Method for detecting areal density of ceramic coating of lithium ion battery separator

A lithium-ion battery, ceramic coating technology, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., to achieve the effect of great practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the method of the present invention is adopted to detect the density of the ceramic coating surface of the ceramic diaphragm sample to be detected.

[0047] Step 1: Scanning electron microscopy (SEM) is used to scan and observe the cross-sectional morphology of the ceramic diaphragm, such as figure 2 As shown, A is the base film, and B is the ceramic coating. It can be determined that the ceramic diaphragm is coated on one side, that is, the number of ceramic coating surfaces n is 1;

[0048] Step 2: Cut a square test sample with a side length of 2.4cm from the ceramic diaphragm to be tested, then its area A=2.4×2.4=5.76cm 2 ; With an electronic balance, its mass m obtained by weighing is 7.1300g;

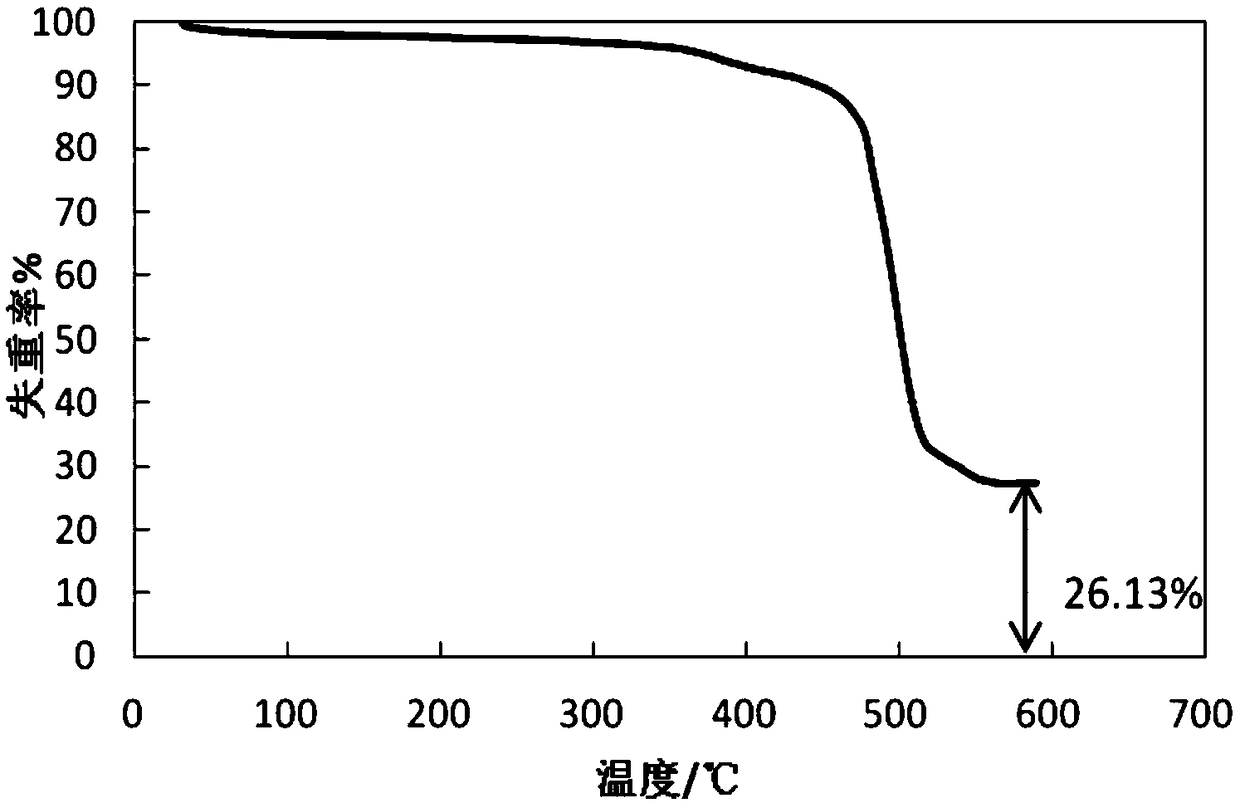

[0049] Step 3: Put the above test samples in the crucible of the thermogravimetric analyzer, set the test conditions of the thermogravimetric analyzer, and detect the thermogravimetric curve of the ceramic diaphragm sample according to the preset test c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com