Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

707 results about "Cyclohexene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclohexene is a hydrocarbon with the formula C₆H₁₀. This cycloalkene is a colorless liquid with a sharp smell. It is an intermediate in various industrial processes. Cyclohexene is not very stable upon long term storage with exposure to light and air because it forms peroxides.

Olefin epoxidation catalysts

A method of synthesizing an olefin epoxidation catalyst comprises the step of treating a porous crystalline aluminosilicate material having an X-ray diffraction pattern including d-spacing maxima at 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07 Angstrom, such as MCM-22, with a dealuminating agent under conditions effective to remove framework aluminium from the material and produce a dealuminated product. The dealuminated product is then treated with a titanium-containing material under conditions effective to insert titanium into the dealuminated product and produce a titanium-containing, dealuminated catalyst composition. The resultant catalyst is useful in the epoxidation of olefins, such as propylene and cyclohexene, with hydrogen peroxide and organic hydroperoxides.

Owner:MOBIL OIL CORP

Process for preparing small crystal ZSM-5 zeolite

The preparation process of small crystal grain ZSM-5 zeolite includes the following steps: mixing alumino sillica gel grain in SiO2 / Al2O3 molar ratio of 20-600 and granularity of 20-300 mesh and water solution of organic template agent, and hydrothermal crystallization of the mixture with or without ZSM-5 zeolite crystal seed; and once filtering, drying and roasting. The said process can preparing ZSM-5 zeolite product with Si / Al molar ratio of 15-200 and initial crystal granularity of 0.1-0.5 micron. The process uses no sodium ion material, needs no ammonium exchange, filtering and roasting process, and thus has high zeolite product yield and simplified production process. The zeolite product is used in the catalyst for hydrolyzing cyclohexene to prepare cyclohexanol and has high cyclohexanol converting rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

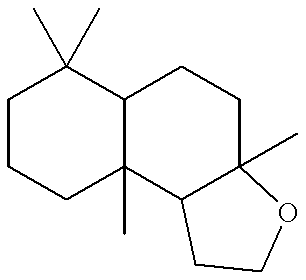

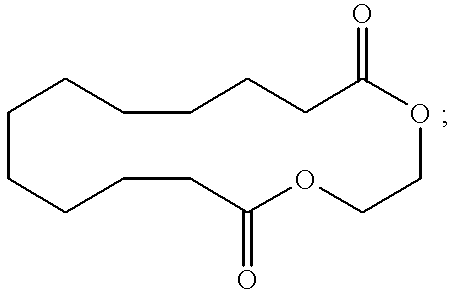

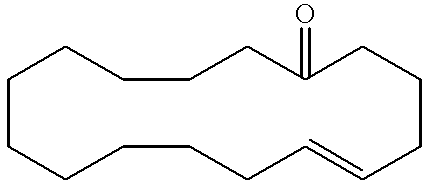

Human sweat malodor counteractant composition and process for using same

InactiveUS6379658B1Increase in level of perceived pleasantnessMalodor-reducing concentrationBiocideCosmetic preparationsFuranPropionate

Described is a process and compositions for counteracting human sweat malodor. The compositions containing at least 10 weight percent of either 3,7-dimethyl-2,6-nonadienenitrile or 3,7-dimethyl-2,6-octadienenitrile. Additional ingredients may be added including napthyl methyl ether, methyl beta-naphthyl ketone, benzyl acetone, methanoinden propionates, methyl ionone, tetramethylnaphtho furan, ethylene glycol cyclic ester of dodecanedioic acid, 1-cyclohexadecen-6-one, 1-cycliheptadecen- 10-one, and corn mint oil. These compositions are applied to either fabric or a defined surface area of the human epidermis.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

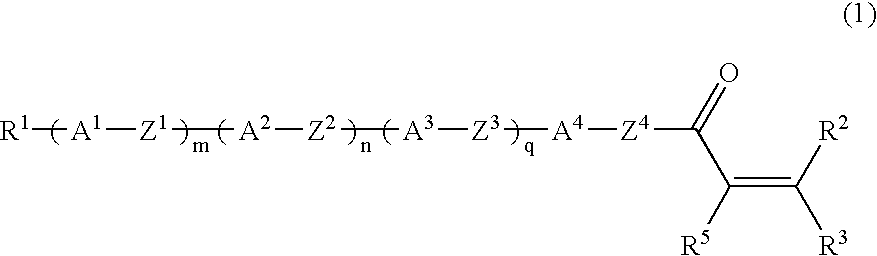

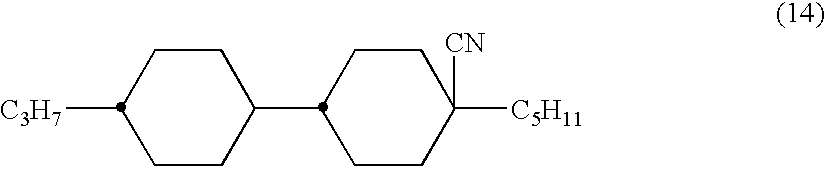

Liquid-crystalline vinyl ketone derivatives and their polymers

ActiveUS20050012070A1Improve compatibilityExcellent characteristicsLiquid crystal compositionsOrganic chemistrySolubilityLiquid crystalline

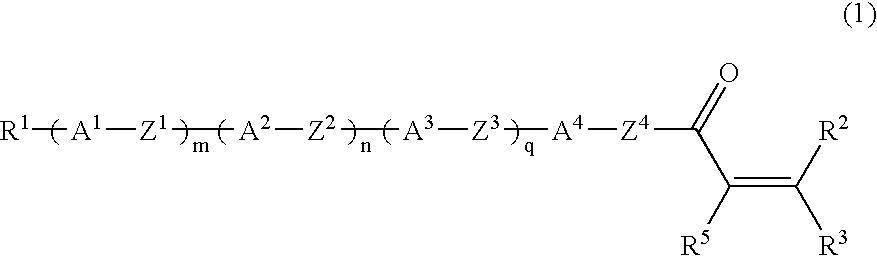

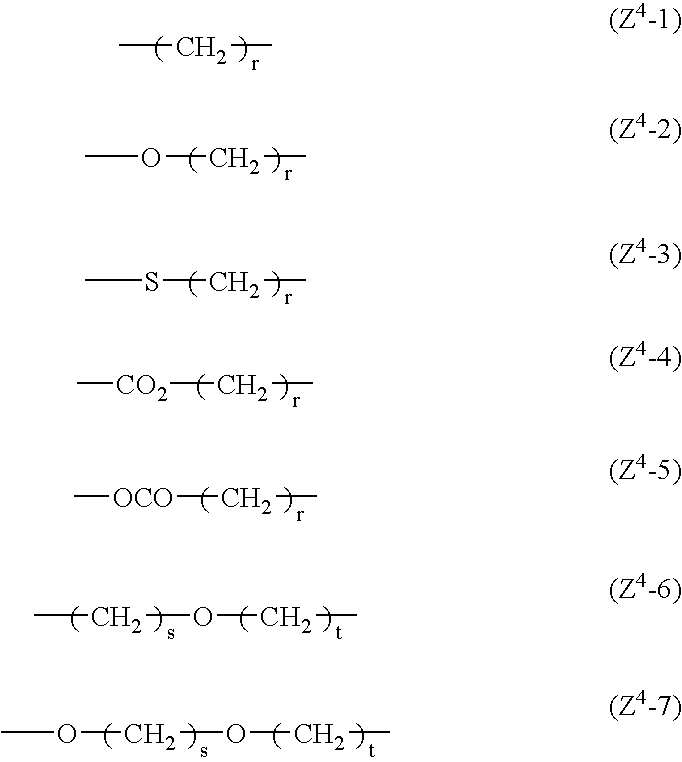

Provided is a liquid-crystalline, polymerizable vinyl ketone compound of formula (1): Preferably, R1 is hydrogen, halogen, —CN, —CF3, —CF2H, —CFH2, —OCF3, —OCF2H, or alkyl, alkoxy, alkoxyalkyl or alkenyl having from 1 to 10 carbon atoms; R2, R3 and R5 are hydrogen; A1 to A4 are independently 1,4-cyclohexylene, 1,4-cyclohexenylene or 1,4-phenylene where any hydrogen may be substituted with halogen; Z1 to Z3 are independently a single bond, —(CH2)2—, —CH═CH—, —CF═CF—, —OCF2— or —CF2O—; Z4 is a single bond, —(CH2)3— or —(CH2)4—; m, n and q are independently 0, 1 or 2. The uppermost temperature of the liquid crystalline phase of the compound is high, and the compound has good compatibility with other compounds and has the necessary characteristics such as optical anisotropy. Also provided are a polymer having many good characteristics of transparency, mechanical strength, coatability, solubility, crystallinity, shrinkage, water permeability, water absorption, melting point, glass transition point, clearing point and chemical resistance; an optically-anisotropic material of the polymer; a liquid-crystal display device that comprises the polymer; and a method for producing the liquid-crystalline compound.

Owner:JNC CORP +1

2,3-difluorophenyl derivative having negative dielectric anisotropy, liquid crystal composition, and liquid crystal display device

InactiveUS6548126B1Good compatibilityIncrease resistanceLiquid crystal compositionsOrganic chemistryLiquid crystallineCrystallography

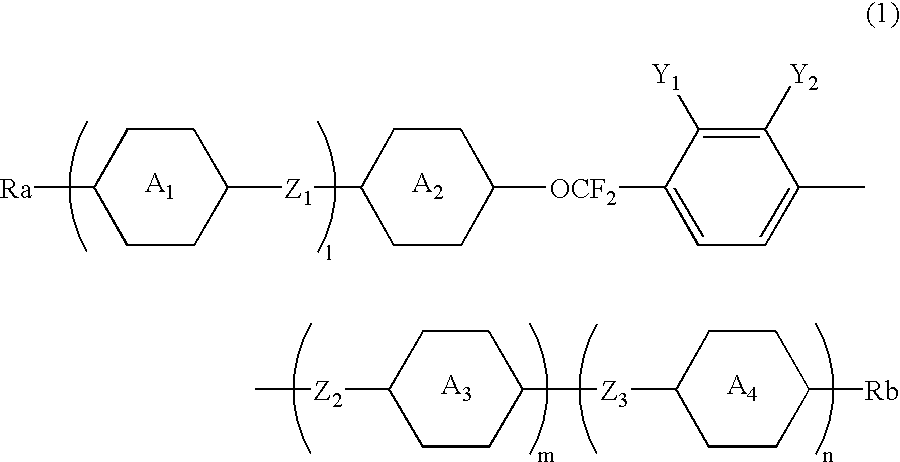

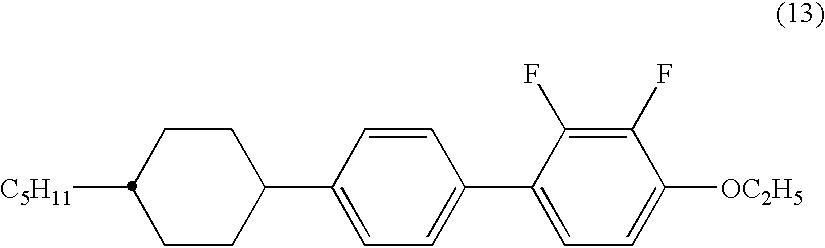

The invention is to provide liquid crystalline compounds having a negative and extremely large dielectric anisotropy value and a small optical anisotropy value at the same time; liquid crystal compositions comprising the compound; and liquid crystal display devices fabricated by using the liquid crystal composition; the liquid crystalline compounds have 2,3-dihalogenophenylene moiety and are expressed by formula (1)wherein Ra and Rb each independently represents a linear or branched alkyl having 1 to 10 carbon, any methylene in the alkyl may be replaced by -O-, -S-, -CH=CH-, or -C=C-, but -O- is not successive, and any hydrogen in the alkyl may be replaced by halogen; rings A1 to A4 each independently represents trans-1,4-cyclohexylene, cyclohexene-1,4-diyl, pyridine-1,4-diyl, pyrimidine-2,5-diyl, or 1,4-phenylene, wherein at least one hydrogen in these rings may be replaced by halogen, and any nonadjacent methylene in cyclohexane ring may be replaced by -O-; Y1 and Y2 each independently represents F or Cl; Z1, Z2 and Z3 each independently represents a single bond, -CH2CH2-, -(CH2)4-, -COO-, -OCO-, -CH2O-, -OCH2-, -CF2O-, or -OCF2-; and l, m and n each independently is 0, 1 or 2, and the sum of l+m+n is 3 and less.

