Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Atomic component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An atomic component is a single entity, both to the user and to the programmer who uses its API. To see pictures of all the atomic components, go to A Visual Index to the Swing Components. All the atomic components descend from the JComponent class. Thus, they all support standard features such as tool tips and borders.

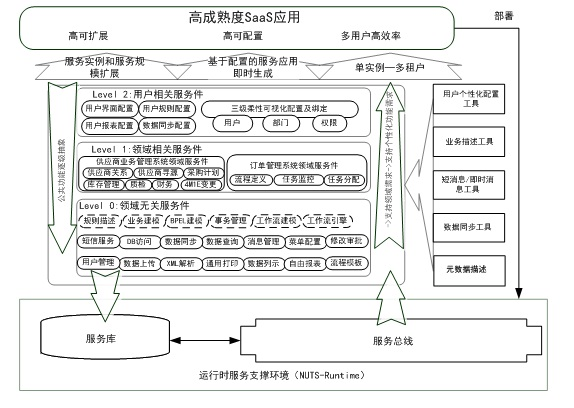

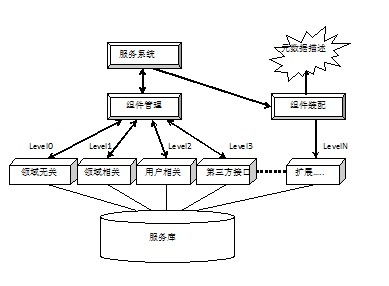

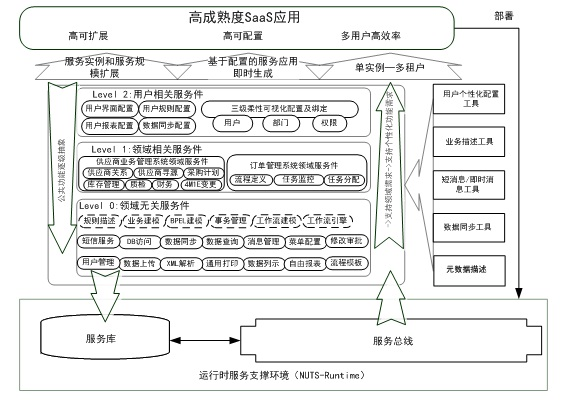

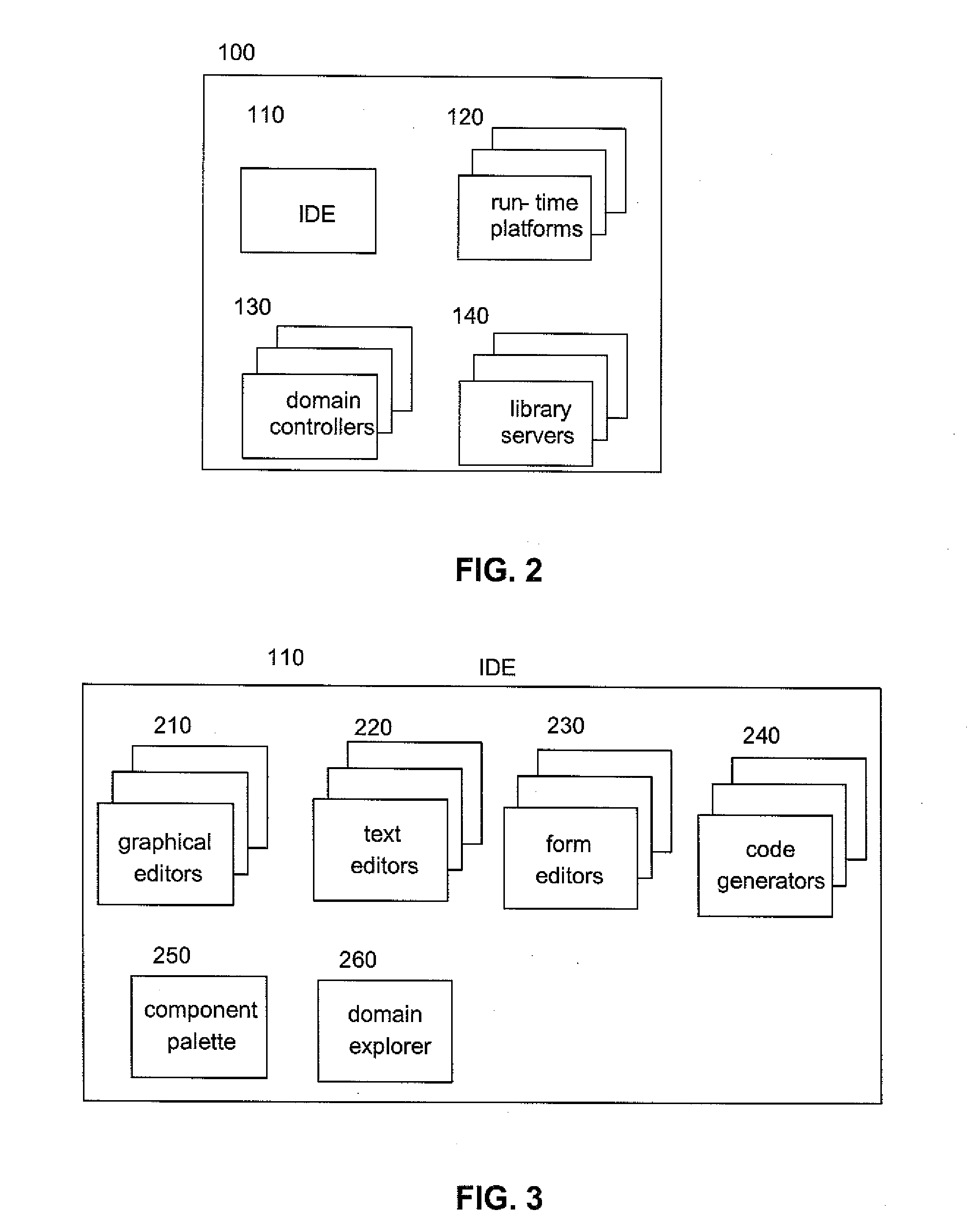

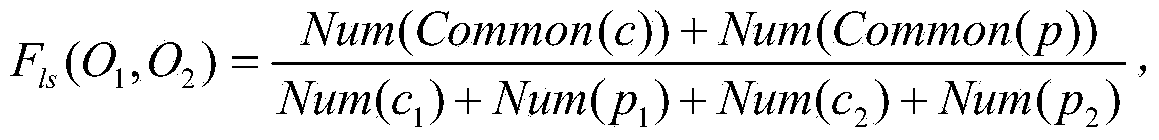

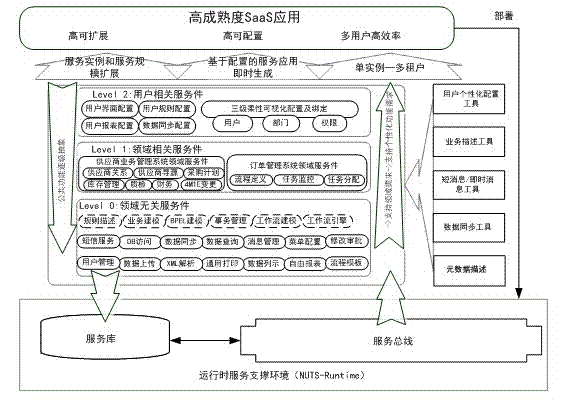

Service software construction method and system adapting to multiple business abstraction levels

InactiveCN101794226AReduced domain knowledge requirementsImprove reusabilityData switching networksSpecific program execution arrangementsAbstraction layerService-orientation

The invention discloses a service software construction method and a system adapting to multiple business abstraction levels. The invention is based on business-oriented frameworks, and constructs the service component resources by a stage-by-stage abstraction method, and a software system is constructed on the basis. According to the application requirements of different business abstraction levels, the invention also provides construction way atom component unrelated to the field, a composite component reconstruction way related to the field, and a configuration way related to the user business. Thus, the construction and the management of the software can aim at different business requirements and abstraction levels, and a proper method can be utilized to adapt to quick reconstruction of large-scale multiple tenants and software, namely quick reconstruction of service mode applications, thereby ensuring the efficiency, economical efficiency and reliability of software production.

