Process and device for treating decopperized slag by adopting bottom-blowing molten pool to produce wet lead and raw copper

A molten pool smelting and crude lead technology, applied in the direction of improving process efficiency, etc., can solve the problems that environmental pollution will not be greatly improved, flue gas is difficult to recover, and slag is highly corrosive, so as to avoid adverse effects, leaching Less corrosion, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

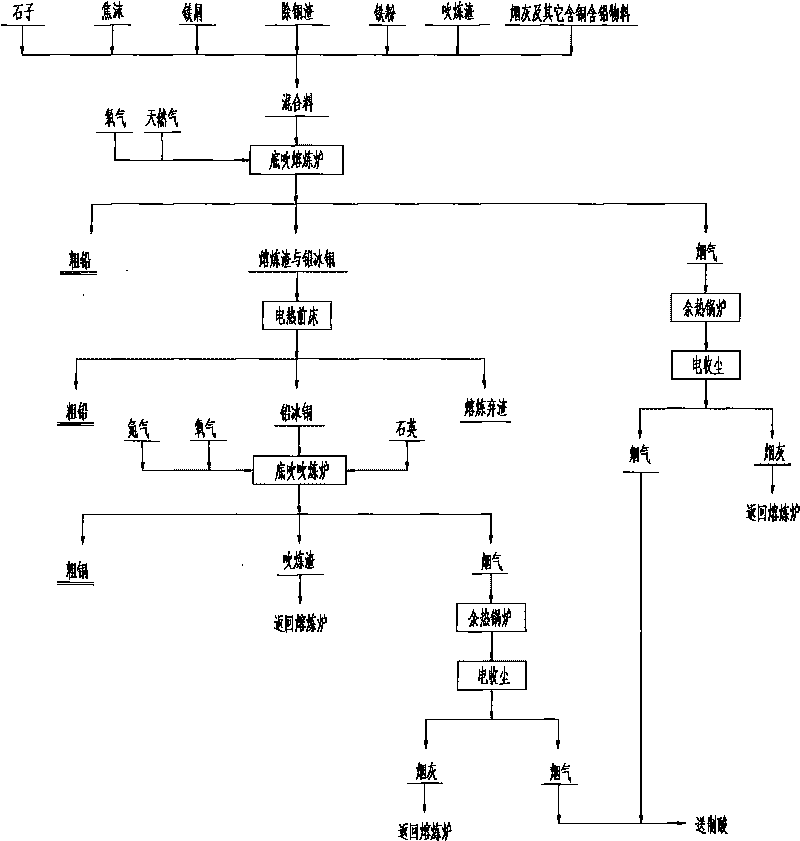

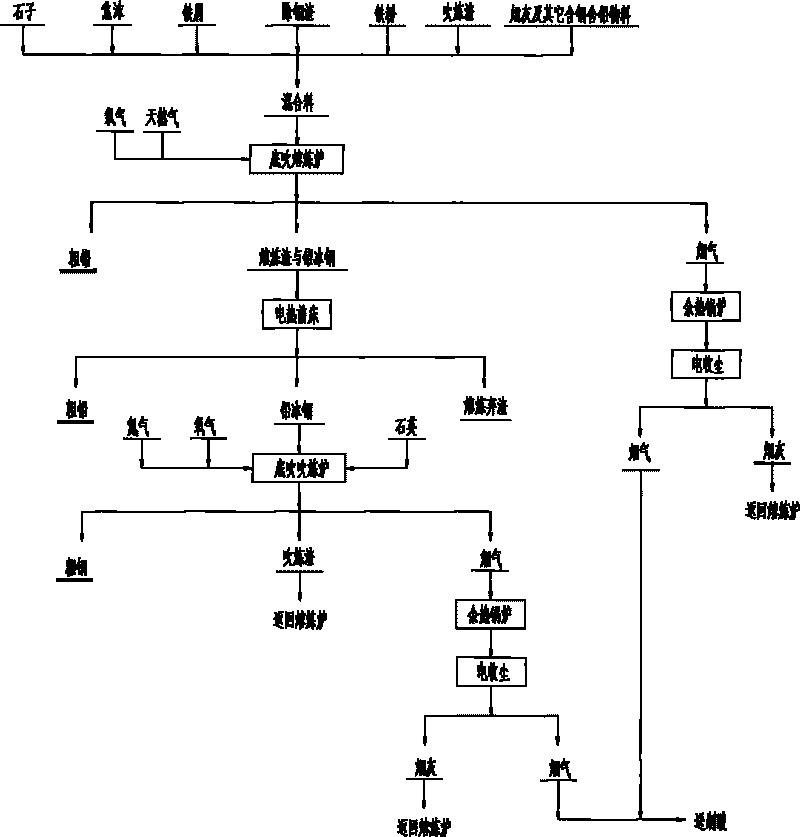

[0042] Such as figure 1 As shown in the schematic diagram, embodiment 1: a process for producing crude lead and blister copper using bottom-blown molten pool smelting treatment to remove copper slag, the specific steps are as follows:

[0043] (1) Preparation of raw and auxiliary materials: After batching copper removal slag, stones, coke foam, iron filings and iron oxide powder according to the weight ratio of 1000:50:70:100:40, they are continuously quantitatively fed into the bottom blowing melting furnace for melting and reduction , settling and separating, producing crude lead and lead matte, and producing smelting slag, maintaining a molten pool of 600-1000mm deep in the furnace consisting of crude lead, lead matte and smelting slag, keeping the temperature at 1050-1200°C, and producing The crude lead is released continuously through the siphon port at one end of the bottom-blown smelting furnace, the lead matte is mixed with the smelting slag continuously and released t...

Embodiment 2

[0048] Such as figure 1 As shown in the schematic diagram, embodiment 2: a process for producing crude lead and blister copper using bottom-blown molten pool smelting treatment to remove copper slag, the specific steps are as follows:

[0049] (1), preparation of raw and auxiliary materials: after the copper removal slag, stones, coke foam, iron filings, and iron oxide powder are batched according to the weight ratio of 1000:50:70:100:40, the copper removal slag, stones, coke foam, iron Chips, iron oxide powder, blowing slag, returned soot and other copper-containing slags are metered and mixed, and then sent to the feeding port on the upper part of the bottom blowing smelting furnace by a belt feeder and continuously added into the furnace, and continuously quantitatively enter the bottom blowing smelting furnace. The raw and auxiliary materials after the furnace are melted, reduced, settled and separated. The natural gas and oxygen are sent into the molten pool through the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com