Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Drop size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In medicine and chemistry a drop is actually defined as 0.05 milliliters. Drop (unit) Free falling raindrops can get much bigger than that of course and can get up to about 8mm diameter (0.5mL) in a thunderstorm. Diameter of a Raindrop.

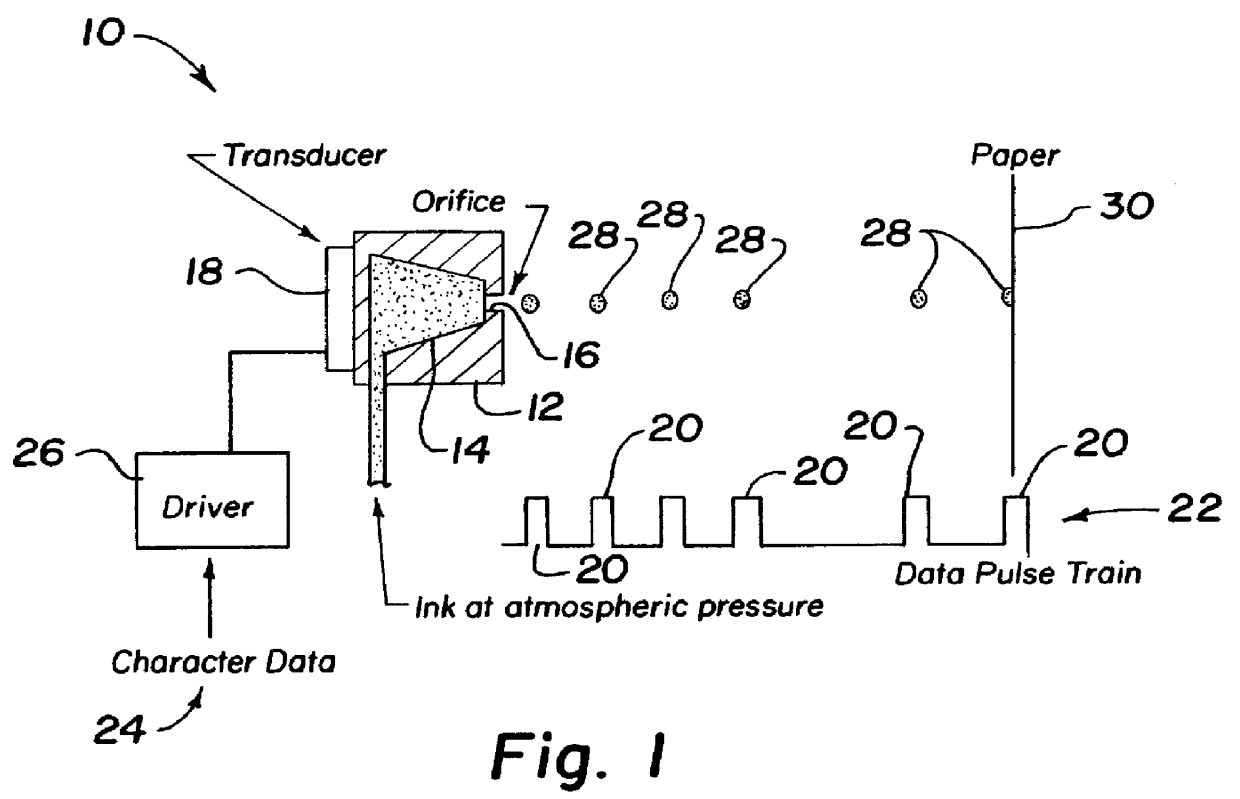

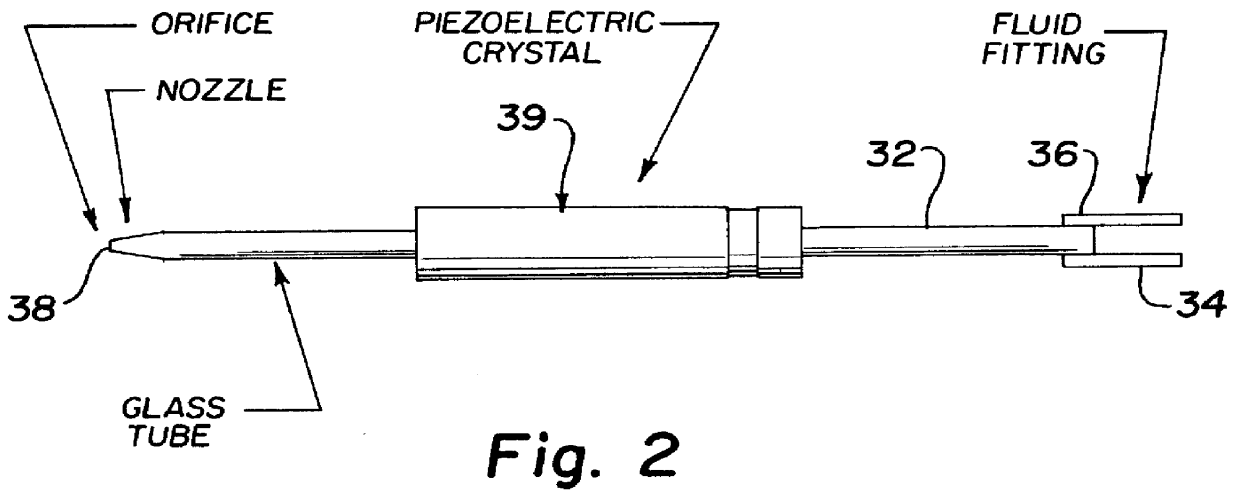

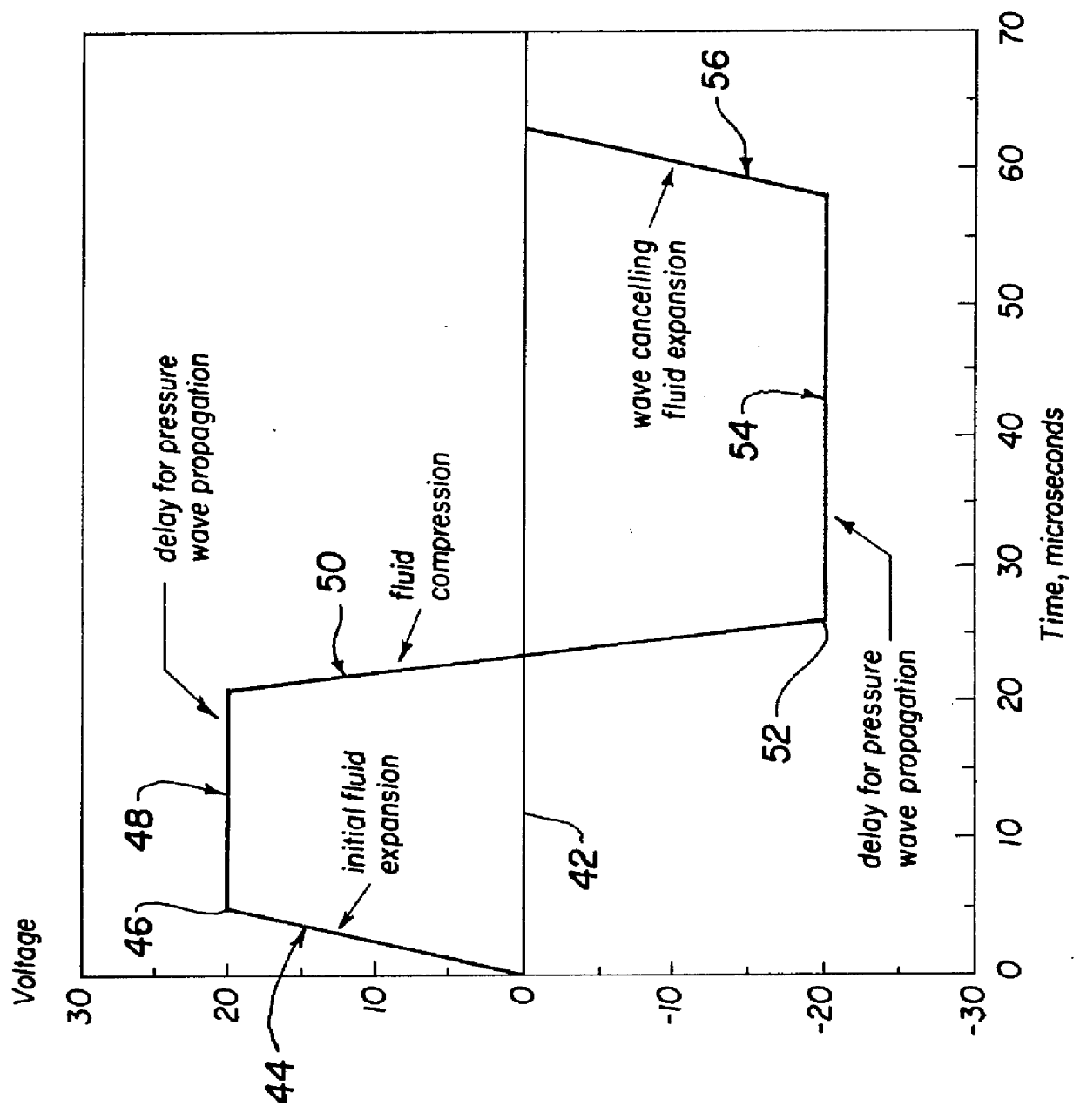

Method of drop size modulation with extended transition time waveform

The present invention uses a novel waveform to allow the droplet volume dispensed from a demand mode inkjet type device to be increased and selected according to easily controllable parameters. The current invention departs from the conventional drive method by significantly increasing the time for energy input in the initial instance as well is in all later application of the drive voltage to the device. In shape, the waveform is the same whether a unipolar or bipolar pulse is utilized; however, the transition times in the initial instance are up to three times the acoustic resonance and the delay times are of the same order. Droplet diameter can be varied from 1X the orifice diameter to 2X the orifice diameter resulting in an 8:1 range of droplet volume. Since the volume modulation results from changes in the waveform used to drive the solder jet device, the drop volume can be changed and altered in real time.