Owner:CHISSO CORP

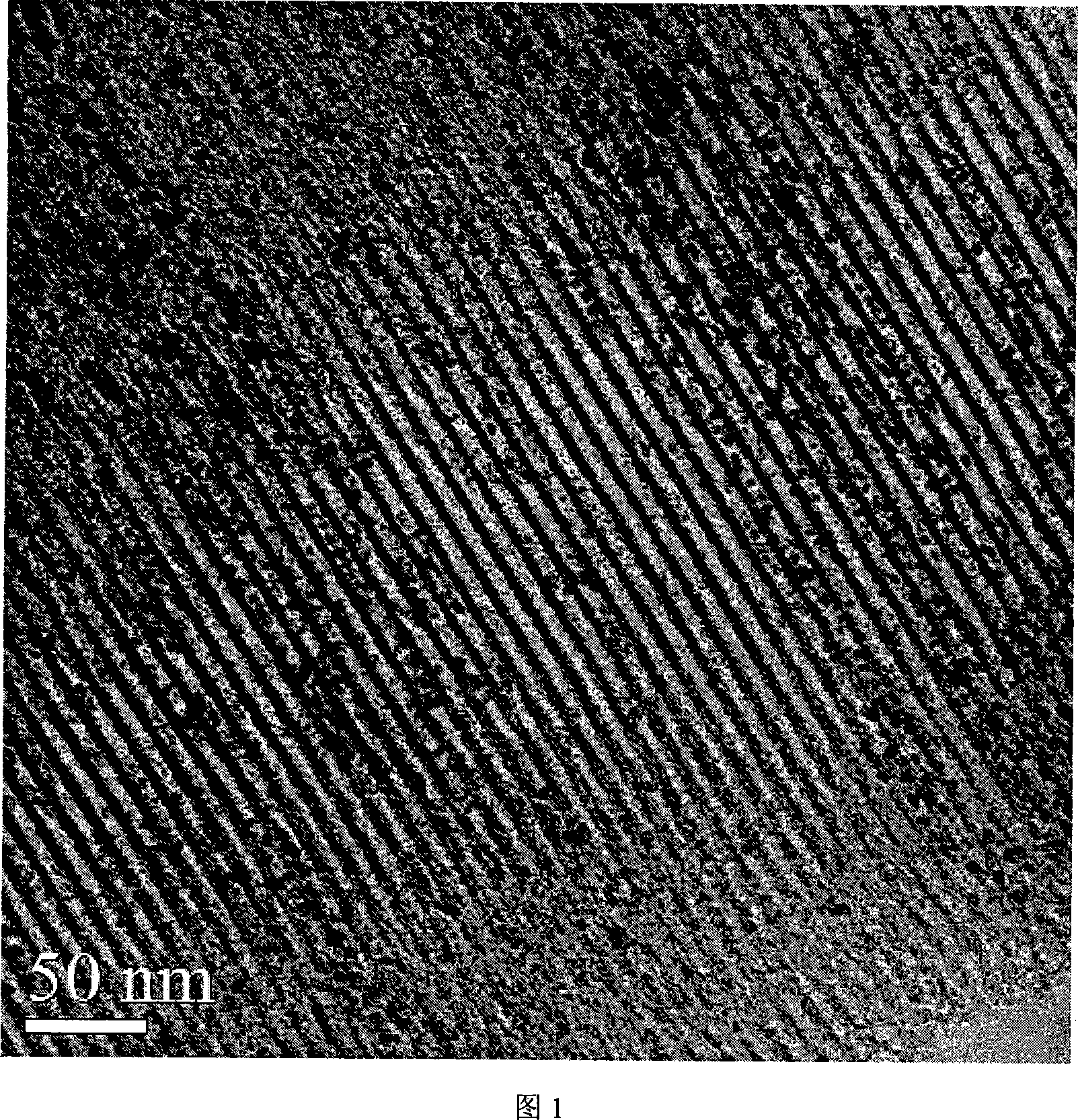

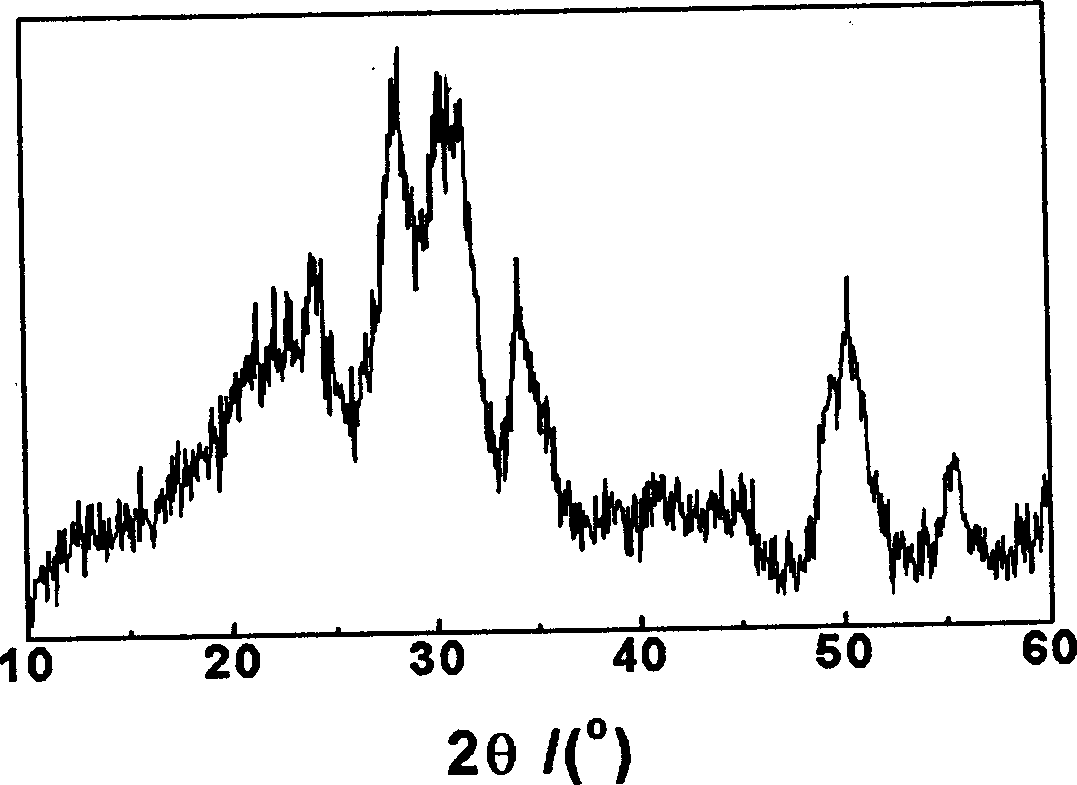

Process for producing ruthenium base catalyst for producing cyclohexene with benzene selective hydrogenation

InactiveCN101219391AAvoid uneven loadHigh catalytic efficiencyMolecular sieve catalystsHydrocarbon by hydrogenationCyclohexeneMesoporous silica

The invention pertains to chemical engineering field, in particular to a preparation method of a Ru-based catalyst, the catalyst has uniform load and high catalytic efficiency and is used for preparing cyclohexene from benzene through selectively hydrogenation reaction. A precursor of the catalyst is prepared through a cyclohexene / water component solvent system, and then reduced by a mixing gas of H2 or Ar to prepare the catalyst, and the catalyst consists of ruthenium, a dressing agent and a mesoporous silicon dioxide carrier L, amongst which the active component is ruthenium metal, the dressing agent is a metal oxide, and the precursor is selected from the nitrate or chloride of metal elements in IIA main group, VIII group and IVA main group in the element periodic table; ruthenium and the dressing agent are uniformly carried on the carrier L through the preparation method of the invention. When being used in preparing cyclohexene from benzene through selectively hydrogenation reaction, and compared with the catalyst used for the selectively hydrogenation of industrial benzene, the catalyst has the advantages that: lower the ruthenium consumption, higher selectively hydrogenation activity and selectivity for benzene.

Owner:FUDAN UNIV

Benzene hydrogenation catalyst as well as preparation method and application thereof

ActiveCN102600888AExcellent benzene hydrogenation catalytic performanceHigh catalytic activityMolecular sieve catalystsHydrocarbon by hydrogenationBenzeneAdjuvant

The invention relates to a benzene hydrogenation catalyst as well as a preparation method and application of the benzene hydrogenation catalyst. The catalyst consists of an active component Ru and adjuvants, wherein the active component Ru is loaded on the catalyst by a carrier; the adjuvants are one or two of La, Ce, Fe, Zn, Cu and B, and the carrier is a mesoporous molecular sieve MCM-41 modified by one or two of ZrO2, ZnO and CuO. The invention also provides a method for preparing cyclohexene and cyclohexane by benzene hydrogenation catalyzed by the catalyst. The catalyst provided by the invention can be prepared by a dipping sedimentation method or a chemical reduction method and has a higher catalytic activity and cyclohexene selectivity.