Owner:SHANDONG UNIV

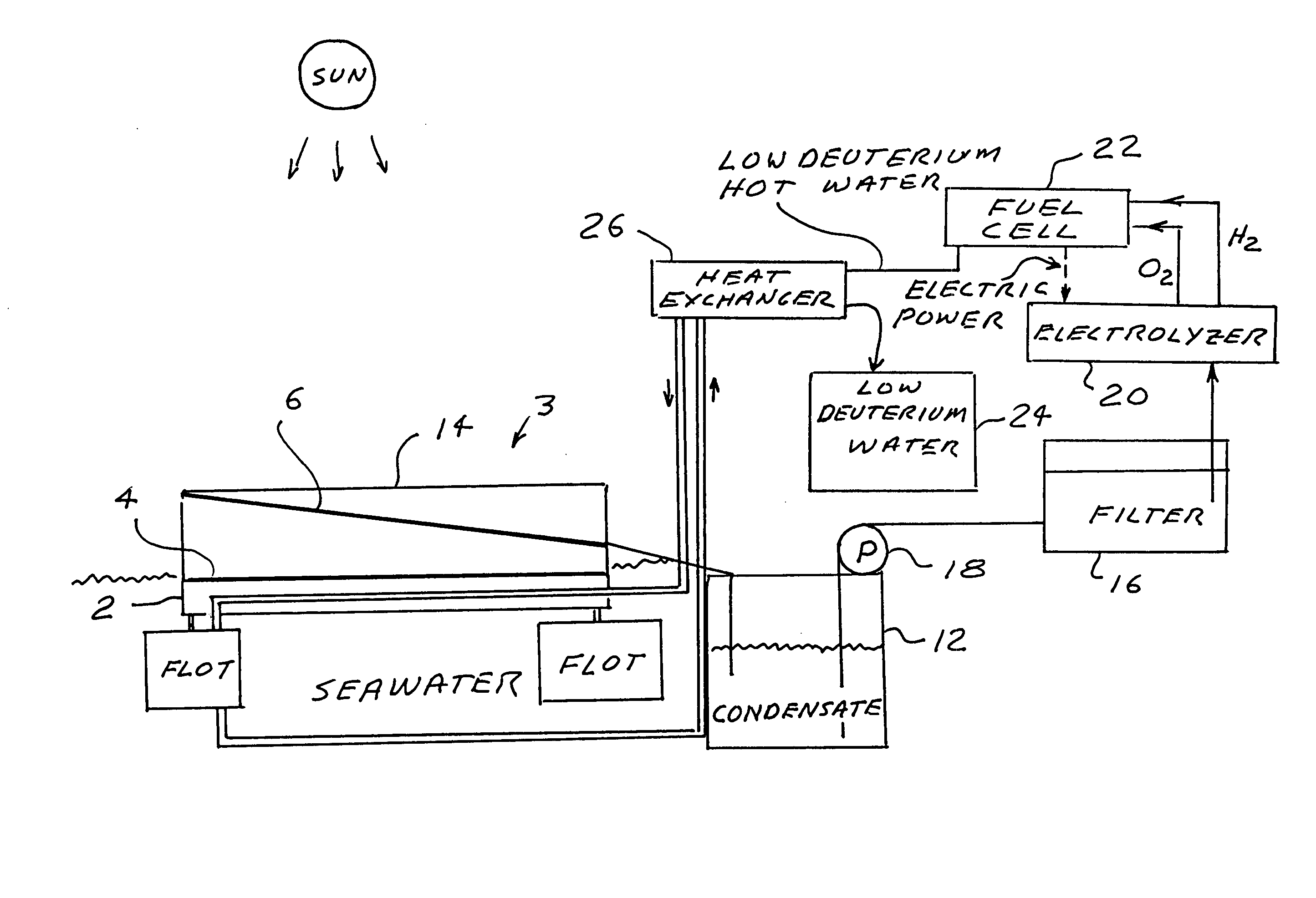

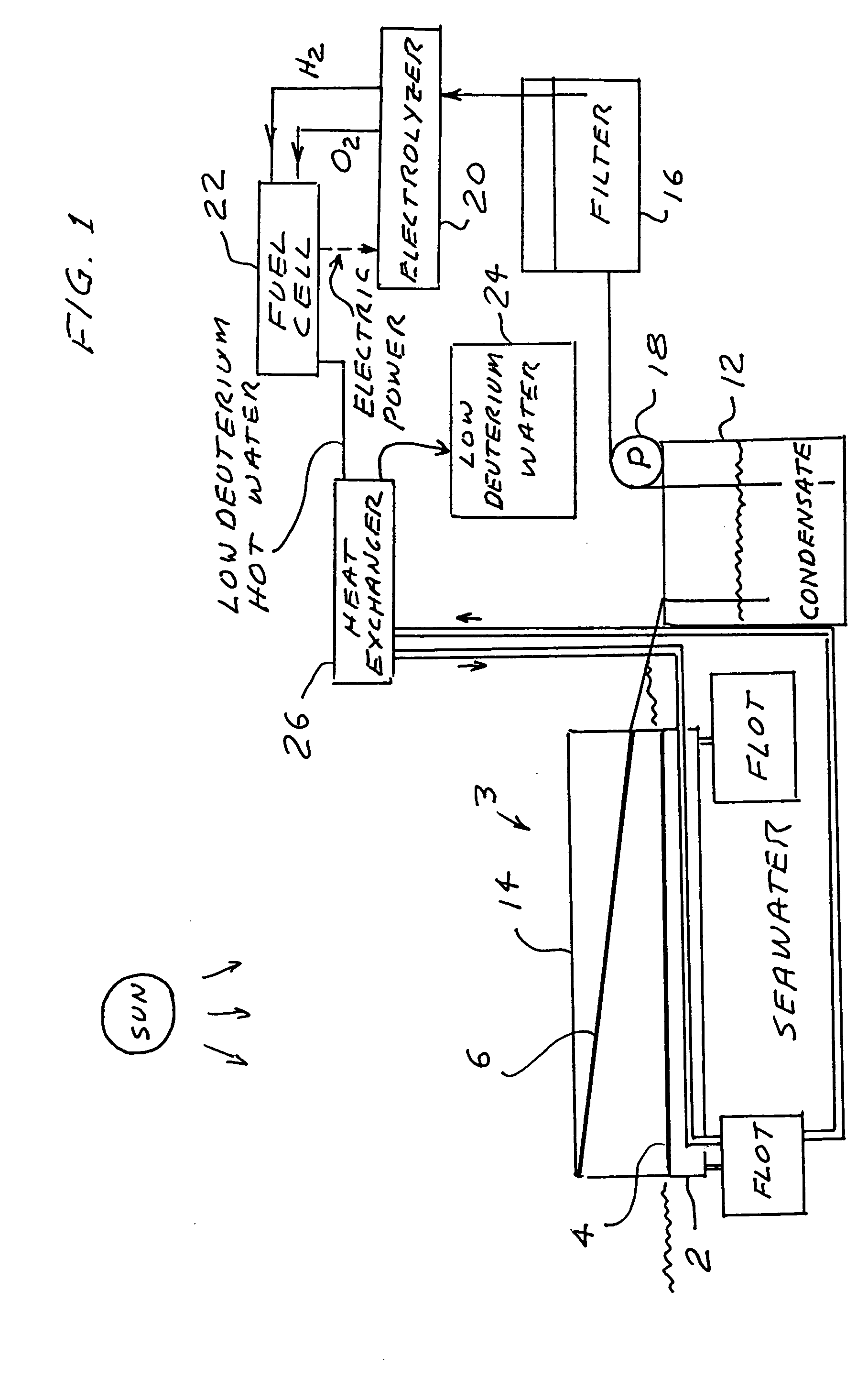

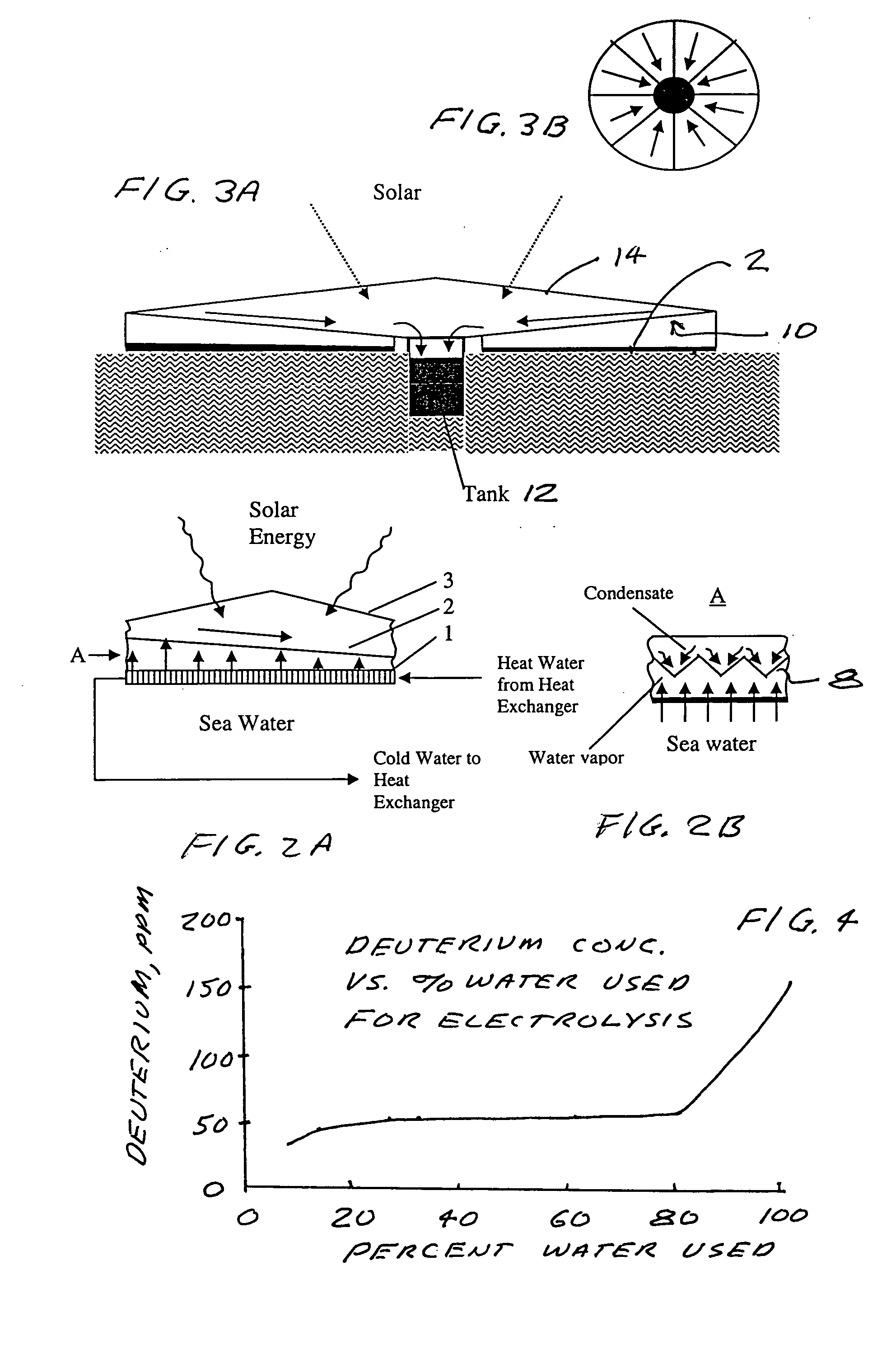

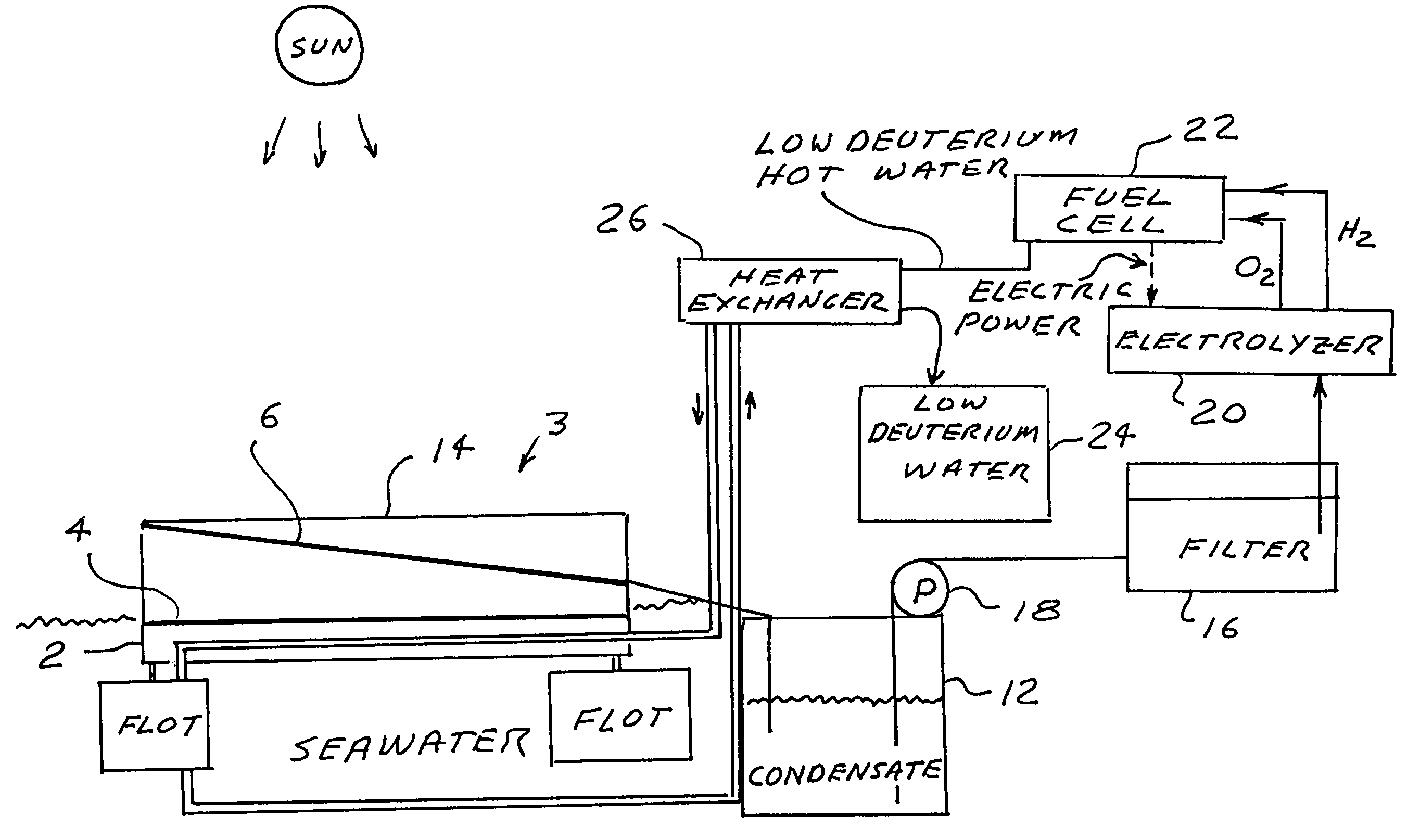

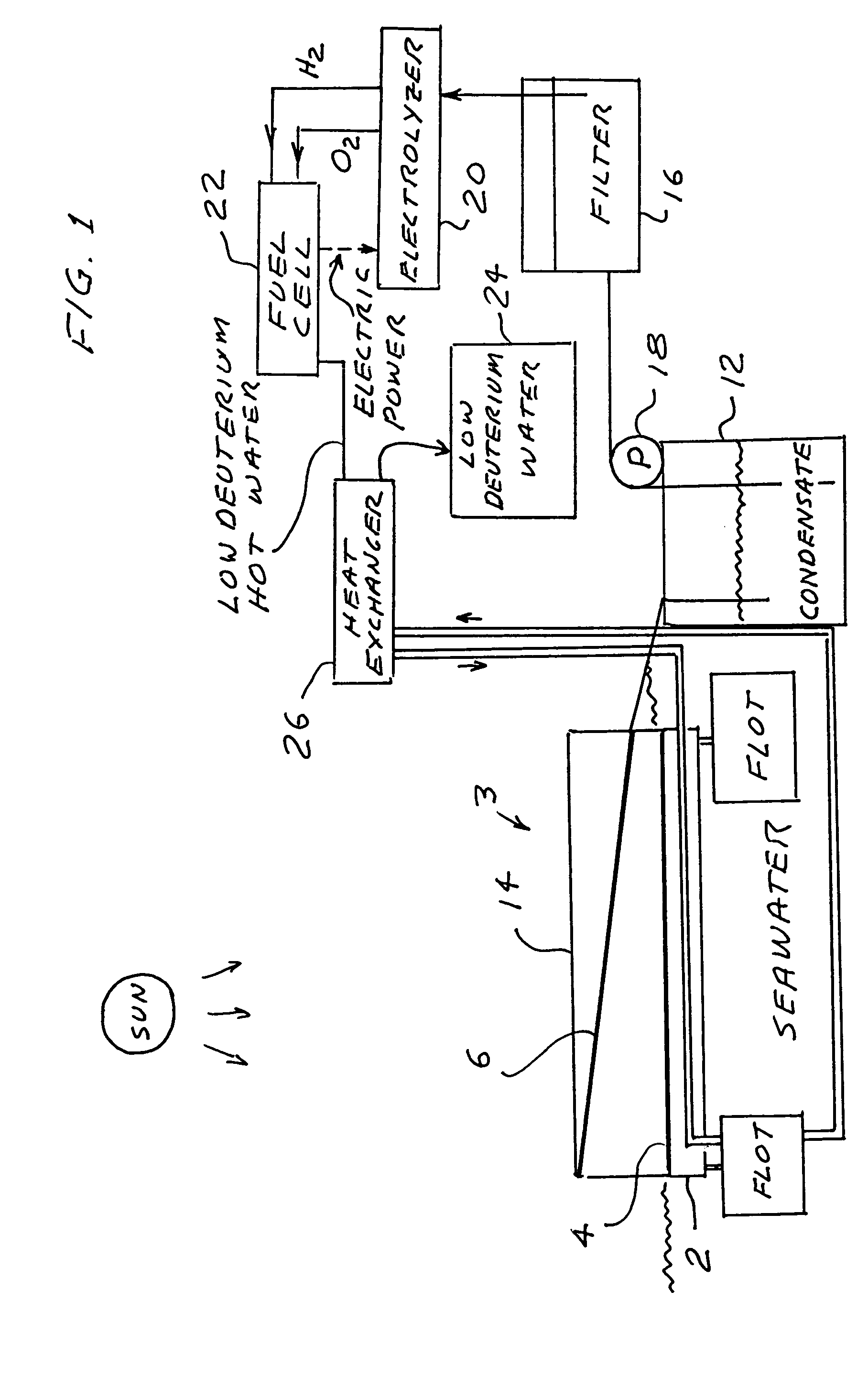

Plant for producing low deuterium water from sea water

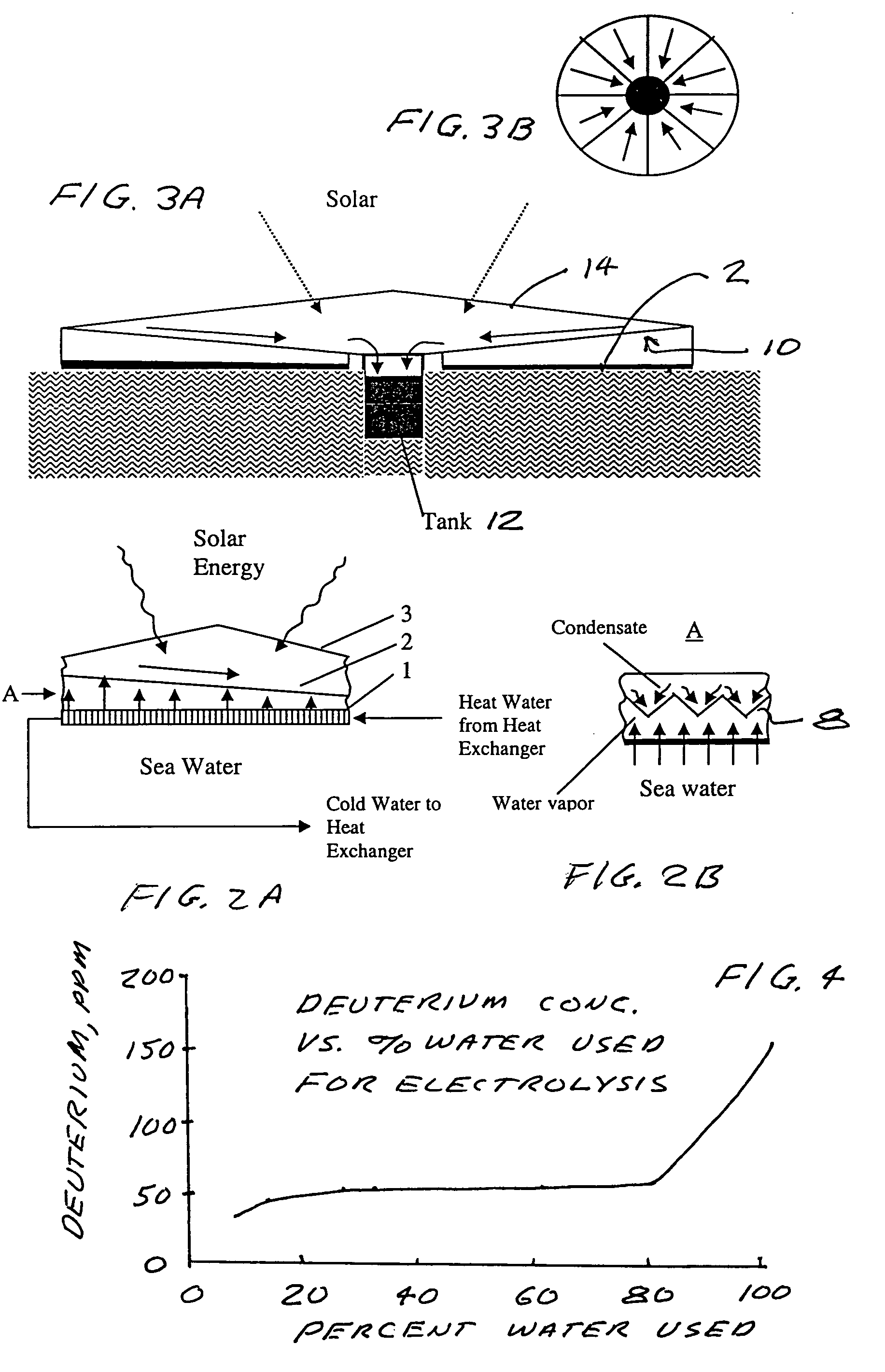

InactiveUS20050109604A1Efficient productionImprove efficiencyElectrolysis componentsPhotography auxillary processesOxygenSeawater

A plant and process for efficient production of low deuterium water from seawater. The plant includes a solar still with a black pan for collecting solar heat, that vaporizes portions of the seawater and a porous sloped membrane positioned over the black pan to collect and condense the vapor and to direct the condensate via gravity to a condensate tank. The condensate water is separated into its atomic components, hydrogen and oxygen, in an electralizer; then the hydrogen and oxygen are combined in a reactor to produce heat and low deuterium water. In preferred embodiments the reactor is a fuel cell which in addition to the heat and water also produces electricity. At least a portion of the heat produced in the reactor is used in the solar still to assist in the vaporization of the seawater and to greatly increase the efficiency of the still.

Owner:ZLOTOPOLSKI VLADIMIR Z

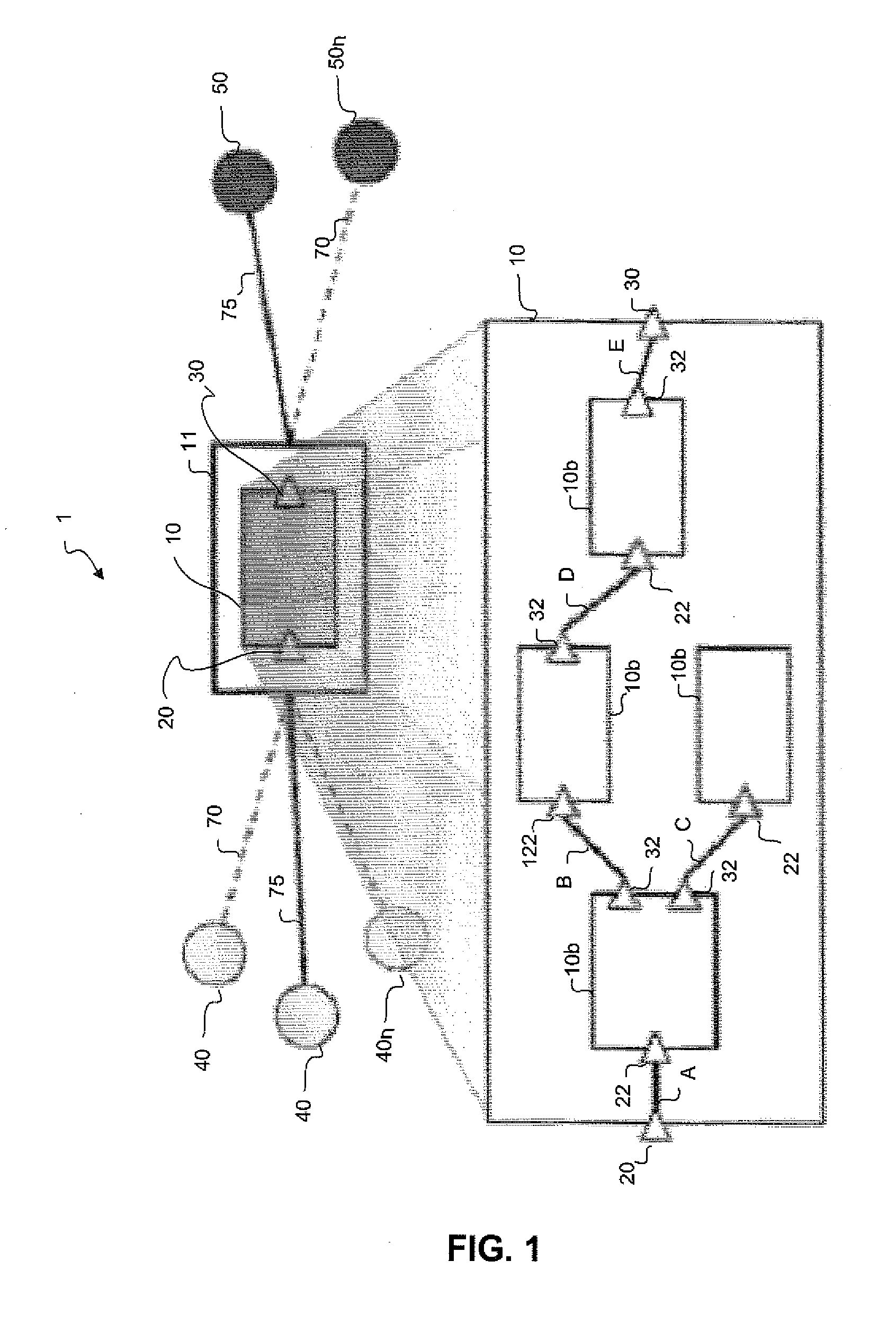

System and method for developing and deploying sensor and actuator applications over distributed computing infrastructure

InactiveUS20090106011A1Geometric CADAnalogue computers for electric apparatusDomain modelDistributed computing infrastructure

The present invention discloses a method for coordinating zero or more modelings, zero or more implementations and zero or more deployments of a computer system, including but not limited to computer systems involving sensors, actuators, or both and a system providing assistance to designers, implementers, and deployers of computer systems. The method and system including: defining one or more interfaces of one or more components; creating models for the one or more components, each of which is either a composite component model or a atomic component, model, creating the one or more composite components as instances of the composite component models creating the one or more atomic components as instances of the atomic component models creating a domain model by specifying the computational resources; and creating a deployment model by specifying one or more component-model instances and specifying which the component-model instances should be executed on which the computational resources of the domain model.

Owner:IBM CORP

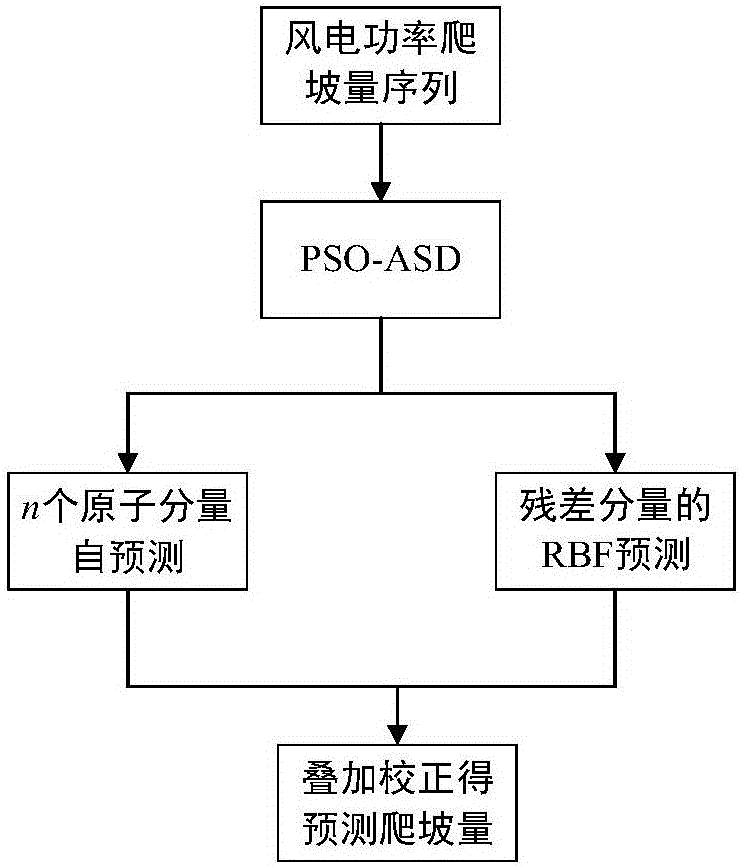

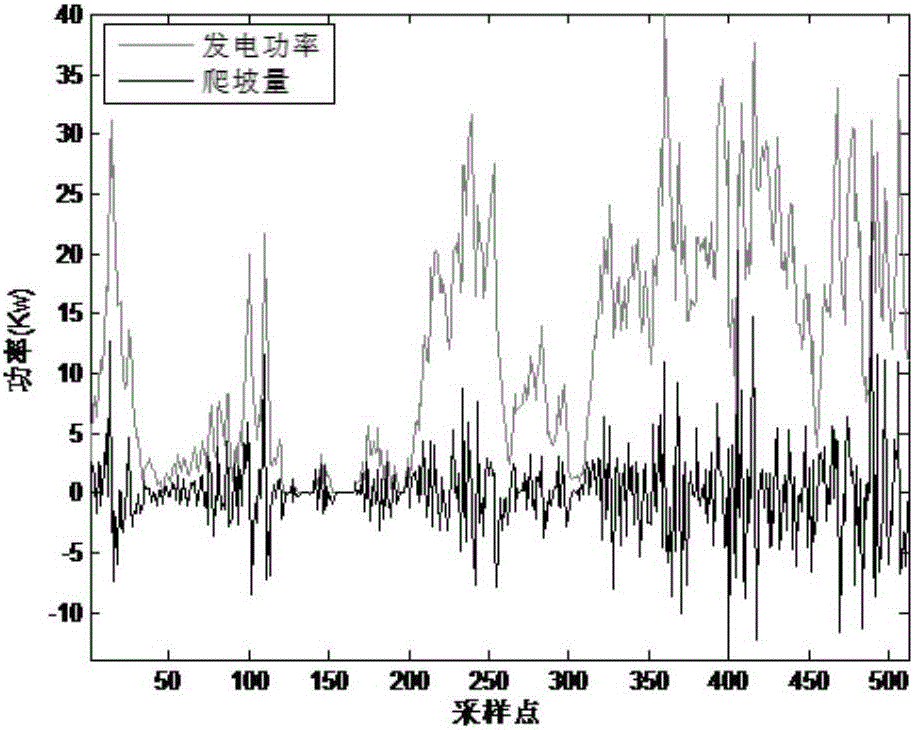

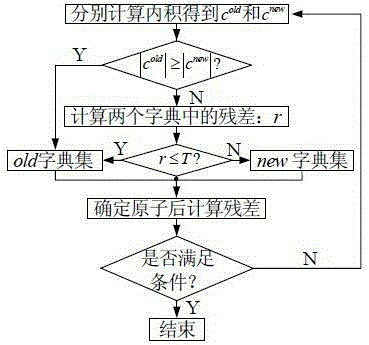

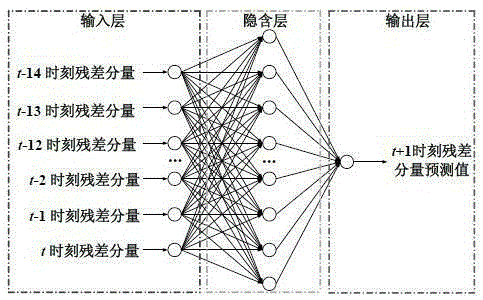

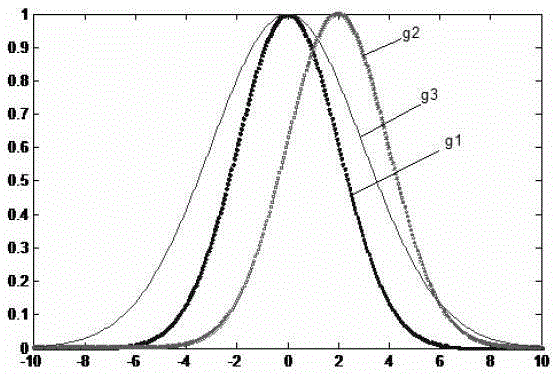

Ultrashort-term slide prediction method for wind power

InactiveCN103117546ASparse decomposition effectReduce the absolute mean errorSpecial data processing applicationsAc network circuit arrangementsDecompositionAlgorithm

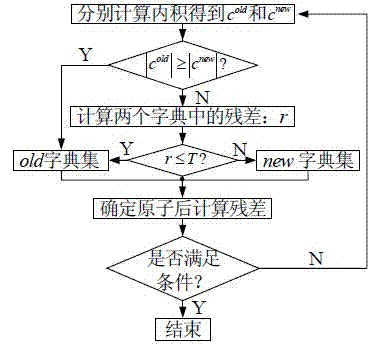

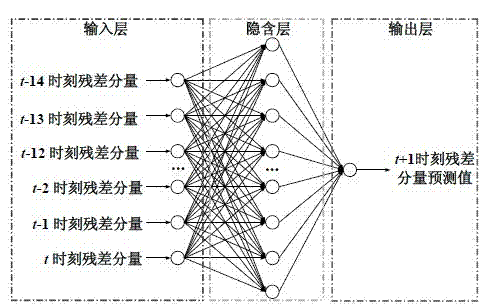

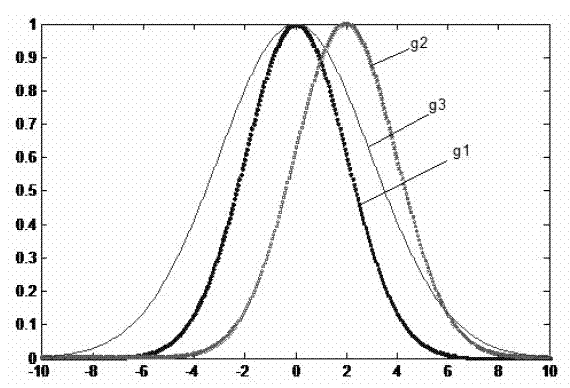

The invention relates to an ultrashort-term slide prediction method for wind power. An atomic sparse decomposition method with quite high non-stable signal tracking and prediction capacity is used as a front decomposition method of a neural network. A wind power time sequence is decomposed into an atomic component and a residual error component, the atomic component is automatically predicted, the residual error component is predicted by the neural network, atomic decomposition results are updated by adding the latest wind power real-time data, and further the wind power of a next moment is slidably predicted. Actual wind field data prove that the model can effectively avoid non-stability of the wind power, sparser decomposition effects are achieved, and statistical intervals of absolute average error and root mean square error computation values can be remarkably reduced. Therefore, the ultrashort-term slide prediction method has the advantages that non-stability of the wind power can be effectively avoided, the sparser decomposition effects are achieved, and the statistical intervals of the absolute average error and root mean square error computation values can be remarkably reduced.