Owner:MICROFAB TECH

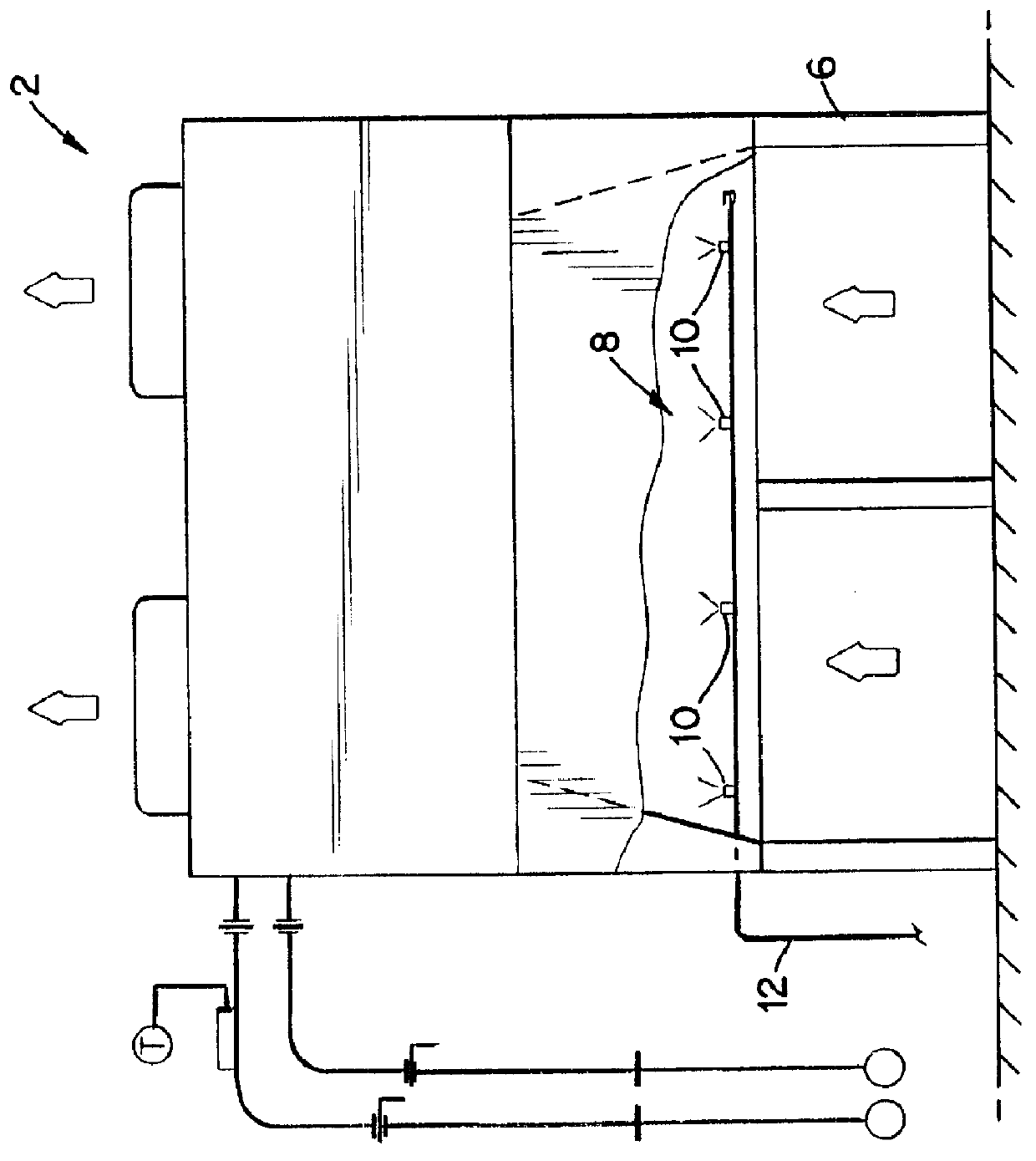

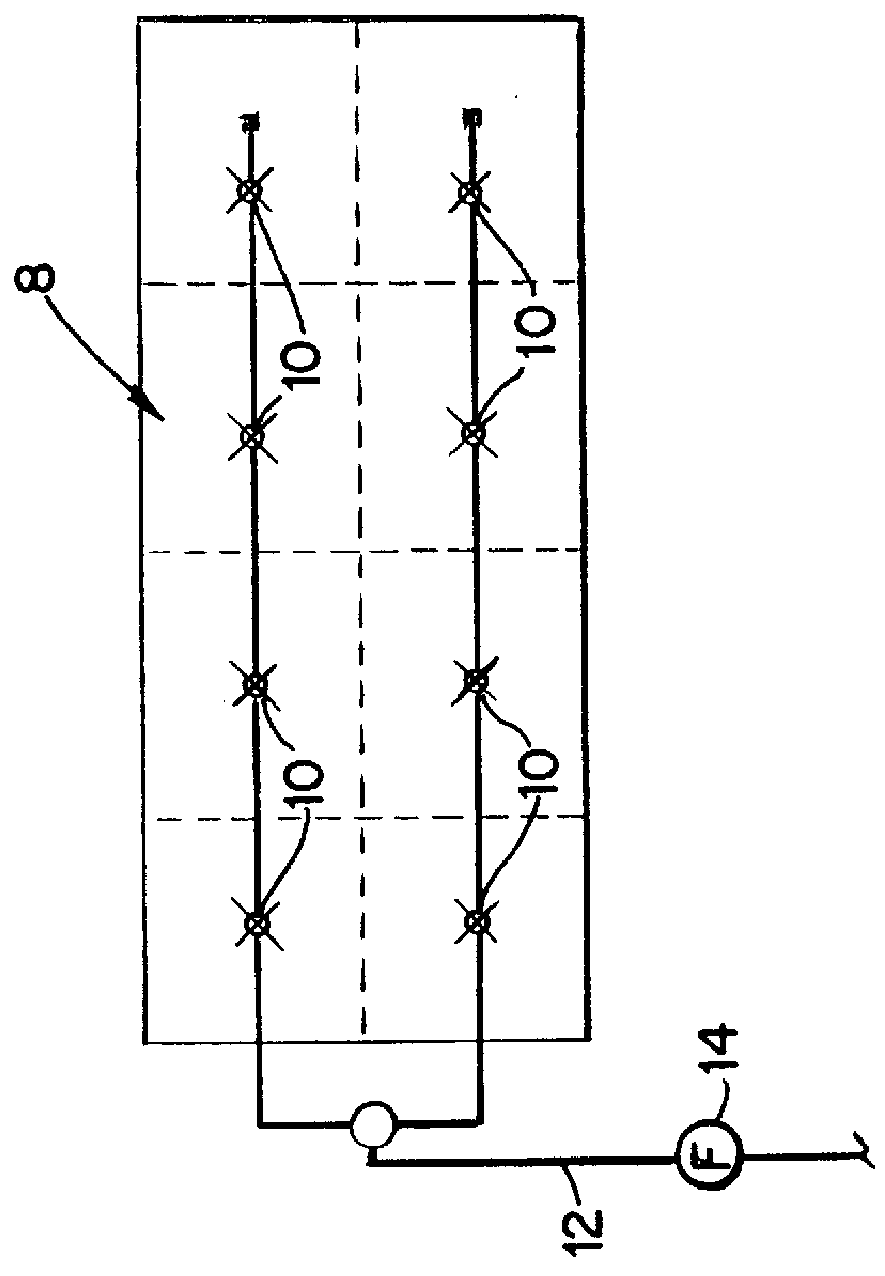

Indirect supplemental evaporation cooler

InactiveUS6141986ARemove heatEasy to eliminateFree-cooling systemsStationary conduit assembliesEvaporative coolerEvaporation

A cooler for an air conditioning system or other system having a heated surface to be cooled has an array of nozzles for issuing a fine spray of liquid. A fan of the cooler induces flow of air over a surface to be cooled, the nozzles issuing into the flow of air the fine spray at a distance from the heated surface such that the liquid of the fine spray is fully evaporated prior to contact with the heated surface. Drop sizes of 20 to 30 microns are typical.

Owner:X NTH INC

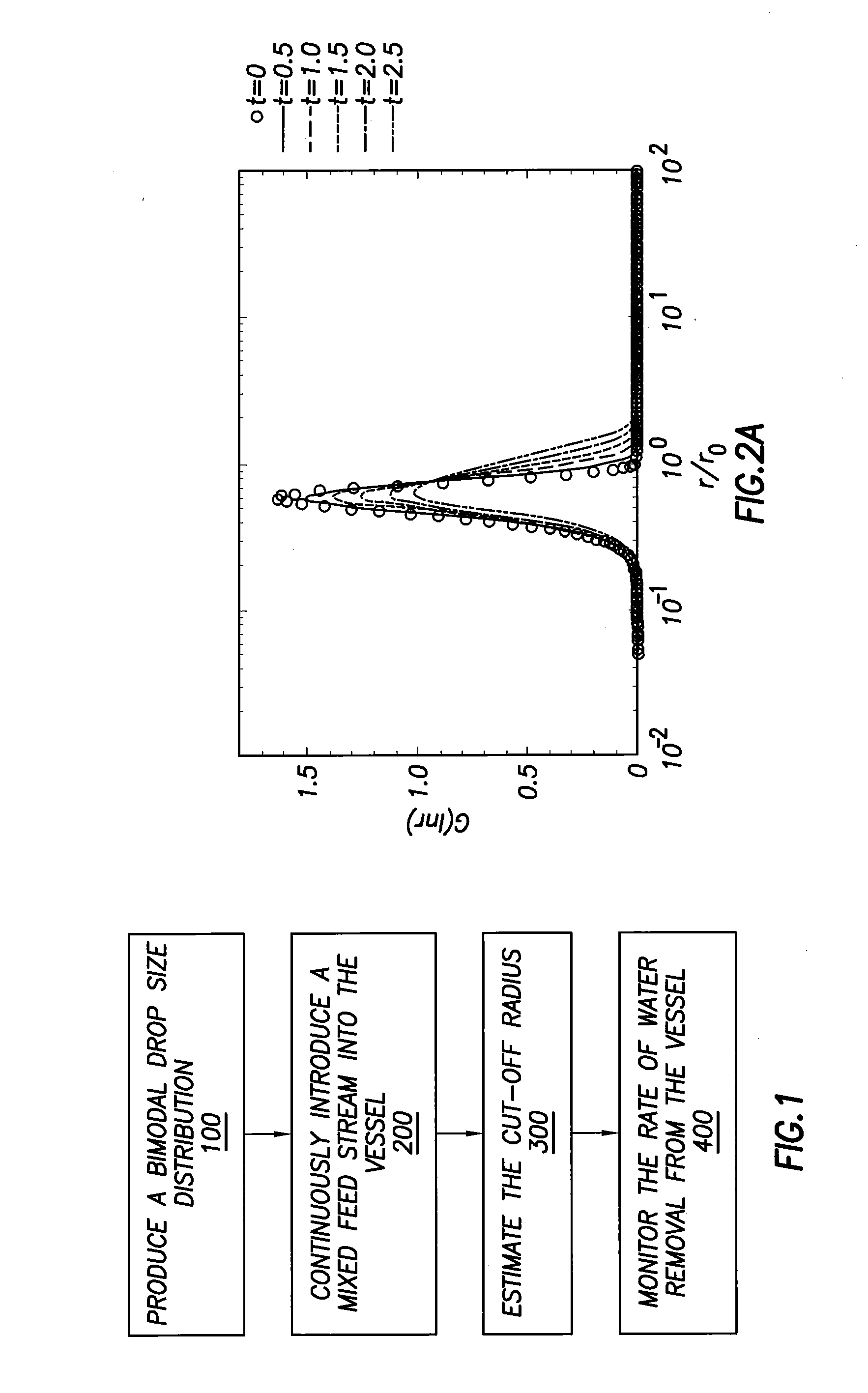

Generating probabilistic estimates of rainfall rates from radar reflectivity measurements

ActiveUS20170075034A1Rainfall/precipitation gaugesData processing applicationsExternal dataRadar reflectivity

A method and system for generating probabilistic estimates of precipitation intensity from radar reflectivity measurements is provided. In an embodiment, an agricultural intelligence computer system receives radar reflectivity measurements for a particular location from an external data source. The agricultural intelligence computer system constructs a probability distribution of drop sizes describing the probability that the precipitation included drops of various sizes based on the radar reflectivity measurements. The agricultural intelligence computer system samples a plurality of values from the probability of distribution of drop sizes and uses the plurality of values and the radar reflectivity measurements to compute a plurality of rainfall rates. Based on the plurality of rainfall rates, the agricultural intelligence computer system constructs a probability distribution of rainfall rates for the particular location.