Owner:XIANGTAN UNIV

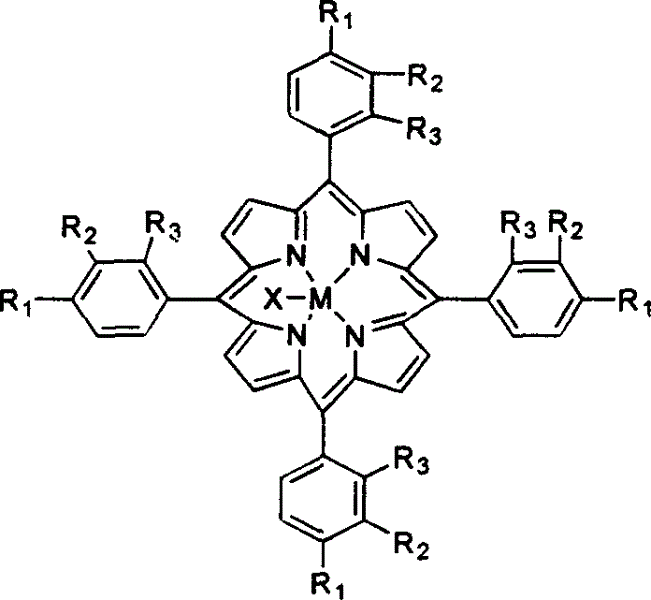

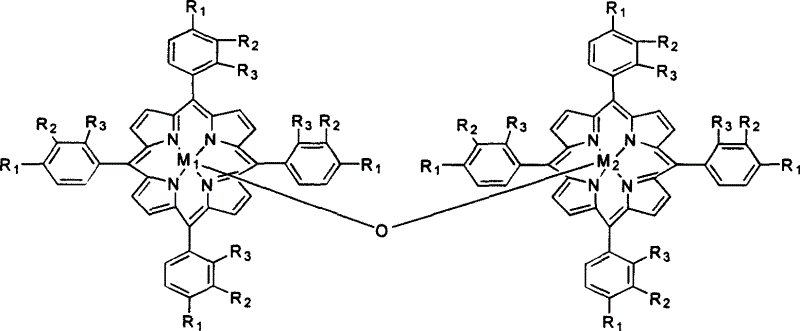

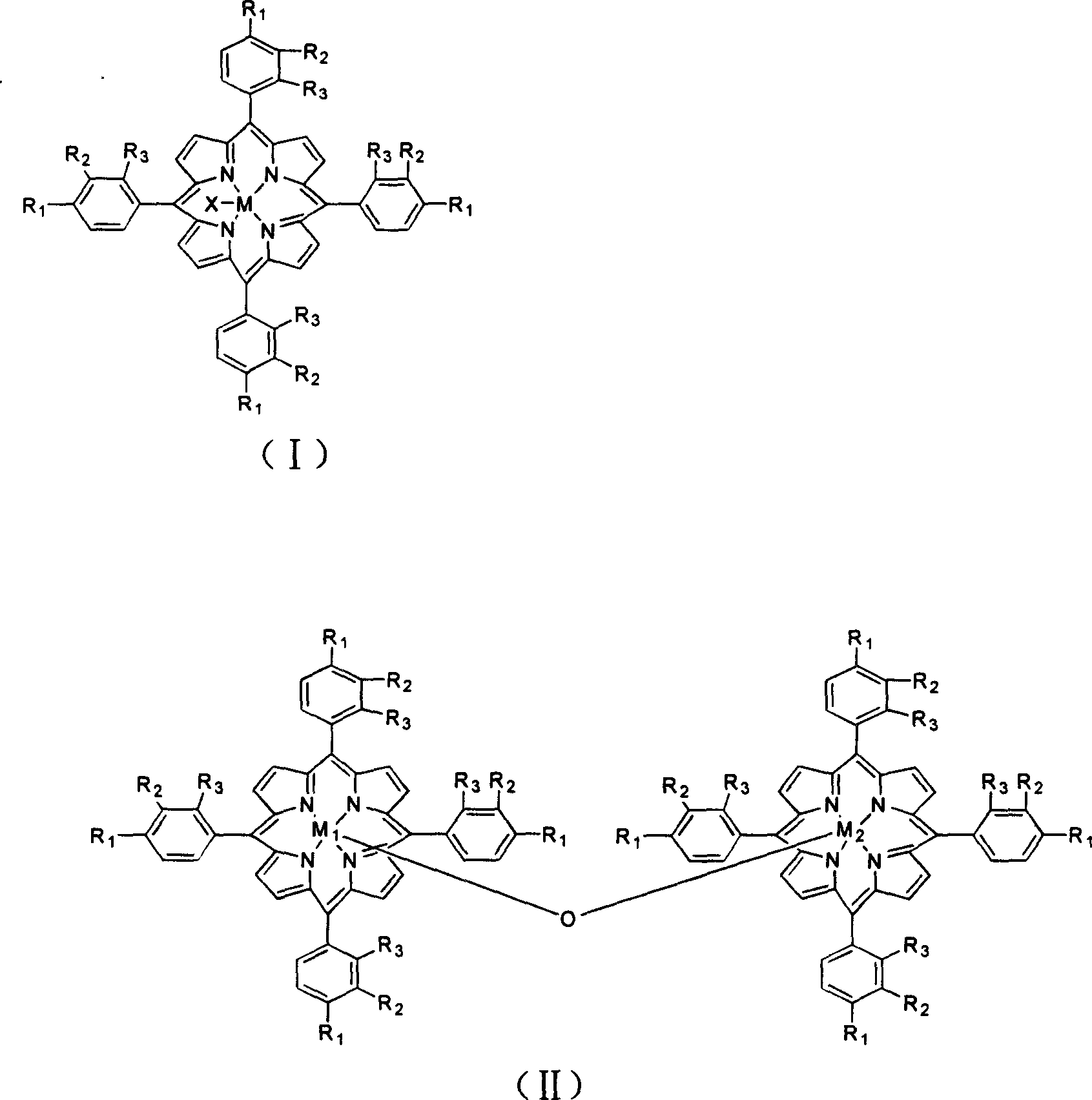

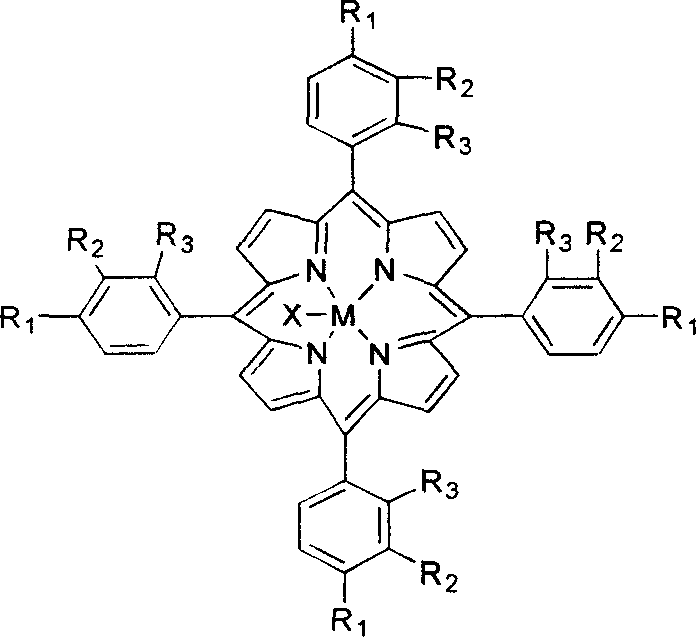

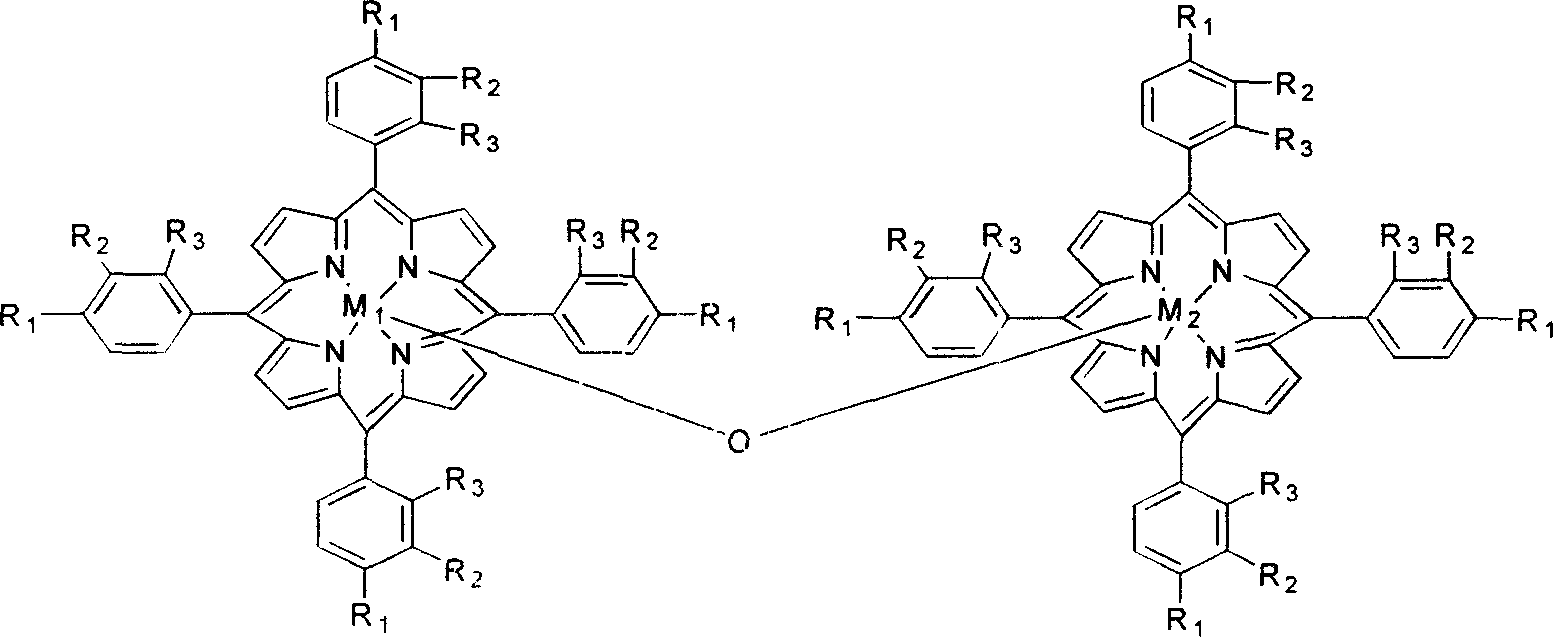

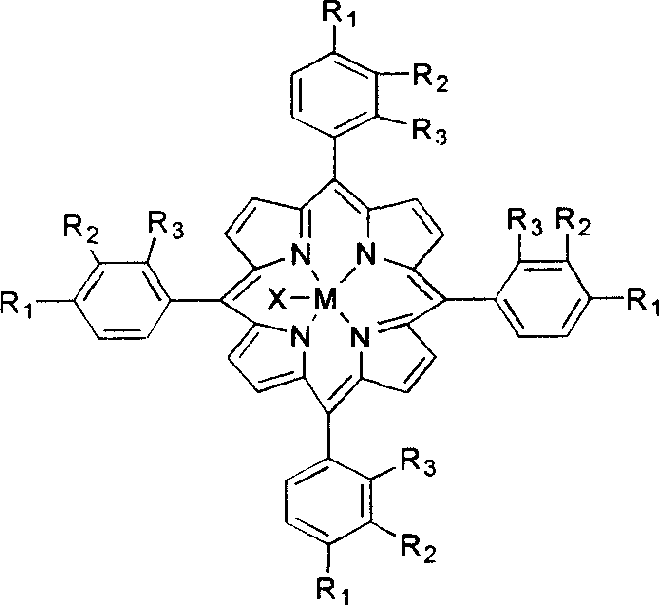

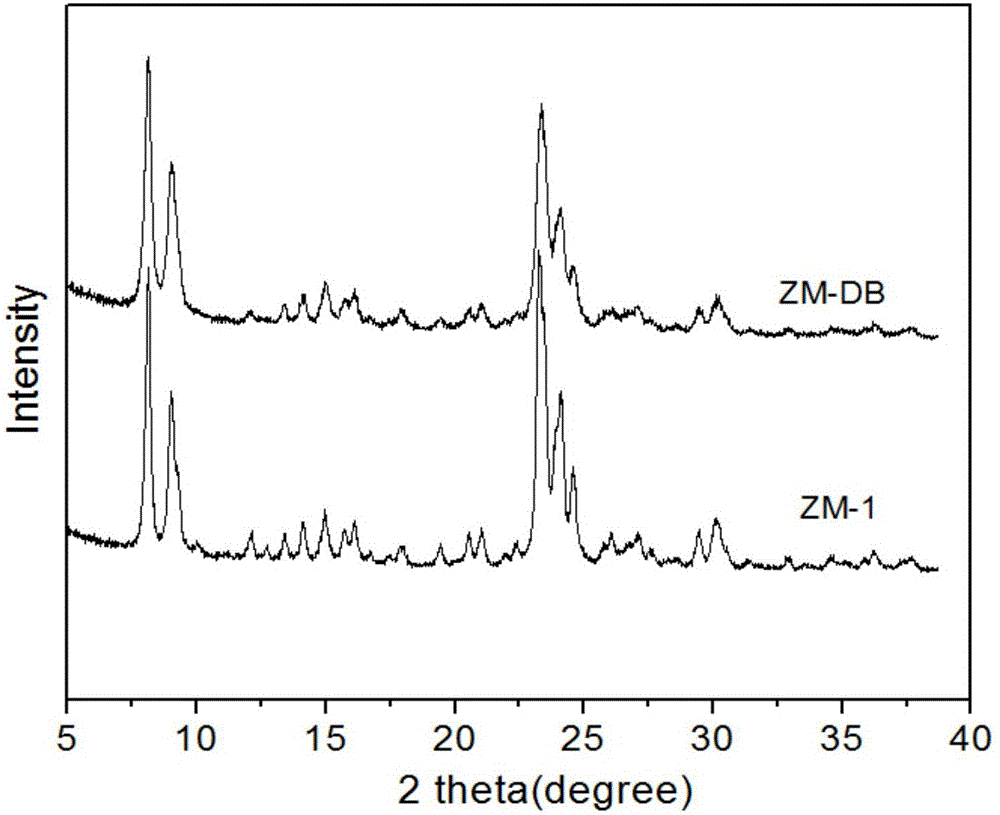

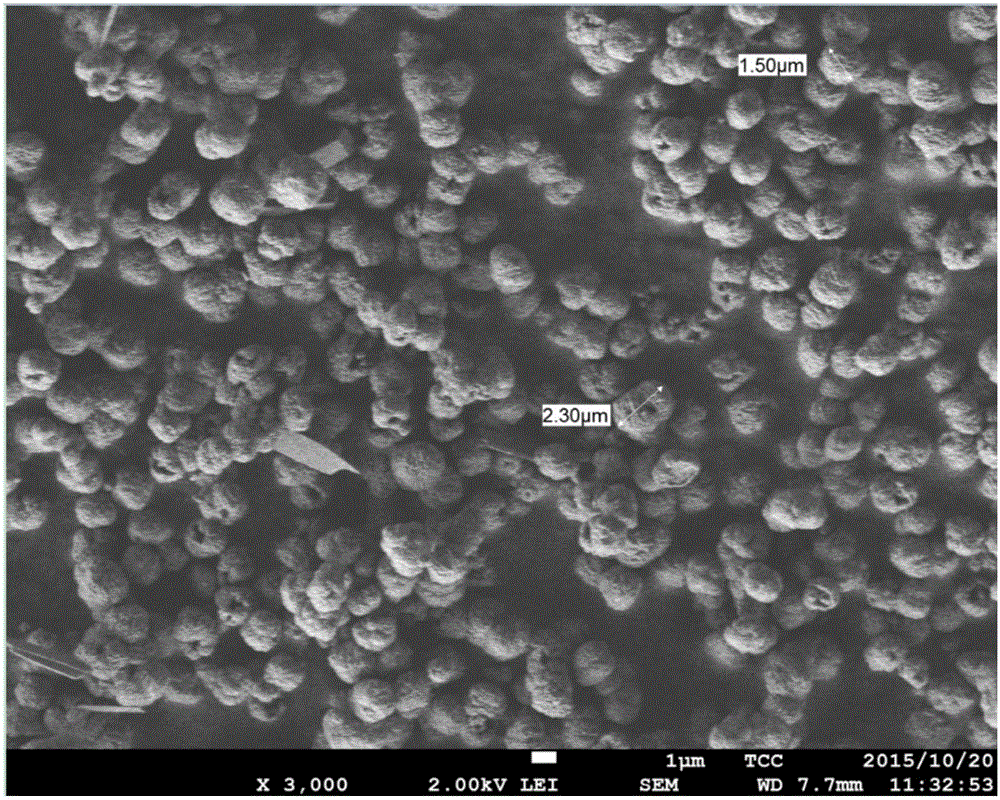

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1535947AReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanoneCyclohexene

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

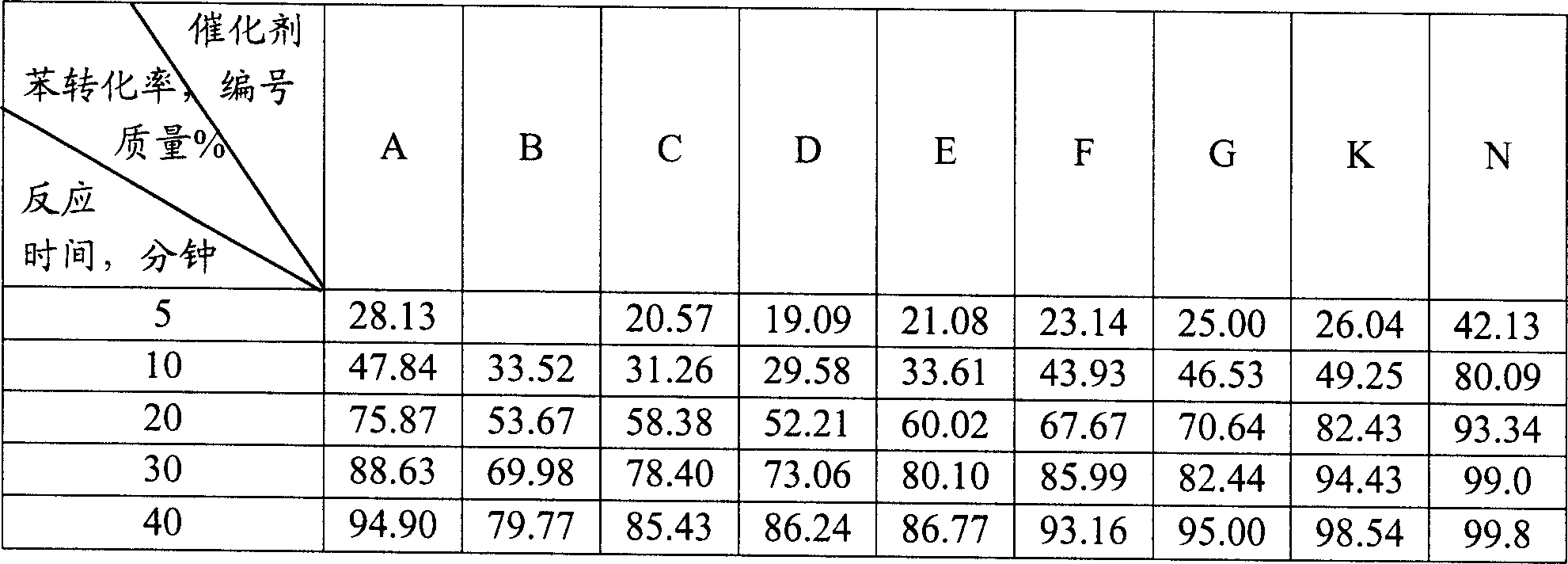

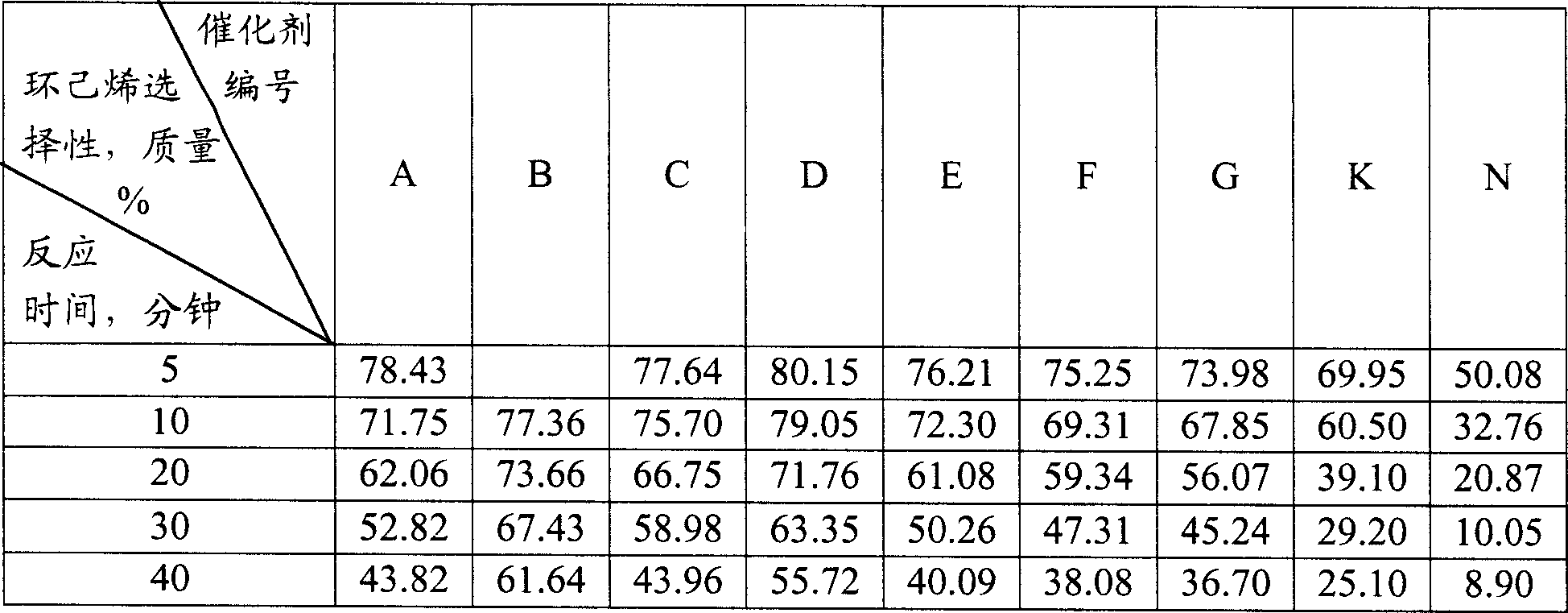

Catalyst for preparing cyclohexene by benzene selective hydrogenation, its preparing method and use

ActiveCN1978053AHigh activityHigh selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneActive component

The present invention relates to a catalyst for benzene selective hydrogenation to prepare cyclohexene. Said catalyst includes carrier and following active components: (by carrier content as reference) Ru 1-20 mss%, M 0.1-3.0 mass%. B 0.1-6.0 mass%, the described carrier is formed from 2-20 mss% of yttrium oxide and 80-98% of zirconium oxide, and M is selected from Co, Fe, Ni or Cu. Said catalyst is prepared by adopting chemical reducing agent, and has higher cyclohexene selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing epoxy cyclohexane by catalytic cyclooxidation of cyclohexene

A process for preparing epoxy cyclohexane by catalytic epoxidation of cyclohexene is disclosed. It is characterized by use of a phase-transfer catalyst which is insoluble in reaction medium but can become the active substance soluble in reactino medium under action of hydrogen peroxide. Said catalyst can be cyclically used. Its advantages are high selectivity (97%), easy recovery of catalyst, no by-product and low cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Benzene selective hydrogenation carried ruthenium based catalyst and its preparation

InactiveCN1424293AHigh catalytic efficiencyHigh selectivityHydrocarbon by hydrogenationCatalyst activation/preparationBenzeneHydrogen

A Ru-base catalyst for selective hydrogenation of benzene to prepare cyclohexene is prepared from Ru, carrier (metal oxide), modifier M chosen from Cr, Mo, W, Fe, Co, Cu and La, and salt solution N through introducing hydrogen gas to aqueous solution to reduce Ru(OH)3 and M, and centrifugal washing to remove impurity ions. Its advantages are high activity and selectivity, and easy storage.

Owner:FUDAN UNIV

ZSM-5 structure zeolite, preparation and use thereof

InactiveCN1530322ATroubleshooting FiltrationImprove conversion rateMolecular sieve catalystsPentasil aluminosilicate zeoliteCyclohexeneSilicon oxide

A ZSM-5 zeolite with 15-200 for the mole ration of silicon oxide to aluminium oxide, 0.5-10 microns for diameter, and 25-250 sq.m / g for mesopore surface area is prepared from the large-grain zeolite through treating in alkaline aqueous solution, ammonium ion exchanging, drying, and calcining. Said zeolite can be used to prepare cyclohexanol from cyclohexene by hydrating with high conversion rate, easy separation from liquid phase and easy filter.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparing cyclohexene catalyst and for benzene hydrogenation its manufacturing method

InactiveCN1597099AHas industrial application valueLow costHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneCyclohexene

A catalyst for preparing cyclohexene from benzene by hydrogenating is prepared from metal Ru, one or two transition metals or RE elements, the hydroxide of alkali metal as precipitator, and hydrophilic indifferent oxide. It has high activity and selectivity.

