Minimal quantity lubricating system device

A system device, micro-lubrication technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of large volume, difficult control of oil mist consumption and oil droplet size, complex structure, etc., and achieve the goal of using Simple, compact, avoid application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0031] Such as figure 1 As shown, a minimal quantity lubrication system device includes a box body 1, an oil system 2, an air system 3, a power system 4 and an injection system 5; the oil system 2, the air system 3, the power system 4 and the injection system System 5 is mounted on box 1 . The oil system 2 includes a fuel tank 201, a conduit 202 and an oil hose 203; the fuel tank 201 is fixed on the top of the tank 1; the upper cover of the fuel tank 201 has a small hole 204; the bottom of the fuel tank 201 is connected to the conduit 202 , the end of the conduit 202 is connected with an oil hose 203 .

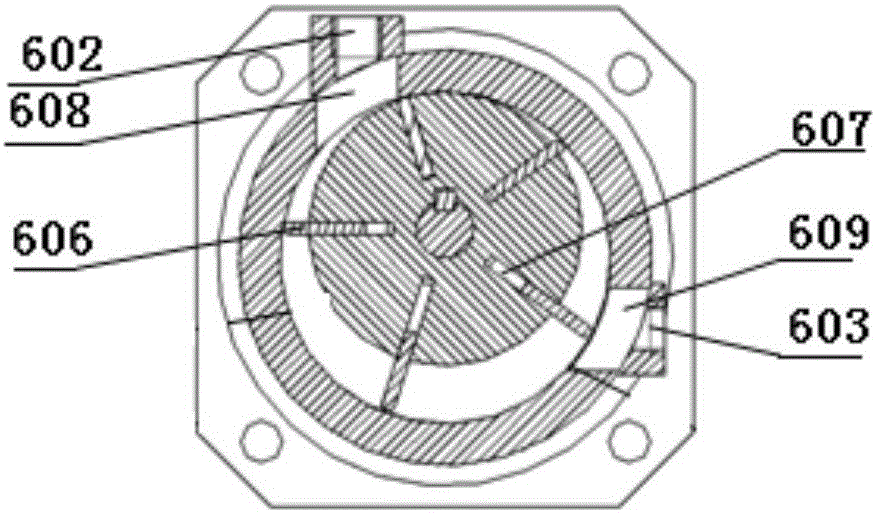

[0032] Such as figure 2 with image 3 As shown, the power system 4 includes an air motor 6 and an oil drive component 7; the air motor 6 is installed on the side pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com