Ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, preparation method of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, and application of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent to flame retarding polymer

A ferrocene-based polyester technology, applied in the application of flame retardant polymers, ferrocene-DOPO double-based polyester flame retardant and smoke suppressant and its preparation field, can solve the problem of low carbon formation rate, additive Large quantity, poor compatibility of matrix materials, etc., to achieve the effect of good flame retardant effect, good compatibility and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

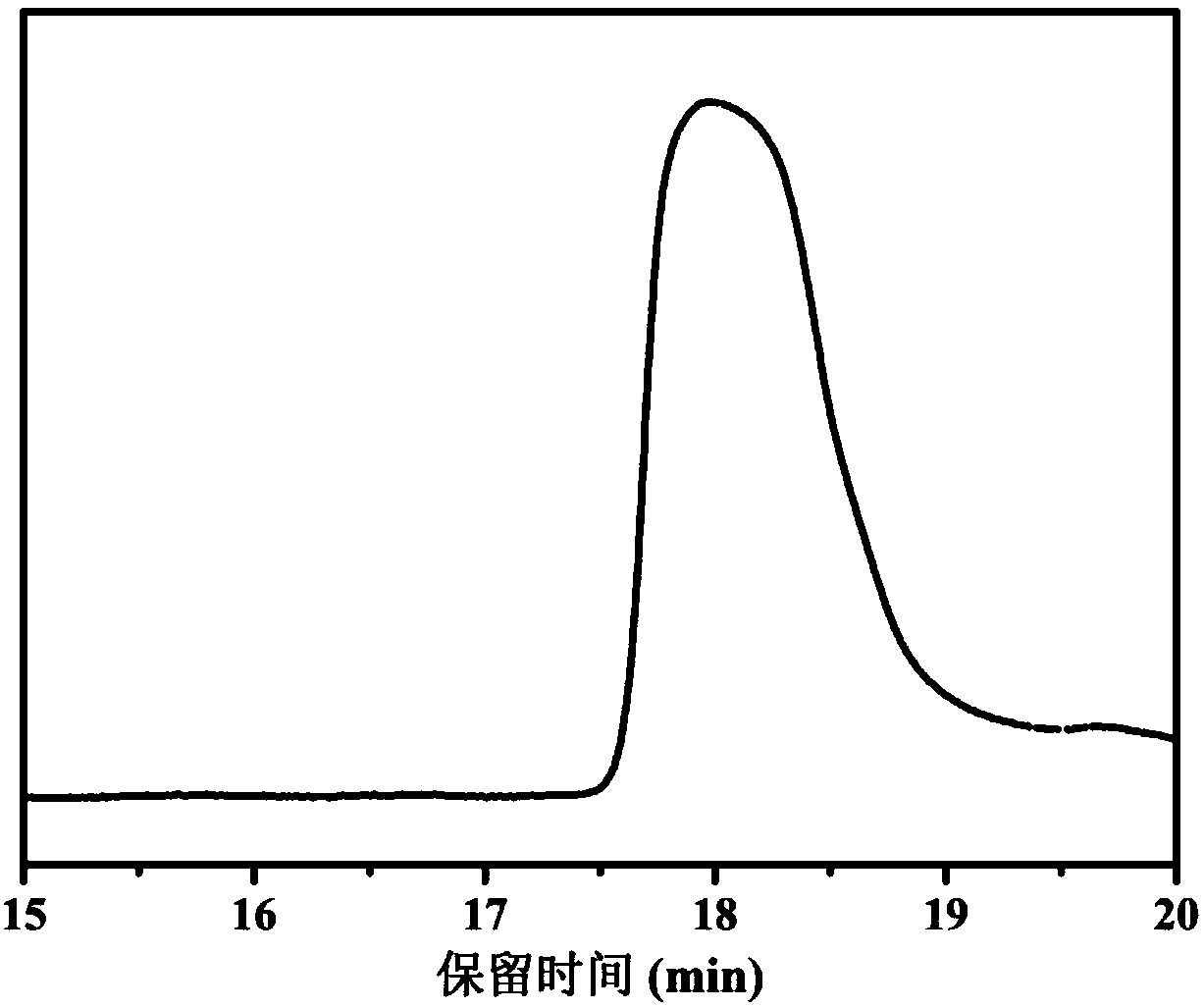

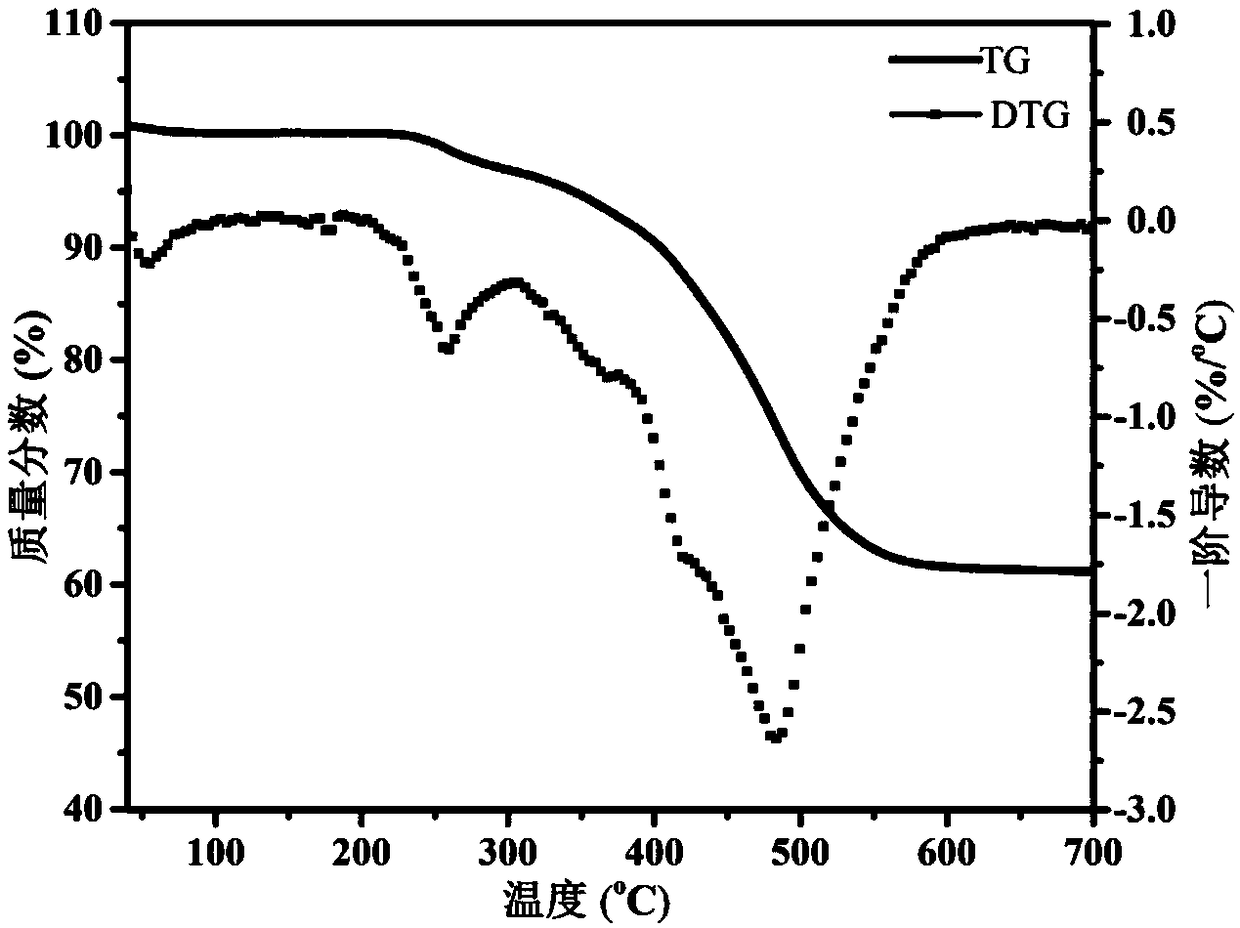

[0043] A preparation method of a ferrocene-DOPO double-base polyester type flame retardant and smoke suppressant, the steps are:

[0044] Weigh 1.6g DOPO-HQ (5mmol) into a 250ml three-neck flask with magnetic stirring, place the flask in an oil bath, measure 30ml of dichloromethane into the flask, stir for a while; add 1.4ml of triethylamine (10mmol) and continue to stir; after 10min, slowly add 20ml 1,1'-ferrocenedicarboxylic acid chloride (1.55g, 5mmol) / dichloromethane solution dropwise through the constant pressure dropping funnel; Stir the reaction for 10 hours, filter after the reaction is complete, pour the filtrate into 400ml of methanol, and immediately precipitate a large amount of yellow solid, filter it with suction, wash it with methanol for 3 times, and dry it in vacuum at 50°C for 5 hours to obtain 2.68g of yellow solid, which is the prepared Ferrocene-DOPO double base polyester flame retardant and smoke suppressant—chemical name is poly 10-(2,5-dihydroxyphenyl)-...

Embodiment 2

[0048] A preparation method of a ferrocene-DOPO double-base polyester type flame retardant and smoke suppressant, the steps are:

[0049] Weigh 1.6g DOPO-HQ (5mmol) into a 250ml three-neck flask with magnetic stirring, place the flask in an oil bath, measure 30ml N,N-dimethylformamide (DMF) into the flask, Stir for a while; add 0.4ml (5mmol) of pyridine and continue stirring; after 10min, slowly add 20ml of 1,1'-ferrocenedicarboxylic acid chloride (1.4g, 4.5mmol) / DMF solution dropwise through a constant pressure dropping funnel; , heated up to 50°C under nitrogen protection and stirred for 1 hour, filtered after the reaction was complete, poured the filtrate into 500ml of deionized water, and immediately precipitated a large amount of yellow solid, filtered it with suction, washed 3 times with deionized water, and dried it in vacuum at 80°C for 5 hours. 2.6 g of a yellow solid was obtained, which was the ferrocene-DOPO double base polyester type flame retardant and smoke suppr...

Embodiment 3

[0051]A kind of preparation method of ferrocene-DOPO double base polyester type flame retardant and smoke suppressant, the steps are: take by weighing 1.6g DOPO-HQ (5mmol) and place in a 250ml three-necked flask with magnetic stirring, place the flask in In the oil bath, measure 30ml of dichloromethane into the flask and stir for a while; add 1.73ml (12.5mmol) of triethylamine and continue stirring; after 10min, slowly add 20ml of 1,1'-di Ferrocene diacetyl chloride (2.33g, 7.5mmol) / dichloromethane solution; after dropping, reflux and stir the reaction for 5h under the protection of nitrogen at 10°C, filter after the reaction, pour the filtrate into 250ml methanol, and immediately precipitate a large amount of yellow solid, Suction filtration, washing with methanol for 3 times, vacuum drying at 40°C for 12 hours to obtain 2.7 g of a yellow solid, which is the ferrocene-DOPO double-based polyester flame retardant and smoke suppressant, with a yield of 85.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com