Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

312results about How to "Reduce heat release rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

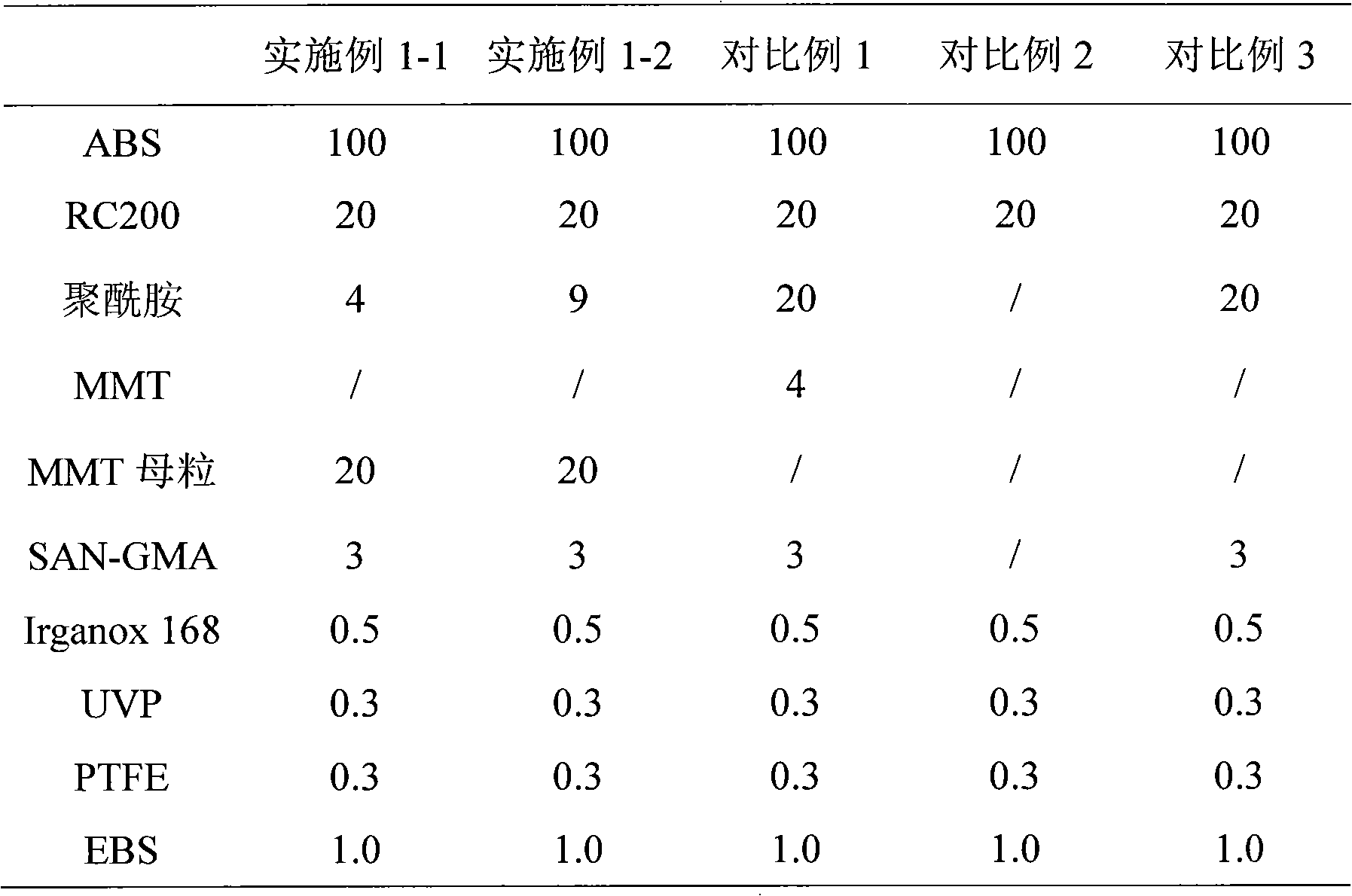

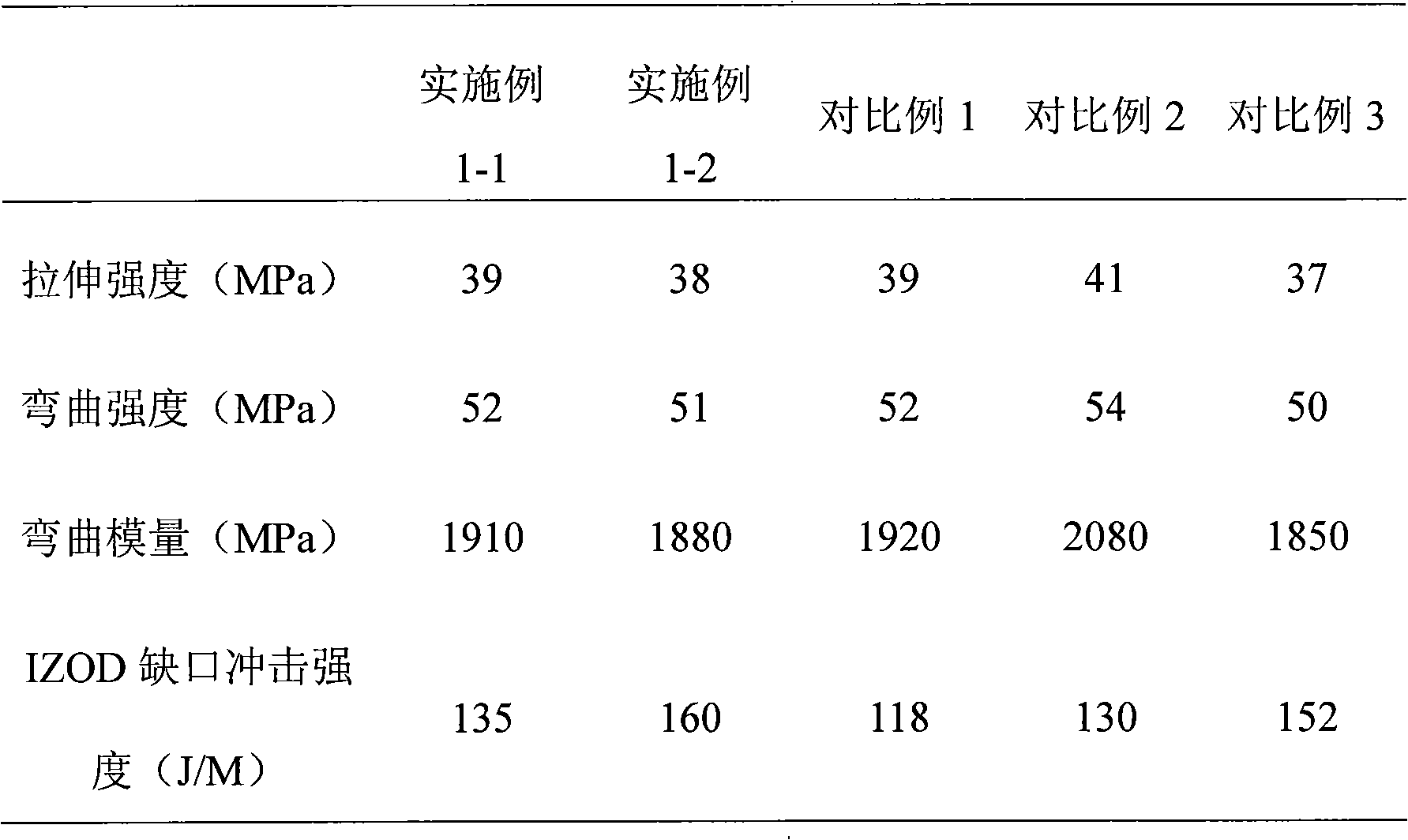

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Preparation method of ceramizing fire-resistant silicon rubber

ActiveCN105694471AImprove flame retardant performanceWill not affect other performanceHalogenCombustion

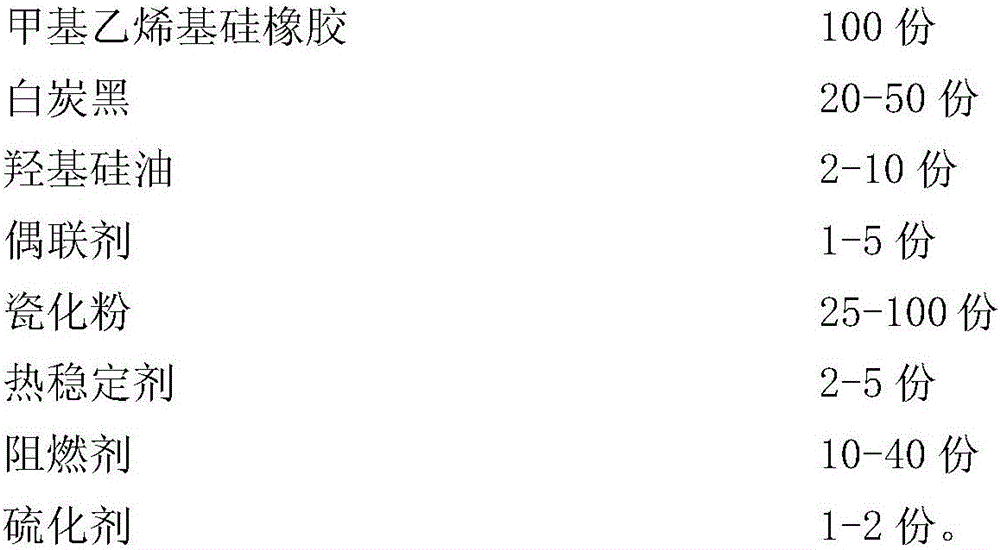

The invention relates to a preparation method of ceramizing fire-resistant silicon rubber. The rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicon rubber, 20-50 parts of white carbon black, 2-10 parts of hydroxyl silicone oil, 1-5 parts of a coupling agent, 25-100 parts of ceramizing powder, 2-5 parts of a heat stabilizer, 10-40 parts of a fire retardant, and 1-2 parts of a vulcanizer. The preparation method includes the following steps: adding the methyl vinyl silicon rubber in a kneading machine; then adding the white carbon black and the hydroxyl silicone oil; mixing for 30 minutes at the temperature of 80 DEG C; then adding the coupling agent, the ceramizing powder, the heat stabilizer and the fire retardant; mixing for 1-1.5 hours; raising the temperature to be 100 DEG C and keeping high vacuum for 30 minutes; and after cooling to room temperature, adding the vulcanizer on an open mixing machine for mixing to obtain the ceramizing fire-resistant silicon rubber. The rubber has good mechanical property and electrical property at normal temperature, does not contain halogen, is smokeless and non-toxic during combustion, can be extinguished quickly and forms a ceramizing shell to guarantee integrity of the inside.

Owner:BEIJING UNIV OF CHEM TECH

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

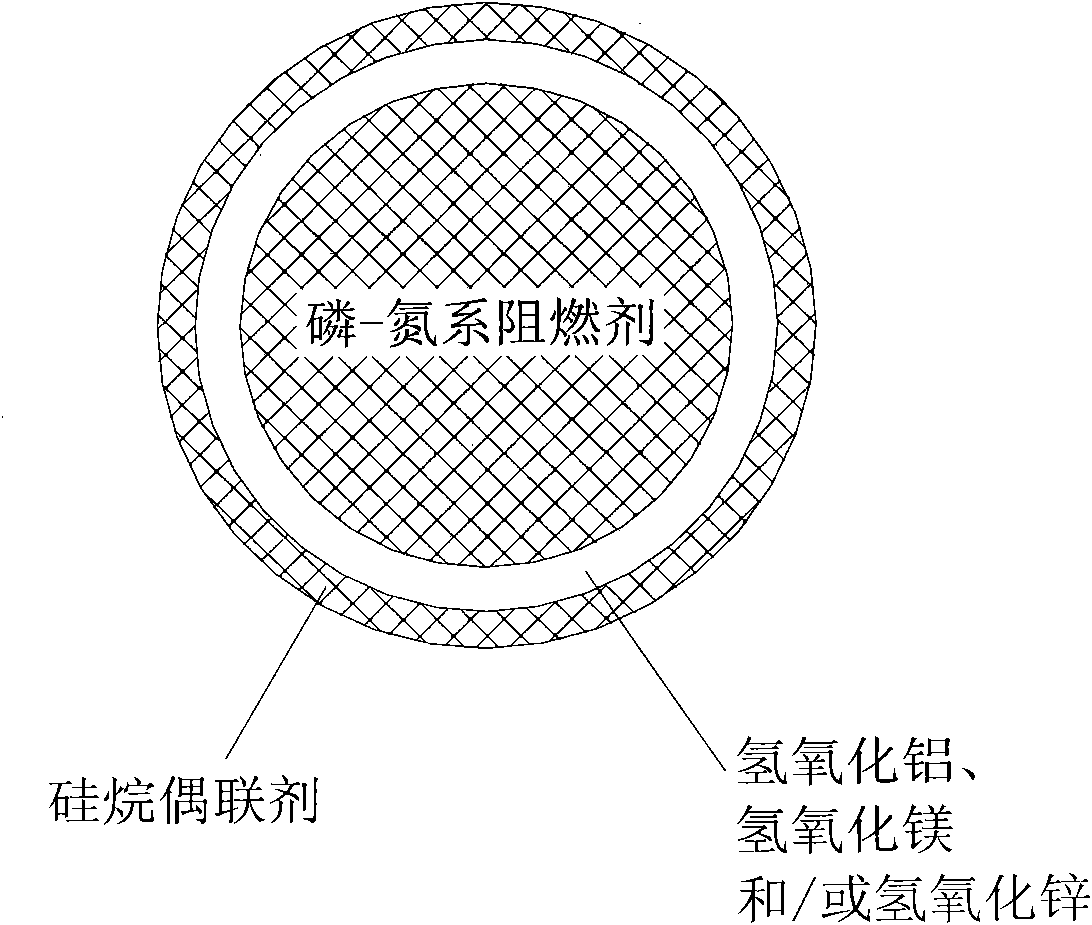

Halogen-free flame-proof cable sheath material

InactiveCN101012326ALow densityNon-flammablePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneCarvacryl acetate

The invention discloses a non-halogen flameproof cable jacket material formula without harming environment, which is characterized by the following: adopting ethylene-octaolefin copolymer, low-density polyethylene, ethylene-vinyl acetate copolymer as basic resin; making magnesium hydroxide as flameproof agent; using bulking graphite and organic montmorillonite as flame-proof assisting agent; adding lubricant and anti-oxidant to form the formula of cable jacket; improving extending strength to 10-14Mpa and fracture extending rate at 150-350%.

