Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Residual mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residual mass is broader and usually employed for % solid after heating in oxidizing environment at high temperatures (metallic impurities, ashes, etc...).

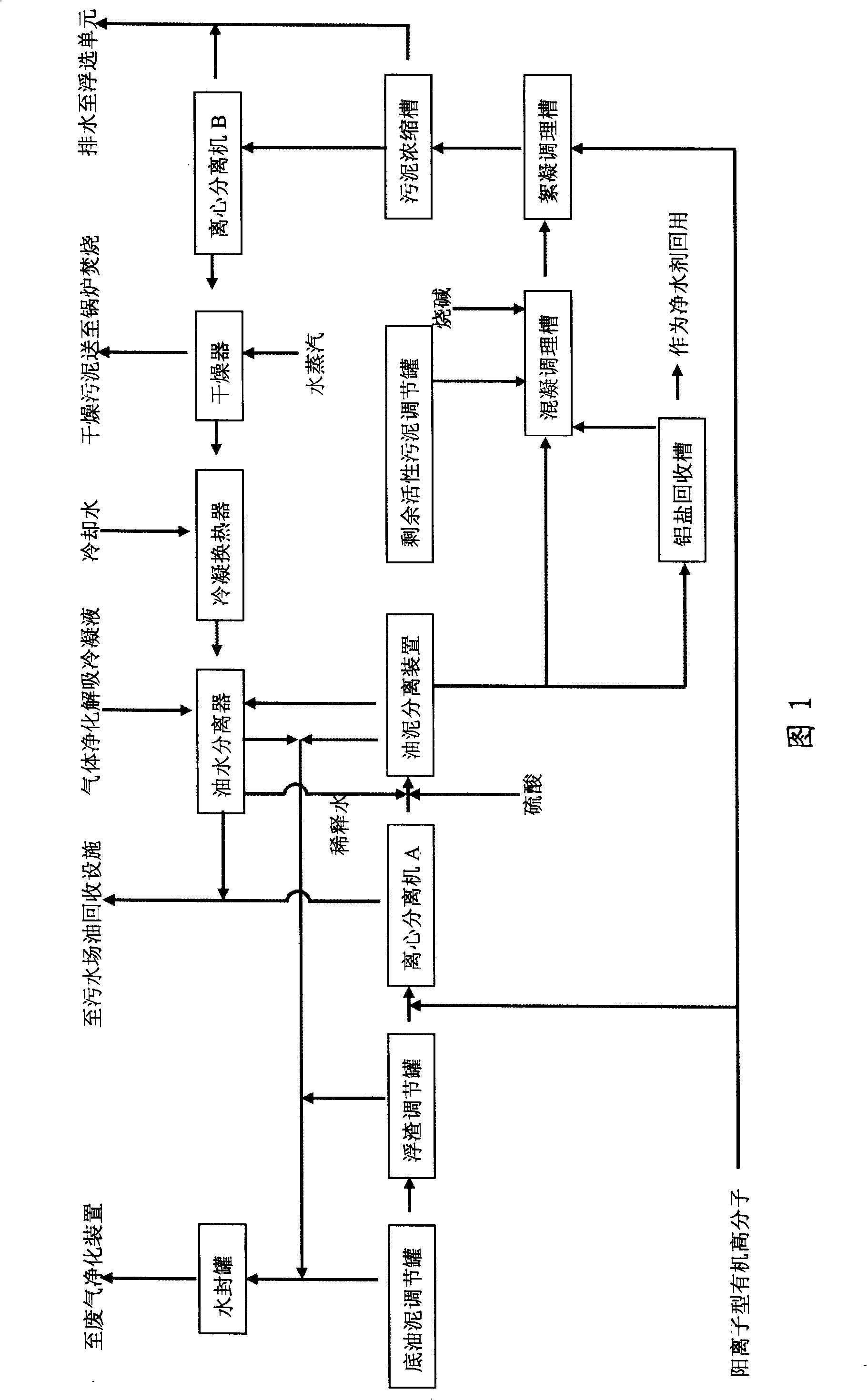

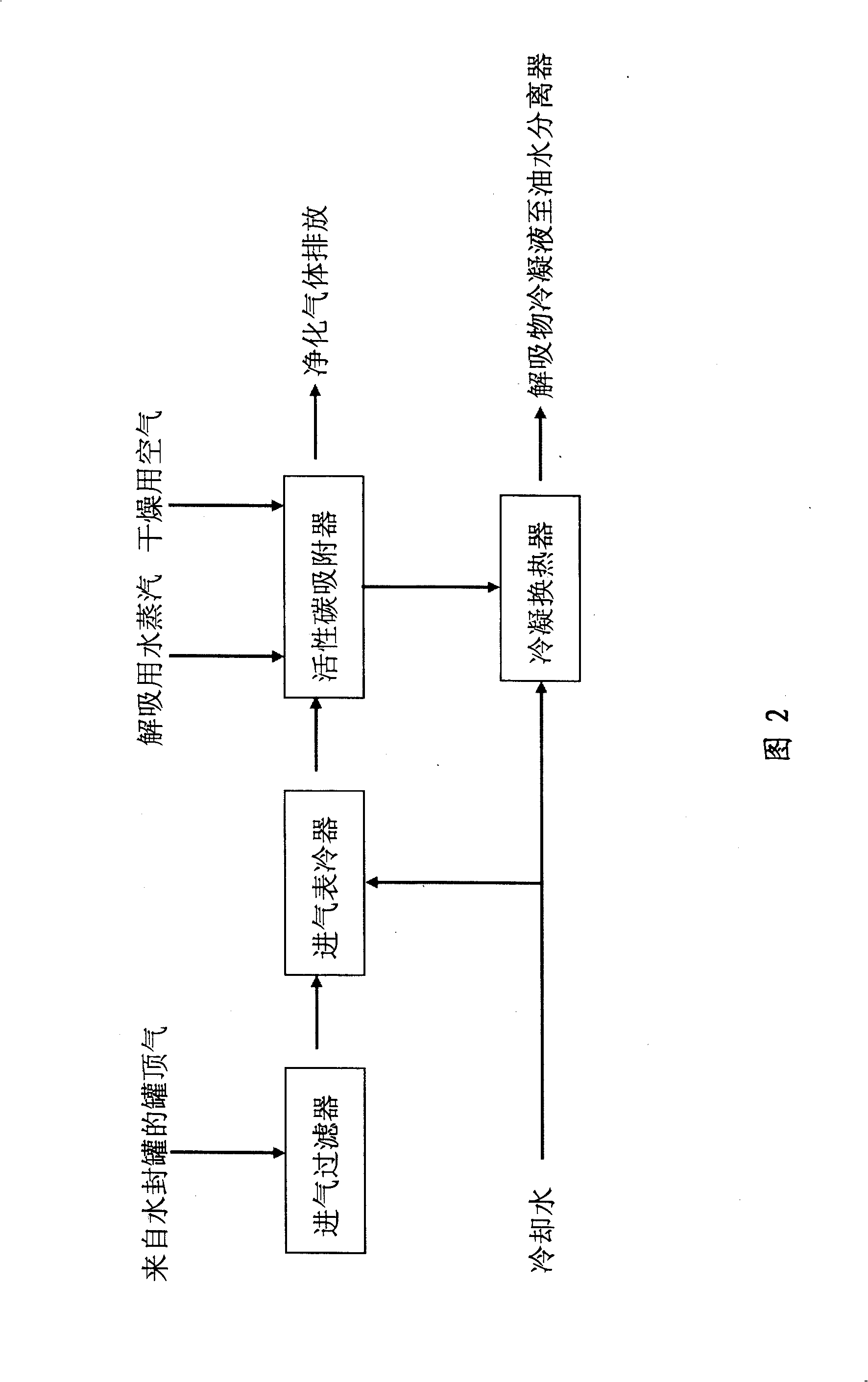

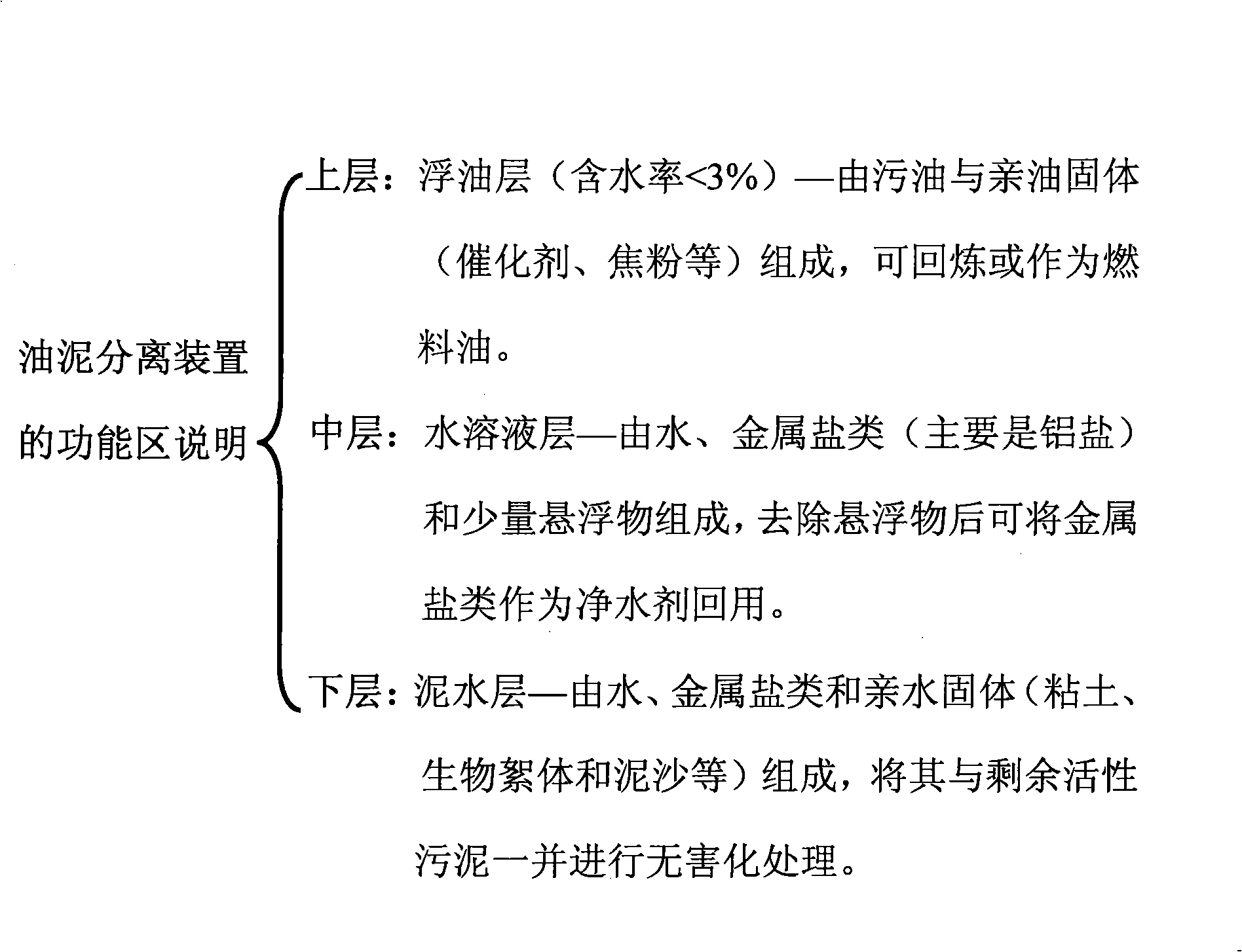

Method for innocent treatment of bottom oil sludge, scruff and active sludge in petro-chemical industry

InactiveCN101343137ASave resourcesReduce pollutionSludge treatment by de-watering/drying/thickeningIncinerator apparatusChemical industryActivated sludge

The invention discloses a method of harmless treatment to residual activated sludge produced by bottom sludge, scum and biochemical treatment units in the petrochemical industry, which comprises: emulsion breaking to the bottom sludge and scum; separation of oil, water and mud of products after emulsion breaking; and recovery of dirty oil at the upper part and sedimentation of mud-water mixture at the lower part, recovery of clear liquor at the upper part, and treatment of coagulation conditioning, flocculation conditioning, sludge concentration, sludge dewatering, sludge drying and sludge incineration to mud-water mixture at the bottom part and the residual activated sludge sequentially. The method can effectively recycle useful oil substances and aluminum-containing compounds in the bottom sludge and scum, purify possibly released malodorous gases in mud produced in the process of storage and disposal, and carry out the treatment such as sludge conditioning, dewatering and drying sequentially to the residual mass hazardous wastes after the recycling treatment, then utilize the current boilers in enterprises to implement the direct incineration treatment. The method has advantages of simple operation and running, safety and reliability, complete resource recovery, controllable water removal, and maximally reducing the environmental pollution.

Owner:罗德春

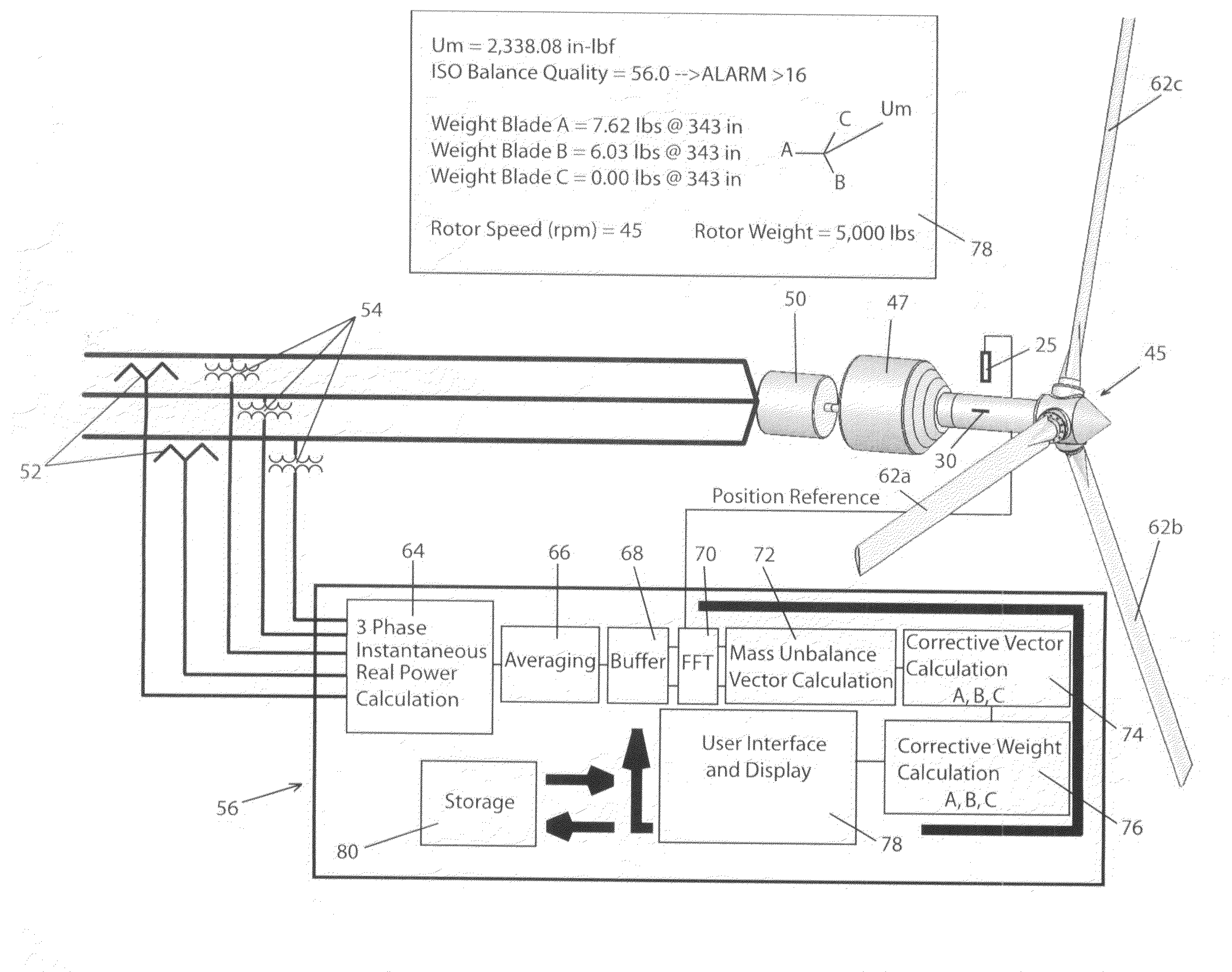

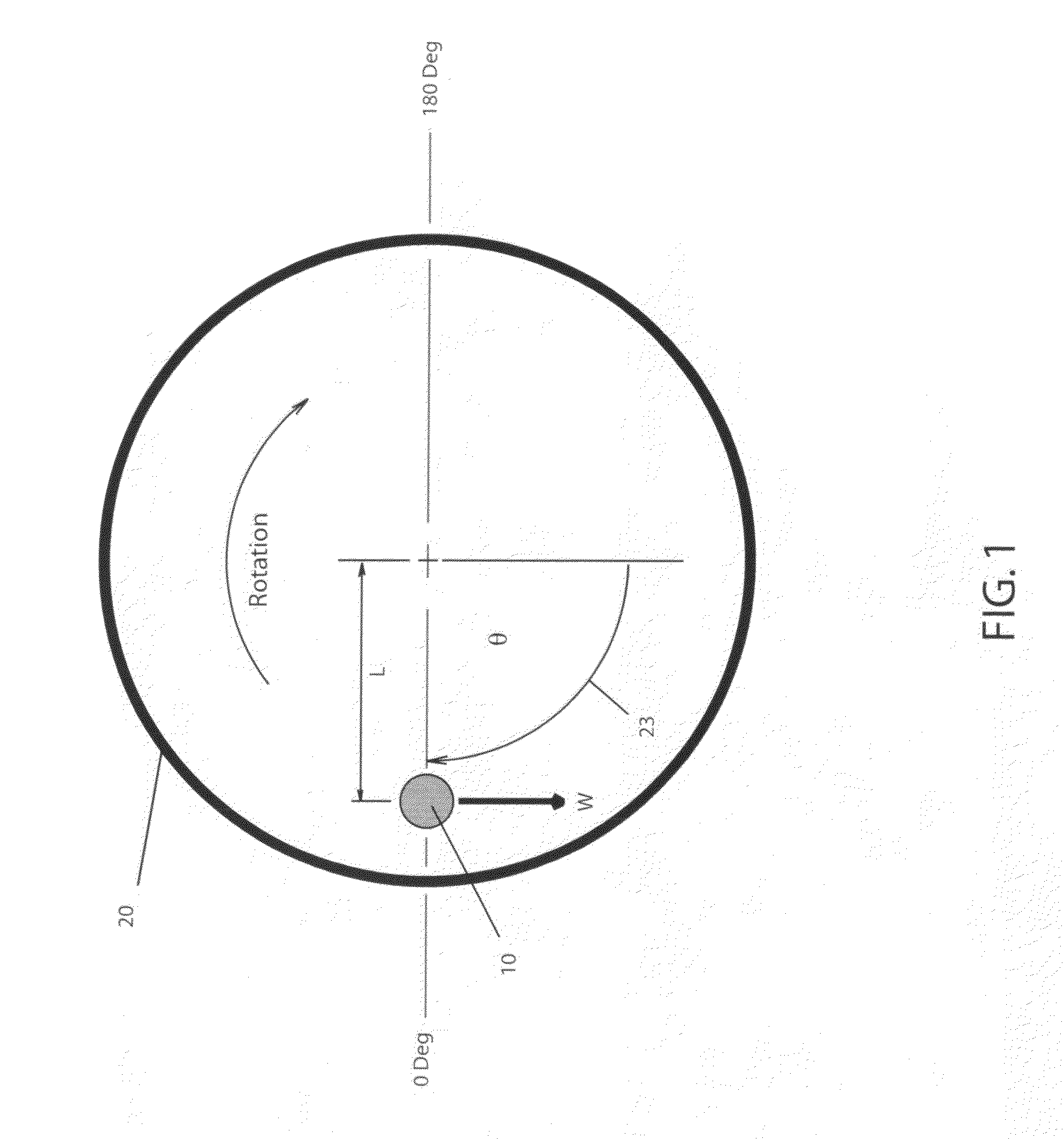

Method and apparatus for in situ unbalance and corrective balance determination for a non-vertical axis rotating assembly

