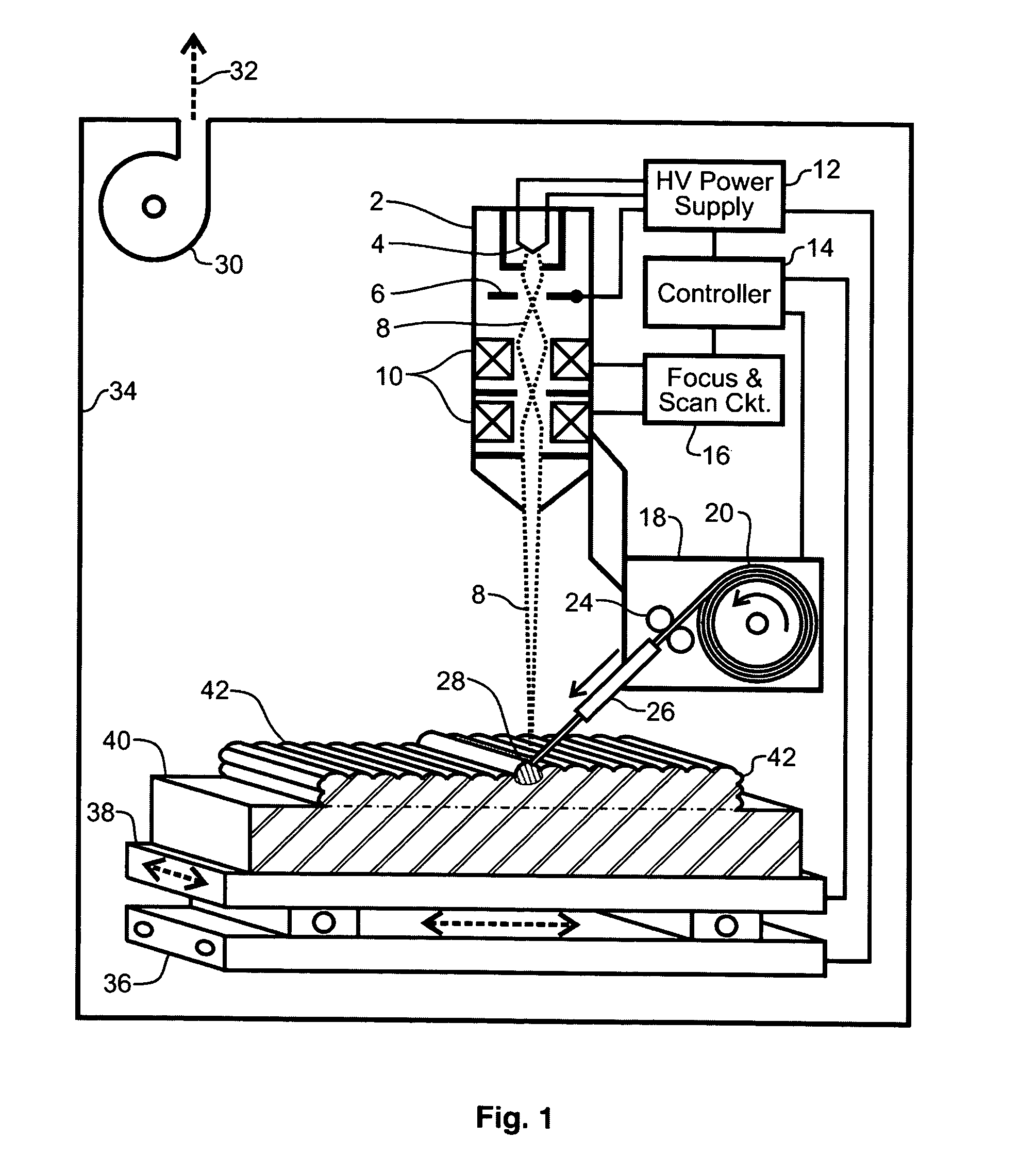

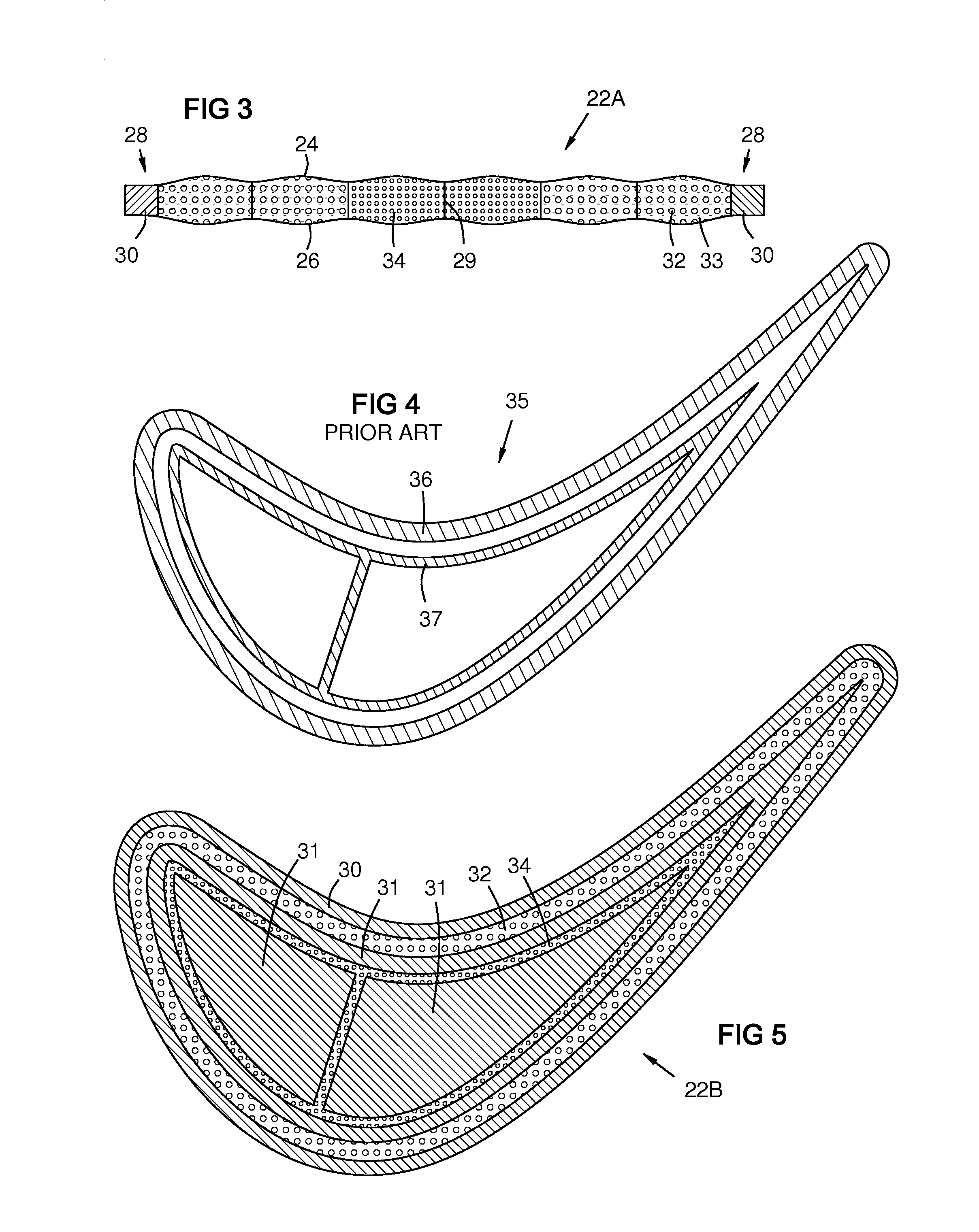

Superalloy solid freeform fabrication and repair with preforms of metal and flux

A preform (22, 22A-U) containing metal (32, 34) and flux (33) for forming a metal layer to be added to a component being repaired or additively manufactured. The metal may be constrained in the preform in a distribution that forms a shape of a sectional layer or a surface repair of a component in response to an energy beam (58) that melts the preform. The preform is placed on a working surface (42), which may be a previously formed layer (42A-C) in additive manufacturing, or may be an existing component surface (122) for repair The preform is then melted by the energy beam (58) to form a new integrated layer (40A-F) on the component with an over-layer of slag (56) that shields and insulates the melt pool (54) and the solidifying layer The slag is removed, and a subsequent layer may be added.