Owner:ZHENGZHOU UNIV

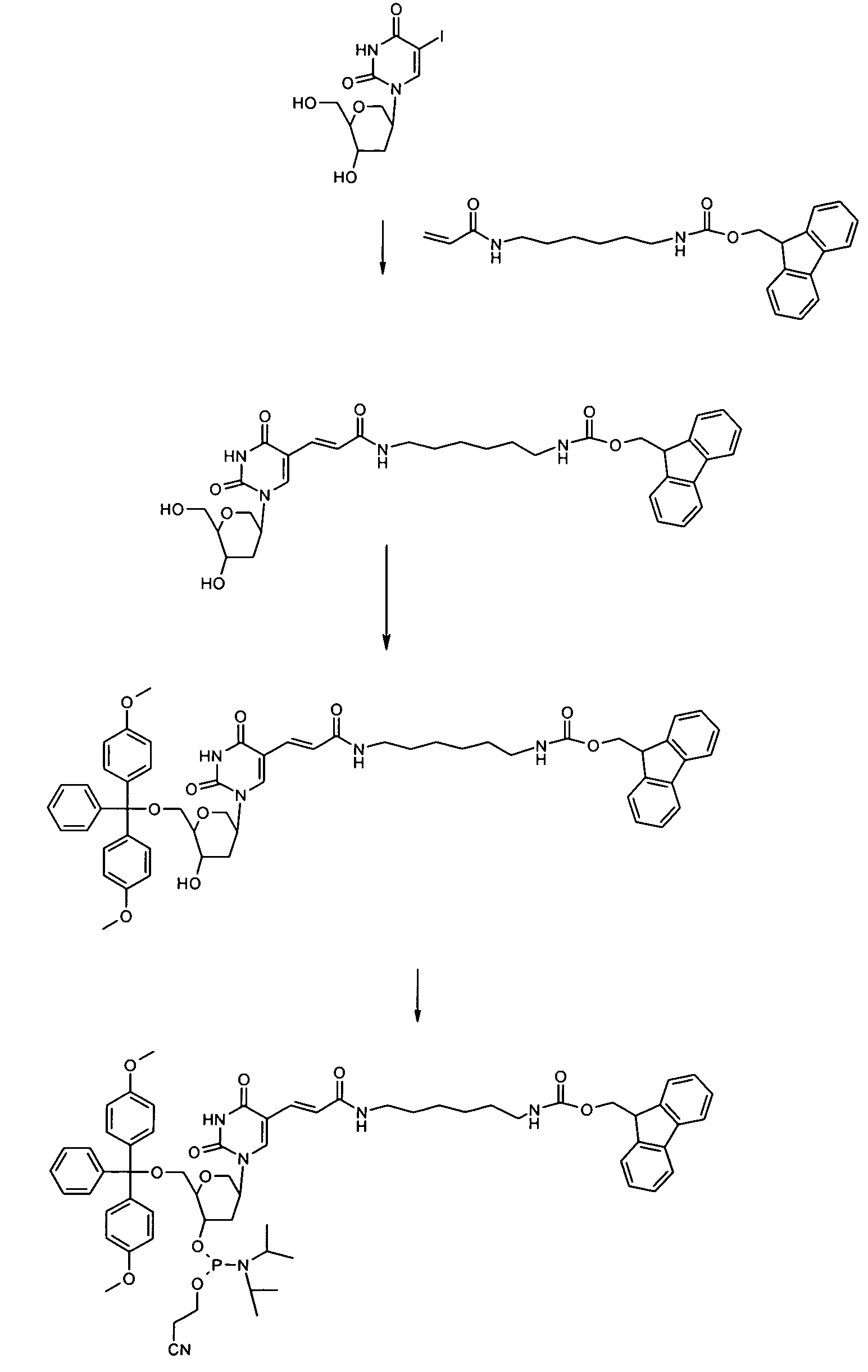

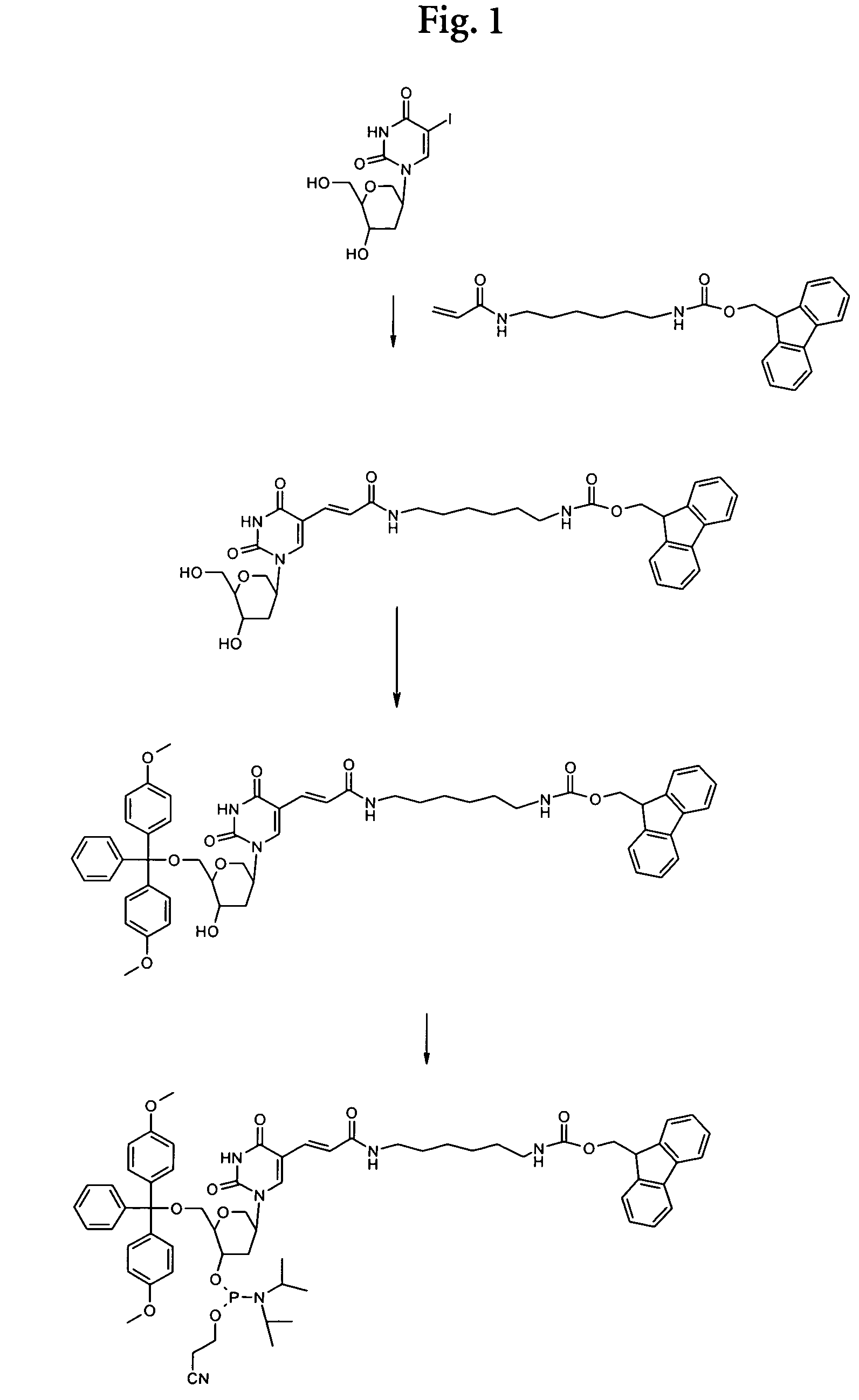

Nucleotide analogs with six-membered rings

InactiveUS7276592B2Efficient synthesisPromote degradationSugar derivativesAntibioticsCyclohexeneTetrahydropyran

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

Preparing of cyclobexene catalyst for benzene selective hydrogenation its preparation method and regulating method and regeneration method

InactiveCN1597098ANo pollution in the processLow costHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneActive component

A catalyst able to be modified or regenerated by washing it with the purified water containing H2O2 and treating it by diluted acid can be used for preparing cyclohexane from benzene by selective hydrogenating. It contains an active component Ru, a RE element La or transition element Zn or Fe and a disperser, and is prepared by chemical reduction method or deposition method.

Owner:ZHENGZHOU UNIV

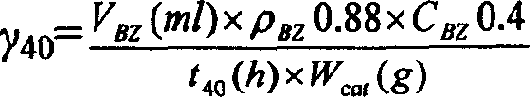

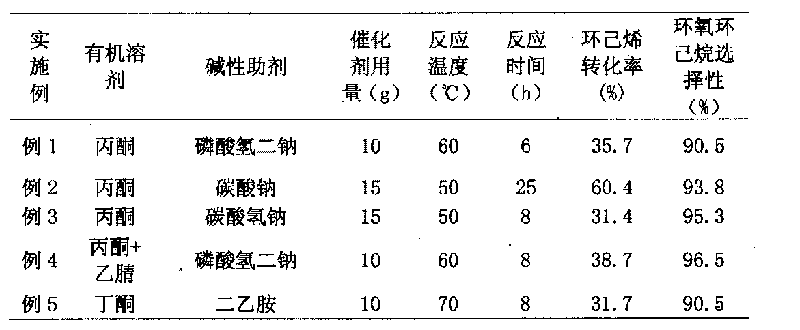

Method for preparing epoxy cyclohexane through catalytic epoxidation of cyclohexene

The invention relates to a method for preparing a fine chemical intermediate, in particular to a method for preparing epoxy cyclohexane through catalytic epoxidation of cyclohexene, which comprises the steps of: taking a synthetic Ti-Si molecular sieve as a catalyst, using an alkaline assistant, controlling the reaction temperature, stirring to react, reacting hydrogen peroxide and the cyclohexene in an organic solvent to obtain epoxy cyclohexane, and then carrying out separation and purification to obtain the epoxy cyclohexane. The reaction time of the invention is between 1 and 48 hours, the single pass conversion rate of the cyclohexene can reach over 40 percent, the selectivity of the epoxy cyclohexane can reach 96 percent, and the utilization rate of the hydrogen peroxide can reach 98 percent. The catalyst can be recovered for repeated use.

