Flame-retardant anti-dropping resin composition

A resin composition and anti-drip technology, applied in the field of flame-retardant and anti-drip resin compositions, can solve the problems of inability to uniformly disperse thermoplastic resins, reduced kneading operation workability, large load on kneaders, etc. Excellent durable flame retardancy, smooth appearance, high oxygen index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] In the following examples and comparative examples, the following commercially available products were used:

[0033] Modified polytetrafluoroethylene anti-dripping agent (PTFE3300B 2 ), produced and provided by Guangzhou Entropy Energy Polymer Co., Ltd.

[0034] Thermoplastic polyester poly(ethylene terephthalate), produced by Toray, is a semi-dull chip with an IV value (intrinsic viscosity coefficient) of 0.66.

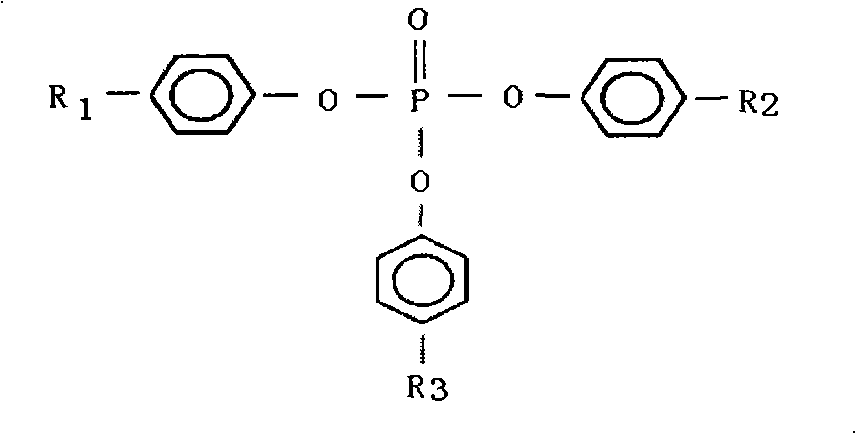

[0035] Phosphorus-containing compound A: produced by Jiangsu Rudong Fine Chemical Company, the structural formula is as follows:

[0036]

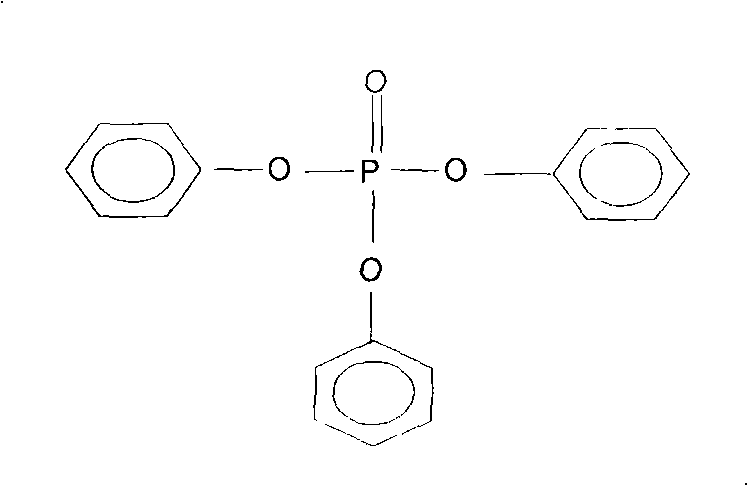

[0037] Phosphorus-containing compound B: provided by Shanghai Dingnai Chemical Co., Ltd., the structural formula is as follows:

[0038]

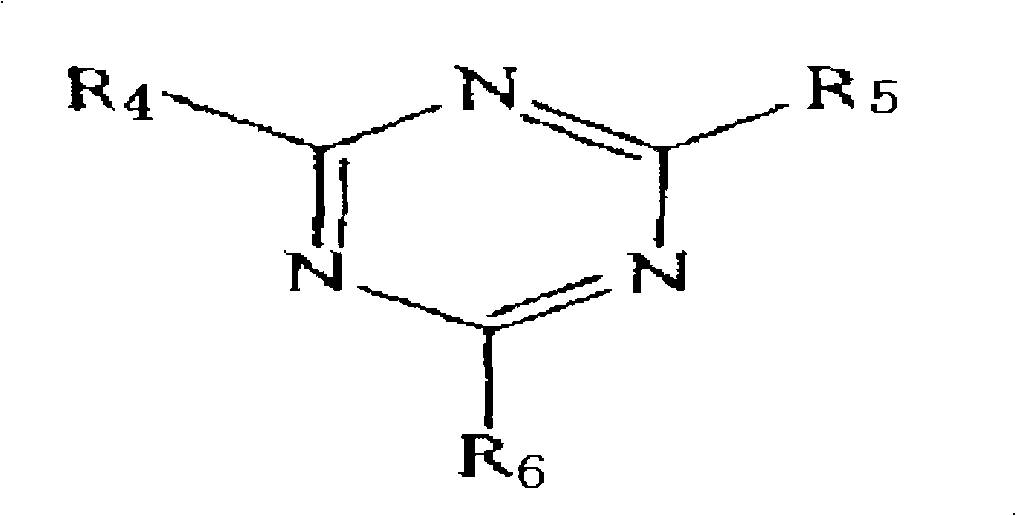

[0039] Nitrogen-containing compound C: provided by Lianyungang Legend Flame Retardant Technology Co., Ltd., its structural formula is as follows:

[0040]

Embodiment approach

[0042] (1) Vacuum drying: the polyethylene terephthalate and polybutylene terephthalate used in each embodiment are put into a vacuum oven, and dried for 12-20 hours at a vacuum degree of 10-15mmHg. hour, control the moisture content to less than 0.5-1‰.

[0043] (2) Mechanical premixing: the polyethylene terephthalate of each embodiment listed in table 1, the specific species and the weight of modified polytetrafluoroethylene anti-dripping agent, phosphorus-containing, nitrogen-based flame retardants Add them together into a high-speed rotator and mix them. Because they contain powdered reagents, they are relatively fine, and it is not easy to mix evenly with granular polyethylene terephthalate. Add 0.01-0.03ml of silicone oil to the alcohol ester, so that the powdered reagent can be evenly attached to the granular polyethylene terephthalate to achieve the purpose of uniform mixing; the mixing time and speed should be determined according to the experimental requirements.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com