Mortar stirring machine

A mixer and mortar technology, which is used in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of uneven mixing of mortar and rough mortar, and achieve the effect of good mixing effect and uniform mortar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

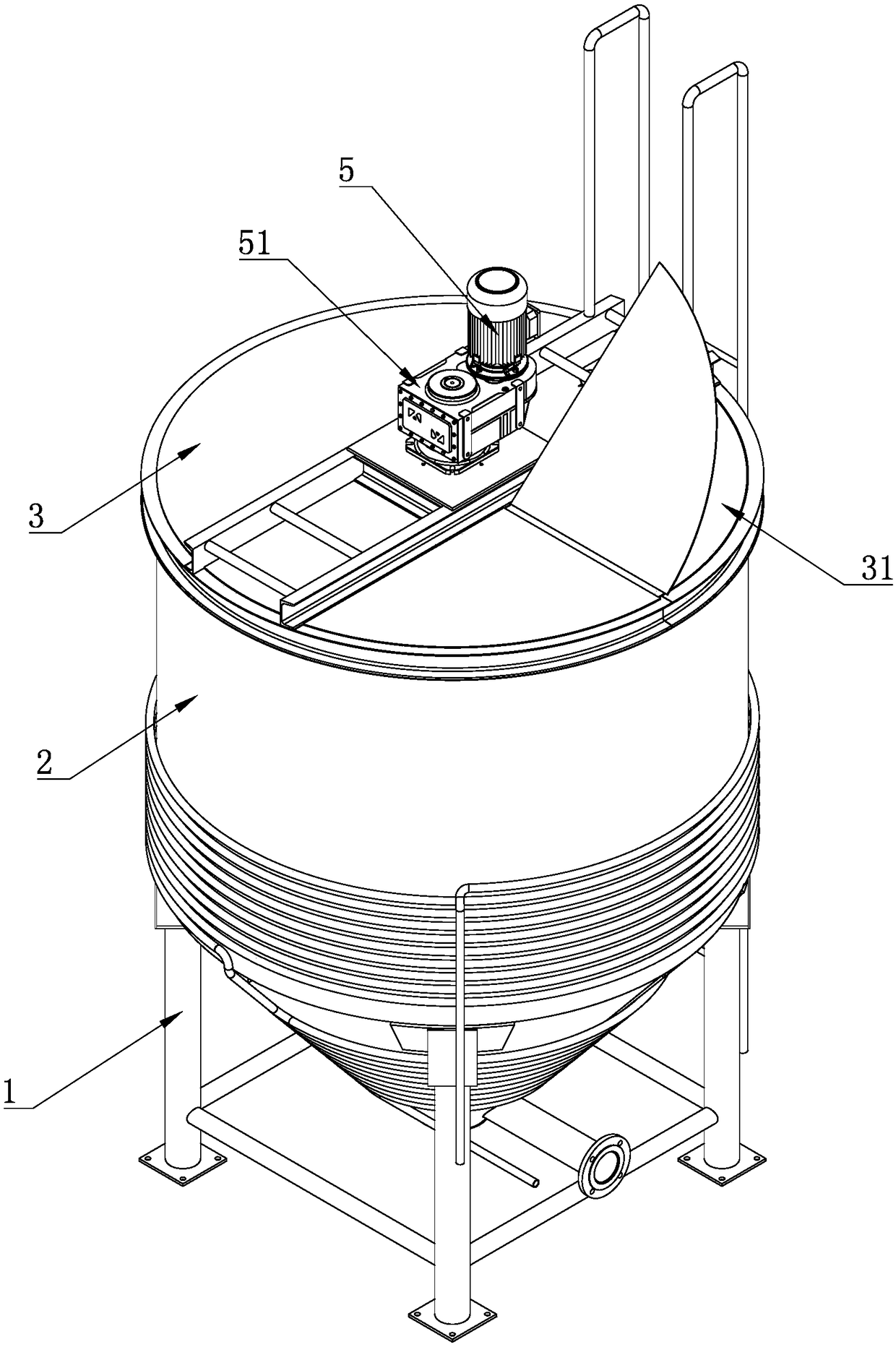

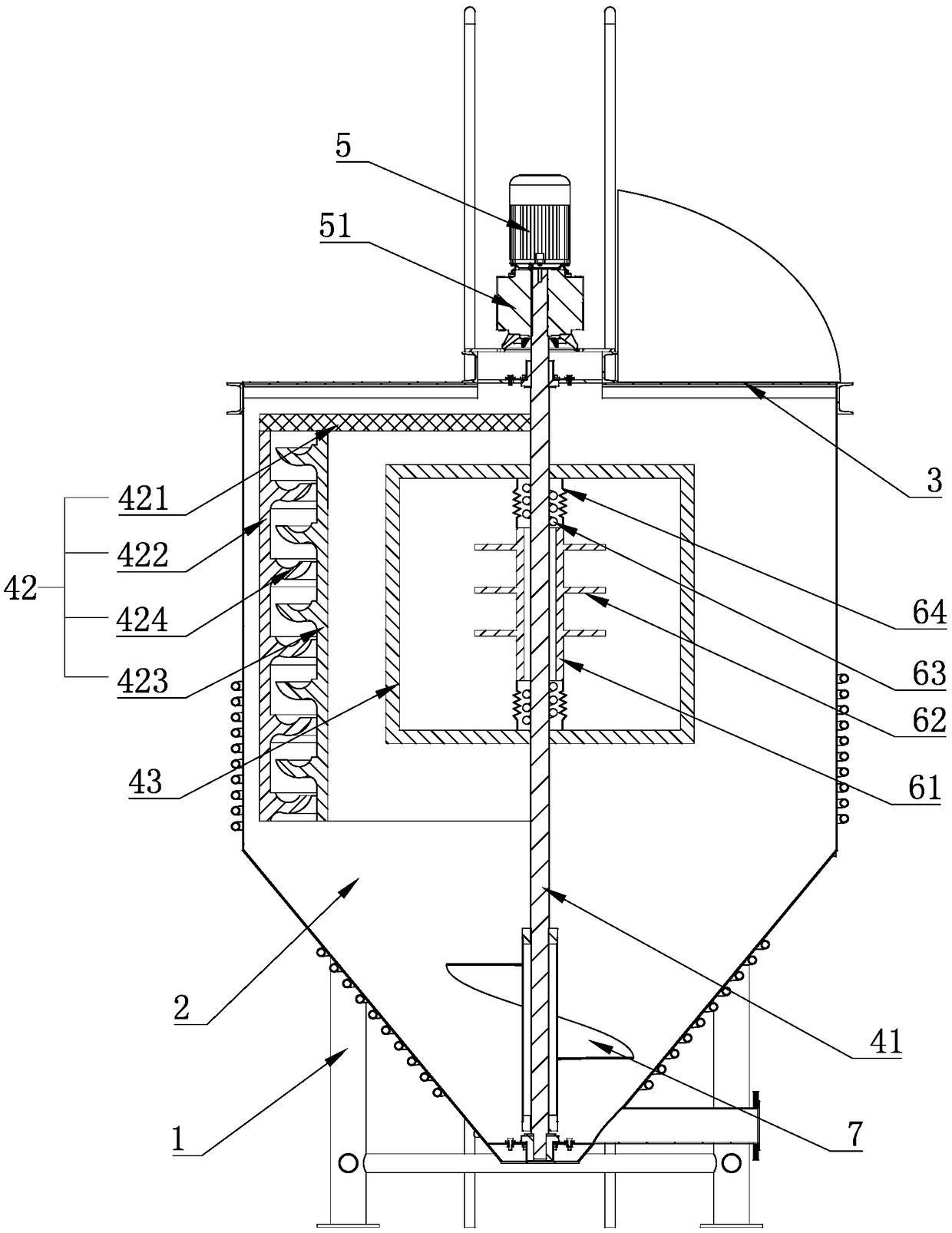

[0028] refer to Figure 1 to Figure 3 The embodiment of a mortar mixer of the present invention will be further described.