InactiveUS20110036166A1Method is inaccurateSampled-variable control systemsComputer controlPhase differenceFourier transform on finite groups

The invention discloses a novel method and apparatus to determine the degree of residual mass unbalance and a corrective balance solution for a rotating assembly having a non-vertical axis of rotation. When the center of mass of the rotating assembly is not concentric with the axis of rotation, the condition of unbalance exists. When the rotating assembly is driven by a motor or drives a generator, fluctuations in power are produced proportional to the degree of unbalance. The method and apparatus to determine the degree of mass imbalance consists of measuring the average instantaneous real power over an interval of time, calculating the Fourier Transform of the demodulated signal, establishing the peak amplitude and phase associated with the angular velocity of the rotating assembly and calculating the amount of unbalance. The method and apparatus to provide for a corrective solution consists of simultaneously acquiring a position reference signal of the rotating assembly with the average instantaneous real power signal, calculating the phase difference between the two acquired signals at the angular velocity of the rotating assembly, calculating the magnitude of the unbalance, and calculating the quantity and location of corrective weight necessary to minimize the unbalance to an acceptable level.

Owner:LENZ MICHAEL A W

Method for estimating disturbance moment in power decreasing process

ActiveCN103303495AAchieve estimatesImprove robustnessSystems for re-entry to earthCosmonautic landing devicesControl systemEngineering

The invention discloses a method for estimating a disturbance moment in a power decreasing process. In the process of decreasing soft landing power in the moon, the disturbance moment generated by centroid shift is possible to endanger landing. An important measure for early warning and answering is that the magnitude of the disturbance moment is estimated online. The method comprises the following steps of firstly, recursively calculating the residual mass of a lander by utilizing motor power and a pulse width command given out by a guidance and control system, and utilizing a curve (function) bound on the ground to calculate the height of center of mass of the lander and inertia; secondly, calculating a control moment according to the height of center of mass and a pulse width command; thirdly, carrying out difference on a gyro output to obtain an angular acceleration calculation value; fourthly, inversely calculating the disturbance moment by utilizing an attitude kinetic equation; finally, utilizing a filter to reduce the influence of noise on a disturbance moment estimated value. The invention provides a method for monitoring the change of the disturbance moment of the lander, and the method is beneficial to improve the robustness of the control system in the landing process and reduce the risk of landing.

Owner:BEIJING INST OF CONTROL ENG

Effectiveness criterion and residual life prediction method of sacrificial anode and cathode protection system

The invention discloses an effectiveness criterion and residual life prediction method of a sacrificial anode and cathode protection system. According to the invention, the effectiveness criterion takes a sacrificial anode critical ground resistance as an evaluation index to perform effectiveness evaluation on a whole group of sacrificial anodes in the sacrificial anode and cathode protection system, if yes, the residual life of the system is calculated. The residual life prediction method can be used for obtaining the allowable minimal mass of the anodes, the residual mass of serving anodes and average output current through measurement and calculation so as to obtain the residual life of the sacrificial anodes. Compared with a traditional cathode protection effectiveness evaluation method, the sacrificial anode critical ground resistance is introduced in the effectiveness criterion for the first time to be taken as the cathode protection effectiveness evaluation index so that the cathode effectiveness evaluation method is more systematic and comprehensive; meanwhile, the invention also provides a simple and effective residual life prediction method for cathode protection engineering.

Owner:BEIJING GAS GRP +2

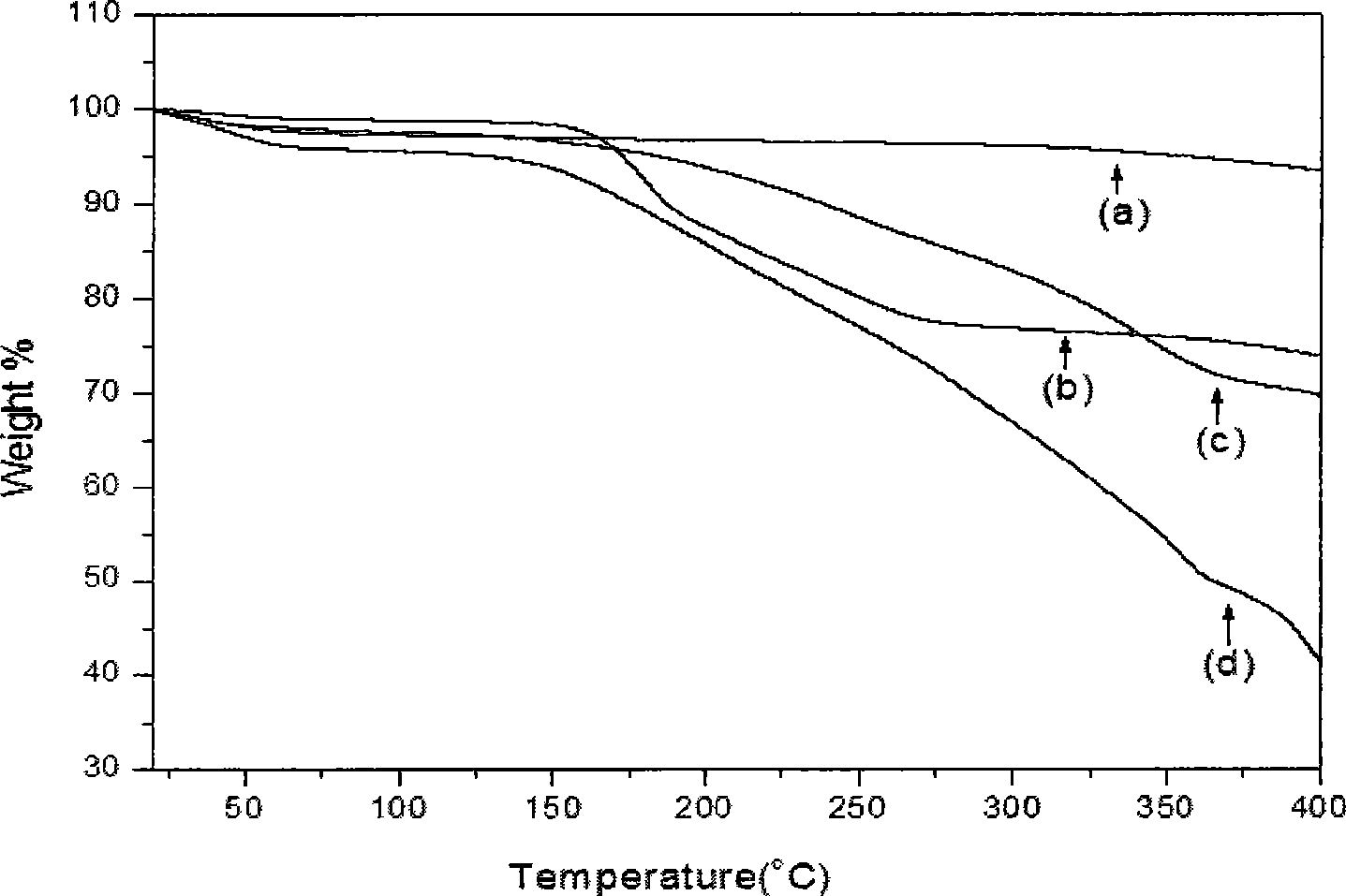

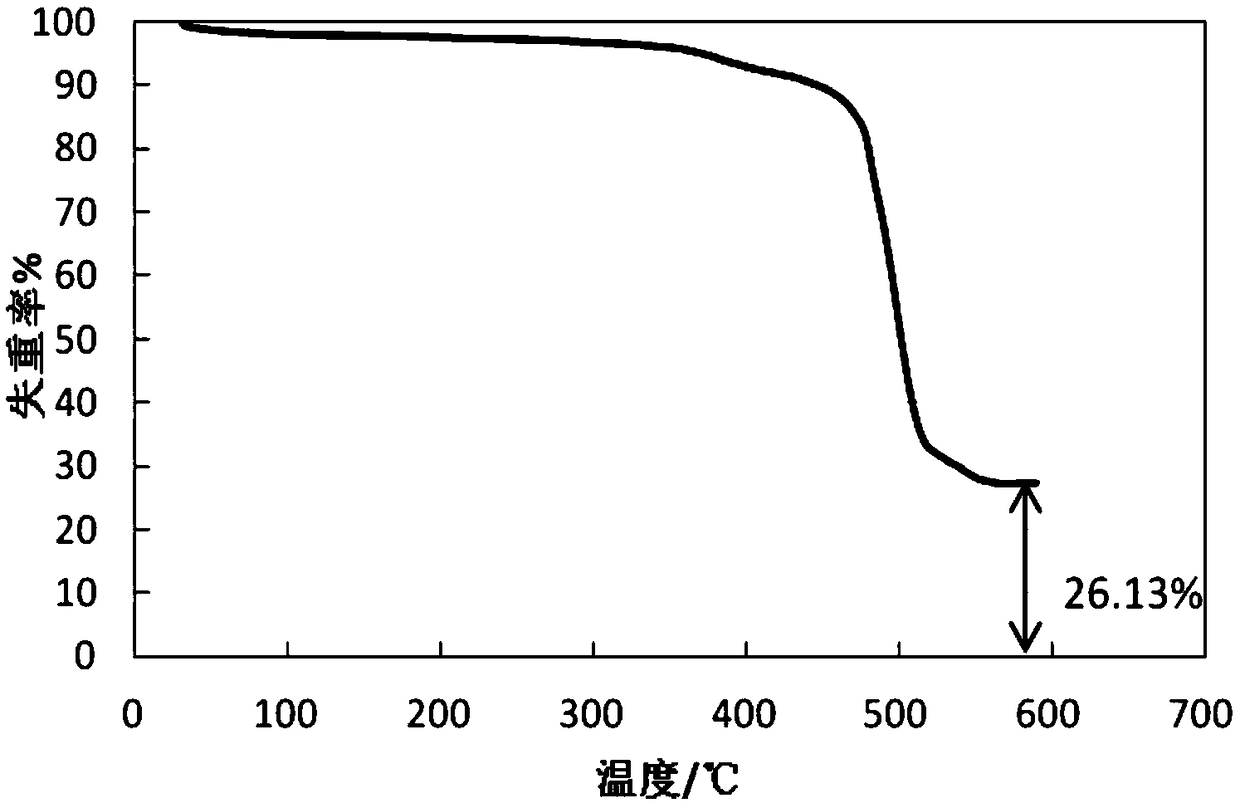

Method for preparing micropore polymer electrolyte by using glyoxaline cation-intercalated montmorillonite

InactiveCN101412819AImprove mechanical propertiesImprove thermal stabilitySecondary cellsPolymer scienceElectrolysis

The invention provides a method for preparing high thermal stability microporous polymer electrolyte from imidazole cation intercalation montmorillonite. In the method, firstly, the imidazole cation intercalation montmorillonite is used to prepare high thermal stability montmorillonite; secondly, by the phase transition method, polyvinylidene fluoride, polyethylene glycol and the imidazole cation intercalation montmorillonite are added to the mixed solution of N,N-dimethylformamide and glycerin and violently stirred at a temperature of between 70 and 85 DEG C for 6 to 10 hours, the obtained evenly mixed solution is poured on a clean and preheated glass plate and vacuum dried at a temperature of between 100 and 130 DEG C for 30 t0 40 hours to obtain a polymer membrane with the thickness of between 100 and 300 micrometers; and finally the polymer membrane is soaked in electrolyte in a simple glass box for 24 to 72 hours to obtain the microporous polymer electrolyte. Tests show that the electrical conductivity of the microporous polymer electrolyte prepared by the method reaches 1.6 to 6.15mS / cm, and the residual mass of the dry membrane at a temperature of 400 DEG C(N2) is between 60 and 70 percent.

