Comprehensive test device and method for rapid solidification heat transfer performance

A technology of heat transfer performance and comprehensive testing, which is applied in the direction of material thermal development, can solve problems such as high hardness and high strength that are difficult to meet, and achieve the effects of simple equipment, convenient installation, and easy operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The rapid solidification heat transfer performance comprehensive test experiment adopts such as figure 1 The comprehensive test device for rapid solidification heat transfer performance is completed. The specific implementation process includes the following steps:

[0065] The first step, sample loading,

[0066] Put 3kg metal sample into graphite crucible;

[0067] The second step is to melt the metal,

[0068] Heat the metal in the graphite crucible to the target melting temperature of the metal sample through the electric heating induction coil, and monitor the temperature with an infrared pyrometer, and use a PID-controlled instrument to regulate the power of the induction coil to keep the temperature at 1550°C;

[0069] The third step is to control the particle size of the metal droplets,

[0070] Adjust the circular hole with a diameter of 0.5mm on the particle size selector to the opening of the graphite crucible through an electric motor, and the particle s...

Embodiment 2

[0079] The rapid solidification heat transfer performance comprehensive test experiment adopts such as figure 1 The comprehensive test device for rapid solidification heat transfer performance is completed. The specific implementation process includes the following steps:

[0080] The first step, sample loading,

[0081] Put 3kg metal sample into the graphite crucible;

[0082] The second step, melting the metal,

[0083] Heat the metal in the graphite crucible to the target melting temperature of the metal sample through the electric heating induction coil, and monitor the temperature with an infrared pyrometer, and use a PID-controlled instrument to regulate the power of the induction furnace to keep the temperature at 1550°C;

[0084] The third step is to control the particle size of the metal droplets,

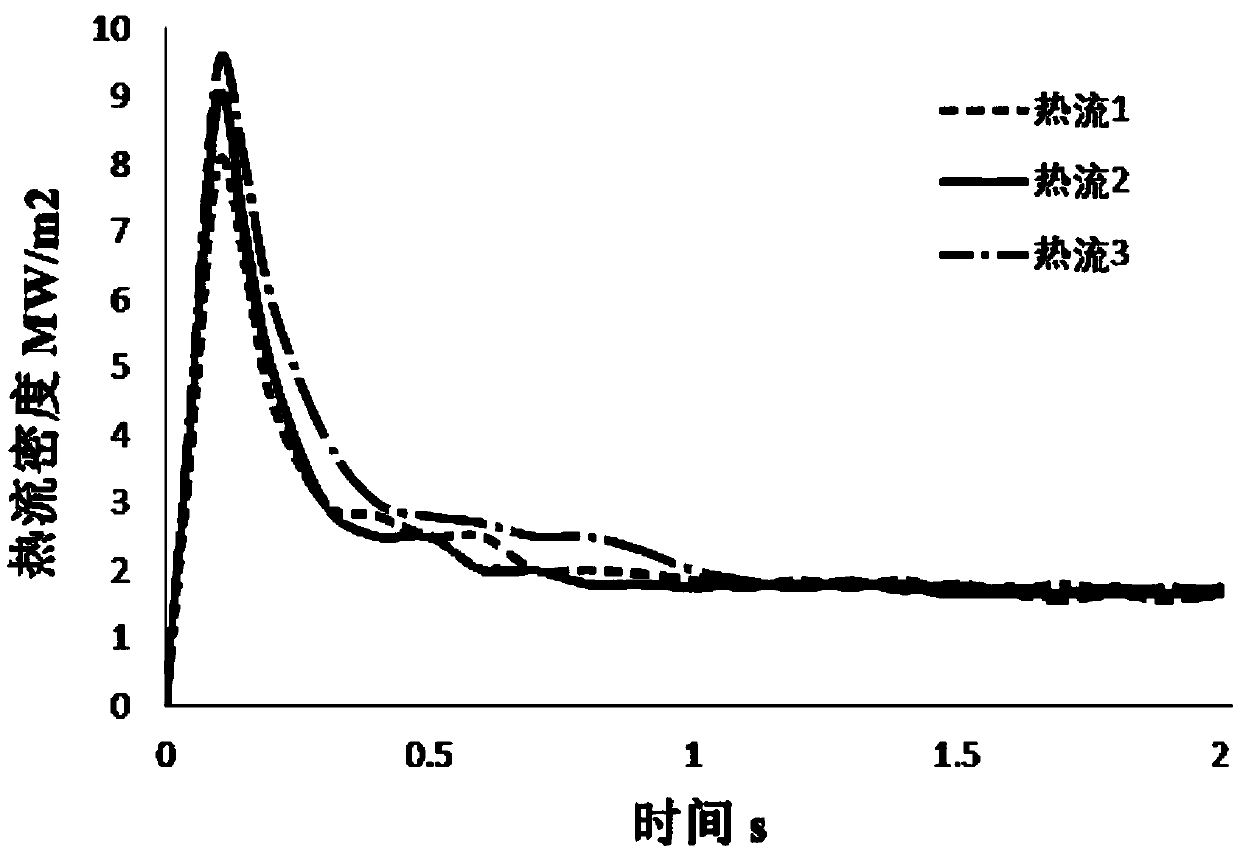

[0085] Adjust the circular hole with a diameter of 1mm on the particle size selector to the opening of the graphite crucible by an electric motor, and the particle siz...