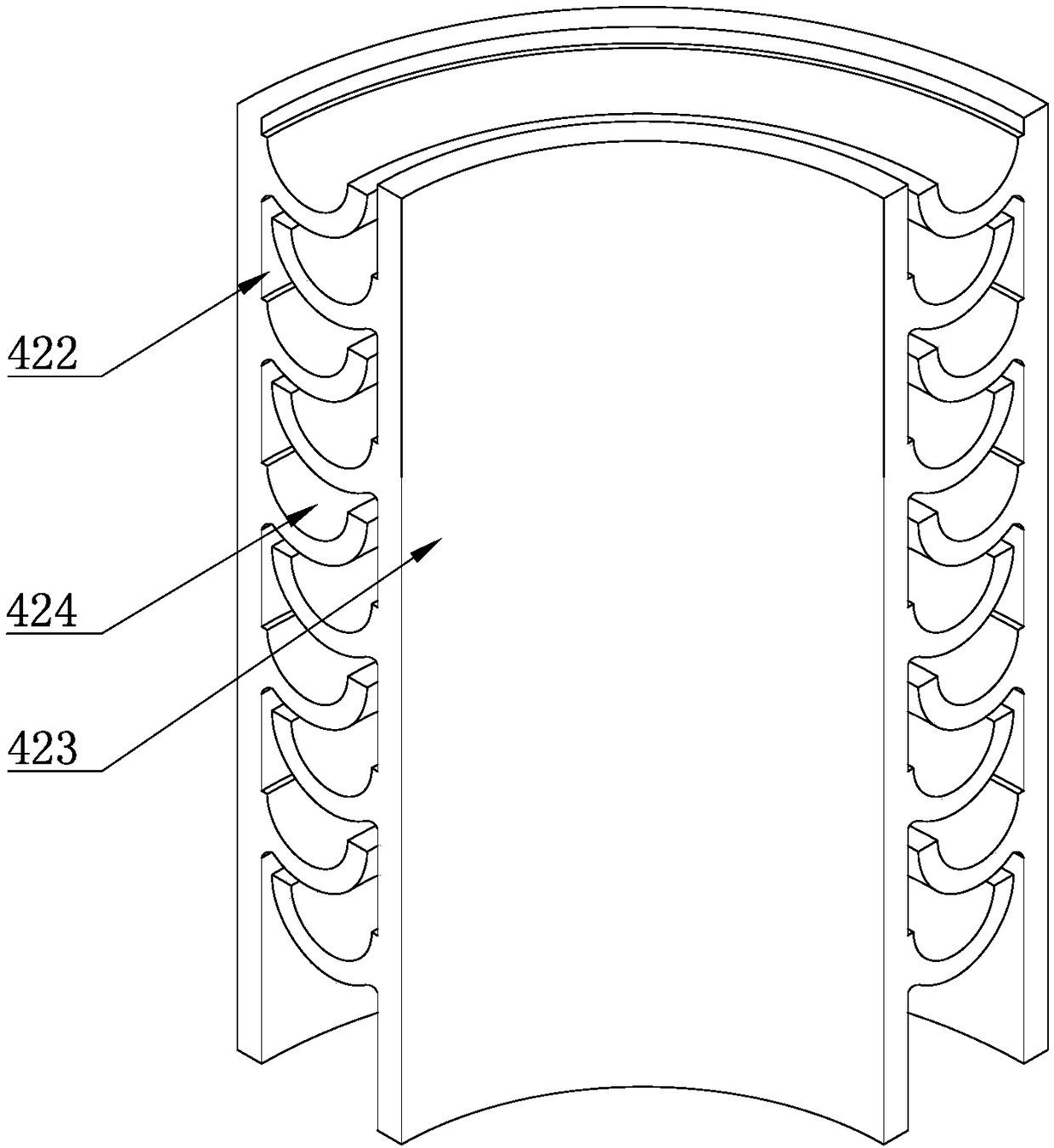

[0029] A mortar mixer, comprising a bracket 1, a bucket body 2, a bucket cover 3, a mixing assembly and a driving device 5 for driving the mixing assembly, the bucket body 2 is located on the bracket 1, the bracket 1 supports the outside of the bucket body 2, and the bucket cover 3 Connected to the upper opening of the barrel body 2 to form a seal on the upper opening of the barrel, the barrel cover 3 is provided with a feed port 31, the feed port 31 is provided with a hinged baffle plate, the stirring assembly is connected to the middle part of the barrel cover 3 and extends Into the bucket body 2, the stirring assembly includes a rotating shaft 41 connected to the driving device 5 and driven by the driving device 5, a grinding piece 42 connected to the rotating shaft 41, and a stirring rod 43 located inside the grinding piece 42. The stirring rod 43 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com