Owner:BEIJING UNIV OF CHEM TECH

Flame-retardant anti-dropping resin composition

InactiveCN101348603AExcellent and durable flame retardantLittle impact on mechanical propertiesPolyesterFiber

The invention discloses a flame-retardant anti-dripping resin compound, consisting of 100 weight portions of thermoplastic resin, 0.01-5 weight portions of modified polytetrafluoroethylene anti-dripping agents and 20 to 40 weight portions of environment-friendly flame retardant containing phosphorus and / or nitrogen. The resin compound has strong anti-dripping effect and heat resisting performance, is level and smooth in exterior appearance, and can endow polyester fiber products with excellent enduring flame retardancy without using halogen (Cl and Br) flame retardant. The resin compound has the advantages of high oxygen index, droplet resistance, low heat release rate, no halogen, little toxicity, low smoke dust emission, little influence on the mechanical properties of base materials, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

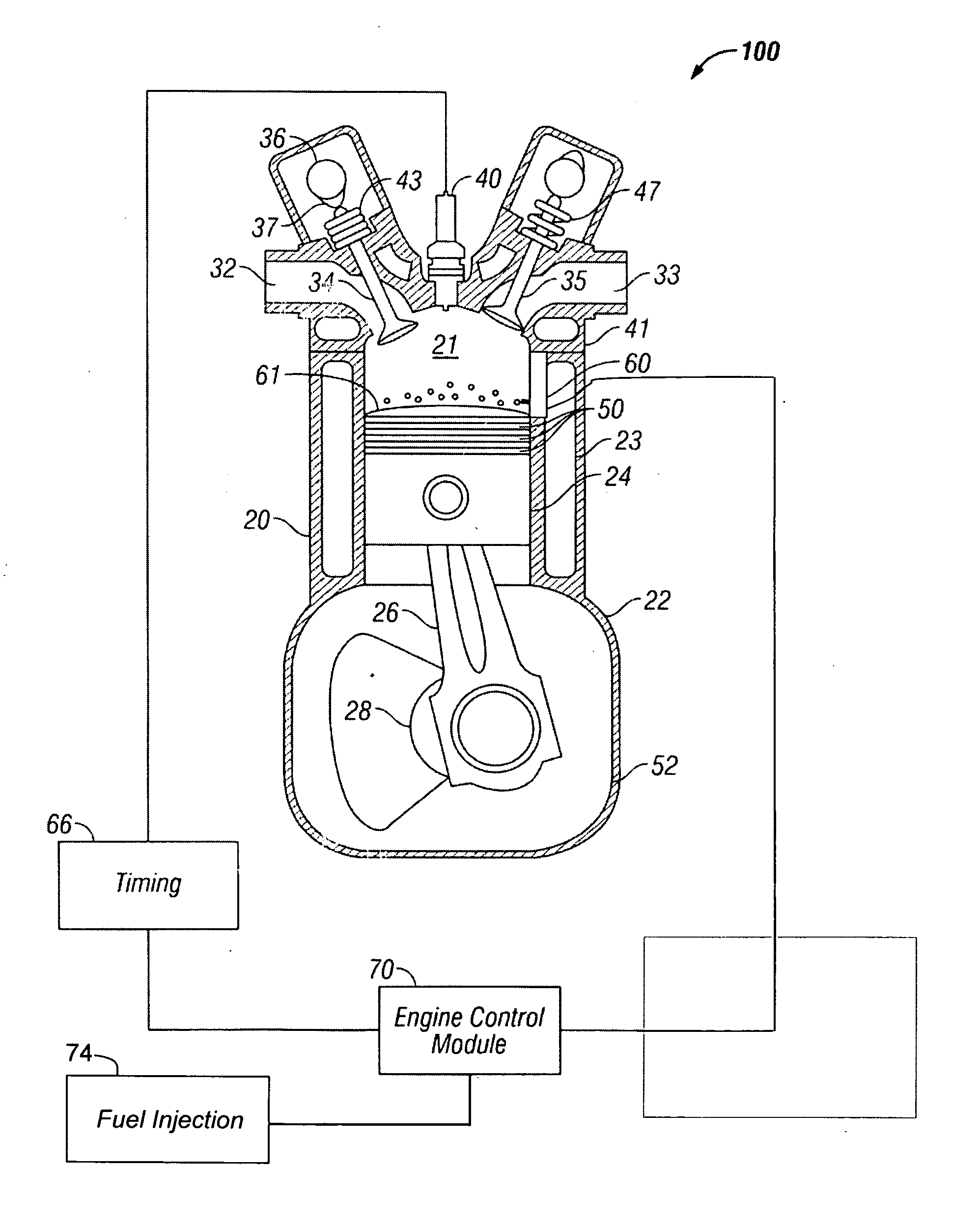

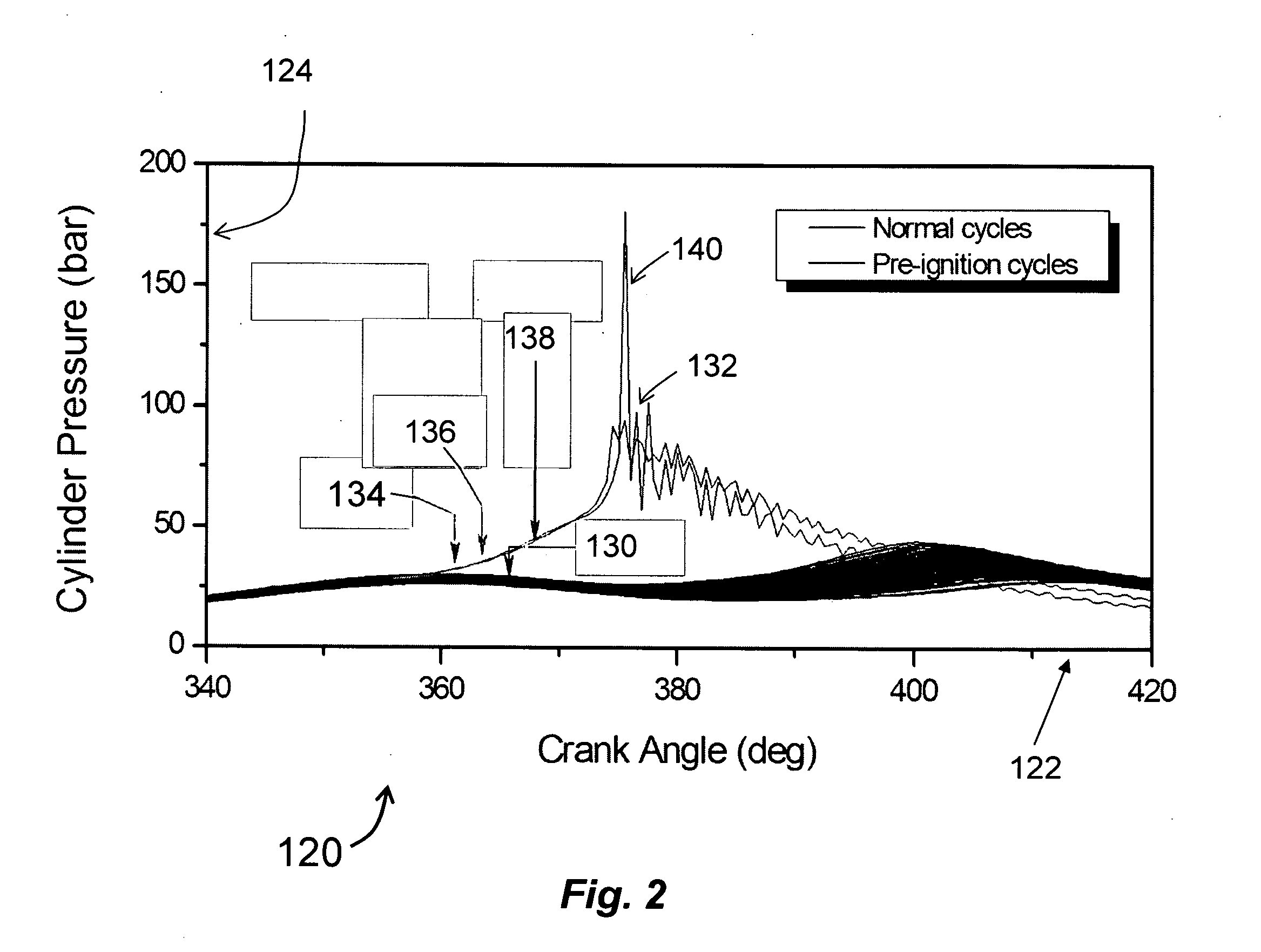

Methods of detecting pre-ignition and preventing it from causing knock in direct injection spark ignition engines

InactiveUS20120029789A1Mitigate engine knockReduce heat release rateInternal-combustion engine testingElectrical controlAutomotive engineeringSpark-ignition engine

A method of preventing a pre-ignition event within a cylinder (20) of a spark ignition engine (100) involves taking in-cylinder measurements and using the measurements to determine the instantaneous heat being released within the cylinder (20) as a function crank angle. If significant heat is being released before the intended spark timing, additional fuel is injected into the cylinder (20) immediately following the detection of early heat release (pre-ignition) within the same engine cycle, preferably within 45 crank angle degrees following the detection of pre-ignition. The additional fuel quenches the heat released within the cylinder (20) to prevent a pre-ignition event.