Owner:NORTHWEST NORMAL UNIVERSITY

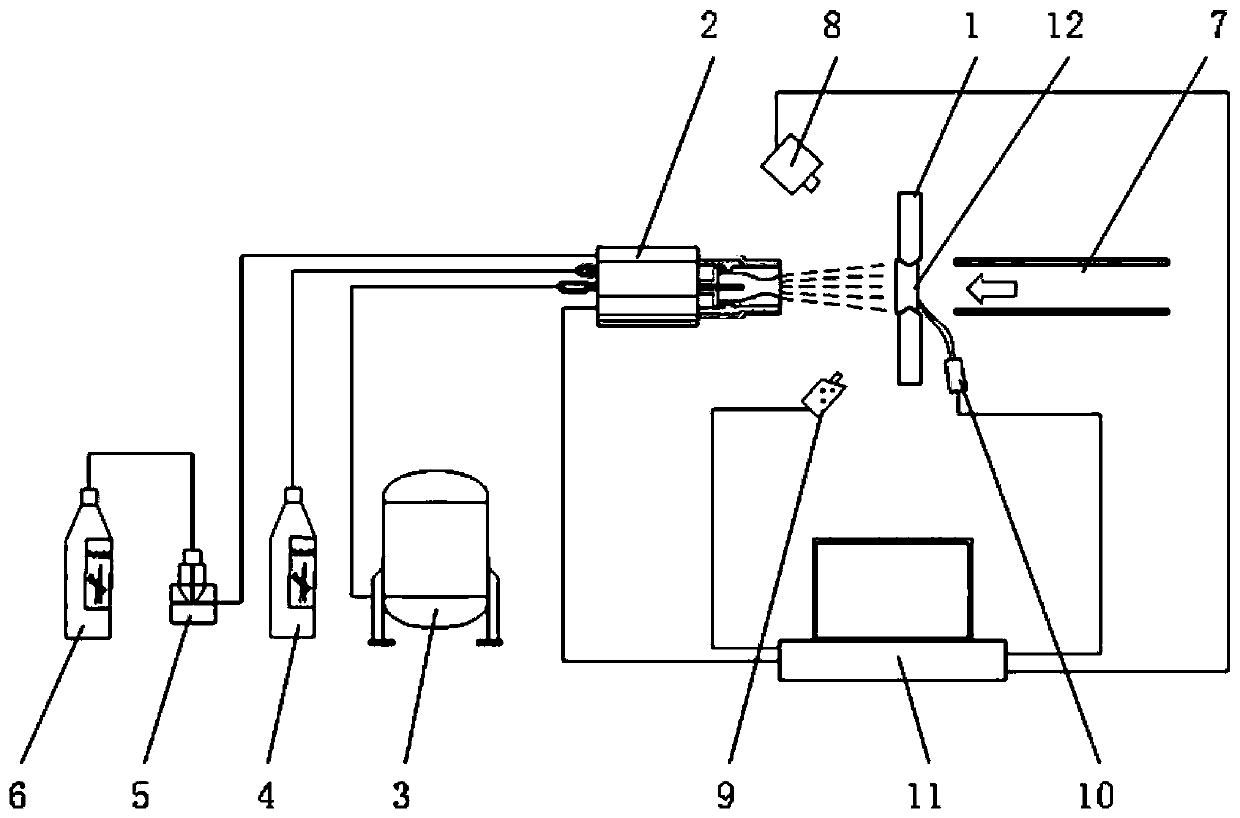

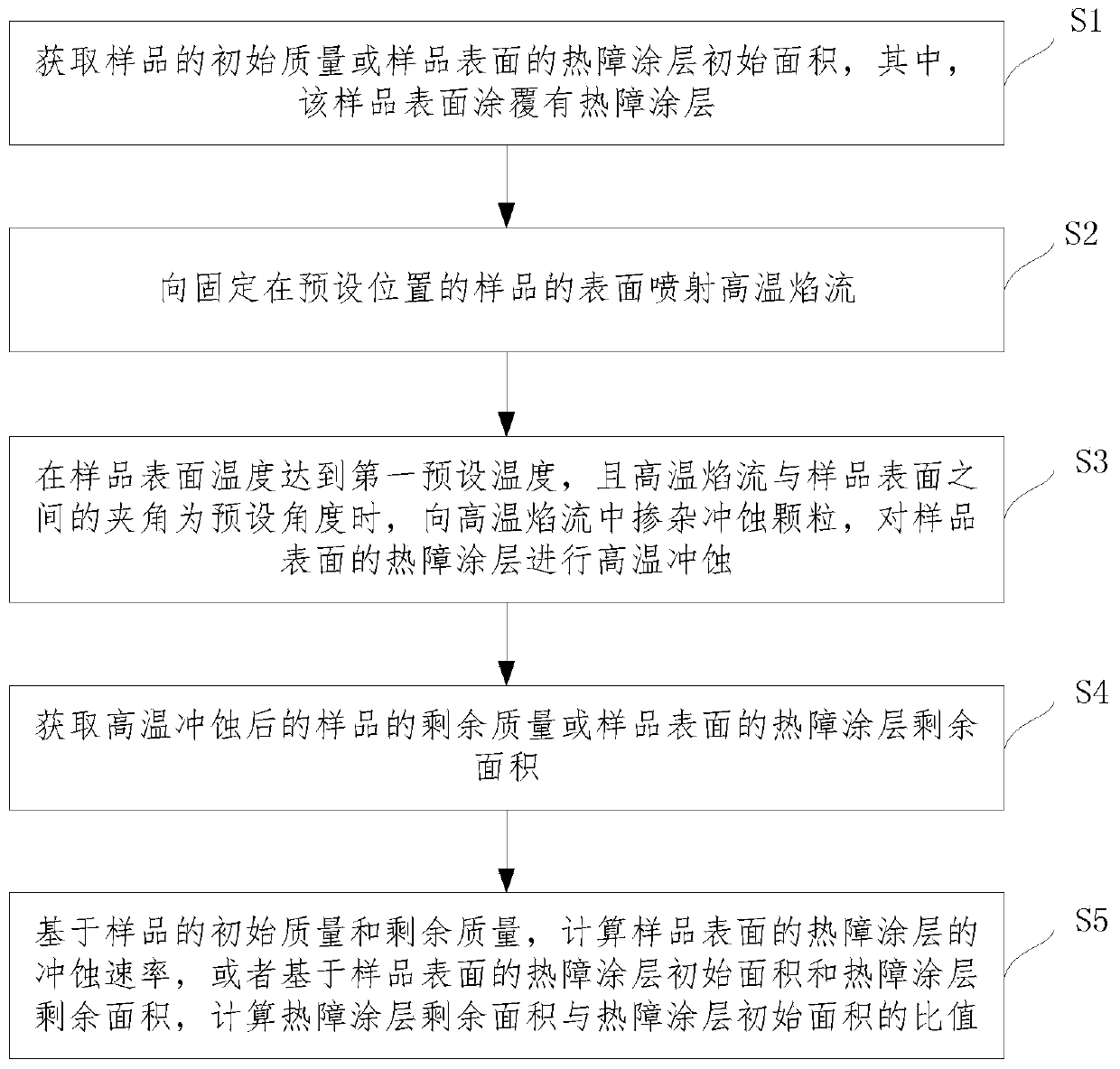

Thermal barrier coating high temperature erosion detection method

ActiveCN109900577AThe erosion rate is scientific and reasonableImprove detection efficiencyInvestigating abrasion/wear resistanceErosion rateThermal barrier coating

A thermal barrier coating high temperature erosion detection method is disclosed. The method comprises the following steps of acquiring initial mass of a sample or an initial area of a thermal barriercoating on a sample surface; spraying a high temperature flame flow to the sample surface fixed at a preset position; when a sample surface temperature and the direction of the high temperature flameflow satisfy certain conditions, doping erosion particles into the high temperature flame flow, and carrying out high temperature erosion on the thermal barrier coating on the sample surface; obtaining residual mass of the sample after high temperature erosion or the remaining area of the thermal barrier coating of the sample surface; and calculating an erosion rate of the thermal barrier coatingof the sample surface based on the initial mass and the residual mass of the sample, or calculating a ratio of the remaining area of the thermal barrier coating and the initial area of the thermal barrier coating based on the initial area of the thermal barrier coating on the sample surface and the remaining area of the thermal barrier coating. Through simulating a high temperature erosion environment under a working condition of an aero-engine, high temperature erosion detection is performed on the thermal barrier coating, a reliable basis is provided for the research of a thermal barrier coating material and detection efficiency of the thermal barrier coating is improved.

Owner:XIANGTAN UNIV

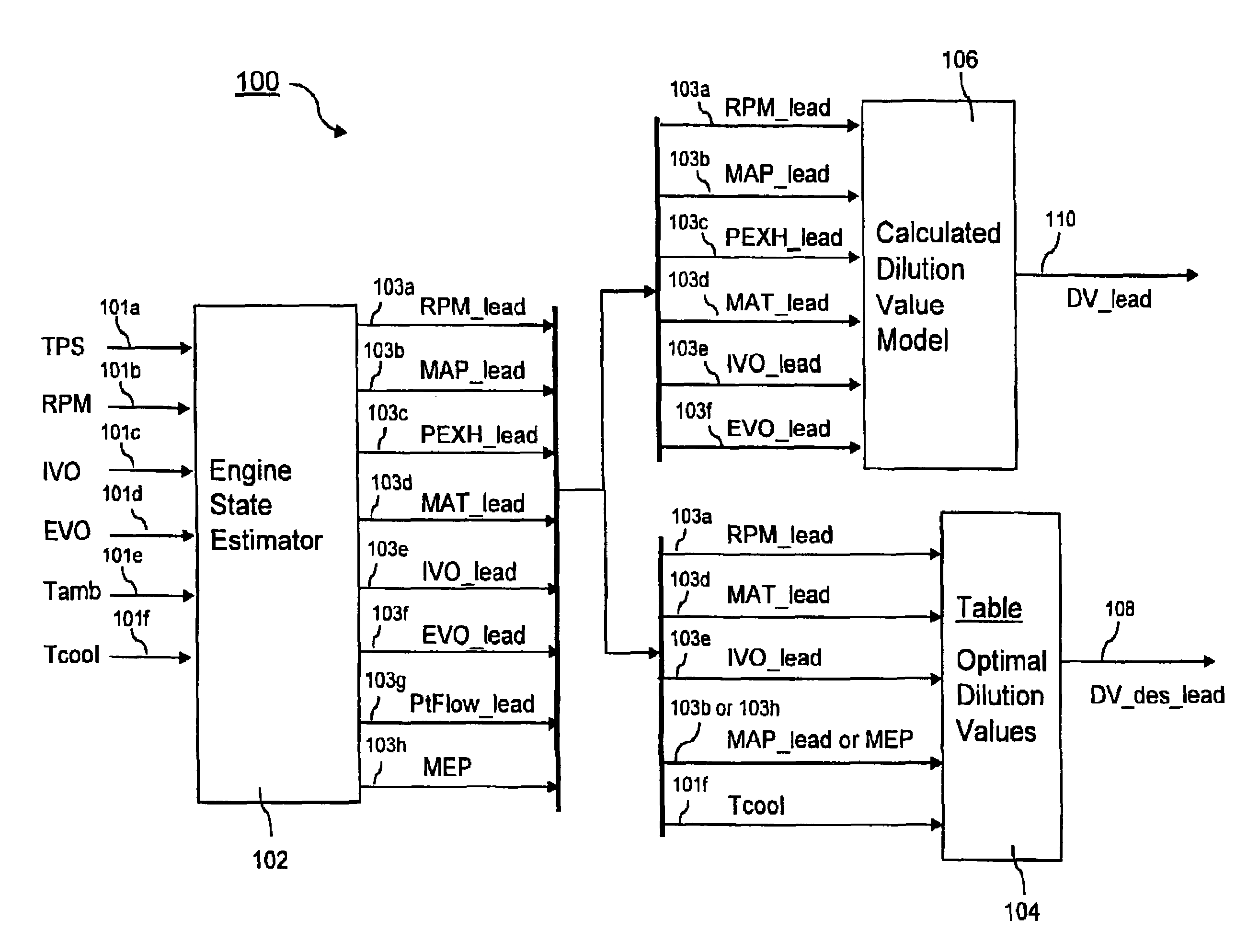

Method for control of dilution in engines during variable camshaft phasing

A method for coordinating engine throttle position with camshaft phaser motion during transient engine operation such that desired internal residual dilution is maintained. A dilution model for residual mass fraction and a table of desired dilution values are embedded in the engine control algorithm. The dilution model is applied to calculate the desired throttle and camshaft phaser positions for the next intake event. In a first method, if the throttle is capable of changing the airflow into the engine cylinders faster than the camshaft phasers can respond, the throttle is modulated to maintain desired dilution levels while the phasers are allowed to move as fast as they can. In a second method, if the phaser response faster than the engine intake port airflow response to a throttle position change, the throttle is allowed to move as fast as it can while phaser motion is modulated to maintain desired dilution levels.

Owner:DELPHI TECH IP LTD

Method for detecting areal density of ceramic coating of lithium ion battery separator

InactiveCN109060595AAreal density effectiveAccurate measurementSpecific gravity measurementCombustionCeramic coating

The invention discloses a method for detecting areal density of a ceramic coating of a lithium ion battery separator. The method comprises the steps: the first step: for a ceramic separator to be detected, observing upper and lower sides of the ceramic separator to determine the coating situation of the ceramic coating on the ceramic separator; the second step: intercepting and weighing a detecting sample of the preset area on the ceramic separator to be detected to obtain the quality of the detecting sample; the third step: placing the detecting sample in a crucible of a thermal gravimetric analyzer, heating the detecting sample, and obtaining a thermal gravimetric curve of the detecting sample by detection of the thermal gravimetric analyzer; the fourth step: obtaining the percentage ofresidual mass of the detecting sample after combustion in an oxygen atmosphere within the thermal gravimetric analyzer; and the fifth step: calculating the areal density of the ceramic coating in thedetecting sample. The invention can accurately and effectively measure the areal density of the ceramic coating in the ceramic separator, and further provides a basis for evaluating the quality of theceramic separator.

Owner:TIANJIN LISHEN BATTERY

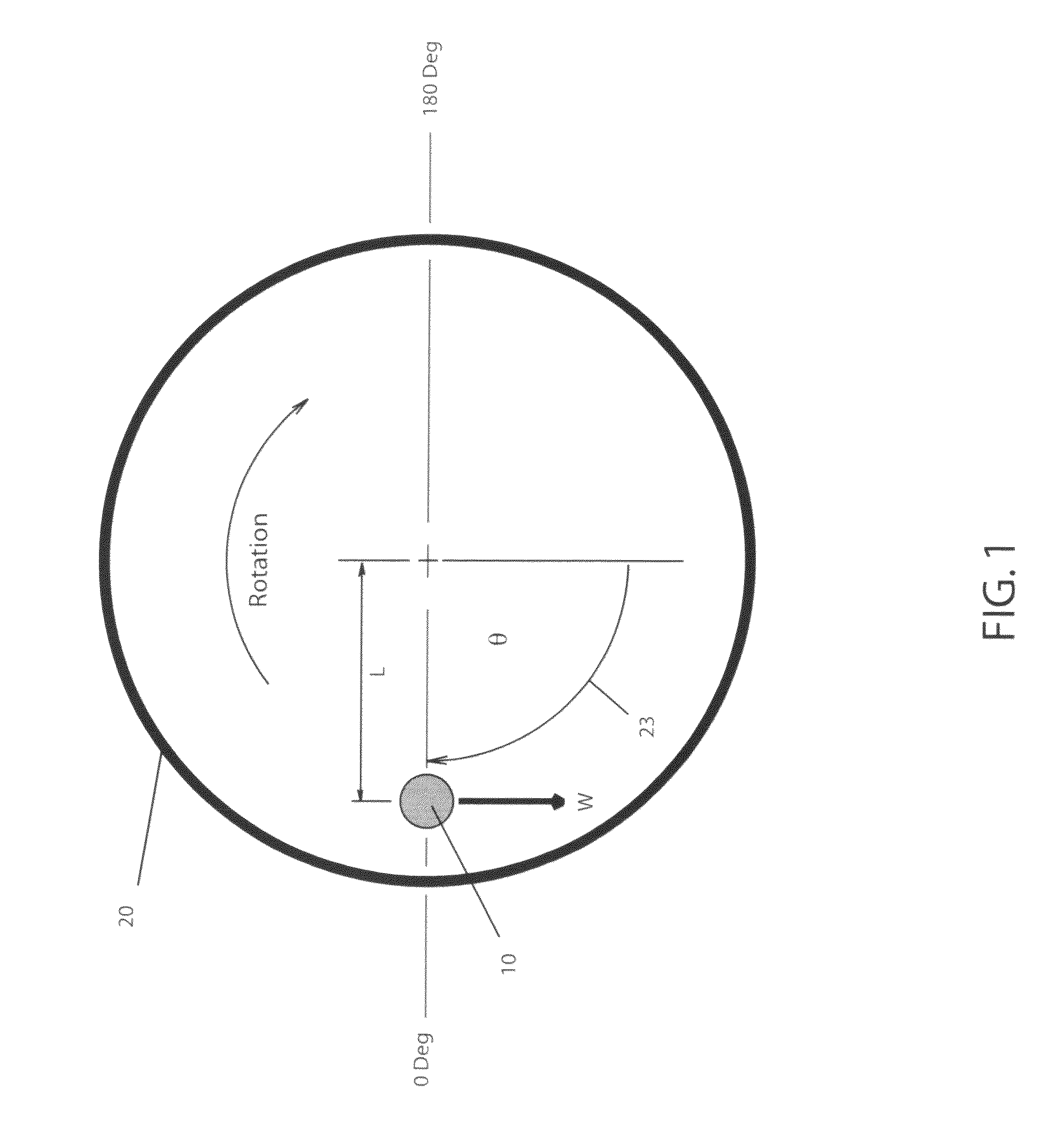

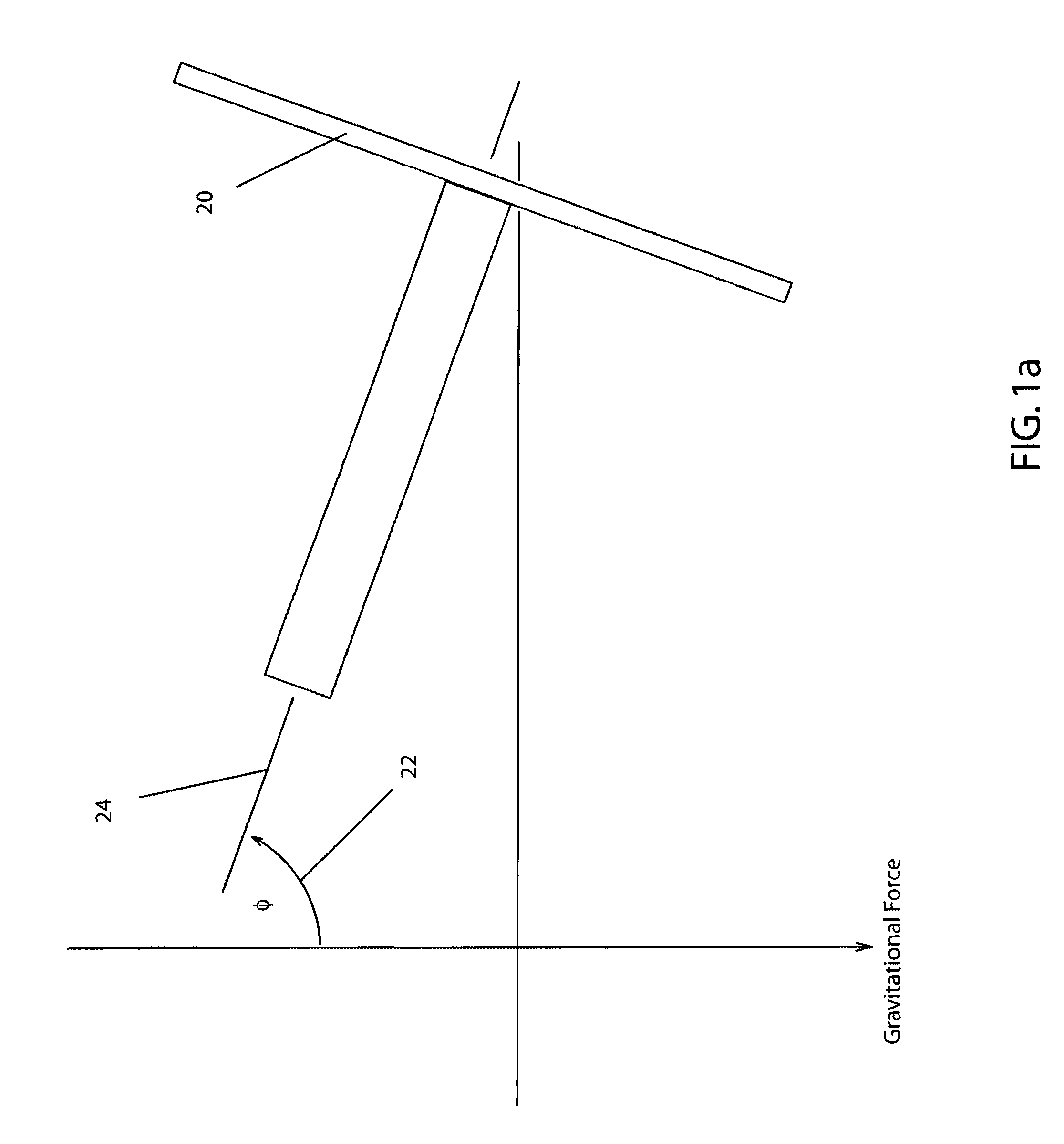

Method and apparatus for in situ unbalance and corrective balance determination for a non-vertical axis rotating assembly

InactiveUS8291764B2Method is inaccurateSampled-variable control systemsComputer controlPhase differenceFourier transform on finite groups

The invention discloses a novel method and apparatus to determine the degree of residual mass unbalance and a corrective balance solution for a rotating assembly having a non-vertical axis of rotation. When the center of mass of the rotating assembly is not concentric with the axis of rotation, the condition of unbalance exists. When the rotating assembly is driven by a motor or drives a generator, fluctuations in power are produced proportional to the degree of unbalance. The method and apparatus to determine the degree of mass imbalance consists of measuring the average instantaneous real power over an interval of time, calculating the Fourier Transform of the demodulated signal, establishing the peak amplitude and phase associated with the angular velocity of the rotating assembly and calculating the amount of unbalance. The method and apparatus to provide for a corrective solution consists of simultaneously acquiring a position reference signal of the rotating assembly with the average instantaneous real power signal, calculating the phase difference between the two acquired signals at the angular velocity of the rotating assembly, calculating the magnitude of the unbalance, and calculating the quantity and location of corrective weight necessary to minimize the unbalance to an acceptable level.

