Process and device for continuous steelmaking from ferriferous material

A material and process technology, applied in the field of continuous steel production process, can solve the problems of high cost and low efficiency, and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Iron-containing materials: iron ore fine powder, carbon-containing materials: coal powder. Iron ore fine powder and flux adopt high-temperature dense-phase conveying bed and serial tank distributor.

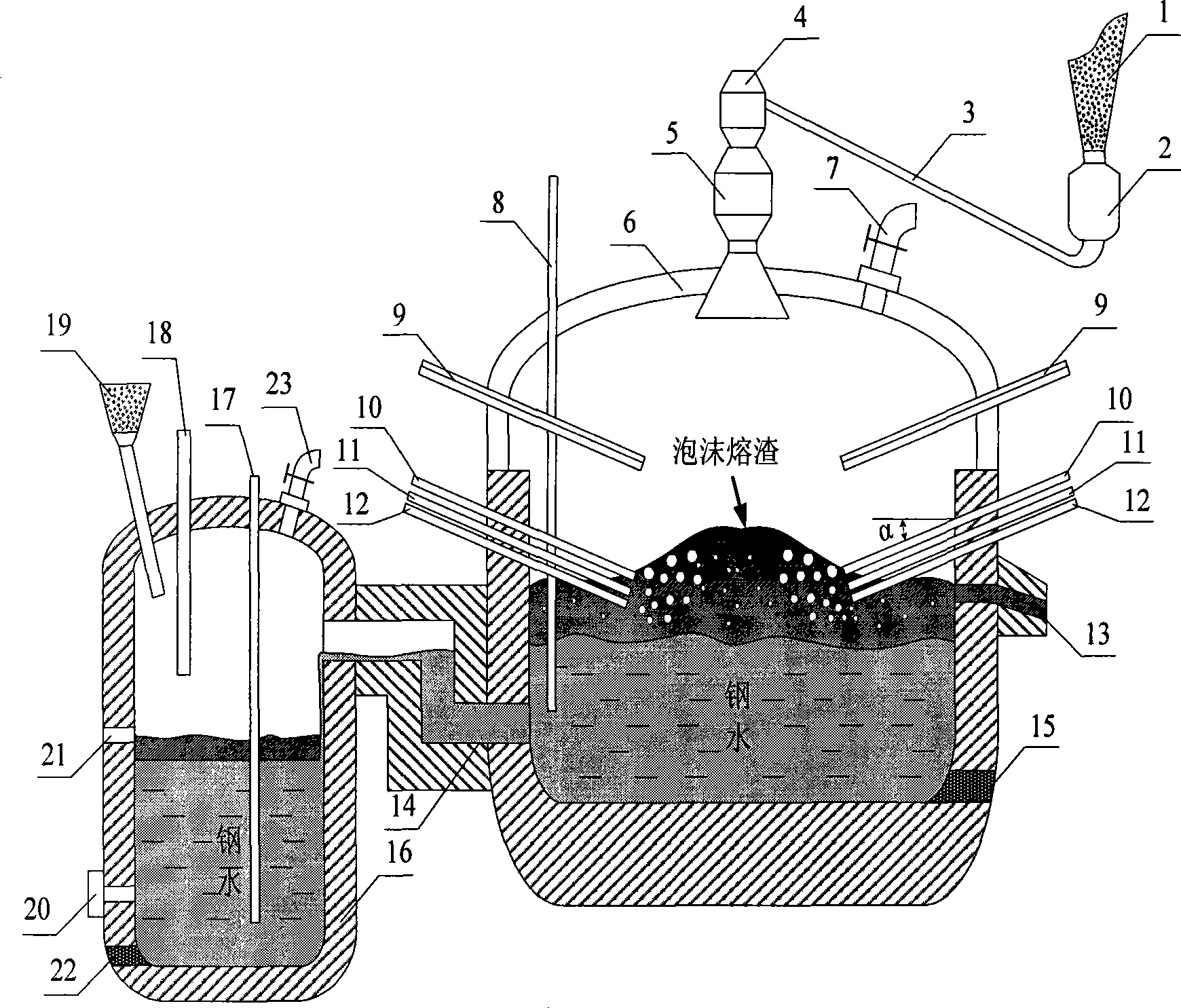

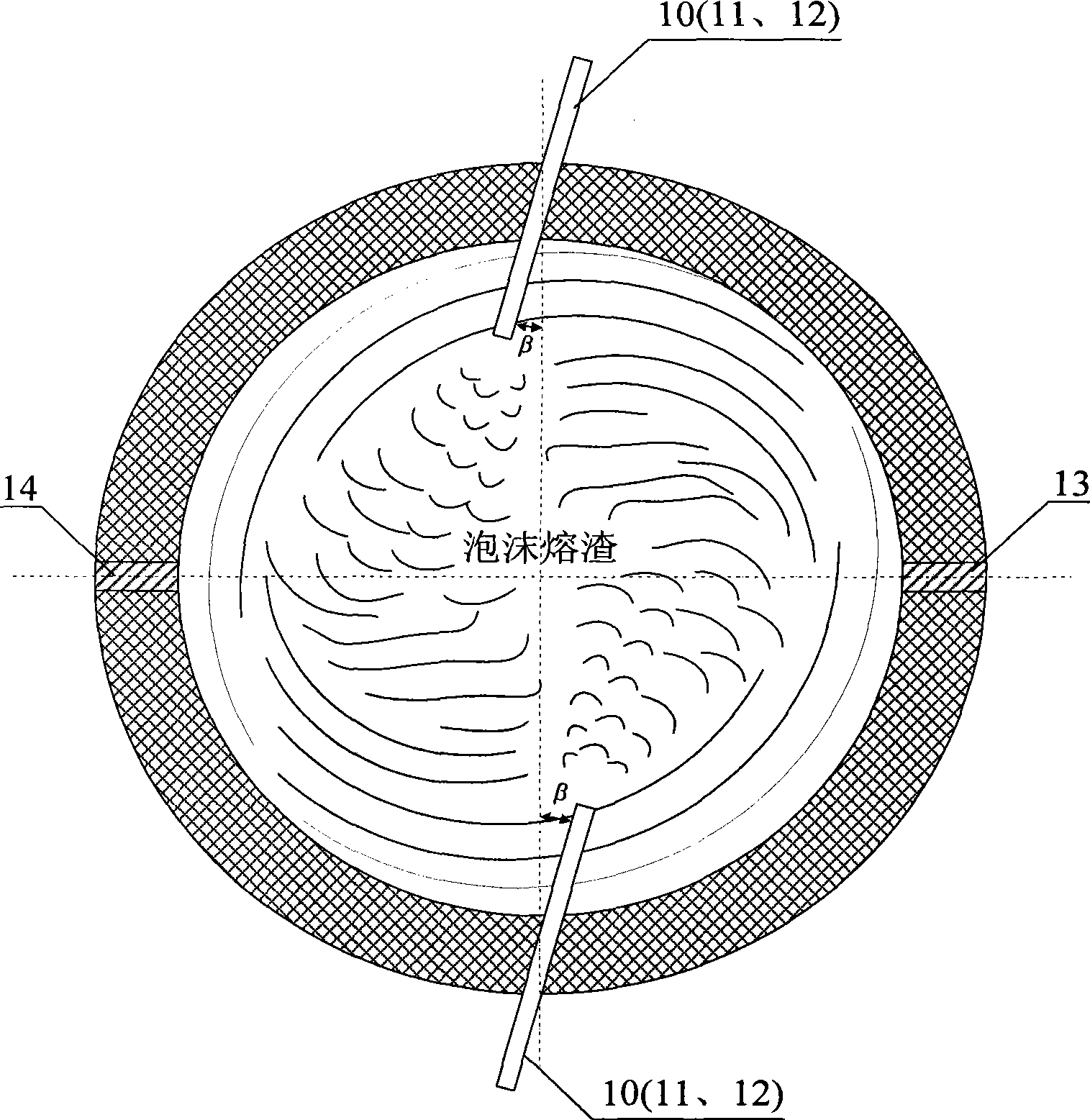

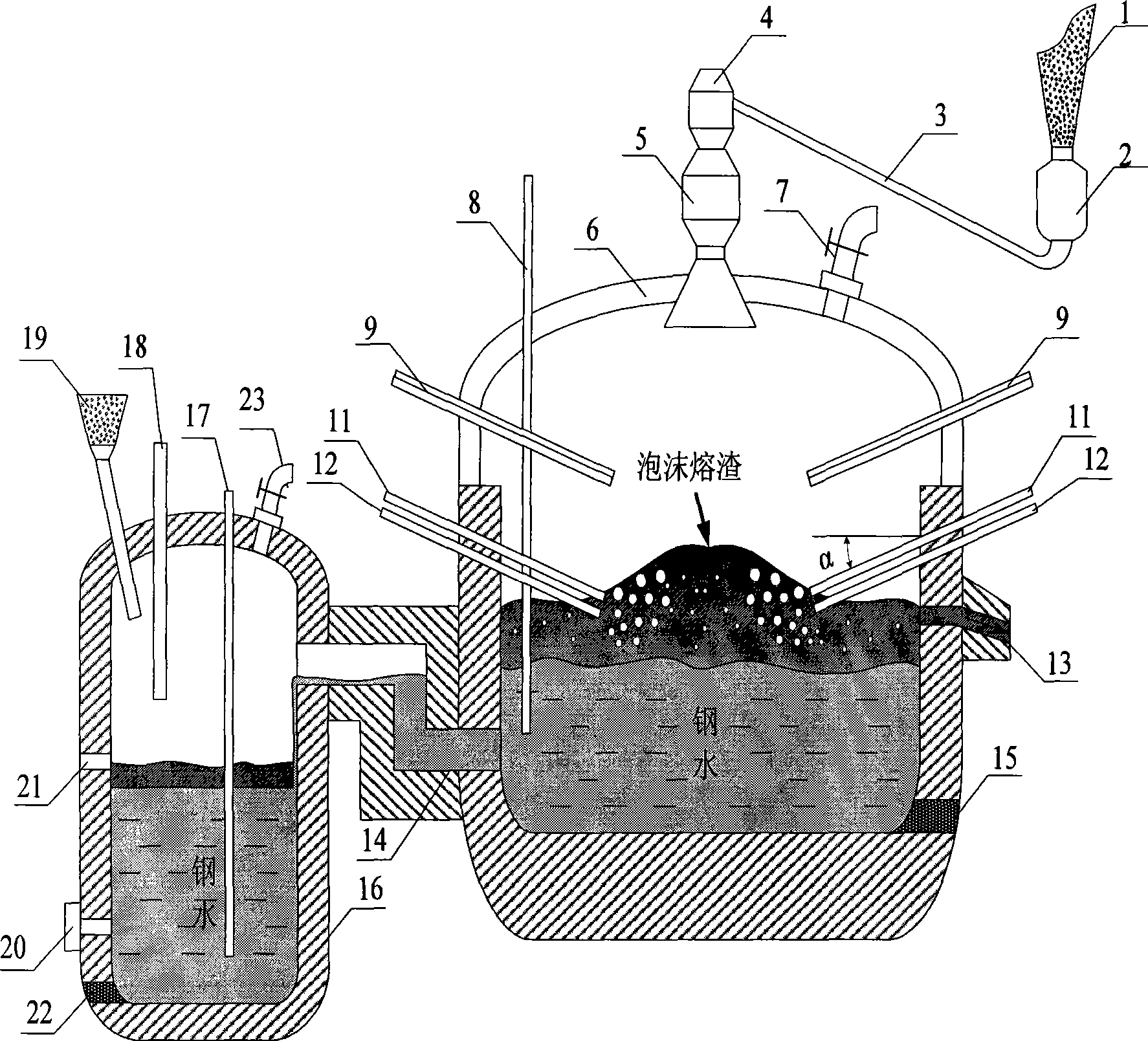

[0056] The continuous steelmaking equipment of the present invention comprises: a high-temperature storage bin (1), a sending tank (2), a conveying pipeline (3), and a collection tank (4) connected to a suspension pre-reduction furnace for mixing iron-containing materials and flux , string tank distributor (5), melting furnace (6), gas output device (7), molten pool