Zn reinforced rare earth sulfur oxide up-conversion luminescent material and preparation method thereof

A rare earth oxysulfide, luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the symmetry of crystal structure and phonon energy, uneven particle size, weak luminous intensity, etc., to reduce symmetry Effects of sex and phonon energy, simple reaction conditions, enhanced luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

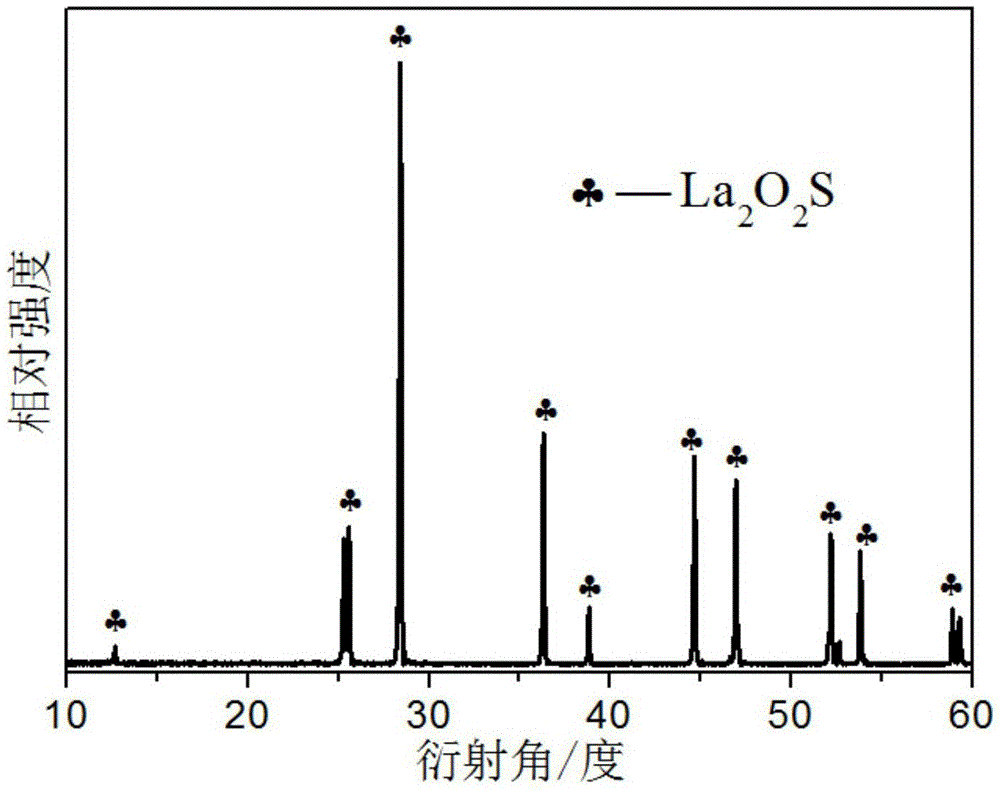

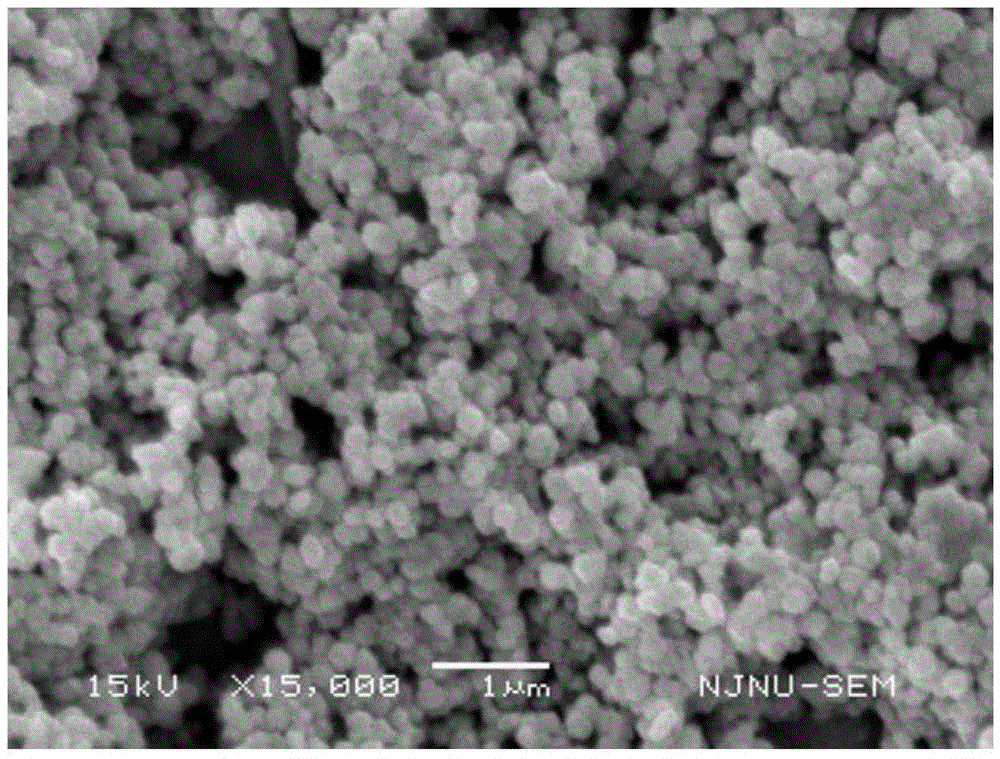

[0047] A Zn-enhanced rare earth oxysulfide up-conversion luminescent material, its chemical formula is (La 0.8175 Yb 0.16 Ho 0.0075 Zn 0.015 ) 2 o 2 S.

[0048] The preparation method of the rare earth sulfur oxide up-conversion luminescent material comprises the following steps:

[0049] S11, according to the chemical formula (La 0.8175 Yb 0.16 Ho 0.0075 Zn 0.015 ) 2 o 2 S, weigh the required raw material 20.171gLa (NO 3 ) 3 ·6H 2 O, 4.095gYb (NO 3 ) 3 ·5H 2 O, 0.187gHo(NO 3 ) 3 ·5H 2 O and 0.254gZn(NO 3 ) 2 ·6H 2 O, above-mentioned raw material is dissolved, is mixed with nitrate solution; According to the amount of raw material, takes by weighing 7.902g oxalic acid, and is mixed with oxalic acid solution;

[0050] S12. Drop the nitrate solution described in step S11 into the precipitant solution, and stir; after the titration, continue to stir, and seal the titrated solution, leave it to age, and filter;

[0051] S13. Wash and dry the precipitate fil...

Embodiment 2

[0054] A Zn-enhanced rare earth oxysulfide up-conversion luminescent material, its chemical formula is (La 0.775 Yb 0.2 Er 0.005 Zn 0.02 ) 2 o 2 S.

[0055] The preparation method of the rare earth sulfur oxide up-conversion luminescent material comprises the following steps:

[0056] S21, according to the chemical formula (La 0.775 Yb 0.2 Er 0.005 Zn 0.02 ) 2 o 2 S, weigh the required raw material 19.020gLa (NO 3 ) 3 ·6H 2 O, 5.091gYb (NO 3 ) 3 ·5H 2 O, 0.126gEr(NO 3 ) 3 ·5H 2 O and 0.337gZn(NO 3 ) 2 ·6H 2 O, above-mentioned raw material is dissolved, is mixed with nitrate solution; According to the amount of raw material, takes by weighing 7.145g oxalic acid, and is mixed with oxalic acid solution;

[0057] S22. Drop the nitrate solution described in step S21 into the oxalic acid solution, and stir; after the titration, continue to stir for 0.5 hours, seal the titrated solution, leave it to age for 10 hours, and filter;

[0058] S23. Wash the filtered...

Embodiment 3

[0061] A Zn-enhanced rare earth oxysulfide up-conversion luminescent material, its chemical formula is (La 0.8175 Yb 0.16 Ho 0.0075 Zn 0.015 ) 2 o 2 S.

[0062] The preparation method of the rare earth sulfur oxide up-conversion luminescent material comprises the following steps:

[0063] S31, according to the chemical formula (La 0.8175 Yb 0.16 Ho 0.0075 Zn 0.015 ) 2 o 2 S, weigh the required raw material 20.171gLa (NO 3 ) 3 ·6H 2 O, 4.095gYb (NO 3 ) 3 ·5H 2 O, 0.187gHo(NO 3 ) 3 ·5H 2 O and 0.254gZn(NO 3 ) 2 ·6H 2 O, above-mentioned raw material is dissolved, is mixed with nitrate solution; According to the amount of raw material, takes by weighing 7.902g oxalic acid, and is mixed with oxalic acid solution;

[0064] S32, drop the nitrate solution described in step S31 into the oxalic acid solution, and stir; after the titration, continue to stir for 1 hour, and seal the titrated solution, leave it to age for 12 hours, and filter;

[0065] S33. Wash the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com