Owner:WUHAN UNIV

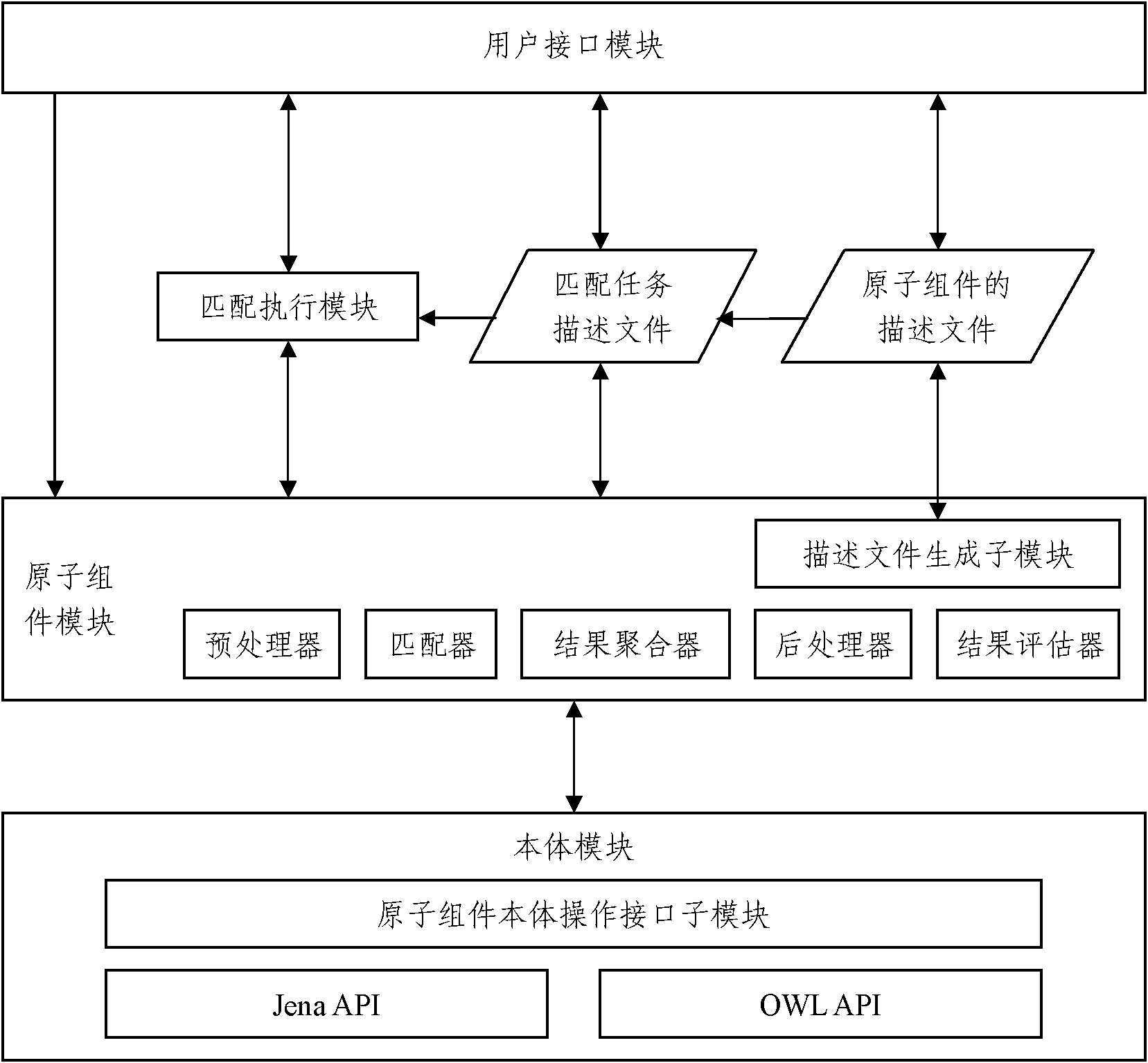

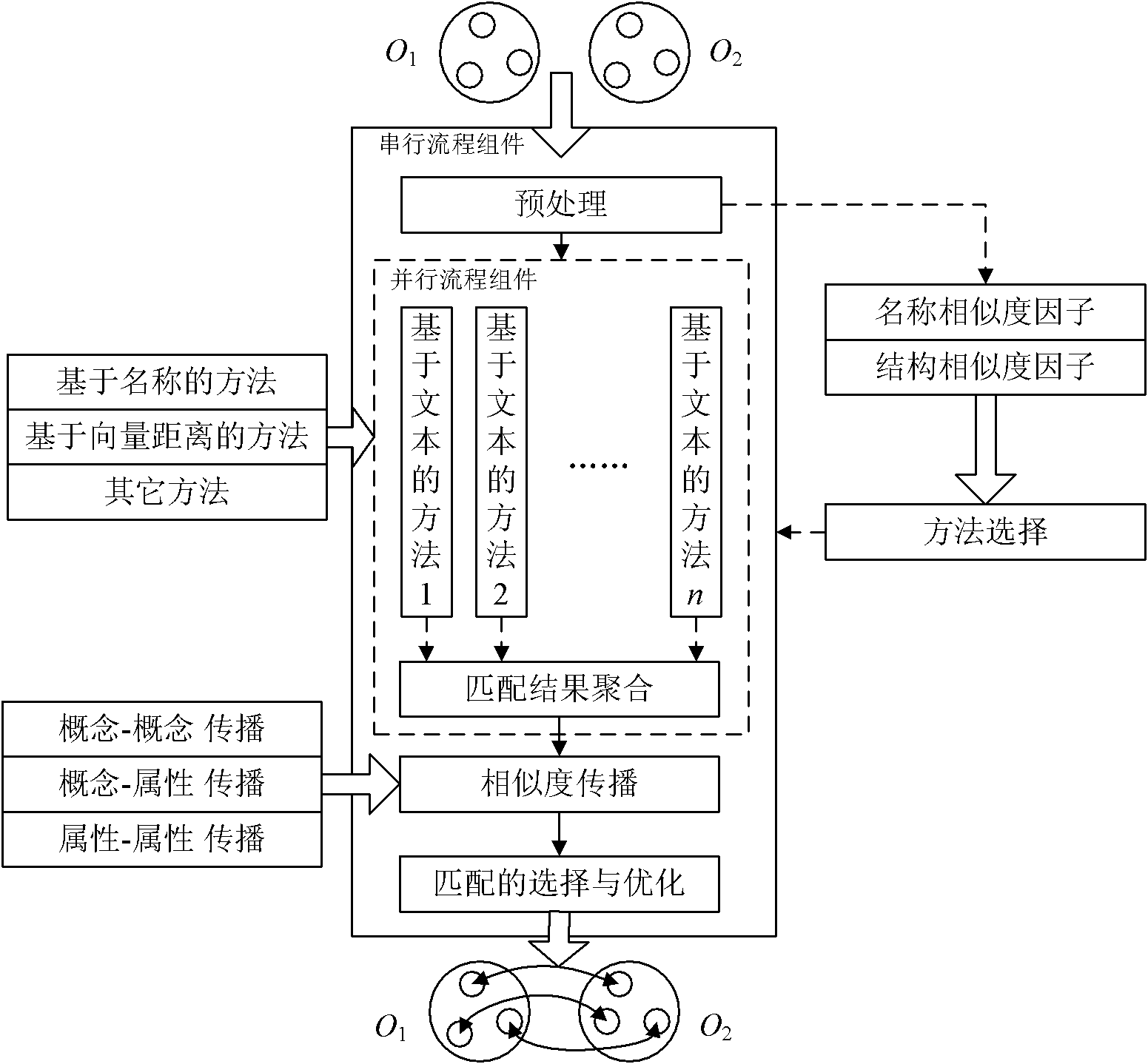

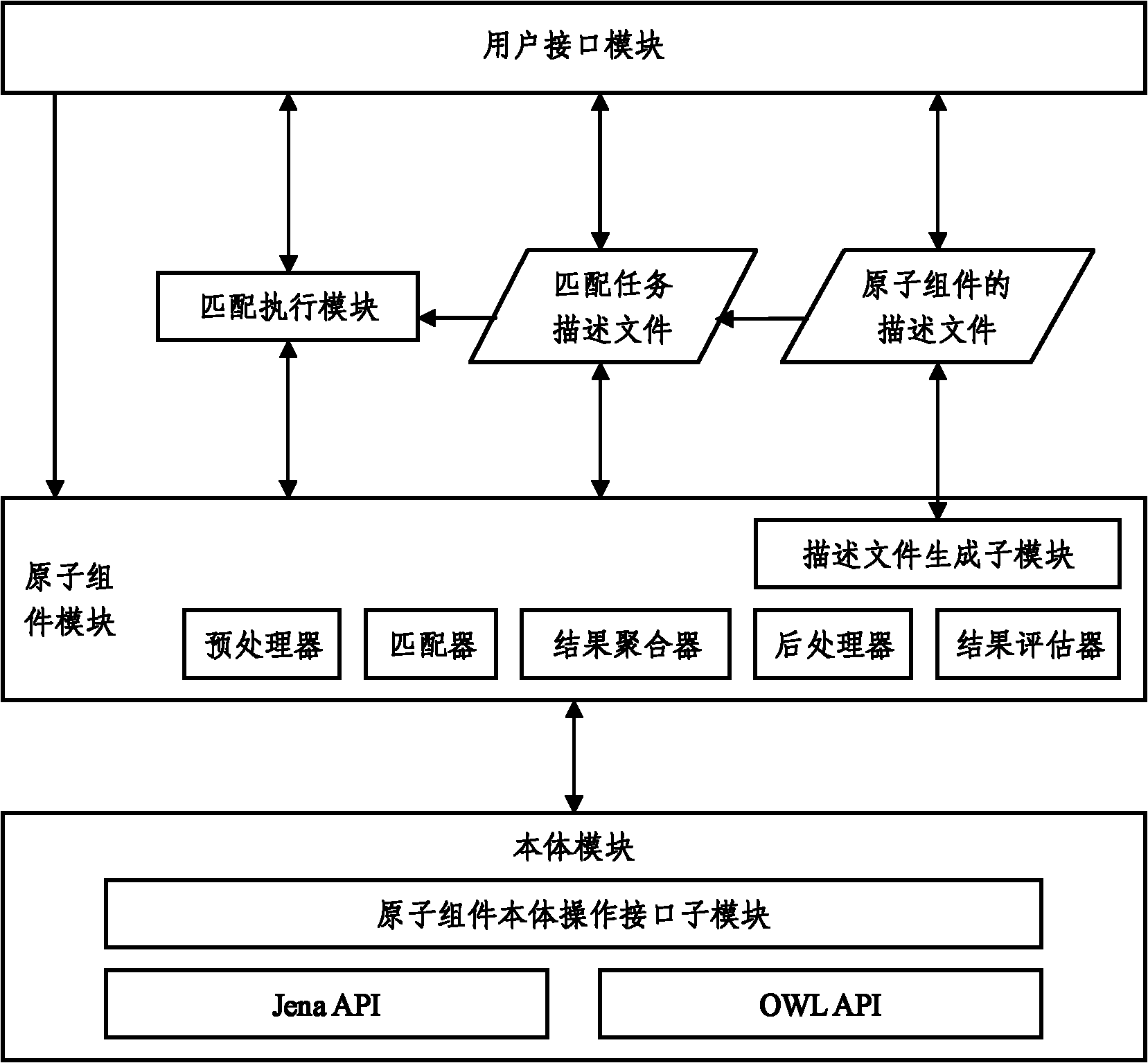

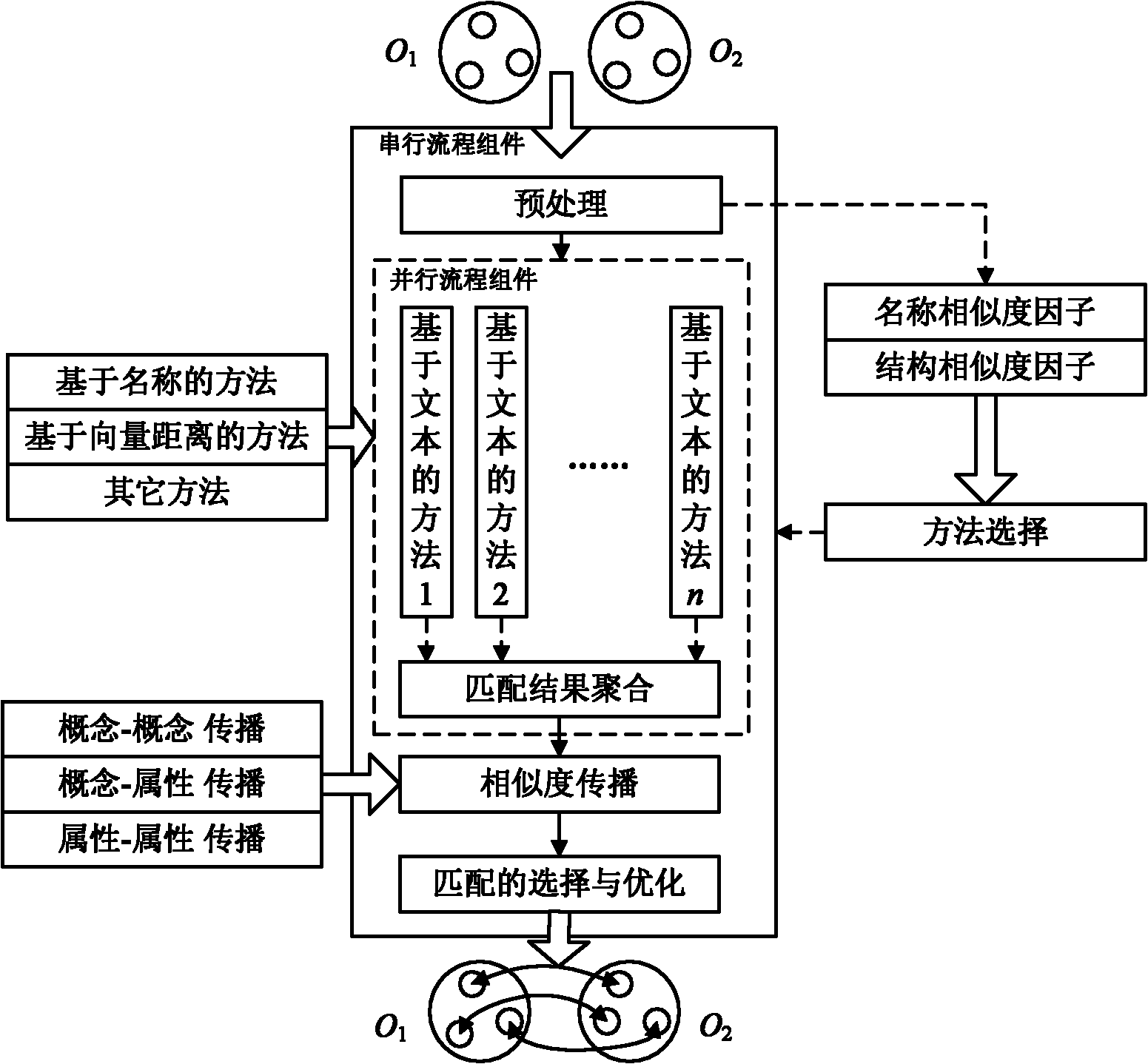

User customization-based body matching system and method

The invention discloses a user customization-based body matching system, which relates to the technical field of semantic web and comprises a body module, an atomic component module, a user interface module and a matching execution module, wherein the body module comprises an atomic interface body operating interface sub-module and a body application program interface (API) sub-module; the atomic component module is used for calling body APIs of the body API sub-module to realize atomic components by the atomic component body operating interface sub-module; the user interface module is used for receiving a body to be matched from a user and autonomously realized atomic components; and the matching execution module is used for generating a matching task description file according to the body to be matched, selecting the atomic component or the autonomously realized atomic component according to the matching task description file to execute a matching task, and generating a matching result. By the system, the user can customize and assemble the atomic components according to the characteristics of the body to be matched to design a body matching flow required per se, generate a proper matching task and obtain the accurate matching result.

Owner:TSINGHUA UNIV

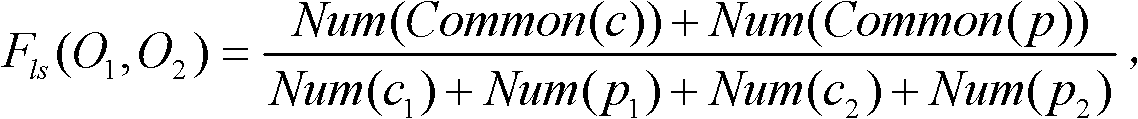

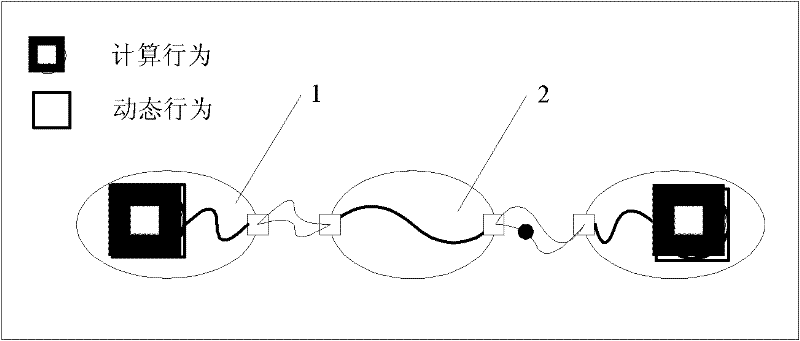

Formal description method for adaptive software architecture during operation

InactiveCN102270130AAchieve dynamic characteristicsSpecific program execution arrangementsSoftware architectureInternetware

The invention discloses a formal description method for adaptive software architecture during operation. The formal description method comprises the following steps of: (1) describing the adaptive software architecture framework and setting a formally described architecture framework, wherein the framework comprises components, a connecting element and architecture configuration; (2) building an adaptive component model based on Agent internetware, and forming the internal part of the adaptive component by using a computing module which finishes calculation action and an adaptive model which finishes dynamic action in a manner of using the adaptive component as a component in the internetware; (3) formally describing various mental attitudes of the adaptive component in sequence, and providing formal definition of an atomic component and the connecting element; and (4) finishing appointed definition of the calculation action and dynamic action of the adaptive component, providing the corresponding relation of pi calculation thereof, and then dynamically reasoning the architecture action according to the performability and embedded background debug interface (EBDI) of the Pi calculation. The formal description method for adaptive software architecture during operation has performability, reasonability and legibility.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Manufacturing method for micro-miniature atomic air chamber

InactiveCN105589326AQualcomm glossy optical qualityImprove optical qualityApparatus using atomic clocksEngineeringAir tightness

The invention belongs to the technical field of atomic air chambers, and specifically relates to a manufacturing method for a micro-miniature atomic air chamber. The method comprises steps of material selecting and cutting, assembly polishing, assembling, surface polishing, exhaust pipe installation, and subsequent processing. The technical problem the method solves is that an atomic air chamber manufactured by an existing manufacturing method for a micro-miniature atomic air chamber cannot satisfies high-precision, low-stress, and high-purity technical requirements of a high-precision atomic component on the air chamber. The method realizes manufacturing of an air chamber glass bulb in high optical quality of a light transmission surface, low stress, and high air tightness.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

