Composite intumescent flame retardant for polypropylene

An intumescent flame retardant and compound intumescent technology, applied in the field of materials, can solve the problems of affecting the performance of raw materials, large addition amount, etc., and achieve the effects of small loss of toughness, low toxicity and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

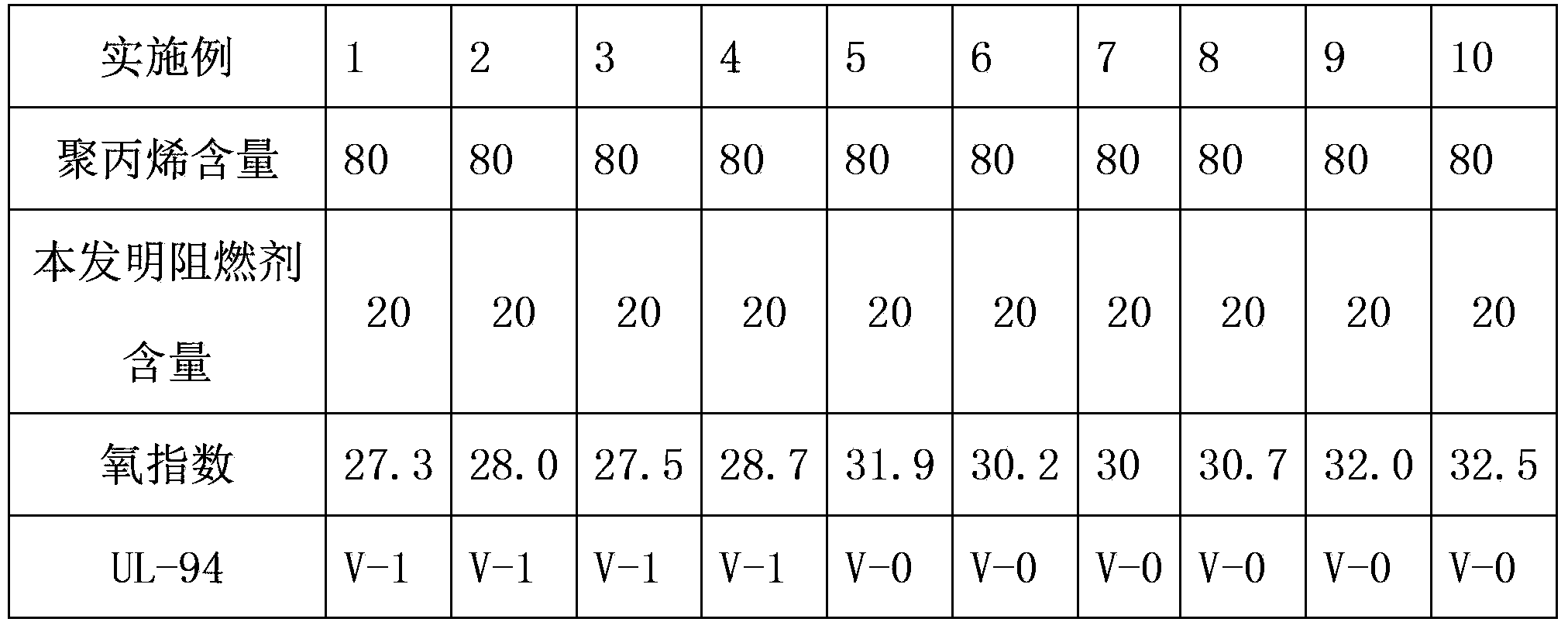

Examples

Embodiment 1

[0028] Composite intumescent flame retardant for polypropylene is composed of the following components by weight ratio: nano-montmorillonite modified dipentaerythritol phosphate: 20 parts; ammonium polyphosphate: 30 parts; bisphenol A diphosphate melamine salt : 50 servings.

[0029] The preparation method of the above-mentioned nano-montmorillonite modified dipentaerythritol phosphate is: add 27g of dipentaerythritol and 100ml xylene in a three-necked flask, slowly add 10g of phosphoric acid dropwise, stir and react at 150°C to obtain a viscous product, filter while hot, Dissolve the product in absolute ethanol, stir and cool to room temperature, suction filter, dry, and grind to obtain a white powdery solid for later use; take 100g of nano-montmorillonite and disperse it in an ethanol aqueous solution with a weight ratio of 1:1 to make a concentration of 0.048g / ml solution, then add 32.8g of aminosilane coupling agent, and reflux at about 75°C for 24h to obtain amino-modifi...

Embodiment 2

[0035] Composite intumescent flame retardant for polypropylene is composed of the following components by weight ratio: nano-montmorillonite modified dipentaerythritol phosphate: 20 parts; ammonium polyphosphate: 40 parts; bisphenol A diphosphate melamine salt : 40 servings.

[0036] The preparation method of the above-mentioned nano-montmorillonite modified dipentaerythritol phosphate is the same as in Example 1.

[0037] The preparation method of the above-mentioned bisphenol A diphosphate melamine salt is the same as in Example 1.

[0038] The degree of polymerization of the above-mentioned ammonium polyphosphate is 200-400.

[0039] The method of granulation is the same as in Example 1.

Embodiment 3

[0041] Composite intumescent flame retardant for polypropylene is composed of the following components by weight ratio: nano-montmorillonite modified dipentaerythritol phosphate: 30 parts; ammonium polyphosphate: 20 parts; bisphenol A diphosphate melamine salt : 50 servings.

[0042] The preparation method of the above-mentioned nano-montmorillonite modified dipentaerythritol phosphate is the same as in Example 1.

[0043] The preparation method of the above-mentioned bisphenol A diphosphate melamine salt is the same as in Example 1.

[0044] The degree of polymerization of the above-mentioned ammonium polyphosphate is 100-200.

[0045] The method of granulation is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com