Flame-retardant polyamide 66 complex fiber and preparation method thereof

A technology of flame retardant polyamide and composite fiber, which is applied in the field of flame retardant polyamide 66 composite fiber and its preparation, phosphorus-containing reactive flame retardant prepolymer block flame retardant polyamide 66 composite fiber and its preparation field. Solve the problems of restricting the use of polyamide and monotonically decreasing melting point, and achieve the effects of small impact on mechanical properties, long-lasting flame retardant effect, good hand feel and washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

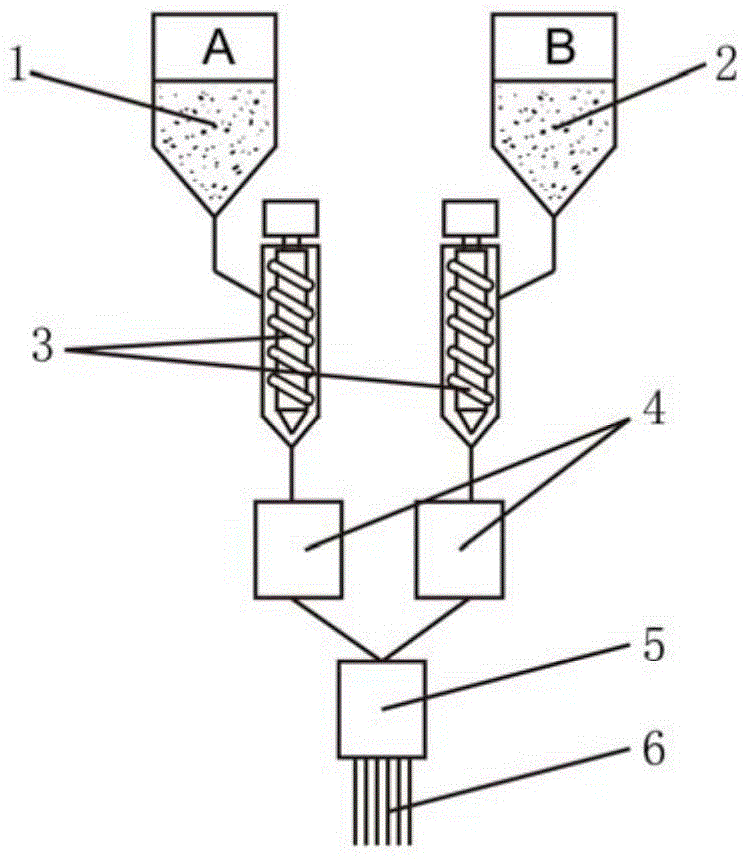

[0046] A preparation method of flame-retardant polyamide 66 composite fiber, specifically comprising the following steps:

[0047] (1) Mix the flame retardant DDP, hexamethylenediamine and water, mix evenly at 50°C for 2 hours under the protection of nitrogen, then stir and react at 90°C for 2 hours, then raise the temperature to 150°C for further polymerization, and finally decompress and vacuumize , the reaction ends to generate a flame retardant prepolymer, which is a viscous liquid with a number average molecular weight Mn of 1.8×10 3 , the molar ratio of flame retardant DDP, hexamethylenediamine and water is 1:0.8:2, and the two ends of the obtained flame retardant prepolymer are active end groups of carboxyl and amine groups respectively;

[0048] The structure of the flame retardant is:

[0049]

[0050] (2) 90 parts by mass of 66 salt and 1 part by mass of adipic acid are made into a 60% aqueous solution, mixed evenly and added to the autoclave, and first fed with ...

Embodiment 2

[0058] A preparation method of flame-retardant polyamide 66 composite fiber, specifically comprising the following steps:

[0059] (1) Mix the flame retardant CEPPA, hexamethylenediamine and water, mix evenly at 80°C for 3 hours under the protection of nitrogen, then stir and react at 130°C for 3 hours, then raise the temperature to 180°C for further polymerization, and finally decompress and vacuumize , the reaction ends to generate a flame retardant prepolymer, which is semi-solid, and the number average molecular weight Mn is 2.5×10 3 , the molar ratio of flame retardant CEPPA, hexamethylenediamine and water is 1:1.2:2.5, and the two ends of the obtained flame retardant prepolymer are active end groups of carboxyl and amine groups respectively;

[0060] The structure of the flame retardant is:

[0061]

[0062] (2) 96.8 parts by mass of 66 salt and 0.2 parts by mass of adipic acid are made into an 80% aqueous solution, mixed evenly and added to the autoclave, and first ...

Embodiment 3

[0070] A preparation method of flame-retardant polyamide 66 composite fiber, specifically comprising the following steps:

[0071] (1) Mix the flame retardant BCPPO, hexamethylenediamine and water, mix evenly at 60°C for 2.5 hours under the protection of nitrogen, then stir and react at 95°C for 2 hours, then raise the temperature to 160°C for further polymerization, and finally vacuumize under reduced pressure , the reaction ends to generate a flame retardant prepolymer, which is a viscous liquid with a number average molecular weight Mn of 2.8×10 3 , the molar ratio of flame retardant BCPPO, hexamethylenediamine and water is 1:1:2.2, and the two ends of the obtained flame retardant prepolymer are active end groups of carboxyl and amine groups respectively;

[0072] The structure of the flame retardant is:

[0073]

[0074] (2) 91.8 parts by mass of 66 salts and 0.2 parts by mass of adipic acid are made into a 66% aqueous solution, mixed evenly and added to the autoclave,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com