Owner:CHINA PETROLEUM & CHEM CORP +1

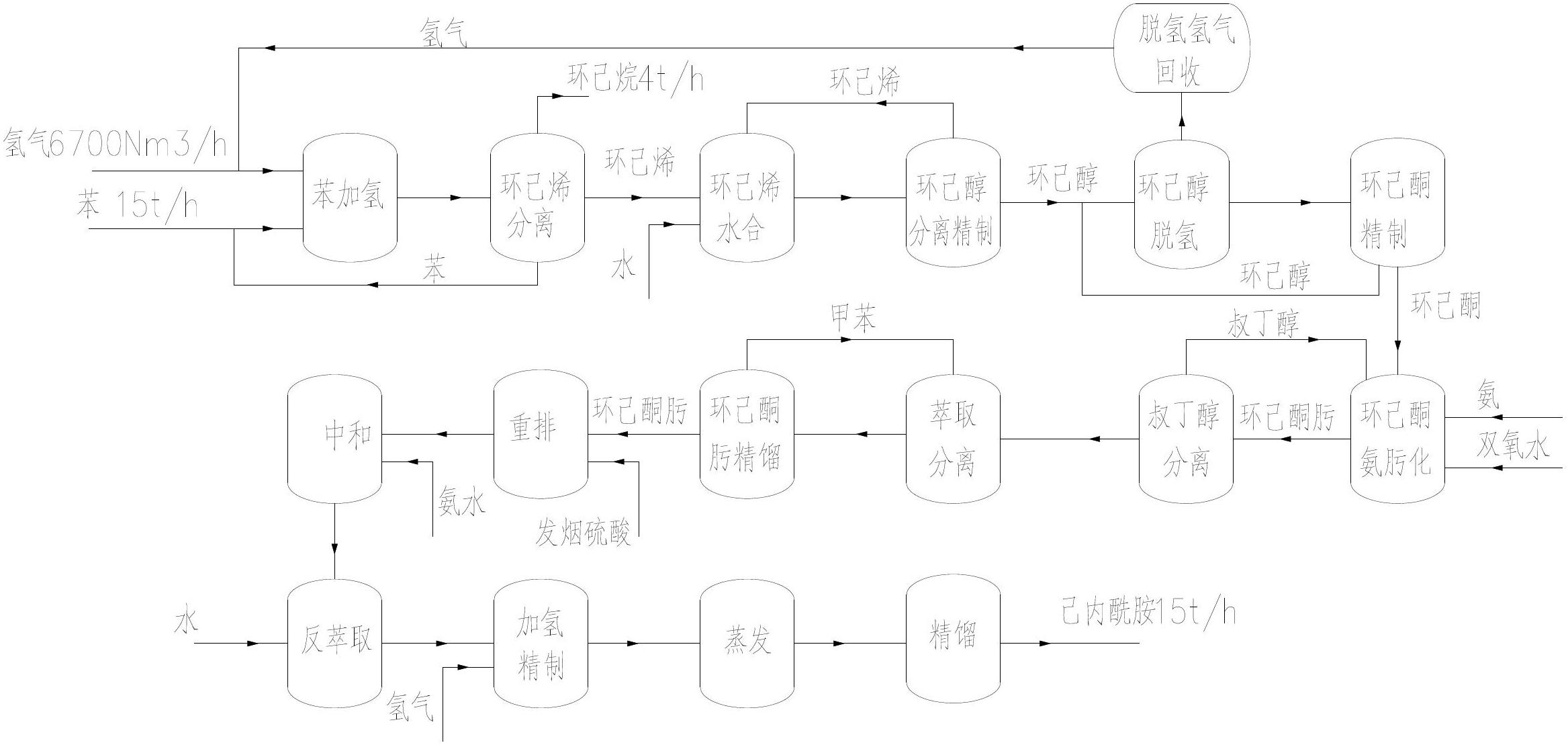

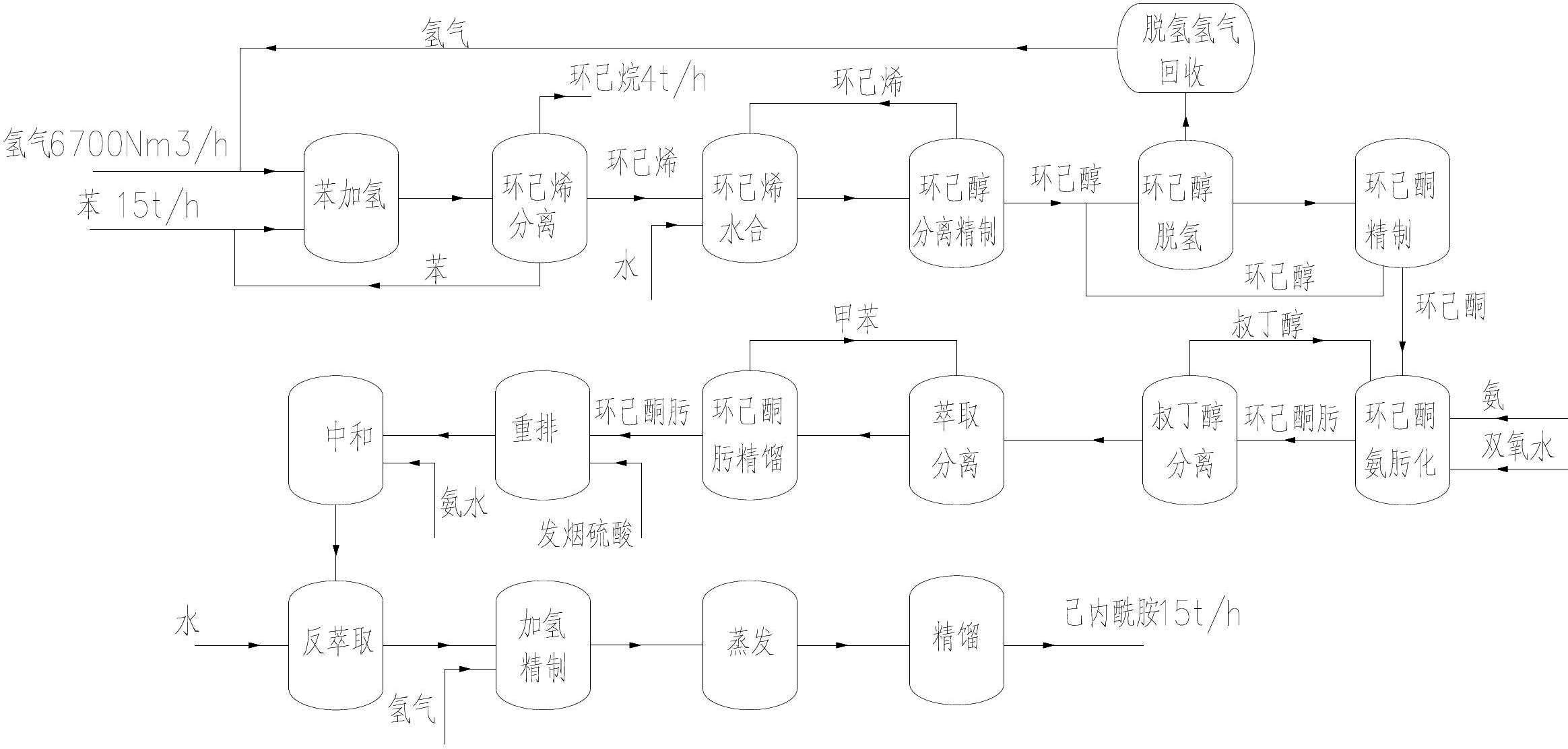

Method for producing caprolactam by taking high-purity benzene as raw material

ActiveCN102675176AAvoid it happening againQuality improvementLactams preparationHydration reactionCyclohexene

The invention provides a method for producing caprolactam by taking high-purity benzene as a raw material, and the method comprises the following steps of: A. preparing cyclohexene from the raw material benzene through hydrogenation; B. separating and purifying cyclohexene; C. carrying out hydration on the cyclohexene for preparing cyclohexanol; D. separating and purifying cyclohexanol; E. carrying out dehydrogenation on cyclohexanol for preparaing cyclohexanone; F. refining cyclohexanone; G. carrying out oximation on cyclohexanone so as to prepare cyclohexanone-oxime; H. refining cyclohexanone-oxime; I. carrying out rearrangement on refined cyclohexanone-oxime so as to prepare caprolactam; and J. refining caprolactam, wherein the high-purity benzene is adopted as a raw material, so that the purity of benzene is more than 99.95%, the sulphur content is less than 5ppm, and the methylbenzene is not more than 100ppm. The method has the beneficial effects that the high-purity benzene is adopted as a raw material, so that the impurity is less, and the product quality is high; the raw material is high in comprehensive utilization rate and low in hydrogen consumption; and the mass of the raw material and intermediate products generated in all the steps of reaction can be strictly controlled, so that the direct commercial value of the intermediate products is fully exerted, and the optimal quality of the product caprolactam can be reached.

Owner:CHINA TIANCHEN ENG +3

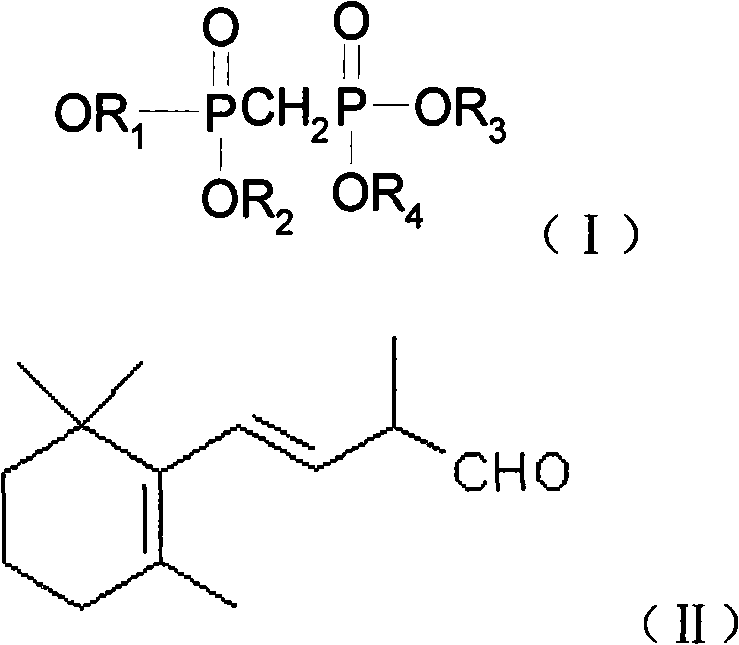

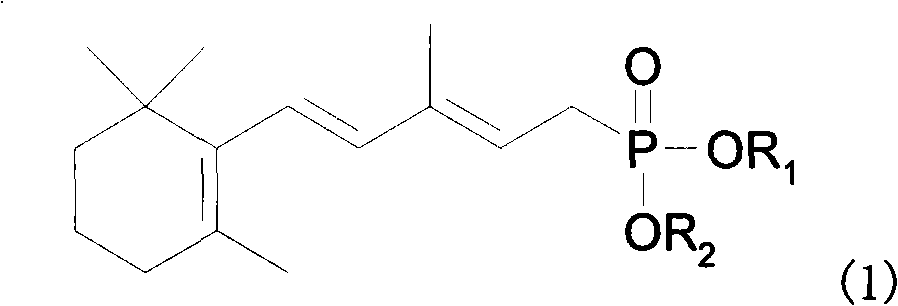

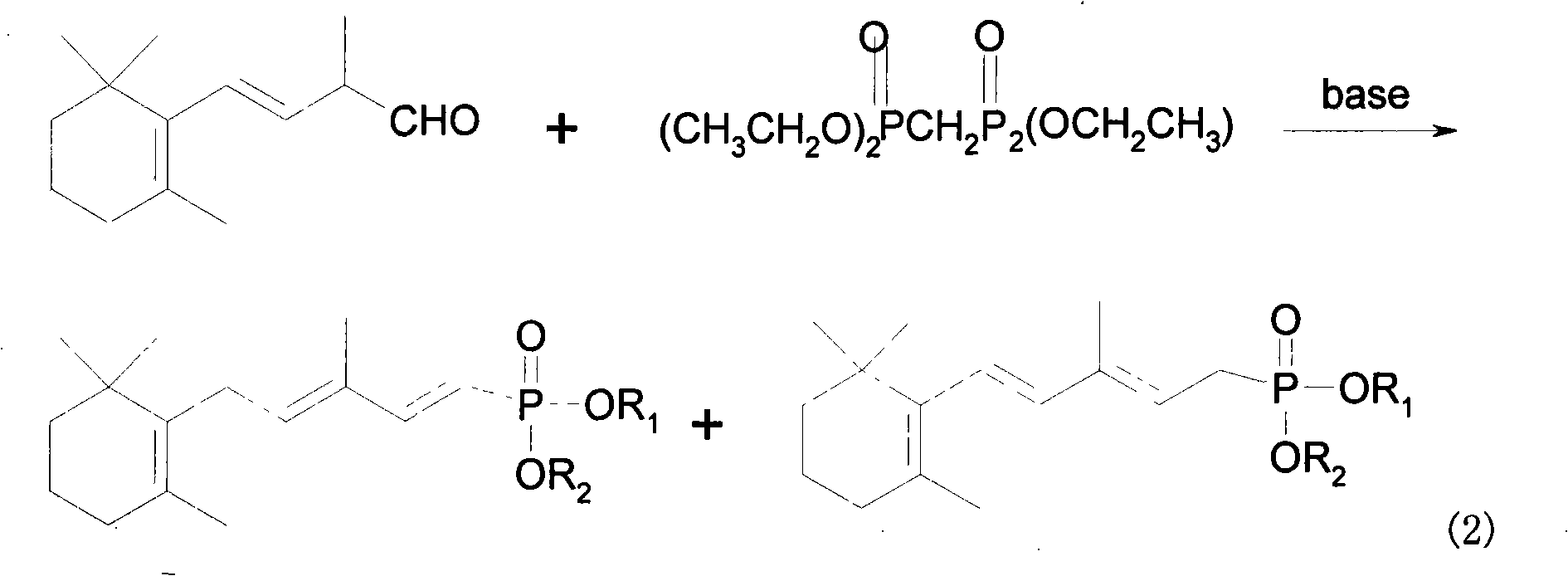

Method for preparing 3-methyl-5-(2,6,6-trimethyl-1-cyclohexene-1-base)-2, 4-pentadiene-dialkyl phosphoric ester

InactiveCN101318975AReduce energy consumption and difficulty of production operationsConducive to industrial productionGroup 5/15 element organic compoundsTolueneCyclohexenes

The invention provides a method for preparing 1, 3-methyl-5-(2, 6, 6-trimethyl-1- cyclohexene-1-yl)-2, 4-pentadiene methyl phosphonate. In the method, a benzophenone compound preventing transposition is added in the process of generating the 1, 3-methyl-5-(2,6,6-trimethyl-1-cyclohexene-1-yl)-2,4-pentadiene methyl phosphonate by the reaction of methylene diphosphate four alkyl and C14 aldehyde in a mixed solvent of methylbenzene and tetrahydrofuran, thereby inhibiting the generation of a target product isomer in order that the content of the target product in a final product reaches up to 97 percent.

Owner:GUANGZHOU WISDOM BIO TECH

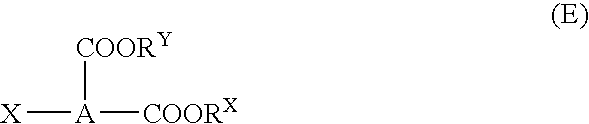

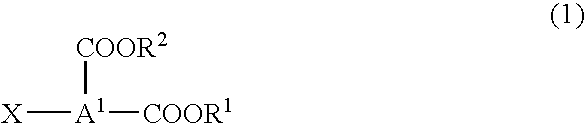

Dicarboxylic diester, process for producing the same, and refrigerating machine lubricating oil comprising the ester

A diester represented by the formula wherein A represents a cyclohexane ring, cyclohexene ring or benzene ring, X is H or methyl group, RX and RY are the same or different and each is C3-C18 branched-chain alkyl group, C1-C18 straight-chain alkyl group, C2-C18 straight-chain alkenyl or C3-C18 cycloalkyl, provided that when A is a benzene ring, RX and RY are different from each other and —COORX and —COORY are attached to two adjacent carbon atoms of the benzene ring, and having the following properties: 1) a total acid number of 0.05 mgKOH / g or less, 2) a sulfated ash content of 10 ppm or less, 3) a sulfur content of 20 ppm or less, 4) a phosphorus content of 20 ppm or less, 5) a peroxide value of 1.0 meq / kg or less, 6) a carbonyl value of 10 or less; 7) a volume resistivity of 1×1011 Ω·cm or more, 8) a hydroxyl value of 3 mgKOH / g or less, and 9) a water content of 100 ppm or less, a process for preparing the same and a refrigerator lubricating oil comprising the diester.

