Stirring device used for wine brewing

The technology of a stirring device and a stirring shaft, which is applied in the field of winemaking, can solve the problems of uneven mixing of fermented grains and bran shells, and achieve the effects of saving consumption, good mixing consistency and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

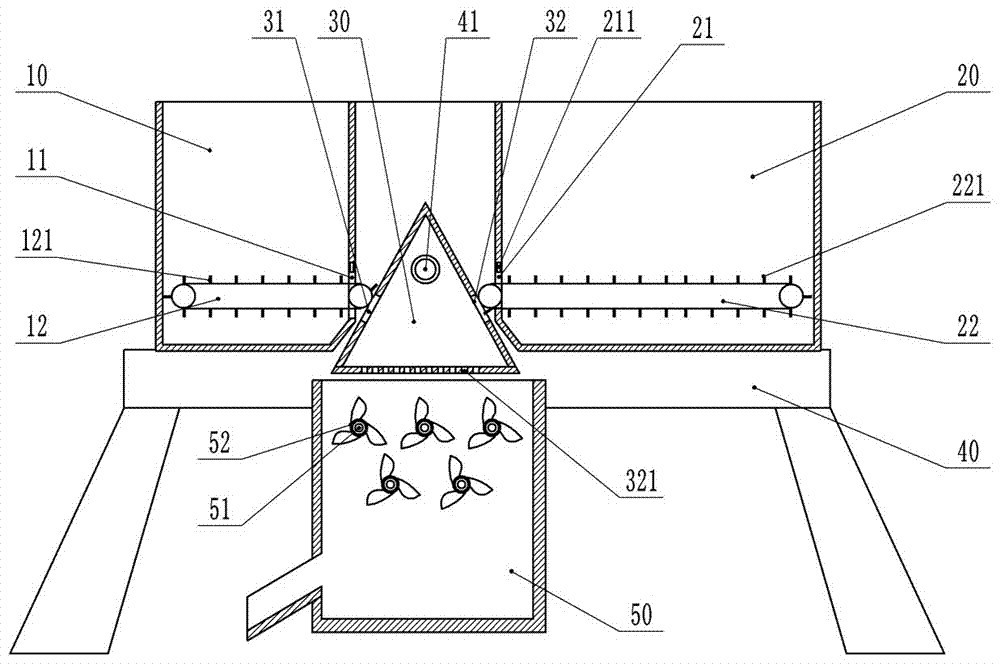

[0019] The reference numerals in the accompanying drawings include: left feed chamber 10, left discharge port 11, first conveyor belt 12, first protrusion 121, right feed chamber 20, right discharge port 21, sliding plate 211, the first Two conveyor belts 22, second protrusions 221, mixing chamber 30, left feed port 31, right feed port 32, through hole 321, support 40, shaft rod 41, stirring chamber 50, stirring shaft 51, agitator 52.

[0020] Such as figure 1 Shown, a kind of mixing device that is used for brewing, comprises left feed chamber 10, right feed chamber 20, mixing chamber 30, first conveyer belt 12, second conveyer belt 22 and support 40, and the longitudinal section of mixing chamber 30 is equal to A waist triangle, the apex of the isosceles triangle is facing upwards, the base is facing downwards, and the base is in a horizontal position. A shaft 41 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com