Owner:LENZ MICHAEL A W

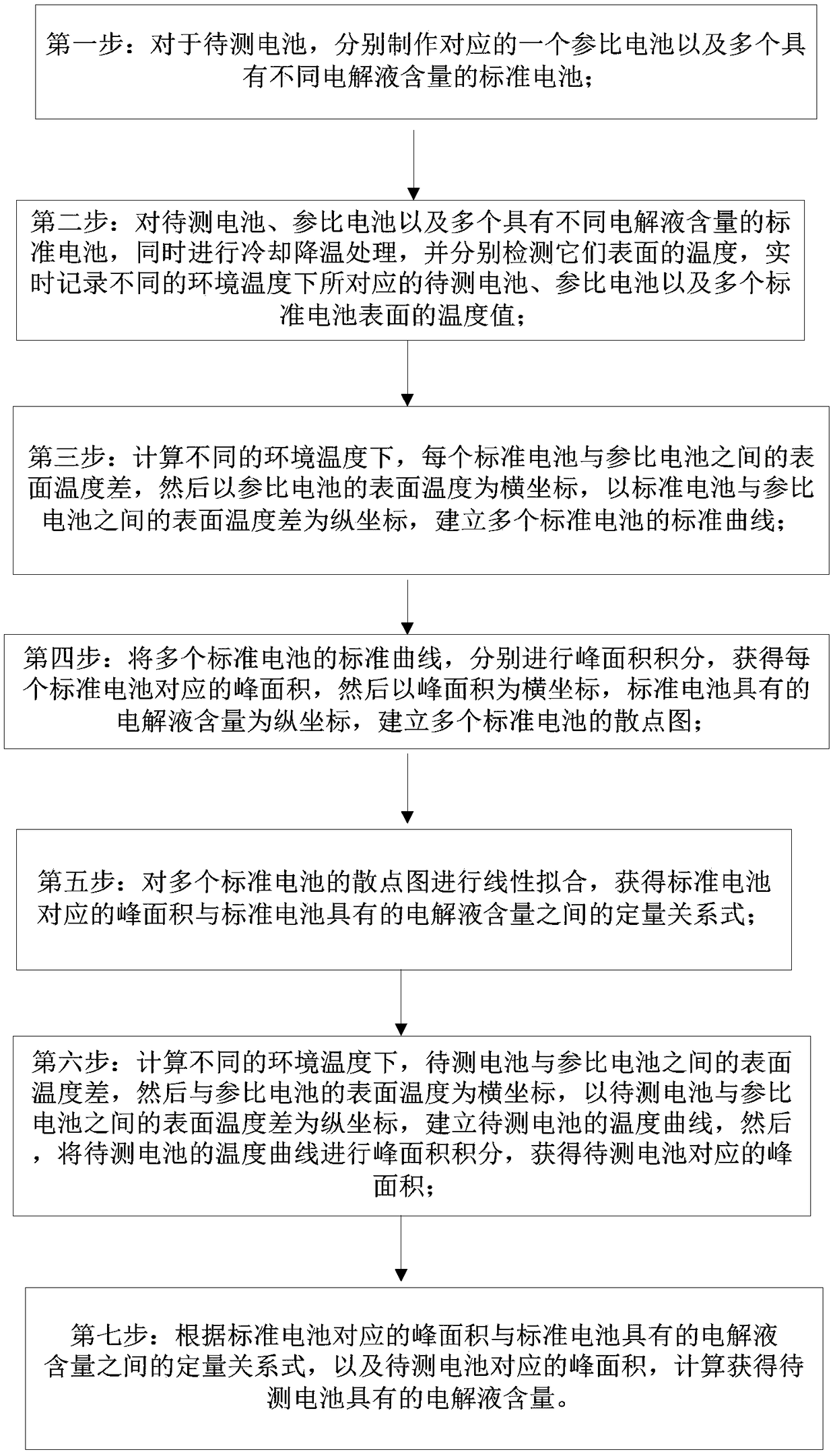

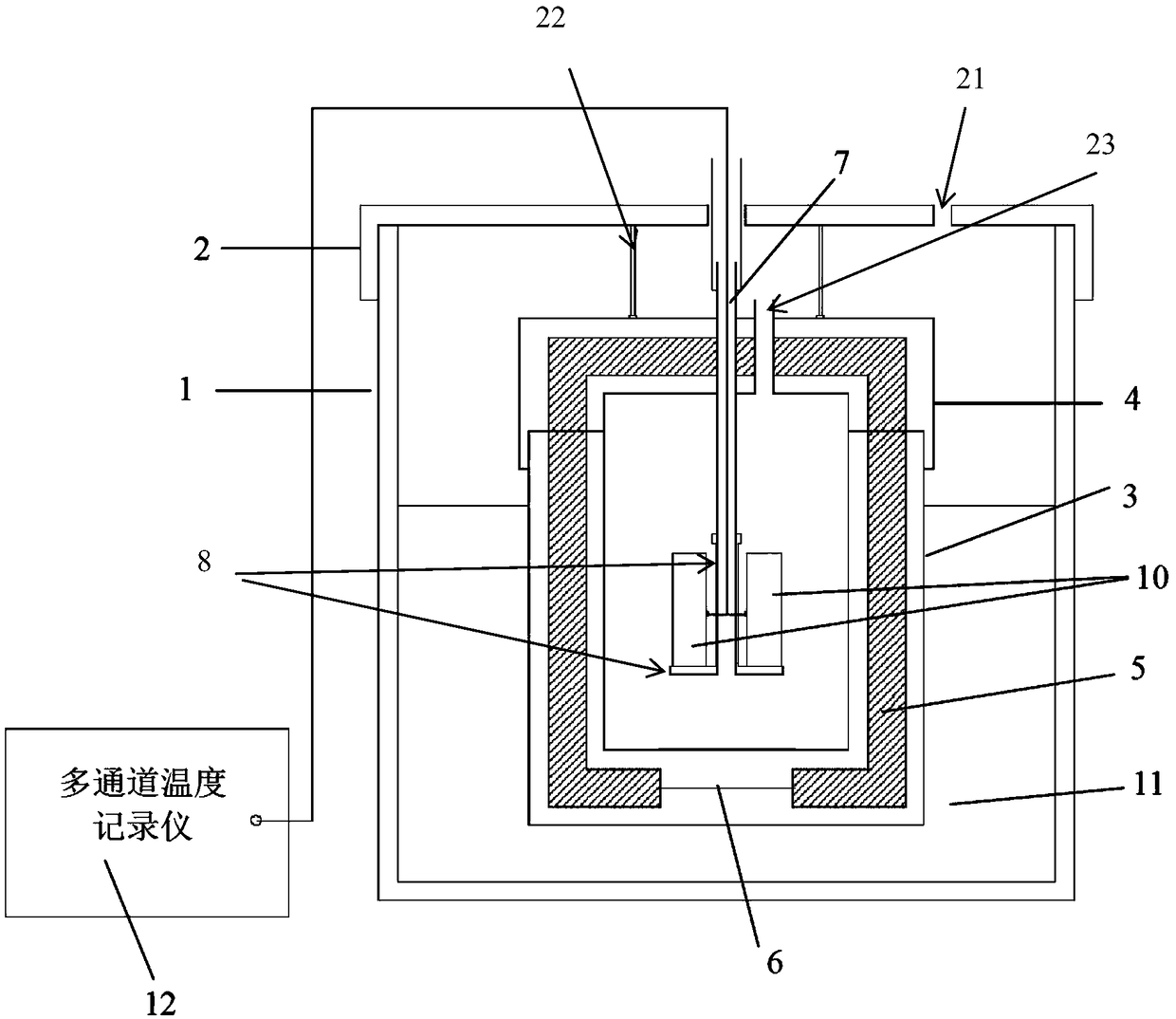

In-situ detection method for content of electrolyte inside lithium battery

ActiveCN109374672AReliable detectionMaterial heat developmentElectrical testingTemperature curveElectrical battery

The invention discloses an in-situ detection method for the content of electrolyte inside a lithium battery. The in-situ detection method comprises the steps: respectively producing a reference battery and a plurality of standard batteries for a to-be-detected battery; simultaneously cooling the to-be-detected battery, the reference battery and the plurality of standard batteries with different electrolyte contents, and respectively detecting surface temperatures; establishing a standard curve of the plurality of standard batteries; establishing a scatter diagram of the plurality of standard batteries; carrying out linear fitting on the scatter diagram of the plurality of standard batteries to obtain a quantitative relation between peak areas corresponding to the standard batteries and theelectrolyte contents of the standard batteries; establishing a temperature curve of the to-be-detected battery, and obtaining a peak area corresponding to the to-be-detected battery; and calculatingthe electrolyte content of the to-be-detected battery. The residual mass of the electrolyte in a lithium ion battery used for a period of time can be reliably detected under the condition that the battery is not destructed, so that the in-situ detection method has great production practice significance.