Owner:NEW JAPAN CHEM CO

Process for the preparation of phenol and cyclohexanone

InactiveUS20120157718A1EfficiencyGood choiceOxygen-containing compound preparationOrganic compound preparationCyclohexanoneCyclohexene

Process for the preparation of phenol and cyclohexanone which comprises:a. the synthesis of cyclohexylbenzene by the hydro-alkylation of benzene by contact with hydrogen or the alkylation of benzene with cyclohexene using Y zeolites;b. the selective aerobic oxidation of cyclohexylbenzene to the corresponding hydroperoxide catalyzed by N-hydroxy-derivatives in the presence of polar solvents; andc. the scission of the hydroperoxide of cyclohexylbenzene to phenol and cyclohexanone by homogeneous or heterogeneous acid catalysts;characterized in that the synthesis of cyclohexylbenzene takes place in the presence of a catalytic system comprising a Y zeolite and an inorganic ligand wherein the Y zeolite has a crystalline structure with openings consisting of 12 tetrahedra and the inorganic ligand is γ-alumina, and wherein said catalytic composition is characterized by a pore volume, obtained by adding the mesoporosity and macroporosity fractions, greater than or equal to 0.7 cm3 / g, wherein at least 30% of said volume consists of pores with a diameter greater than 100 nanometers.

Owner:POLIMERI EUROPA SPA

Catalyst for use in ternary polymerization of norbornene, maleic anhydride and cyclohexene and ternary polymerization method

The invention relates to a catalyst for use in ternary polymerization of norbornene, maleic anhydride and cyclohexene and a ternary polymerization method. The catalyst is characterized by being prepared by using a method comprising the following steps of: dissolving ferric trichloride, a ligand and an alkyl metal compound into a first solvent, putting into a dry single-mouth glass bottle in an inert atmosphere, sealing a bottleneck with a latex tube, preserving heat in a water bath of 50 DEG C for 20-30 minutes, and cooling to obtain an iron complex catalyst; adding norbornene, maleic anhydride and cyclohexene into a dry single-mouth glass bottle in an inert atmosphere, adding a second solvent into the single-mouth glass bottle, dissolving, and sealing the bottleneck; adding the iron complex catalyst into the single-mouth glass bottle, and reacting at the constant temperature of 40-100 DEG C for 2-3 hours; and precipitating an obtained reaction product, washing and drying to obtain a norbornene-maleic anhydride-cyclohexene terpolymer. The catalyst provided by the invention can be used for catalyzing polymerization under the normal pressure at a low temperature, and the copolymer yield is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

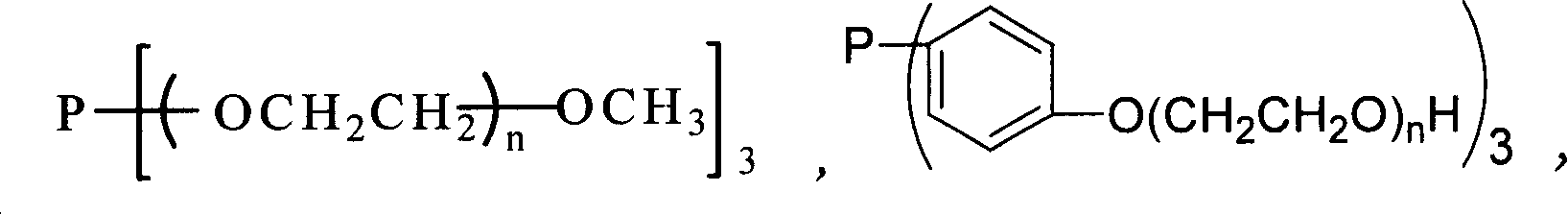

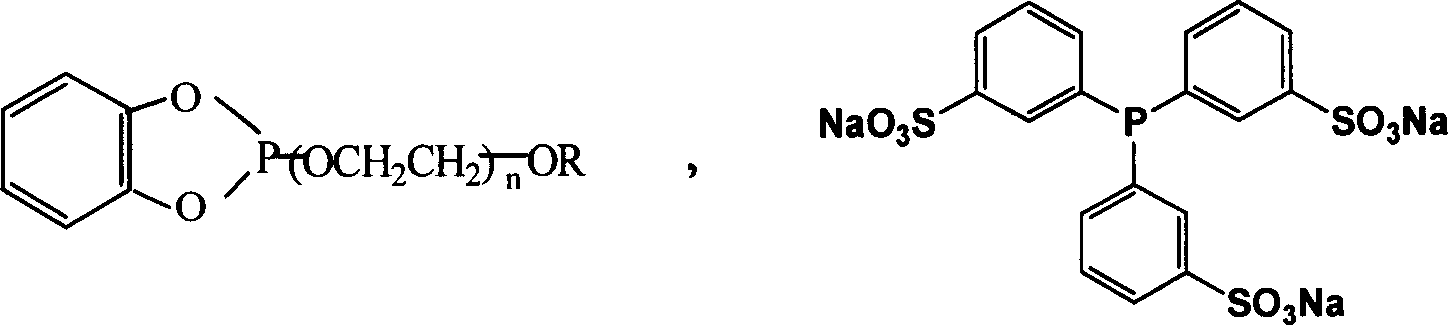

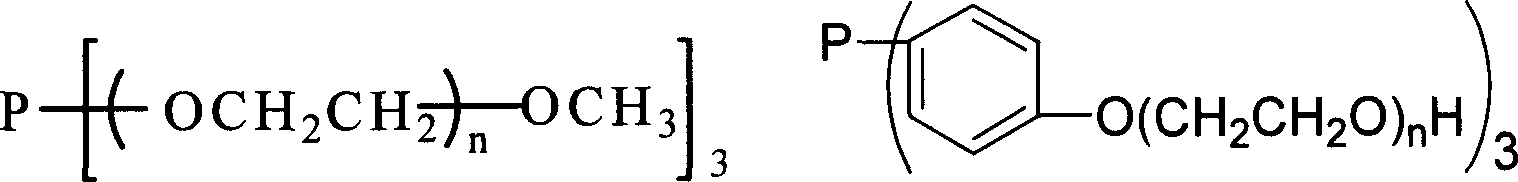

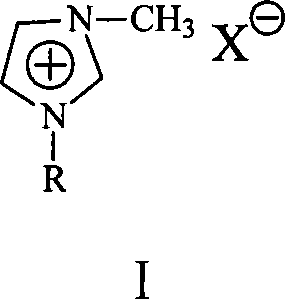

Prepn. of high carbon aldehyde by formylating high carbon olefinic hydrogen in temp ion liquid two-phase system

InactiveCN1833774AEasy to prepareLow costOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionCyclohexeneFormylation reaction

A process for preparing high-C aldehyde from high-C olefin by hydroformylation in a two-phase system consisting of the quaternary ammonium salt ion liquid containing ethoxy chain and the non-polar (or weak-polar) organic solvent features high-temp mixing and dissolving, ordinary-temp phase separation, temp control, homogeneous reaction and two-phase separation. Its advantages are high catalytic activity, selectivity and output rate, and long cyclic life of catalyst (at least 9 cycles).

Owner:DALIAN UNIV OF TECH

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1218922CReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanonePtru catalyst

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

Catalyst for preparing cyclohexene by benzene hydrogenation, its preparing method and using method

InactiveCN1714932AHigh activityGood choiceHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCyclohexeneRare earth

The catalyst for hydrogenating benzene to prepare cyclohexene is supported non-crystal alloy Ru-M-B / ZrO2, with weight ratio between Ru-M-B and ZrO2 of 10-30 %. The preparation process of the catalyst is one chemical reduction process with micron level ZrO2 as carrier, Rh as active component, RE as assistant and borohydride as reductant. In the process, metal Rh, light RE and metal-like B are supported firmly in the non-crystal alloy Ru-M-B form onto ZrO2. The present invention also provides the usage of the catalyst in producing cyclohexene, and by considering the characteristic of continuous benzene hydrogenating reaction, the reaction slurry comprising water, ZrO2, ZnSO4.7H2O is used in deactivating the catalyst to raise the yield of cyclohexene and reduce the production of side product cyclohexane. The present invention is suitable for industrial cyclohexene production.

Owner:ZHENGZHOU UNIV +1

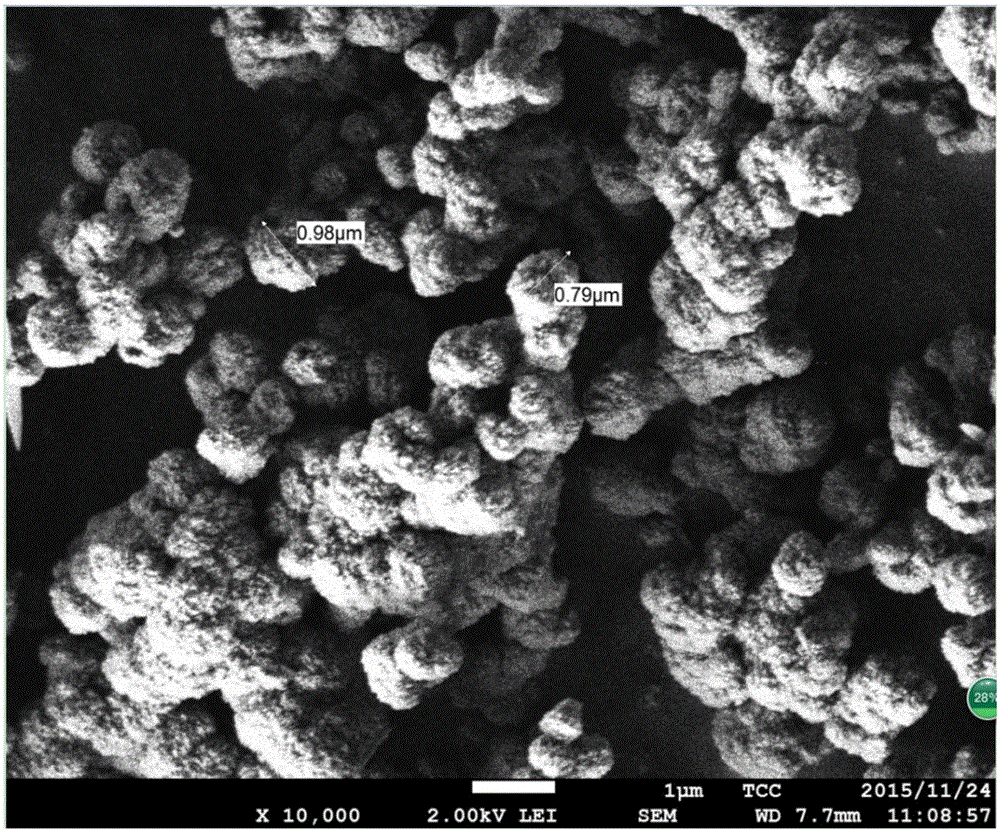

Application and preparation method of ZSM-5 molecular sieve with mesopores and micropores

ActiveCN105728019ASimple stepsEven stepsMolecular sieve catalystsPreparation by hydroxy group additionCyclohexeneCyclohexanol

The invention provides an application and a preparation method of a ZSM-5 molecular sieve with mesopores and micropores. The preparation method includes steps of precursor preparation, silica-alumina gel preparation and preparation of the ZSM-5 molecular sieve with the mesopores and micropores.In a preparation process of a hierarchical porous catalyst, consumption of a microporous templating agent and a mesoporous templating agent can be substantially reduced, synthesis steps of the hierarchical porous catalyst are simple, and the synthesized molecular sieve is large in specific surface area, uniform in particle size and controllable in mesopore quantity and size, and intrinsic lipophilicity of the molecular sieve is enhanced due to abundant surface terminal hydroxide radicals. By adoption of the molecular sieve as the catalyst, a method for preparing cyclohexanol by direct hydration of cyclohexene is established, and the catalyst is high in cyclohexene conversion rate and cyclohexanol selectivity.

Owner:CHINA TIANCHEN ENG +1

Method for producing epoxy cyclohexane

The epoxy cyclohexane producing process includes using cyclohexene as main material, molecular oxygen as oxygen source, n-valeraldehyde or isovaleraldehyde or isobutylaldehyde as intermediate; adopting re-compounded catalyst including at least one oxide of Mn, Fe, Co and Ni, at least one oxide of Mo and W, and at least one oxo acid of N, P and As; and reaction at 30-80 deg.c for 2-12 hr. The re-compounded catalyst can oxidize aldehyde into per-acid in high selectivity and catalyze the reaction between per-acid with cyclohexene in high selectivity to obtain epoxy cyclohexane as the destination product in the same reactor, with the single-path cyclohexene converting rate reaching 23 % and selectivity reaching 98 %. The reaction process uses no solvent and the metal oxide in the re-compounded catalyst may be reused.