oxygen lance (8), CO oxygen combustion lance (9), carbonaceous material spray lance (11) melting furnace oxygen lance (12), smelting furnace slag outlet (13), smelting furnace siphon steel outlet (14), smelting furnace bottom steel opening (15); oxygen blowing furnace (16), oxygen blowing furnace oxygen lance (17), blowing Oxygen furnace carbonaceous material combustion gun (18), oxygen blowing furnace flux ad...

Embodiment 2

[0064] Iron-containing materials: iron ore fine powder 80%, iron-containing metallurgical dust 20%, carbon-containing materials: coal powder. Iron-containing materials and flux are sprayed into the furnace by spray guns.

[0065] Iron-containing metallurgical dust composition: iron oxide scale, blast furnace dust, converter dust, electric furnace dust, sintering pellet dust, etc.

[0066] Finely grind iron ore micropowder, iron oxide scale, blast furnace ash, converter ash, electric furnace ash, sinter pellet ash, limestone and dolomite into 10-40μm micropowder.

[0067] The continuous steelmaking equipment of the present invention comprises: smelting furnace (6), coal gas output device (7), molten pool oxygen lance (8), CO oxygen combustion lance (9), iron-containing material and flux spray gun (10), containing Carbon material lance (11) smelting furnace oxygen lance (12), smelting furnace slag outlet (13), smelting furnace siphon steel outlet (14), smelting furnace bottom s...

Embodiment 3

[0070] Iron-containing materials: 10%-90% iron ore fine powder, 90%-10% iron-containing metallurgical dust, carbon-containing materials: one or more of natural gas, combustible ice, coke oven gas, and produced gas. Iron-containing materials and flux are sprayed into the furnace by spray guns.

[0071] One or more of natural gas, combustible ice, coke oven gas and generated coal gas are sprayed into the slag layer carbonaceous material spray gun (11). Others are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com