Owner:TIANJIN LISHEN BATTERY +1

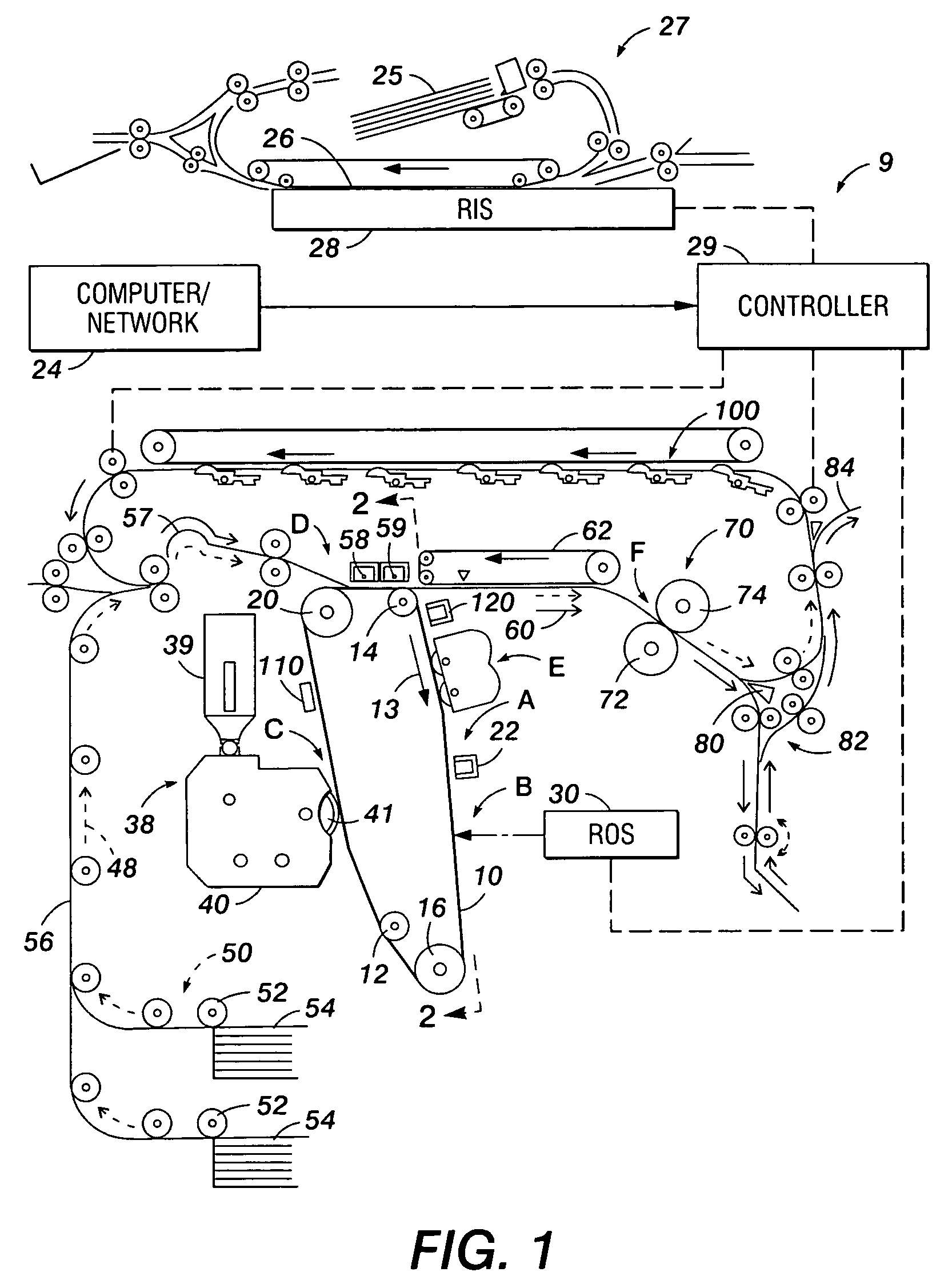

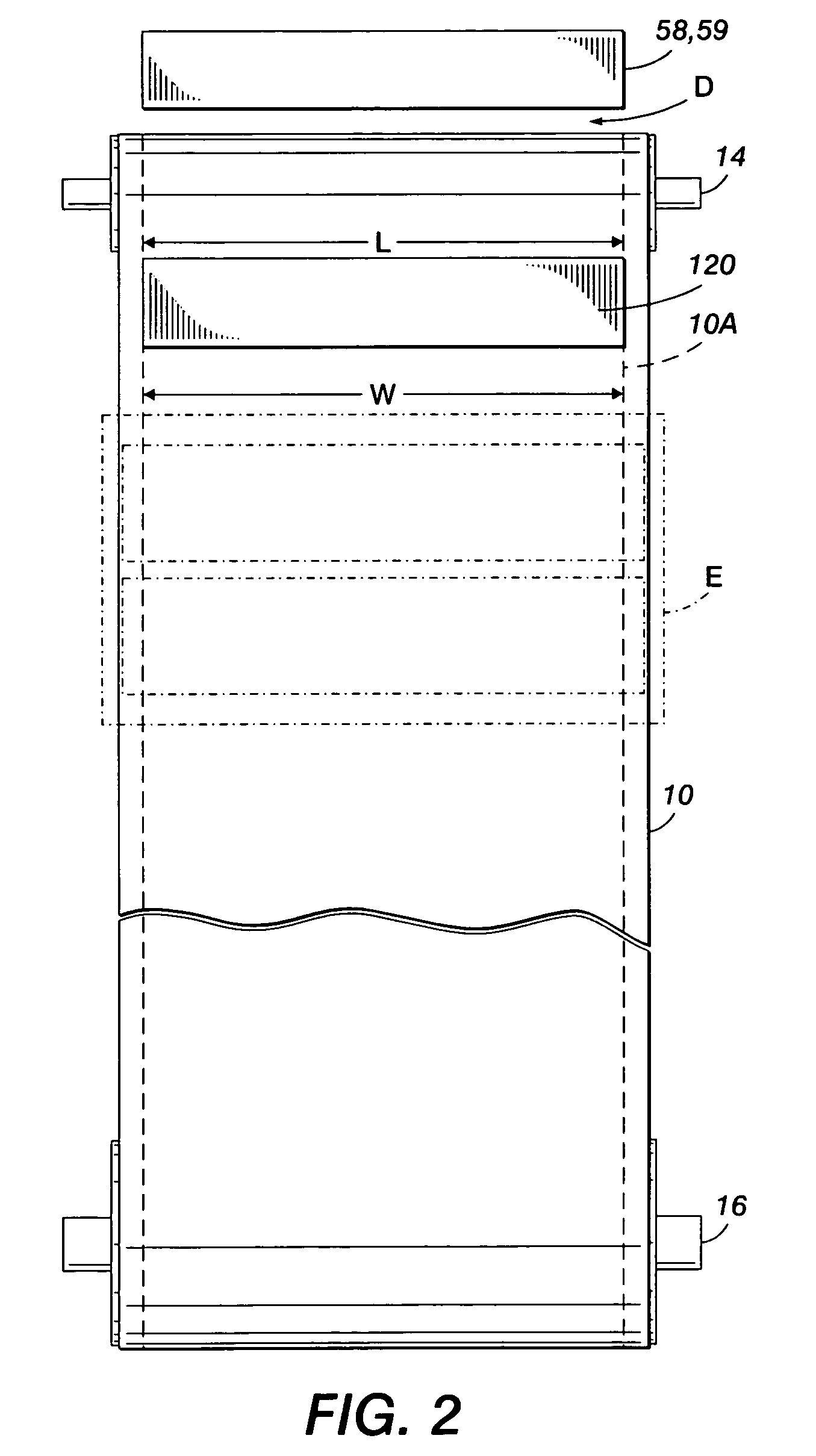

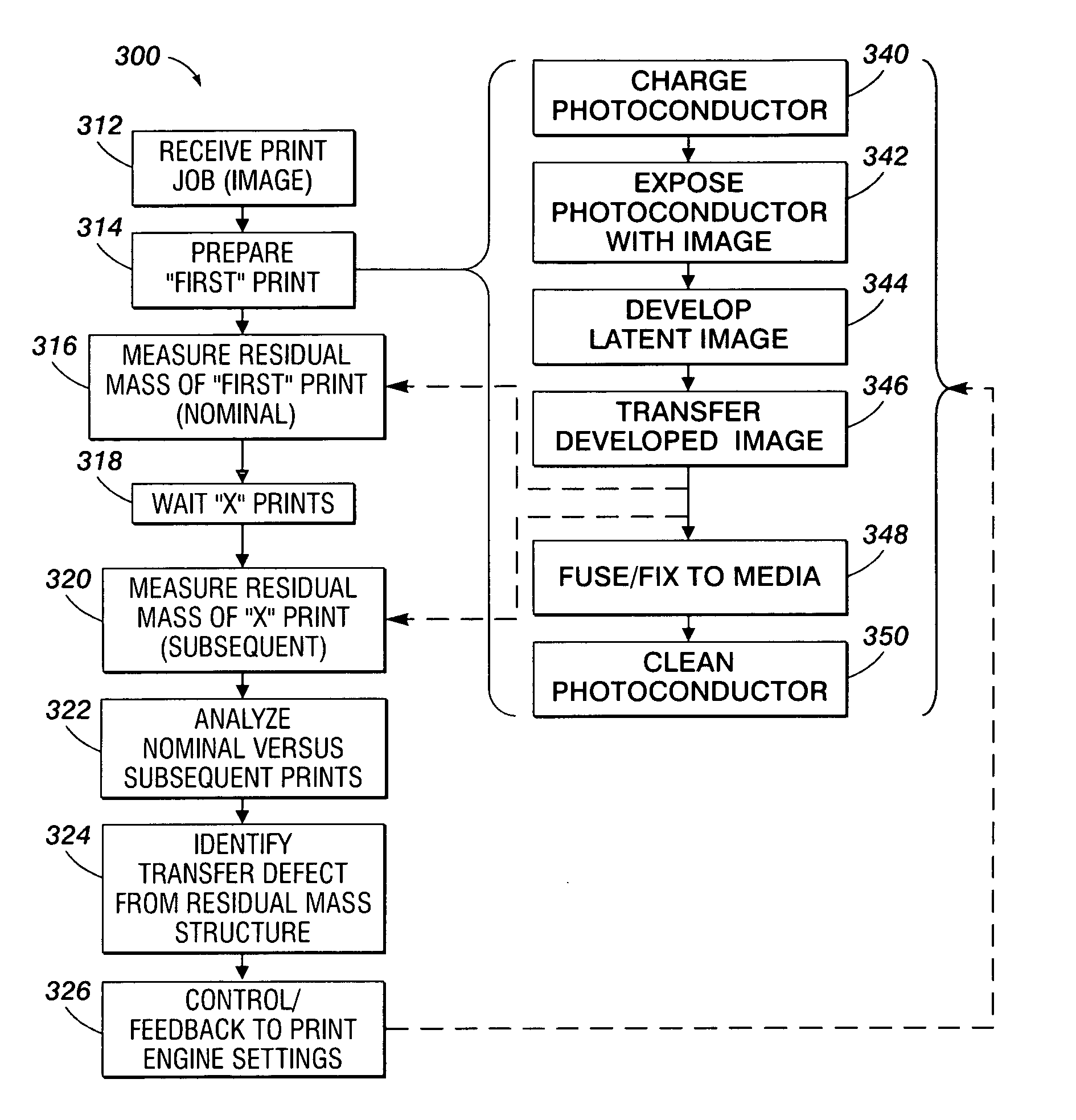

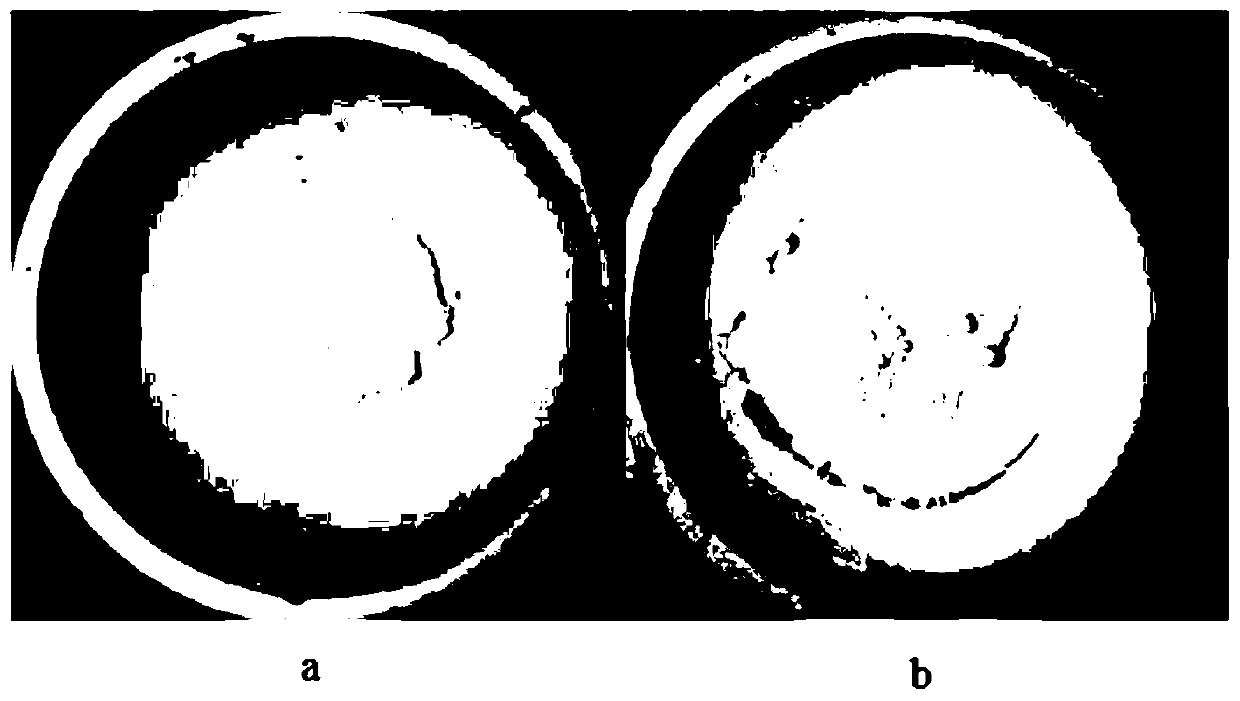

Method and apparatus for sensing and controlling residual mass on customer images

Disclosed is a method and apparatus for sensing residual toner mass after transfer of a xerographic image, to facilitate the identification and characterization of different types of transfer defects. The technique employed utilizes a nominal residual mass signature, measured at the start of a job, in conjunction with subsequent residual mass signature, where the calculated difference between the nominal and subsequent signatures is used to indicate transfer defects and changes in transfer efficiency.

Owner:XEROX CORP

Volatile anesthetic dosage monitoring system and method for realizing same

InactiveCN103330984AKnowing the qualityUse the speed to master in real timeRespiratorsElectricityMonitoring system

The invention discloses a volatile anesthetic dosage monitoring system, belongs to the technical field of medical monitoring and solves the problems that in the prior art, the initially added anesthetic mass cannot be detected, the residual anesthetic mass cannot be detected in real time, the using speed of anesthetic cannot be detected, and the residual using time of residual anesthetic cannot be detected. The system comprises an anaesthesia machine which is provided with a display screen and a volatilization pot, wherein a weighing sensor is arranged between the anaesthesia machine and the volatilization pot. One end of the weighing sensor is electrically connected with a microprocessor which comprises an anesthetic initial mass operational module, an anesthetic residual mass operational module, an anesthetic residual volume operational module, a unit time anesthetic using speed operational module and a residual anesthetic using time operational module. The microprocessor is electrically connected with the display screen on the anesthesia machine. The invention further discloses a method for realizing the volatile anesthetic dosage monitoring system.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Composite intumescent flame retardant and application thereof to preparation of flame-retardant epoxy resin composite material

ActiveCN103525004AImproved residual qualityDecrease in Specific Optical DensityEpoxyEpoxy resin composite

Owner:QINGDAO UNIV OF SCI & TECH

Method and apparatus for sensing and controlling residual mass on customer images

ActiveUS20070086799A1Improve stabilityAccurate feedbackElectrographic process apparatusEngineeringResidual mass

Disclosed is a method and apparatus for sensing residual toner mass after transfer of a xerographic image, to facilitate the identification and characterization of different types of transfer defects. The technique employed utilizes a nominal residual mass signature, measured at the start of a job, in conjunction with subsequent residual mass signature, where the calculated difference between the nominal and subsequent signatures is used to indicate transfer defects and changes in transfer efficiency.

Owner:XEROX CORP

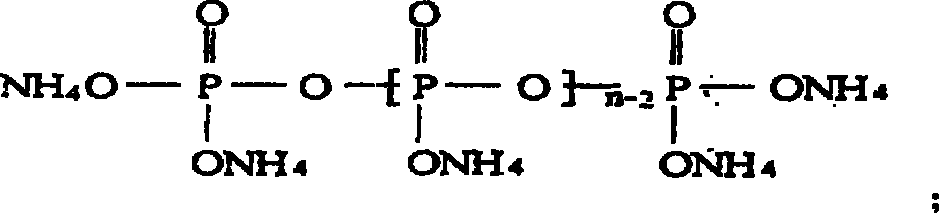

Halogen-free expansion fire retardant for polypropylene

A halogen-free intumescent flame retardant for polypropylene relates to a flame retardant for polyolefine, which is formulated by melamine salt, ammonium polyphosphate, lubricant, coupling agent and char-forming accelerator, wherein the percentage of each component in the total weight of the flame retardant is: 14 percent-90 percent of melamine salt, 9 percent-85 percent of ammonium polyphosphate, 0.1 percent-2 percent of lubricant, 0.1 percent-2 percent of coupling agent, and 0.1 percent-5 percent of char-forming accelerator; when the flame retardant of the invention is used for flame retardant of polyethylene powder or granular materials, and the lowest addition of the main frame element is 21 percent(wt), the flame retardancy grade reaches the V-0 grade according to US UL94 test, so compared with the prior art, the addition of the flame retardant of the invention is greatly decreased, the cost is reduced and the processing property of the polypropylene is not affected. Compared with brominated, the halogen-free flame retardant of the invention is environment-friendly with low smoke density, small smoke mass, lower mass loss rate and big residual mass when used for the flame retardancy of polypropylene.

Owner:PETROCHINA CO LTD

Preparation method for iron-nickel-molybdenum soft magnetic alloy sheet

The invention discloses a preparation method for an iron-nickel-molybdenum soft magnetic alloy sheet. Iron and molybdenum are molten in a vacuum induction smelting furnace first according to the mass ratio of 1:1-1.2, and molybdenum-iron intermediate alloy blocks are formed through pouring; then according to a mass ratio, 2%-8% of molybdenum-iron intermediate alloy blocks, 75%-85% of nickel, 0.05%-0.4% of phosphorus, 0.1%-0.45% of sulfur and smelting pure iron with the residual mass percent are molten in the induction smelting furnace, when the temperature of a molten alloy melt is increased to 1530-1580 DEG C, the alloy sheet is formed through quick solidification pouring, the sheet is soaked into water to be cooled and is then subjected to drying treatment, and the alloy sheet uniform in thickness, free of agglomeration and little in oxidation is obtained. Through the preparation method, the problem of large burning loss of precious metal molybdenum during smelting of iron-nickel-molybdenum alloy can be solved, the prepared alloy sheet can be directly used for a powder making procedure, alloy powder is obtained through ball milling, the technological process is simplified, production cost is reduced, meanwhile, the condition of alloy oxidation during production is reduced, and product performance is improved.

Owner:SOUTH CHINA AGRI UNIV

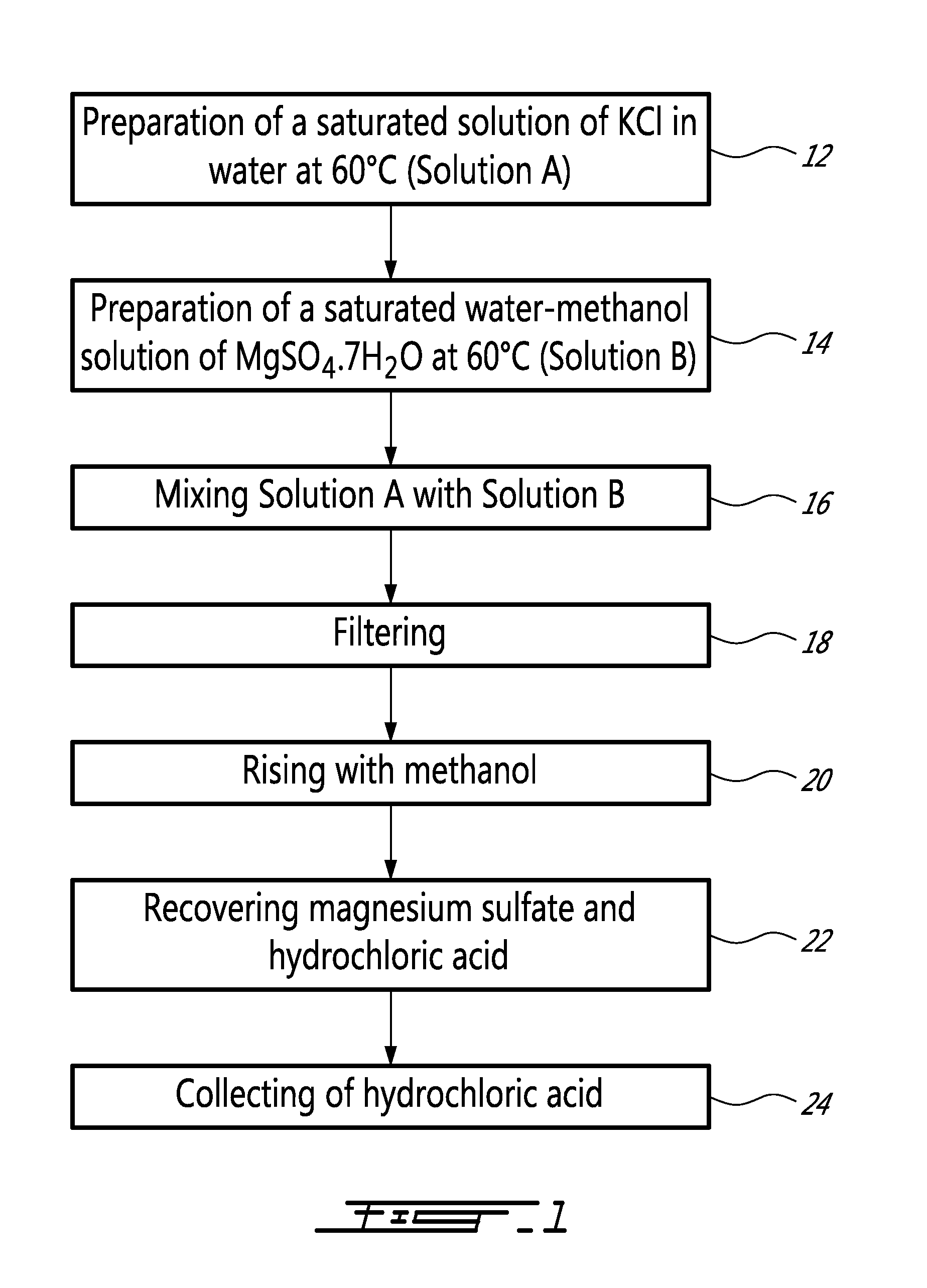

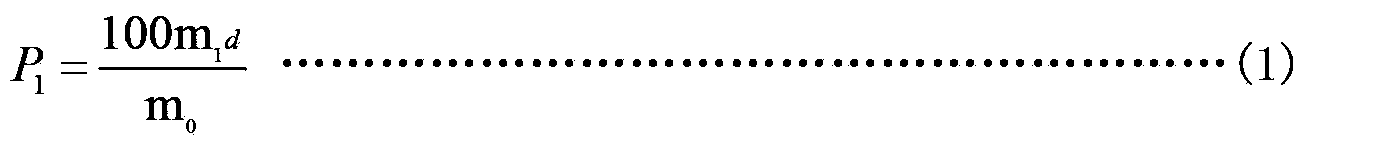

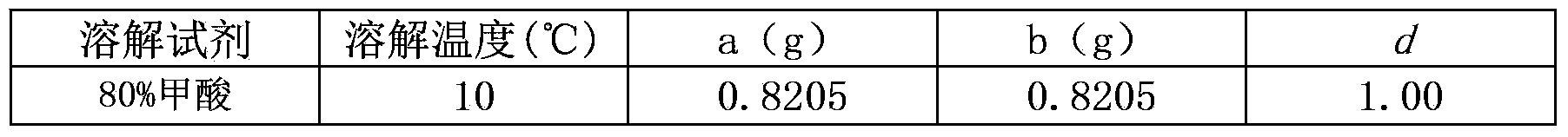

Quantitative determination method for fiber content of viloft fiber and acrylic fiber or spandex blended textiles