Owner:SIEMENS ENERGY INC

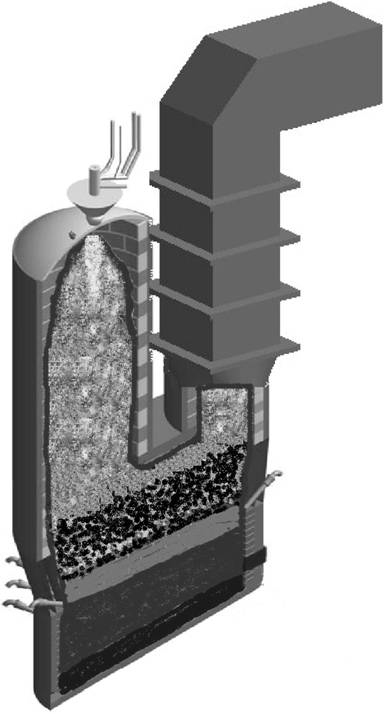

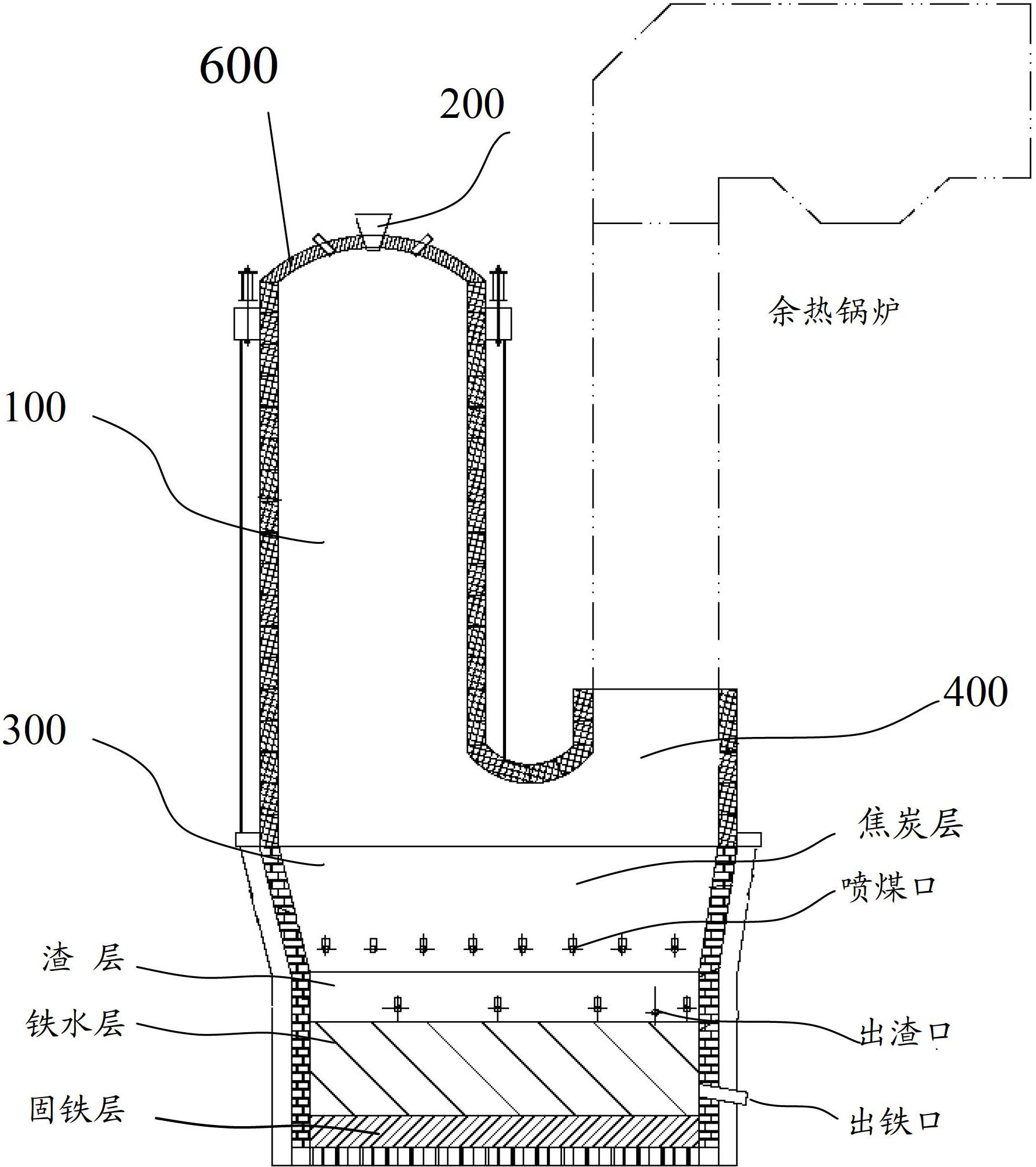

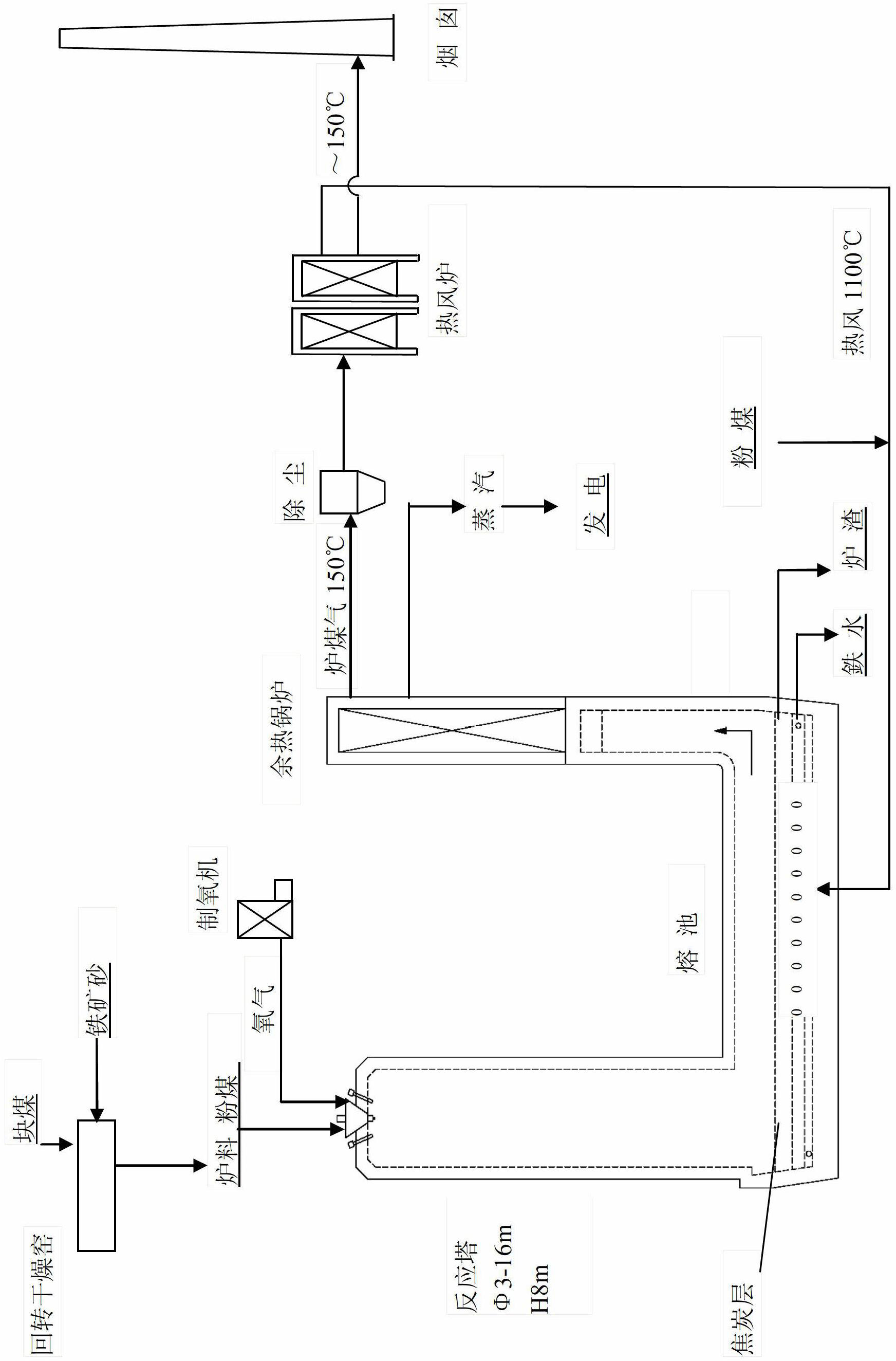

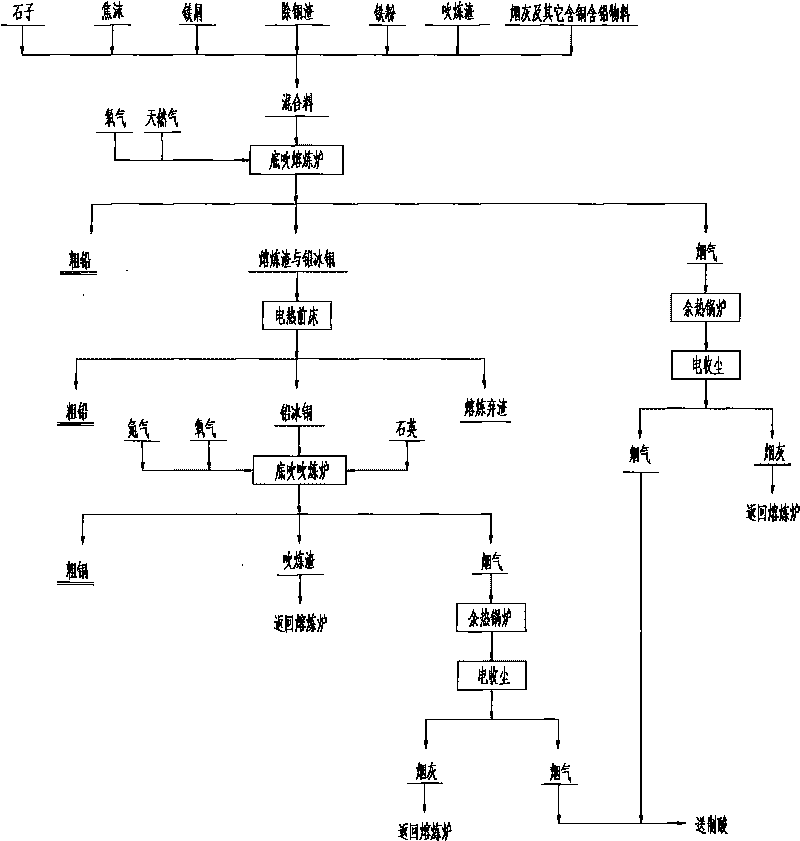

Flash smelting method of iron

The invention discloses a flash smelting method of iron. A flash smelting furnace comprises a reaction tower, a furnace charge nozzle, a molten bath and a flue, wherein a reaction space is limited in the reaction tower, the furnace charge nozzle is arranged at the top of the reaction tower, the molten bath is arranged on the lower portion of the reaction tower and used for containing melt fallen from the space of the reaction tower after reaction and for a subsequent reduction reaction of the melt, and the flue is communicated with the reaction tower through the molten bath and used for discharging flue gas generated during the reaction. The flash smelting furnace in the embodiment can be effectively used for flash smelting of the iron.

Owner:CHINA NERIN ENG

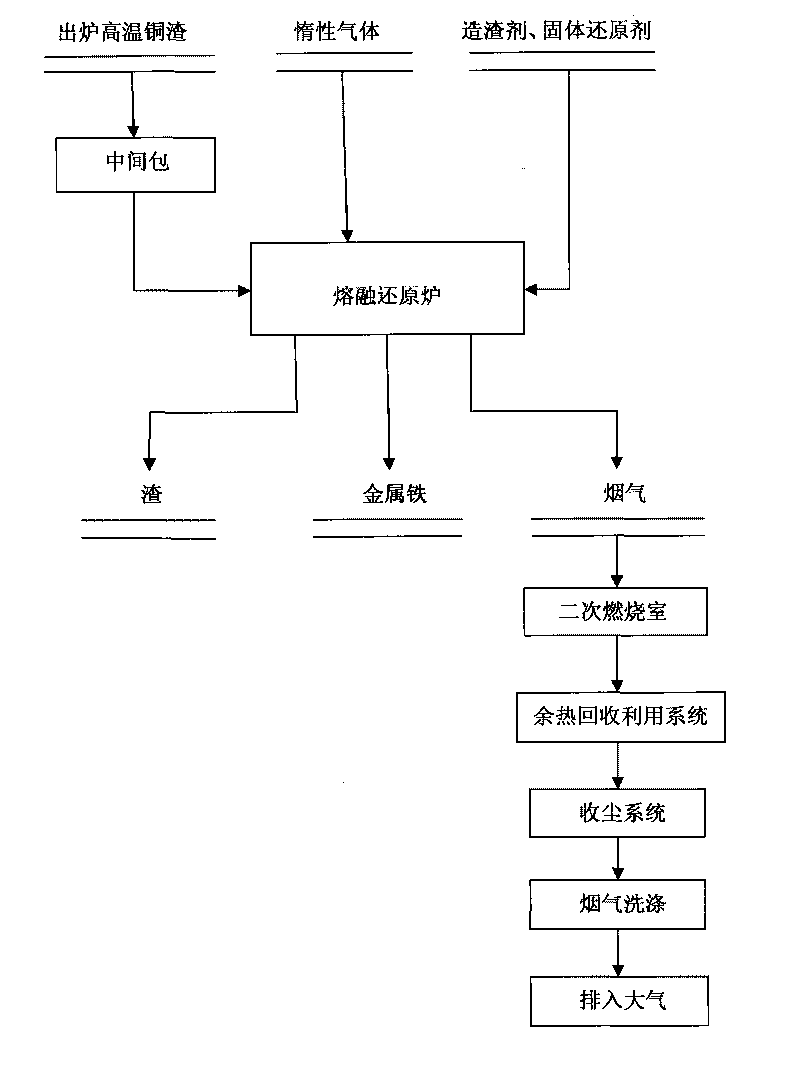

Method for fusing and reducing iron from copper residue by blowing inert gas

InactiveCN101736112AMeet the requirements of energy saving and emission reductionEmission reductionFluidised-bed furnacesMelting tankCombustion

The invention discloses a method for fusing and reducing iron from copper residue by blowing inert gas which comprises the steps of: transferring a high-temperature copper residue from a pouring packet to a high-temperature reduction furnace, adding reducing agent and slagging agent which are crushed into the reduction furnace, performing high-temperature iron reduction reaction, stirring inert gases and blowing into a furnace hearth during the reaction, spraying the inert gases and stirring the fused residue, performing high-temperature smoke secondary combustion, collecting dust and washing after recycling the waste heat, injecting into the atmosphere after emptying, and discharging high-temperature molten iron and slag from an iron outlet and a slag outlet after finishing the reaction. The invention takes full advantages of high-temperature waste heat of the discharged copper residue in order to save energy and reduce emission. The process flow is short; the discharge of contaminant is less, the recovering ratio is high; the applicability is wide; the process flow for recycling iron from copper residue is shortened; the operation in each process flow is simple; and the maintenance cost for furnace is lower.

Owner:KUNMING UNIV OF SCI & TECH

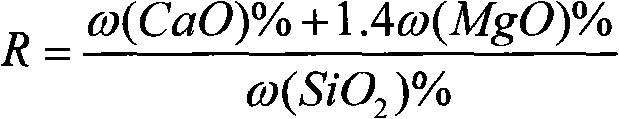

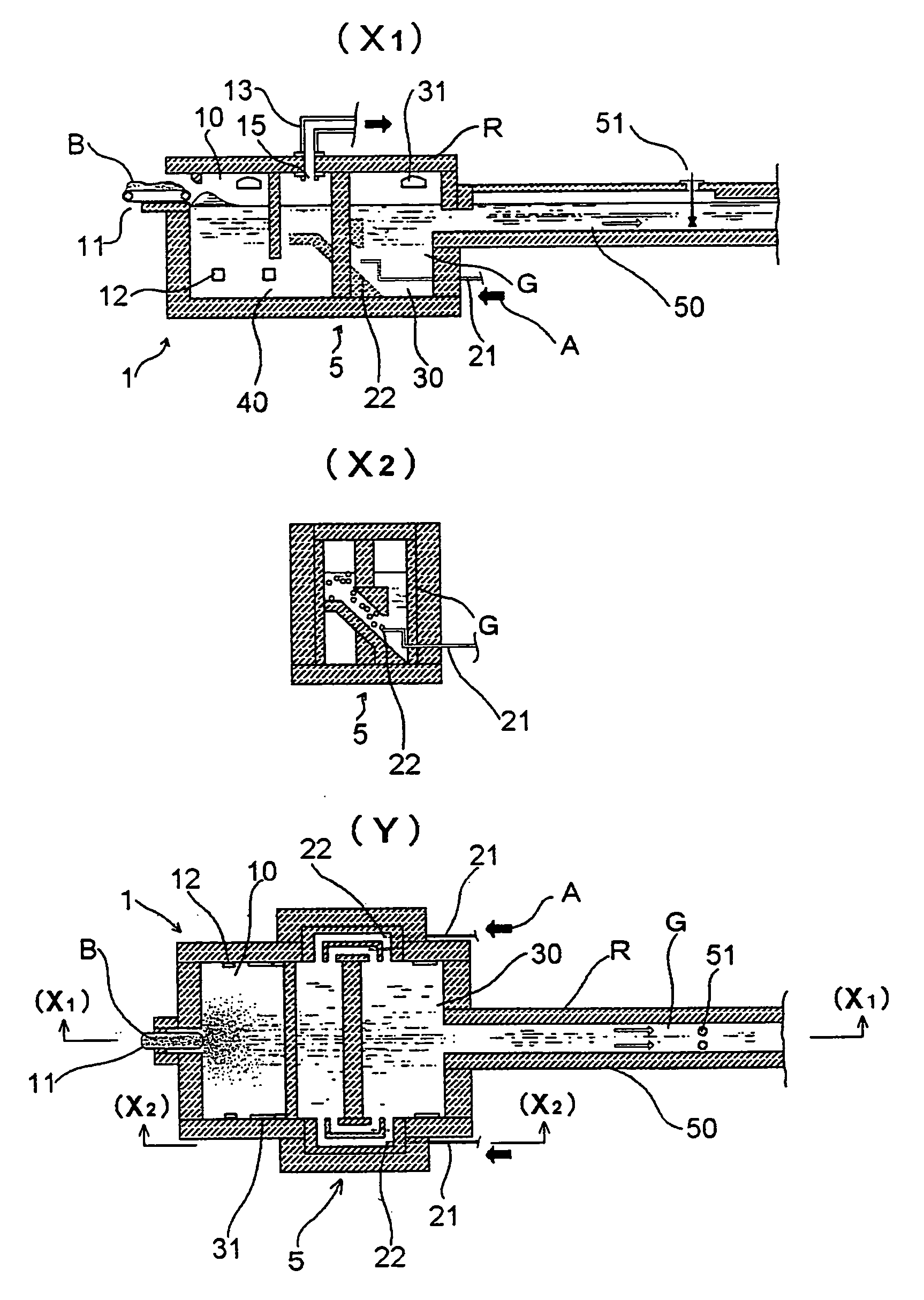

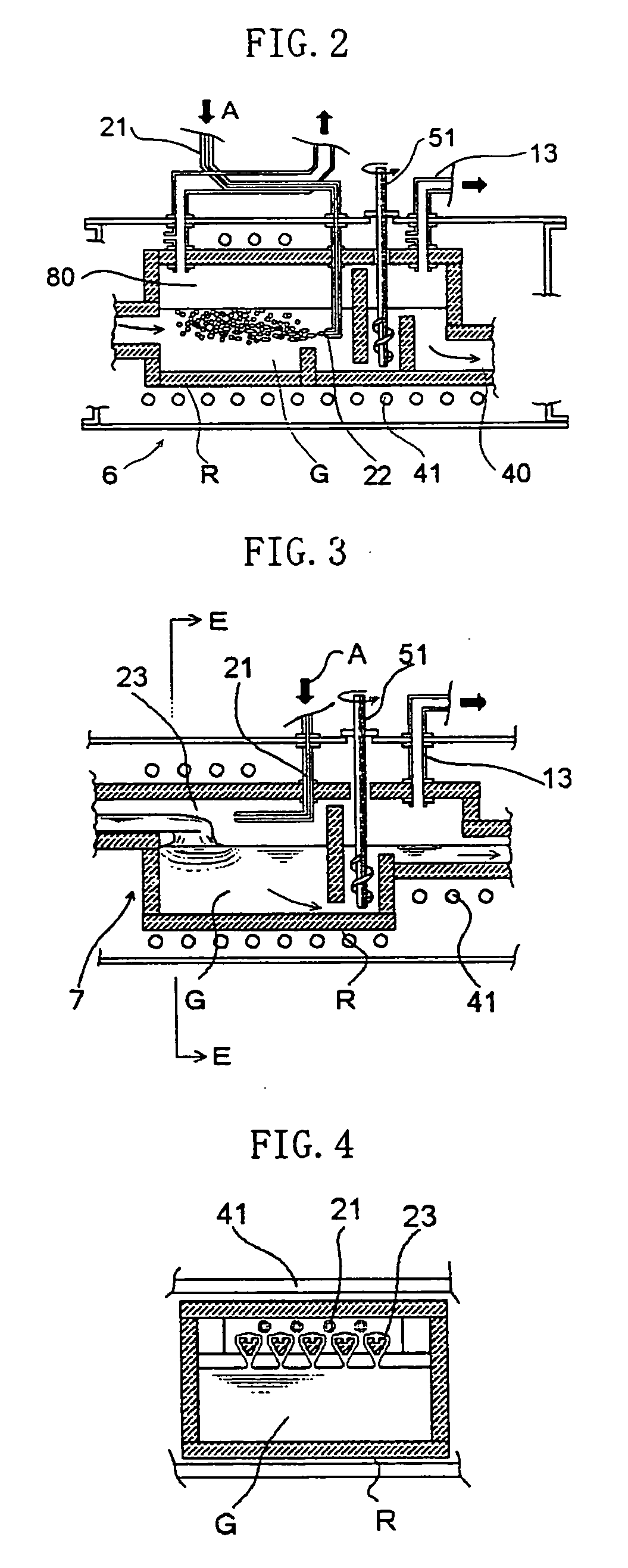

Glass melting gurnace and method for producing glass

InactiveUS20060101859A1Precise maintenanceReduce the environmentGlass furnace apparatusGlass pressing apparatusMelting tankNoble gas

A charged glass raw material B is melted in a melting tank 10 by heating with a burner 31 and by heating with electrodes 12, to form molten glass G. Then, the molten glass G flows into a tank additionally provided as a noble gas dissolving tank 20 through a throat 40. The noble gas dissolving tank 20 is provided with a noble gas dissolving device 53, and the noble gas dissolving device 53 is provided with sixteen noble gas inlets 22 for introducing a helium or neon gas supplied to a hearth through heat resistant gas introduction tubes 21 into the noble gas dissolving tank 20. Bubbles of a helium gas A having a purity of 99% are blown out from the noble gas inlets 22 in volumes such that the bubbles have an average diameter of 80 mm or less in the molten glass G.