Owner:SOUTHWEST RES INST

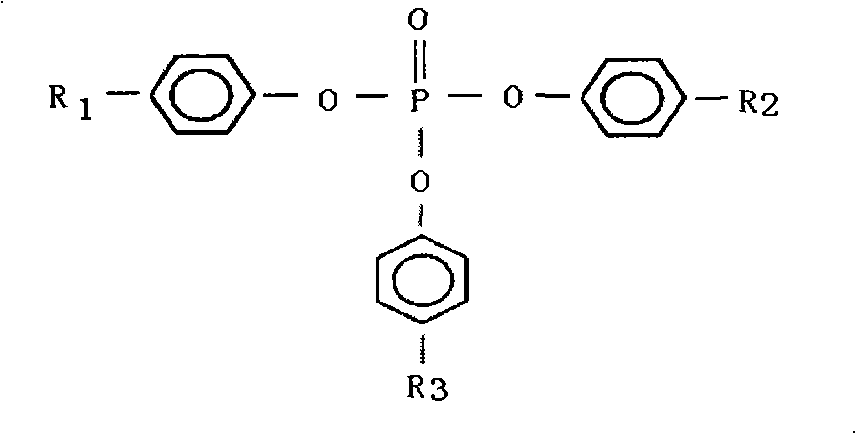

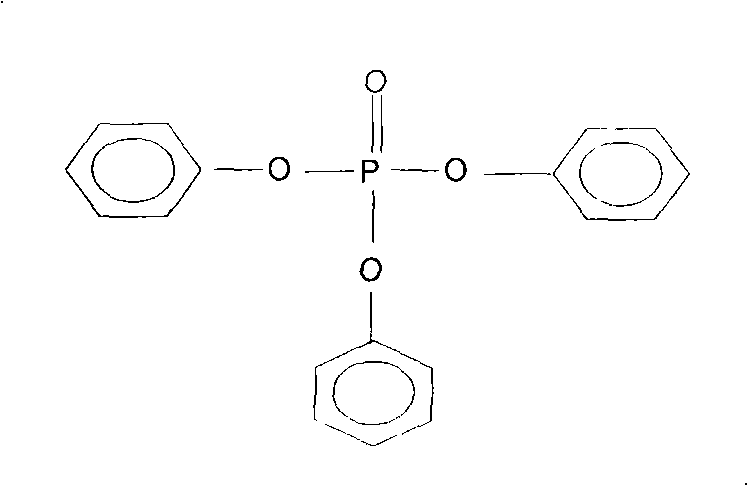

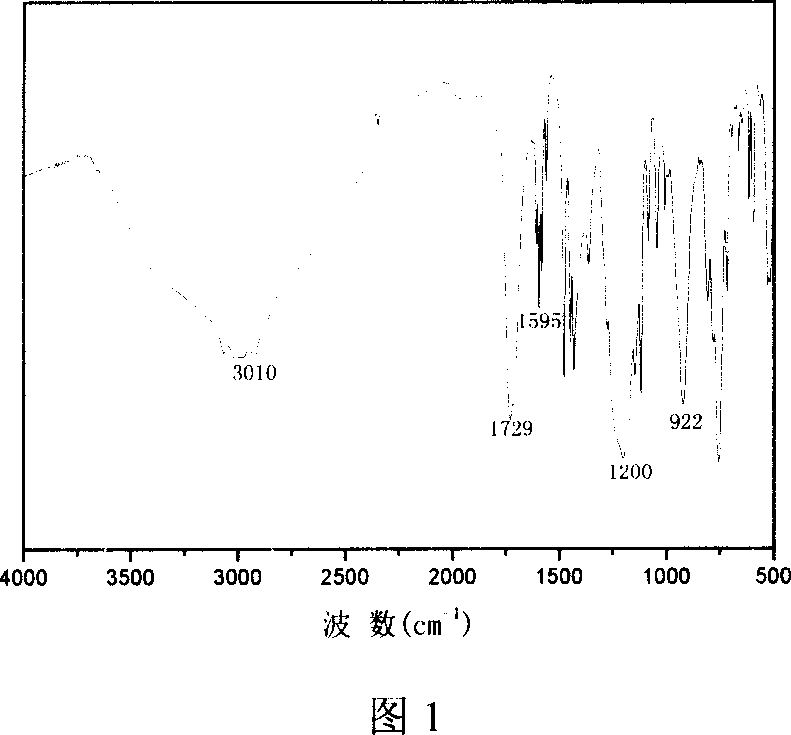

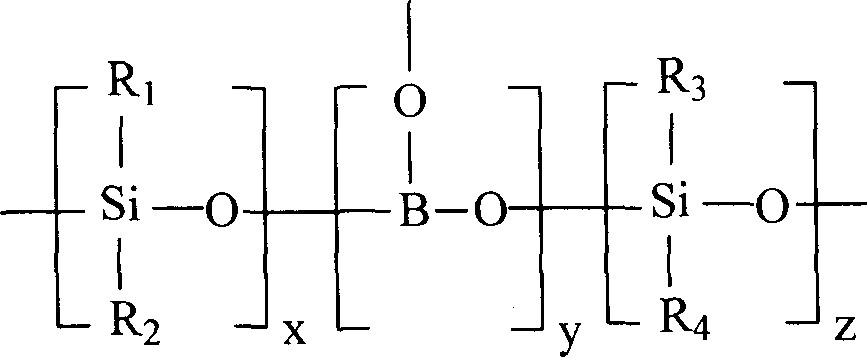

Silicious expanding fire retardant and its prepn process

InactiveCN1974721AImprove thermal stabilityImprove flame retardant performanceFireproof paintsHalogenPhosphate

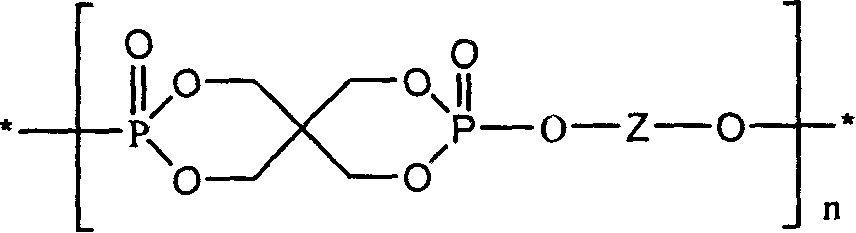

The present invention discloses silicious expanding fire retardant in the structure as shown and its preparation process. Being superior to traditional fire retardant, which contains halogen and hydroscopic, the silicious expanding fire retardant has three essentials as expanding fire retardant, and 9, 10-dihydro-9-oxo-10-phospha phenanthryl-10-oxide without phosphate ester structure as acid source, and possesses excellent fire retarding performance.

Owner:凌庆平

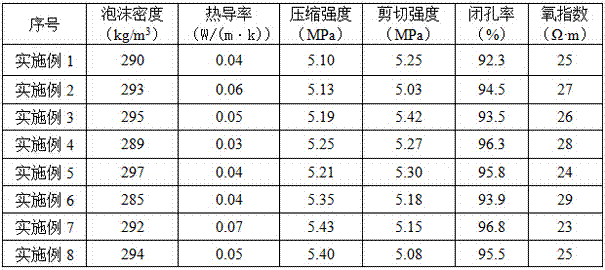

Nano composite expansion flame-retardant polyurethane foam plastic and preparation thereof

The invention discloses a nano composite expansion flame retardant polyurethane foamed plastic and a preparation method thereof. The nano composite expansion flame retardant polyurethane foamed plastic is characterized in that the preparation method comprises the following steps: evenly mixing 40 to 80 percent of polyol, 0.1 to 3 percent of foaming agent, 0.1 to 2 percent of foam stabilizer, 0.1 to 2 percent of catalyst, 0.5 to 4 percent of expandable graphite, 0.5 to 9 percent of halogen free phosphate ester or phosphonate ester and 0.5 to 5.5 percent of organic modified nano inorganic filler by weight percentage; and then mixing the mixture evenly with two or more isocyanate polyisocyanate compounds in the weight ratio of 1:2-2:1, and injecting the mixture into a die at 5 to 40 DEG C for foaming. The obtained nano composite expansion flame retardant polyurethane foamed plastic product effectively reduces the heat release rate and the total heat release amount of the material, improves the oxygen index and the vertical firing flame retardant property of the material, reduces the effect of an expansion type flame retardant on reducing the mechanical properties of the material, and meets the requirements of fire safety and project application.

Owner:UNIV OF SCI & TECH OF CHINA

Sheet molding compound with high flame resistance, low smoke and non-toxic and preparation method thereof

InactiveCN101514254AFully dispersedImprove flame retardant performancePolymer scienceAluminium hydroxide

The invention relates to a sheet molding compound with high flame resistance, low smoke and non-toxic and a preparation method thereof. The formula of the sheet molding compound comprises the following substance in mass portion: 50-80 portions of unsaturated polyester resin, 15-60 portions of low shrink additive, 1-3 portions of evocating agent, 0.01-0.05 portions of polymerization inhibitor, 0.7-7 portions of wetting and dispersing agent, 3-8 potions of inner mold release agent, 1-2 potions of thickening agent, 20-50 potions of viscosity reduction filler, 100-200 portions of flame retardant A, 50-100 portions of flame retardant B and 50-250 portions of reinforced material; the flame retardant A is micron aluminum hydroxide and the grain diameter is 0.4-3.5 microns; the flame retardant B is nanometer aluminum hydroxide and the grain diameter is 30-80 nanometers. The sheet molding compound of the invention has the advantages of high flame resistance, low smoke and non-toxic, well mechanical performance and surface decorative effect.

Owner:BEIJING ZHONGTIE LONGDRAGON ADVANCED COMPOSITE MATERIAL

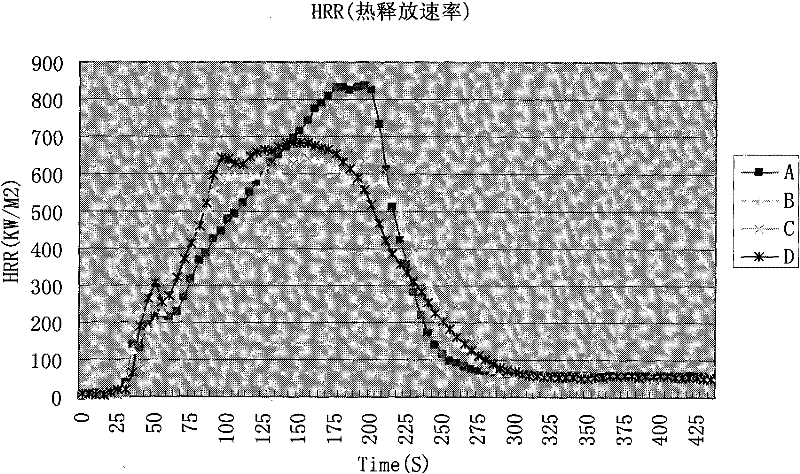

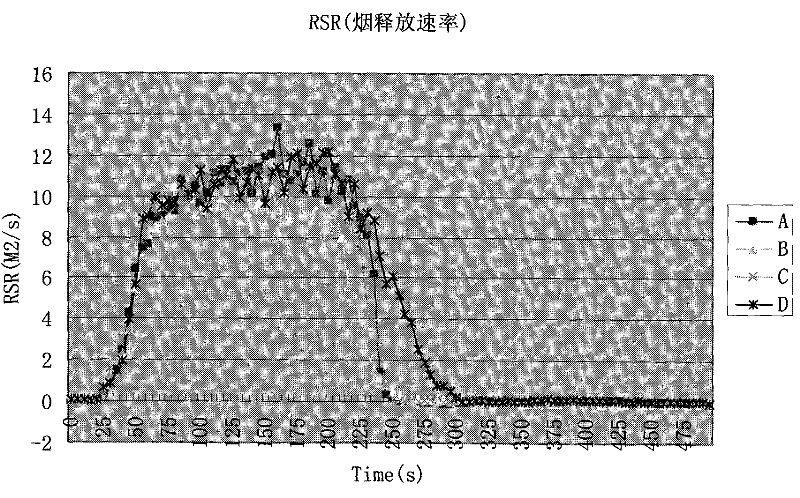

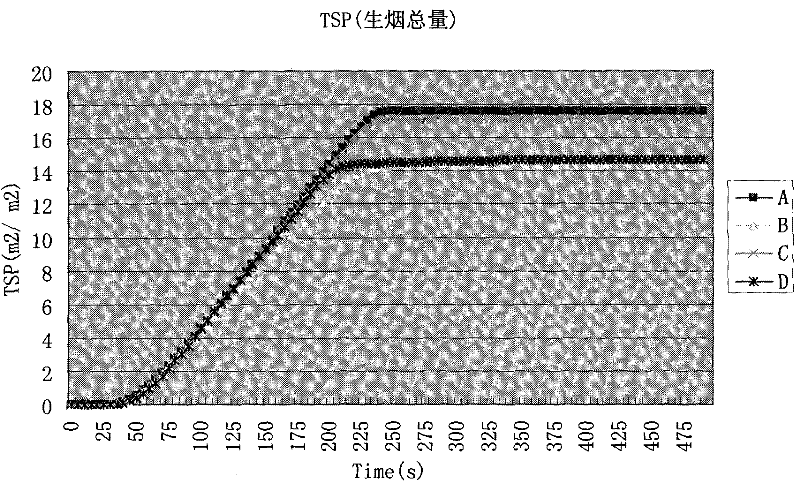

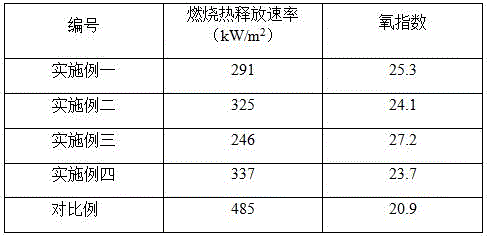

Low-heat low-smoke flame retardant and application thereof in preparing flame-retardant master batch

The invention relates to a low-heat low-smoke flame retardant and application thereof in preparing a flame-retardant master batch. The low-heat low-smoke flame retardant comprises the following components in percentage by weight: 40-70% of hypophosphite, 20-50% of melamine compound, 0.1-10% of nano inorganic substance and 5-15% of assistant. The low-heat low-smoke flame retardant can be used for preparing a flame-retardant master batch. Compared with the prior art, the invention can effectively reduce the heat release rate, smoke release rate and total smoke generation quantity, thereby performing active functions of postponing the propagation of flame, reducing the rate of burning released substances and increasing the escape probability.