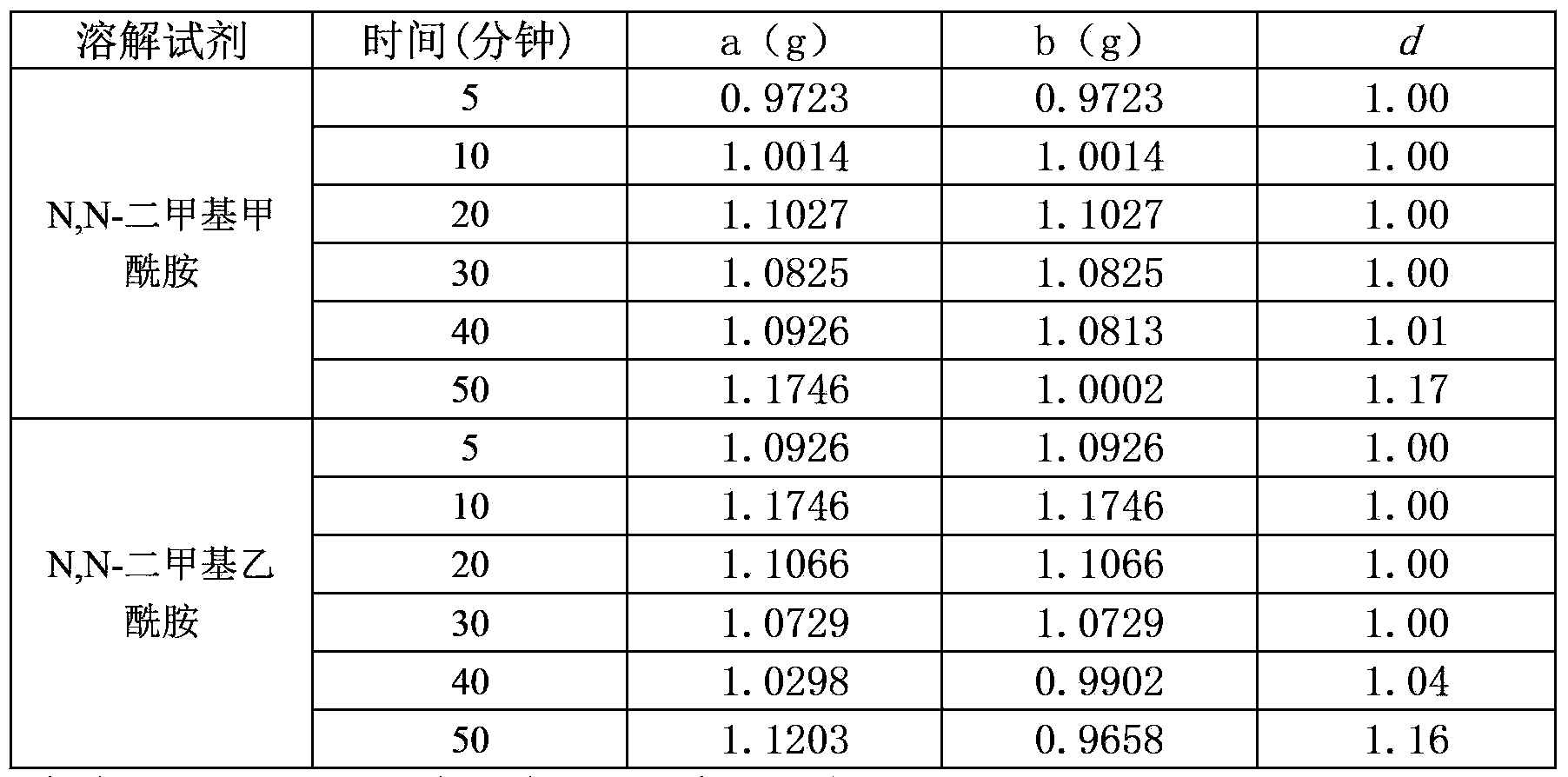

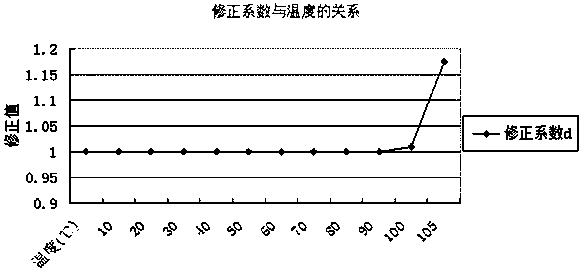

InactiveCN104122162AAvoid damageImprove solubilityWeighing by removing componentN dimethylformamideQuantitative determination

A provided quantitative determination method for fiber content of viloft fiber and acrylic fiber or spandex blended textiles comprises the following steps: S1, putting viloft fiber and acrylic fiber or spandex blended textiles in a baking box with a constant temperature of 102-108 DEG C to bake to dry, then rapidly taking out and putting in a dryer to cool to room temperature, and weighing the mass of the blended textiles and recording as m0; S2, putting the blended textiles in N,N-dimethylformamide or N,N-dimethylacetamide according to the sample (g) to reagent (mL) bath ratio of 1:100-200, continuously shaking at 90-100 DEG C for 5-30 min; and S3, washing fiber indissolvable in N,N-dimethylformamide or N,N-dimethylacetamide reagent in the step S2 with water to neutral, putting in a baking box with a constant temperature of 102-108 DEG C to bake to dry, rapidly taking out and putting in a dryer to cool to room temperature, and weighing the residual mass of the blended textiles and recording as m1. The dissolving temperature is controlled at 90-100 DEG C, and the method has extremely high accuracy and helps to substantially shorten the detection time.

Owner:GUANGDONG DONGGUAN QUALITY SUPERVISION TESTING CENT

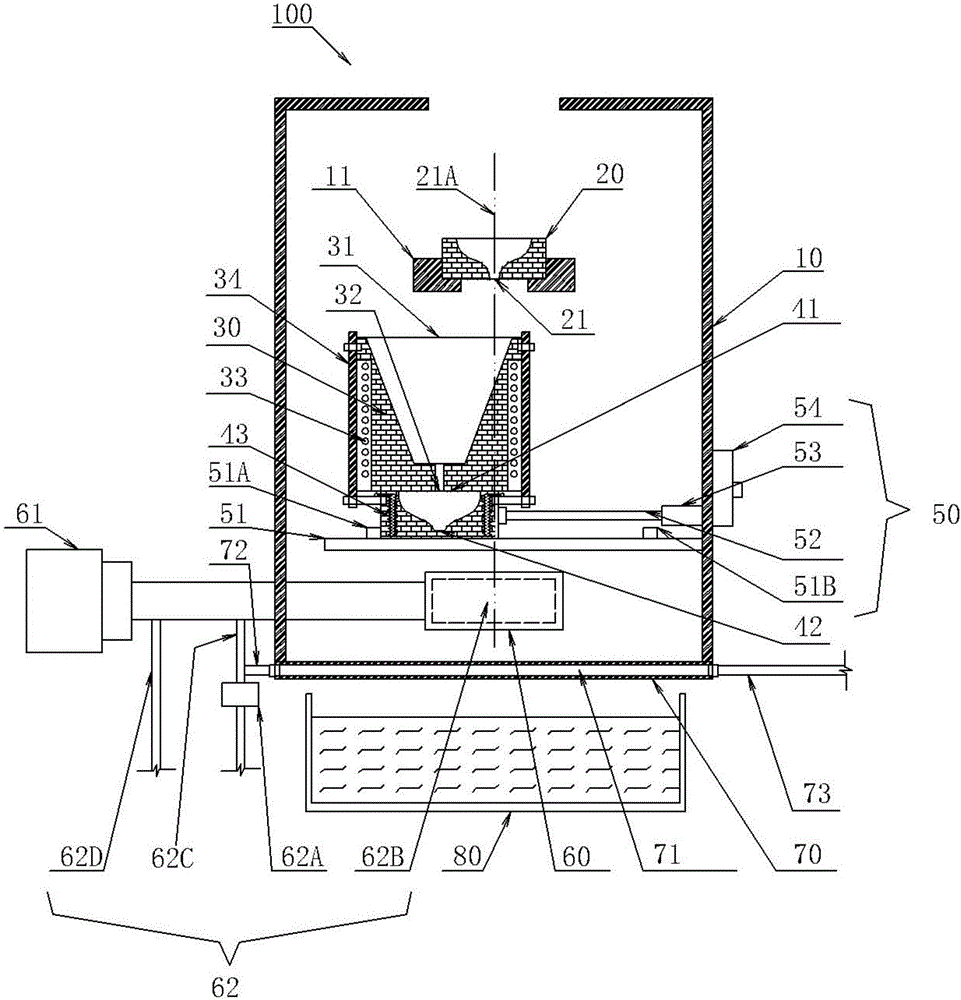

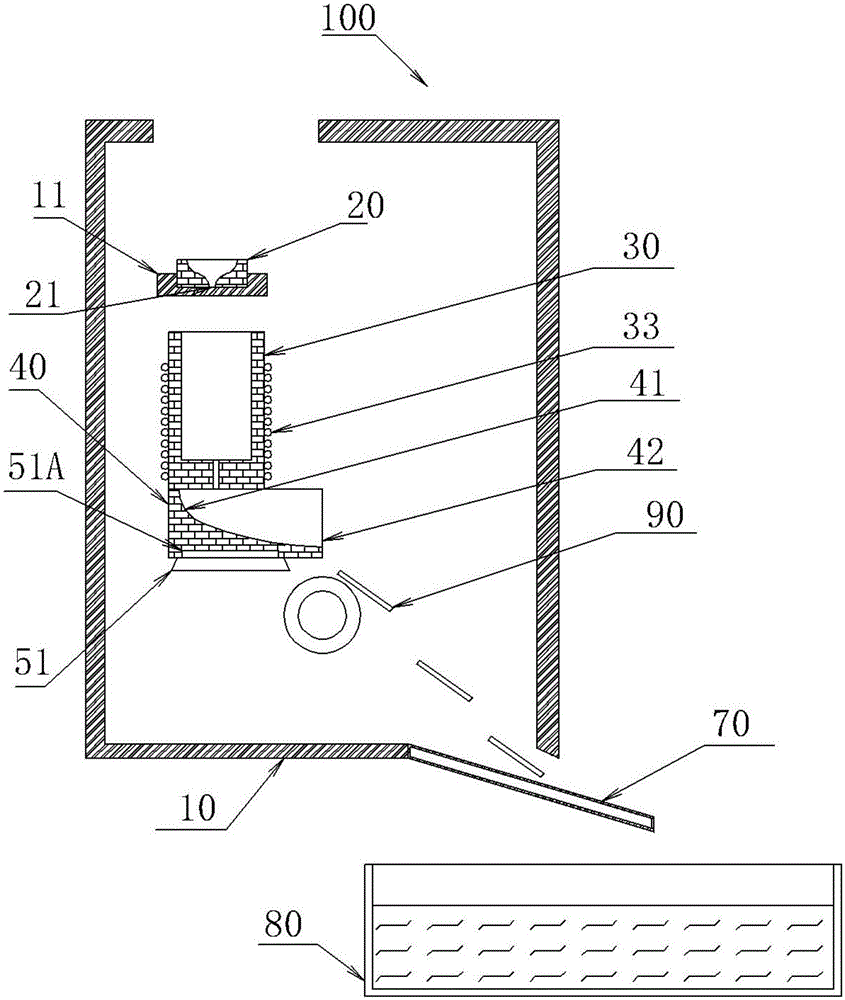

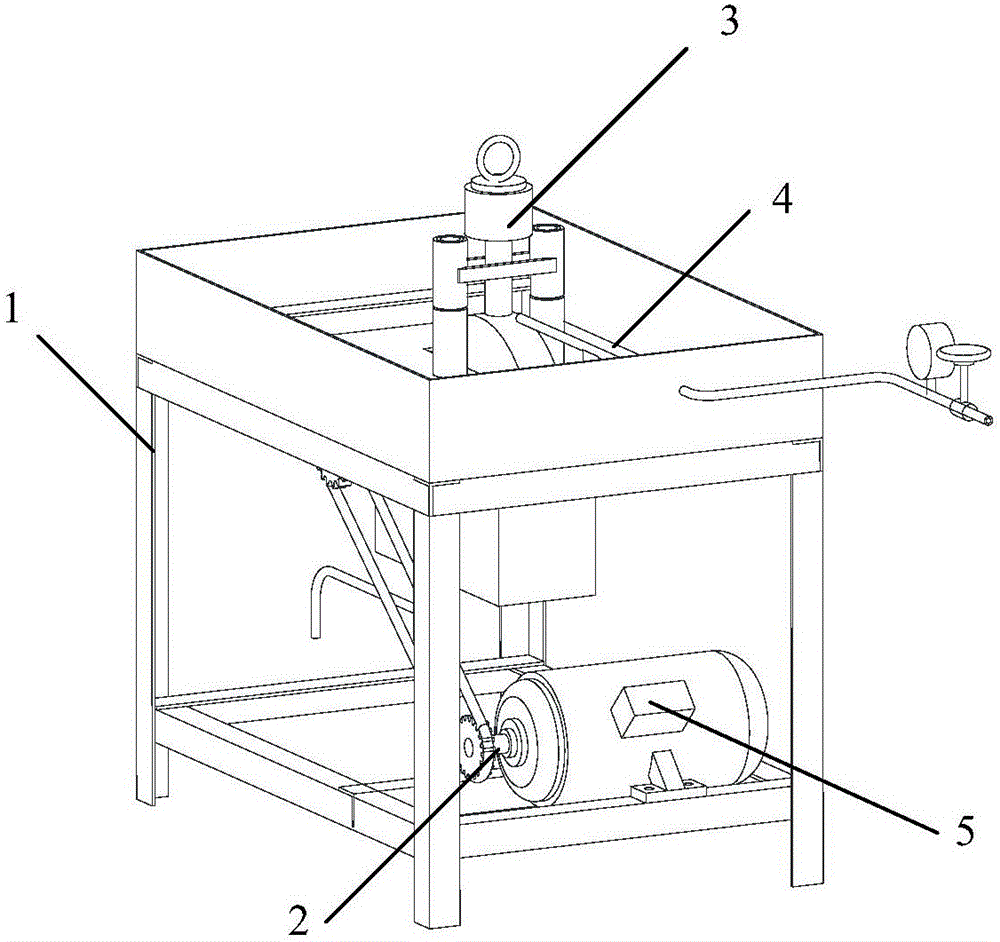

Experimental method and equipment for detecting wear of vulcanized rubber under high temperature and high humidity conditions

InactiveCN106226181AOptimized wear resistance against heat and humidityInvestigating abrasion/wear resistanceExperimental methodsHigh humidity

The embodiment of the invention discloses an experimental method and equipment for detecting wear of vulcanized rubber under high temperature and high humidity conditions, the experimental method is as follows: putting a vulcanized rubber sample in the testing equipment, setting work parameters of the testing equipment; setting the experimental high temperature and high humidity environment conditions, and starting the equipment; reaching set experimental time, turning off the testing equipment, weighing residual mass of the vulcanized rubber sample, and calculating the wear quantity in unit time of the vulcanized rubber under the high temperature and high humidity environment conditions. The experimental method and equipment solve the problem that the wear level of the vulcanized rubber under the high temperature and high humidity conditions cannot be detected, according to product requirements, the high temperature and high humidity environment conditions can be set for vulcanized rubber samples for wear experiments, and the wear value is more closer to control standards of approved products; and according to the experimental results and the laws of the parameters, anti-humid anti-heat wear resistance of heat resistant rubber can be optimized to a larger degree.

Owner:BAODING HUAYUE RUBBER BELTS

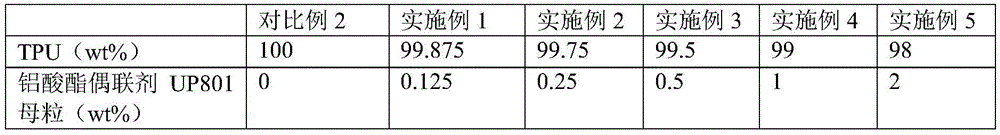

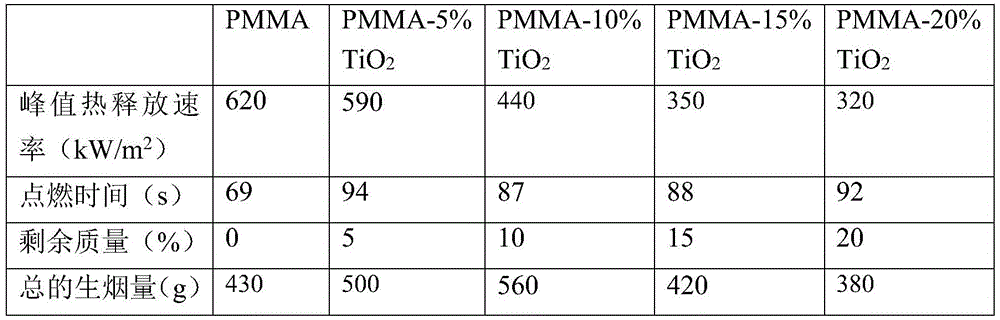

Application of aluminate substances to flame-retardant thermoplastic plastic as flame retardant

The invention discloses an application of aluminate substances to flame-retardant thermoplastic plastic as a flame retardant. An aluminate compound serving as a nano inorganic oxide precursor can be dispersed in a polymer substrate well and can be hydrated to generate nano inorganic oxide in a polymer molecule segment when encountering with moisture in air, so as to form an interpenetrating polymer network with the polymer substrate; compared with a case where nanoparticle oxide is added directly, a method of adding the inorganic oxide precursor effectively reduces agglomeration, migration and separation of nanoparticles in the polymer substrate. The flame-retardant thermoplastic which is prepared from the aluminate compound serving as the flame retardant is remarkably reduced in heat release rate, total heat release, smoke generation speed, total smoke generation amount and smoke factors, and the residual mass of carbon residues is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

Oil agent for carbon-fiber-precursor acrylic fiber, oil agent composition for carbon-fiber-precursor acrylic fiber, oil-treatment-liquid for carbon-fiber-precursor acrylic fiber, and carbon-fiber-precursor acrylic fiber bundle

ActiveUS20170284016A1Easy to emulsifyAvoid fusesFibre typesFibre chemical featuresSimple Organic CompoundsAir atmosphere

An oil for a carbon fiber precursor acrylic fiber including: a hydroxybenzoate ester (A) indicated by formula (1a); an amino-modified silicone (H) indicated by formula (3e); and an organic compound (X) which is compatible with the hydroxybenzoate ester (A), in which a residual mass rate R1 at 300° C. in thermal mass analysis in an air atmosphere is 70-100 mass % inclusive, and which is a liquid at 100° C., and a carbon fiber precursor acrylic fiber bundle to which the oil for a carbon fiber precursor acrylic fiber is adhered.