Owner:NIPPON ELECTRIC GLASS CO LTD

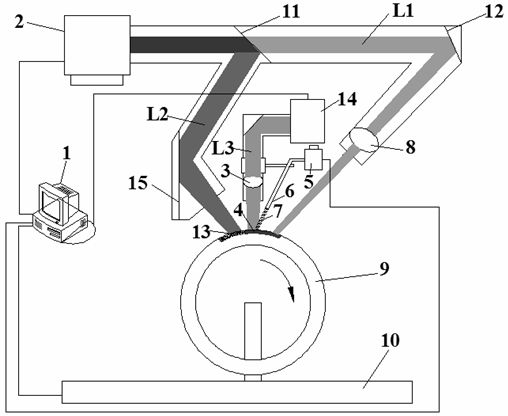

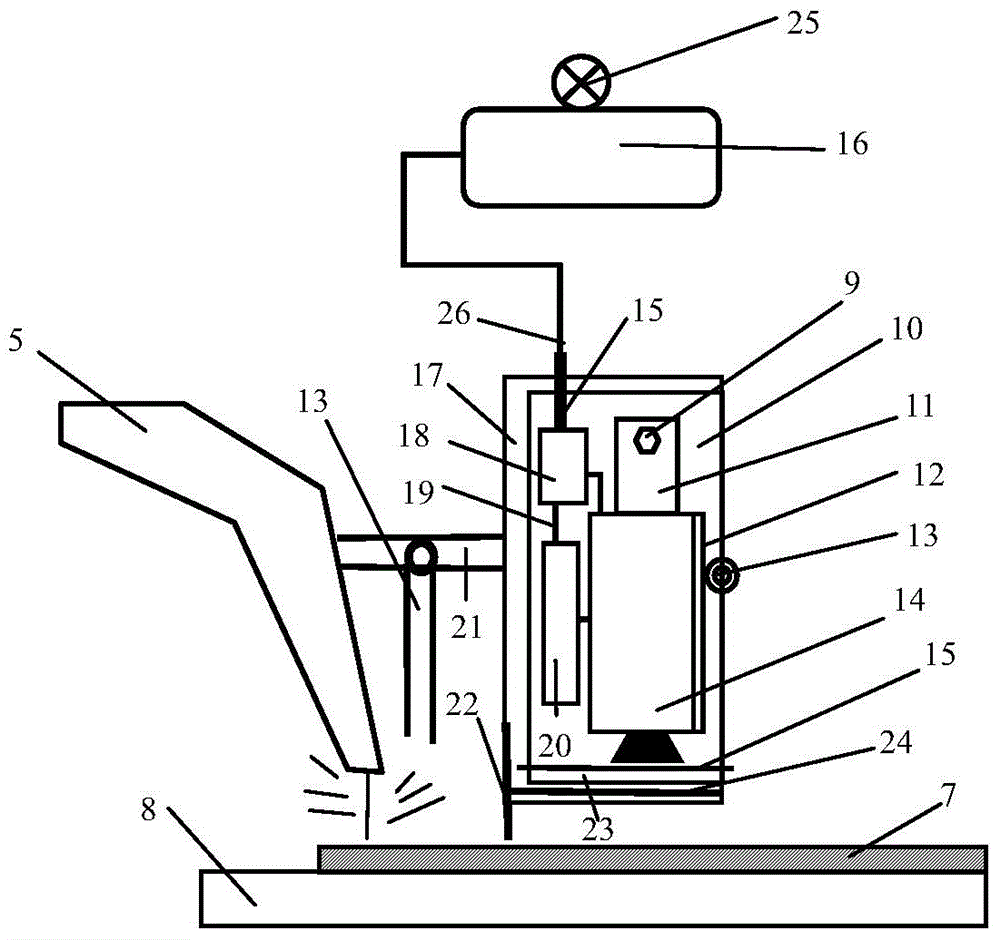

Welding quality analysis device based on infrared vision and analysis method thereof

InactiveCN104977305ALower regenerationIncrease the level of automationWelding/cutting auxillary devicesOptically investigating flaws/contaminationMelting tankVision processing

The invention discloses a welding quality analysis device based on infrared vision and an analysis method thereof. The analysis device comprises an infrared vision collecting system that is adjustably and fixedly connected to a welding facility, a vision processing system, in which welding defect intelligent recognition algorithm is embedded, and a feed control system, which can evaluate the welding quality, give an alarm, and adjust the parameters of the welding facility. The analysis method comprises the following steps: (1) collecting the infrared vision information of a molten pool or an area near a molten pool in real time through infrared sensing; (2) processing the infrared vision information by the welding defect intelligent recognition algorithm so as to obtain the weld seam positions and welding defect characteristics; (3) evaluating the welding quality in real time, and controlling the welding facility and giving an alarm aiming at different welding defects. According to the provided intelligent analysis device and intelligent analysis method, the welding process can be monitored in real time, the welding defects can be recognized, the welding seam position can be traced, the welding quality can be evaluated, the welding loss can be reduced, and the finished product yield rate can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

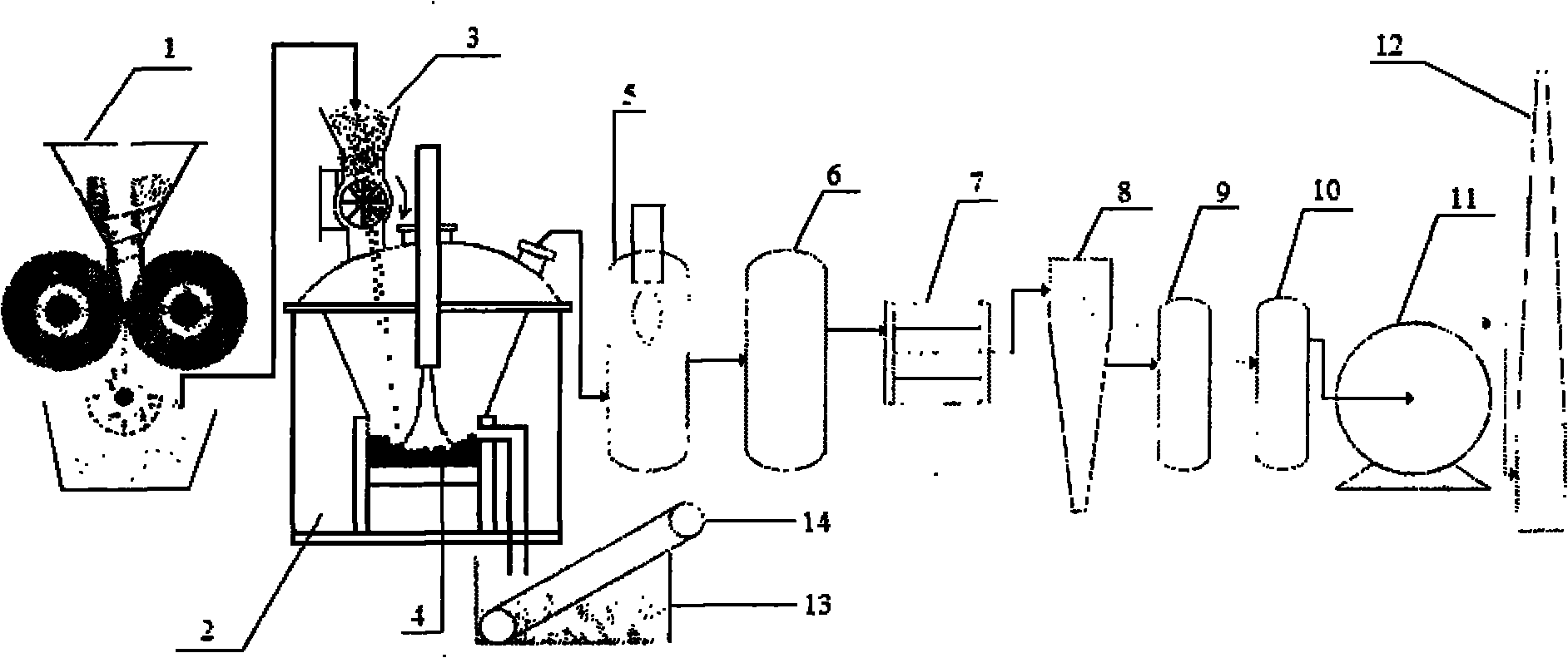

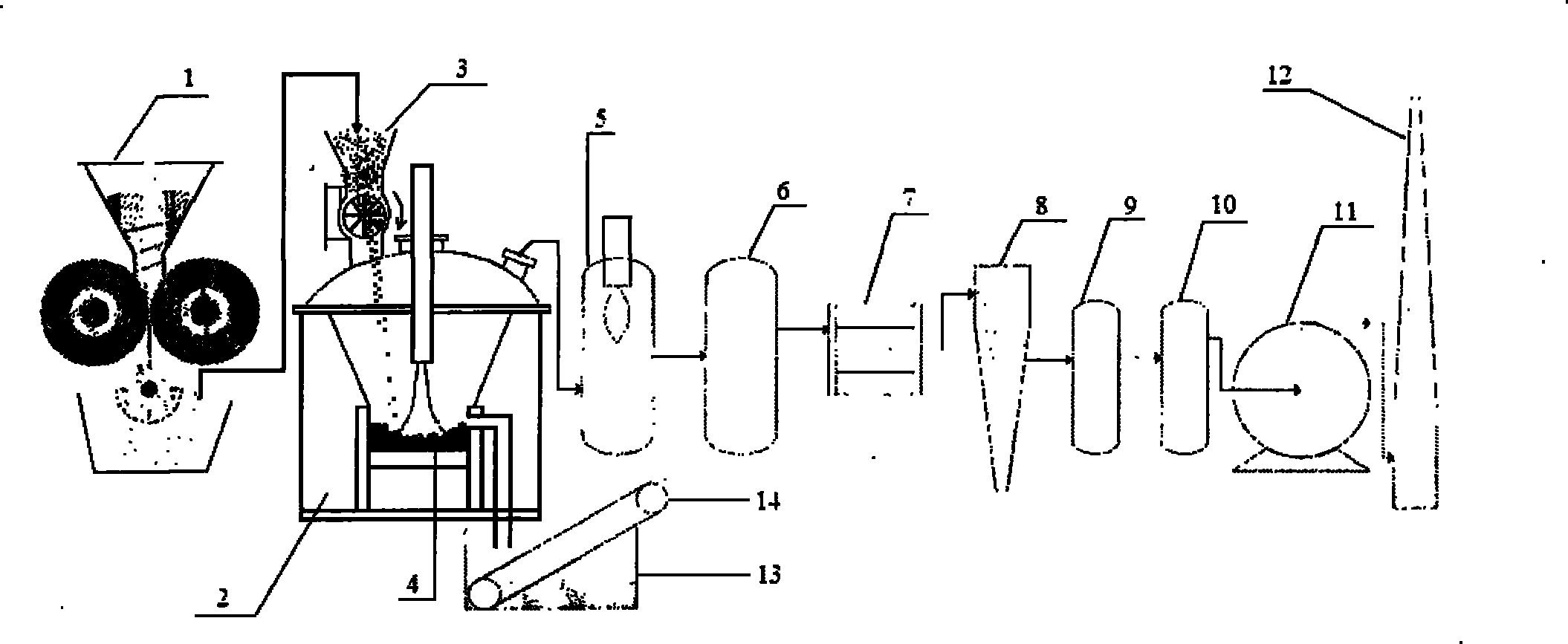

Method for treating waste incineration fly ash by using plasmas

InactiveCN101797572APromote vitrificationSolve the "bridge" problemSolid waste disposalMelting tankVitrification