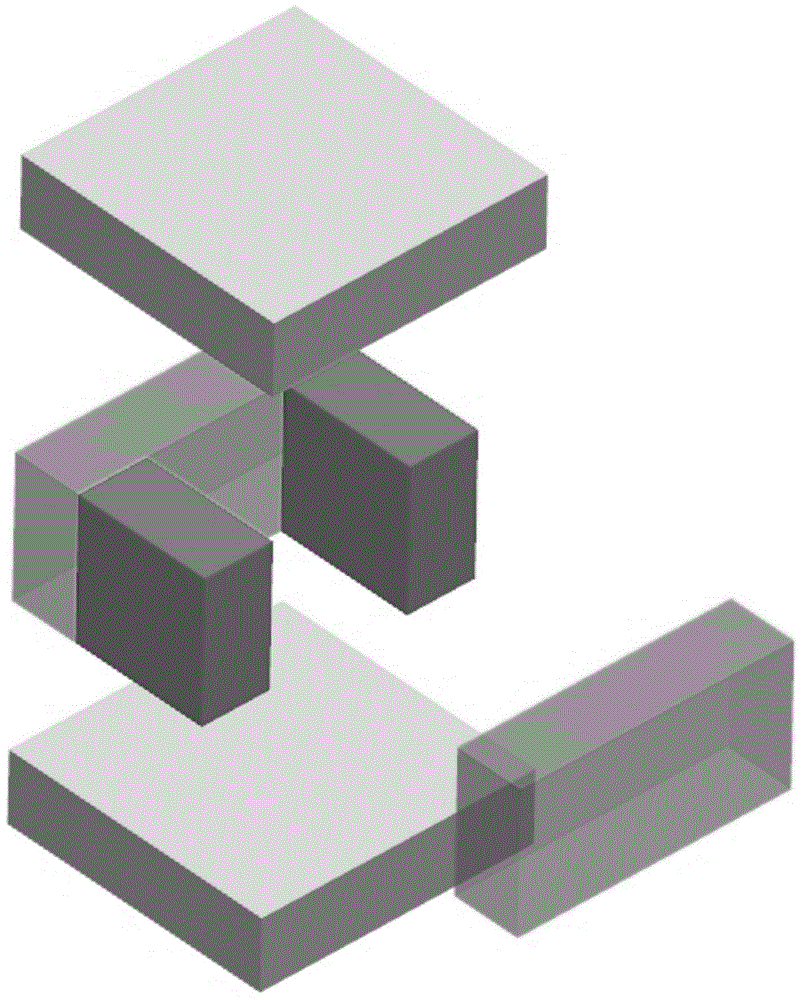

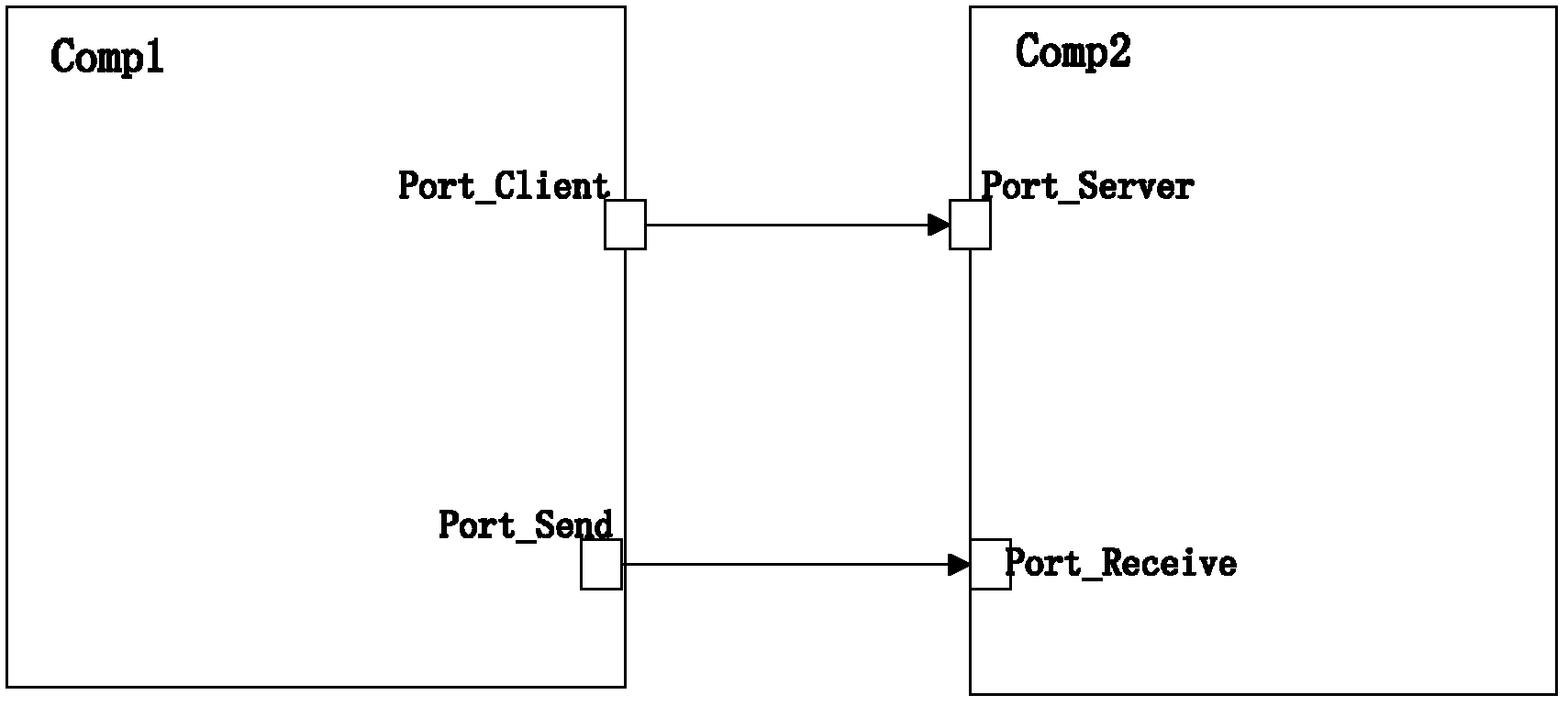

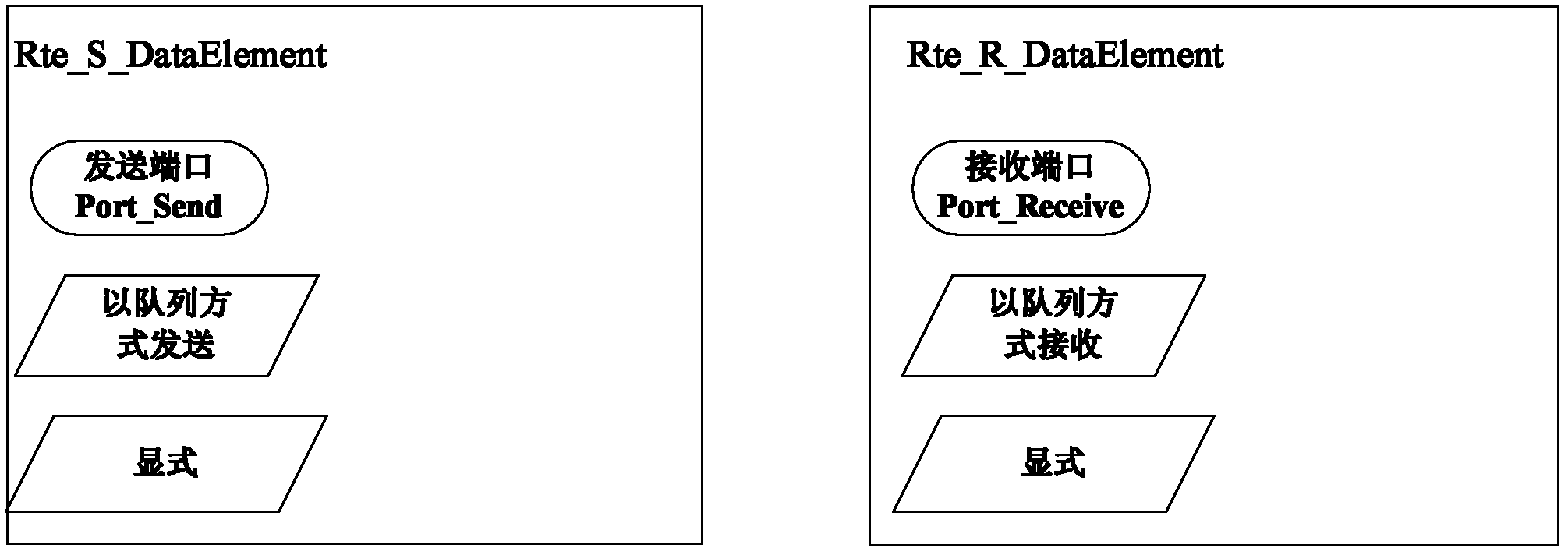

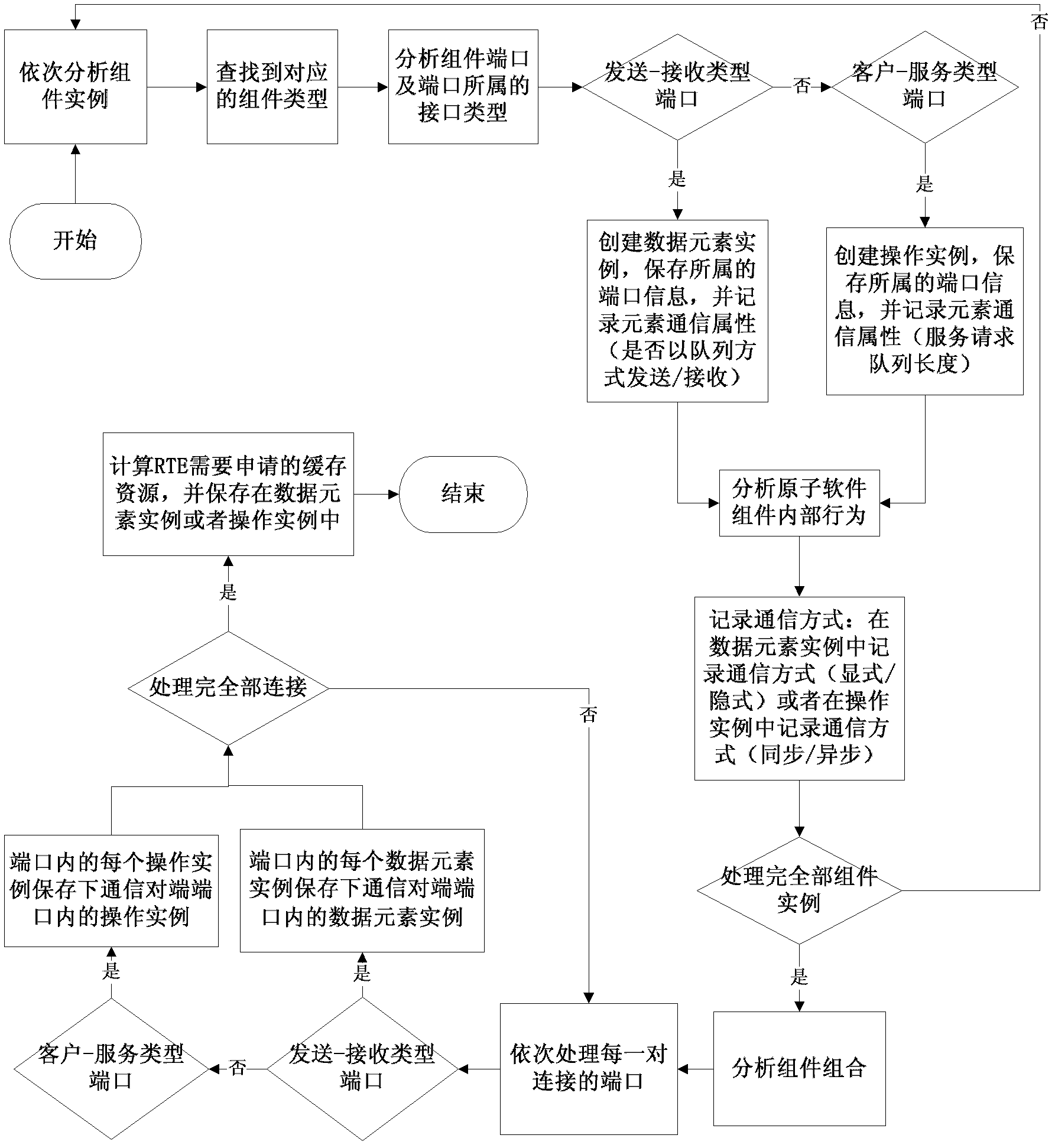

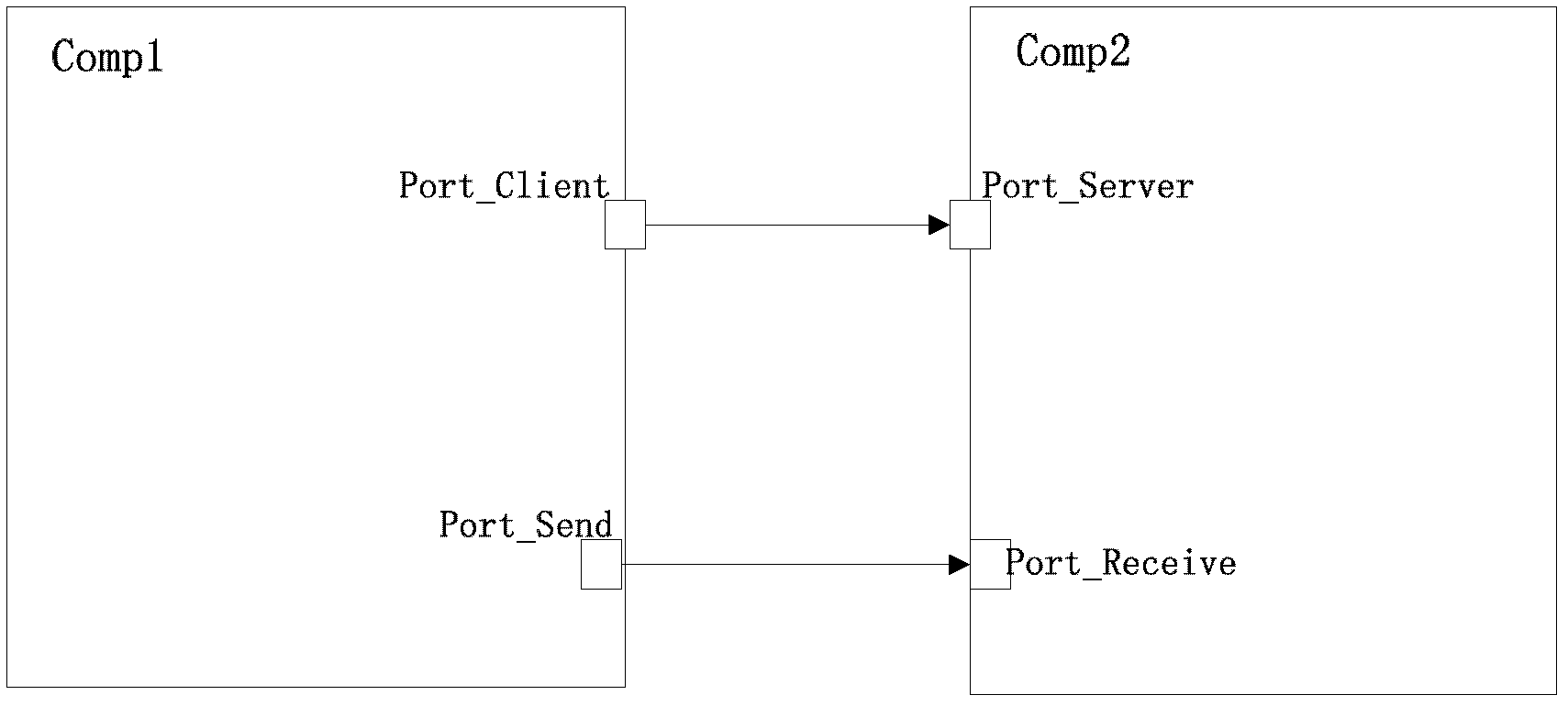

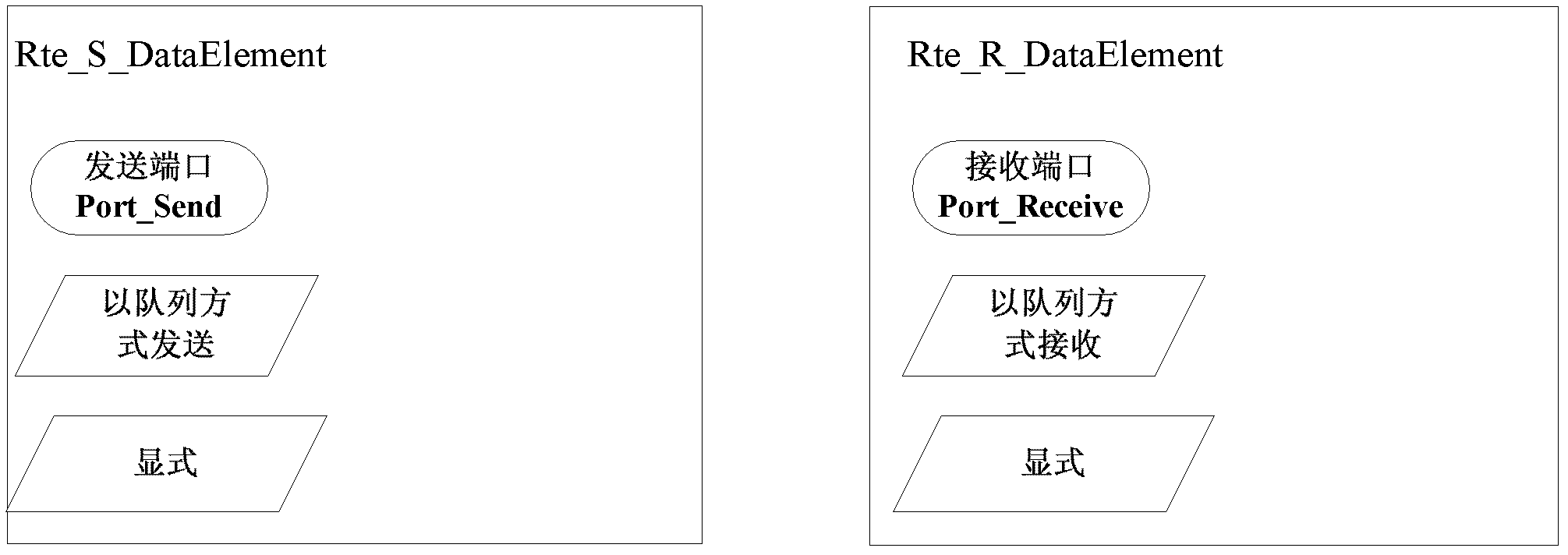

Automatic run-time environment (RTE) code generating method for automobile system architecture (AUTOSAR)

ActiveCN102214099AImprove developmentPromote generationSpecific program execution arrangementsSoftware engineeringData element

The invention discloses an automatic run-time environment (RTE) code generating method for automobile system architecture (AUTOSAR). The method comprises the following steps of: 1) sequentially analyzing component instances in the AUTOSAR, creating data element instances or operating instances, storing port information and element communication attributes, analyzing internal behaviors of atomic components in the component instances, and recording corresponding communication modes in the data element instances or the operating instances; 2) sequentially analyzing component groups of the component instances with connecting relationship, and storing the operating instances or the data element instances in ports of opposite communication ends; and 3) acquiring cache resources required by the data element instances or the operating instances corresponding to the RTE, and correspondingly storing the acquired caches in the corresponding data element instances or the operating instances. The method has the advantages of strong logicality, good readability, simplicity and quickness in development and high development efficiency.

Owner:ZHEJIANG UNIV

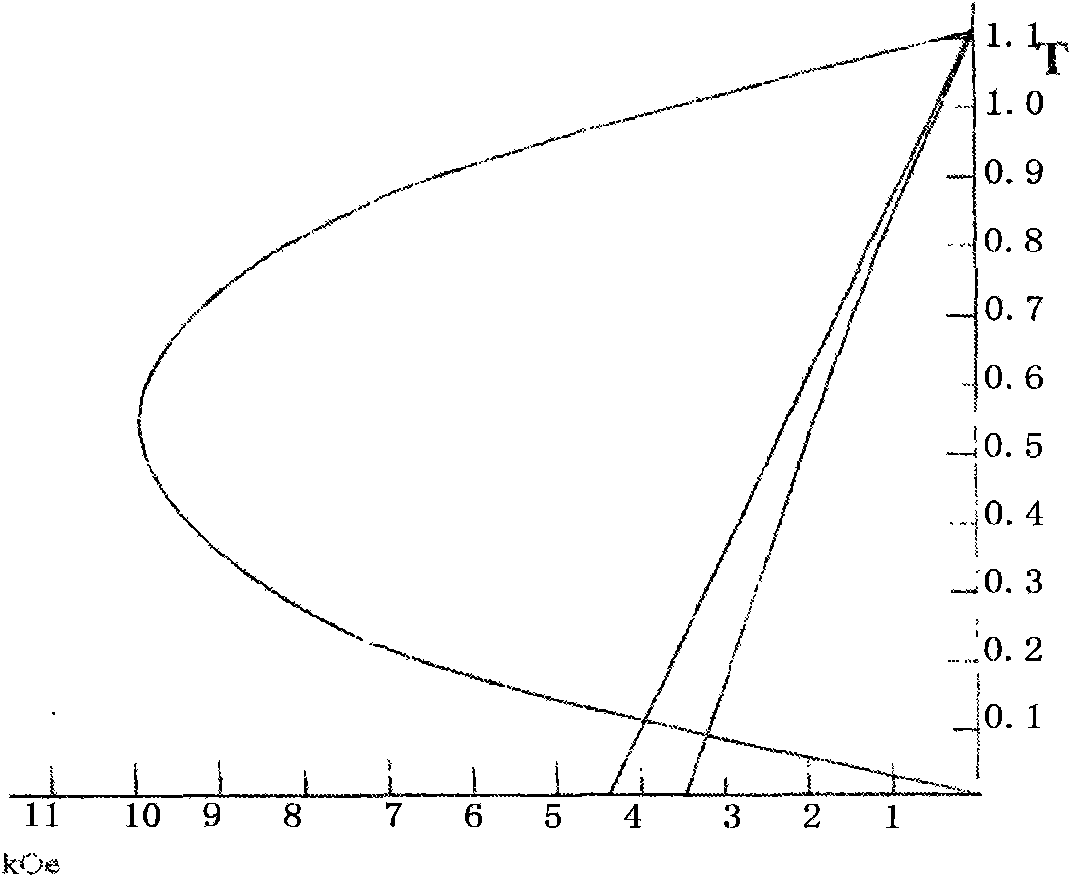

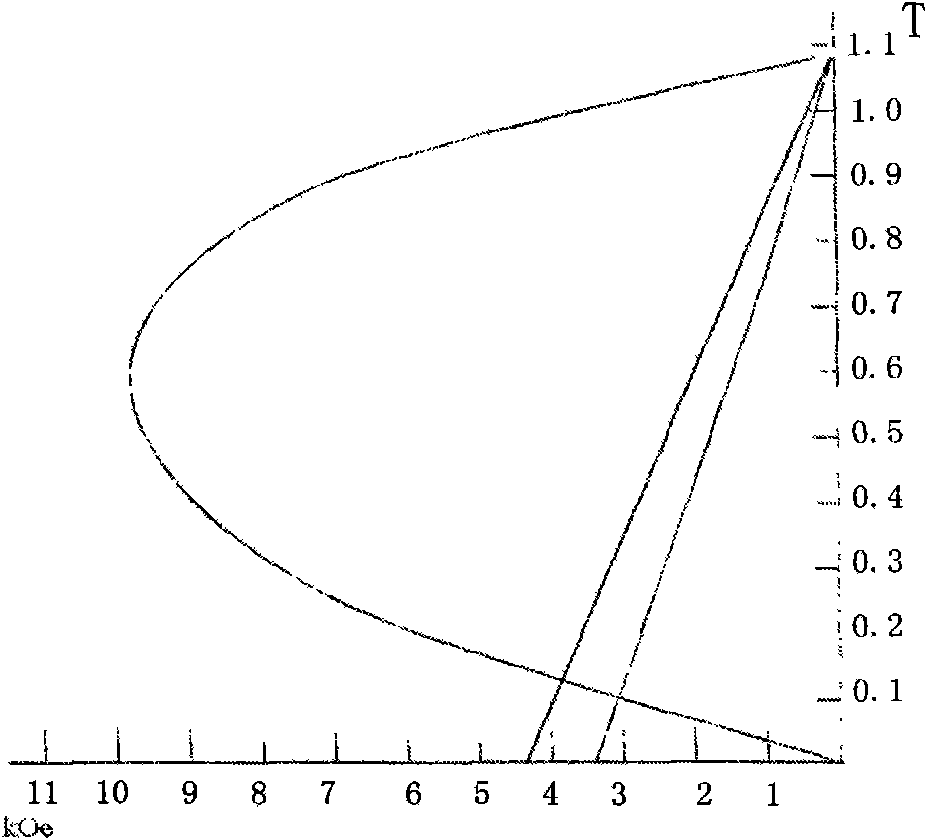

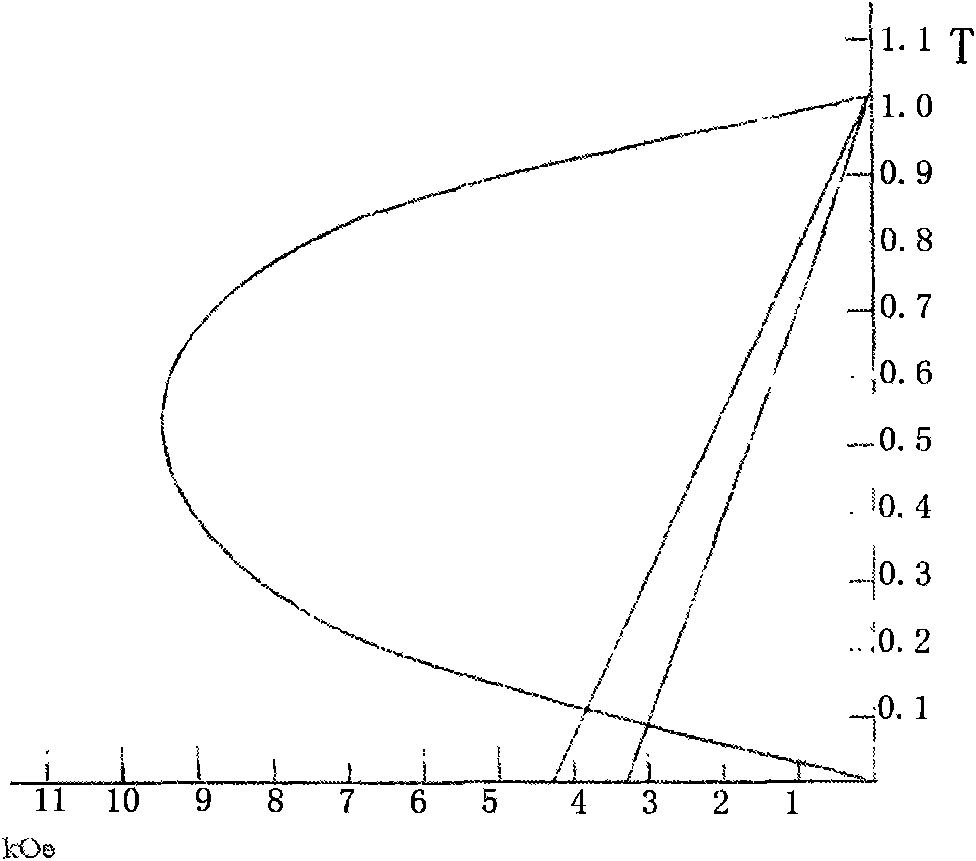

Vertical magnetism anisotropic film

InactiveCN101620915AMeet the use requirementsHigh perpendicular magnetic anisotropy fieldMagnetic film to substrate applicationMagnetic layersFilm planeSpin valve

The invention relates to a vertical magnetism anisotropic film which belongs to the field of magnetic materials, and an easy magnetizing shaft is perpendicular to a film plane. The vertical magnetism anisotropic film is characterized by comprising the component: Tbx(Co2FeZ)y, wherein Z stands for Al, Si, and the like, Co2FeZ is a semimetal Heusler alloy component, and Tb and Fe have an atomic ratio: x: y is greater than 0.2 and is less than 2. The vertical magnetism anisotropic film has a high vertical magnetism anisotropic field and can regulate coercive force by controlling the atomic component ratio, the coercive force of the vertical magnetism anisotropic film is obviously lower than the coercive force of the traditional vertical magnetism anisotropic film, and therefore, the vertical magnetism anisotropic film can be used as a ferromagnetic layer to be applied to a vertical spin valve or a magnetic tunnel-junction. When used, the vertical magnetism anisotropic film can overcome magnetic curliness and vortex magnetic domain structure under a small size, has adjustable coercive force and can satisfy the use requirement of a magnetic sensor or a memory with ultrahigh sensitivity and memory density.

Owner:UNIV OF SCI & TECH BEIJING

Plant for producing low deuterium water from sea water

InactiveUS7491298B2Efficient productionImprove efficiencyElectrolysis componentsGeneral water supply conservationElectricityFuel cells

A plant and process for efficient production of low deuterium water from seawater. The plant includes a solar still with a black pan for collecting solar heat, that vaporizes portions of the seawater and a porous sloped membrane positioned over the black pan to collect and condense the vapor and to direct the condensate via gravity to a condensate tank. The condensate water is separated into its atomic components, hydrogen and oxygen, in an electralizer; then the hydrogen and oxygen are combined in a reactor to produce heat and low deuterium water. In preferred embodiments the reactor is a fuel cell which in addition to the heat and water also produces electricity. At least a portion of the heat produced in the reactor is used in the solar still to assist in the vaporization of the seawater and to greatly increase the efficiency of the still.

Owner:ZLOTOPOLSKI VLADIMIR Z

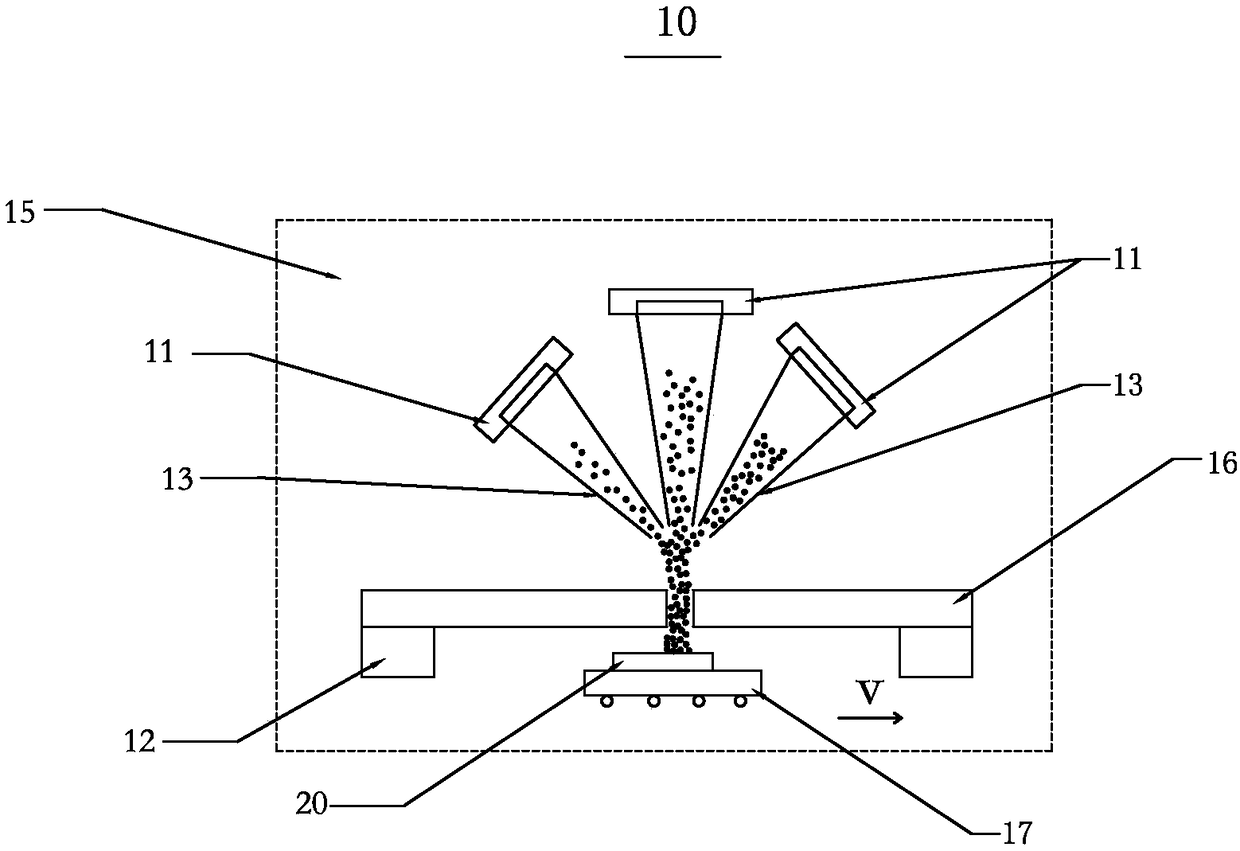

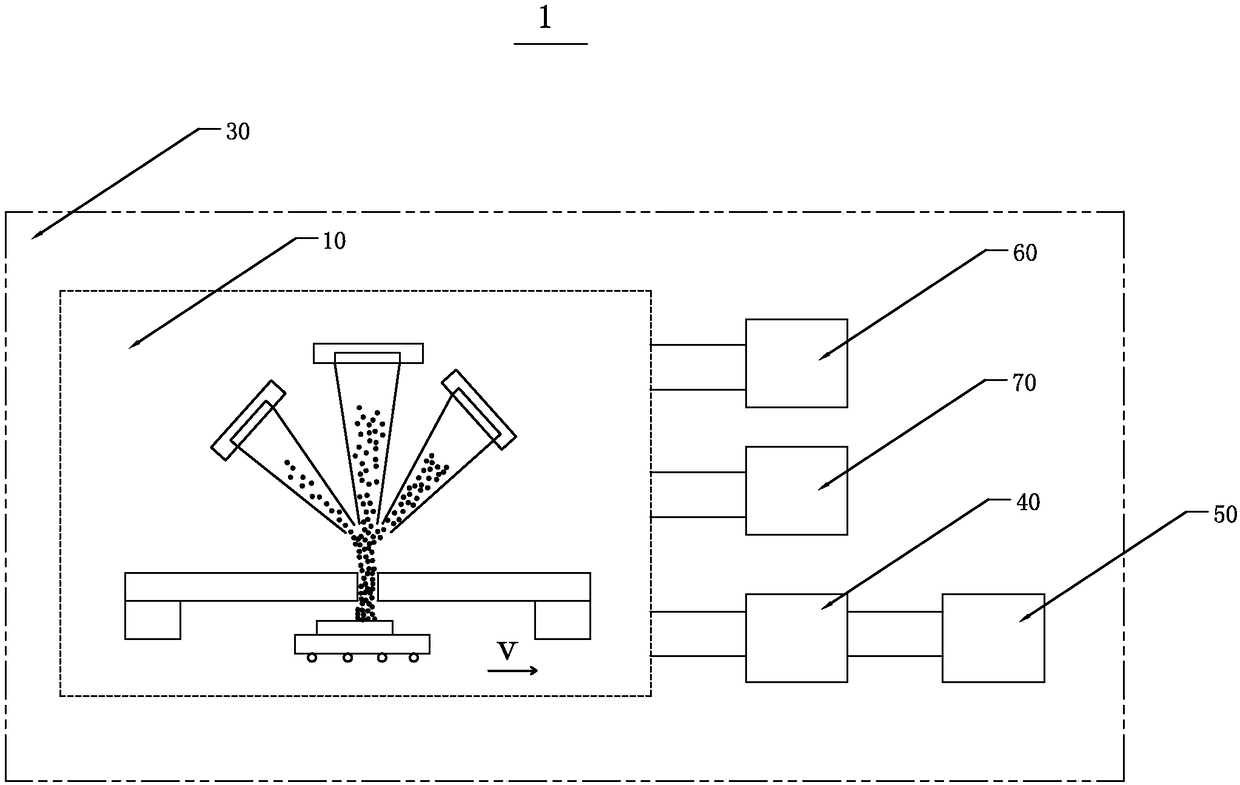

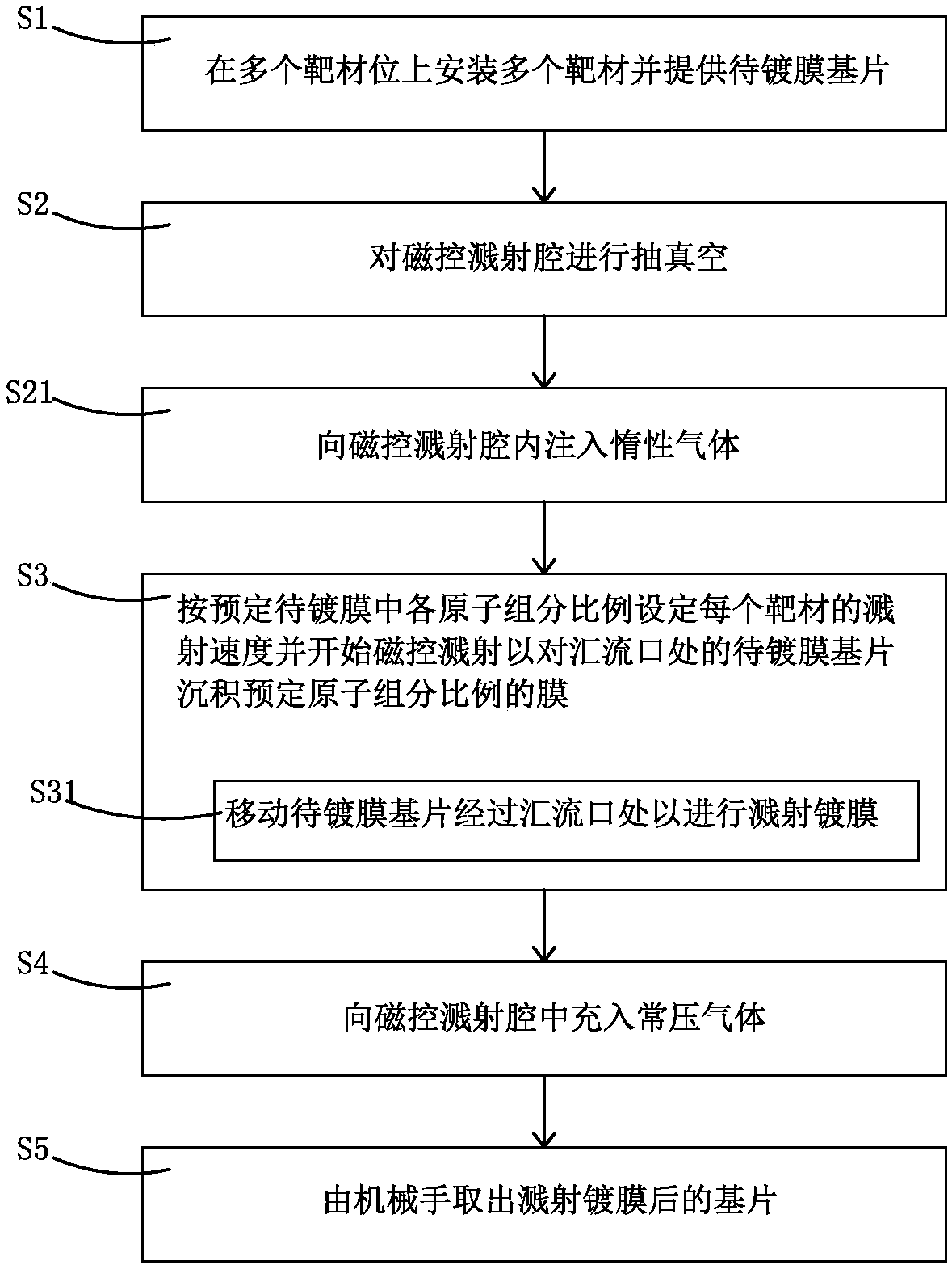

Method for preparing positive electrode of metal oxide

InactiveCN108281618AImprove uniformitySimple processCell electrodesVacuum evaporation coatingMaterials scienceMetal

The invention relates to the technical field of lithium batteries, in particular to a method for preparing a positive electrode of a metal oxide. According to the method for preparing the positive electrode of the metal oxide, sputter coating of multiple target materials can be carried out at the same time, a film with different atomic component ratios can be obtained according to the sputtering speeds of various target materials, and the target materials can be directly replaced when the positive electrode film, containing different components, of the metal oxide needs to be obtained throughsputtering, so that the process is simple and fast, the production efficiency is high and the massive production requirements are met.