Owner:上海安凸塑料添加剂有限公司

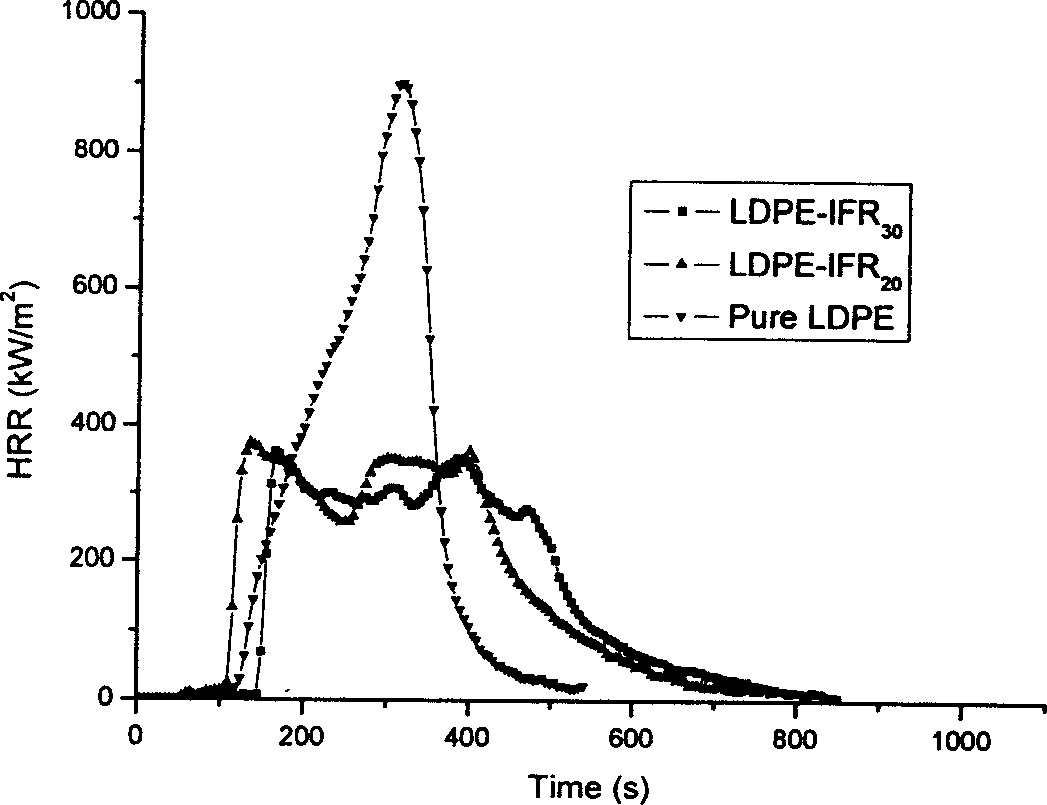

Halogon-free expansion flame-retarded polyolefin complex substance

The invention discloses a kind of non-halogen inflating fire-retarding polyolefine composition, which includes 50 - 90 weight shares of thermosplasticity polyolefine basic material and 10 - 50 weight shares of non-halogen inflating fire retarder. The non-halogen inflating fire retarder is comprised of non-halogen charcoal becoming fire retarder, non-halogen nitrous fire retarder and APP, weight proportions of which are 1 - 6 : 0.5 - 2 : 0.5 - 2. The compound has high oxygen index, melting drops resistance, low heat emitting velocity, no halogen, low toxicity, low smoke emission and small effect to dynam performance of basic material. It can be used in various fire retarding fields, and is especially suitable to be used in electrical wire cable, communications cable, shipping and auto industries.

Owner:SICHUAN UNIV

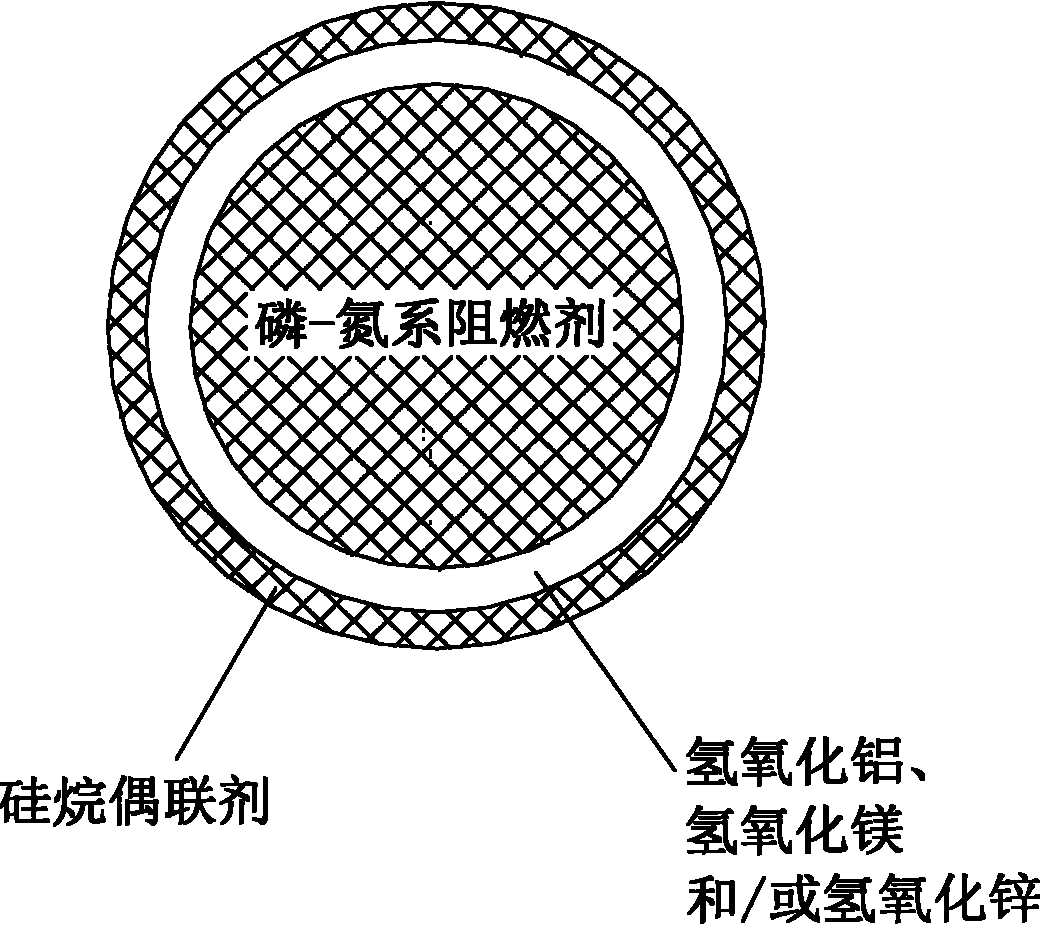

Ceramic fire-resistant and flame-retardant silicone rubber and preparation method thereof

InactiveCN106398231AImprove fire and flame retardant performanceImprove performancePolymer scienceSilanes

The invention relates to the technical field of silicone rubber, and particularly relates to a ceramic fire-resistant and flame-retardant silicone rubber and a preparation method thereof. The ceramic fire-resistant and flame-retardant silicone rubber is composed of a component A and a component B in a weight ratio of 0.8-1.2: 1. The component A comprises the following raw materials in weight part: 60-140 parts of silicone rubber A, 35-45 parts of reinforcing agent, 60-100 parts of filler A, 11.4-17.2 parts of silane auxiliary agent A, 0.15-0.25 part of lubricant A, 0.1-0.3 part of flame retardant, and 0.5-1.5 parts of vulcanizing agent. The component B comprises the following raw materials in weight part: 60-140 parts of silicone rubber B, 230-290 parts of filler B, 3-6 parts of silane auxiliary agent B, and 0.2-0.4 part of lubricant B. According to the technical scheme of the invention, the ceramic fire-resistant and flame-retardant silicone rubber is good in fire-resistant and flame-retardant property, and excellent in comprehensive performance.

Owner:东莞市朗晟材料科技有限公司

Micro foam polystyrene group composite material of wood and plastic, and method of producing the same

A micro-foaming polystyrene wood-plastic composite material and the preparation method relates to a micro foaming wood-plastic composite material and the preparation method. The present invention solves the problems of poor impact resistance and easy combustion of the current wood-plastic composite material. The present invention is made of wood fiber material, coupling agent, plasticizer, lubricant, polystyrene, foamer, assistant foamer, fire retardants and smoke suppressant according to a weight portion. The preparation method is as follows: first, hot mixing; secondly, cooling and mixing; thirdly, extruding and molding. Then the micro-foaming polystyrene wood-plastic composite material can be made. The micro-foaming polystyrene wood-plastic composite material of the present invention has the advantages of small density, good fire-resistant and smoke-suppression effects, and impact resistance.