Owner:安徽中科华炬环保科技有限公司

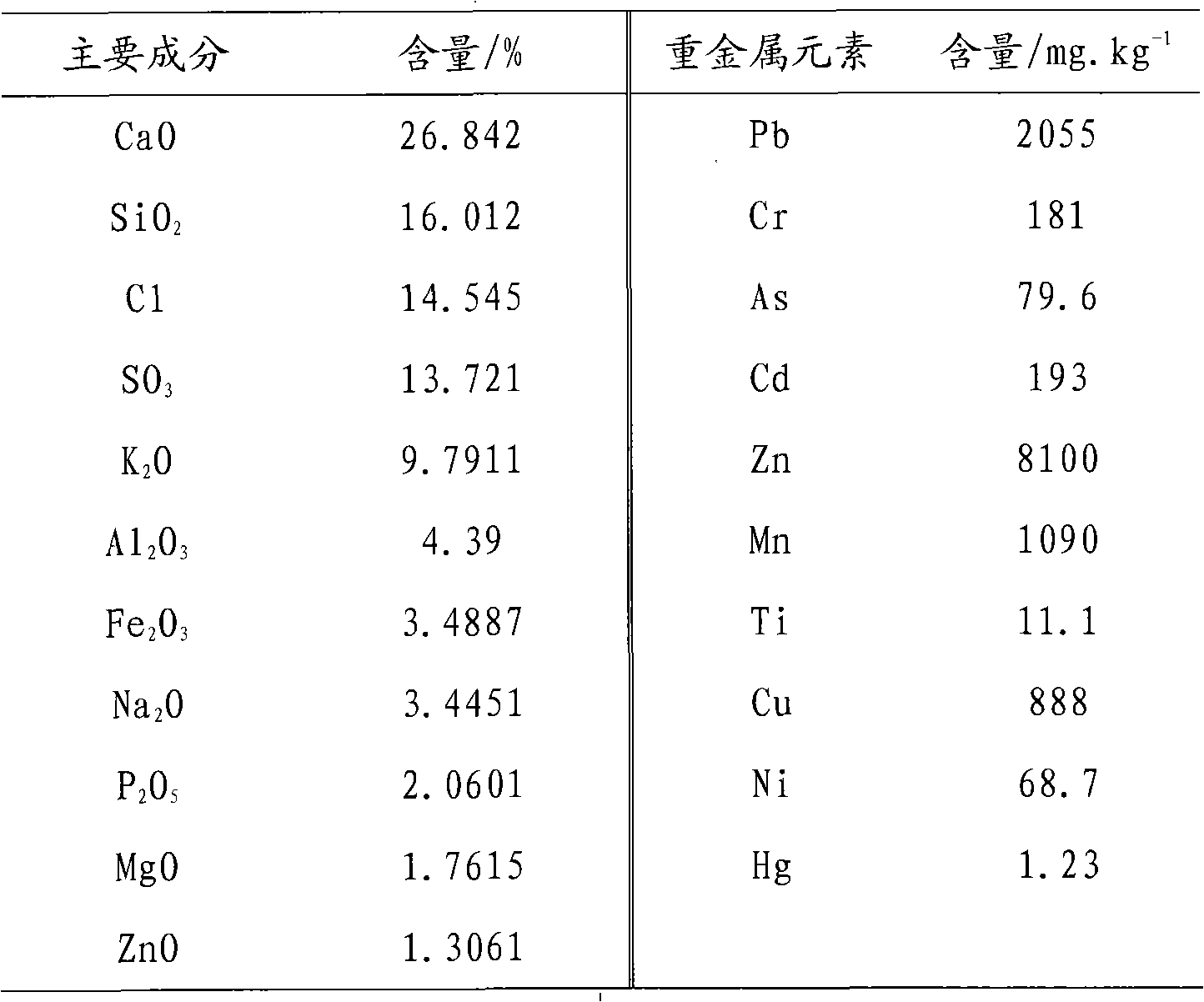

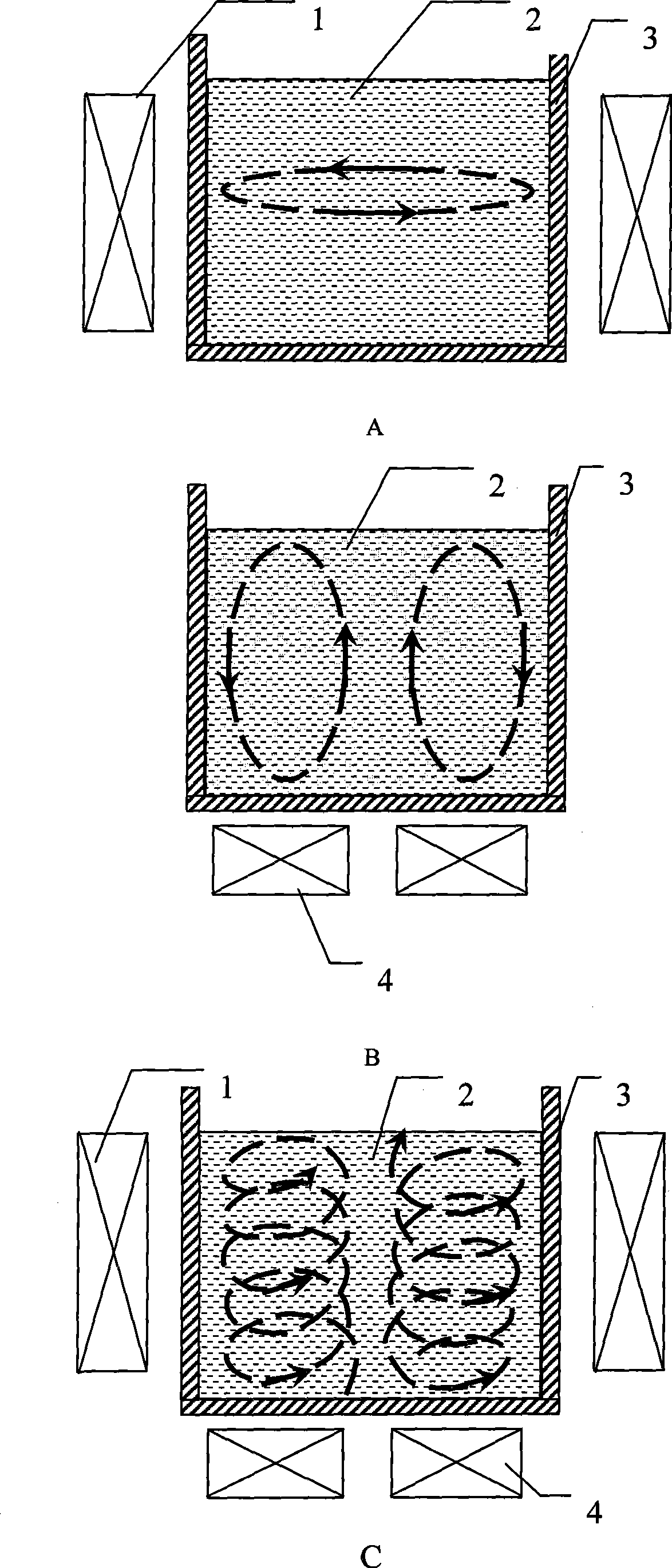

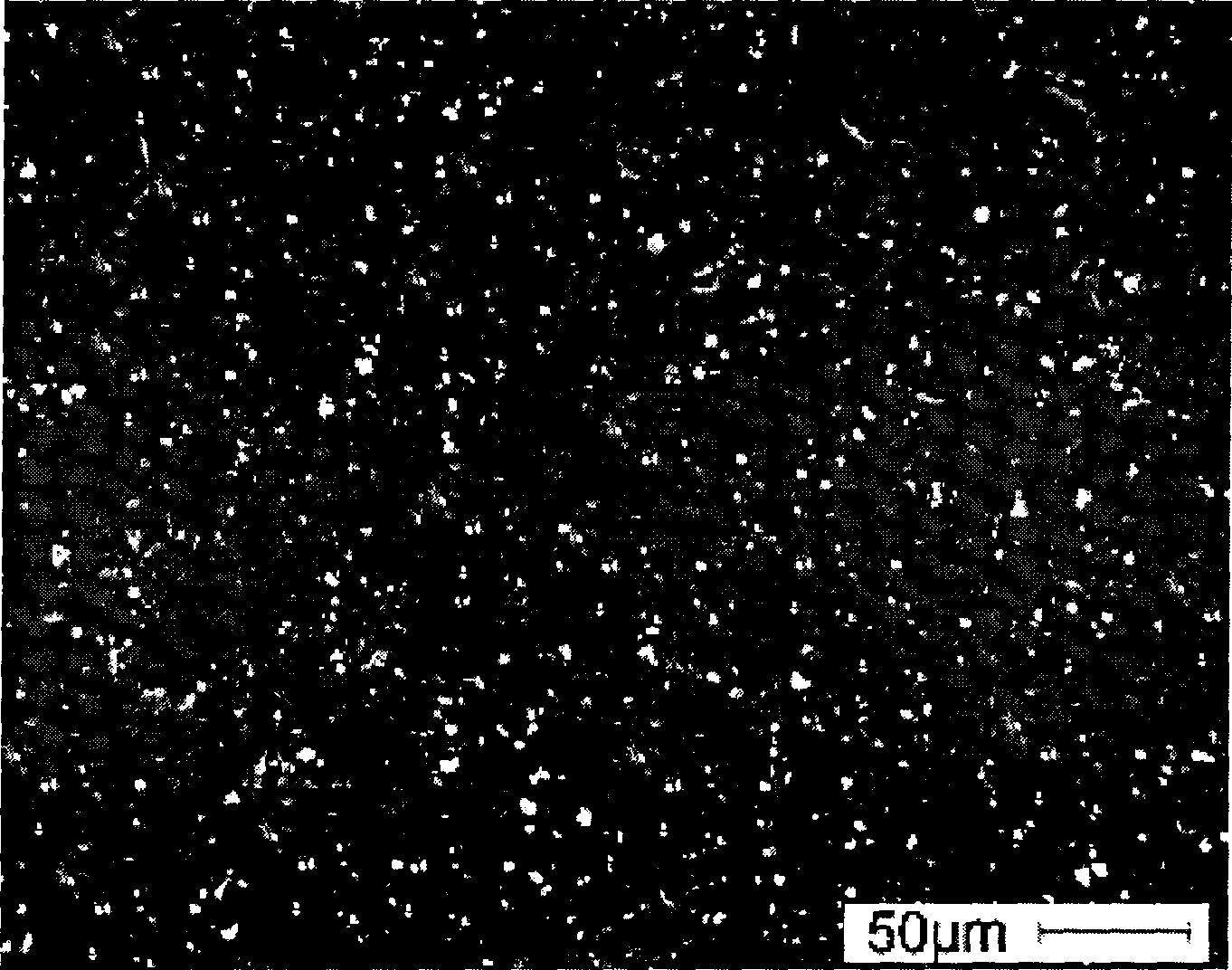

Metal matrix composition home-position synthesizing method in combined electric magnetic field

The invention provides a method for continuously producing particle reinforced metal matrix composites in an industrial scale, which adopts the synthesis of metal matrix composites in a combination magnetic field. The method is characterized in that: the combination of a rotating magnetic field and a travelling wave magnetic field is adopted to synthesize a preparation particle reinforced metal matrix composite fused mass in the in-situ synthesis process of composites. The low frequency rotating magnetic field is placed at the outer side of a composite material molten pool, and the center of a coil of the magnetic field and the center of the fused mass are at the same height; and the travelling wave magnetic field is exerted at the bottom part of the composite material molten pool, and the coil center of the travelling wave magnetic field and the center of the composite material molten pool are at the same position. The composite material particle reinforced phases prepared by the method are distributed evenly and thinned, interior tissues are compact and have no structural defects such as loosening and hole shrinkage, the degree of finish of external surfaces of casting blanks is high, defects are eliminated, and the friction resistance and the abrasion resistance of the composites are obviously improved.