Owner:THE CLIMATE CORP

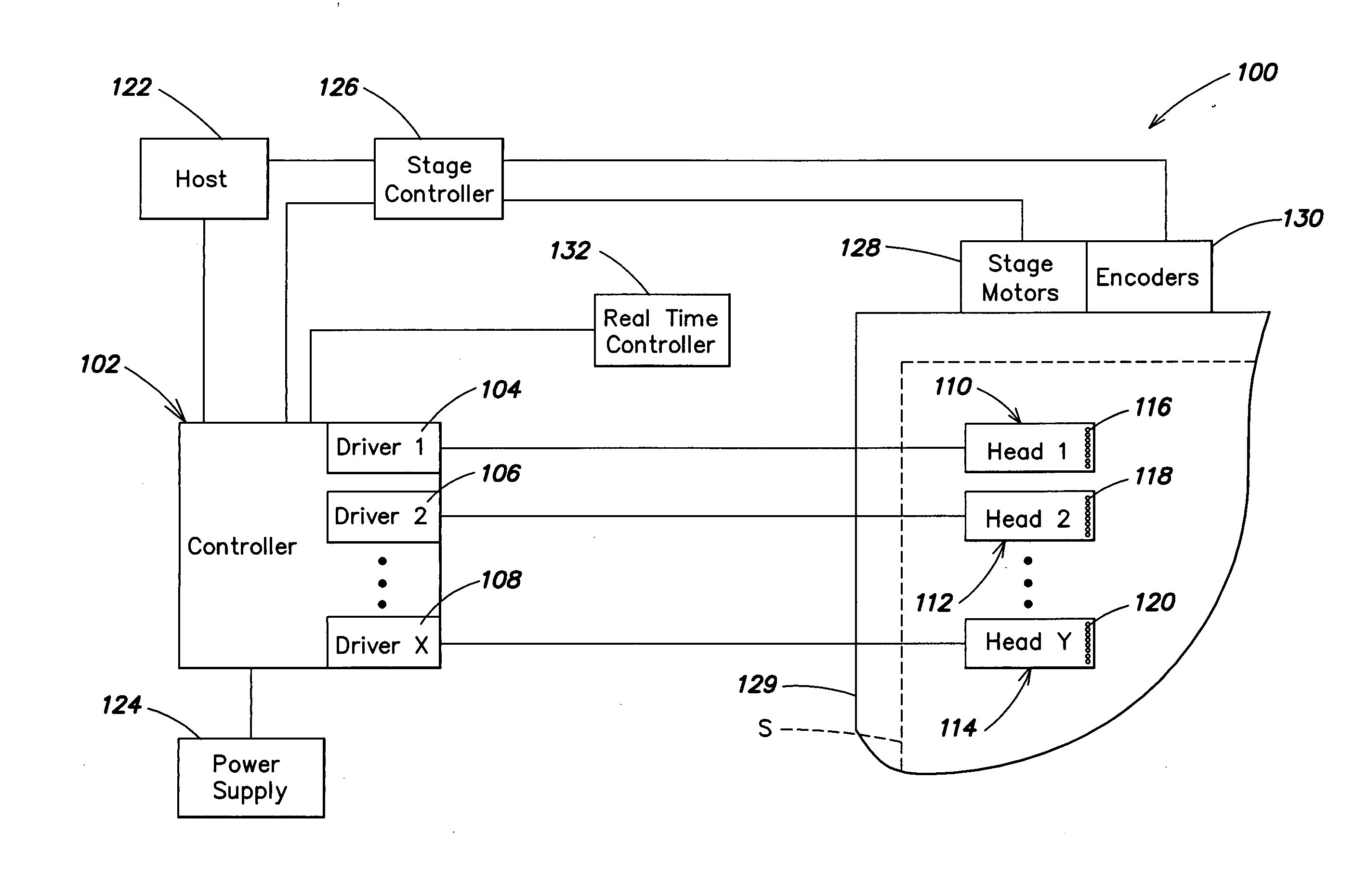

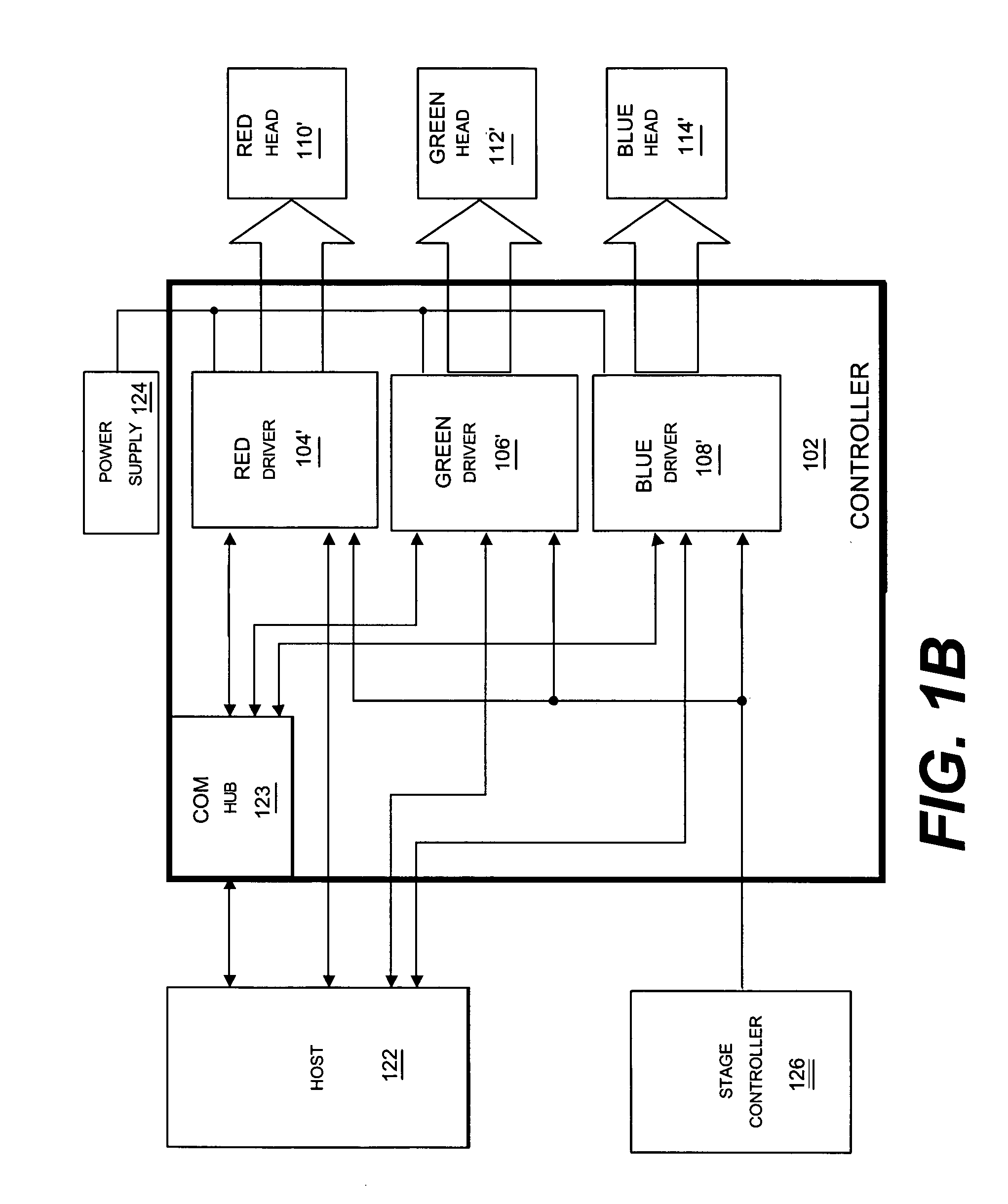

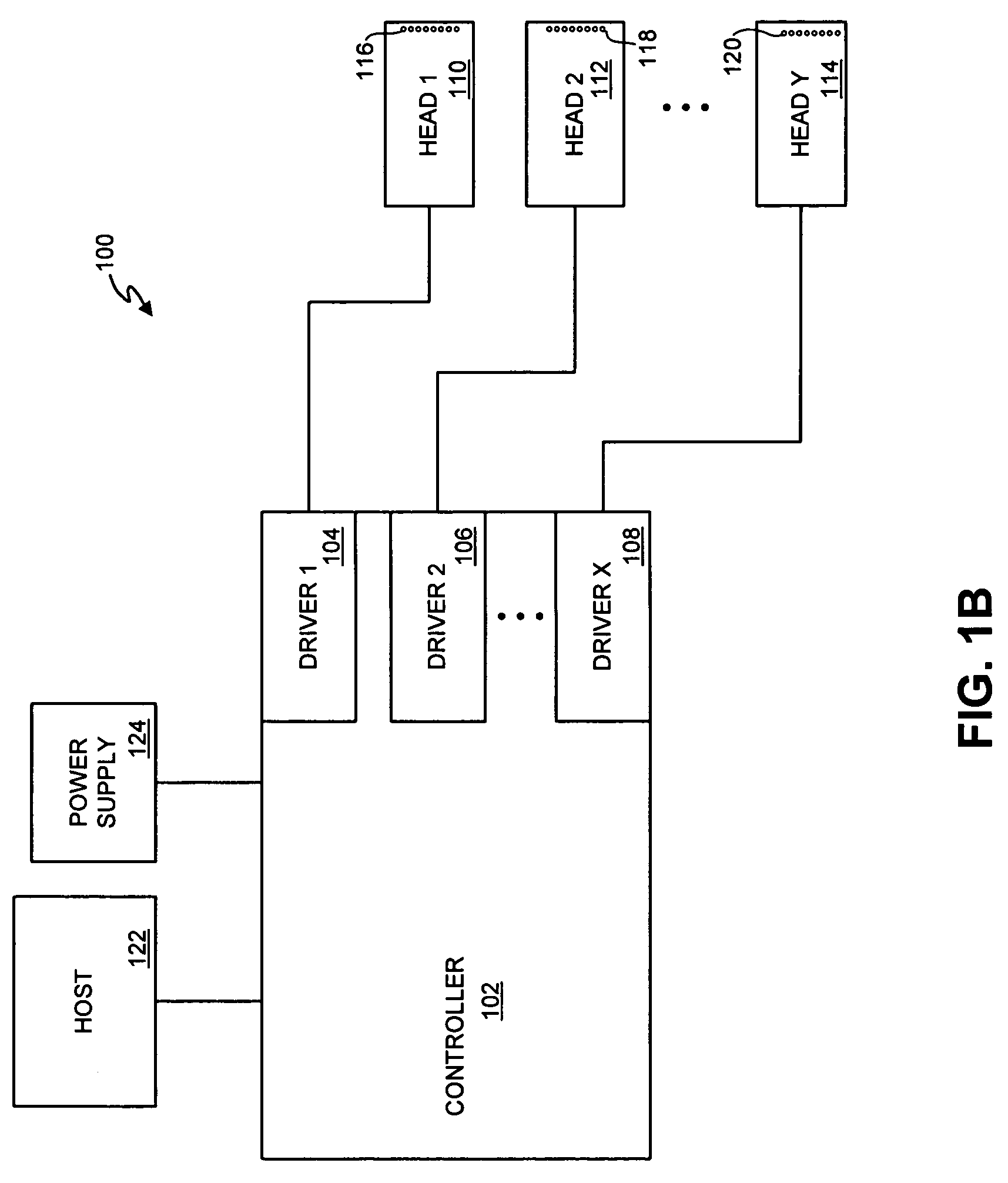

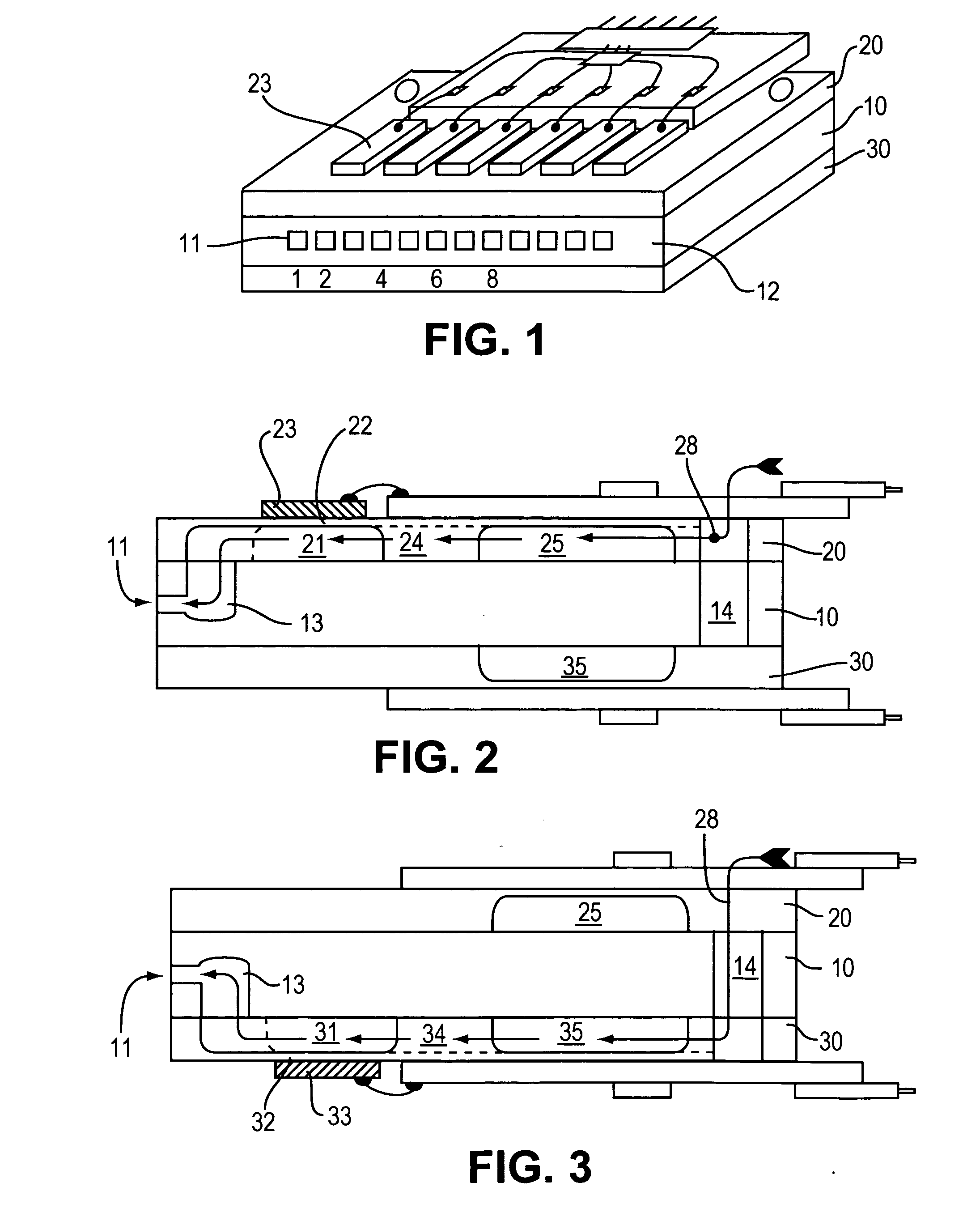

Methods and apparatus for a high resolution inkjet fire pulse generator

InactiveUS20060109290A1Efficiently and accurately depositAdd dimensionTypewritersPower drive mechanismsData fileEngineering