Owner:成都大超科技有限公司

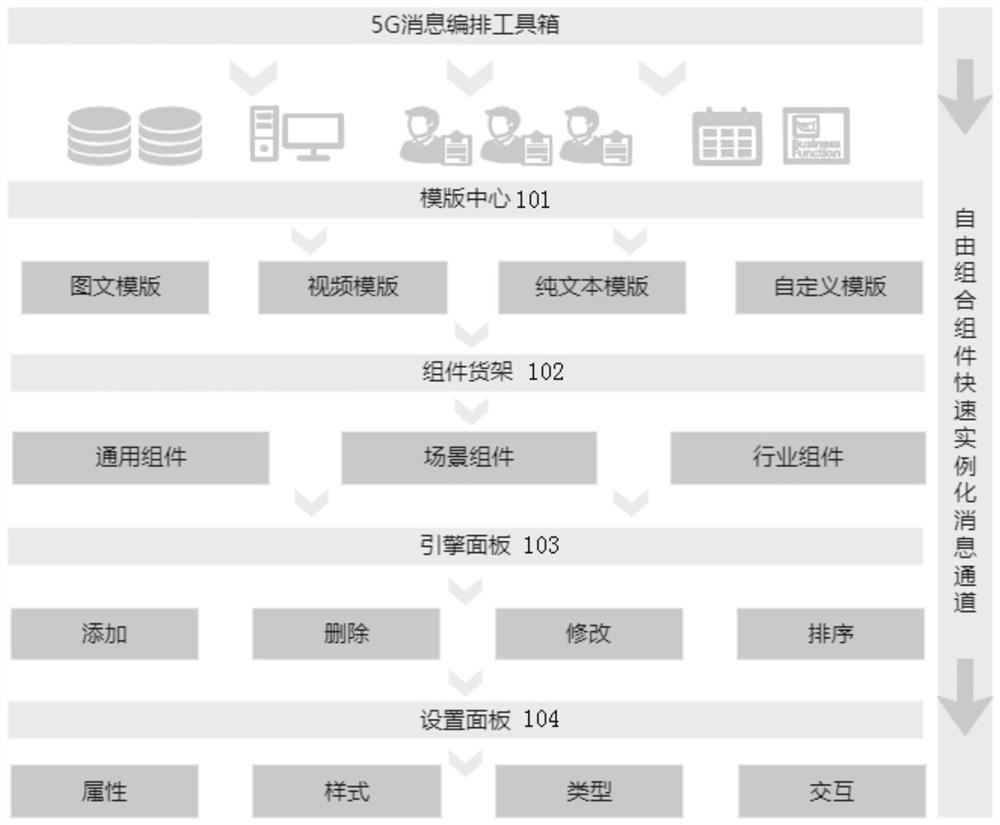

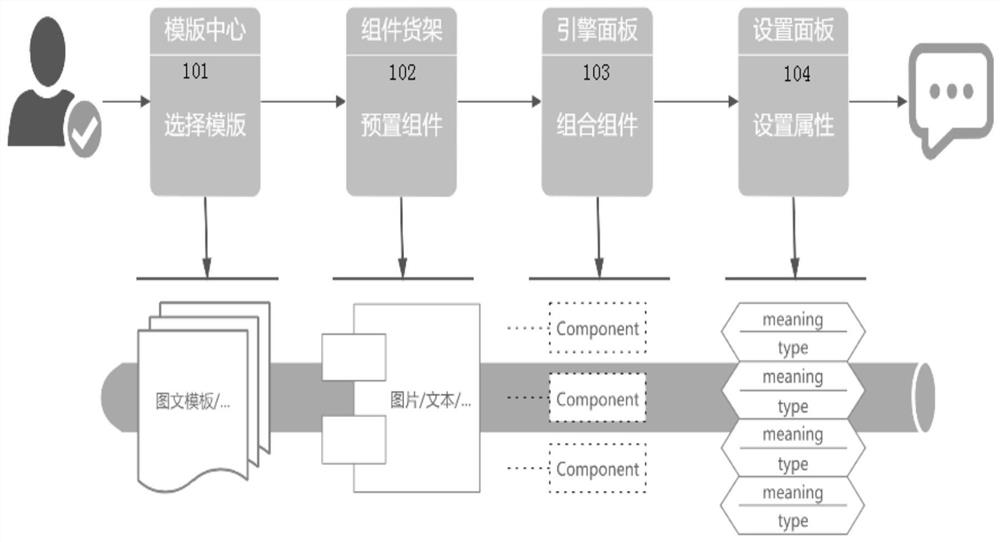

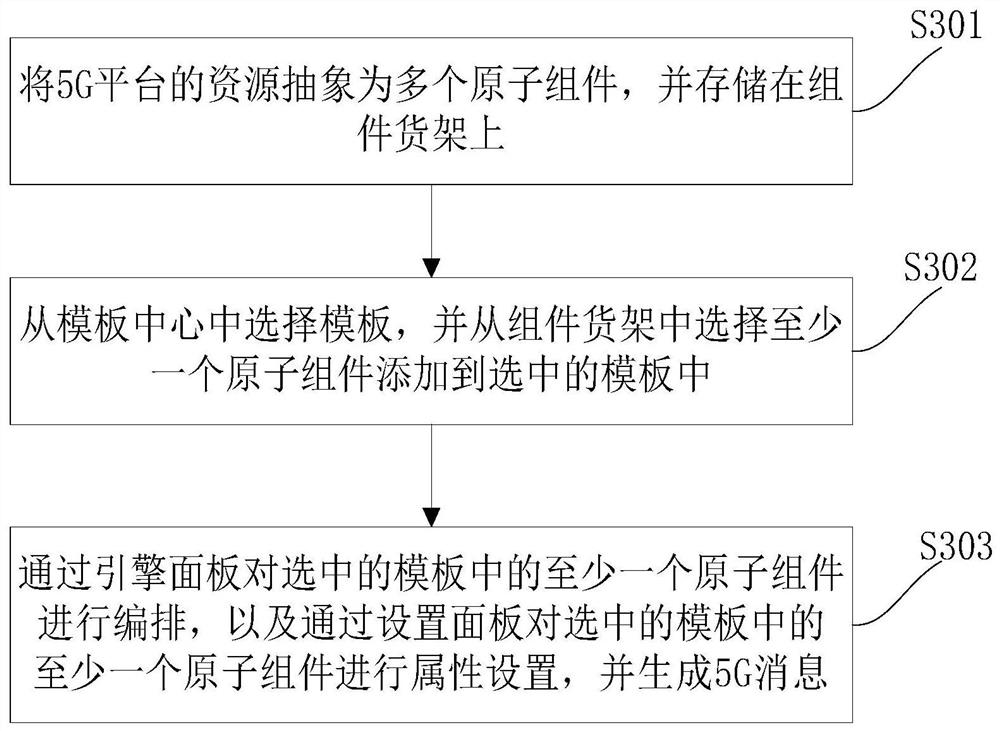

5G message orchestration method and orchestration tool box based on component capability

PendingCN112653584AImprove resource utilization efficiencyLower barriers to useMessaging/mailboxes/announcementsData switching networksResource utilizationEngineering

The invention provides a 5G message orchestration method and an orchestration toolbox based on component capability. The method comprises the following steps: abstracting resources of a 5G platform into a plurality of atomic components, and storing the atomic components on a component shelf; selecting a template from a template center, and selecting at least one atomic component from the component shelf and adding the atomic component into the template; and arranging at least one atomic component in the selected template through an engine panel, performing attribute setting on the at least one atomic component through a setting panel, and generating a 5G message. 5G message resources are packaged into an independent component by introducing the component capability, the northbound can flexibly support the flexible arrangement and organization of 5G messages, the service scene requirement of quick response of agile iteration is met, a standardized atomic power interface can be formed in the southbound to be connected with a message resource entity, and the resource utilization efficiency of a 5G message platform is improved.

Owner:HANGZHOU EASTCOM SOFTWARE TECH

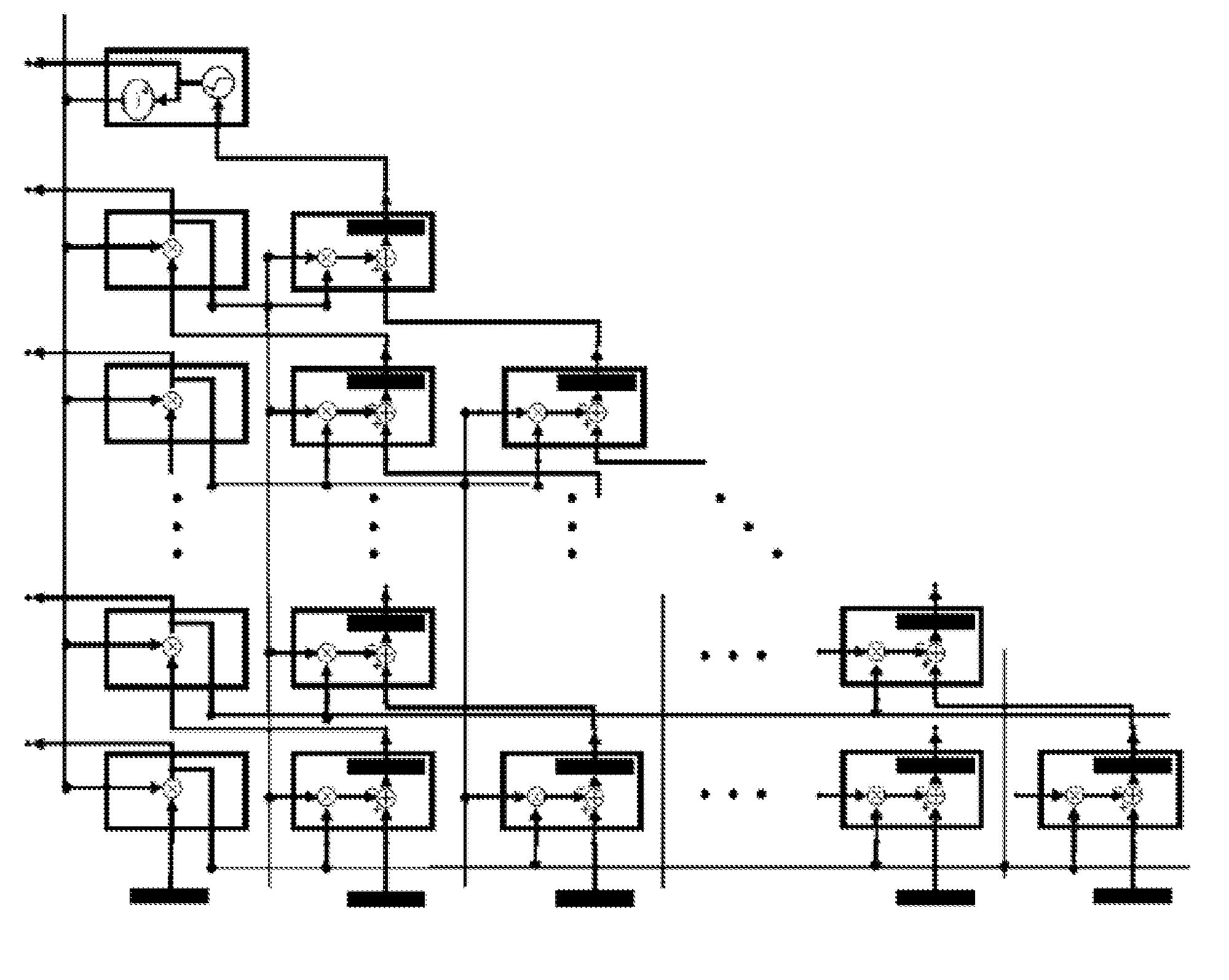

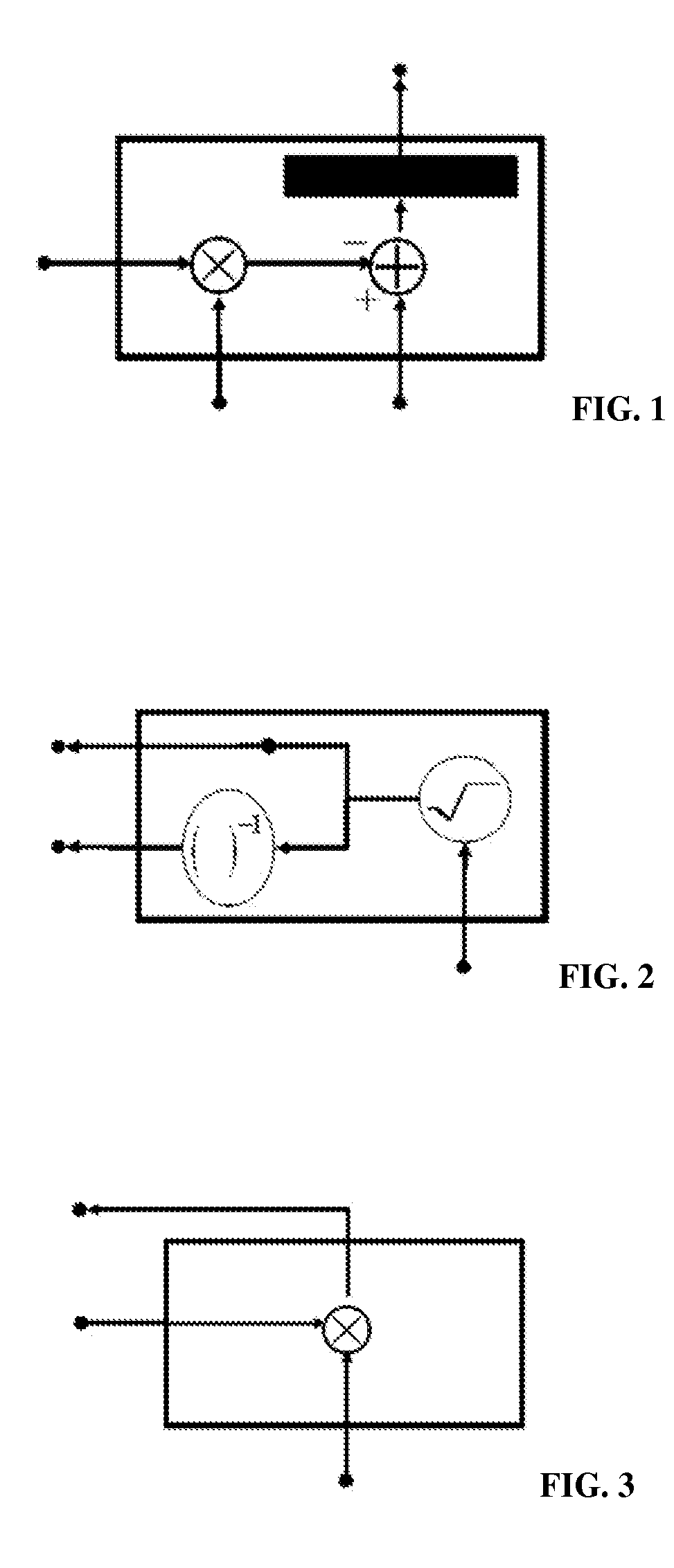

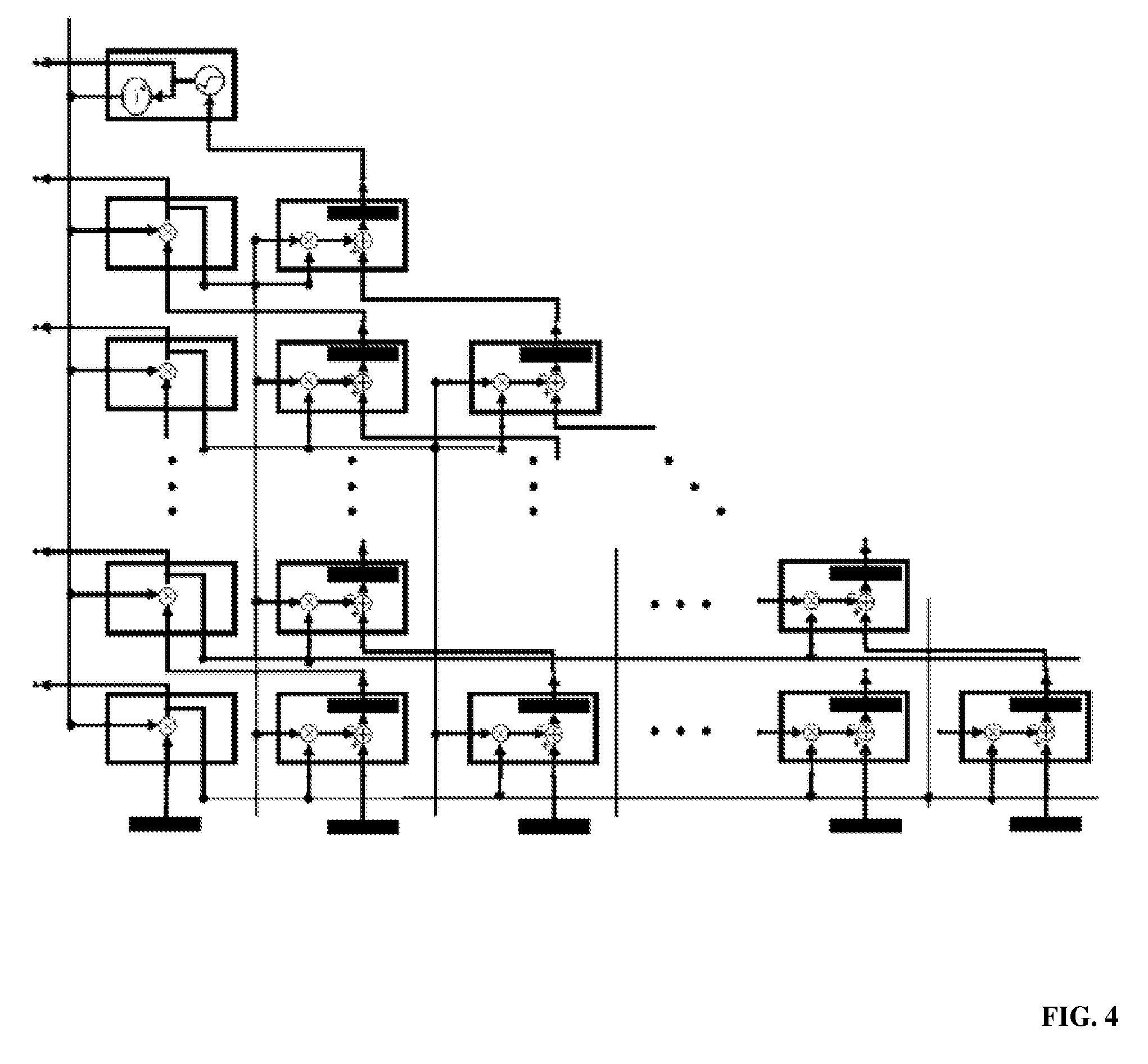

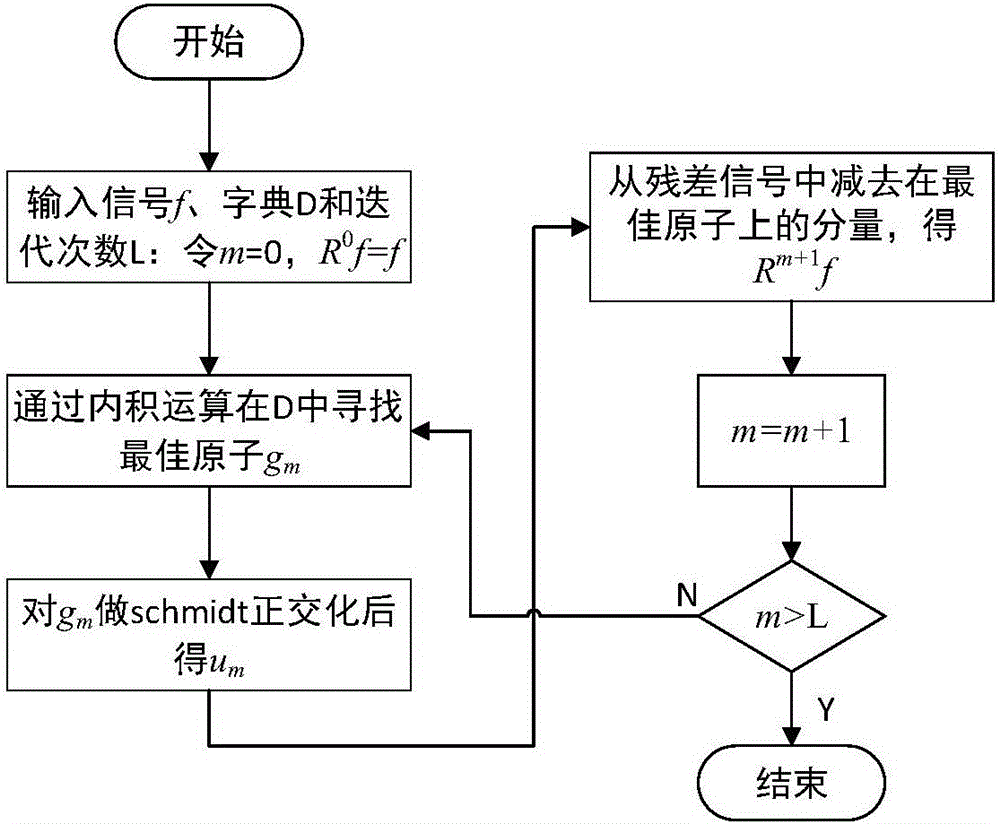

System and method for fast matrix factorization

InactiveUS7849126B1Fast computerReduce computing timeComputation using non-contact making devicesData mergingMatrix decompositionAlgorithm

The Present invention provides a system and method for fast computing the Cholesky factorization of a positive definite matrix. In order to reduce the computation time of matrix factorizations, the present invention uses three atomic components, namely MA atoms, M atoms, and an S atom. The three kinds of components are arranged in a configuration that returns the Cholesky factorization of the input matrix.