Owner:JIANGSU UNIV

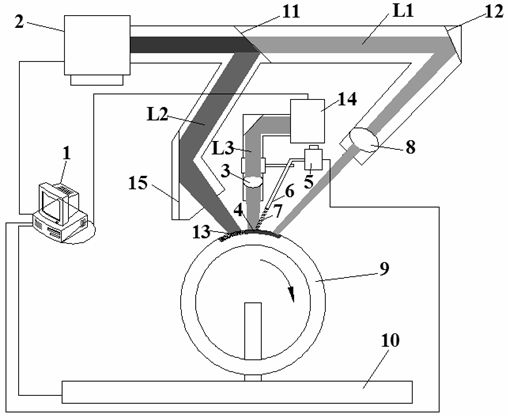

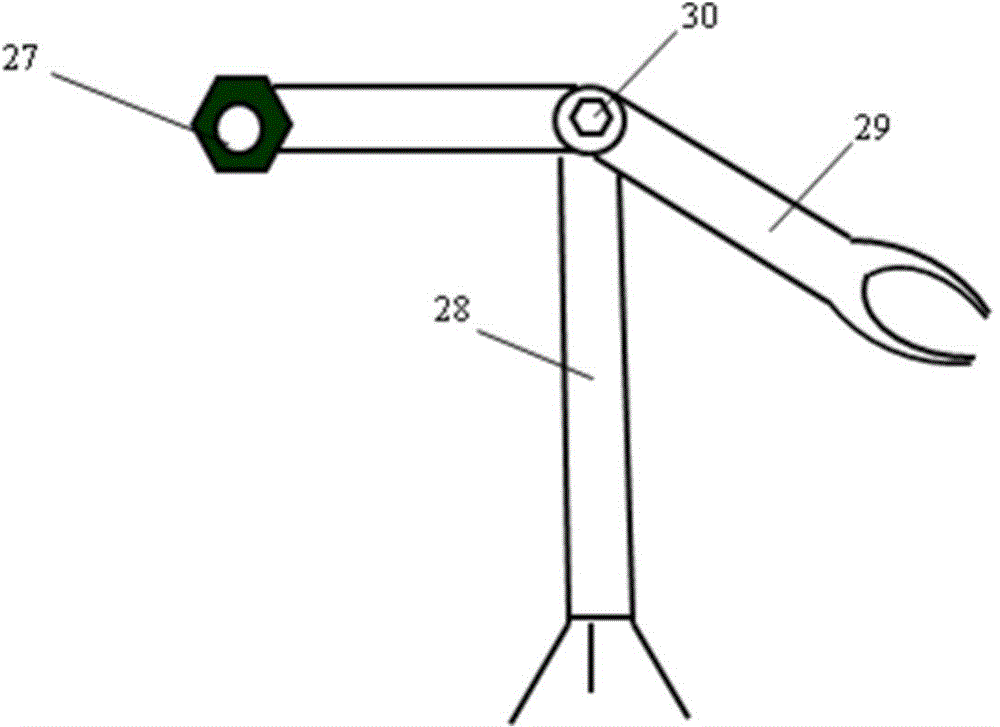

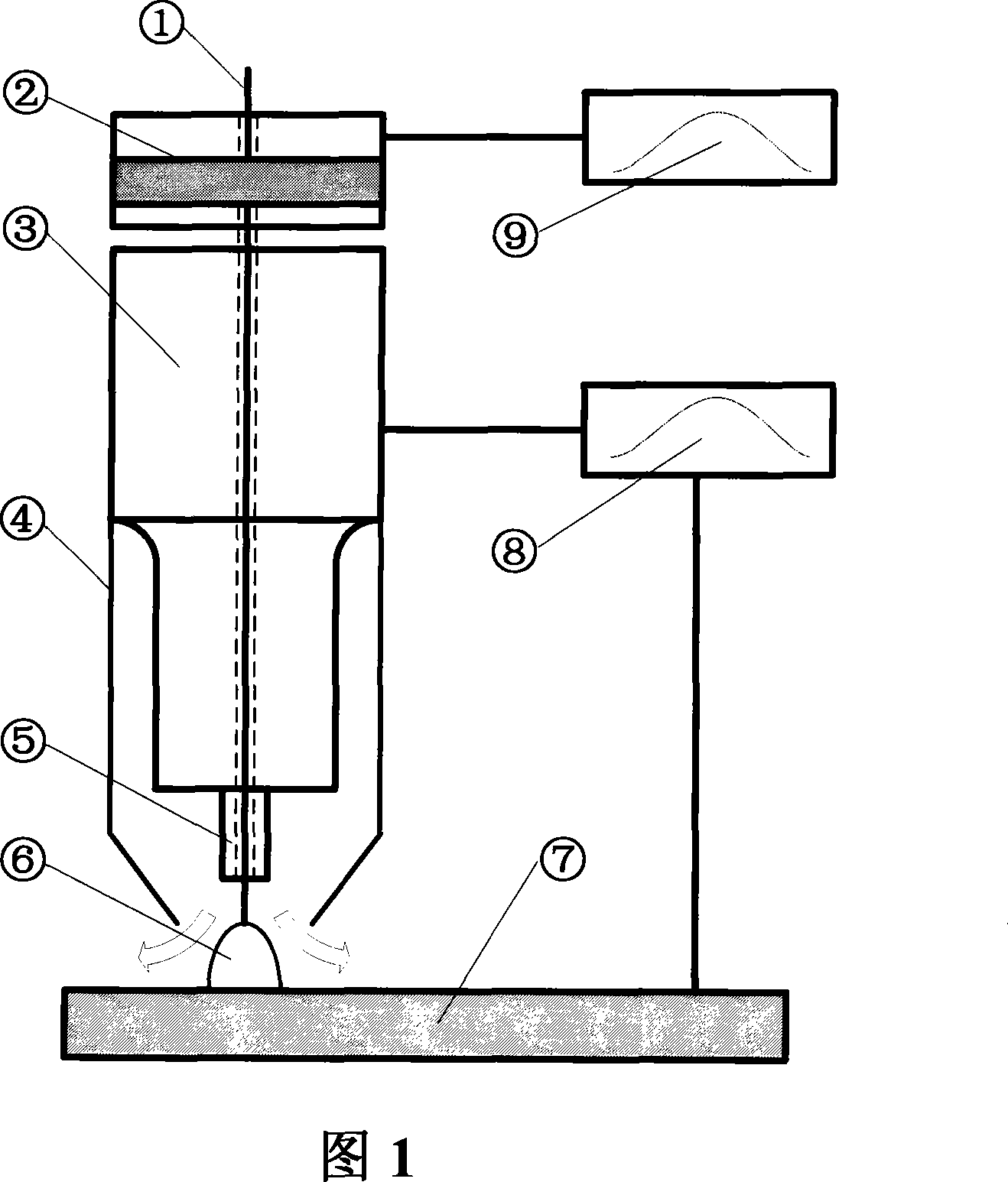

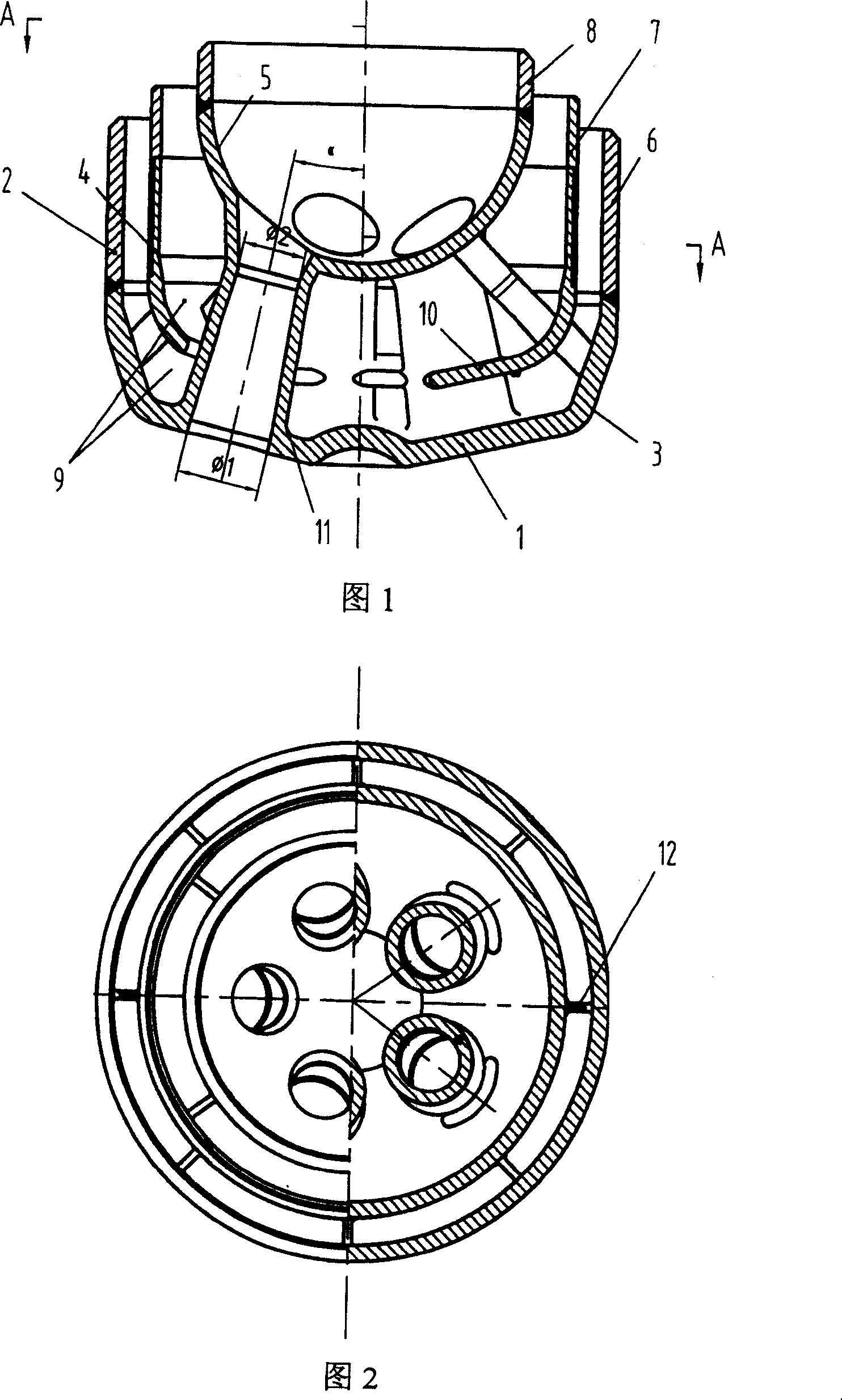

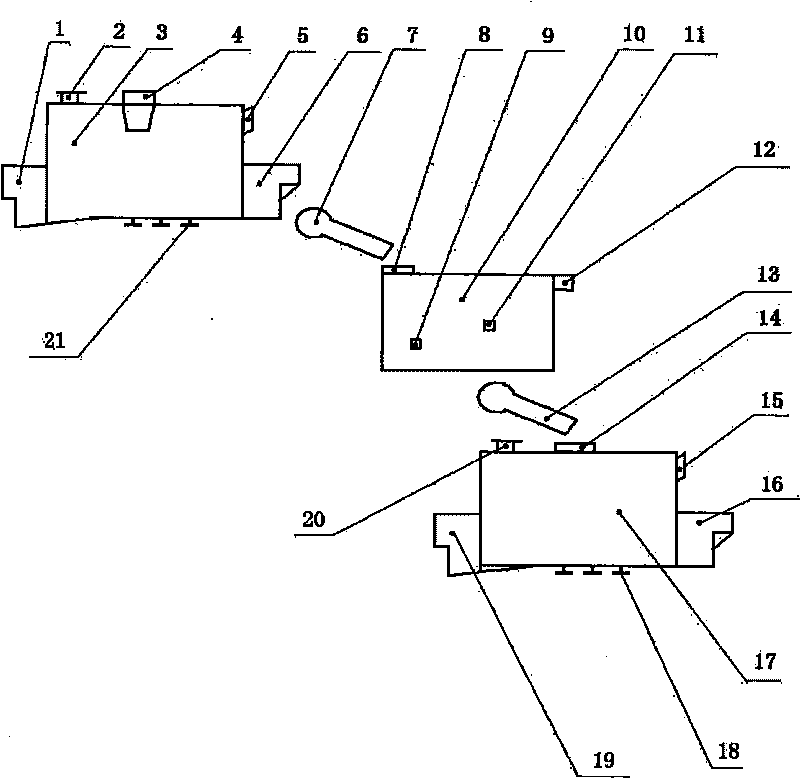

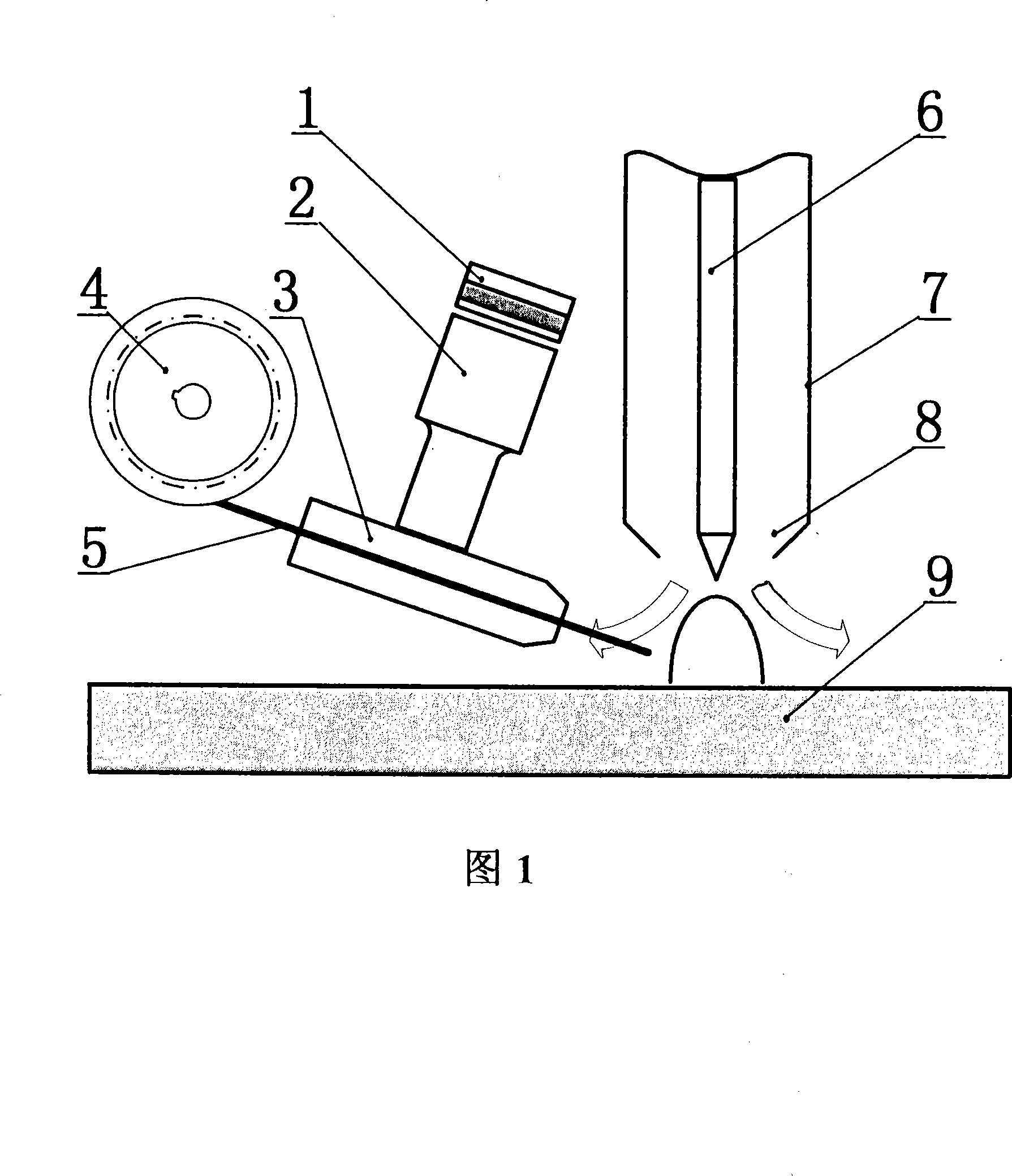

Ultrasound wave and melt pole electrical arc compound welding method

The invention provides a weld method compounding an ultrasonic and a gas metal arc welding so as to make use of the cavitation effect and the vibration effect of the ultrasonic to lead welding drops generated by the gas metal arc welding to be smoothly transmitted to a welding pool when the drops are still small. And when in welding, an electric arc shrinks under the effect of the ultrasonic and then the stiffness of the electric arc can be enhanced, which has a significant application value for welding of special positions such as a full-position welding, an overhead position welding, a flat position welding and a horizontal position welding, etc.. The invention includes the following steps: an ultrasonic generator is connected with an ultrasonic transducer 2 to convert ultrasonic energy into mechanical vibration; an ultrasonic transformer 3 enlarges amplitude; a conductive tip 5 is combined with the ultrasonic transformer; a protective gas nozzle 4 is fixed on the vibration node of the transformer; a welding wire 1 is connected with the conductive tip 5 to start a welding power supply 9 and then start an ultrasonic power supply after the electric arc becomes stable, then the transducer converts electrical energy into vibration and the ultrasonic transformer enlarges the ultrasonic amplitude which is transmitted to a melting electrode.

Owner:HARBIN INST OF TECH

Method for smelting high-carbon steel from semi-steel

InactiveCN102766722ARealize the purpose of simultaneous dephosphorization and carbon conservationShorten the formation timeManufacturing convertersMelting tankSilicon alloy

The invention provides a method for smelting high-carbon steel from semi-steel. The method adopts the semi-steel after extraction of vanadium as a raw material, and comprises the following steps of: adopting a low vanadium extraction process during smelting of a vanadium extraction converter to ensure that the carbon content of the semi-steel after the extraction of vanadium is not smaller than 3.70 weight percent, and the temperature of the semi-steel is not lower than 1,290 DEG C; adding active lime into the converter according to a standard of 10 to 15 kg in a ton of steel, adding high-magnesium lime into the converter according to a standard of 7 to 10 kg in a ton of steel, shaking the converter back and forth to ensure that the active lime and the high-magnesium lime are uniformly mixed with steel slag in the converter, then adding the semi-steel into the converter, and adding a ferro-silicon alloy into the converter, wherein the added amount of the ferro-silicon alloy can ensure that the initial alkalinity of furnace slag is 2 to 3; performing converting, and pouring out the furnace slag when the temperature of a molten pool is raised to be 1,400 to 1,500 DEG C; adding active lime into the converter according to a standard of 12 to 18 kg in a ton of steel and adding high-magnesium lime into the converter according to a standard of 9 to 12 kg in a ton of steel to perform secondary slagging; performing converting, and adding manganiferous iron ore into the converter to ensure that the alkalinity of the furnace slag is 4 to 5 and a CaO-SiO2-FeO-MnO low-melting-point slag system is formed; adding a cooling agent into the converter after converting for 3 to 5 minutes, and continuously converting until target molten steel and terminal furnace slag are obtained; and tapping. According to the method, dephophorization and carbon maintenance can be realized at the same time.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

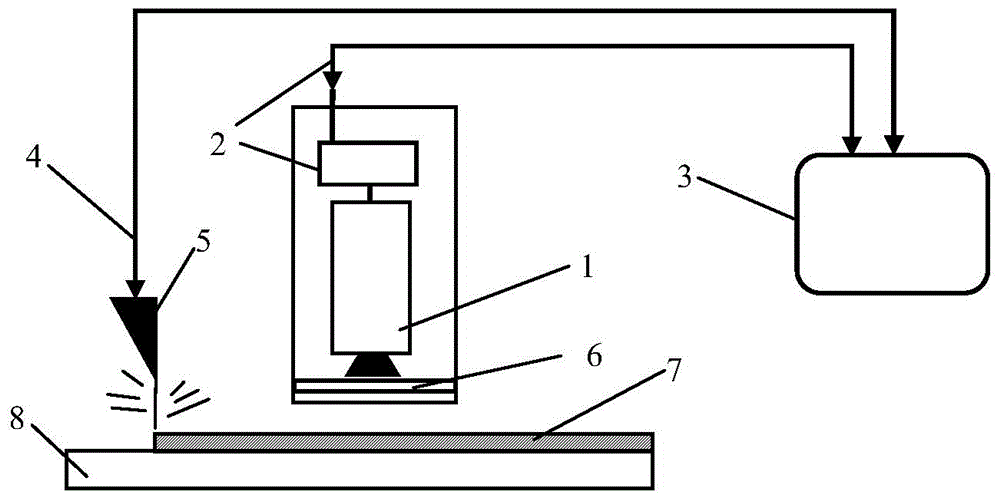

Part-geometry independent real time closed loop weld pool temperature control system for multi-layer dmd process

ActiveUS20060032840A1Additive manufacturing apparatusIncreasing energy efficiencyMelting tankTemperature control

In a direct metal deposition system which builds up a metallic overlay on a substrate by moving the substrate relative to a laser in a metallic powder feed, the laser power is adjusted for successive layers by sensing the weld pool in a plurality of selected points in each layer and adjusting the power during successive layers to maintain a weld pool that corresponds to those achieved during deposition of a lower optimal layer. This compensates for heating of the substrate resulting from the deposition which tends to increase the pool size or temperature in the higher layers.

Owner:DM3D TECH

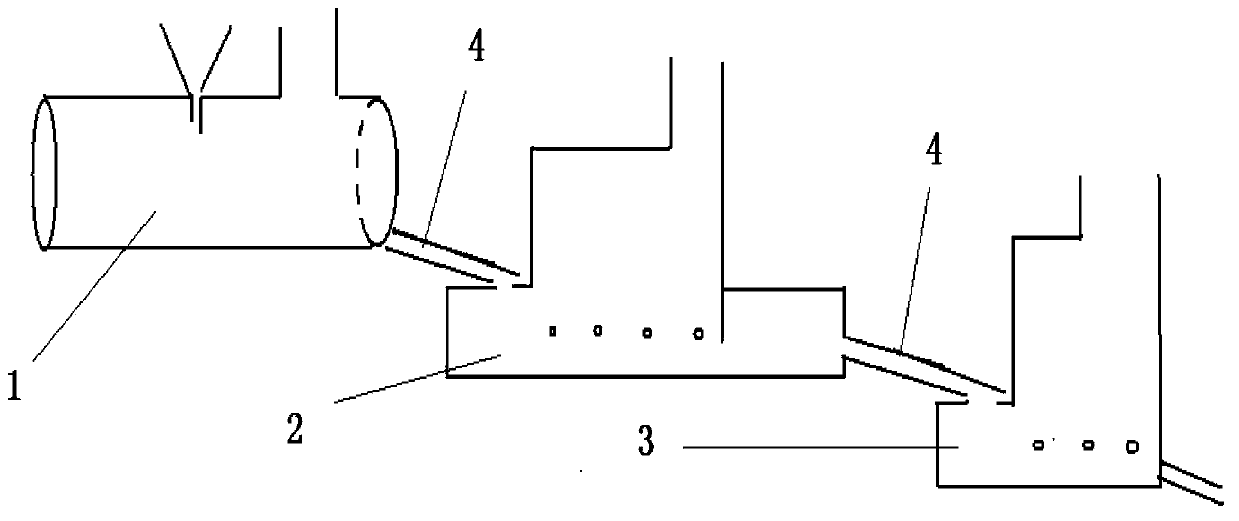

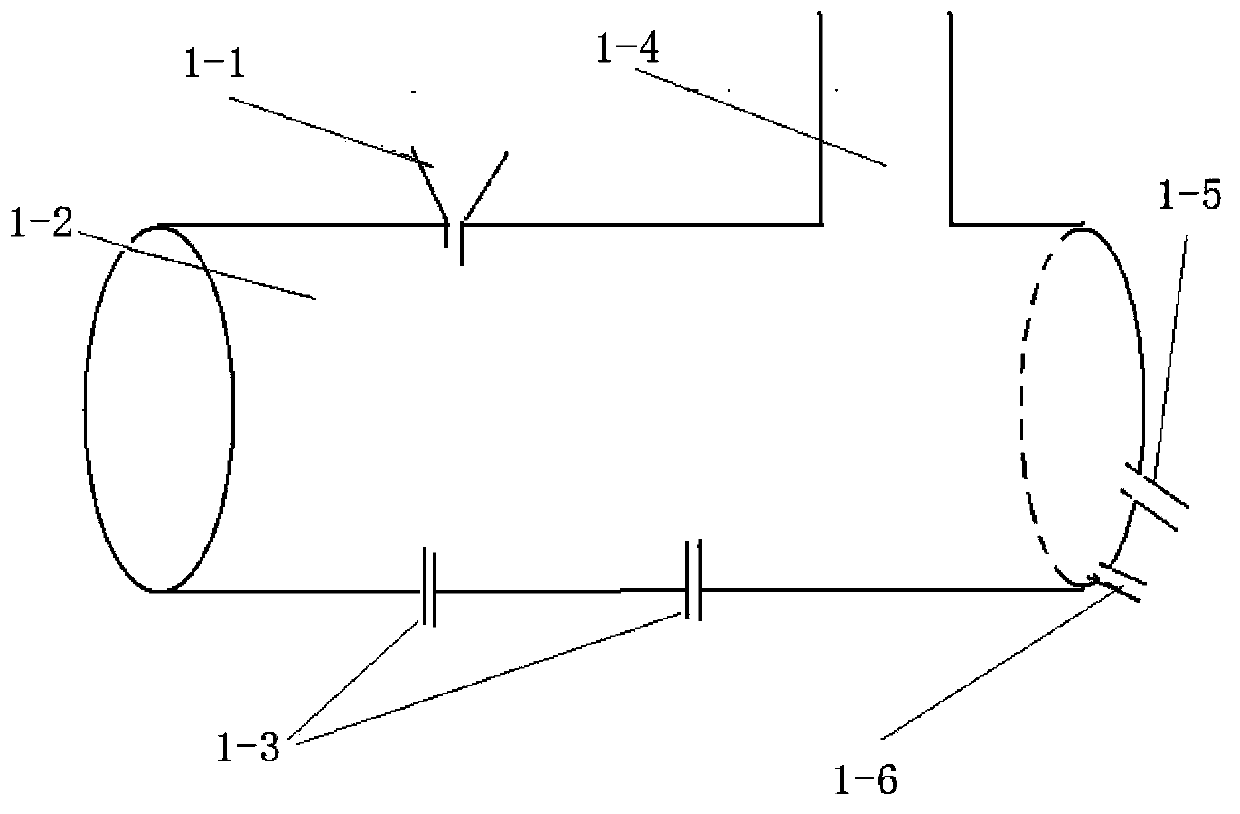

Manufacturing method for GTAW double-synchronization filler rod additive of non-closed thin-wall structural member

InactiveCN106238876ASolve the difficult problem of high-efficiency fuseImprove build-up forming qualityArc welding apparatusMelting tankEngineering

The invention provides a manufacturing method for a GTAW double-synchronization filler rod additive of a non-closed thin-wall structural member. The non-closed thin-wall structural member is a multi-layer single-channel structural member which is not connected end to end. Wire feed systems are symmetrically mounted on the left side and the right side of a GTAW welding gun. When the welding gun moves along the stacking path, the same wire feed system serves a rear wire feed system when wire feed is conducted from the rear end of the welding gun and serves as a front wire feed system when wire feed is conducted from the front end of the welding gun, and the directions of stacking paths between adjacent stacking layers are opposite, so that on the different stacking layers, the wire feed system on the left side and the wire feed system on the right side alternately serve as the front wire feed system and the rear wire feed system, the wire feed amount of the front wire feed system and the wire feed amount of the rear wire feed system are adjusted independently, the front wire feed system is used for efficient wire fusion, and meanwhile a small amount of wire fusion is conducted through the rear feeding system. By the adoption of the manufacturing method, the problems that the wire fusion efficiency is low and the forming quality is poor by means of a rear wire feed manner in the non-closed structural piece alternate type stacking process are solved efficiently, the cooling rate of a fusion pool is increased effectively, grains can be refined, and the mechanical performance of formed components is improved.

