Preparation method of ceramizing fire-resistant silicon rubber

A ceramic and silicone rubber technology, which is applied in the field of new polymer refractory materials, can solve the problems of slow burning speed, good thermal stability, and low heat release rate, and achieve slow burning speed, good thermal stability, and low heat release rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

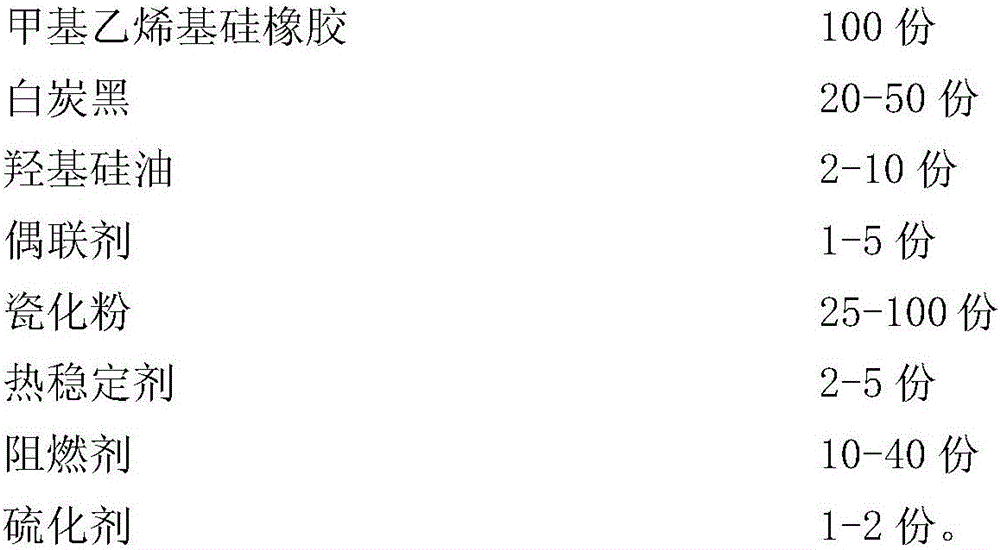

[0029] Embodiment 1, is suitable for molding heat vulcanization, and its composition is by mass parts:

[0030] Methyl vinyl silicone rubber

100 copies

Hydrophobic Fumed Silica

40 copies

Hydroxy silicone oil

8 servings

A171

1 copy

20 copies

Zinc borate

5 copies

Titanium dioxide

5 copies

Aluminum hydroxide

30 copies

2,5-Dimethyl-2,5-bis(tert-butylperoxy)

1.2 parts

[0031] The production process is as follows:

[0032] Add methyl vinyl silicone rubber to the kneader, then add hydrophobic fumed silica and hydroxyl silicone oil, knead at 80°C for 30 minutes to mix all components evenly, then add A171, mica, zinc borate, titanium dioxide and hydrogen Alumina, kept at 80°C and continued kneading for 1 hour, then raised the temperature to 100°C and evacuated for 30 minutes, the degree of vacuum was -0.07MPa. After the rubber material is cooled, add 2,5-dimethyl-2,5-bis...

Embodiment 2

[0035] Embodiment 2 is suitable for molded heat vulcanization, and its composition is in parts by mass:

[0036] Methyl vinyl silicone rubber

100 copies

Hydrophobic Fumed Silica

20 copies

Hydroxy silicone oil

2 copies

A151

2 copies

KH550

1 copy

50 copies

10 copies

Titanium dioxide

5 copies

40 copies

1 copy

[0037] The production process is as follows:

[0038] Add methyl vinyl silicone rubber to the kneader, then add hydrophobic fumed silica and hydroxy silicone oil, knead at 80°C for 30 minutes to mix the components evenly, then add A171, KH550, wollastonite, zinc oxide , titanium dioxide and magnesium hydroxide, keep at 80°C and continue mixing for 1.2h, then raise the temperature to 100°C and vacuumize for 30min, the vacuum degree is -0.07MPa. After the rubber material is cooled, add dicumyl ...

Embodiment 3

[0041] Embodiment 3 is suitable for hot air vulcanization, and its composition is by mass parts:

[0042] Methyl vinyl silicone rubber

100 copies

Hydrophobic Fumed Silica

30 copies

Hydroxy silicone oil

5 copies

A151

5 copies

Kaolin

80 copies

glass powder

15 copies

5 copies

Ferric oxide

2 copies

magnesium hydroxide

10 copies

Aluminum hydroxide

10 copies

Bis(2,4-dichlorobenzoyl) peroxide

2 copies

[0043] The production process is as follows:

[0044] Add methyl vinyl silicone rubber to the kneader, then add hydrophobic fumed silica and hydroxyl silicone oil, and knead at 80°C for 30 minutes to mix the components evenly, then add A151, kaolin, glass powder, zinc oxide, Ferric oxide, aluminum hydroxide and magnesium hydroxide were kept at 80°C for 1.5h and then heated to 100°C and vacuumed for 30min with a vacuum degree of -0.07MPa. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com