Owner:INTPROP SYST

Wind power climbing prediction method

InactiveCN106682760AImprove forecast accuracyForecastingBiological neural network modelsElectricityRadial basis function neural

The invention provides a wind power climbing prediction method which includes the following steps: 1. conducting sparse decomposition on the amount of power while climbing; 2. conducting self-prediction on the atomic component which is obtained after decomposition, conducting radial basis function neural network prediction on the residual component; and 3. conducting linear adding on each prediction component to obtain the predicted value of a next moment. The method predicts the amount of wind power climbing by the sliding prediction method which combines the sparse decomposition and the radial basis function neural network, establishes a model for predicting wind power climbing events, can predict the amount of wind power climbing, and increases prediction precision.

Owner:SHANGHAI DIANJI UNIV

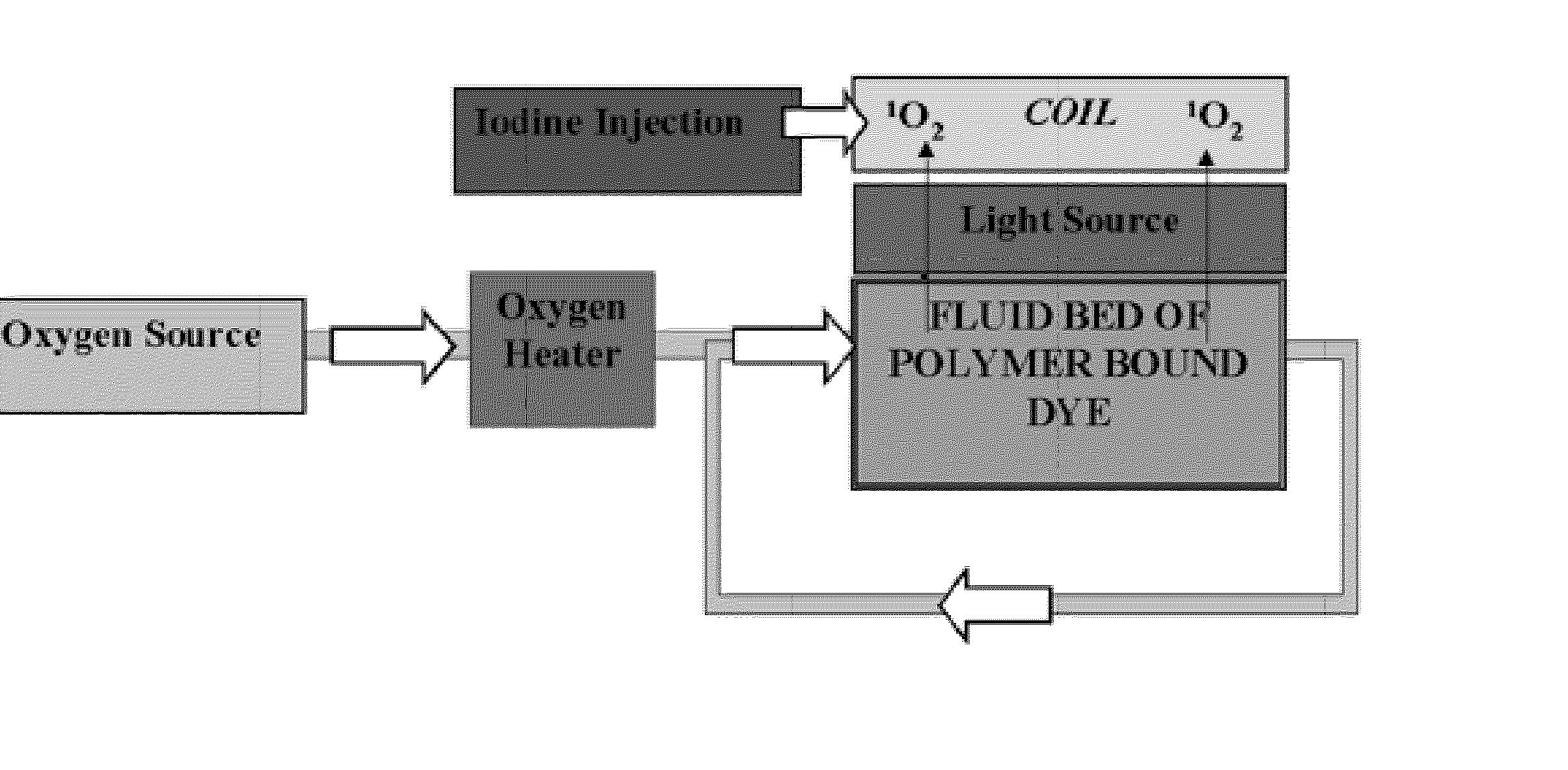

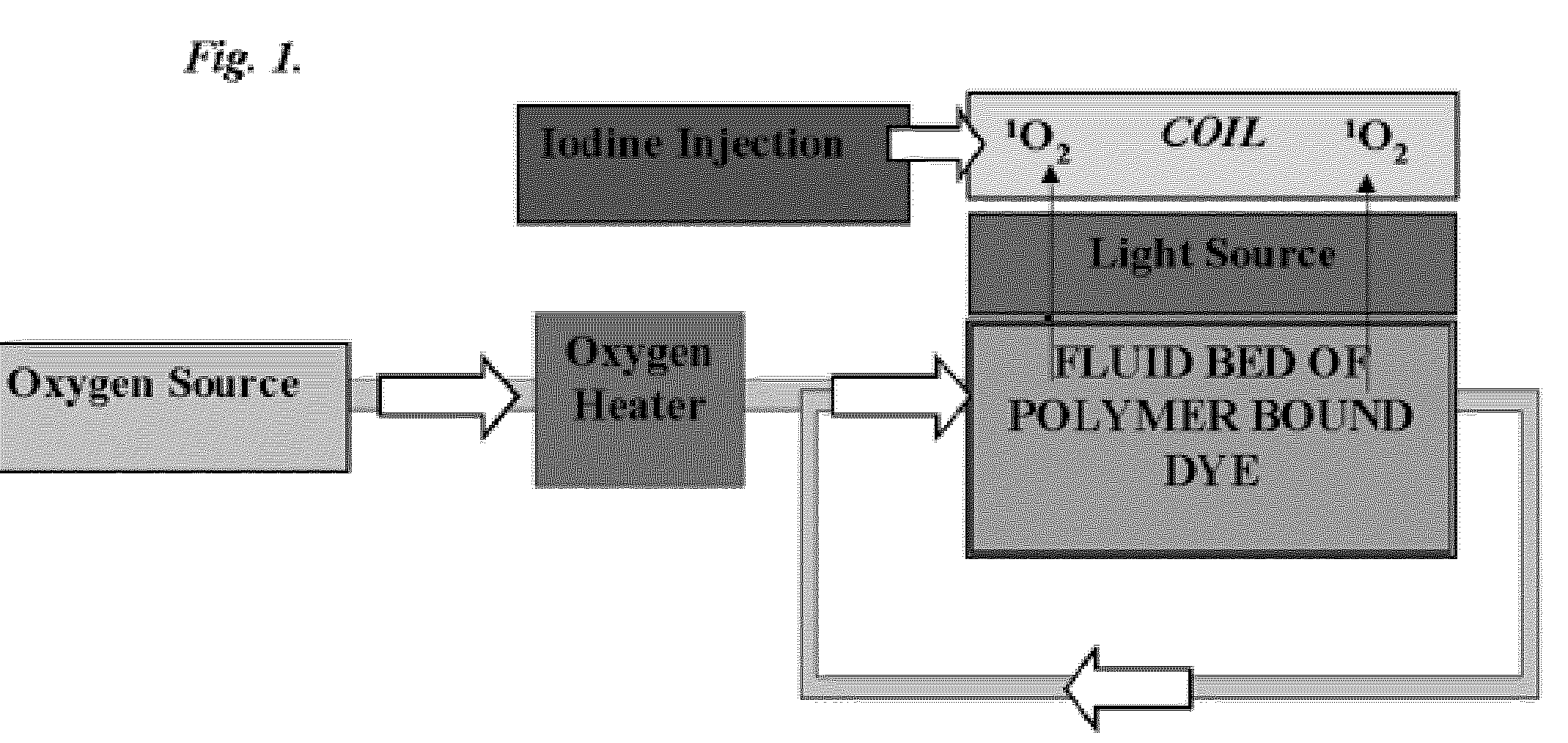

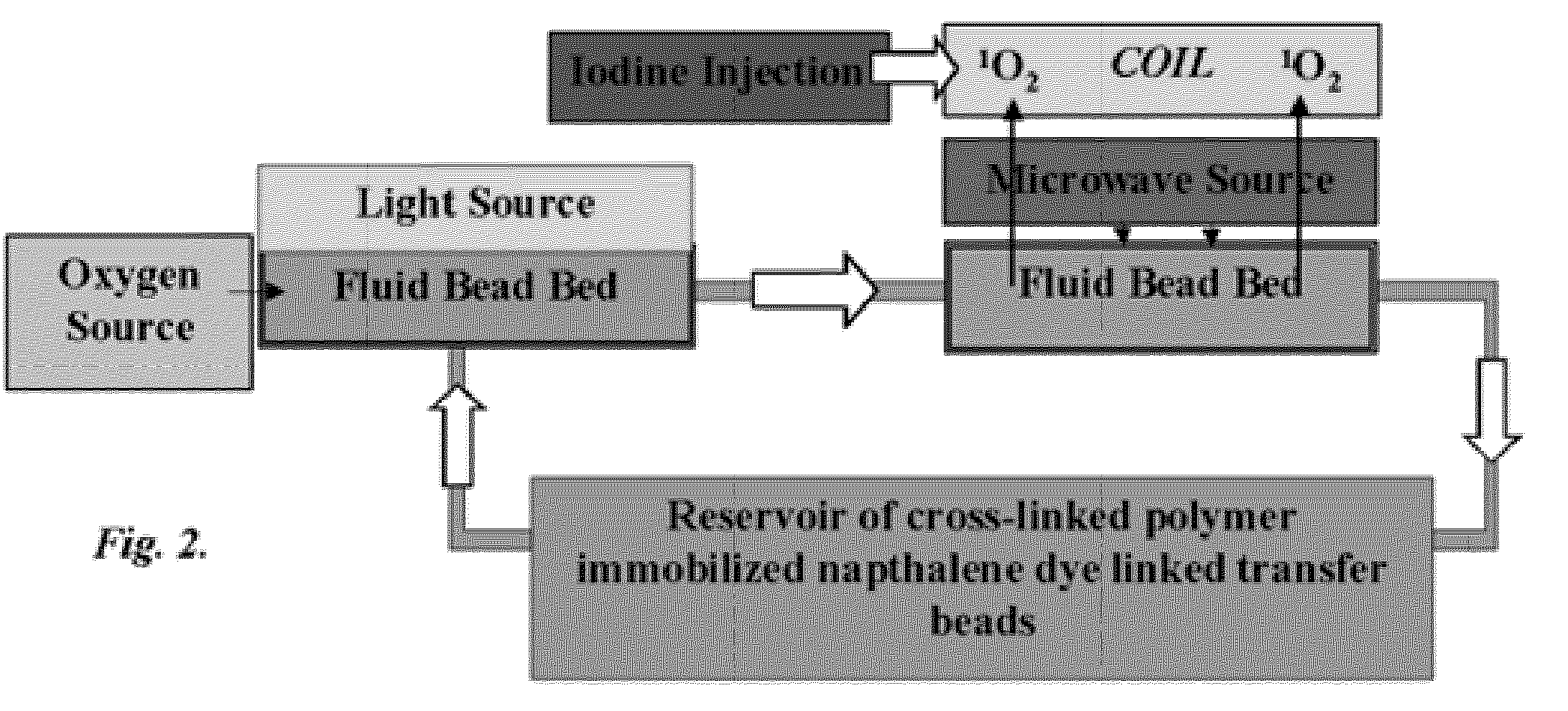

Irradiated fluid bed reactor

InactiveUS20050069470A1Low efficiencyEnergy based chemical/physical/physico-chemical processesOxygen preparationParticulatesChemical physics

A fluid bed reactor uses energy sources to excite and energize atomic components so as to effect and increase orbital energy. In a preferred embodiment light irradiates agitated particulate in a photolysis reaction to generate singlet oxygen in the gas phase. In a second embodiment microwave radiation stimulates a particulate linked endoperoxide to release singlet oxygen.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Method for preparing TiCN coating on surface of screw tap

ActiveCN109182984AHigh hardnessReduce coefficient of frictionVacuum evaporation coatingSputtering coatingAtomic componentTin

The invention discloses a method for preparing a TiCN coating on a surface of a screw tap. The method comprises the following steps that after the screw tap made from high-speed steel is treated in advance, the screw tap is placed on a rotating frame rod of electric arc ion coating equipment, a Ti target is used as a Ti element source for preparing the TiCN coating, and a sputtering rate of the Titarget is controlled through a current of an arc power supply; high-purity Ar is adopted as a main ionization gas, high-purity N2 and high-purity CH2 are adopted as reaction gases, the N2 gas and theCH2 gas are enabled to be ionized and combined with the Ti element, and the TiCN coating is formed on the surface of the screw tap; and the prepared TiCN coating is of a multi-layer structure, namelya Ti / TiN / TiCN / TiN / TiCN structure. The total thickness of the TiCN is 2 microns, the TiCN coating comprises the following atomic components of 52at.% of Ti, 28at.% of C and 20at.% of N; coating hardness is HV3000, under the condition of room temperature dry friction and GCr15 friction pairs, a friction coefficient of the coating is 0.15 through detection by a pin-on-disc test, the coating has excellent antifriction performance, and the method is suitable for being applied to tapping machining of refractory materials.

Owner:XIAN HAOYUAN COATING TECH

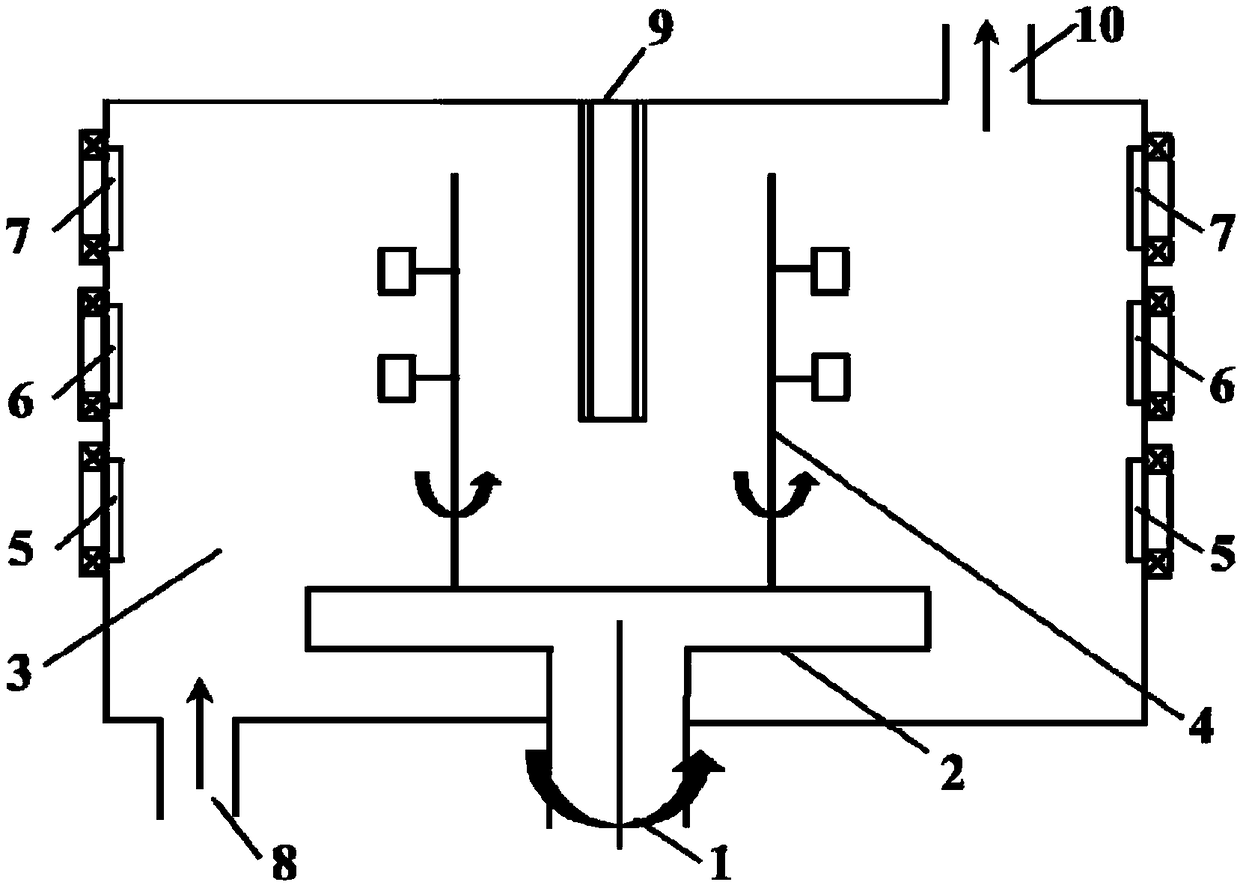

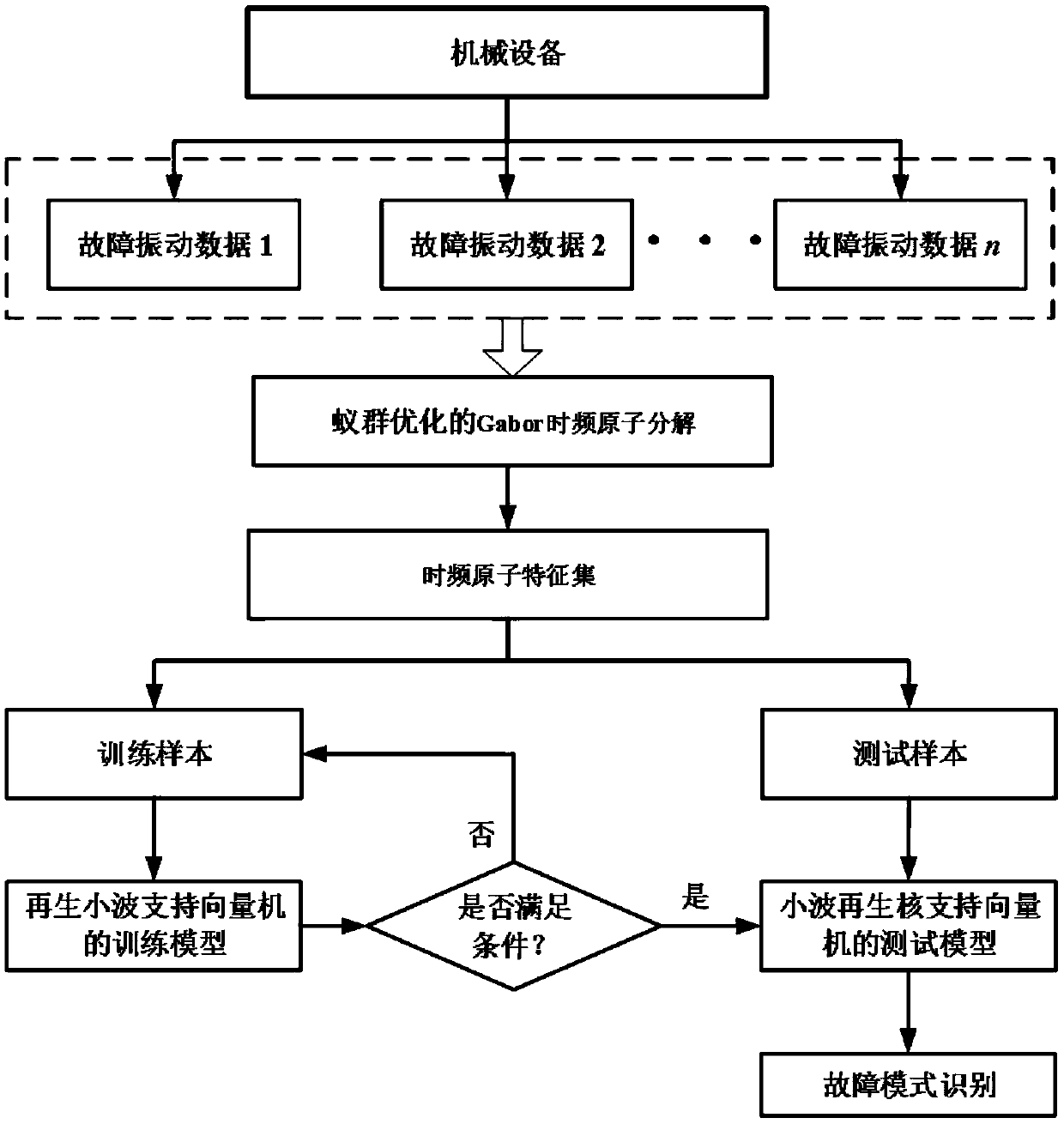

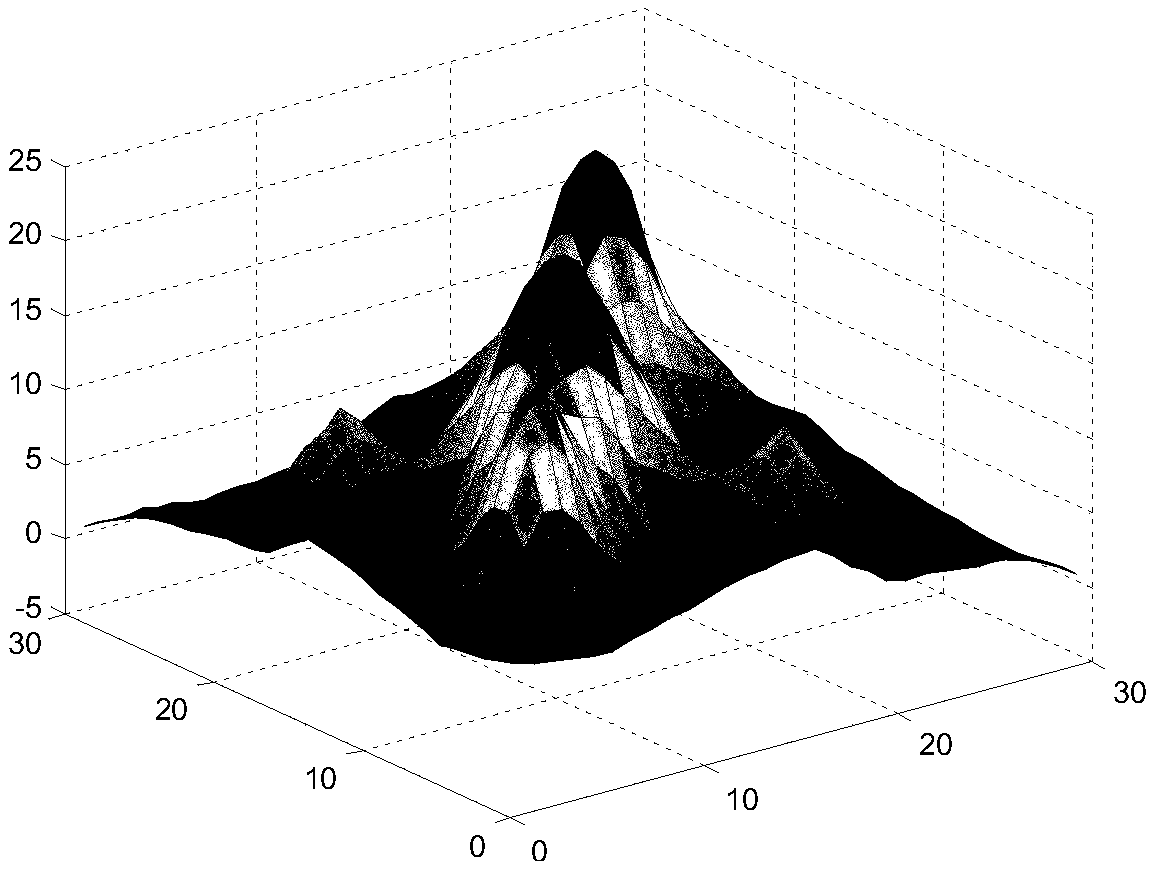

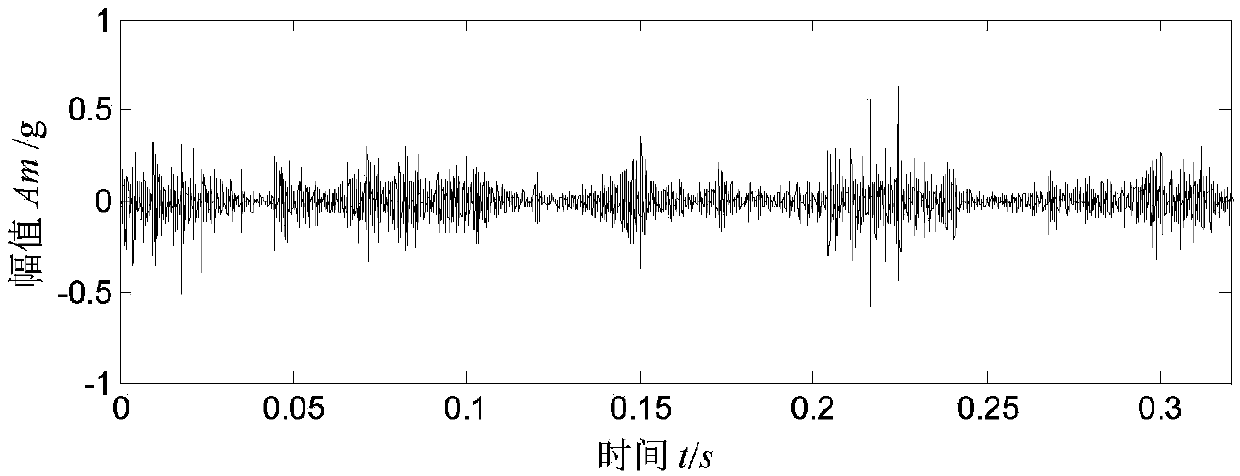

Mechanical multi-fault diagnosis method based on signal atomic-driven wavelet reproducing kernel machine learning

InactiveCN109029940AImprove computing efficiencyImprove recognition accuracyMachine part testingCharacter and pattern recognitionGabor atomSupport vector machine classifier

The invention discloses a mechanical multi-fault diagnosis method based on signal atomic-driven wavelet reproducing kernel machine learning. The method comprises the following steps that: collecting the to-be-analyzed signal of mechanical equipment, carrying out fault setting on the mechanical equipment, and collecting the non-stationary mechanical vibration signal of the fault equipment; adoptinga Gabor atomic orthogonal matching tracking method based on an ant colony search algorithm to track and decompose the non-stationary mechanical vibration signal to obtain a plurality of atomic components and residual components optimally matched with the to-be-analyzed signal; and inputting the plurality of obtained atomic components into a machine learning-wavelet reproducing kernel support vector machine classifier as a characteristic sample to be subjected to training and testing learning so as to identify the type of a mechanical multi-fault mode. By use of the method, identification accuracy can be improved.