Owner:BALING PETRO CHEM CO LTD SINOPEC

Method for preparing 3,5-dimethylphenol

InactiveCN101348421AReduce dosageHigh yieldOrganic chemistryOrganic compound preparationCyclohexeneKetone

The invention provides a preparation method of 3, 5-dimethyl phenol. The method comprises the following steps that halogenated hydrocarbon catalysts such as methyl iodide or n-bromobutane are premixed with 3, 5, 5-trimethyl 2-cyclohexene-1-ketone and then are fed into a tubular reactor so as to carry out reaction under the conditions of 400 to 600 DEG C and 1 to 5atm; then, a target product can be obtained after separation. The method can reduce the consumption of catalysts, and can substantially increase conversion rate and selectivity; moreover, reaction conditions are more moderate and more suitable for industrial production.

Owner:HUNAN LIJIE BIOCHEM

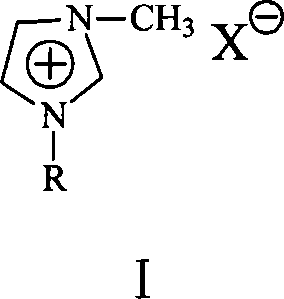

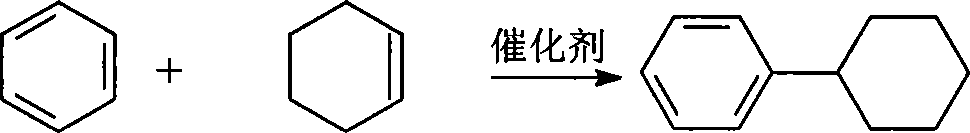

Process for producing cyclohexylbenzene

InactiveCN101219922AEasy to recycleHigh purityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsBenzeneAlkyl transfer

The invention relates to a method for preparing cyclohexylbenzene by benzene and cyclohexene through alkylation reaction, comprising the main step that under the condition with a catalyst, target substance is prepared by the benzene and the cyclohexene through the alkylation reaction; the invention is characterized in that the catalyst is imidazole ionic liquid or triethylamine hydrochloride ionic liquid. The invention overcomes the defects that the catalyst in the prior art can not be repeatedly used or the reaction activity decreases after repeated usage.

Owner:EAST CHINA UNIV OF SCI & TECH

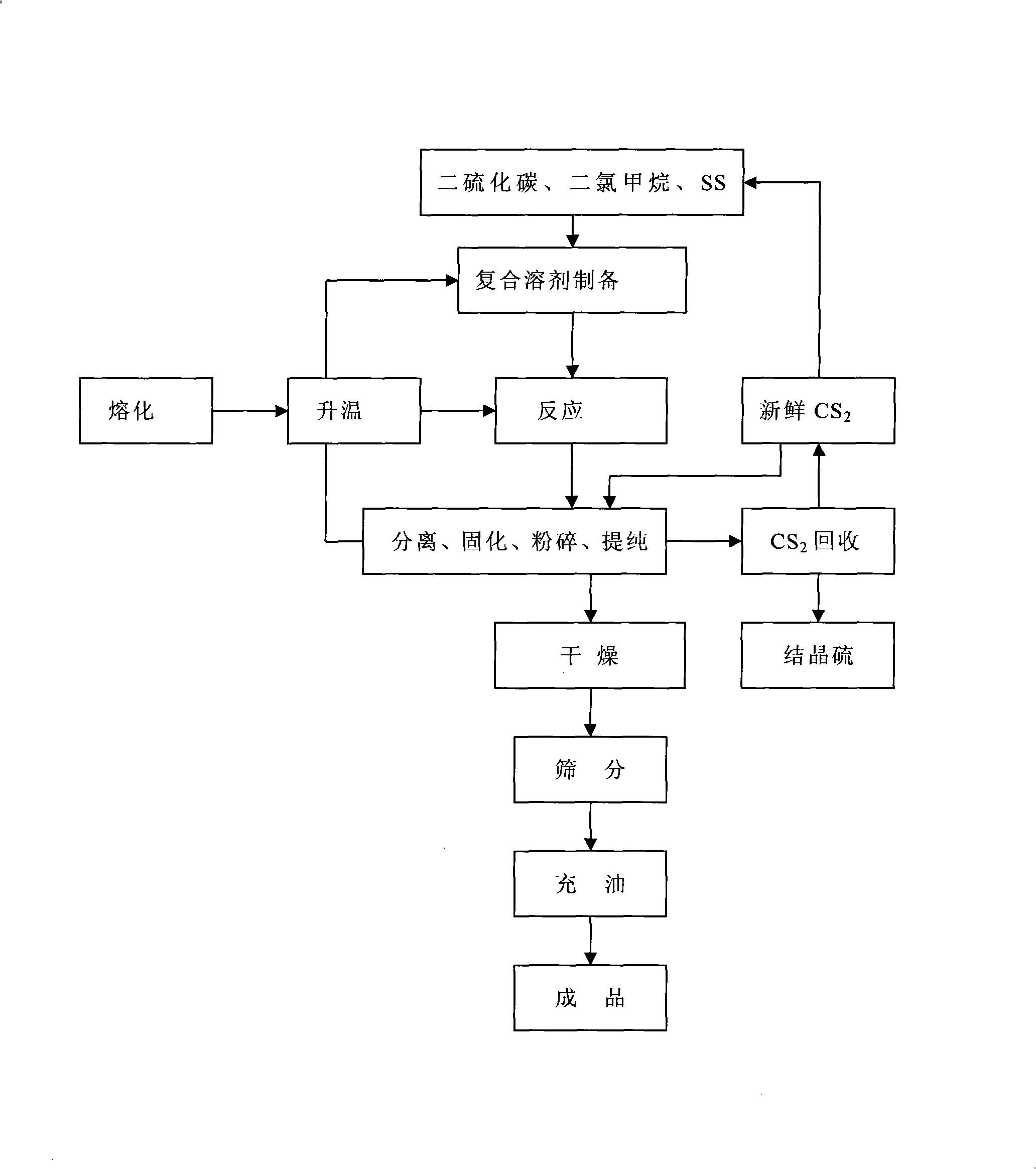

Method for continuous preparation of sulfur with high heat-stability and insolubility

ActiveCN101343045AImprove labor productivityUniform qualitySulfur preparation/purificationCyclohexeneSulfur

The invention provides a method of producing high thermostability insoluble sulfur continuously, which includes the steps that: a melting and heating-up; b the solvent preparation; c reaction; d separation, solidification, grinding and purification; e drying; f screening and oil filling; in the step b, the solvent is composite solvent and composed of carbon bisulfide, dichloromethane and SS auxiliary agent; the weight proportion of the three compositions is 78-95: 5-20: 0.01-2; wherein, the SS auxiliary agent is olefin with unsaturated bonds; the SS auxiliary agent can adopt the Alfa-methylstyrene, isoprene or 1-ethylene-3-cyclohexene. The method of producing high thermostability insoluble sulfur continuously has the advantages that the sulfur is produced through the composite solvent method; the obtained product can satisfy the requirement of the belt tyre; the continual production is adopted to improve the labor productivity greatly which is higher than the intermittent method production level; the quality of the products is ensured to be consistency; the grinding in fluid is adopted to avoid the flammability and explosiveness problems caused by the grinding of the infusible sulfur powder; no is generated so that the producing method belongs to an environmental protection method.

Owner:SHANDONG SUNSINE CHEM

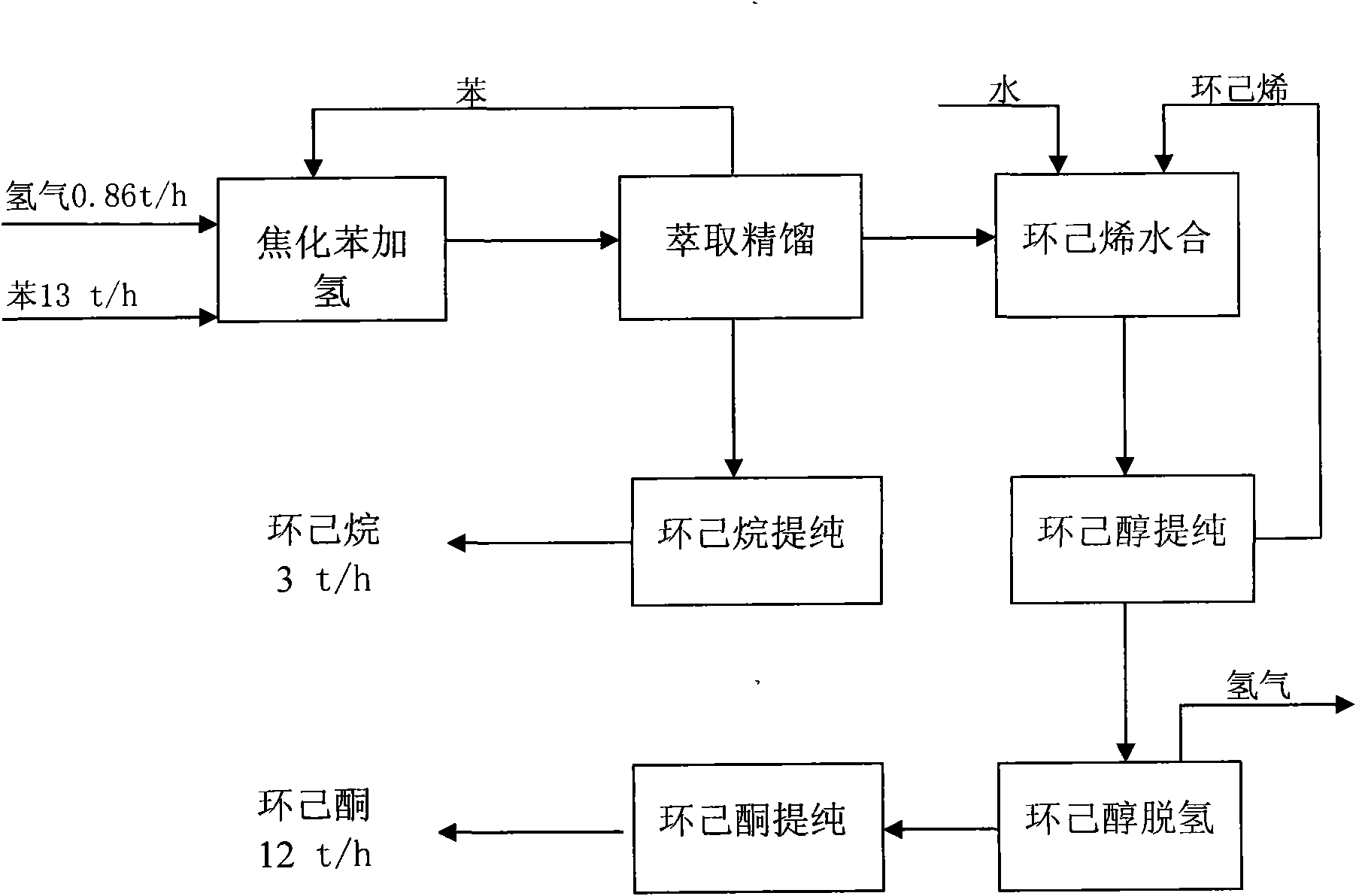

Method for producing cyclohexanone by using coked benzene

ActiveCN101628862AHave resourcesHas costOrganic compound preparationCarbonyl compound preparationCyclohexanoneHydration reaction

The method for producing cyclohexanone by using coked benzene is implemented according to the following steps: A. hydrogenation of the coked benzene to prepare cyclohexene; B. extraction and rectification; C. hydratization of the cyclohexene to prepare cyclohexanol; D. separation and extraction of the cyclohexanol; E. dehydrogenation of the cyclohexanol to prepare the cyclohexanone; and F. refining of alcohol and ketone. The method has the advantages that 1. as the coked benzene, the product of the coal chemical industry, is used as the raw material, the method has resource advantage and cost advantage and saves 15-20 percent of resource and cost when compared with a cyclohexane method; 2. the method has high comprehensive yield rate and low hydrogen consumption, almost 99 percent of the coked benzene is converted into usable products, namely the cyclohexanone and the cyclohexane, the ratio between the cyclohexanone and the cyclohexane is 1:0.25, and the hydrogen consumption is reduced by two thirds; 3. the method is environment friendly; a small amount of waste gas and waste liquid is generated, and the investment in waste disposal is small, therefore the method is a clean production technology; and 4. the method is safer; the hydrogenation reaction and the hydratization reaction are both carried out in liquid, conditions are mild, and the method is safer when compared with a traditional oxidation technology, prevents the corrosion and the byproduct blockage and has high operation stability.

Owner:HEBEI SHIJIAO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com