Owner:NORTHEAST FORESTRY UNIVERSITY

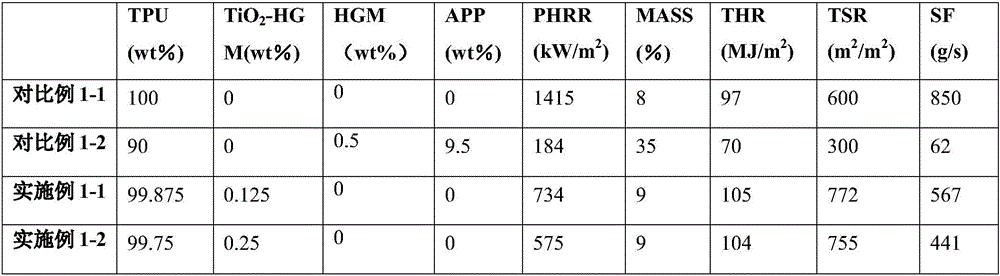

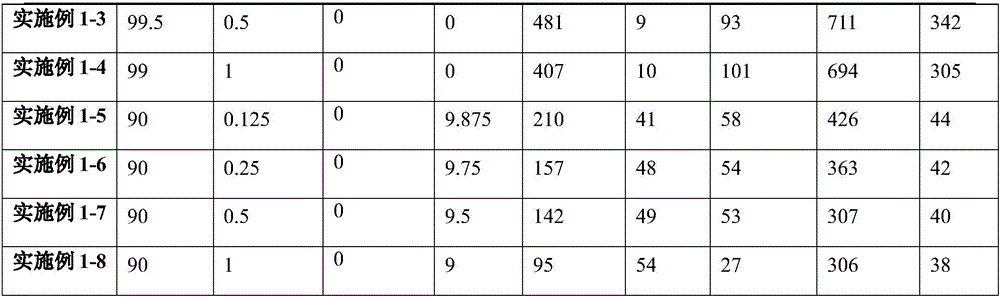

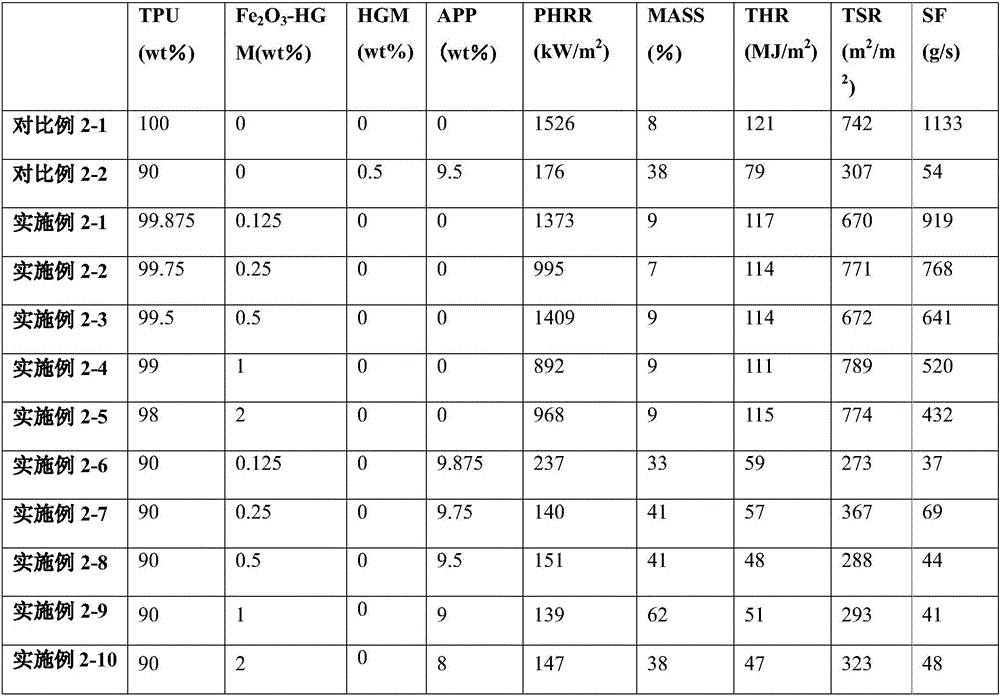

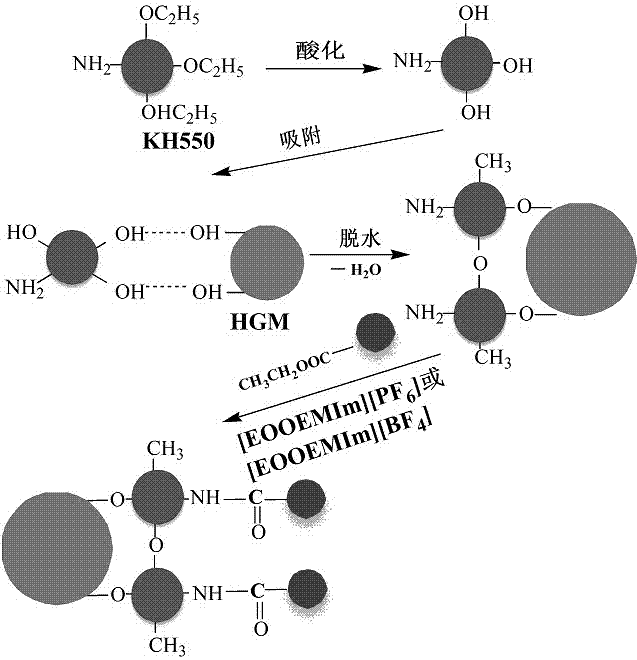

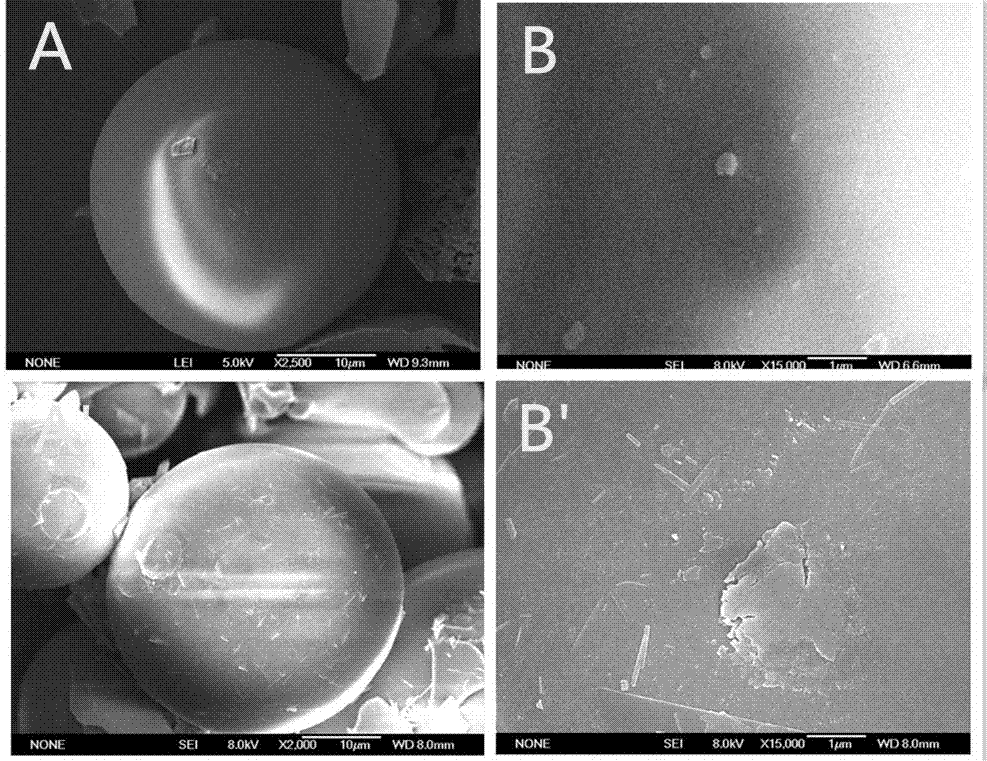

Surface modifying method of hollow glass beads and flame-retardant application thereof

InactiveCN106009044ASimple processEasy to operatePigment treatment with organosilicon compoundsIonFire retardant

The invention relates to a surface modifying method of hollow glass beads and a flame-retardant application thereof. The surface modifying method of the hollow glass beads comprises the following steps: (1) performing ultrasonic washing of the hollow glass beads by using a sodium hydroxide solution; (2) repeatedly washing the hollow glass beads obtained in the step (1) with deionized water and absolute ethyl alcohol respectively, and drying; and (3) dissolving the treated hollow glass beads in a mixed solution of ethanol and deionized water, and performing reflux, heating and stirring; in the heating process, dropwise adding a solution for obtaining a coating, and then adding the sodium hydroxide solution while keeping a neutral environment; and stirring for 5h, performing suction filtration and drying. In the invention, the modified hollow glass beads are adopted as a flame retardant to prepare a flame-retardant thermoplastic polyurethane composite; cone calorimeter experiments indicate that the parameters of the composite such as heat release rate, total heat release, smoke generation rate and smoke factor are remarkably reduced while the residual mass of carbon residues is greatly increased.

Owner:QINGDAO UNIV OF SCI & TECH

Nano-clay-containing irradiation crosslinked polyolefin cable material and preparation method thereof

InactiveCN104650446AIncrease melt viscosityBlock escapePlastic/resin/waxes insulatorsLinear low-density polyethylenePolymer science

The invention relates to a nano-clay-containing irradiation crosslinked polyolefin cable material, which comprises the following raw materials in parts by weight: 55-75 parts of an ethylene-vinyl acetate copolymer, 25-45 parts of metallocene linear low-density polyethylene, 5-10 parts of a grafting material, 2-8 parts of a lubricant, 0.5-2 parts of an antioxidant, 120-160 parts of inorganic filler, 8-15 parts of a charing promoter, 5-15 parts of nano-clay, 0.5-3 parts of a crosslinking sensitizer, and 3 parts of carbon black masterbatch. According to the invention, in the polyolefin cable material, by adding the nano-clay as a flame retardant synergist of the inorganic filler and being fitted with the charing promoter, the nano-clay can increase the viscosity of a melt in the process of polymer burning, so that the barrier property of the melt can be enhanced, the escape of small molecules can be stopped, the heat release rate and the smoke density are greatly reduced, the fireproof performance is improved, and then cables can be subjected to A-class bundled burning, therefore, the cable material can be applied to the spaces with high requirements on oil-resistant and flame retardant properties.

Owner:JIANGSUSNGSHANG CABLE GROUP

External wall thermal insulation material and preparation method thereof

InactiveCN105440657AImprove flame retardant performanceGood heat release rateFiberThermal insulation

The invention discloses an external wall thermal insulation material and a preparation method thereof. The external wall thermal insulation material is prepared from the following raw materials in parts by weight: 80-90 parts of methylene diphenyl diisocyanate, 65-75 parts of polyether polyol, 20-30 parts of straw fiber, 10-15 parts of glass fiber, 20-25 parts of organic nano-montmorillonite, 30-35 parts of flame retardant, 25-30 parts of smoke suppressor, 1-5 parts of reaction catalyst, 8-15 parts of crosslinking catalyst, 1-5 parts of coupling agent, 15-25 parts of deionized water and 1.5-5 parts of foam stabilizer. The prepared external wall thermal insulation material has the advantages of good fireproof property, high thermal insulation property, high wear resistance, high stability, high physical and mechanical properties, low cost and saving of energy.

Owner:NANYANG INST OF TECH

High-flame-retardancy paint

InactiveCN106366740AHigh tensile strengthImprove adsorption capacityFireproof paintsPolyurea/polyurethane coatingsWater basedDimethyl methylphosphonate

The invention discloses a high-flame-retardancy paint which is prepared from a water-based acrylate emulsion, a water-based polyurethane resin, aluminasol, an epoxy resin, polydimethylsiloxane, zinc oxide, hollow glass microspheres, nano zirconium oxide, montmorillonite, nano silicon dioxide, a film forming aid, a defoaming agent, a leveling agent, a wetting agent, a flame retardant and water. The flame retardant is formed by mixing boron oxide, dimethyl methyl phosphonate, phosphorus pentoxide, tri(2-chloropropyl) phosphate, guanylurea phosphate, ammonium polyphosphate, pentaerythritol, melamine and hexamethyl disiloxane. The high-flame-retardancy paint has the advantages of favorable water resistance, favorable wear resistance, excellent flame retardancy and long service life.