Owner:MITSUBISHI CHEM CORP

Quantitative determination method for fiber content of viloft fiber and polyester fiber blended textiles

InactiveCN104122164AShorten detection timeImprove detection efficiencyWeighing by removing componentPolyesterFiber

A quantitative determination method for fiber content of viloft fiber and polyester fiber blended textiles compriess the following steps: S1, putting viloft fiber and polyester fiber blended textiles in a baking box with a constant temperature of 102-108 DEG C to bake to dry, then rapidly taking out and putting in a dryer to cool to room temperature, and weighing the mass of the blended textiles and recording as m0; S2, putting the blended textiles into sulfuric acid with the concentration of 70%-80%according to the sample (g) to reagent (mL) bath ratio of 1:100-200, continuously shaking at 40-100 DEG C for 2-60 min; and S3, washing fiber indissolvable in sulfuric acid reagent in the step S2 with water to neutral, putting in a baking box with a constant temperature of 102-108 DEG C to bake to dry, rapidly taking out and putting in a dryer to cool to room temperature, and weighing the residual mass of the blended textiles and recording as m1. The dissolving temperature is controlled at 40-100 DEG C, because polyester fiber at the temperature shows extremely strong acid resistance and viloft fiber can be completely dissolved, a final detection result is highly consistent with an actual value, and the method has extremely high accuracy.

Owner:GUANGDONG DONGGUAN QUALITY SUPERVISION TESTING CENT

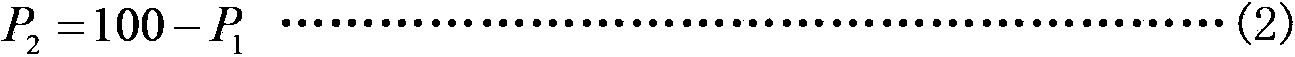

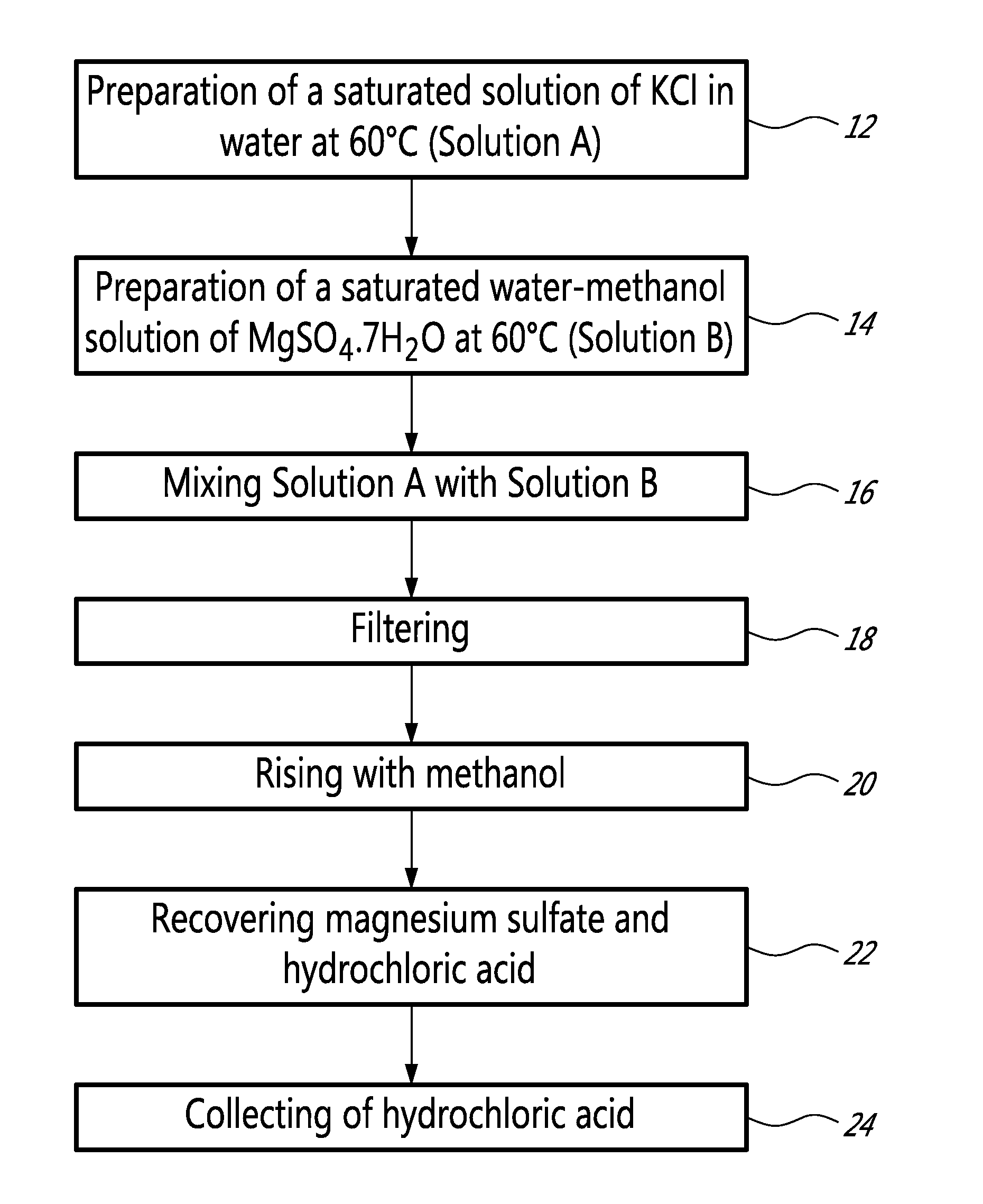

Method and system for the production of potassium sulfate from potassium chloride

ActiveUS20120321547A1Sulfate/bisulfate preparationRubidium/caesium/francium compoundsSlurryWater soluble

A method and a system for the production of potassium sulfate. The method comprises reacting a source of water soluble potassium with a magnesium sulfate-containing substance in presence of an aqueous alcoholic solution. The system comprises a first reactor for dissolving a water soluble potassium in water into a first solution; a second reactor for dissolving magnesium sulfate hydrate in water and adding methanol into a second solution; a third reactor, adapted to receive the first and the second solutions, mixed then under stirring and cool them down into a slurry; a filter collecting and filtering the slurry from the third reactor; delivering, after rinsing of the solid part with methanol, chloride-free potassium sulfate, and a combined filtrate and rinsings; a column receiving and distilling the combined filtrate and rinsings, delivering methanol back to the second reactor and to the filter and a concentrated solution of magnesium chloride; a fourth reactor, adapted to receive the concentrated solution of magnesium chloride, which crystallizes upon cooling, and to treat the concentrate with sulfuric acid, delivering hydrochloric acid and a residual mass; a collector, adapted to absorb the hydrochloric acid delivered form the fourth reactor; and a fifth reactor, adapted to collect and crystallise the residual mass from the fourth reactor, for recycling to the second reactor as magnesium sulfate heptahydrate.

Owner:KOREA SHEET METAL

Quantitative determination method for fiber content of viloft fiber and natural cellulose fiber blended textiles

InactiveCN104122166AAvoid damageHigh precisionWeighing by removing componentCooking & bakingCellulose fiber

A provided quantitative determination method for fiber content of viloft fiber and natural cellulose fiber blended textiles comprises the following steps: S1, putting viloft fiber and natural cellulose fiber blended textiles in a baking box to bake to dry, then cooling to room temperature, and weighing the mass of the blended textiles, wherein the natural cellulose is cotton, flax and ramie which are not subjected to chemical degradation; S2, putting the blended textiles in a formic acid-zinc chloride reagent with the formic acid mass fraction of 68% and the zinc chloride mass fraction of 20% according to the sample (g) to reagent (mL) bath ratio of 1:100-200, continuously shaking at 40-70 DEG C for 20-60 min; and S3, washing fiber indissolvable in the formic acid-zinc chloride reagent in the step S2 with water to neutral, putting in a constant-temperature baking box to bake to dry, rapidly taking out and cooling to room temperature, and weighing the residual mass of the blended textiles. A detection result is highly consistent with an actual value, and the method has extremely high accuracy.

Owner:GUANGDONG DONGGUAN QUALITY SUPERVISION TESTING CENT

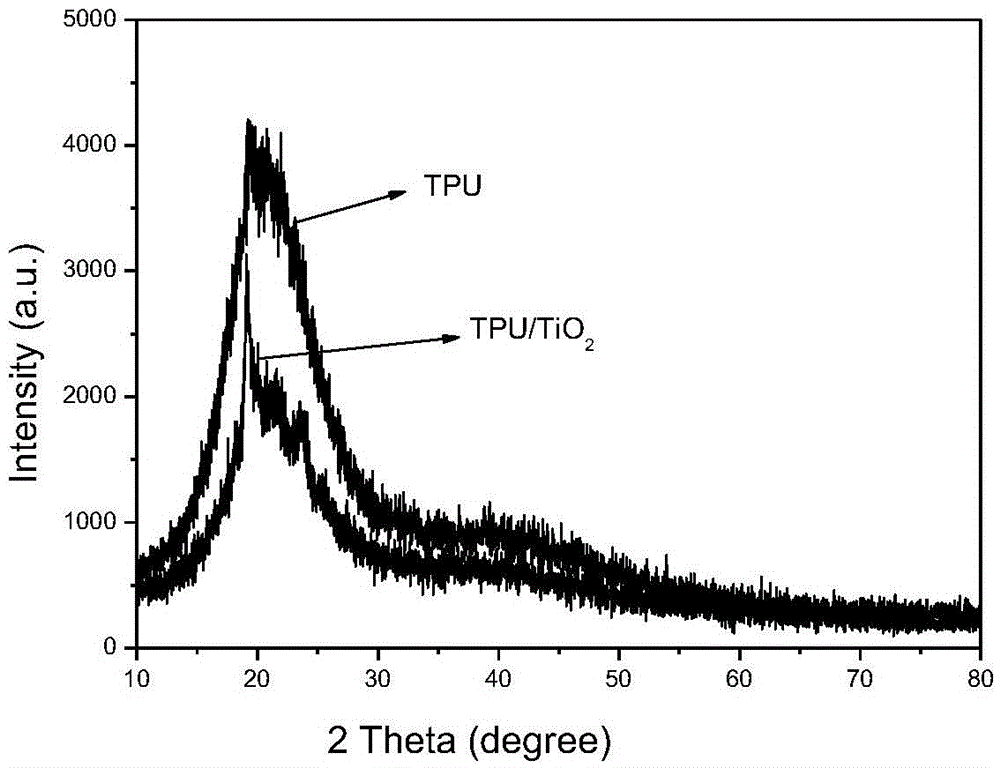

Application of titanate substances to flame-retardant thermoplastic plastic as flame retardant

The invention discloses an application of titanate substances to flame-retardant thermoplastic plastic as a flame retardant. A titanate substance serving as a nano inorganic oxide precursor can be dispersed in a polymer substrate well and can be hydrated to generate nano inorganic oxide in a polymer molecule segment when encountering with moisture in air, so as to form an interpenetrating polymer network with the polymer substrate; compared with a case where nanoparticle oxide is added directly, a method of adding the inorganic oxide precursor effectively reduces agglomeration, migration and separation of nanoparticles in the polymer substrate. The flame-retardant thermoplastic which is prepared from the titanate compound serving as the flame retardant is remarkably reduced in heat release rate, total heat release, smoke generation speed, total smoke generation amount and smoke factors, and the residual mass of carbon residues is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

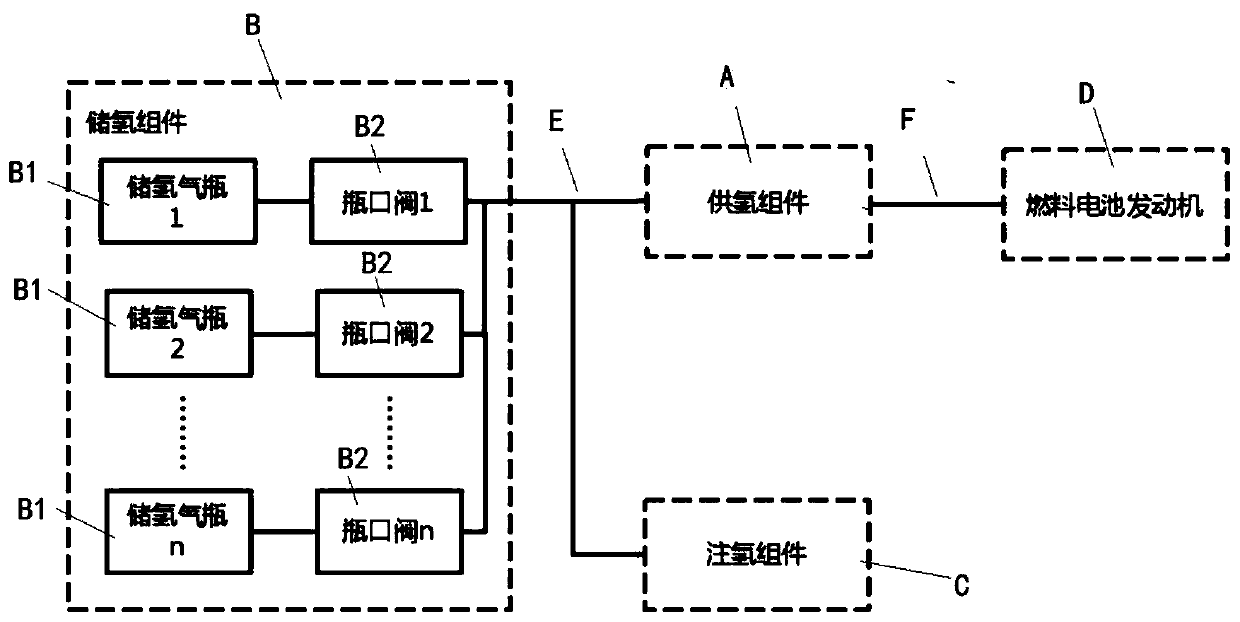

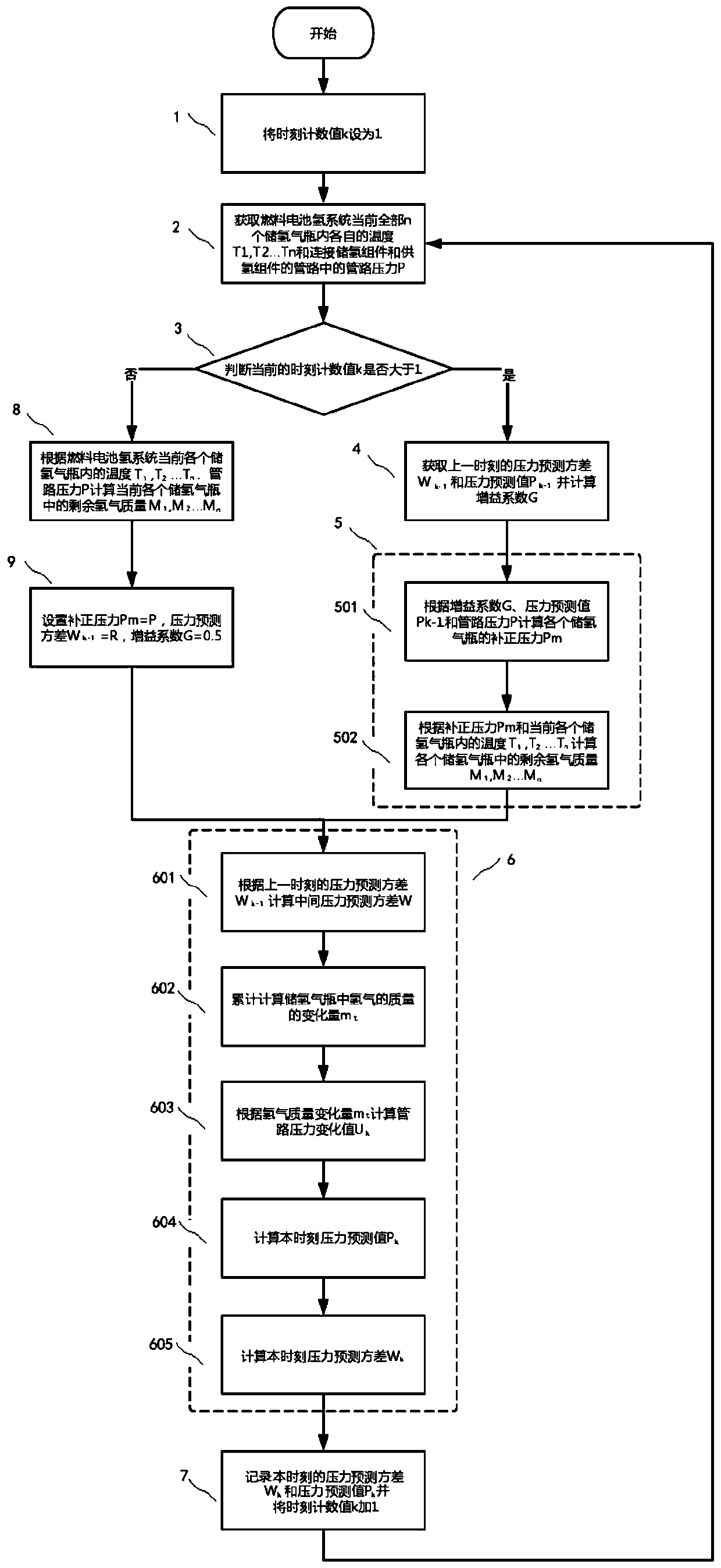

Method for calculating residual hydrogen of fuel cell hydrogen system

InactiveCN110112446AImprove performanceEasy to useMotive system fuel cellsGain coefficientEngineering

The invention provides a method for calculating residual hydrogen of a fuel cell hydrogen system. The method comprises the steps of: setting a moment count value as 1; obtaining respective temperatures in all the n hydrogen storage cylinders of the fuel cell hydrogen system and pipeline pressures in pipelines connected with a hydrogen storage component and s hydrogen supply component; determiningwhether the current moment count value is larger than 1 or not, and if yes, obtaining the pressure prediction variance and the pressure prediction value at the last moment, and calculating a gain coefficient; calculating a correction pressure and the mass of the residual hydrogen in each hydrogen storage cylinder; calculating the pressure prediction variance and the pressure prediction value at the current moment; and adding 1 to the moment count value, and recording the pressure prediction variance and the pressure prediction value at this moment. The method has the advantages that: the errorof the data of the pressure sensor of the hydrogen system is corrected by adopting a statistical online iterative calculation method, so that the calculation precision of the hydrogen residual mass of the hydrogen system of the fuel cell is improved.