Owner:成都赛基科技有限公司

Label configuration method and device and computer storage medium

PendingCN110866054AImprove management efficiencySolve technical problems with heavy workloadDatabase management systemsSpecial data processing applicationsComputer hardwareTheoretical computer science

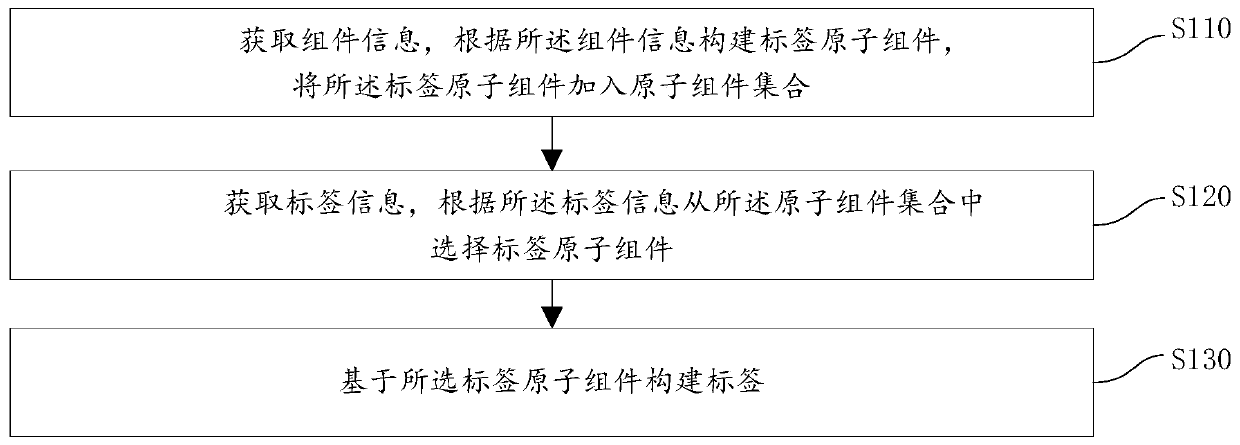

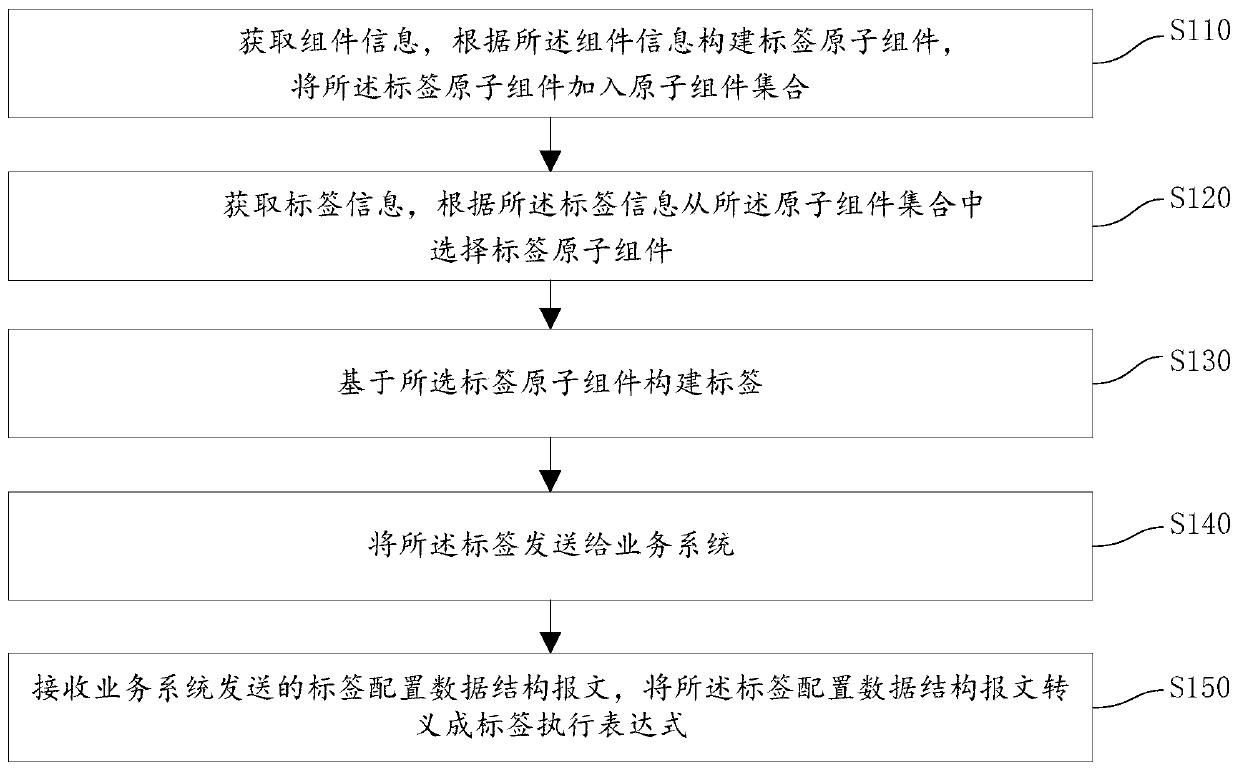

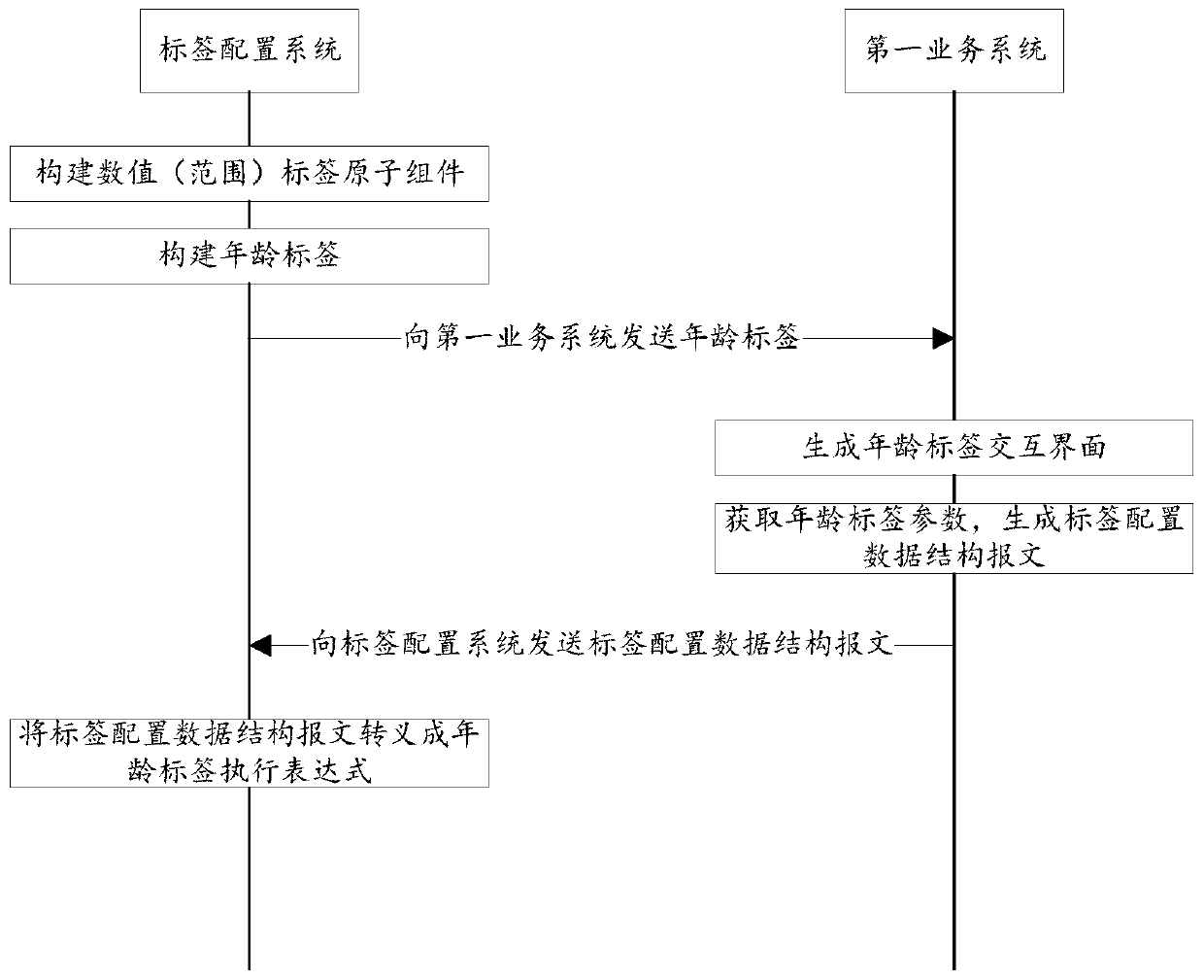

The embodiment of the invention discloses a label configuration method and device and a computer storage medium, solving the technical problems that similar labels cannot be reused, and the workload is large when the labels are newly added and updated. According to the embodiment of the invention, the label configuration method comprises the steps: obtaining component information, constructing a label atomic component according to the component information, and adding the label atomic component into an atomic component set; obtaining label information, and selecting label atomic components from the atomic component set according to the label information; and constructing a label based on the selected label atomic component. According to the embodiment of the invention, the label is modularized, and the label is constructed based on the label atomic component, so that the complex label can be formed by splicing a plurality of label atomic components, and similar labels can be reused aslong as the formed label atomic components are the same, and repeated development is avoided. When the label is newly added or updated, only the label atomic component needs to be newly added or updated, and the label constructed by the label atomic component can be updated, so that the workload is greatly reduced, and the online difficulty of the updated or newly added label is reduced.

Owner:SUNING CLOUD COMPUTING CO LTD

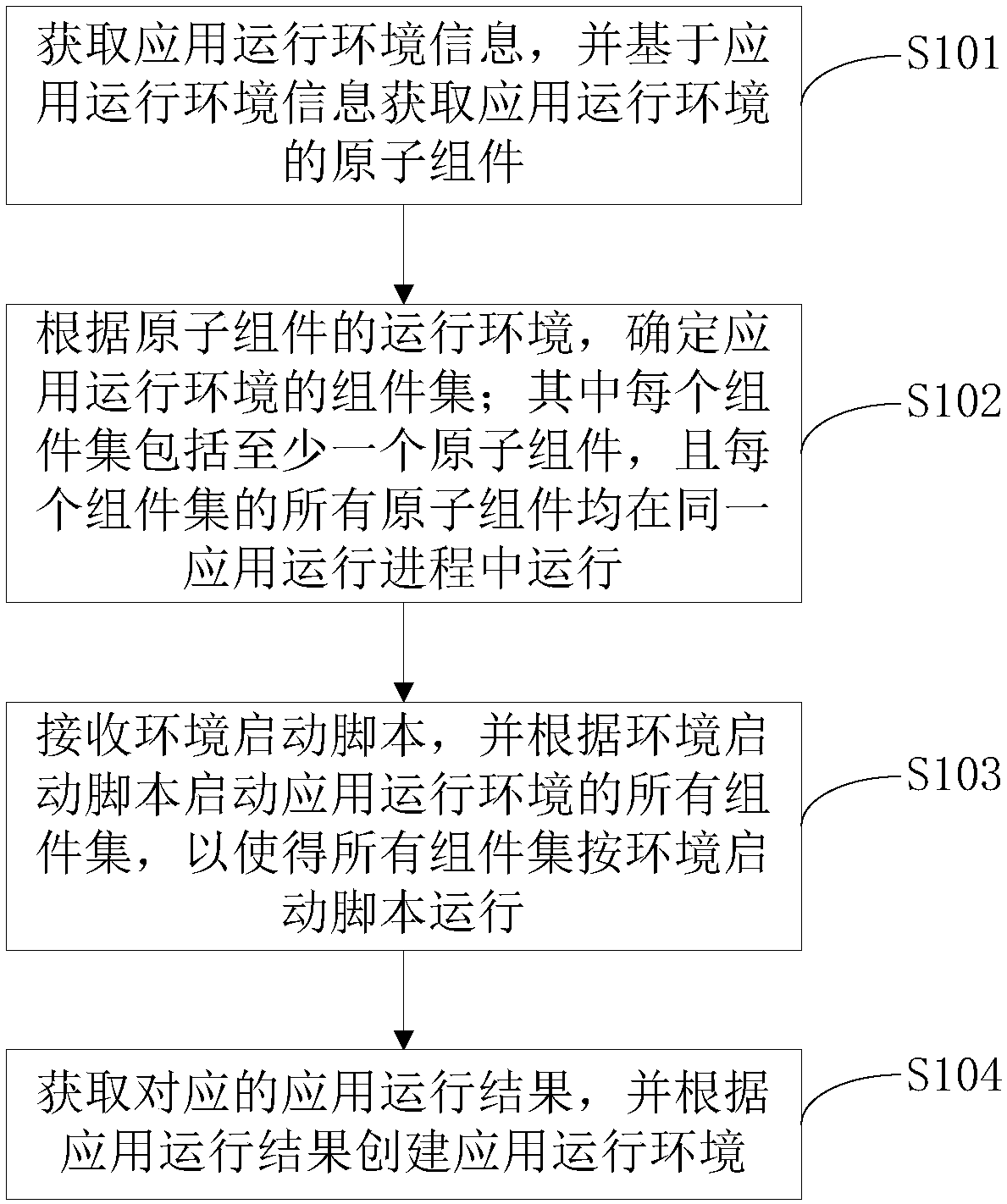

Application running environment creating method and device, electronic equipment and storage medium

ActiveCN110245066AImprove deployment efficiencySolve technical problems with low deployment efficiencySoftware testing/debuggingEnergy efficient computingSoftware engineeringAtomic component

The invention provides an application running environment creating method which comprises the following steps: acquiring application running environment information, and acquiring an atomic component of an application running environment based on the application running environment information; determining a component set of the application operation environment according to the operation environment of the atomic component; receiving the environment starting script, and starting all the component sets of the application running environment according to the environment starting script, so that all the component sets run according to the environment starting script; and obtaining a corresponding application running result, and creating an application running environment according to the application running result. The invention further provides an application running environment creating device. According to the application running environment creating method and the creating device, detection, feedback and creation of the application running environment are carried out by taking the component set as a unit, so that a relatively complicated application running environment can be conveniently created through superposition of the component set, and the deployment efficiency of the application running environment is improved.

Owner:TENPAY PAID TECH

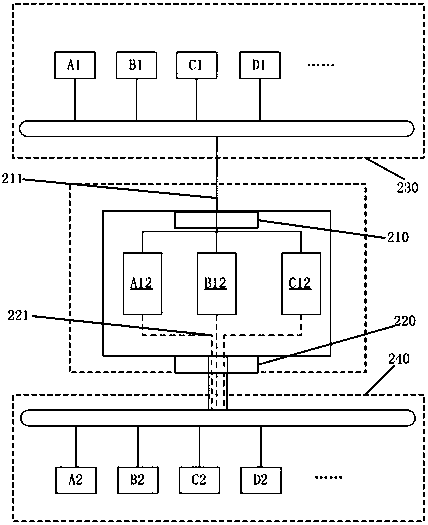

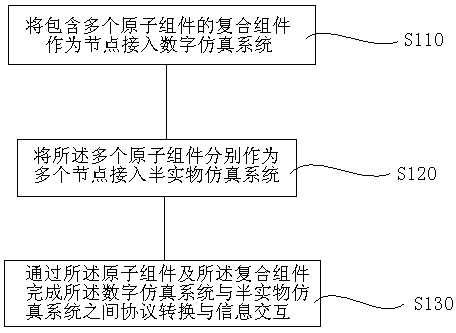

Information interaction method, device and simulation system based on component function agent technology

ActiveCN104702636BEasy to implementImprove scalabilityTransmissionSoftware simulation/interpretation/emulationAtomic componentInteraction method

The invention discloses a method and a device for information interaction based on a component function agent technology and a simulation system. The method comprises the following steps of taking a composite component including a plurality of atomic components as a node to be connected to a digital simulation system; taking a plurality of atomic components as a plurality of nodes to be connected to a semi-physical simulation system; and complementing protocol conversion and information interaction between the digital simulation system and the semi-physical simulation system through the atomic components and the composite component.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

An ultra-short-term wind power sliding prediction method

InactiveCN103117546BSparse decomposition effectReduce the absolute mean errorSpecial data processing applicationsAc network circuit arrangementsAlgorithmDecomposition

The invention relates to an ultrashort-term slide prediction method for wind power. An atomic sparse decomposition method with quite high non-stable signal tracking and prediction capacity is used as a front decomposition method of a neural network. A wind power time sequence is decomposed into an atomic component and a residual error component, the atomic component is automatically predicted, the residual error component is predicted by the neural network, atomic decomposition results are updated by adding the latest wind power real-time data, and further the wind power of a next moment is slidably predicted. Actual wind field data prove that the model can effectively avoid non-stability of the wind power, sparser decomposition effects are achieved, and statistical intervals of absolute average error and root mean square error computation values can be remarkably reduced. Therefore, the ultrashort-term slide prediction method has the advantages that non-stability of the wind power can be effectively avoided, the sparser decomposition effects are achieved, and the statistical intervals of the absolute average error and root mean square error computation values can be remarkably reduced.

Owner:WUHAN UNIV

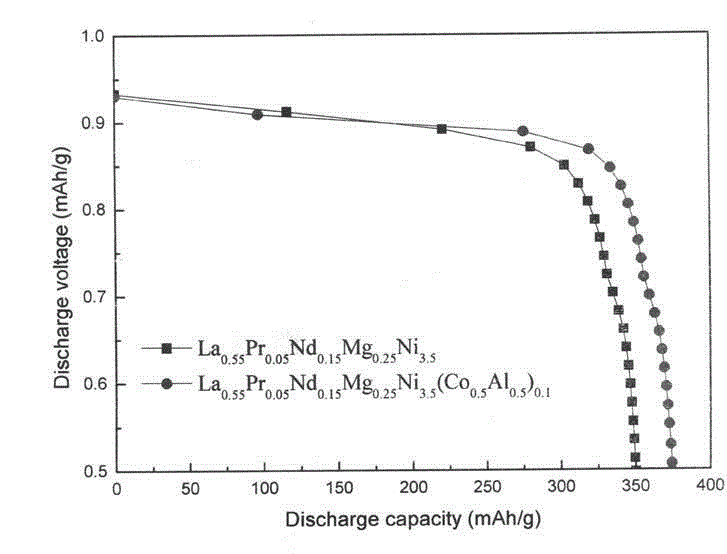

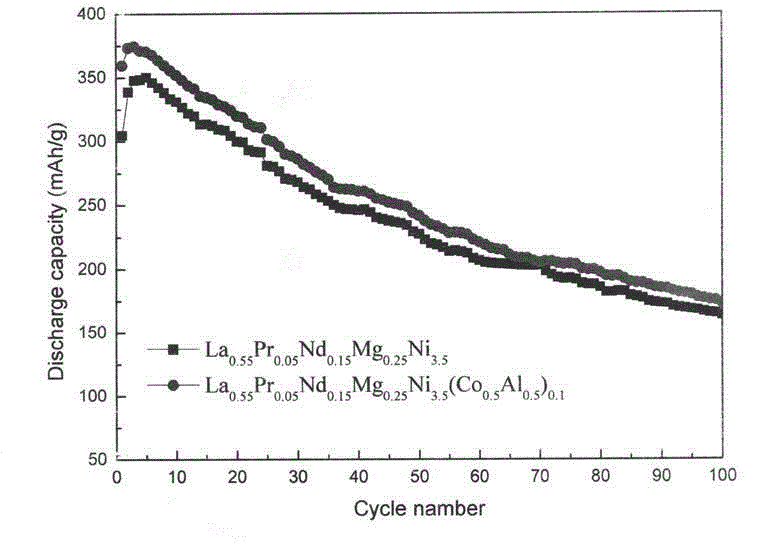

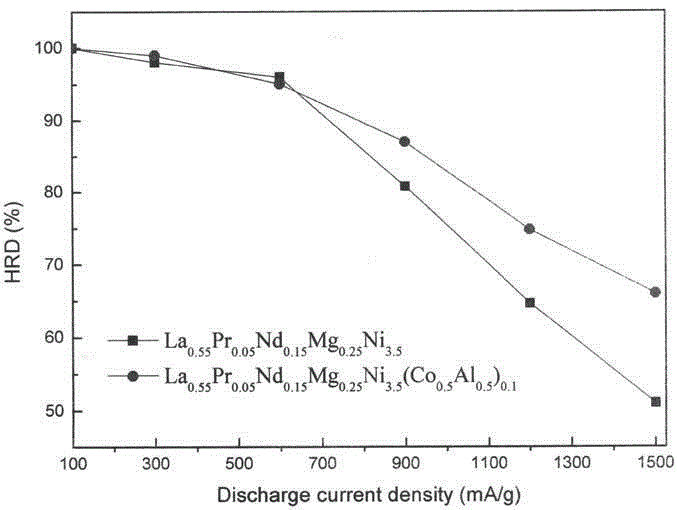

Novel La-Mg-Ni-series hydrogen storage alloy

The invention discloses a novel La-Mg-Ni-series hydrogen storage alloy with an atomic component composition as shown in the following formula: La0.55Pr0.05Nd0.15Mg0.25Ni3.5 (Co0.5Al0.5) x, wherein x is greater than or equal to 0 but less than or equal to 0.5. The alloy is a negative electrode hydrogen storage material applied to a nickel-metal hydroxide storage battery, and is obtained by substituting La with cerium-rich rear earth as a side A and carrying out multi-component co-substitution on a side B; meanwhile, Co and Al are added into the alloy, so that the hydrogen storage amount of the alloy is increased, the corrosion of the alloy in electrolyte is alleviated, the cycling stability of an alloy electrode is improved, and the product cost is further reduced.

Owner:BAISE UNIV

User customization-based body matching system and method

The invention discloses a user customization-based body matching system, which relates to the technical field of semantic web and comprises a body module, an atomic component module, a user interface module and a matching execution module, wherein the body module comprises an atomic interface body operating interface sub-module and a body application program interface (API) sub-module; the atomic component module is used for calling body APIs of the body API sub-module to realize atomic components by the atomic component body operating interface sub-module; the user interface module is used for receiving a body to be matched from a user and autonomously realized atomic components; and the matching execution module is used for generating a matching task description file according to the body to be matched, selecting the atomic component or the autonomously realized atomic component according to the matching task description file to execute a matching task, and generating a matching result. By the system, the user can customize and assemble the atomic components according to the characteristics of the body to be matched to design a body matching flow required per se, generate a proper matching task and obtain the accurate matching result.

Owner:TSINGHUA UNIV

Service software construction method and system adapting to multiple business abstraction levels

InactiveCN101794226BReduced domain knowledge requirementsImprove reusabilityData switching networksSpecific program execution arrangementsAbstraction layerService-orientation

The invention discloses a service software construction method and a system adapting to multiple business abstraction levels. The invention is based on business-oriented frameworks, and constructs the service component resources by a stage-by-stage abstraction method, and a software system is constructed on the basis. According to the application requirements of different business abstraction levels, the invention also provides construction way atom component unrelated to the field, a composite component reconstruction way related to the field, and a configuration way related to the user business. Thus, the construction and the management of the software can aim at different business requirements and abstraction levels, and a proper method can be utilized to adapt to quick reconstruction of large-scale multiple tenants and software, namely quick reconstruction of service mode applications, thereby ensuring the efficiency, economical efficiency and reliability of software production.