Owner:SOUTHWEST JIAOTONG UNIV

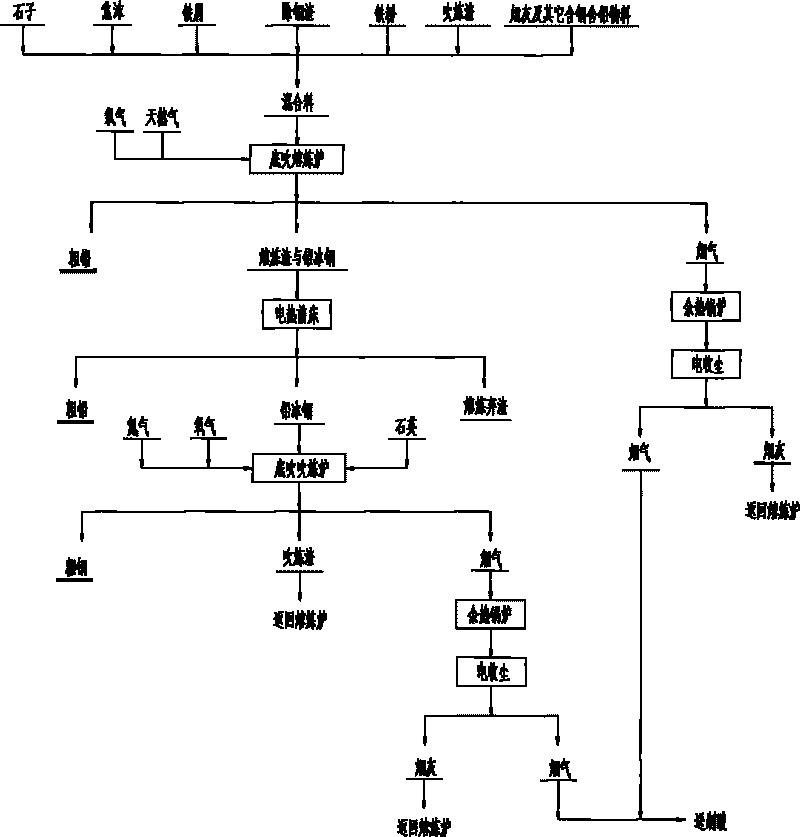

Bath smelting method and apparatus of zinc sulfide concentrate and lead-zinc containing materials

InactiveCN103388081AMeet the requirements of smeltingReduce energy consumptionMelting tankHigh concentration

The invention discloses a bath smelting method and an apparatus of zinc sulfide concentrate and lead-zinc containing materials. The smelting method comprises the following steps: mixing lead-zinc-containing mixed materials according to a certain proportion and pelletizing; and then, adding the pelletized materials into an oxidation furnace having a lead-containing high-zinc-slag bath with proper ingredients and smelting points, and blowing oxygen-enriched air into the bath for generating an oxidation reaction with the pelletizing materials to generate high-concentration SO2 flue gas and lead-containing high-zinc slag, wherein the SO2 flue gas is used for preparing acid, the lead-containing high-zinc slag is continuously discharged from the oxidation furnace into a reduction furnace bath, zinc in the lead-containing high-zinc slag is reduced into zinc vapor to be collected, and the lead is reduced into metal lead and such precious metals as gold and silver in the raw materials are captured and gathered at the bottom part of the bath to be discharged. The bath smelting method disclosed by the invention has the advantages of short flow, strong raw material adaptability, low energy consumption, environment friendliness, efficient source utilization and the like and is expected to solve the current treatment difficulty of high-iron zinc sulfide concentrate, zinc oxide ores, iron and steel plant zinc dust and gold-containing iron ores and the long-term pollution problems of zinc slag of hydrometallurgy.

Owner:CENT SOUTH UNIV

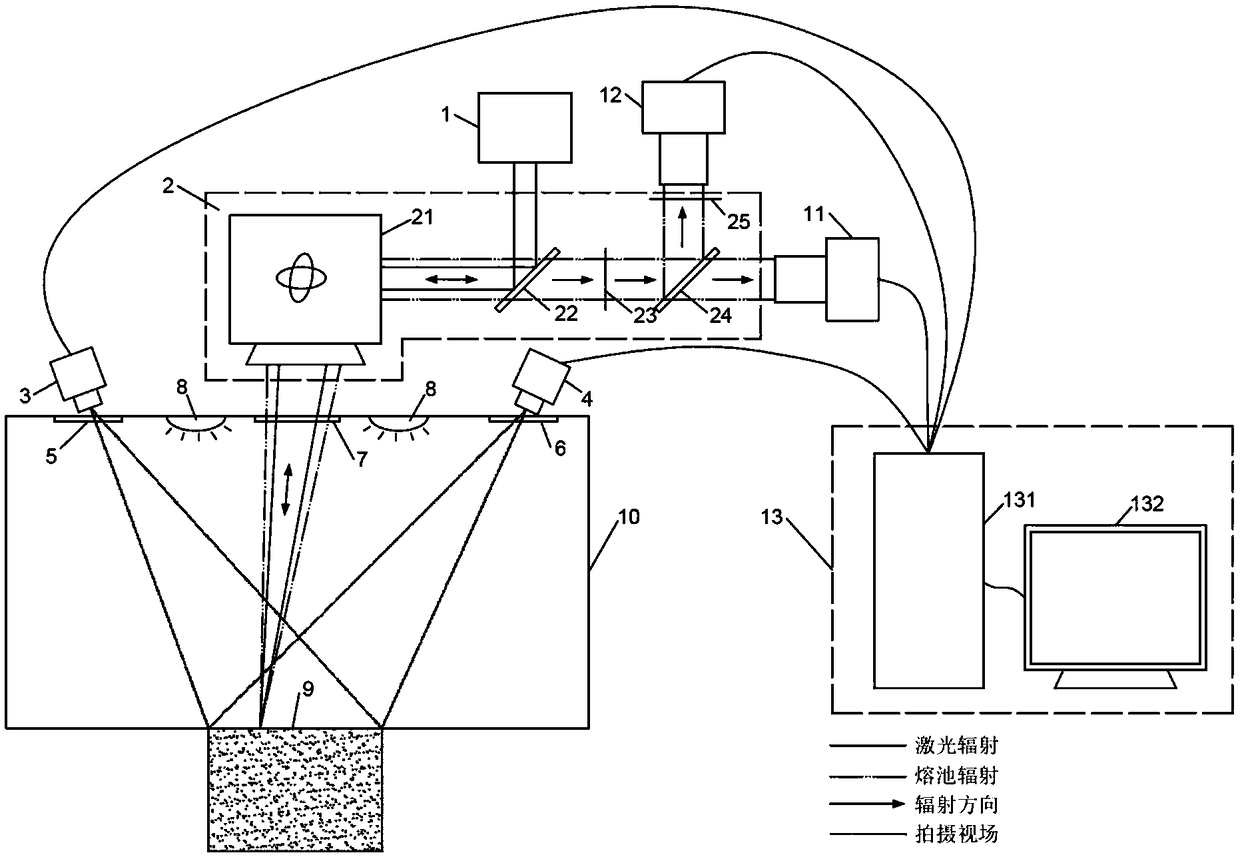

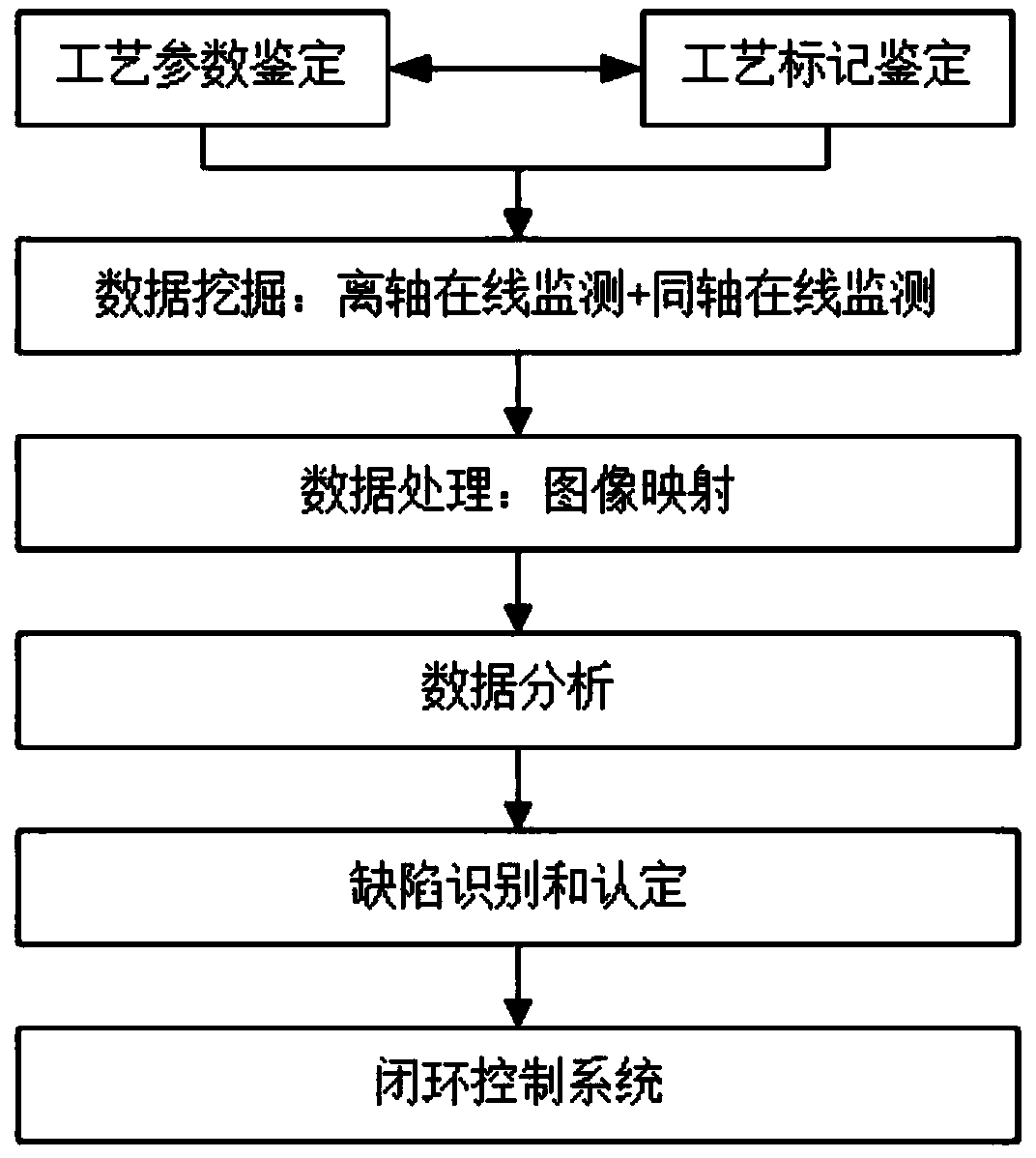

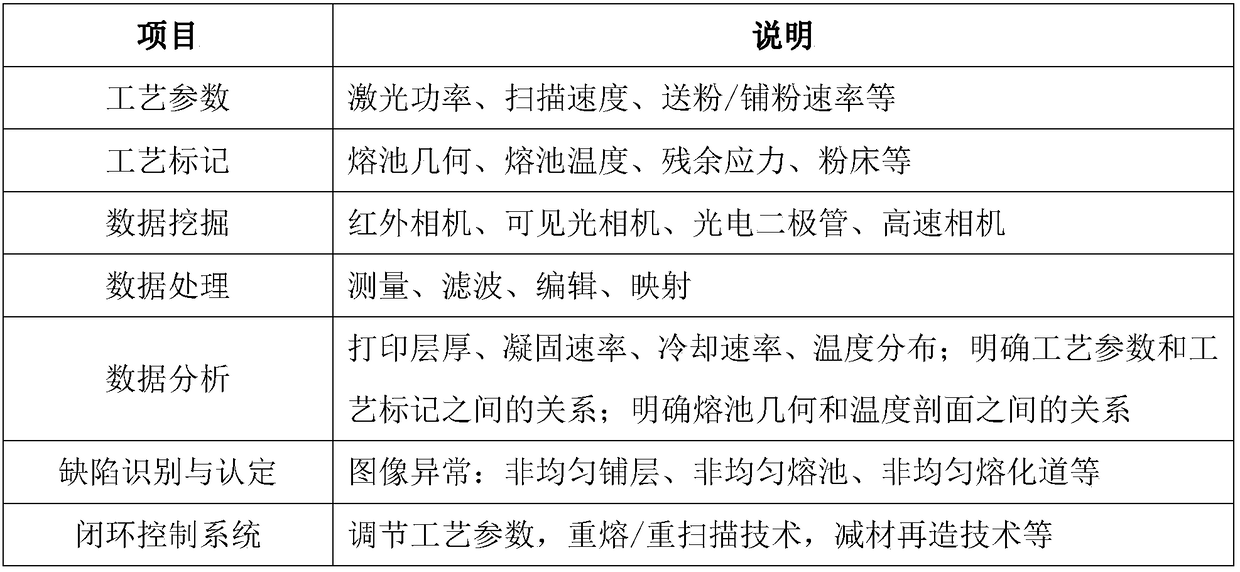

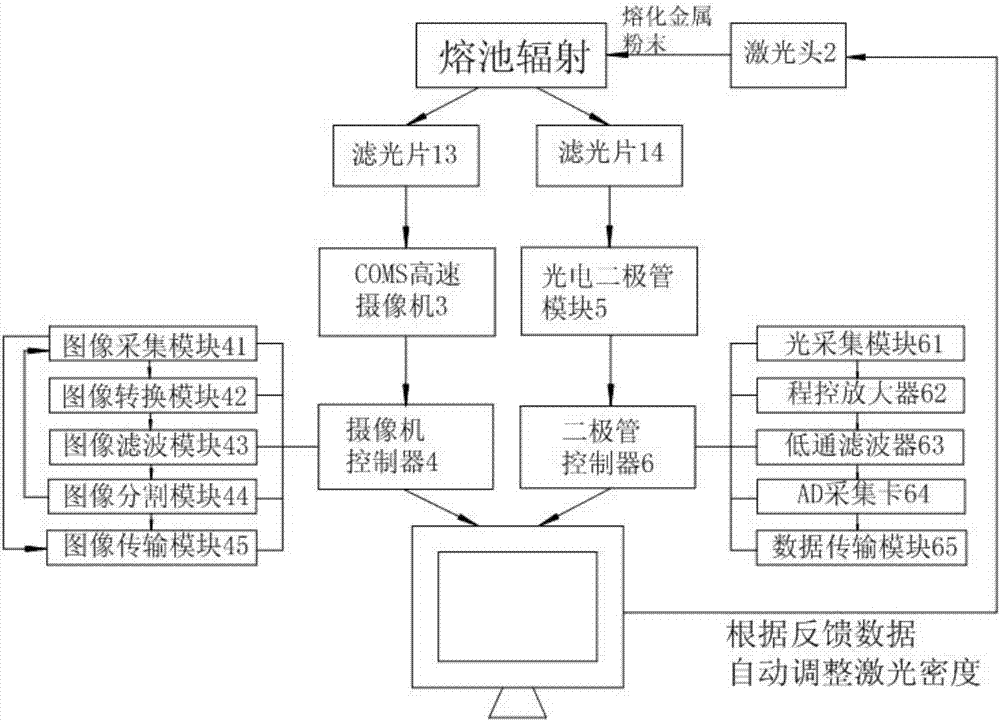

Real-time quality monitoring device and method for selective laser melting processing process

InactiveCN108788153ARealize online monitoringAvoid interferenceAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a real-time quality monitoring device and method for a selective laser melting processing process. Advantages of non-contact measurement means such as an industrial camera, aninfrared thermal imager, a high-speed camera and a photodiode are comprehensively utilized, and a set of complete monitoring method is formed. Through the on-line monitoring method combining an off-axis on-line monitoring device with a coaxial on-line monitoring device, the working condition of a printing work plane can be captured, and real-time molten pool data can also be collected. The meltingand condensation processes of metal powder can be monitored in a microcosmic manner, and a printer system and a workpiece layer-by-layer quality can also be monitored in a macroscopic manner. The industrial camera is adopted to monitor powder bed defects and printing defects, and the infrared thermal imager tracks the scanning path and captures the thermal stress; and the high-speed camera observes the geometrical morphology of a molten pool, and the photodiode captures the radiation strength of the molten pool. The process marks are made to correspond to printing process parameters, and on-line monitoring of the selective laser melting processing process can be realized more effectively.