Owner:ANHUI JINDUN PAINT

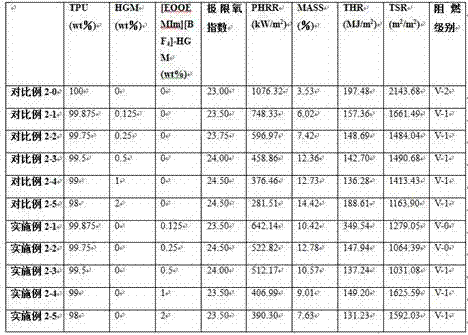

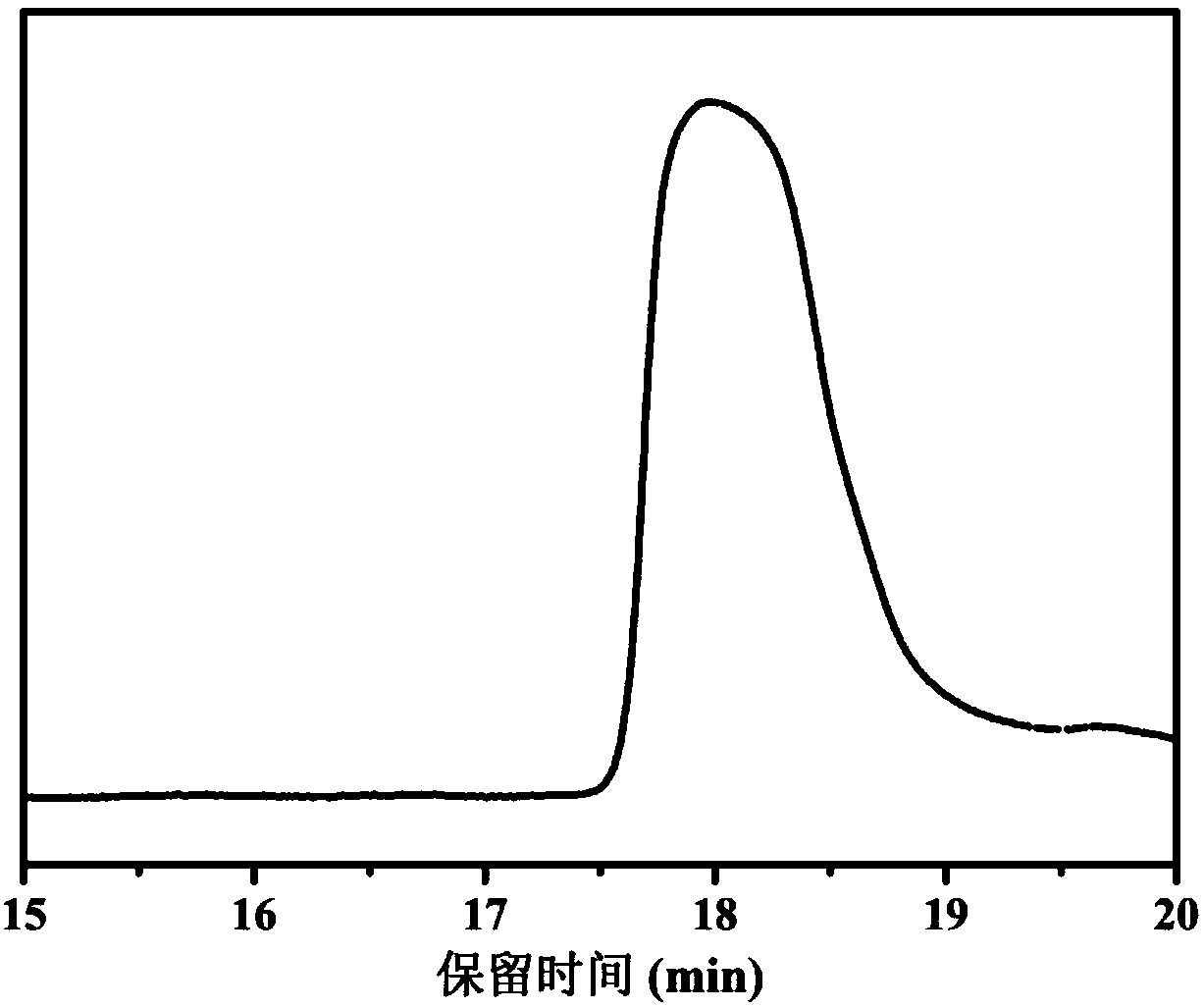

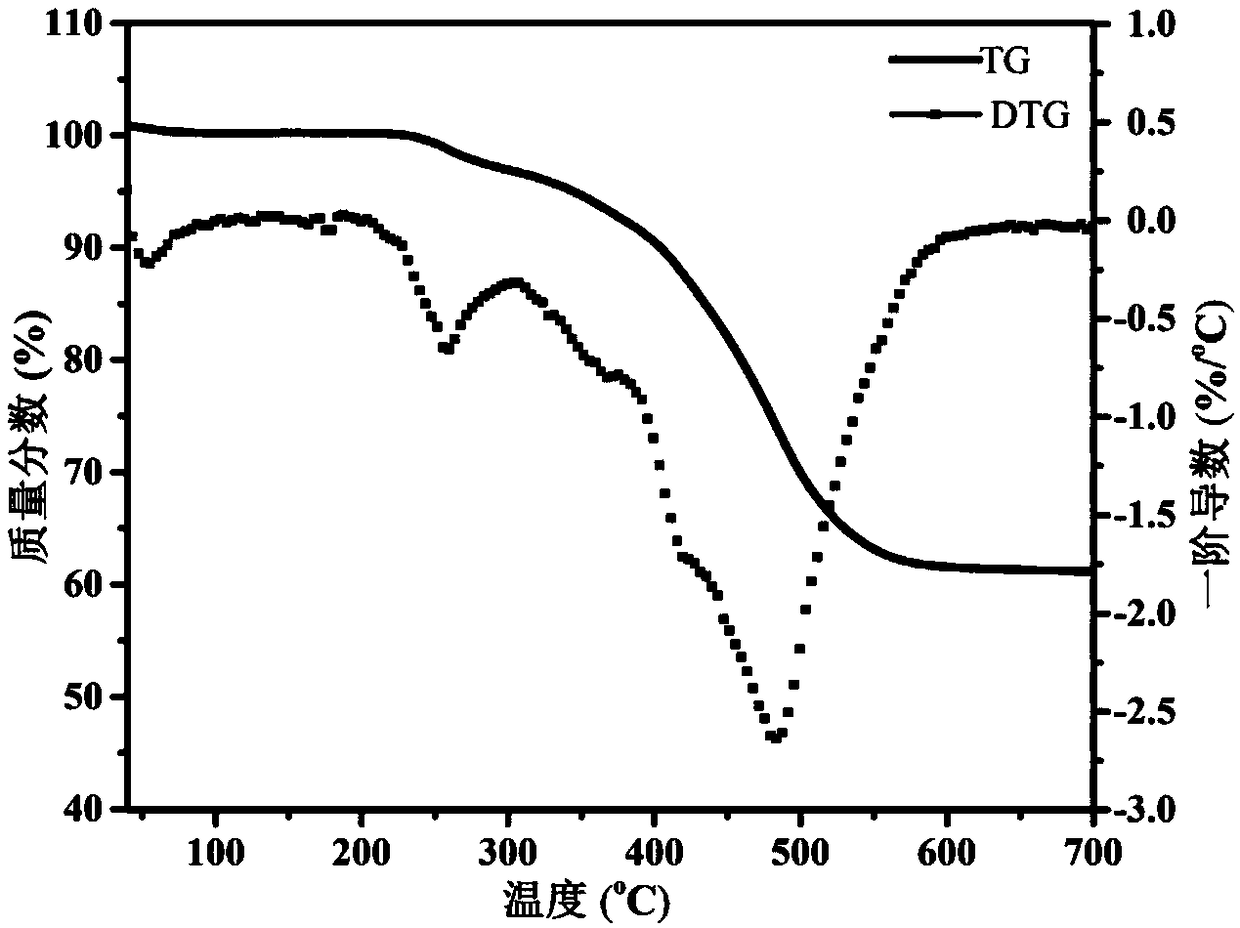

Method of modifying hollow glass microbeads with ionic liquid and flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as flame retardant

The invention discloses a method of modifying hollow glass microbeads with an ionic liquid and a flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as a flame retardant. The method includes the steps of: 1) treating the hollow glass microbeads with a hydrochloric acid solution; 2) after the acid treatment, repeatedly washing and drying the hollow glass microbeads; 3) activating the hollow glass microbeads, adding a silane coupling agent, and performing mechanical stirring reflux; 4) stopping the reaction and cooling the reaction product to room temperature, and performing suction filtration with acetonitrile, ethanol and deionized water and drying the reaction product; 5) adding the ionic liquid to the silanized hollow glass microbeads and performing mechanical stirring reflux; 6) stopping the reaction and cooling the reaction product to room temperature, performing suction filtration successively with ethanol, a mixed solution of ethanol and deionized water, and ethanol, and drying the reaction product. By means of the hollow glass microbeads modified with the ionic liquid as the flame retardant for preparing flame-retarding thermoplastic polyurethane (TPU) elastomer, not only is oxygen index of the composite material improved, but also the vertical combustion performance, which reflects melt-dripping resistance, is improved, so that heat release rate is reduced and smoke is significantly inhibited.

Owner:JIANGSU STERRIC CHEM IND

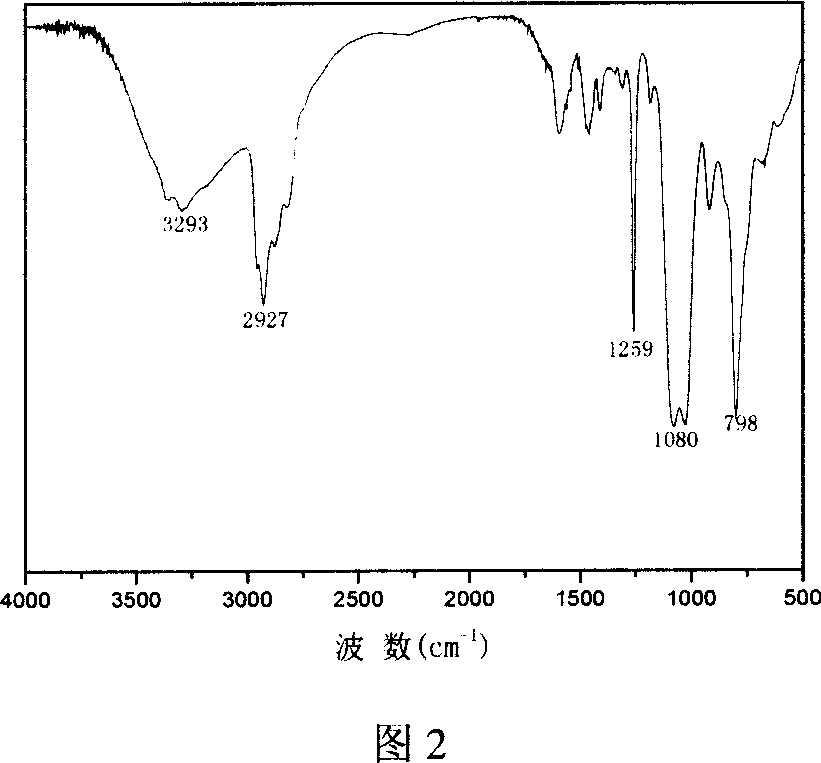

Silicious fire retard ant for polyolefin and its prepn and application

The present invention provides one kind of silicious fire retardant for polyolefin with the molecular structure as shown. The fire retardant is white or yellowish powder and has smelting temperature of 220-260 deg.c. The present invention provides the preparation process of the silicious fire retardant and the application of the silicious fire retardant as halogen-free environment fire retarding additive for polyolefin material.

Owner:SOUTH CHINA UNIV OF TECH

Low-smoke low-toxicity flame-retardation hard polyurethane foam plastics and preparation method thereof

The invention discloses low-smoke low-toxicity flame-retardation hard polyurethane foam plastics and a preparation method thereof. The low-smoke low-toxicity flame-retardation hard polyurethane foam plastics comprise the following raw materials: 100 parts of polyether polyol, 120-150 parts of isocyanate, 10-20 parts of an intumescent flame retardant, 1-3 parts of a metallic compound, 0.5-2 parts of attapulgite, 1-5 parts of a foaming agent, 1-4 parts of a foaming stabilizer, and 3-6 parts of a foaming catalyst. The preparation method comprises the following steps: mixing, casting and foaming. The low-smoke low-toxicity flame-retardation hard polyurethane foam plastics have good flame resistance, and achieve a V-0 grade in an UL94 vertical combustion test. At the same time, an expandable charcoal layer formed after combustion of the fire retardant, and the added metallic compound and the attapulgite are capable of absorbing and catalyzing toxic gas, effectively reduce heat release rate and total heat release rate of the materials, and can solve the problem of large flue gas generation amount of the foam plastics prepared by the additive-type flame retardant.

Owner:HEFEI GENIUS NEW MATERIALS

Halogen-free expanded flame retardant cable outer sheath material composition and preparation method thereof

InactiveCN103102579ALow priceLow costPlastic/resin/waxes insulatorsInsulated cablesAntioxidantMechanical property

The invention relates to a halogen-free expanded flame retardant cable outer sheath material composition and a preparation method thereof, and belongs to the technical field of cable material. The material is characterized by comprising an ethylene-vinyl acetate copolymer binder, an antioxidant, an ethylene vinyl acetate grafted maleic anhydride copolymer compatilizer, an antioxidant, an ammonium polyphosphate flame retardant, a pentaerythritol flame retardant, a release agent, and further comprising 1-3% of halloysite nanotubes and 1-2% of a silane coupling agent. The invention introduces halloysite nanotubes into the halogen-free expanded flame retardant ethylene-vinyl acetate cable sheath material to realize the purpose of flame retardant modification without affecting properties of the material, and at the same time to enhance the mechanical properties of the material. The invention has the advantages of simple process, easy operation and control, low cost of raw materials and wide range of sources; and the halogen-free expanded flame retardant cable sheath material prepared from the halogen-free expanded flame retardant cable outer sheath material composition provided by the invention has good mechanical and flame retardant properties.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC +1

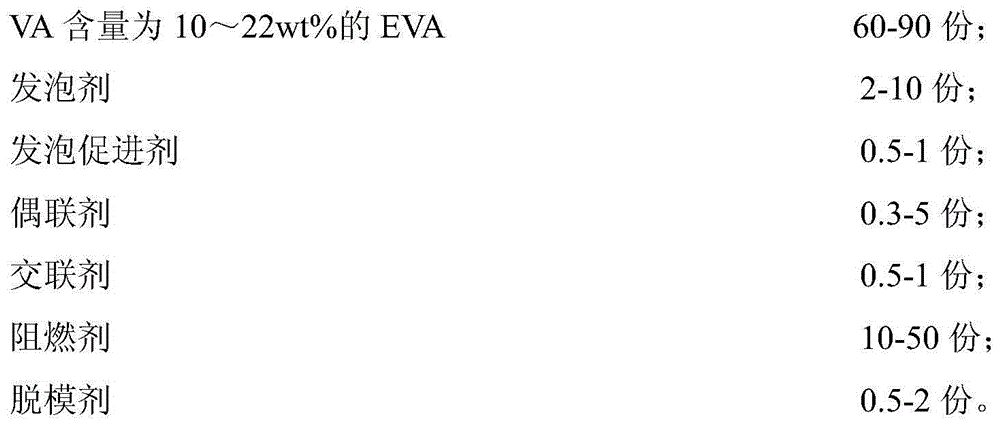

Nano-Mg-Al hydrotalcite fire-retardant EVA foaming material and preparation method thereof

InactiveCN105440420AImprove mechanical propertiesImprove flame retardant performanceCombustionFoaming agent

The present invention relates to a nano-Mg-Al hydrotalcite fire-retardant EVA foaming material comprising, by weight, 60-90 parts of an ethylene-vinyl acetate copolymer with 10-22wt% of VA, 2-10 parts of a foaming agent, 0.5-1 part of a foaming accelerator, 0.3-5 parts of a coupling agent, 0.5-1 part of a crosslinking agent, 10-50 parts of a flame retardant and 0.5-2 parts of a releasing agent, and the flame retardant is nano-Mg-Al hydrotalcite. Compared with traditional metal hydroxide flame retardants, the nano-Mg-Al hydrotalcite has great advantages in improvement of the limiting oxygen index, improvement of vertical combustion performances and reduction of heat release rate and other flame retardant aspects, and is better fire-retardant inhibitor. The present invention also provides a preparation method of the foaming material, and the method is simple to operate, the foaming process is not needed to be further modified or changed, production cost can be reduced, and energy can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