Owner:APPLIED MATERIALS INC

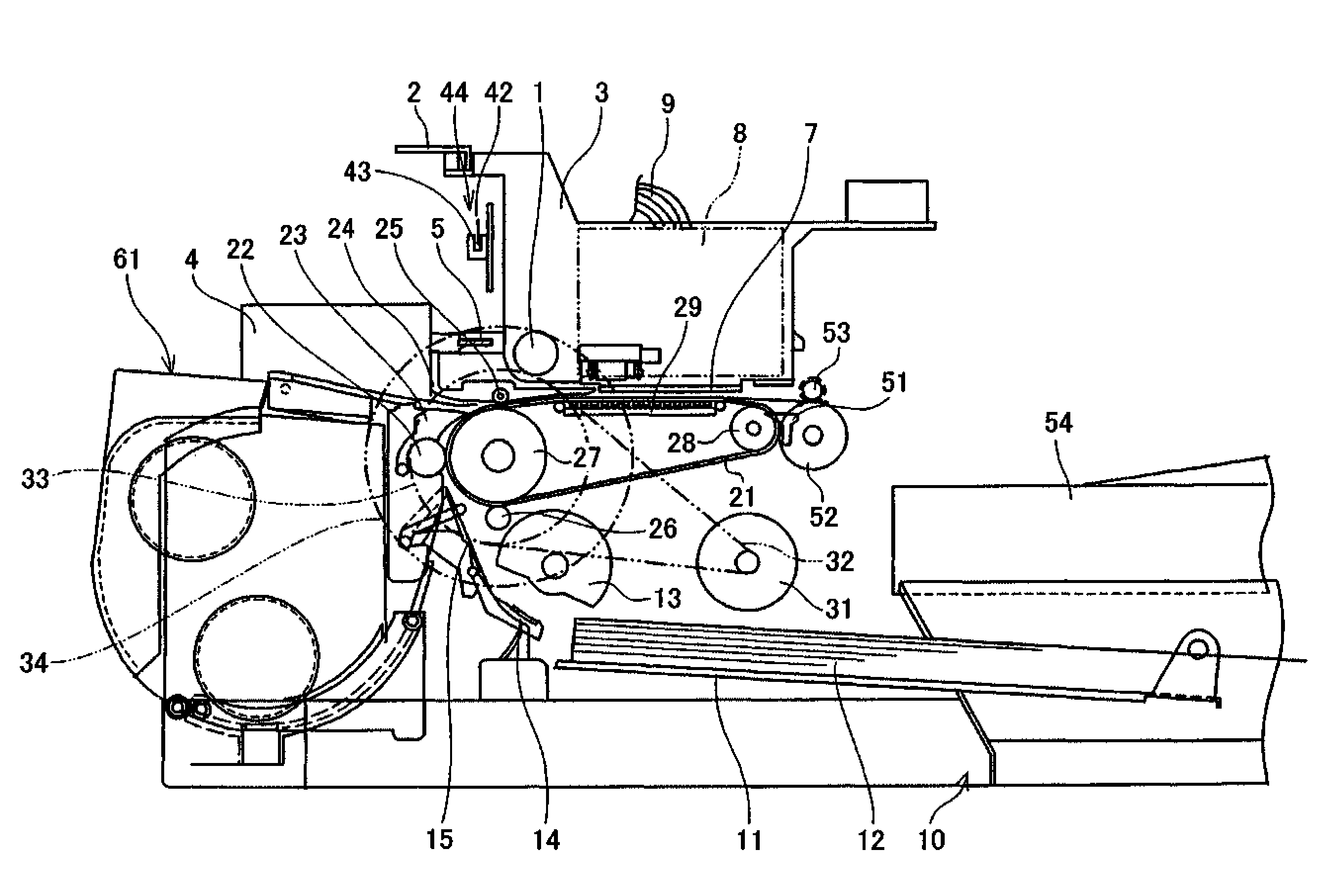

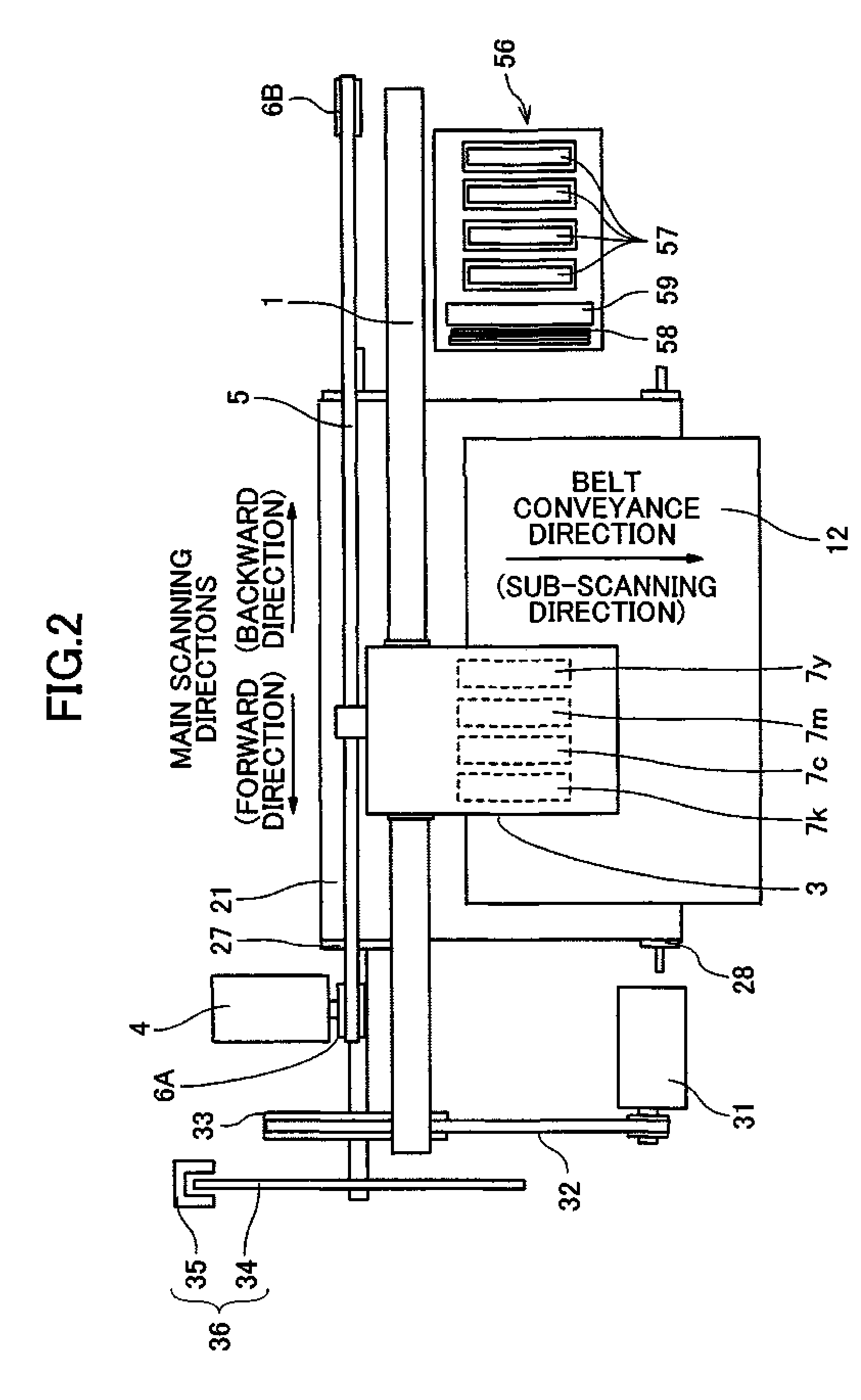

Image processing method, program, recording medium, image processing device, and image forming apparatus

InactiveUS20080117467A1Digitally marking record carriersDigital computer detailsImaging processingImage formation

An image processing method configured to produce image data output from an image forming apparatus configured to form an image by using a recording head composed of a liquid ejecting head having plural arranged nozzles configured to eject a liquid drop and an energy generating device configured to generate ejection energy corresponding to each nozzle while conducting a halftone processing configured to covert input image data to an N value which is less than a tone (M value) thereof (N value: M>N≧2) is provided, wherein a halftone processing configured to substantially reduce a driving frequency of a driving wave pattern applied to the energy generating device is conducted when a liquid drop with a drop size causing ejection irregularity or a liquid drop from a nozzle causing ejection irregularity is ejected.

Owner:RICOH KK

Surface treatments and coatings for atomization

InactiveUS20090283611A1Promote atomizationReduce mean drop sizeLiquid spraying apparatusMedical atomisersNon wettingInstability

An atomizer, comprising a pre-filming region comprising a surface configured to reduce a mean drop size of a liquid to be atomized, wherein the surface has an effective contact angle, with reference to the liquid, of less than about 30 degrees; and a lip portion disposed at an end of the pre-filming region and configured to create hydrodynamic instabilities in a liquid film, wherein the lip portion comprises an alternating pattern of wetting and non-wetting surfaces, wherein the non-wetting surface comprises a contact angle, with reference to the liquid, of greater than 90 degrees, and the wetting surface comprises a contact angle, with reference to the liquid, of less than 90 degrees.

Owner:GENERAL ELECTRIC CO

Method for operating an air-breathing engine

ActiveUS7340902B2Avoid negative effectsAvoid disadvantagesGas turbine plantsJet propulsion plantsMeasurement deviceControl system

When operating an air-breathing engine, a liquid is injected in atomized form into an air intake duct of the engine. A measurement apparatus for determining the injected drop size or the drop concentration is arranged in or on the intake duct downstream of the location of the injection. These measured values are input into a control system, which controls suitable parameters of the injection apparatus in such a manner that the determined variables are controlled to desired values or into desired value ranges.

Owner:ANSALDO ENERGIA SWITZERLAND AG

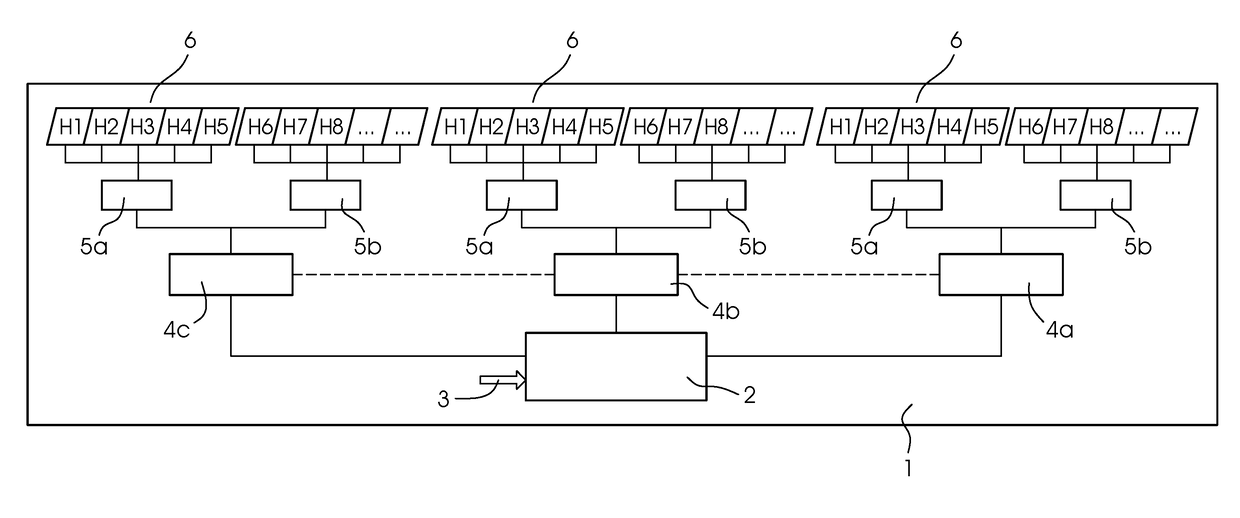

Methods and apparatus for precision control of print head assemblies

The present invention provides methods and apparatus for controlling the quantity of fluid output (e.g., drop size) by individual nozzles of a print head to a very high precision at a frequency equal to the frequency at which fluid is normally dispensed. This is achieved by mapping fluid quantity control information into the data that represents the image to be printed. Data representative of an image is received and converted into pixel data. In at least one embodiment, the pixel data includes pixels represented by N bits, and the N bits may represent a drop size for the pixel and a union of the N bits may represent a nozzle status. A print head may be controlled based on the pixel data, and the print head may include nozzles that are each adapted to deposit at least one drop size quantity of a fluid on a substrate.

Owner:APPLIED MATERIALS INC

Methods and apparatus for precision control of print head assemblies

The present invention provides methods and apparatus for controlling the quantity of fluid output (e.g., drop size) by individual nozzles of a print head to a very high precision at a frequency equal to the frequency at which fluid is normally dispensed. This is achieved by mapping fluid quantity control information into the data that represents the image to be printed. Data representative of an image is received and converted into pixel data. In at least one embodiment, the pixel data includes pixels represented by N bits, and the N bits may represent a drop size for the pixel and a union of the N bits may represent a nozzle status. A print head may be controlled based on the pixel data, and the print head may include nozzles that are each adapted to deposit at least one drop size quantity of a fluid on a substrate.

Owner:APPLIED MATERIALS INC

Image processing method, image processing apparatus, image forming apparatus, image forming system, and storage medium

ActiveCN102083628APrevent sprayingSize removes one or more oversized ink drops or reducesPrintingPictoral communicationImaging processingImage formation

The present invention provides an image processing method including a conversion step of converting multilevel data of an image into a dot pattern using a multilevel error diffusion process. The conversion step includes the steps of determining a pixel corresponding to an abnormal nozzle based on abnormal nozzle information provided for each of droplet sizes supported by nozzles of an image forming apparatus; preventing jetting of a droplet onto the determined pixel; distributing a quantization error of the determined pixel calculated in the multilevel error diffusion process to neighboring pixels; and if extra- large droplets with a droplet size greater than the droplet size of a full-size droplet capable of filling a pixel are to be formed in the neighboring pixels as a result of distributing the quantization error, removing one or more of the extra-large droplets or reducing the droplet size of one or more of the extra-large droplets.

