Epoxy resin composition used for fiber winding and preparation method of epoxy resin composition

A technology of epoxy resin and composition, applied in the field of composite materials, can solve the problems of decreased temperature resistance, phase separation, etc., and achieve the effects of improving mechanical properties, increasing toughness, and excellently enhancing the effect of activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

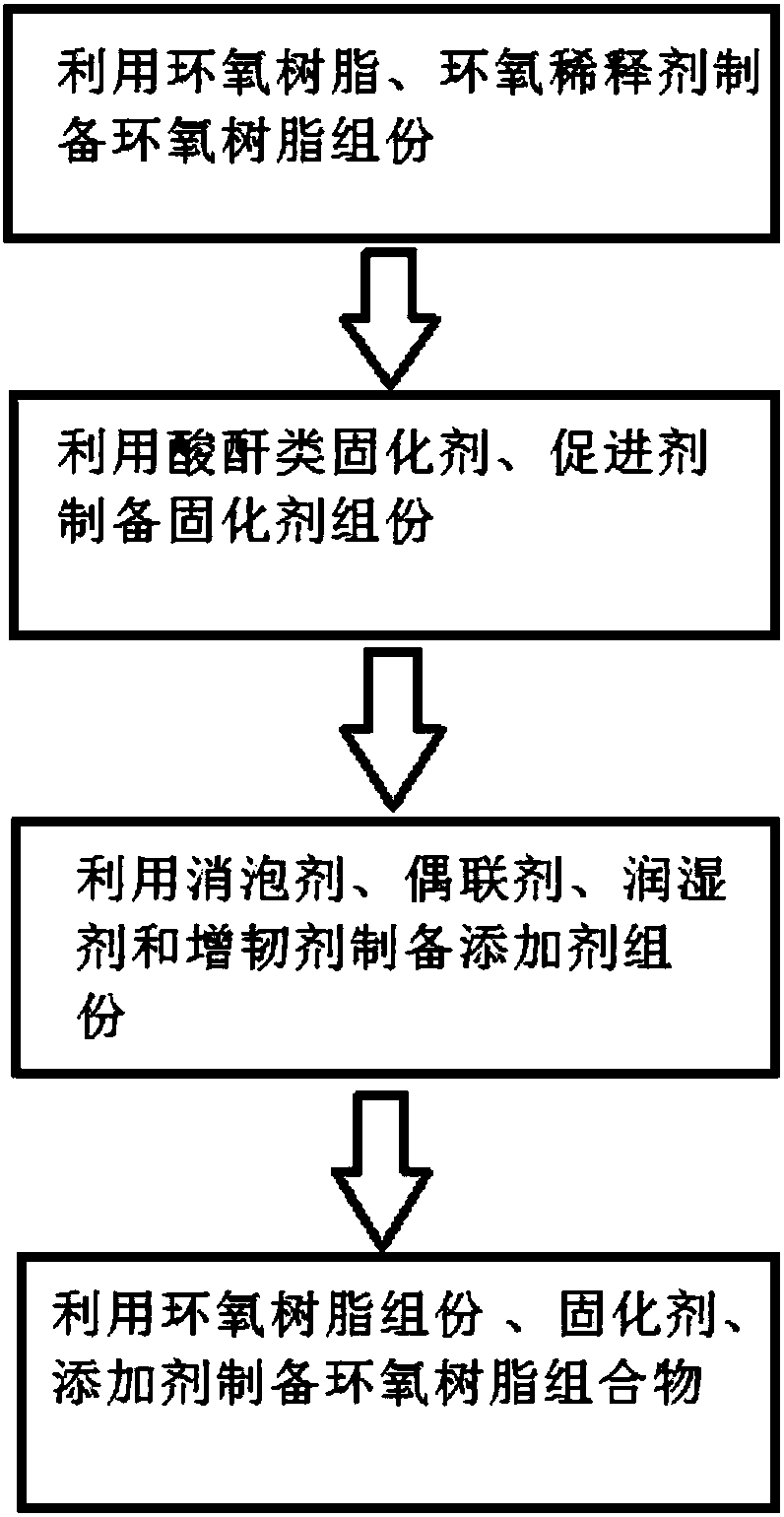

[0044] The present invention also provides a kind of preparation method that can be applied to the epoxy resin composition of filament winding, such as figure 1 shown, including the following steps:

[0045] Step 1, prepare epoxy resin component (A):

[0046] Preheat 5-65 parts of one or more epoxy resins to 50-60°C in the reactor;

[0047] Add 10-20 parts of epoxy diluent to the reaction kettle, keep the vacuum and negative pressure state, keep the temperature of the reaction kettle at 40-50°C, and use high speed 28rpm, low speed 24rpm to continue stirring for 60-90min;

[0048] After the stirring is finished, wait for the temperature to cool down to room temperature and return to normal pressure to obtain the resin component (A).

[0049] Step 2, prepare curing agent component (B):

[0050] Add 90-99 parts of acid anhydride curing agent to the reaction kettle, add 1-10 parts of accelerator to maintain a vacuum and negative pressure state, keep the temperature of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com