Method of modifying hollow glass microbeads with ionic liquid and flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as flame retardant

The technology of hollow glass microspheres and thermoplastic polyurethane is applied in the field of flame retardant modification of thermoplastic polyurethane elastomer, which can solve the problems of low flame retardant efficiency, large addition amount, and large heat release of thermoplastic polyurethane elastomer, so as to improve the flame retardancy. Effects of performance, small vapor pressure, and wide electrochemically stable potential window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

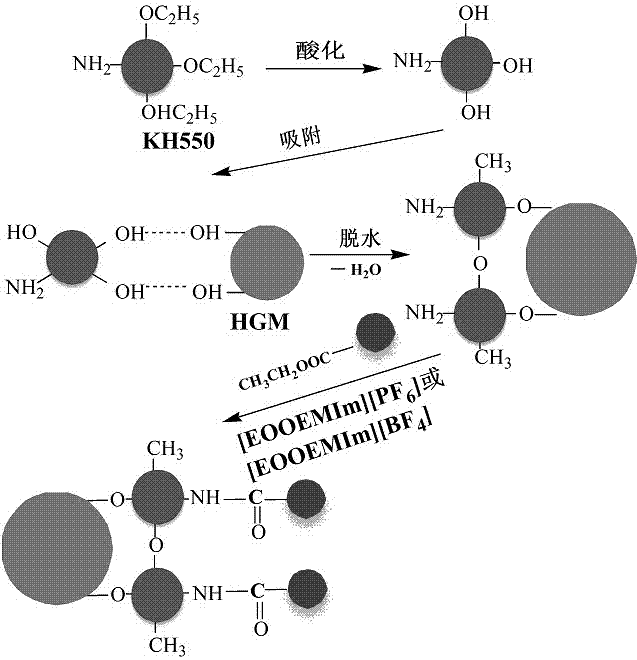

Method used

Image

Examples

Embodiment 1-1

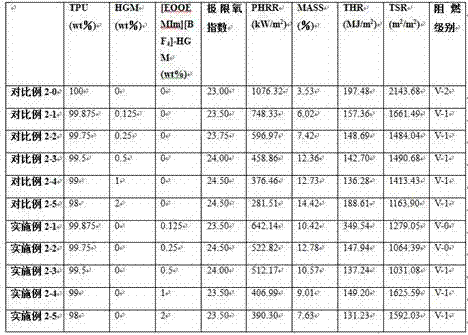

[0038] [ EOOEMIm][PF 6 ]) Modified hollow glass microspheres, at room temperature, control the rotational speed at 10-50r / min, and banbury for 10min; press the obtained material with a flat vulcanizing machine, control the temperature at 175-180°C, and hold the pressure for 10-20min , cooled for 1-2min to obtain the product; cut into 130×6.5×3mm 3 , 130×13×3mm 3 and 100×100×3mm 3 The standard size of the oxygen index, UL94, cone calorimeter experiment (radiation power 35kW / m 2 ), its limiting oxygen index is 23.75, the vertical combustion level can reach UL94V-1, and the peak heat release rate (PHRR) is 779.33kW / m 2 , the remaining mass is (MASS) 7.21%, and the total heat release (THR) is 108.80MJ / m 2 , the total smoke production (TSR) is 828.83 m 2 / m 2 .

Embodiment 1-2

[0039] [ EOOEMIm][PF 6 ]) Modified hollow glass microspheres, at room temperature, control the rotational speed at 10-50r / min, and banbury for 10min; press the obtained material with a flat vulcanizing machine, control the temperature at 175-180°C, and hold the pressure for 10-20min , cooled for 1-2min to obtain the product; cut into 130×6.5×3mm 3 , 130×13×3mm 3 and 100×100×3mm 3 The size of the oxygen index, UL94, cone calorimeter experiment (radiation power 35kW / m 2 ), its limiting oxygen index is 23.75, the vertical combustion level can reach UL94V-1, and the peak heat release rate (PHRR) is 675.53kW / m 2 , the remaining mass is (MASS) 9.64%, and the total heat release (THR) is 104.14MJ / m 2 , the total smoke production (TSR) is 825.56 m 2 / m 2 .

Embodiment 1-3

[0040] Example 1-3: 99.5% of the thermoplastic polyurethane elastomer was added to the internal mixer for internal mixing for 3 minutes according to the mass percentage, and 0.5% 1-acetate-3-methylimidazolium hexafluorophosphate was added in the mass percentage ([EOOEMIm][PF 6 ]) Modified hollow glass microspheres, at room temperature, control the rotational speed at 10-50r / min, and banbury for 10min; press the obtained material with a flat vulcanizer, control the temperature at 175-180°C, and hold the pressure for 10-20min , cooled for 1-2min to obtain the product; cut into 130×6.5×3mm 3 , 130×13×3mm 3 and 100×100×3mm 3 The standard size of the oxygen index, UL94, cone calorimeter experiment (radiation power 35kW / m 2 ), its limiting oxygen index is 24.50, the vertical combustion level can reach UL94V-1, and the peak heat release rate (PHRR) is 577.55kW / m 2 , the remaining mass is (MASS) 10.42%, and the total heat release (THR) is 103.18MJ / m 2 , the total smoke production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com