Owner:RICOH KK

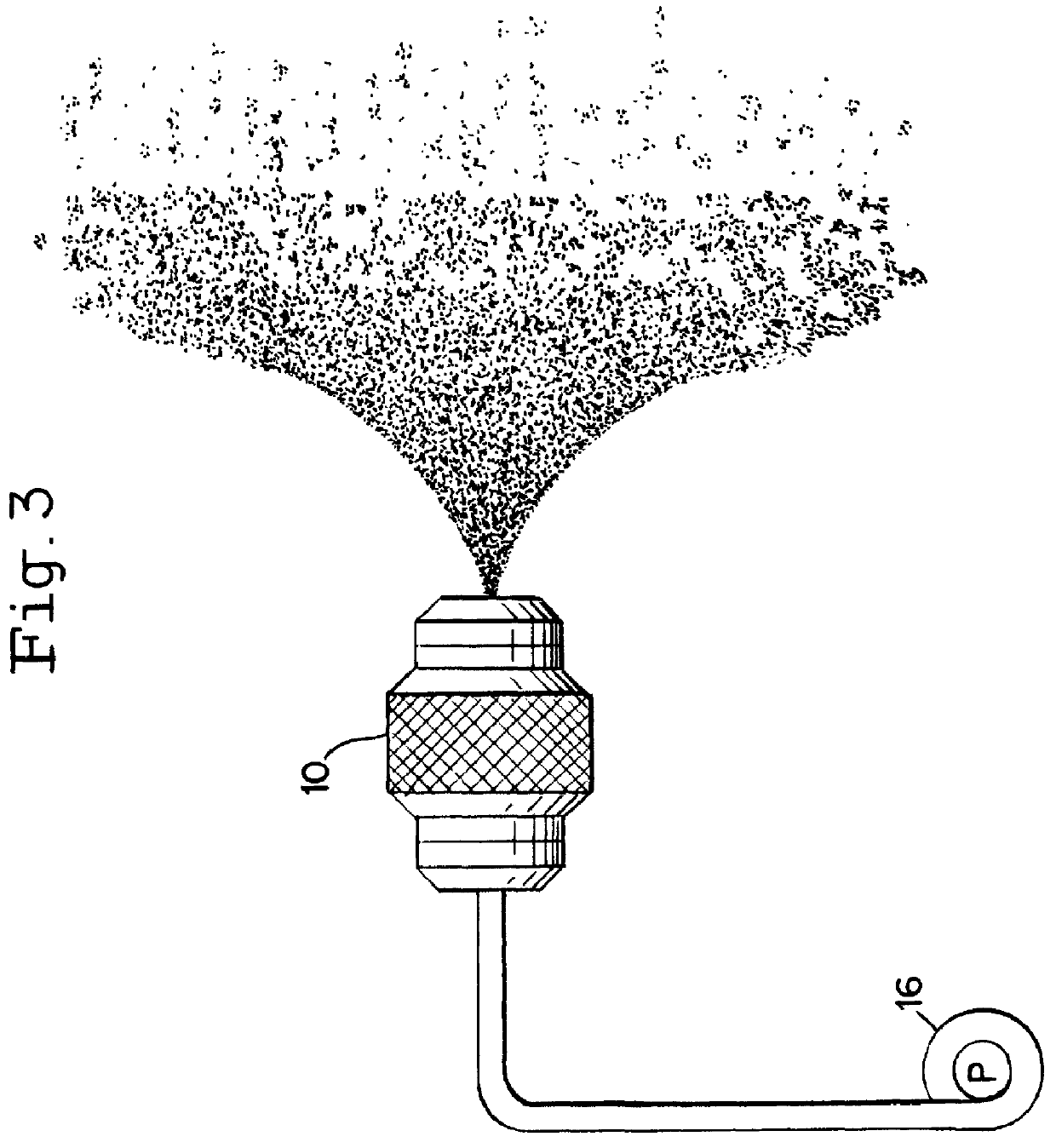

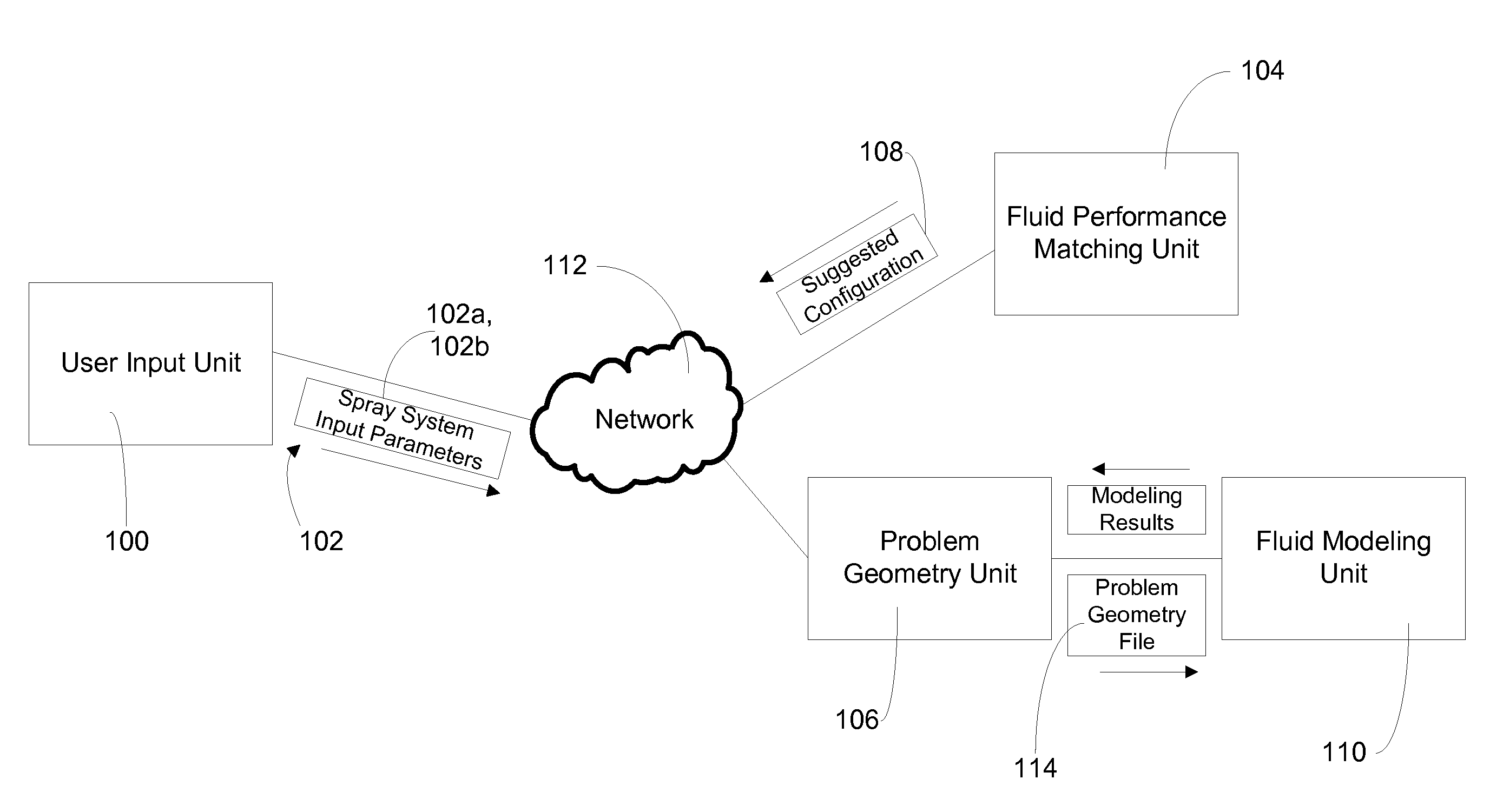

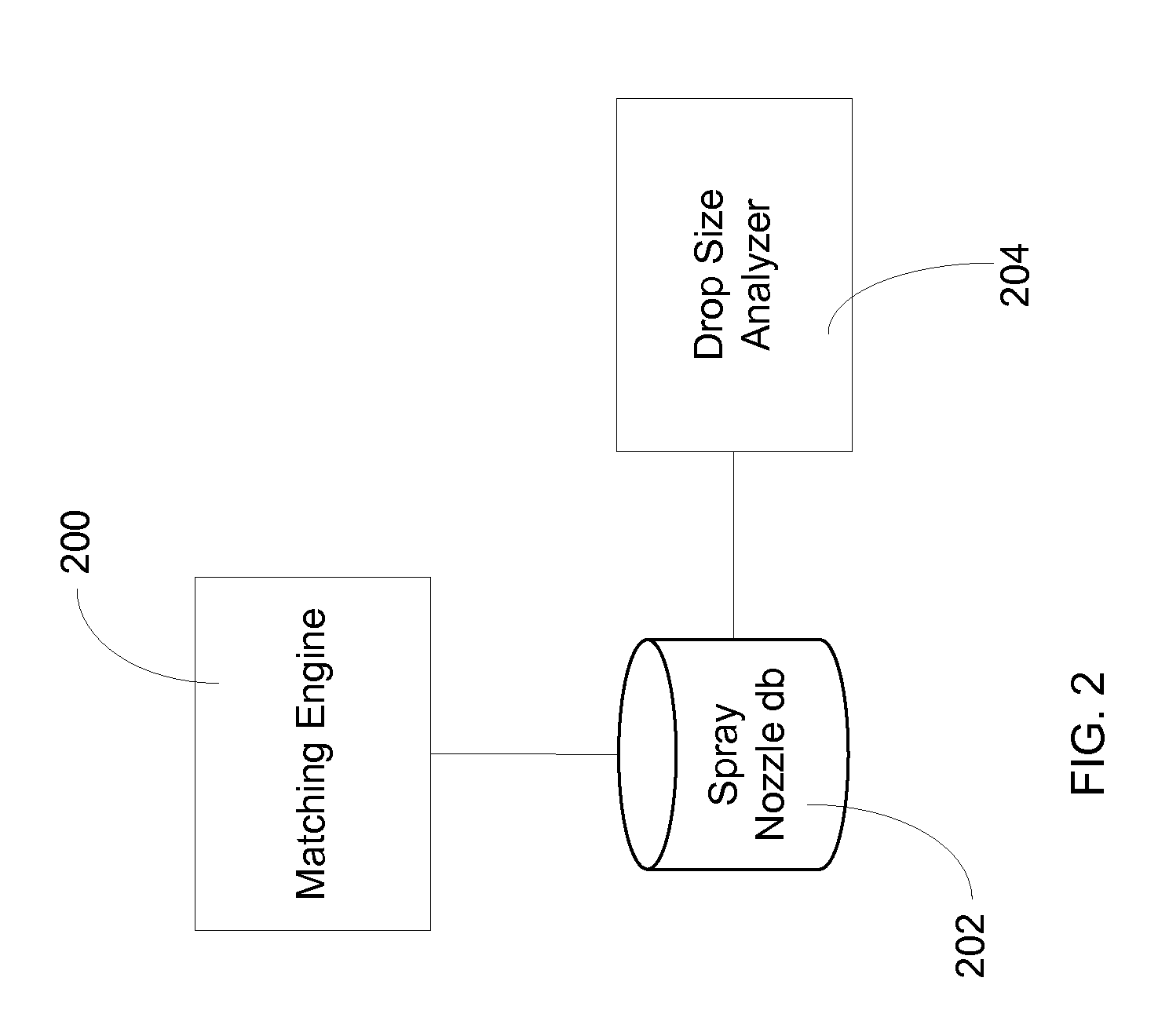

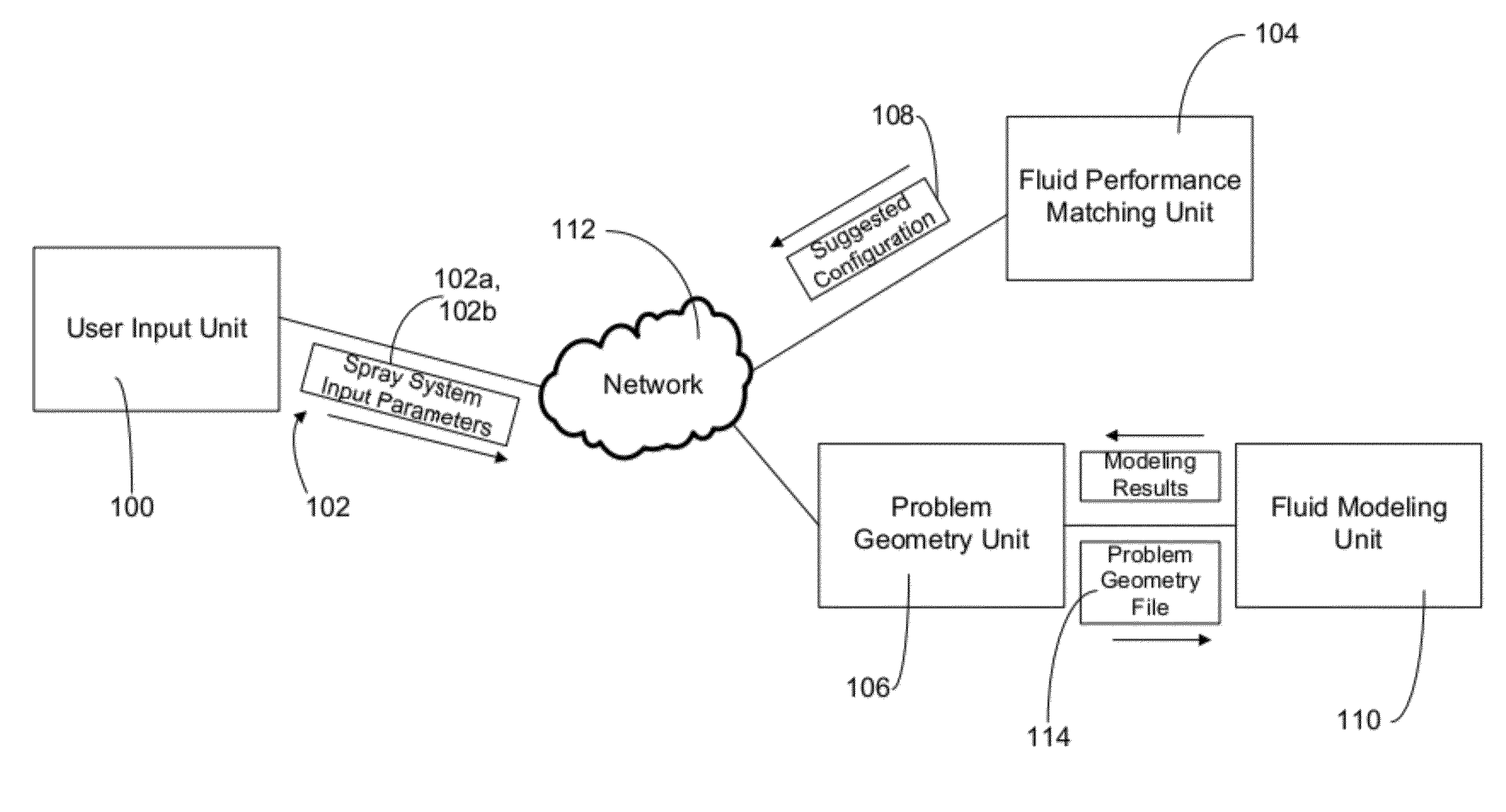

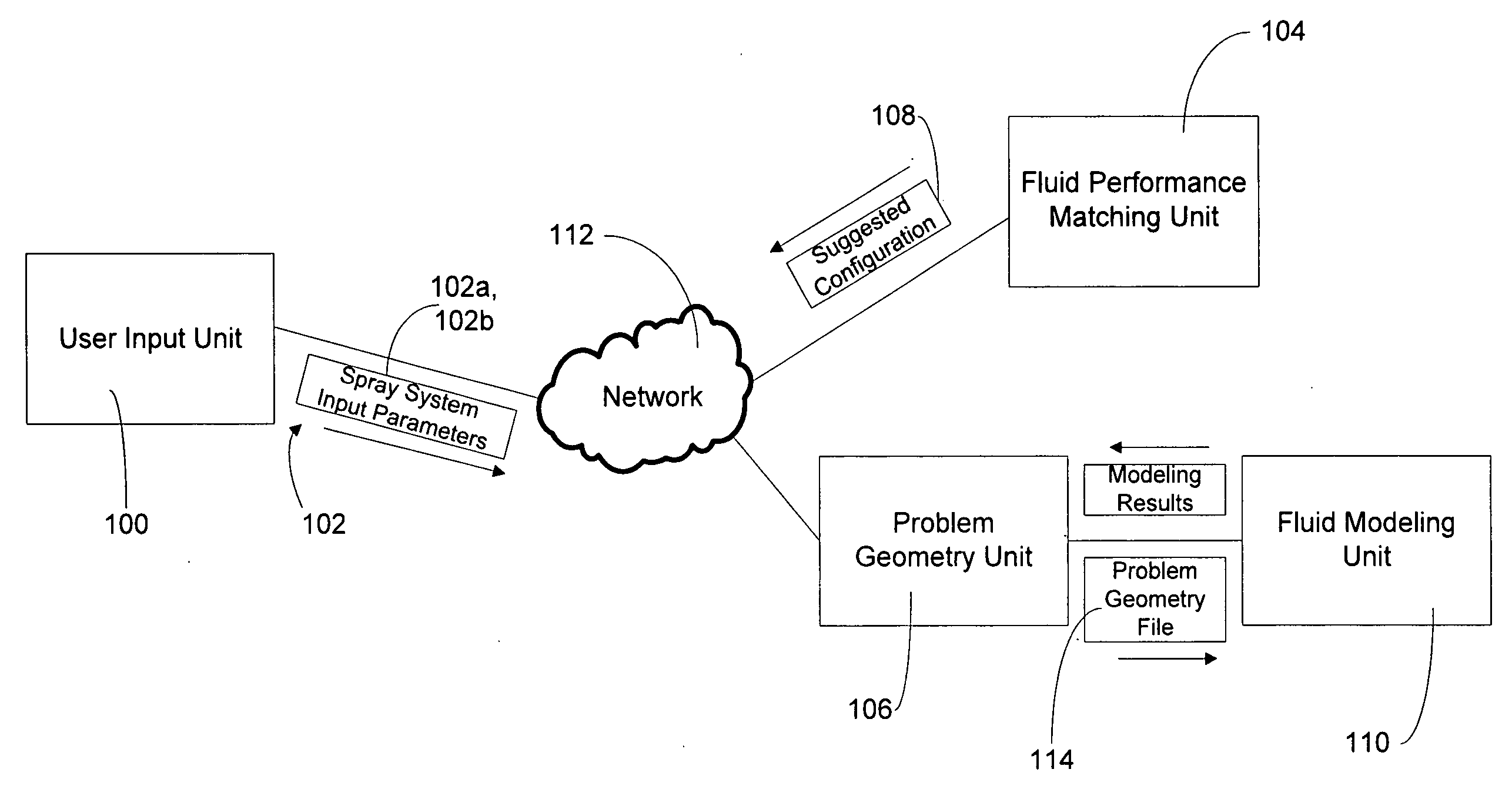

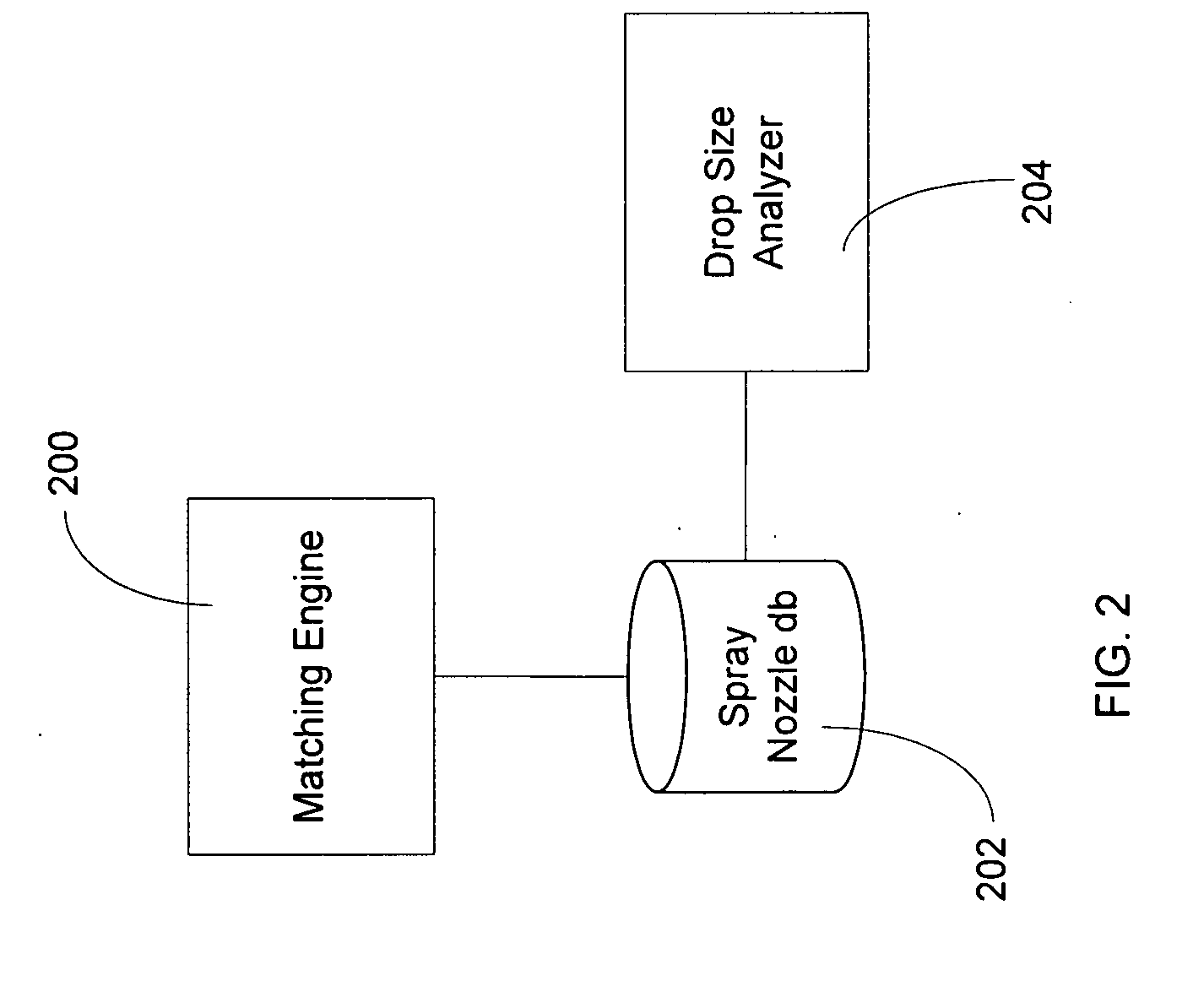

Spray nozzle configuration and modeling system

ActiveUS20100121620A1Facilitates automatic creationSure easyMovable spraying apparatusComputation using non-denominational number representationUser inputEngineering

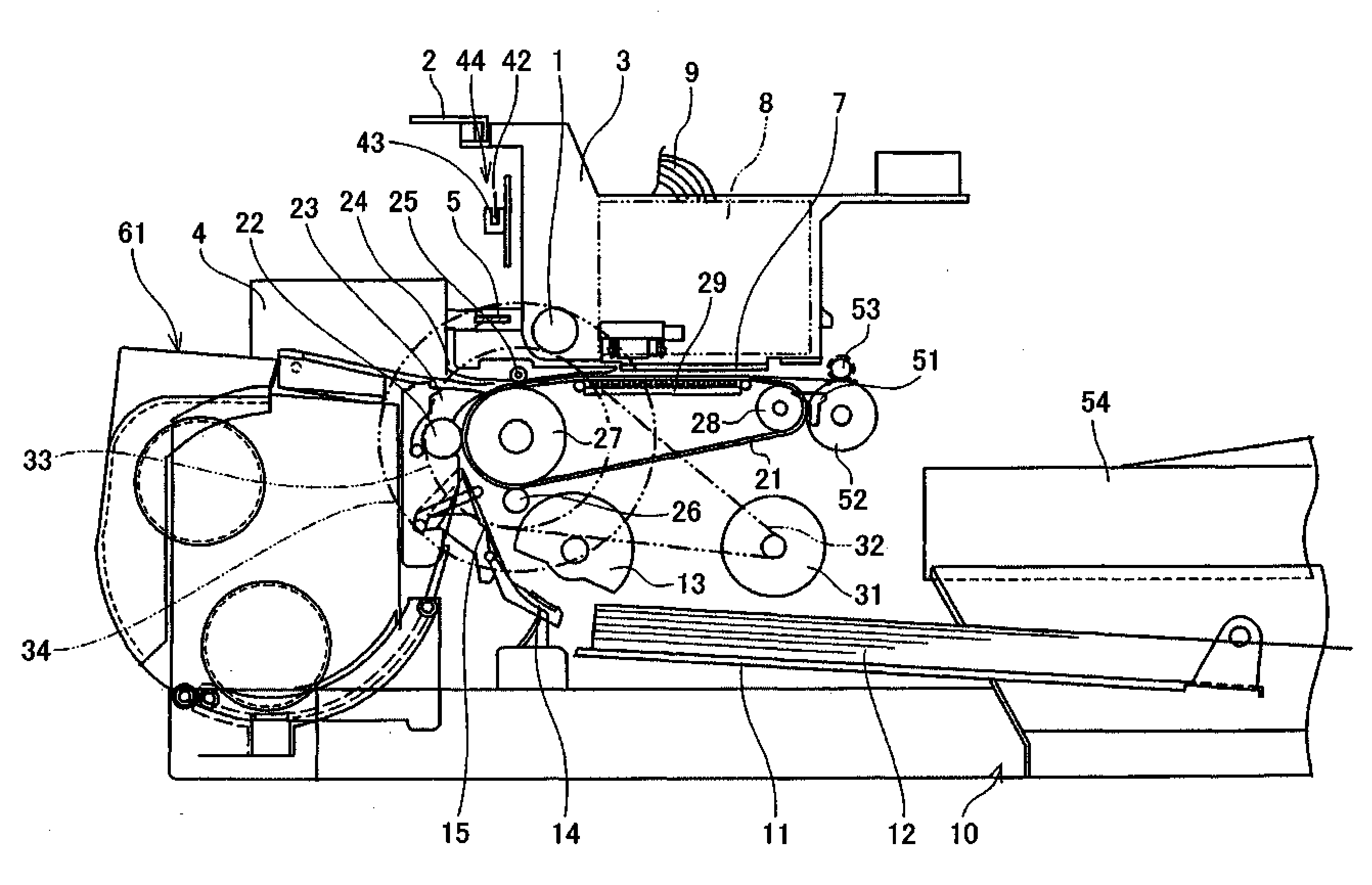

A spray injection analysis and nozzle configuration system is described having a user input unit that collects spray system input parameters and relays the collected parameters to a fluid performance matching unit and / or problem geometry unit for subsequent processing. The user inputs basic system parameters, including the desired spray fluid characteristics, to obtain suggested system configuration, including spray nozzle types and quantities. Accuracy of suggested spray nozzle type and configuration is increased via approximating the viscosity and / or surface tension parameters of the desired spray fluid with that of collected performance data. When a user already knows the desired spray nozzle type and associated system parameters, the user input unit routes this information to the problem geometry unit for creation of a problem geometry file, including calculation of the drop size distribution and spray velocity, and performance modeling via the fluid modeling unit.

Owner:SPRAYING SYST

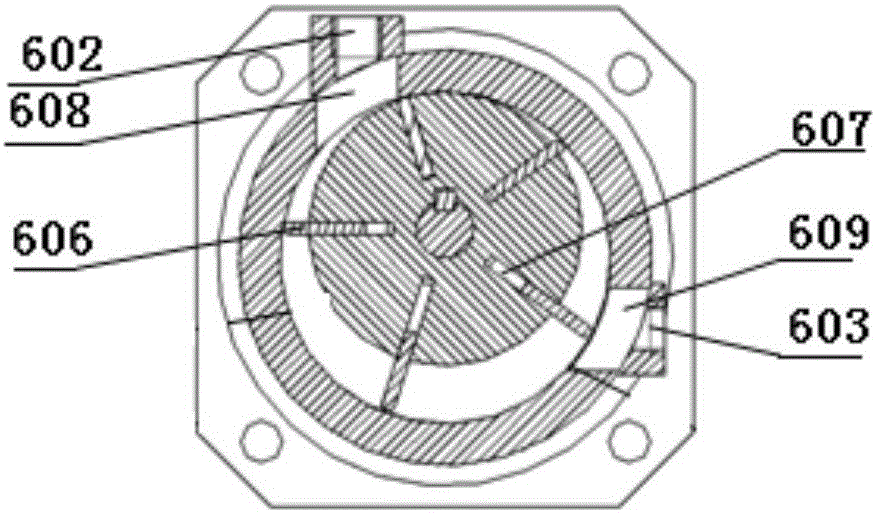

Minimal quantity lubricating system device

ActiveCN105834826AAdjust the rotation speedAdjust the jet speedMaintainance and safety accessoriesFuel tankCheck valve

The invention provides a minimal quantity lubricating system device. The device comprises a box, an oil way system, a gas way system, a power system and an injection system. The power system comprises a pneumatic motor and an oil liquid driving assembly. The oil liquid driving assembly comprises a driving base, a rolling body, a sleeve and an end cap B. The oil way system comprises an oil tank, a guide pipe and an oil liquid hose. The gas way system comprises a connector A, a gas flow regulating valve, a gas pipe A, a connector B, a connector C and a check valve. The injection system comprises an injection valve body, a piston, an oil amount regulating handle and an end cap A. The pressure of lubricating oil is regulated by rotating the oil amount regulating handle, so that the injection speed and the oil drop size of the lubricating oil are changed. The flow of compressed air is regulated by rotating the gas flow regulating valve, so that the oil amount of the lubricating oil is changed. The minimal quantity lubricating system device is compact in structure and easy to use, and does not need a power source. The industrial commonly used 0.8-1 MPa compressed air is used as a power source, the oil amount and oil drop size can be regulated, and the minimal quantity lubricating system device can be used for general production fields or anti-explosion special environment.