Owner:西安智造人企业管理合伙企业(有限合伙)

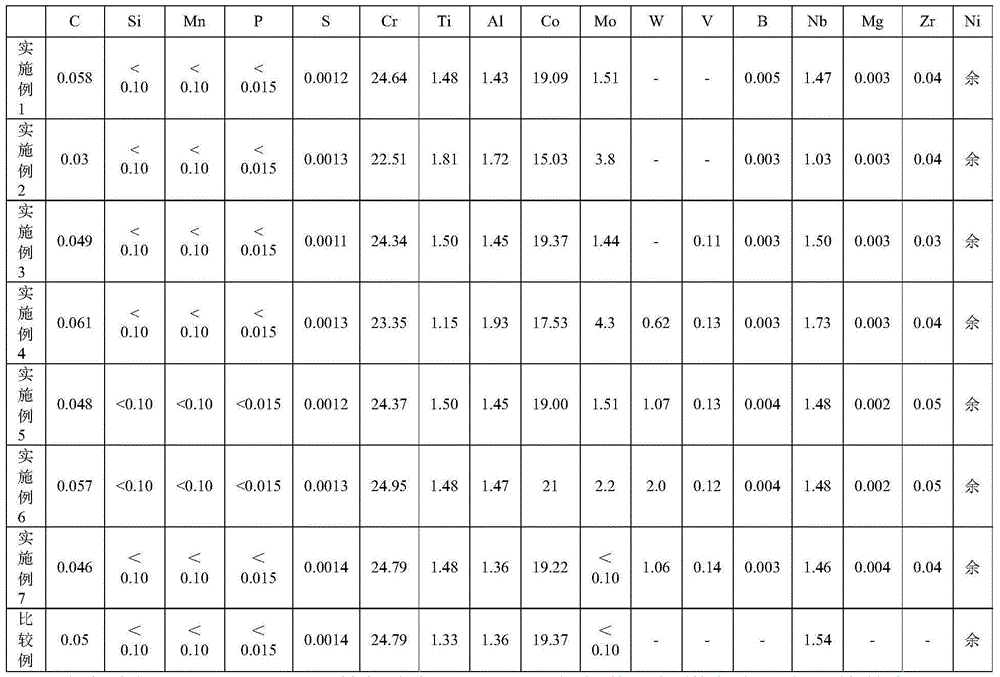

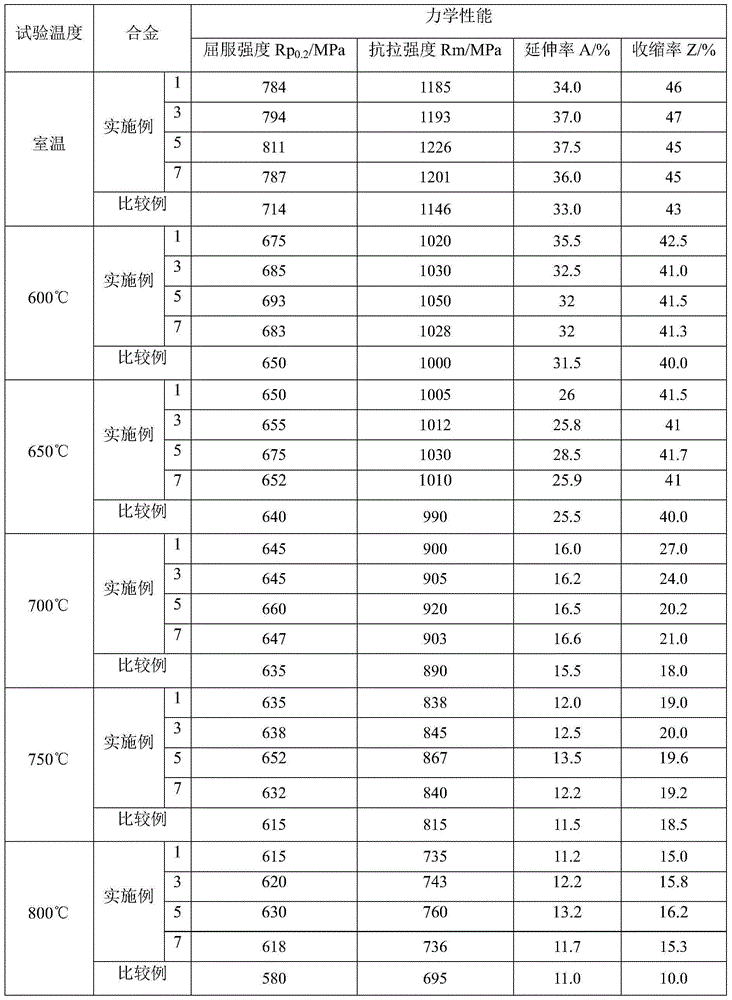

Nickel-base superalloy welding wire for 700 DEG C-above ultra-supercritical coal power generation equipment

InactiveCN105014258AImproved hot and cold processing performanceImprove high temperature strengthWelding/cutting media/materialsSoldering mediaMelting tankChemical composition

The invention discloses a nickel-base superalloy welding wire for 700 DEG C-above ultra-supercritical coal power generation equipment, and belongs to the technical field of nickel-base superalloys. The nickel-base superalloy welding wire comprises the following chemical components: 0.005-0.08 wt% of C, 22-25 wt% of Cr, 12-22 wt% of Co, 0.5-2.0 wt% of Ti, 1.0-2.5 wt% of Al, 0.5-2.0 wt% of Nb, 0.5-4.5 wt% of Mo, 0.1-3.0 wt% of W, 0.01-0.3 wt% of V, 0.001-0.05 wt% of Zr, no more than 0.02 wt% of Mg, 0.001-0.006 wt% of B, no more than 1.5 wt% of Fe, and the balance Ni and inevitable impurity elements. As such elements as Co, Cr, Mo, W, Al, Ti and Nb and proper amounts of other microelements are added in a nickel-base alloy, the cold / hot machinability, the high-temperature strength and in particular the high-temperature durability of the alloy welding wire are all improved. The alloy welding wire is better in high-temperature strength and durability, and is more excellent in welding process performance; and in the welding process, a molten pool is better in fluidity, and the welding line formability is excellent.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Hot wire consumable electrode gas protection welding method and realization device thereof

InactiveCN101862886AFast meltingIncrease the melting speed, so that the welding deposition speedArc welding apparatusMelting tankWelding power supply

The invention relates to a hot wire consumable electrode gas protection welding method and a realization device thereof, which belong to the technical field of welding. The invention solves the problems of low welding efficiency and low welding quality in the existing consumable electrode gas protection welding method and the device for realizing the welding method caused by incapability of realizing the reasonable distribution of welding wires and hot input of fusing tanks. The welding method comprises the following steps: placing the tail end of the consumable electrode welding wire near a part to be welded of a work piece to be welded; forming a main arc between the tail end of the consumable electrode welding wire and the surface to be welded of the work piece to be welded under the effect of a constant voltage welding power supply for realizing the welding; placing the tail end of a conductive annular sleeve of a welding gun near the side wall of the consumable electrode welding wire in the welding process; and forming a preheating electric arc between the tail end of the conductive annular sleeve of the welding gun and the side wall of the consumable electrode welding wire under the effect of a constant current welding power supply for realizing the preheating on the consumable electrode welding wire. The realization device consists of the constant current power supply, the constant voltage welding power supply and the welding gun. The invention is used for the implementation of the gas protection welding.

