Method for extracting and separating shikimic acid from fructus anisi stellati

A technology of shikimic acid and star anise, applied in the extraction field of the field of biotechnology, can solve the problems of large difference in content index, large damage and loss of effective components, etc., and achieves the effect of narrow particle distribution range and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

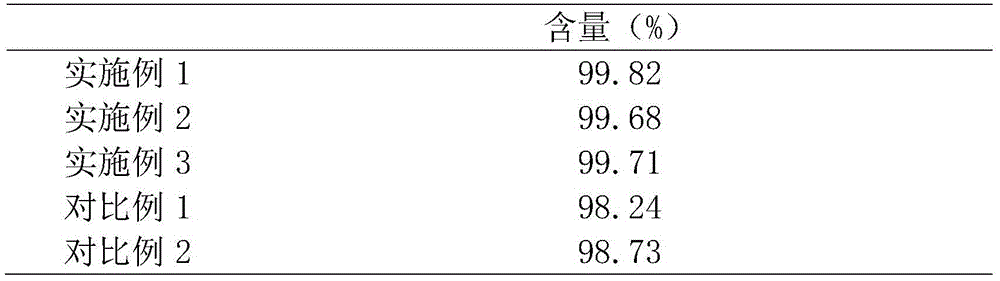

Examples

Embodiment 1

[0022] A method for extracting and separating shikimic acid from star anise, specifically comprising the following steps:

[0023] 1) Pre-treatment: crush the star anise, extract it with pure water, concentrate it to obtain the extract, add the same weight of pure water, put it into a high-speed dispersing emulsifier for processing, the speed is 2500r / min, and the time is 10min to obtain a high-speed dispersing emulsion;

[0024] 2) Column chromatography: pass the high-speed dispersion emulsion obtained in step 1) through a 330 weakly basic epoxy-based anion resin column, so that shikimic acid is exchanged and adsorbed, and then eluted with 5% sodium hydroxide solution to obtain the washed Dehydration;

[0025] 3) Desalting: desalting the eluent obtained in step 2) through a 732 strongly acidic styrene-based cationic resin column to remove sodium salt;

[0026] 4) Crystallization: Concentrate the desalted eluate, add it to acetone, precipitate and crystallize shikimic acid, a...

Embodiment 2

[0028] A method for extracting and separating shikimic acid from star anise, specifically comprising the following steps:

[0029] 1) Pre-treatment: Grind the star anise, extract it with alcohol, concentrate it to obtain the extract, add the same weight of pure water, put it into a high-speed dispersing emulsifier for processing, the speed is 2000r / min, and the time is 8min to obtain a high-speed dispersing emulsion;

[0030] 2) Column chromatography: pass the high-speed dispersion emulsion obtained in step 1) through a D-941 macroporous weak base anion resin column, so that shikimic acid is exchanged and adsorbed, and then eluted with 8% sodium hydroxide solution to obtain the washed Dehydration;

[0031] 3) Desalting: desalting the eluent obtained in step 2) through a D001 macroporous strongly acidic styrene-based cationic resin column to remove sodium salt;

[0032] 4) Crystallization: Concentrate the desalted eluate, add it to acetone, precipitate and crystallize shikimic...

Embodiment 3

[0034] A method for extracting and separating shikimic acid from star anise, specifically comprising the following steps:

[0035] 1) Pretreatment: Degrease the extract obtained from star anise industrial residues with petroleum ether, add the same weight of pure water, put it into a high-speed dispersing emulsifier for processing, the speed is 3000r / min, and the time is 5min to obtain a high-speed dispersing emulsion ;

[0036] 2) Column chromatography: pass the high-speed dispersion emulsion obtained in step 1) through a D318 macroporous weak base anion resin column, so that shikimic acid is exchanged and adsorbed, and then eluted with 1% sodium hydroxide solution to obtain an eluent ;

[0037] 3) Desalting: the eluent obtained in step 2) is superacid 1 # Cationic resin column desalting to remove sodium salt;

[0038] 4) Crystallization: Concentrate the desalted eluate, add it to acetone, precipitate and crystallize shikimic acid, and then use acetone to recrystallize.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com