Halogon-free expansion flame-retarded polyolefin complex substance

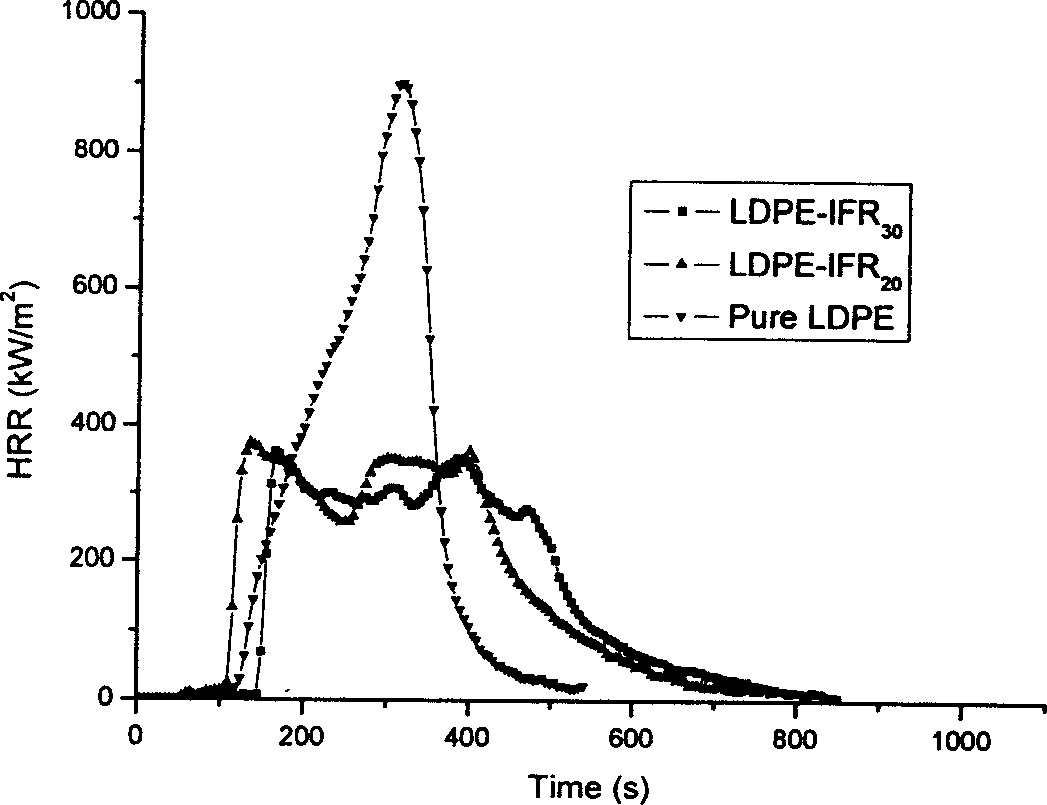

An intumescent flame retardant and compound technology, which is applied in the field of flame retardant polyolefin blends, can solve the problems of adverse effects of flame retardant expansion process, physical mechanical and processing properties cannot be changed too much, and achieve Effects of high oxygen index, excellent moldability, and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example is a preparation example of the halogen-free char-forming flame retardant SPS.

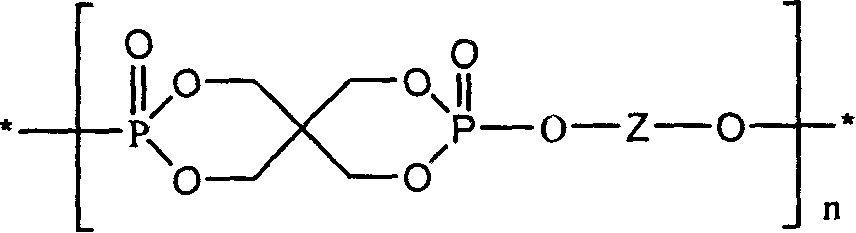

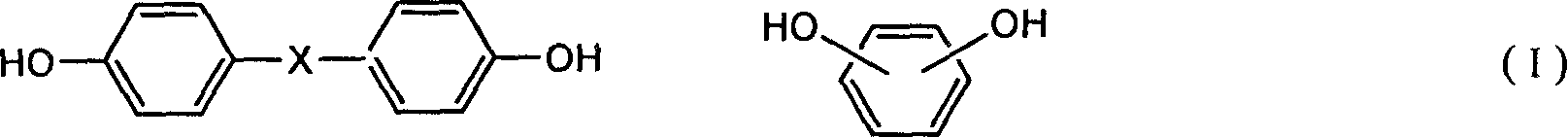

[0031] The reaction equation of the present embodiment is as follows:

[0032]

[0033]

[0034] Among them, the monomer 3,9-dichloro 2,4,8,10-tetrachloro-3,9-diphosphorous spiro-3,9 dioxo[5.5]-undecane (referred to as double spiro, SPDPC) The synthesis of is prepared by referring to the method disclosed in US Pat. No. 3,169,863.

[0035]In a 50ml polymerization bottle equipped with a nitrogen inlet and outlet and a mechanical stirrer, add 12.5g of bisphenol S (SDP) and 14.8g of double spiro rings; Gas is generated, and the system is in a solid state reaction; when kept at 170°C for 2 hours, the system softens slowly, and after about 20 minutes the system becomes liquid, continue to maintain the temperature until the rod climbing phenomenon occurs, and then raise the temperature to 220°C to continue After reacting for 3 hours, 22.5 g of light yellow solid product was ob...

Embodiment 2

[0037] This example is a preparation example of the halogen-free char-forming flame retardant SPA.

[0038] The reaction equation of the present embodiment is as follows:

[0039]

[0040]

[0041] Among them, the monomer 3,9-dichloro 2,4,8,10-tetrachloro-3,9-diphosphorous spiro-3,9 dioxo[5.5]-undecane (referred to as double spiro, SPDPC) The synthesis of is prepared by referring to the method disclosed in US Pat. No. 3,169,863.

[0042] In the 50ml polymerization bottle equipped with nitrogen inlet and outlet and mechanical stirrer, add 25g bisphenol A and 29.6g double spiro; The system is in a solid phase reaction; when kept at 180°C for 2 hours, the system softens slowly, and after about 20 minutes the system is in a liquid state. Continue to maintain the temperature until the rod climbing phenomenon occurs, and then raise the temperature to 210°C and continue to react for 2 hours. 44 g of light yellow solid product was obtained. The hydrogen chloride gas discharge...

Embodiment 3

[0044] This example is a preparation example of the halogen-free nitrogen-containing flame retardant PTEN (triazine ring flame retardant).

[0045] This reaction equation is as follows:

[0046]

[0047] The synthesis method of the monomer 2-methoxy-4,-dichloro-1,3,5-s-triazine is prepared by referring to the method reported in the literature (Thurston J.T., J AmChem Soc. 1951, 73, 2989-3105).

[0048] In a 500ml four-necked bottle equipped with a mechanical stirrer, a thermometer, a spherical reflux condenser and a constant pressure dropping funnel, add 100ml of acetonitrile, 18g of 2-methoxy-4,6-dichloro-s-triazine, Cool to 5°C; fully stir, and dropwise add 10.3g of diethylenetriamine in acetonitrile solution; after the dropwise addition, raise the temperature to 60°C, and react for 1h; then raise the temperature to reflux of the system, and add dropwise an aqueous solution containing sodium carbonate, keep The pH value of the system was neutral, and reacted for 4 hours;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com