Owner:东台城东科技创业园管理有限公司

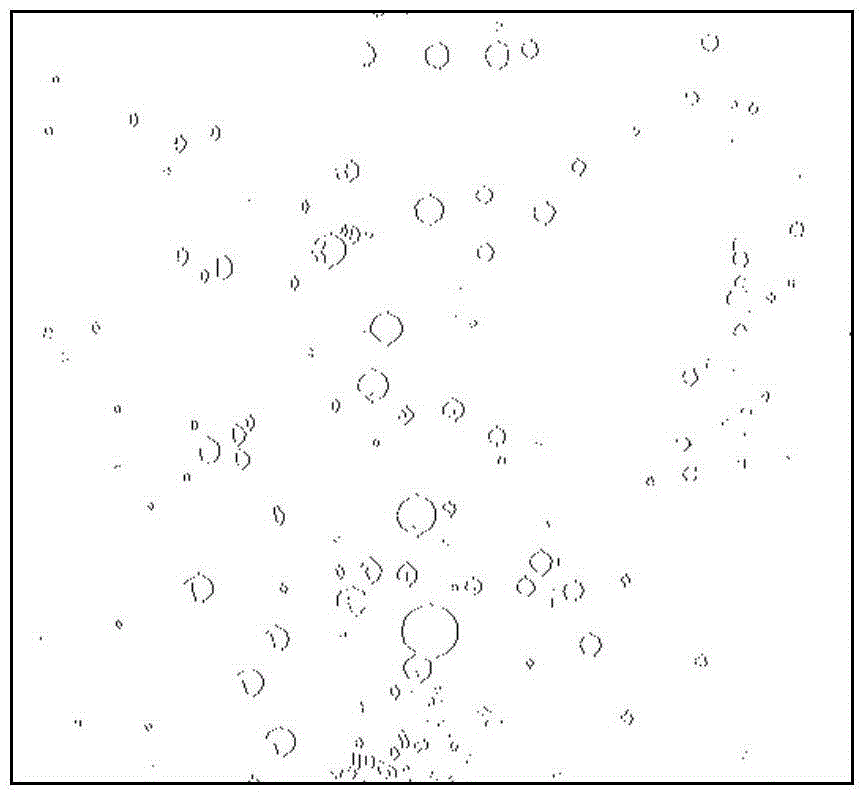

Measuring method of oil drop size

InactiveCN104089857AOvercoming agglomerationOvercoming phenomena such as overlapParticle size analysisEdge extractionOil water

The invention relates to a measuring method of oil drop sizes. The measuring method comprises the steps: manufacturing a two-phase flow fluid sampler, wherein a middle sampling shooting section is shaped like flat cuboid space and is made of transparent materials; connecting both ends of the two-phase flow fluid sampler to a to-be-measured pipeline by flanges, and arranging a high-speed camera lens opposite to two-dimensional surfaces formed by long edges and wide edges of the sampler, so as to shoot fluid in the sampler when oil-water two-phase flow flows across the middle sampling shooting section of the sampler; extracting oil drop edges by utilizing a multi-scale edge detection algorithm; processing the extracted edges and dividing the extracted edges into oil drop adhering images and oil drop non-adhering images; dividing the oil drop adhering images by utilizing a watershed algorithm, and then performing circle fitting operation; directly performing circle fitting operation on the oil drop non-adhering image; integrating two fitting results, so as to obtain an oil drop edge extraction result chart; and calculating the diameter D of each oil drop. By using the measuring method of the oil drop sizes, which is provided by the invention, the size of each oil drop can be accurately measured on the basis of obtaining a high-definition oil-water two-phase flow image.

Owner:TIANJIN UNIV

Spray nozzle configuration and modeling system

ActiveUS8160851B2Sure easyEasy to createMovable spraying apparatusSoftware simulation/interpretation/emulationUser inputEngineering

A spray injection analysis and nozzle configuration system is described having a user input unit that collects spray system input parameters and relays the collected parameters to a fluid performance matching unit and / or problem geometry unit for subsequent processing. The user inputs basic system parameters, including the desired spray fluid characteristics, to obtain suggested system configuration, including spray nozzle types and quantities. Accuracy of suggested spray nozzle type and configuration is increased via approximating the viscosity and / or surface tension parameters of the desired spray fluid with that of collected performance data. When a user already knows the desired spray nozzle type and associated system parameters, the user input unit routes this information to the problem geometry unit for creation of a problem geometry file, including calculation of the drop size distribution and spray velocity, and performance modeling via the fluid modeling unit.

Owner:SPRAYING SYST

Image processing method, program, recording medium, image processing device, and image forming apparatus

InactiveUS8040567B2Digitally marking record carriersVisual representation by matrix printersImage formationComputer science

An image processing method configured to produce image data output from an image forming apparatus configured to form an image by using a recording head composed of a liquid ejecting head having plural arranged nozzles configured to eject a liquid drop and an energy generating device configured to generate ejection energy corresponding to each nozzle while conducting a halftone processing configured to covert input image data to an N value which is less than a tone (M value) thereof (N value: M>N≧2) is provided, wherein a halftone processing configured to substantially reduce a driving frequency of a driving wave pattern applied to the energy generating device is conducted when a liquid drop with a drop size causing ejection irregularity or a liquid drop from a nozzle causing ejection irregularity is ejected.

Owner:RICOH KK

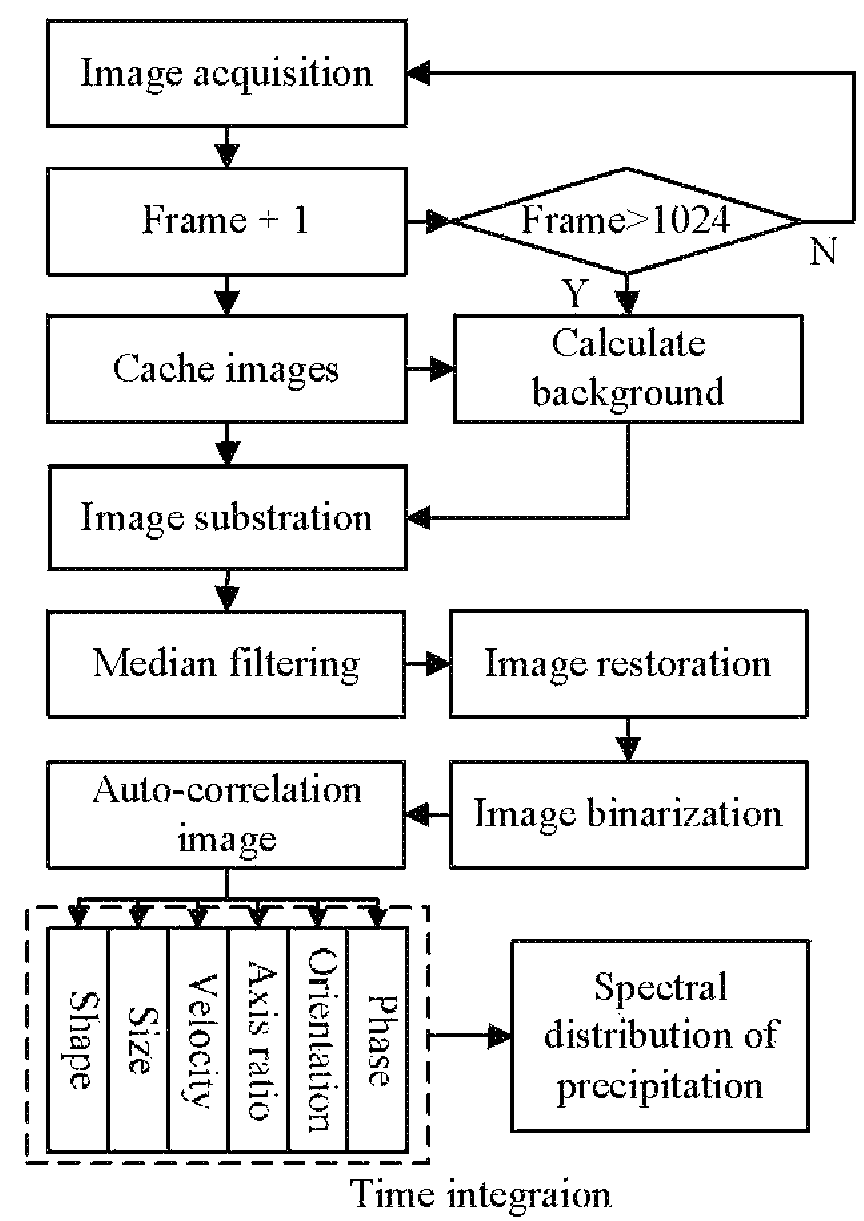

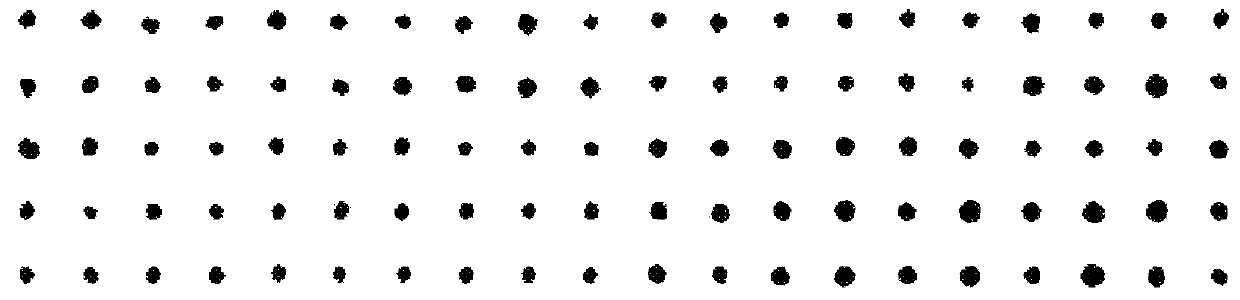

Method for measuring microphysical characteristics of natural precipitation using particle image velocimetry

ActiveUS9342899B2Image can be preventedImage enhancementTelevision system detailsVideo sensorsCcd camera

Owner:PLA UNIV OF SCI & TECH

Fluid jet print module

A print module having nozzles which are centrally disposed in a nozzle face of the module is disclosed. The arrangement of the nozzles is symmetric with respect to fluidic paths in the nozzle plates or chamber plates. The connecting channels between chambers and nozzles can also be symmetric, allowing improved performance and uniformity of drop formation, drop size and drop velocity. The module does not suffer from fluid path differences between chamber plates, uses materials similar to the completed print module without the use of bonding agents such as adhesives, and greatly improves the jetting quality by using uniform or symmetric nozzles. In addition, the print module is slim, flat, robust, and can be slanted in order to increase resolution. A variety of fluids may be dispensed by the print module, including ink. The nozzles and nozzle arrangements in the print module can be made using advanced laser structuring.

Owner:PICOSYS

Frequency correction for drop size control

The present invention provides a method and device for the acoustic ejection of fluid droplets having a constant drop size from fluid-containing reservoirs having varying fluid heights contained therein without the need for repositioning the acoustic ejector in the z direction by adjusting the RF frequency and amplitude. In one embodiment, the device is comprised of: a plurality of reservoirs each adapted to contain a fluid; an ejector comprising a means for generating acoustic radiation, means for controlling the RF frequency and amplitude used to generate the acoustic radiation, means for focusing the acoustic radiation at a focal point near the fluid surface in each of the reservoirs; and a means for positioning the ejector in acoustically coupled relationship to each of the reservoirs. The invention is useful in a number of contexts, particularly in the preparation of biomolecular arrays.

Owner:LABCYTE

Spray nozzle configuration and modeling system

ActiveUS20100121616A1Accurately approximatedSure easySpraying apparatusComputation using non-denominational number representationJet injectionUser input

A spray injection analysis and nozzle configuration system is described having a user input unit that collects spray system input parameters and relays the collected parameters to a fluid performance matching unit and / or problem geometry unit for subsequent processing. The user inputs basic system parameters, including the desired spray fluid characteristics, to obtain suggested system configuration, including spray nozzle types and quantities. Accuracy of suggested spray nozzle type and configuration is increased via approximating the viscosity and / or surface tension parameters of the desired spray fluid with that of collected performance data. When a user already knows the desired spray nozzle type and associated system parameters, the user input unit routes this information to the problem geometry unit for creation of a problem geometry file, including calculation of the drop size distribution and spray velocity, and performance modeling via the fluid modeling unit.