Embodiment 3

[0093] The rapid solidification heat transfer performance comprehensive test experiment adopts such as figure 1 The comprehensive test device for rapid solidification heat transfer performance is completed. The specific implementation process includes the following steps:

[0094] The first step, sample loading,

[0095] Put 3kg metal sample into graphite crucible;

[0096] The second step is to melt the metal,

[0097] Heat the metal in the graphite crucible to the target melting temperature of the metal sample through the electric heating induction coil, and monitor the temperature with an infrared pyrometer, and use a PID-controlled instrument to regulate the power of the induction furnace to keep the temperature at 1550°C;

[0098] The third step is to control the particle size of the metal droplets,

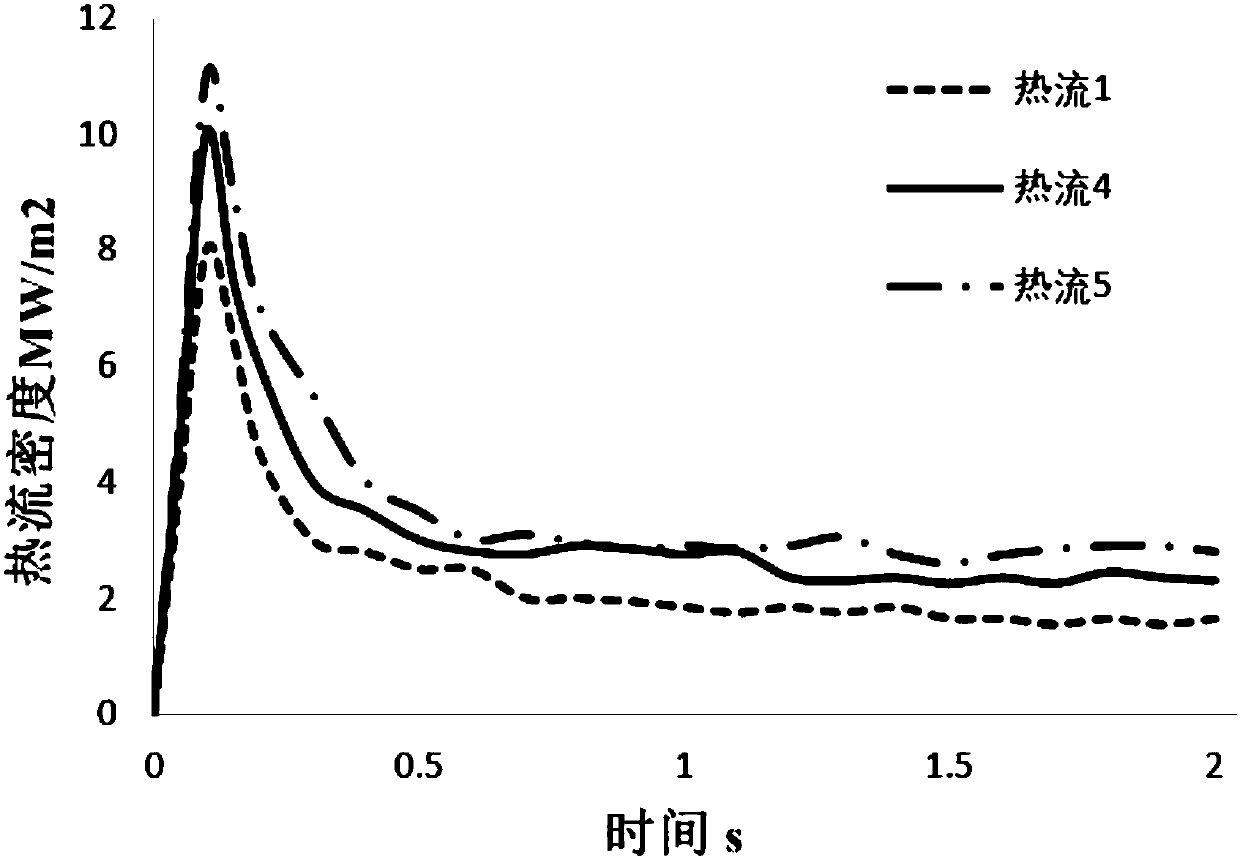

[0099] Adjust the circular hole with a diameter of 1.5mm on the particle size selector to the opening of the graphite crucible through the electric motor, and the partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com