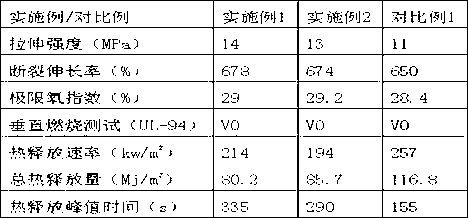

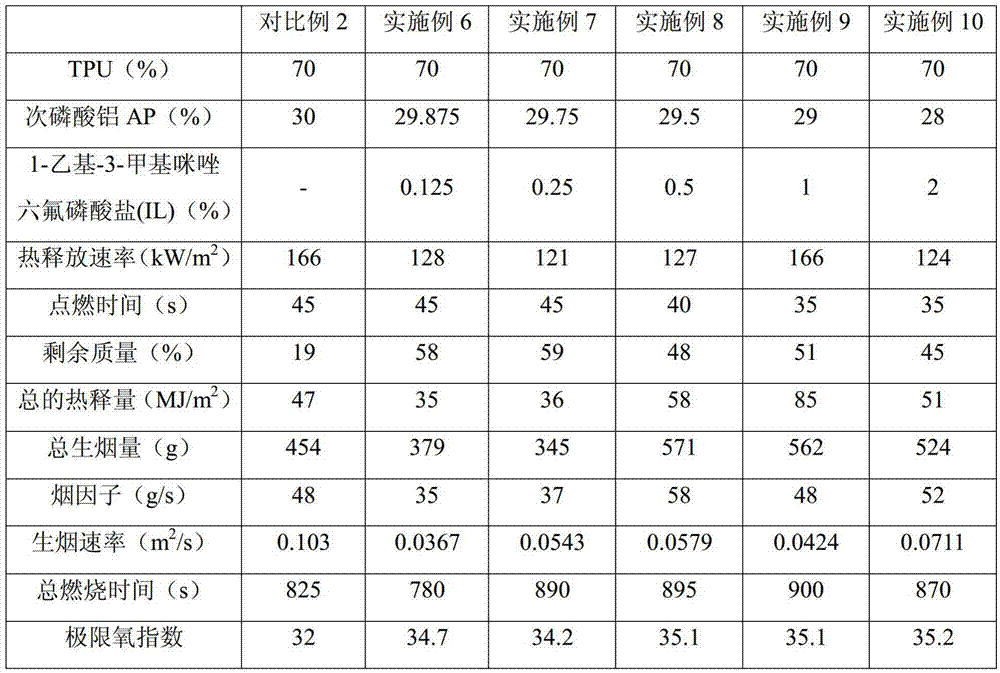

Flame retardant thermoplastic polyurethane elastomer (TPU) and preparation method thereof

ActiveCN105440652AHigh oxygen indexIncreased vertical burn test levelThermoplastic polyurethaneOxygen

The invention relates to a flame retardant thermoplastic polyurethane elastomer (TPU) and a preparation method thereof. The flame retardant TPU comprises the following components in parts by mass: 70-90 parts of TPU, 9.7-29.875 parts of intumescent flame retardants and 0.025-3.75 parts of ionic liquids. The intumescent flame retardant TPU composite material is prepared by adopting the composite intumescent flame retardant. The vertical flame test level of the composite material is increased to V-0. A dense intumescent char layer is formed on the specimen surface of the composite material, so that the composite material has good flame retardant effects. Under the condition of small additive amount of the ionic liquids, the oxygen index of the ionic liquid and intumescent flame retardant synergistic flame retardant TPU composite material is increased, so that the vertical flame performance embodying molten drop resistance is obviously improved, the heat release rate and total heat release can be well reduced, the charring performance during flaming is improved and the composite material has certain effects on smoke suppression.

Owner:盛鼎高新材料有限公司

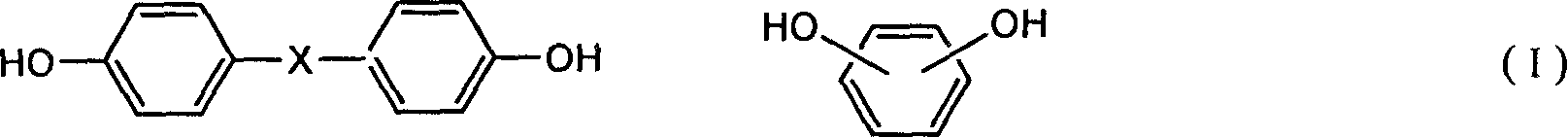

Ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, preparation method of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, and application of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent to flame retarding polymer

The invention discloses a ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent and a preparation method of the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The preparation method of the polymer is as follows: putting 10-(2,5-dyhydroxyl phenyl)-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a reactor, adding a solvent,stirring for 5-10 minutes, adding an acid-binding agent; taking R1,R2'-ferrocene oxalyl chloride, adding the solvent, mixing, adding into the reactor dropwise, thermally insulating, stirring and reacting for 1-15 hours at the temperature of 0-50 DEG C under the protection of nitrogen after finishing adding dropwise; pouring a liquid obtained after the reaction into a precipitator while stirring, wherein the volume of the precipitator is 5-10 times that of the liquid, precipitating a yellow solid, carrying out suction filtration, washing a filter cake by using the precipitator, and drying to obtain the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent can be used to retard flame and suppress smoke of high polymer materials like polyolefins and epoxy resins.