Owner:SPRAYING SYST

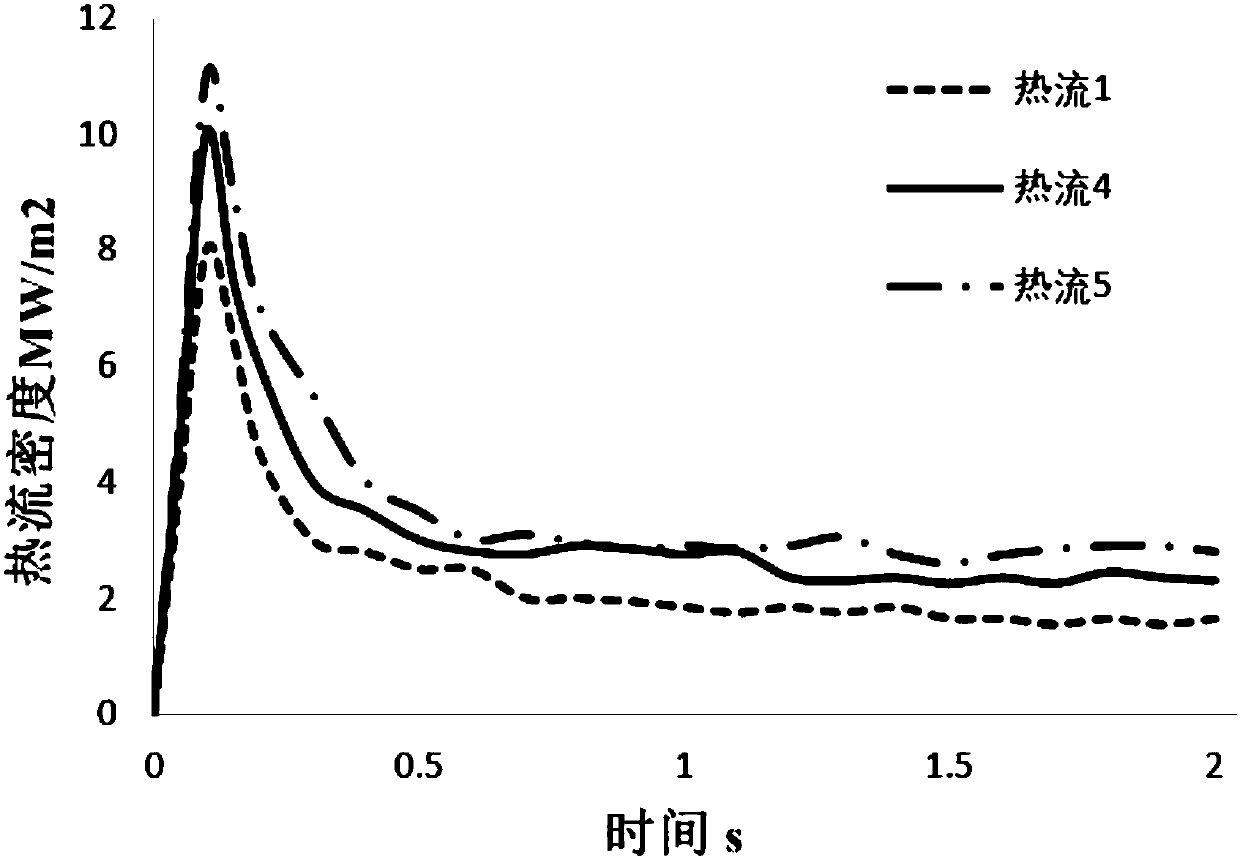

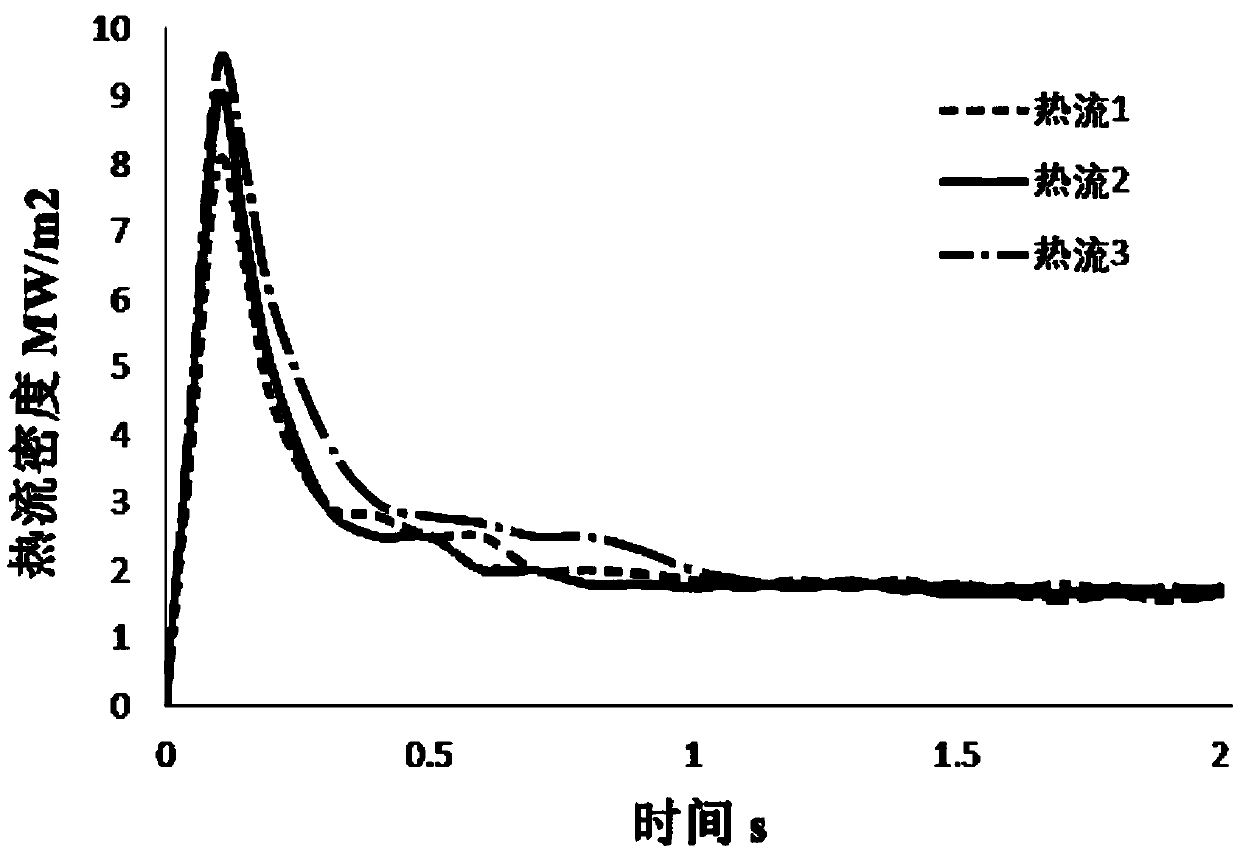

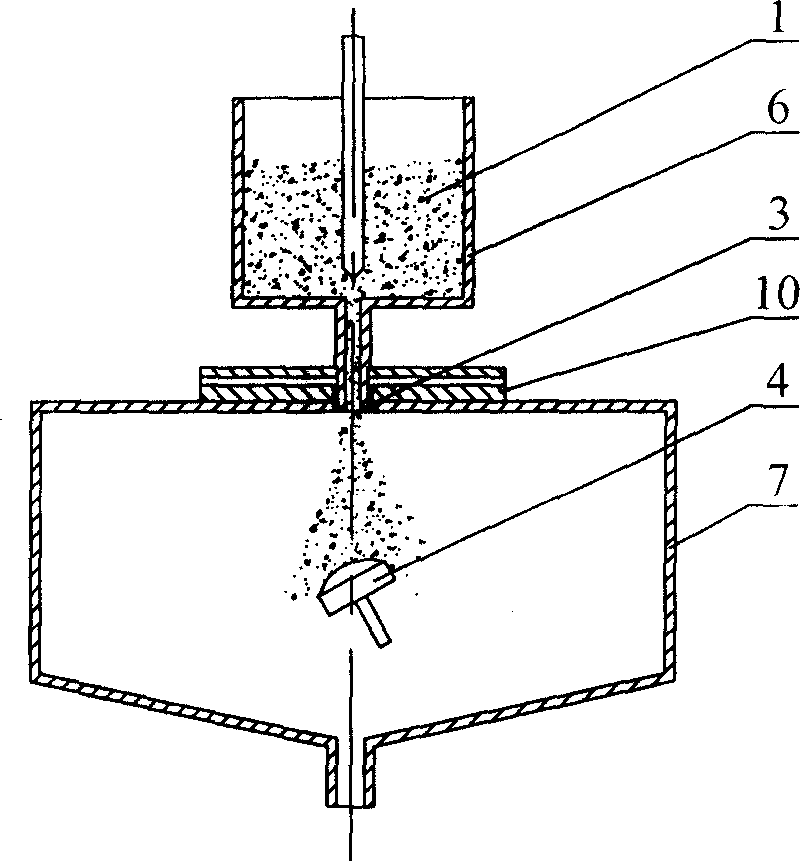

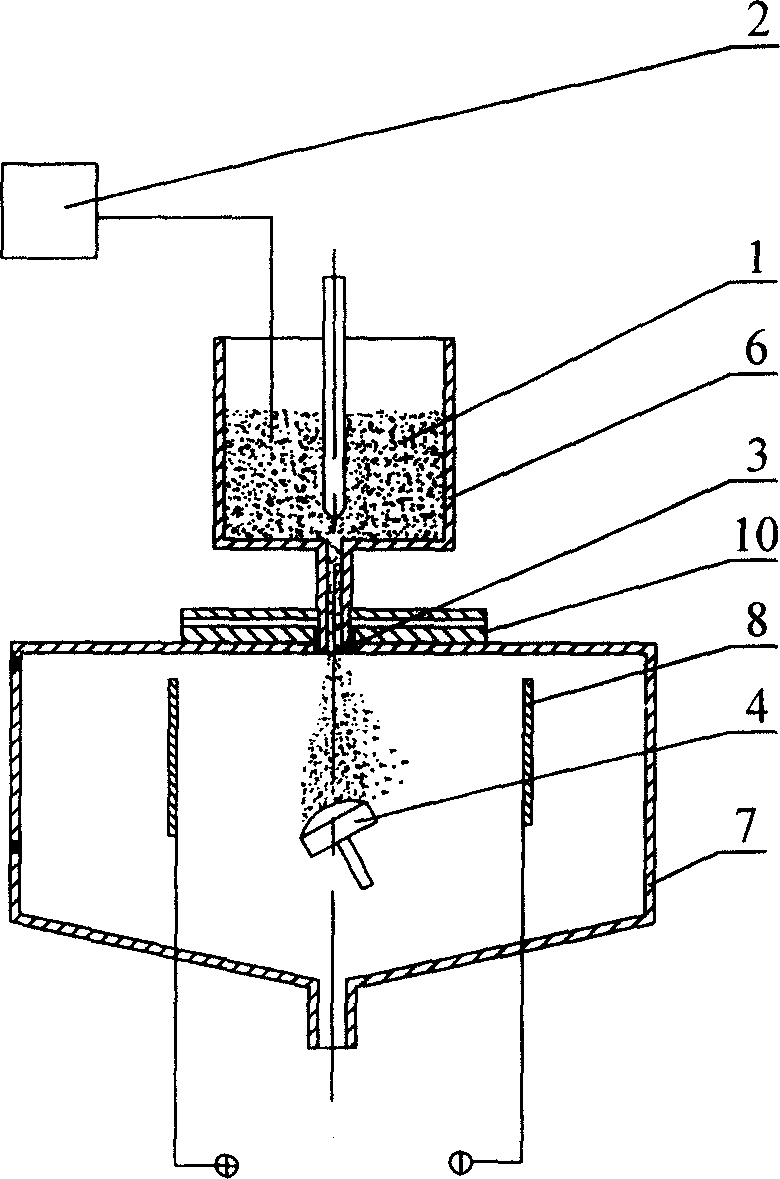

Comprehensive test device and method for rapid solidification heat transfer performance

ActiveCN107643316ADrop speed controlConstant heating temperatureMaterial heat developmentData acquisitionMetal droplets

The invention discloses a comprehensive test device and method for rapid solidification heat transfer performance. The comprehensive test device comprises a metal smelting system, a particle size andspeed control system and a sample collection and measurement system; the metal smelting system comprises a graphite crucible and an infrared thermometer with temperature feedback and is used for heating a metal test sample into liquid; the particle size and speed control system comprises a particle size selector used for controlling dropping size of molten metal droplets and a static electric field used for controlling dropping speed of the molten metal droplets; the sample collection and measurement system comprises a cooling base, a high-speed camera, a thermocouple and a computer and is used for bearing and cooling the metal droplets dropped from the metal smelting system and acquiring data. By the arrangement, low cost and less consumption of materials are achieved, the test method issimple in operation, test results are accurate, initial solidification conditions of the metal droplets in different dropping states (dropping size and dropping speed) can be tested comprehensively, the entire rapid solidification process can be reflected clearly, and high persuasion is achieved.

Owner:CENT SOUTH UNIV

Piezoelectric dispenser with a longitudinal transducer and replaceable capillary tube

ActiveCN106687221AEliminates the need for cleaningEliminate the risk of contaminationSequential/parallel process reactionsLaboratory glasswaresRadial motionPiezoelectric actuators

A dispenser and methods for transferring liquids are disclosed. The dispenser may include a capillary tube with tip having an aperture, a piezoelectric actuator coupled to the capillary tube at a location. Actuation of the piezoelectric actuator causes a pressure wave to propagate along the capillary tube toward the tip such that radial motion at the location is transmitted as distally extending axial motion of the tip, thereby causing a droplet of a predetermined volume to be ejected from the aperture. In some embodiments, the capillary tube has a modulus of elasticity in a range which dampens acoustical noise from the actuation and provides single drop stability over a range of drop sizes.

Owner:BIODOT

Selective metal drop size spray-deposition method

Owner:HARBIN INST OF TECH

Method for density compensation by drop size adaptation

ActiveCN107009770AAvoid Brightness DifferencesEquilibrium volatilityVisual presentationOther printing apparatusMechanical engineeringDrop size

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Methods of printing filter material to fabricate color filter

Owner:PALO ALTO RES CENT INC

Method for preparing gold nanoclusters based on microfluidic chip

ActiveCN106825605ASimple designGood lookingMaterial nanotechnologyTransportation and packagingSynthesis methodsCarbon chain

The invention provides a method for preparing gold nanoclusters based on a microfluidic chip and belongs to the field of gold nanocluster synthesis methods. The method is characterized in that gold nanoclusters which have small monodisperse particle sizes and are protected by an alkyl carbon chain sulfhydryl monolayer are synthesized based on the microfluidic chip, hydrophobic modification is performed on the inner wall of the chip channel, and drops can be stably and smoothly formed and fused accurately and are uniform in size. Meanwhile, by the method, the drop sizes are small, chaotic mixing and mass transfer velocities are high, and reactants are uniformly distributed in the channel to facilitate nucleation and growth of nano-particles. The microfluidic chip is made of a transparent PDMS material, the material formation can be monitored and regulation and control can be performed on line in real time through integration with a microscope, the chip is simple in design, a plurality of groups of parallel reaction channels can be easily constructed, high-throughout synthesis can be performed, and the product yield is improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Joint quantization of drop probability functions in multi-size drop inkjet printers

ActiveUS9643408B1Easy to understandPrintingPictoral communicationNormal densityVolumetric Mass Density

Methods and systems for sequentially quantizing probability density functions for inkjet printing. In an example embodiment, an operation can be implemented to quantize probability density functions associated with larger drops among a plurality of drops provided by an inkjet printer. Non-quantized probability functions associated with remaining ink drops are then modified utilizing an error incurred at each quantization during quantization of the probability density functions associated with the larger drops. Quantizing the probability density functions and modifying the non-quantized probability functions continue until all drop size probability functions associated with the plurality of drops are quantized.

Owner:XEROX CORP

Adsorption decoloring method for vegetable oil

The invention discloses an adsorption decoloring method for vegetable oil. The method includes the steps of: firstly conducting micronization treatment on vegetable oil, then transferring the treated oil into a decoloring tank to conduct adsorption decoloring, and then carrying out filtering. The method provided by the invention combines the conventional adsorption decoloring method with micronization treatment, i.e. firstly conducts micronization treatment on vegetable oil and then carries out adsorption decoloring, not only can reduce the oil drop size of finished vegetable oil product obtained by further refining after decoloring, but also can further effectively improve the decoloring effect.

Owner:玉山县大成仓食品有限公司

Method for density compensation by drop size adaptation

ActiveUS20170217163A1Density fluctuation be correctedQuick and flexibleVisual presentation using printersOther printing apparatusDrop sizeMechanical engineering

A method for modifying color density values in a dot-based printing system uses a control unit. The control unit implements the modification of the color density values after a raster image has been created and modifies the number and / or size of print dots to be applied to a printing substrate in order to attain pre-defined color density target values.

Owner:HEIDELBERGER DRUCKMASHINEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com