Owner:BEIJING SINOHYTEC

Quantitative determination method for fiber content of viloft fiber and polyamide blended textiles

InactiveCN104122163AImprove solubilityShorten detection timeWeighing by removing componentCooking & bakingFiber

A provided quantitative determination method for fiber content of viloft fiber and polyamide blended textiles comprises the following steps: S1, putting viloft fiber and polyamide blended textiles in a baking box with a constant temperature of 102-108 DEG C to bake to dry, then rapidly taking out and putting in a dryer to cool to room temperature, and weighing the mass of the blended textiles and recording as m0; S2, putting the blended textiles into formic acid with the mass concentration of 80%-88% or hydrochloric acid with the mass concentration of 20% according to the sample (g) to reagent (mL) bath ratio of 1:100-200, continuously shaking at 10-40 DEG C for 15-30 min; and S3, washing fiber indissolvable in formic acid or hydrochloric acid reagent in the step S2 with water to neutral, putting in a baking box with a constant temperature of 102-108 DEG C to bake to dry, rapidly taking out and putting in a dryer to cool to room temperature, and weighing the residual mass of the blended textiles and recording as m1. The dissolving temperature is controlled at 10-40 DEG C, because viloft fiber at the temperature shows relatively strong acid resistance, a final detection result is highly consistent with an actual value, and the method has extremely high accuracy.

Owner:GUANGDONG DONGGUAN QUALITY SUPERVISION TESTING CENT

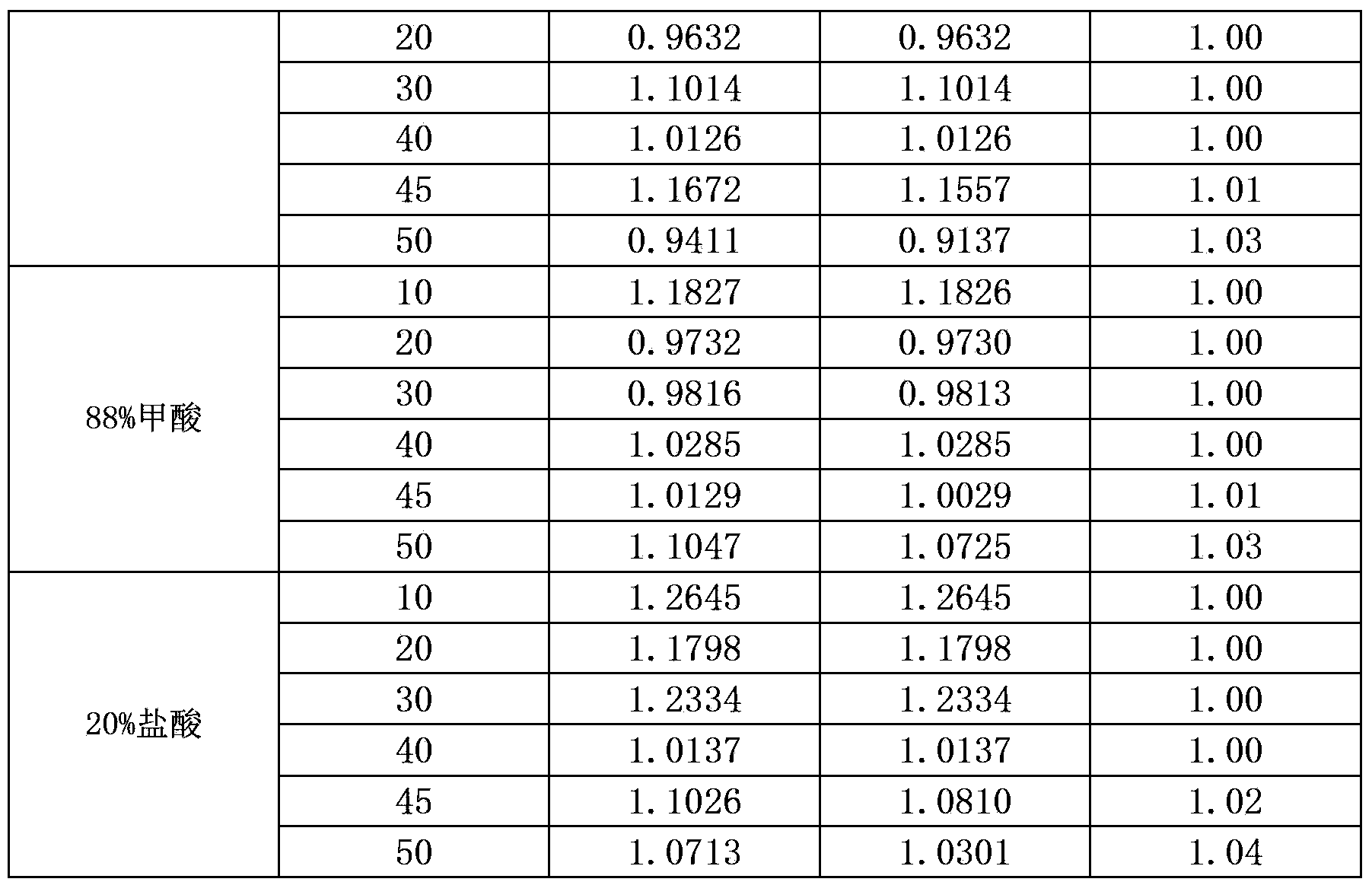

Full-reference mixed-distortion image quality evaluation method based on sparse decomposition residuals

ActiveCN107590796AEase of evaluationGood correlationImage analysisPattern recognitionImaging quality

The invention relates to a full-reference mixed-distortion image quality evaluation method based on sparse decomposition residuals. The method comprises steps: a natural image is selected, and image blocks are selected from the natural image as training image blocks to train a dictionary D; a sparse decomposition residual energy graph is acquired; and the image distortion level is evaluated basedon the sparse decomposition residual energy graph. The third step comprises the following sub steps: the local residual energy feature similarity is calculated; a variogram solved by a reference imageis used as a weight to acquire a local residual mass fraction Qrl; a global residual Gres<r> is solved by the local residual energy graph; the mass fraction of the global residual feature is calculated; and the local residual mass fraction Qrl and the global residual mass fraction Qrg are integrated to obtain the evaluation mass fraction Qr of the final residual feature.

Owner:TIANJIN UNIV

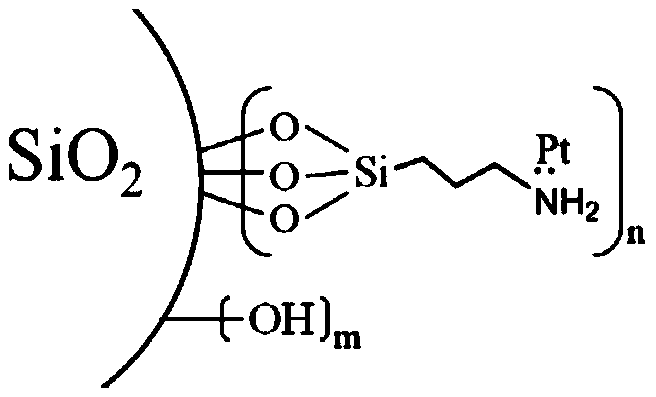

Hydrophilic polyurethane composite grouting liquid with high strength of consolidation body and preparation method of hydrophilic polyurethane composite grouting liquid

The invention discloses hydrophilic polyurethane composite grouting liquid with high strength of a consolidation body. After being modified organically, nano silicon dioxide is added in raw materials, can be dispersed uniformly and cannot be agglomerated easily, while the performance of the traditional polyurethane grouting liquid is kept basically, the thermal decomposition temperature and the residual mass of the hydrophilic polyurethane composite grouting liquid are obviously higher than those of the traditional polyurethane grouting liquid, active modifiers such as modified calcined kaolin, glass fibers and bisphenol A epoxy resin are further added, various components are mutually dispersed uniformly and do not sink, while the viscosity of the composite grouting liquid is improved, the strength of the consolidation body is further improved, the hydrophilic polyurethane composite grouting liquid can be quickly injected and permeates in tiny gaps of drift sand or sludge to form the consolidation body with certain strength, and accidents such as sand permeation, roof fall and rib spalling in a tunneling process are prevented.

Owner:ANHUI LENCAQI BUILDING MATERIAL

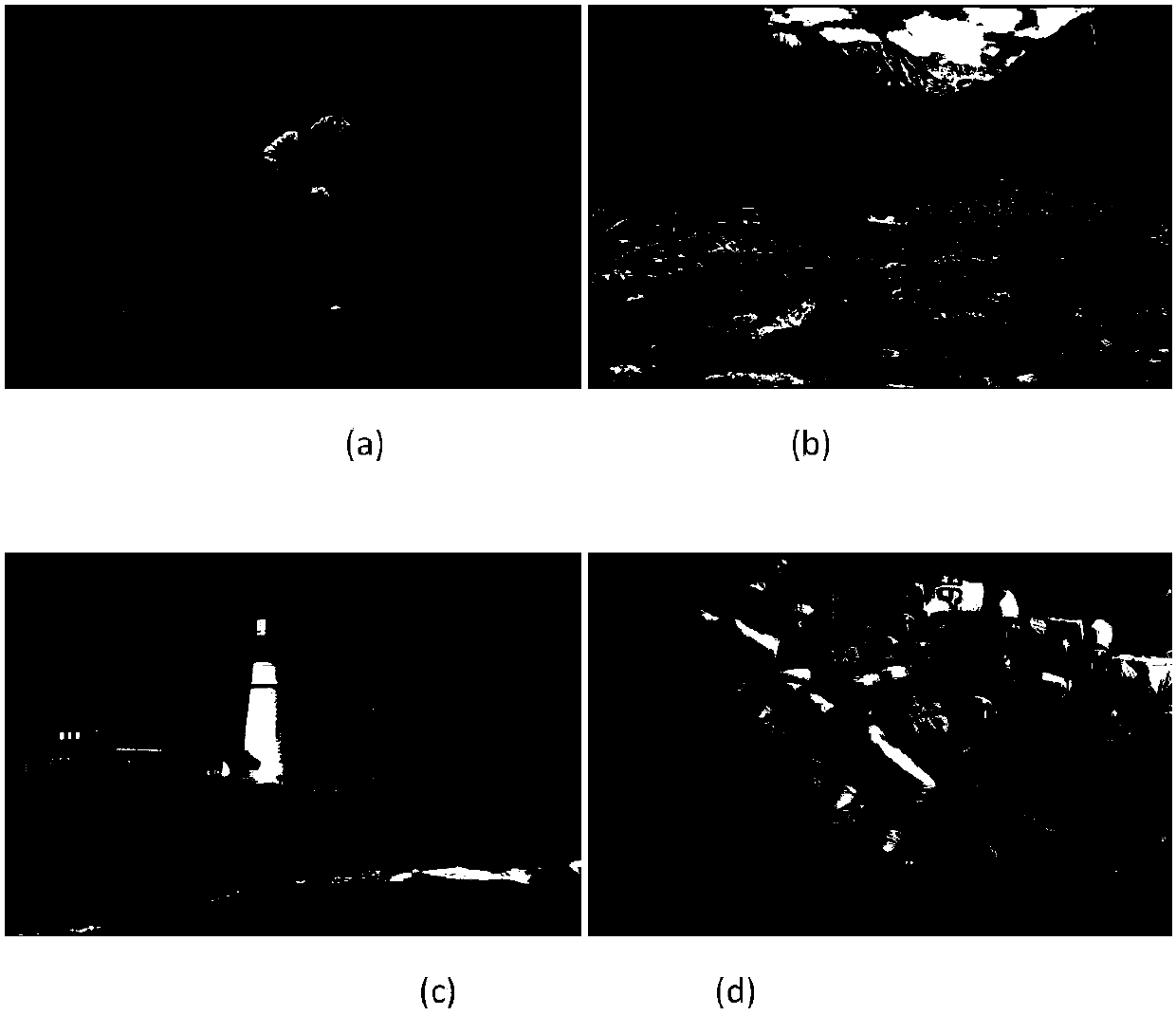

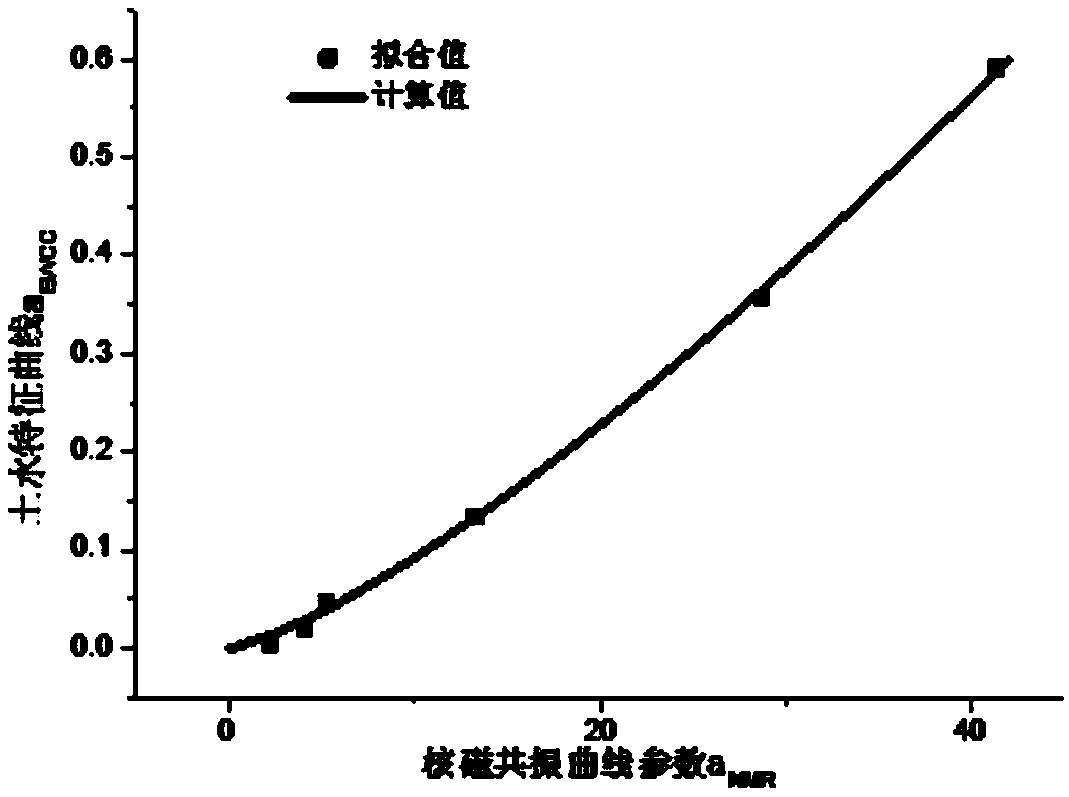

Method for predicting soil-water characteristic curve VG (Van Genuchten) model on the basis of NMR (Nuclear Magnetic Resonance) curve

InactiveCN109239118AOvercome limitationsSave manpower and material resourcesAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceSoil mass

The invention discloses a method for predicting a soil-water characteristic curve VG (Van Genuchten) model on the basis of an NMR (Nuclear Magnetic Resonance) curve. Under known dry density, accordingto experiment data, a relationship curve, i.e., a magnetic resonance imaging curve of the soil mass relaxation time T2-semaphore S of the soil-water characteristic curve is obtained under the same dry density, a part which is smaller than an actual measurement residual mass moisture content is detected, and the obtained processed magnetic resonance imaging curve carries out fitting on the basis of the VG model of a classical soil-water characteristic curve model to obtain a fit parameter to obtain N groups of fitting parameters under N different dry densities to establish a prediction model of the soil-water characteristic curve parameter. Therefore, the boundedness of an indoor experiment is overcome, a great quantity of manpower and material resources can be saved, a new direction is provided for researching the soil-water characteristic curve of unsaturated soil, and the method has important scientific significance for developing the relevant mechanics and penetration theory of theunsaturated soil.

Owner:HUBEI UNIV OF TECH

High temperature-resistant silicone rubber and preparation method thereof

The present disclosure provides a high temperature-resistant silicone rubber. The silicone rubber comprises methyl vinyl silicone rubber, white carbon black, hydroxy silicone oil, hydrogen-containingsilicone oil, a heatproof additive and 2,5-dimethyl-2,5-di-(tert-butylperoxy)hexane. The heatproof additive added to the high temperature-resistant silicone rubber can significantly improve the residual quality of the silicone rubber at a high temperature, overcomes the disadvantage of poor compatibility between a commonly used heatproof additive and the silicone rubber, and maintains the originalmechanical properties of the silicone rubber.

Owner:FOSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com