Owner:SOUTHWEAT UNIV OF SCI & TECH

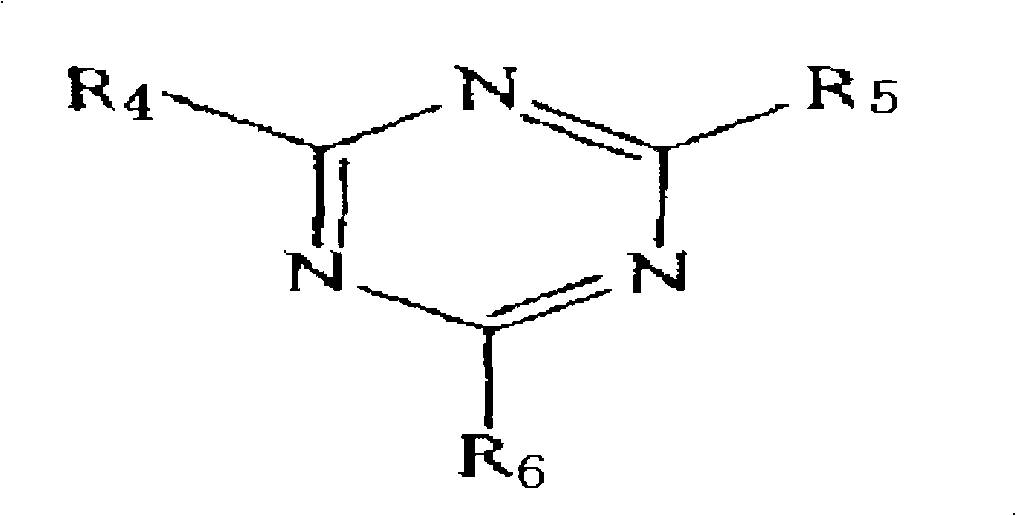

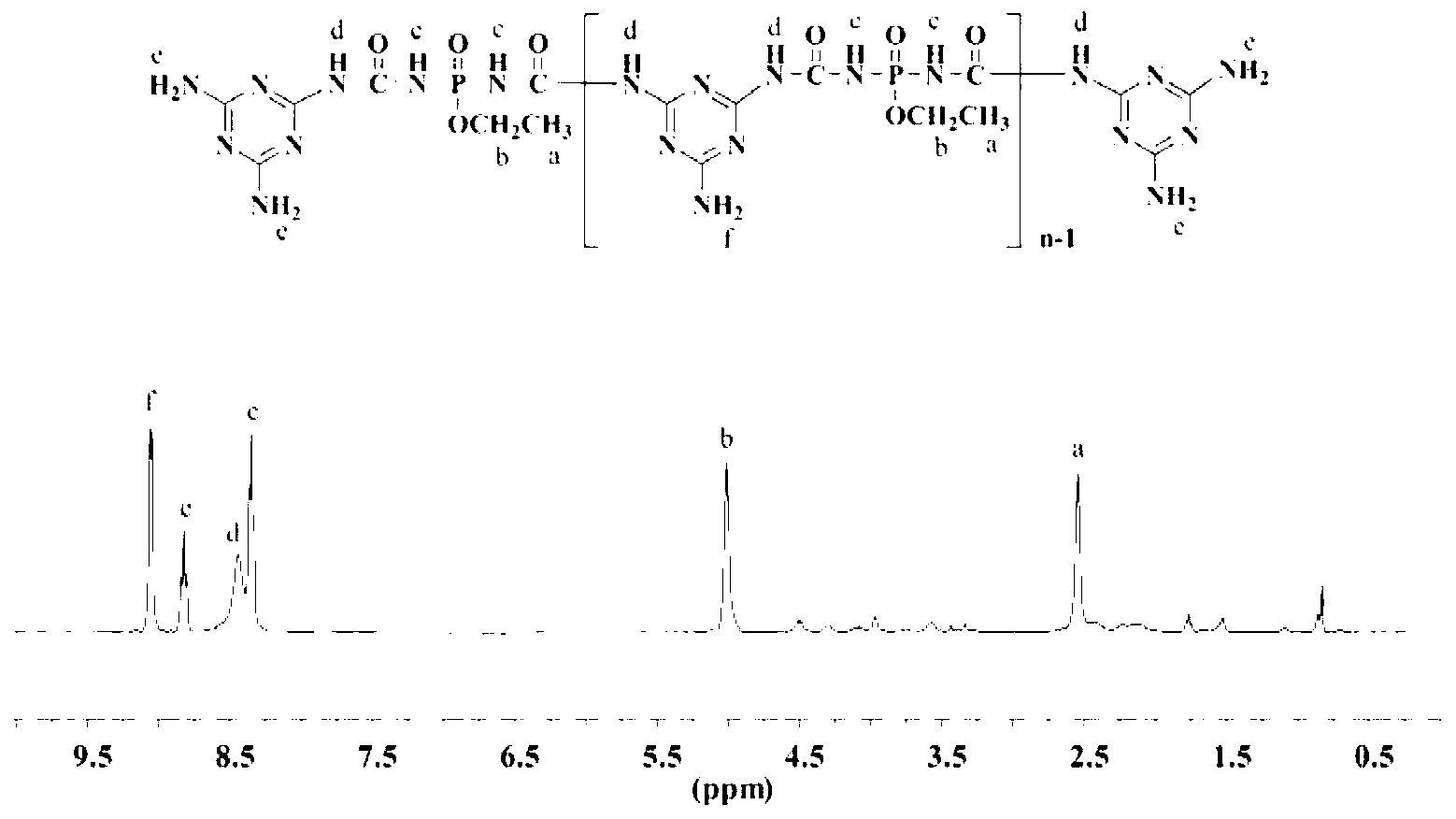

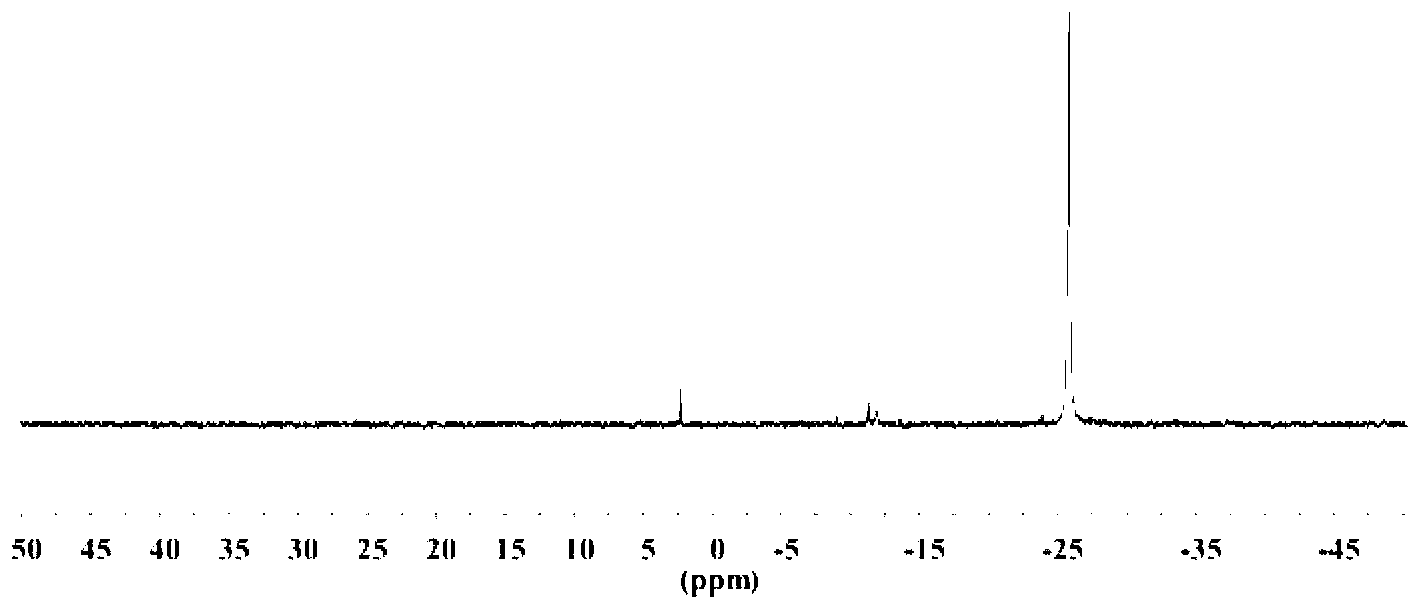

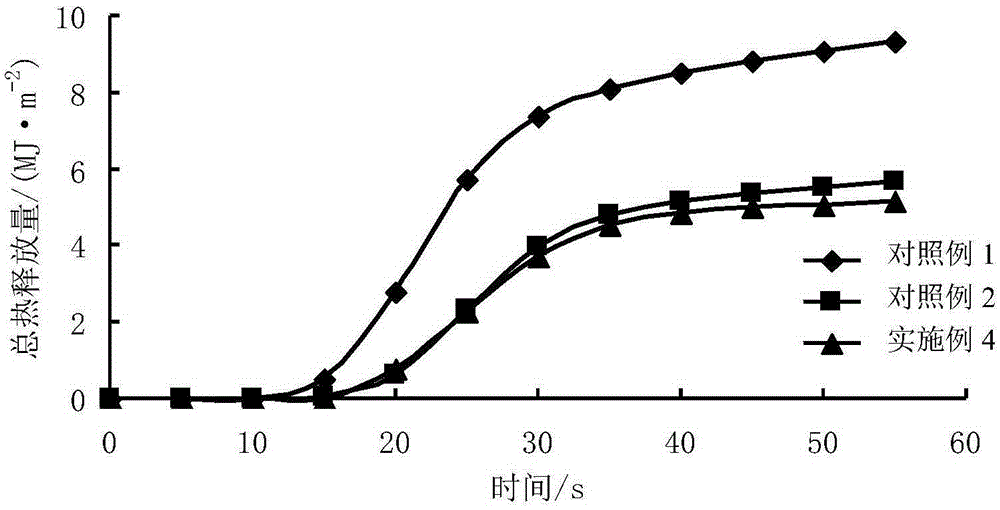

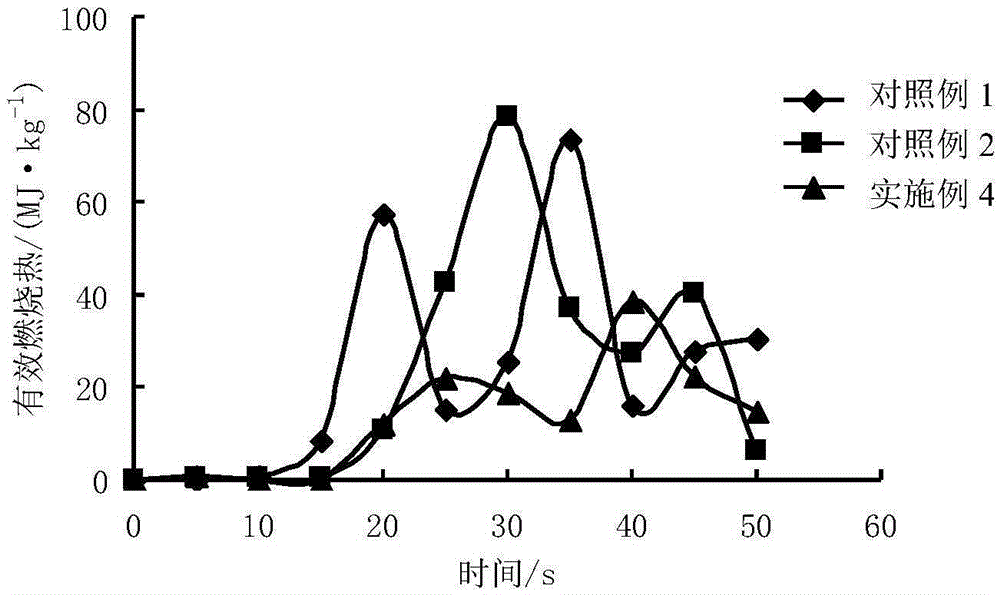

Melamine polymer type intumescent flame retardant and preparation method and application thereof

ActiveCN103289084AReduce heat release rateReduce riskGroup 5/15 element organic compoundsHalogenPolymer science

Owner:SICHUAN UNIV

Flame-retardant wallpaper and preparation method thereof

ActiveCN105297551AImprove flame retardant performanceTotal calories lowSpecial paperLaminationToxic gasFire risk

The invention discloses flame-retardant wallpaper as an indoor wall decoration material and a preparation method thereof. The preparation method for the flame-retardant wallpaper includes the following steps: after being immersed in a flame retardant solvent, a decorative veneer and a wallpaper substrate (backing paper) are ultrasonically immersed, so that a flame-retardant decorative veneer and a flame-retardant substrate are obtained; the flame-retardant decorative veneer is attached onto the surface of the flame-retardant substrate. The flame-retardant property of the wallpaper is good, the potential fire risk is low when the material burns, and the flame-retarding effect is remarkable; the smoke suppression effect is obvious, the amount of CO released from smoke is obviously reduced, toxic CO gas can be partially turned into non-toxic gas, and the wallpaper has a good effect of suppressing CO released at fire scenes. Moreover, since the adopted materials are natural materials, the wallpaper is safe to use.

Owner:沈阳领拓科技有限公司

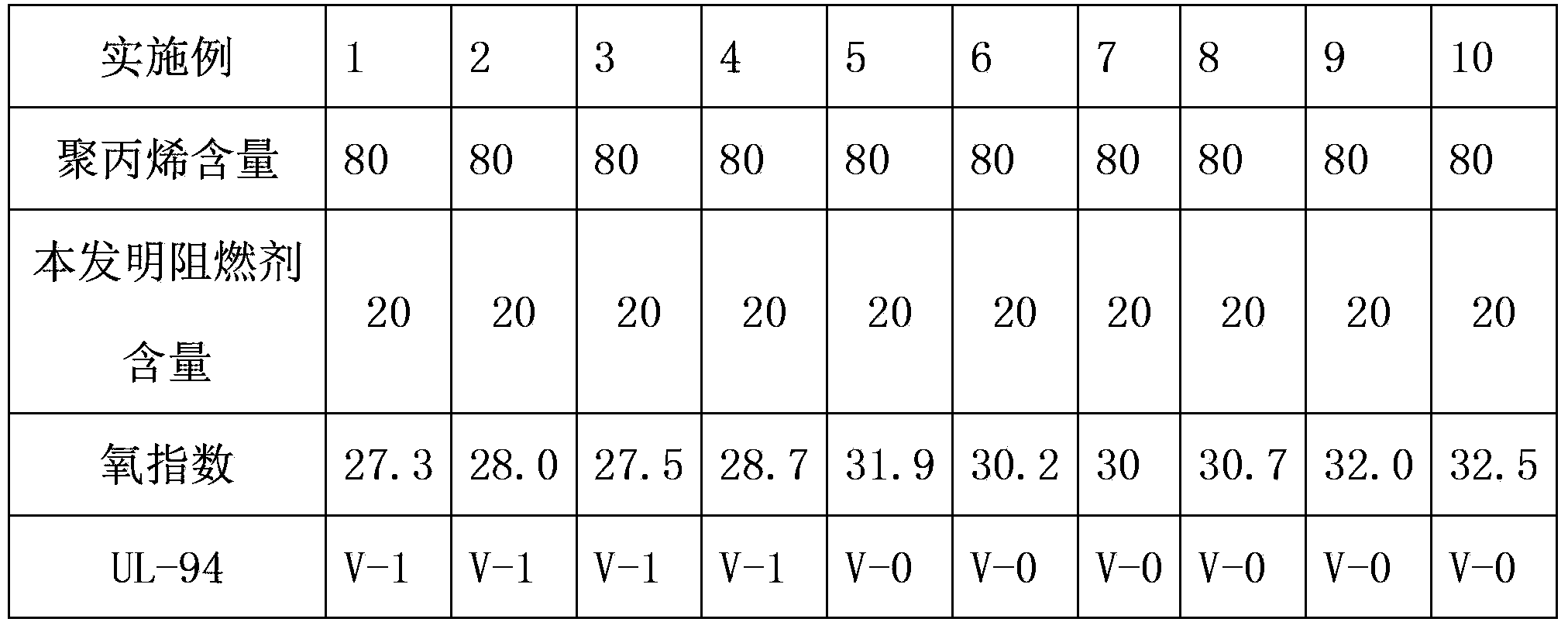

Composite intumescent flame retardant for polypropylene

A composite intumescent flame retardant for polypropylene is prepared by compositing the following components in parts by weight: 20-40 parts of dipentaerythritol phosphate modified by nano montmorillonite, 10-40 parts of ammonium polyphosphate, 20-50 parts of bisphenol A phosphoric acid melamine salt and 0-2 parts of flame retardant synergist. The composite intumescent flame retardant for the polypropylene, provided by the invention, has an excellent flame retardant property, and is halogen-free, low in smoke and toxicity, and non-corrosive in gases.

Owner:大禹节水(天津)有限公司

Preparation method of flame-retardant type wood-plastic composite

The invention discloses a preparation method of a flame-retardant type wood-plastic composite. The preparation method includes the steps of adding plant fiber to a reaction still, adding an aluminum sulfate solution or a magnesium sulfate solution over stirring, dropwise adding ammonia water, standing for 15-40 min, conducting drying at 80 DEG C after even stirring, obtaining flame-retardant modified plant fiber, fusing, mixing and forming 10-250 parts of flame-retardant modified plant fiber, 90-120 parts of plastic and 1-10 parts of compatilizer, and obtaining the flame-retardant type wood-plastic composite. The heat release speed is low and the smoke yield is small when the wood-plastic composite combusts; compared with a composite without fire retardant, the flame retardance performance of the composite is remarkably improved; the method is easy to operate, and production cost is low.

Owner:GUANGDONG UNIV OF TECH

Preparation method and application of inorganic hybrid smoke-suppression flame retardant

The invention discloses a preparation method of an inorganic hybrid smoke-suppression flame retardant, which comprises the following steps: a) preparing a 0.4-0.6 mg / ml graphene oxide suspension; b) adding a soluble zinc salt into the graphene oxide suspension until the concentration of the soluble zinc salt is 2.5-9 mmol / L, stirring for 15-20 minutes, and adding a soluble stannate with the same mole number as the soluble zinc salt; stirring for 30-40 minutes to obtain a precursor solution; c) carrying out hydrothermal reaction on the precursor solution at 120-160 DEG C for 6-12 hours; and after the reaction finishes, cooling, filtering, washing with water and drying to obtain the inorganic hybrid smoke-suppression flame retardant. The invention also discloses application of the flame retardant in epoxy resins. The method is simple to operate, has the advantage of mild and controllable reaction conditions, and can easily implement large-scale production. The prepared flame retardant has favorable flame retardancy, overcomes the defects of low flame-retardant efficiency, high aggregation tendency, high addition amount and the like in the single graphene flame retardant. The flame-retardant material prepared by adding into the epoxy resin has flame-retardant and smoke-suppression functions.

Owner:HEBEI UNIVERSITY

Phosphated lignin-based flame-retardant and reinforced rigid polyurethane foam and preparation method thereof

ActiveCN103910850AReduce heat release rateImprove flame retardant performancePolymer sciencePtru catalyst

The invention discloses phosphated lignin-based flame-retardant and reinforced rigid polyurethane foam and a preparation method thereof. The polyurethane foamed plastic is prepared by mixing, pouring and foaming 50-90 parts of bio-based polyhydric alcohols, 10-50 parts of phosphated lignin, 1-3 parts of amine catalyst, 0.05-0.2 part of tin catalyst, 0.5-2 parts of foam stabilizer, 100-140 parts of isocyanate and 4-7 parts of water. The activity of the lignin is improved through phosphorization modification, and formation of a crosslinking network of the polyurethane foam system is promoted, so that the mechanical property of the foam is improved, the utilization rate of the lignin in the polyurethane foam is increased, and the production cost of the polyurethane foam is reduced. In addition, an anhydrous phosphate solution in modified liquid directly serves as a flame retardant component and is uniformly dispersed in the polyurethane foam, and the heat release rate of the polyurethane foam is reduced, so that the polyurethane foam has high flame-retardant property.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com