Owner:HARBIN INST OF TECH

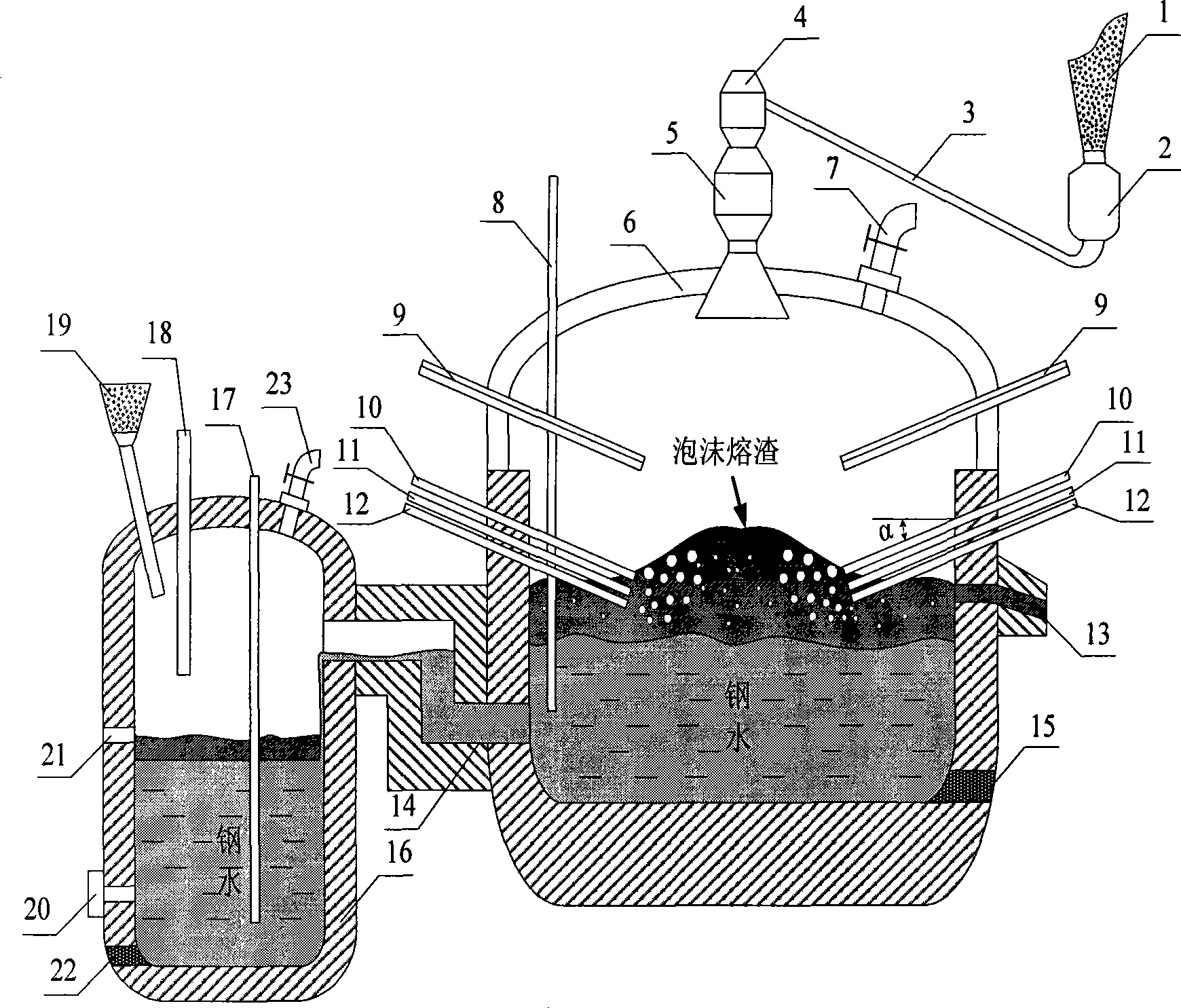

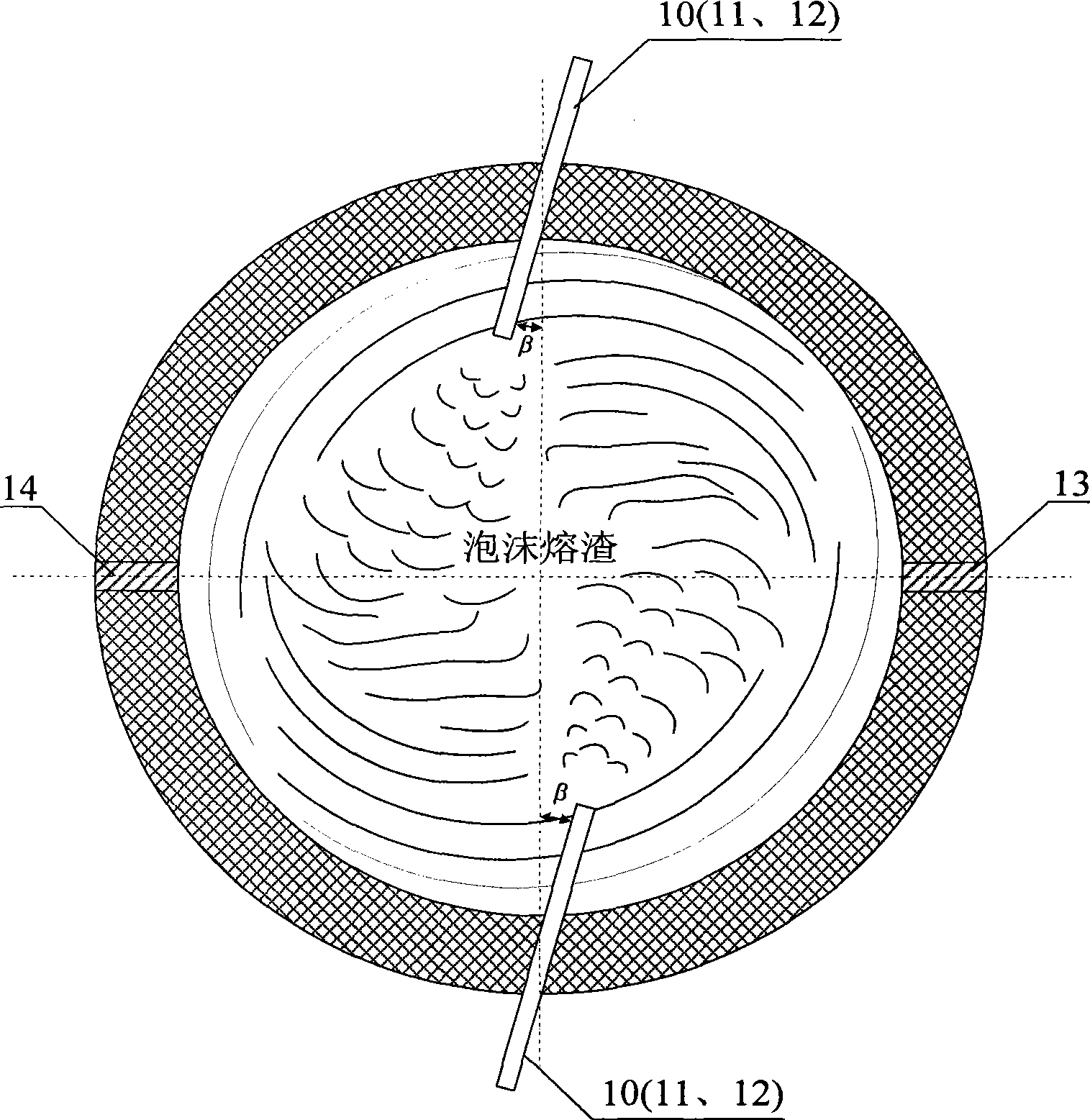

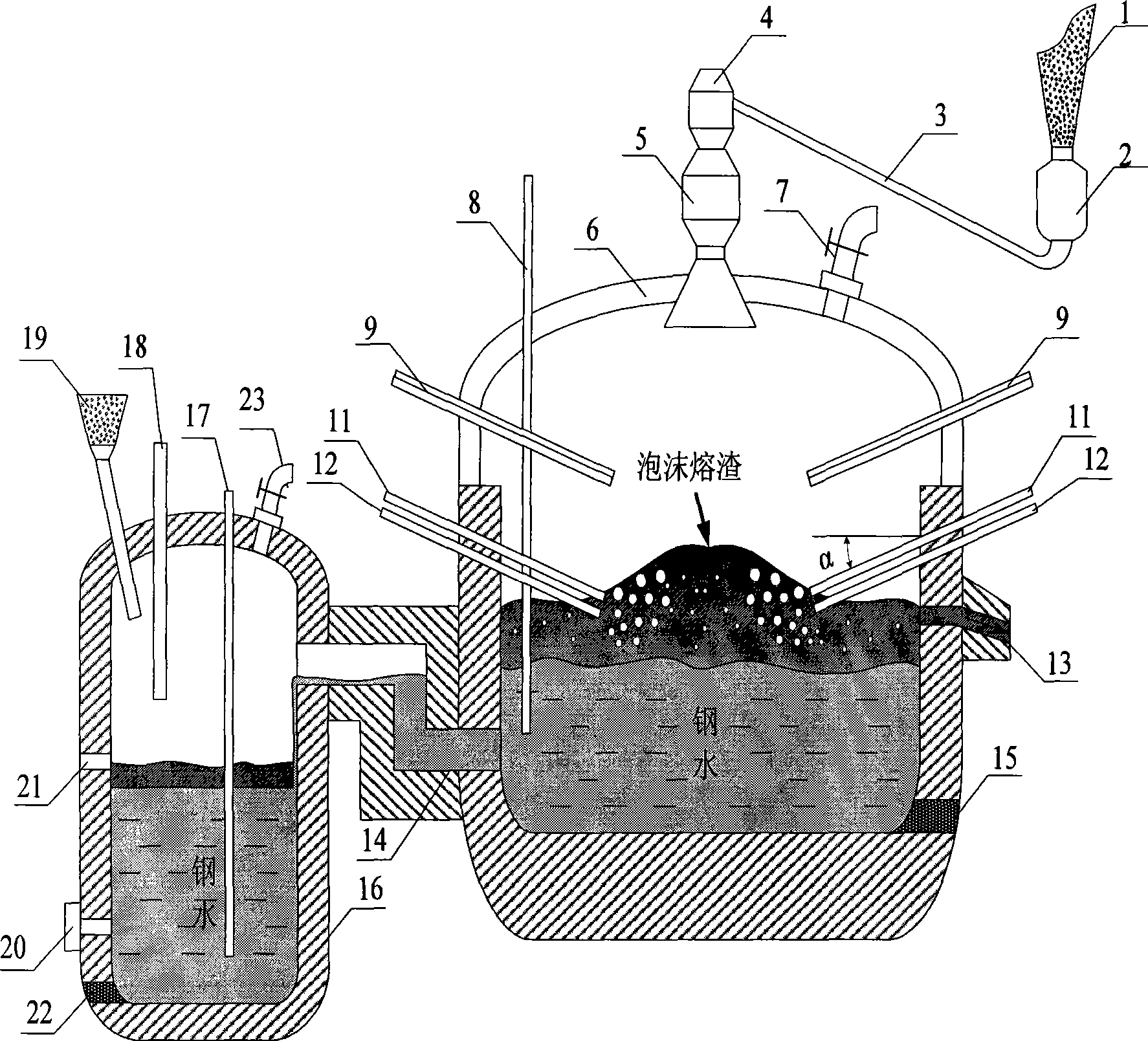

Process and device for continuous steelmaking from ferriferous material

ActiveCN101445848AReduce carbon contentIncrease temperatureFurnace typesProcess efficiency improvementSteelmakingMelting tank

The invention relates to a process for continuous steelmaking from a ferriferous material. A molten pool is formed in a steel-smelting furnace at first, and carbonic material and oxygen are insufflated to form foaming slag; the ferriferous material and a fluxing agent are added into the smelting furnace to be molten and reduced, oxygen is insufflated into the molten steel so as to reduce the carbon content in the molten steel, the temperature of the molten steel is risen, and the molten steel is stirred with the generated CO gas; high temperature oxygen or oxygen-enriched air is insufflated and burns with CO gas generated in the smelting furnace; and the molten steel continuously flows into an oxygen blowing furnace through a siphon nozzle, and a small quantity of the fluxing agent is added into the oxygen blowing furnace so that slag formation, desulfurization and dephosphorization are performed, the C content and the temperature in the molten steel are further adjusted through blowing oxygen by an insertion oxygen lance, therefore, the obtained molten steel is directly supplied for an LF refining furnace or an RH refining furnace. The invention has the advantages that the productivity equipment including a suspended pre-reduction furnace, the smelting furnace and the oxygen blowing furnace, the investment for devices and capital construction is saved, the land is saved, the physical distribution is simplified, and the continuous production and the automatic control are facilitated.

Owner:LAIWU IRON & STEEL GRP

Converting process for converter low-silicon molten iron

ActiveCN101117651AOxygen blowing time shortenedGood foamingManufacturing convertersProcess efficiency improvementMelting tankSlag

The present invention provides a siliconeisen iron melt blowing and refining method in a converter, and the method includes the steps as follows: (1) waste steel and iron melt are loaded into the converter, and oxygen blowing and steel making begin, the oxygen flux is 900Nm3 / min to 1050Nm3 / min, the height that the oxygen gun spraying head departs the metal liquid surface in the melt pond is 1.8-3.0m; (2) a first batch of slag charge is added after oxygen is blown in the first batch of the slag charge is 60-80 percent of the total slag charge, and the rest slag charge can be charged in 2-3 batches after the first batch of the slag charge is melted. The consumption of the slag charge: the lime 18-28kg / t steel, the light calcined dolomite 15-25kg / t steel, the ironstone 5-10kg / t steel, the carbonaceous heat generating agent 0-7kg / t steel, the compound slag 0-6kg / t steel; and the rest process are same as the prior art. The oxygen blowing duration of the present invention decreases 1.8min per furnace averagely, and the problem that the heat quantity is short and the slag forming is difficult can be solved simultaneously, and the present invention can make the converter steel-making to produce efficiently.

Owner:BAOSHAN IRON & STEEL CO LTD +1

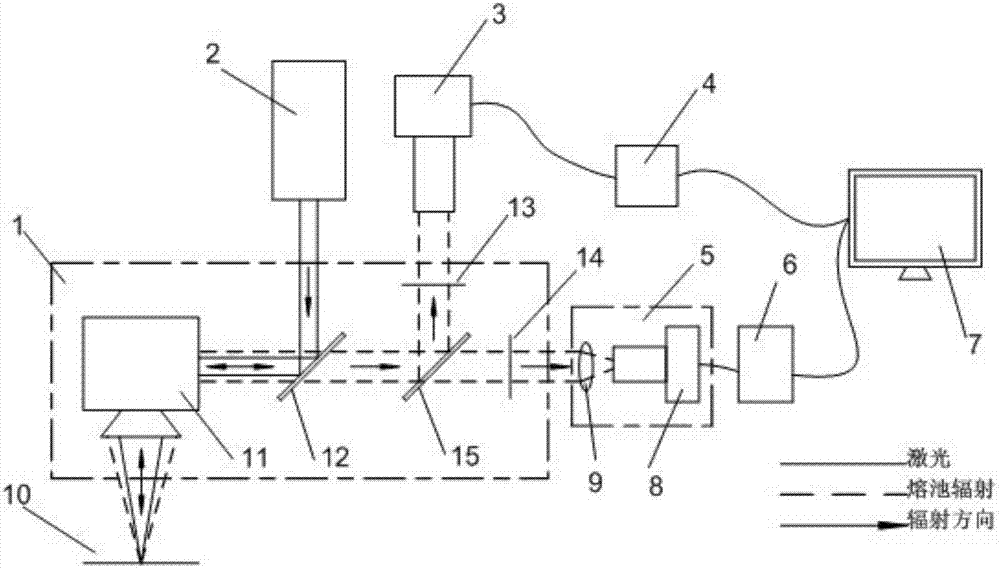

Coaxial monitoring method and device in selective laser melting process

ActiveCN106984813AEasy to detect and analyzeHigh local resolutionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMelting tank

The invention discloses a coaxial monitoring method and a device in a selective laser melting process. The device comprises a light path module, a photodiode module, a diode controller, a laser head, a COMS high-speed camera, a camera controller and a computer. Metal powder on a workbench base plate is melted selectively by a scanning galvanometer of the light path module, and molten pool radiation is reflected into the COMS high-speed camera 3 and a photodiode in the selective laser melting process; the COMS high-speed camera and the photodiode module are used for processing molten pool radiation data converted into image information transmitted to the corresponding controller; the camera controller is used for processing the image data converted into feedback information for controlling the laser; the diode controller is used for processing optical signals exempted from external electromagnetic interference, and the device is applicable for collection; in the selective laser melting process, by combining the COMS high-speed camera and the photodiode, the coaxial monitoring method is beneficial to improving the local resolution ratio and quick scanning rate.

Owner:SOUTH CHINA UNIV OF TECH

Process and device for treating decopperized slag by adopting bottom-blowing molten pool to produce wet lead and raw copper

ActiveCN101705368ALow melting pointImprove liquidityProcess efficiency improvementMelting tankAutomatic control

The invention belongs to the field of nonferrous metal, in particular to a process and a device for treating decopperized slag by adopting a bottom-blowing molten pool to produce wet lead and raw copper. A bottom-blowing smelter hearth is utilized to smelt decopperized slag to produce wet lead, furnace slag and lead copper matte, ferrum-silico-calcium slag is produced in the smelting process, the furnace slag serves as building material factory raw materials after meeting the disposal slag requirements, and a bottom-blowing converting furnace is utilized to convert the lead copper matte to produce raw copper. The process has low energy consumption, long service life of the furnace, high metal recovery efficiency, low product cost, high smelting environment protectiveness , easy realization of automatic control of process, and high labour productivity; the disposal slag contains low-grade valuable metal, and therefore, the disposal slag can be comprehensively utilized as raw materials in building material industry, which accords with the recycling economy principle.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

Cast rolling composite production device and method of metal composite plate

The invention designs a cast rolling composite production device and method of a metal composite plate. The cast rolling composite production method provided by the invention comprises the steps that a base metal to be composited enters a molten pool of a thin belt continuous casting machine from top to bottom through a base metal uncoiler and a guide roller, wherein the molten pool is internally provided with a to-be-composited layer metal liquid, and as the temperature of the base metal is lower than that of the to-be-composited layer metal liquid, the liquid can crystallize on the surface of the base metal, which is equivalent to a hot dipping process; meanwhile, a crystallizing roller is cooled through water, the metal liquid also crystallizes on a contact region of the crystallizing roller and the metal liquid, and when the base metal reaches an occlusion hole of the crystallizing roller, the crystallizing roller can press a crystallized metal thin layer on a roller surface on a crystallizing layer of the base metal, thereby forming a composite plate material; when the composite plate material leaves the occlusion hole to enter a secondary cooling region, the composite plate is further cooled through a smooth roller and is rolled through a rolling mill, and finally, the composite plate is reeled up so as to form a roll. According to the invention, the production processes are simplified, the production cycle is shortened, the equipment investment is correspondingly reduced, and the product cost is obviously reduced.

Owner:武汉钢铁有限公司

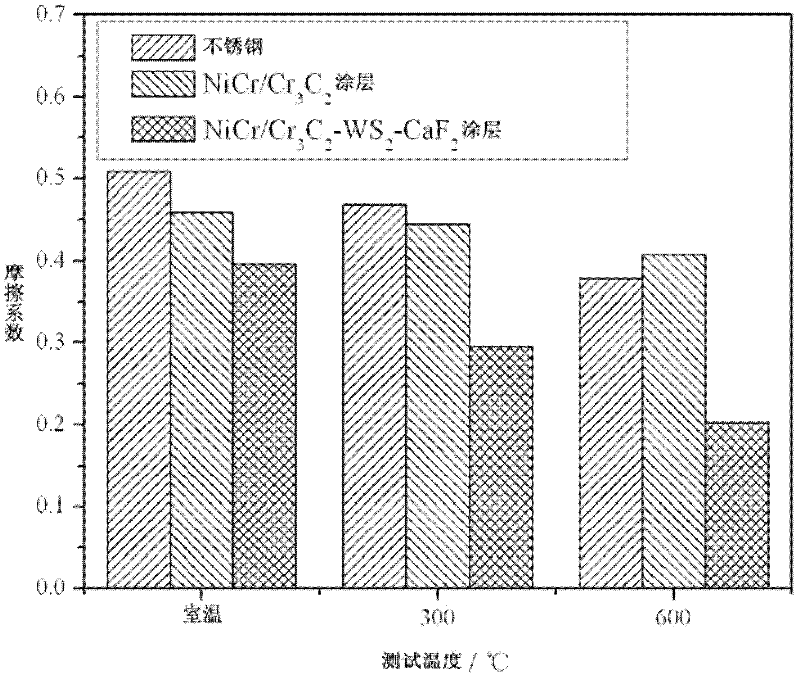

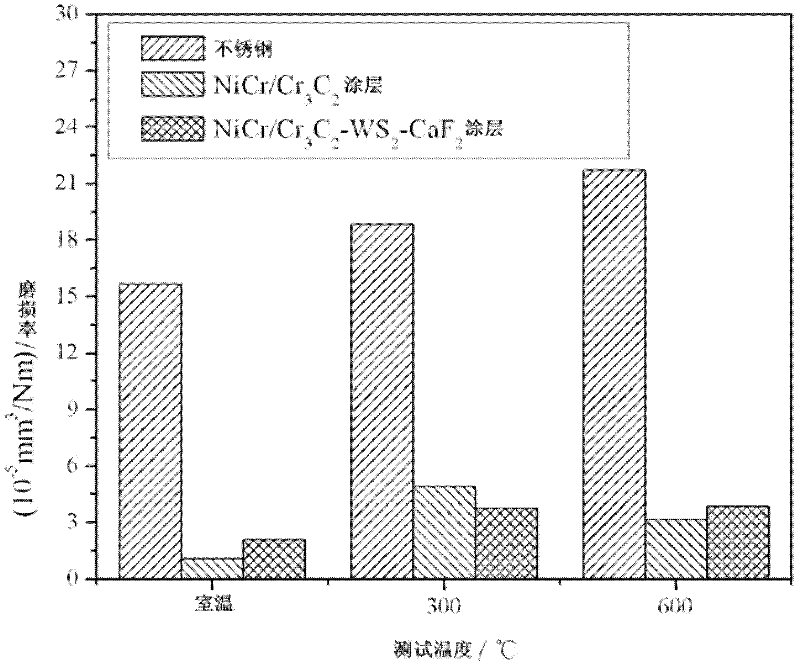

Self-lubricating solid composite material and preparation method of self-lubricating solid coating

ActiveCN102363853AImprove wear resistanceReduce coefficient of frictionMetallic material coating processesMelting tankChromium carbide

The invention provides a self-lubricating solid composite material, which comprises 15-30 wt% of nickel-chromium alloy, 40-60 wt% of chromium carbide, 10-20 wt% of tungsten disulfide and 10-20 wt% of calcium fluoride. The invention also provides a preparation method of a self-lubricating solid coating. By a laser cladding method, the self-lubricating solid coating is formed on a matrix material. The self-lubricating solid composite material can be firstly coated on the matrix material and forms a coating by laser cladding; and also the matrix material can be firstly irradiated by a laser beam to form a molten pool, and then the self-lubricating solid composite material is sent into the molten pool and is continuously irradiated to form the coating. The prepared self-lubricating solid coating has excellent wear resistance and good lubrication performance within the temperature range of room temperature to 600 DEG C, and can satisfy the usage requirement under severe working conditions.

Owner:SUZHOU UNIV

Double-slag converter process for producing high carbon low-phosphorus molten steel

InactiveCN1995403AReduce smelting costReduce consumption costManufacturing convertersMelting tankHigh carbon

The invention discloses a rotary furnace technique to manufacture high-carbon low-phosphor molten steel, which is characterized by the following: transmitting high-silicon high-phosphor molten iron into rotary furnace; blowing through gun-change and oxygen-change flow operation; removing phosphor first; pouring rich phosphoric slag at blowing time; adjusting terminal temperature and terminal carbon.

Owner:武钢集团有限公司

Ultrasonic vibration and welding stick feeding system compound welding method and device thereof

InactiveCN101239415AControl transitionAchieve welding productionArc welding apparatusMelting tankCavitation

The invention discloses an ultrasonic vibration and welding wire feed system composite welding method and a device thereof which are provided with a stable welding process, high quality of welding seams, controllable welding pool grain growth phenomenon after welding, and high welding quality in normal welding surroundings. The objective is achieved by following steps: transmitting cavitation effect and vibration effect to the welding pool during the welding wire and welding pool contacting process by broadcasting the ultrasonic in the welding wire feed system. The melt drop size at the terminal of the welding wire is controlled effectively by ultrasonic action during welding process, transition from melt drop to welding pool is more stable, and welding seam quality is further improved. Since ultrasonic is applied in the welding feed system during welding process, welding wire melt drop transition condition is affected, energy distribution status during welding process is improved, thereby refinement and homogenization degree of the joint, and mechanical property such as intensity are further enhanced.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com