Owner:SHANDONG UNIV

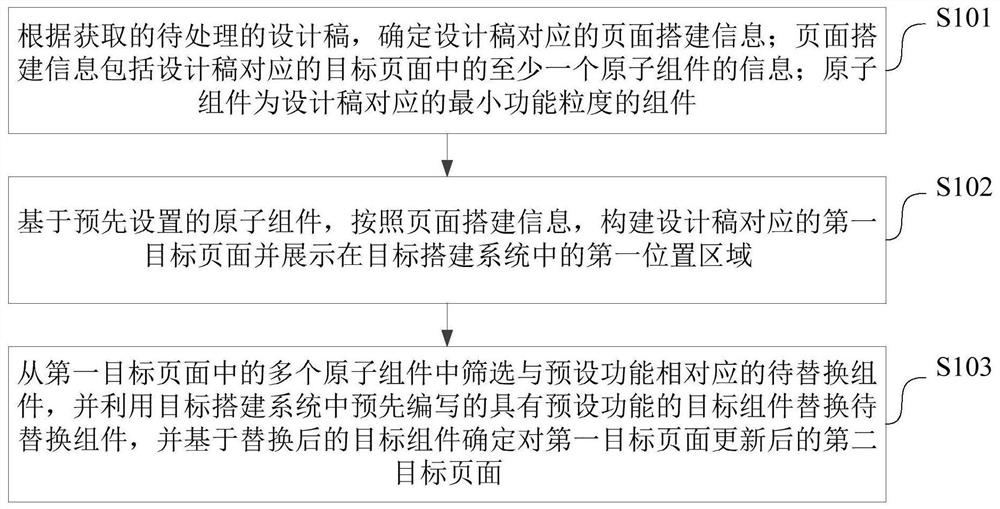

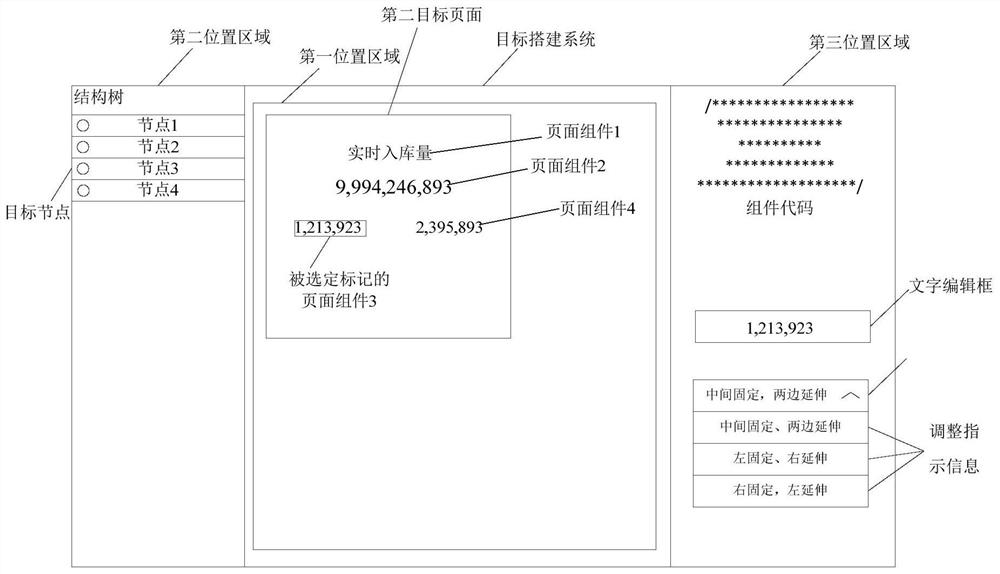

Design draft conversion method and device, computer equipment and storage medium

PendingCN113946336AImprove efficiencyHigh speedTransformation of program codeGranularitySoftware engineering

The invention provides a design draft conversion method and device, computer equipment and a storage medium. The method comprises the steps: determining page building information corresponding to a design draft according to an obtained to-be-processed design draft; the page building information comprises information of at least one atomic component in a target page corresponding to the design draft; the atomic component is a component with the minimum function granularity corresponding to the design draft; based on a preset atomic component, according to the page building information, building a first target page corresponding to the design draft, and displaying the first target page in a first position area in a target building system; and screening a to-be-replaced component corresponding to the preset function from the plurality of atomic components in the first target page, replacing the to-be-replaced component with a target component which is pre-written in the target building system and has the preset function, and determining a second target page after updating the first target page based on the replaced target component. According to the embodiment of the invention, the target page corresponding to the design draft can be automatically generated.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

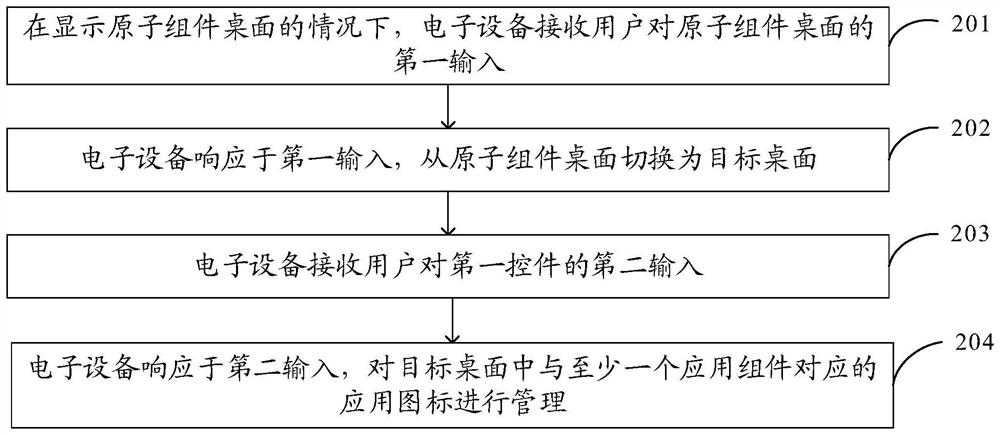

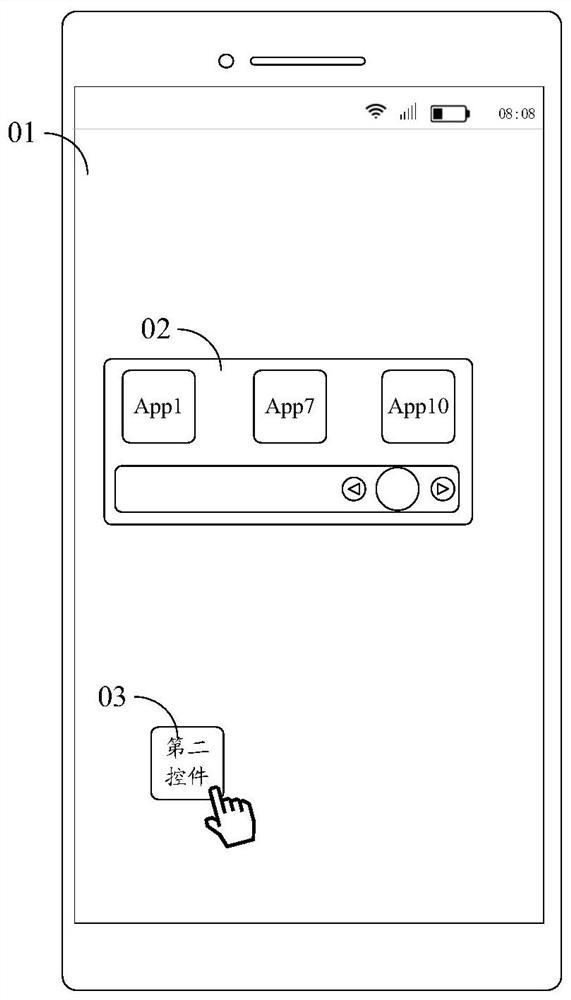

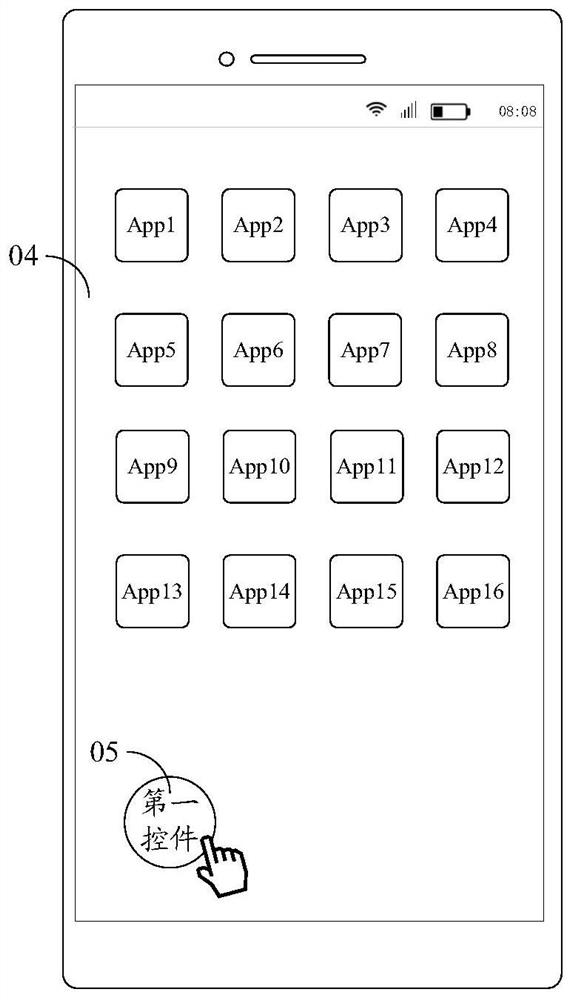

Application icon management method and device, electronic equipment and readable storage medium

PendingCN114089885AShort timeImprove interactivityInput/output processes for data processingComputer hardwareOperating system

The invention discloses an application icon management method and device, electronic equipment and a readable storage medium. The method comprises the steps of under the condition that an atomic component desktop is displayed, receiving a first input of a user to the atomic component desktop, wherein the atomic component desktop comprises at least one application component, and each application component comprises at least two application icons, in response to the first input, switching the atomic component desktop to a target desktop, wherein the target desktop comprises a first control, and the first control is used for managing application icons in the target desktop, receiving a second input of the user to the first control, and in response to the second input, managing an application icon corresponding to the at least one application component in the target desktop.

Owner:VIVO MOBILE COMM CO LTD

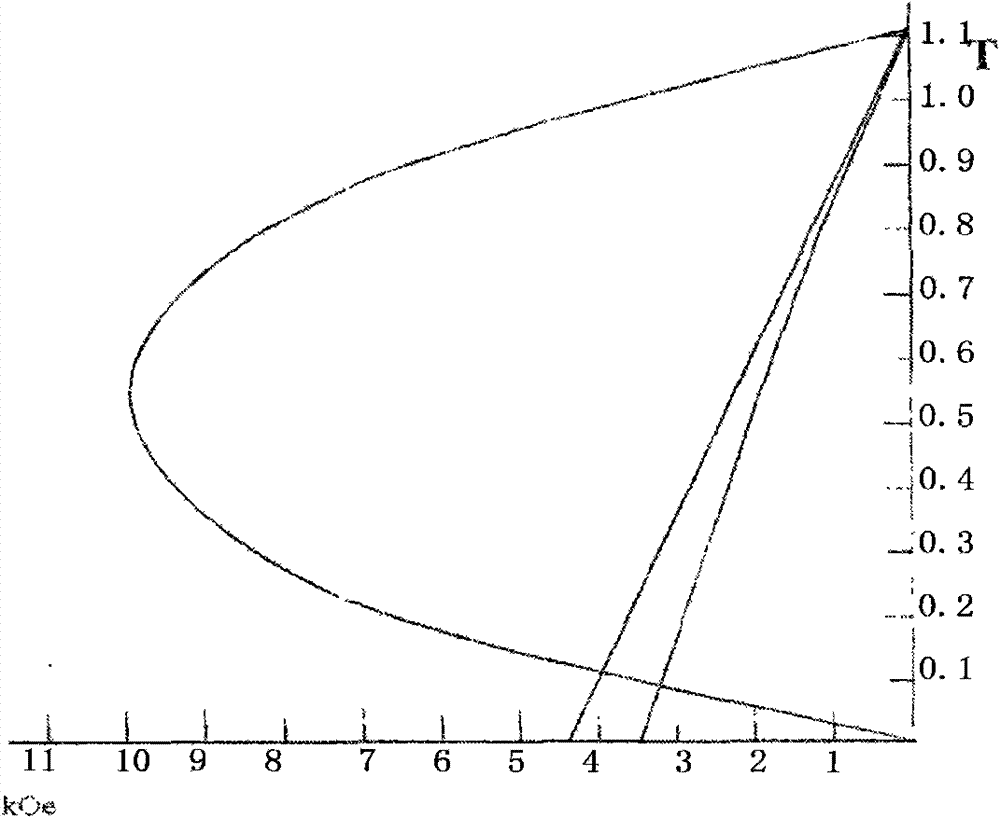

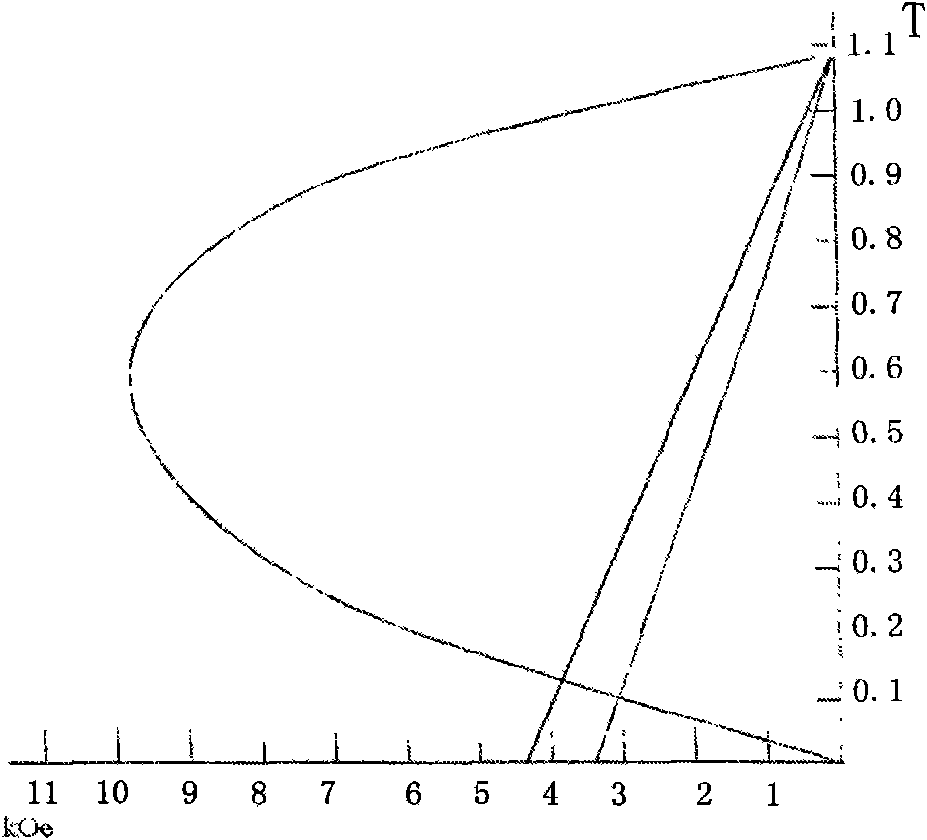

High-remanence low-coercivity permanent magnetic material and preparation method thereof

InactiveCN101819844BΑ-Fe phase reductionIncrease internal stressMagnetic materialsRare-earth elementRemanence

The invention belongs to the field of magnetic materials, and in particular relates to a high-remanence low-coercivity permanent magnetic material and a preparation method thereof. The material has the atomic components shown as RxFe100-x-y-a-b-cAlaCubSicBy, wherein x is 4 to 4.5; y is 18 to 19.5; a is not zero and is no more than 1.5; b is not zero and is no more than 0.8; c is not zero and no more than 1.4; R is rare-earth element; and Fe, Al, Cu, Si and B respectively refer to iron, aluminum, copper, silicon, boron elements. The material consists of ultra-fine crystals of which the main phase is a mixture of three metal phases, namely R2Fe14B, Fe3B and alpha-Fe, wherein iron atoms are substituted by Al, Cu and Si atoms compositely. The permanent magnetic material prepared by the invention has more outstanding characteristics of high remanence and low coercivity.

Owner:LUOHE SANXIN RARE EARTH PERMANENT MAGNETIC MATERIAL

Automatic run-time environment (RTE) code generating method for automobile system architecture (AUTOSAR)

ActiveCN102214099BPromote generationImprove readabilitySpecific program execution arrangementsSoftware engineeringData element

The invention discloses an automatic run-time environment (RTE) code generating method for automobile system architecture (AUTOSAR). The method comprises the following steps of: 1) sequentially analyzing component instances in the AUTOSAR, creating data element instances or operating instances, storing port information and element communication attributes, analyzing internal behaviors of atomic components in the component instances, and recording corresponding communication modes in the data element instances or the operating instances; 2) sequentially analyzing component groups of the component instances with connecting relationship, and storing the operating instances or the data element instances in ports of opposite communication ends; and 3) acquiring cache resources required by the data element instances or the operating instances corresponding to the RTE, and correspondingly storing the acquired caches in the corresponding data element instances or the operating instances. The method has the advantages of strong logicality, good readability, simplicity and quickness in development and high development efficiency.

Owner:ZHEJIANG UNIV

High-remanence low-coercivity permanent magnetic material and preparation method thereof

InactiveCN101819844AΑ-Fe phase reductionIncrease internal stressMagnetic materialsRare-earth elementRemanence

The invention belongs to the field of magnetic materials, and in particular relates to a high-remanence low-coercivity permanent magnetic material and a preparation method thereof. The material has the atomic components shown as RxFe100-x-y-a-b-cAlaCubSicBy, wherein x is 4 to 4.5; y is 18 to 19.5; a is not zero and is no more than 1.5; b is not zero and is no more than 0.8; c is not zero and no more than 1.4; R is rare-earth element; and Fe, Al, Cu, Si and B respectively refer to iron, aluminum, copper, silicon, boron elements. The material consists of ultra-fine crystals of which the main phase is a mixture of three metal phases, namely R2Fe14B, Fe3B and alpha-Fe, wherein iron atoms are substituted by Al, Cu and Si atoms compositely. The permanent magnetic material prepared by the invention has more outstanding characteristics of high remanence and low coercivity.

Owner:LUOHE SANXIN RARE EARTH PERMANENT MAGNETIC MATERIAL

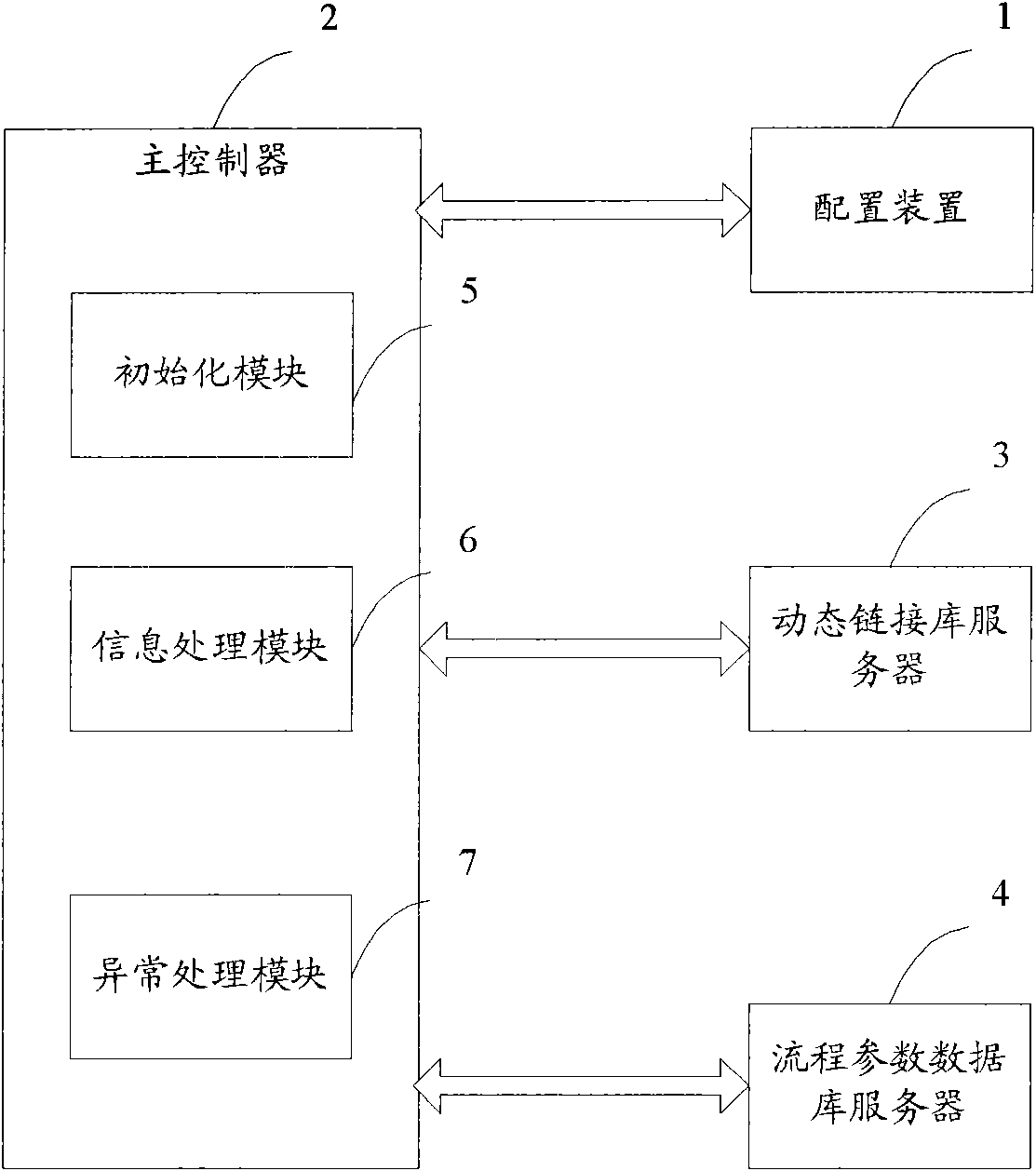

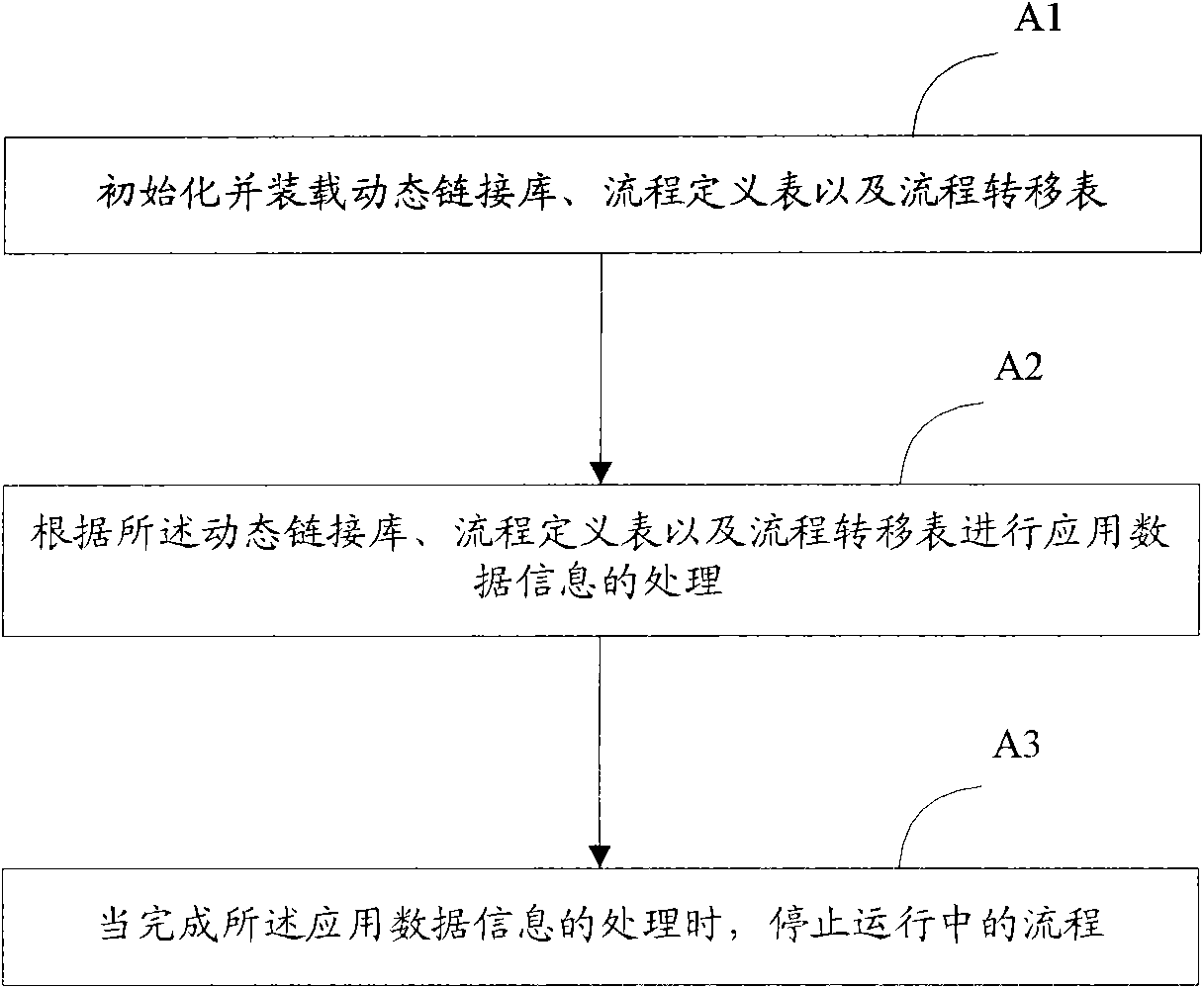

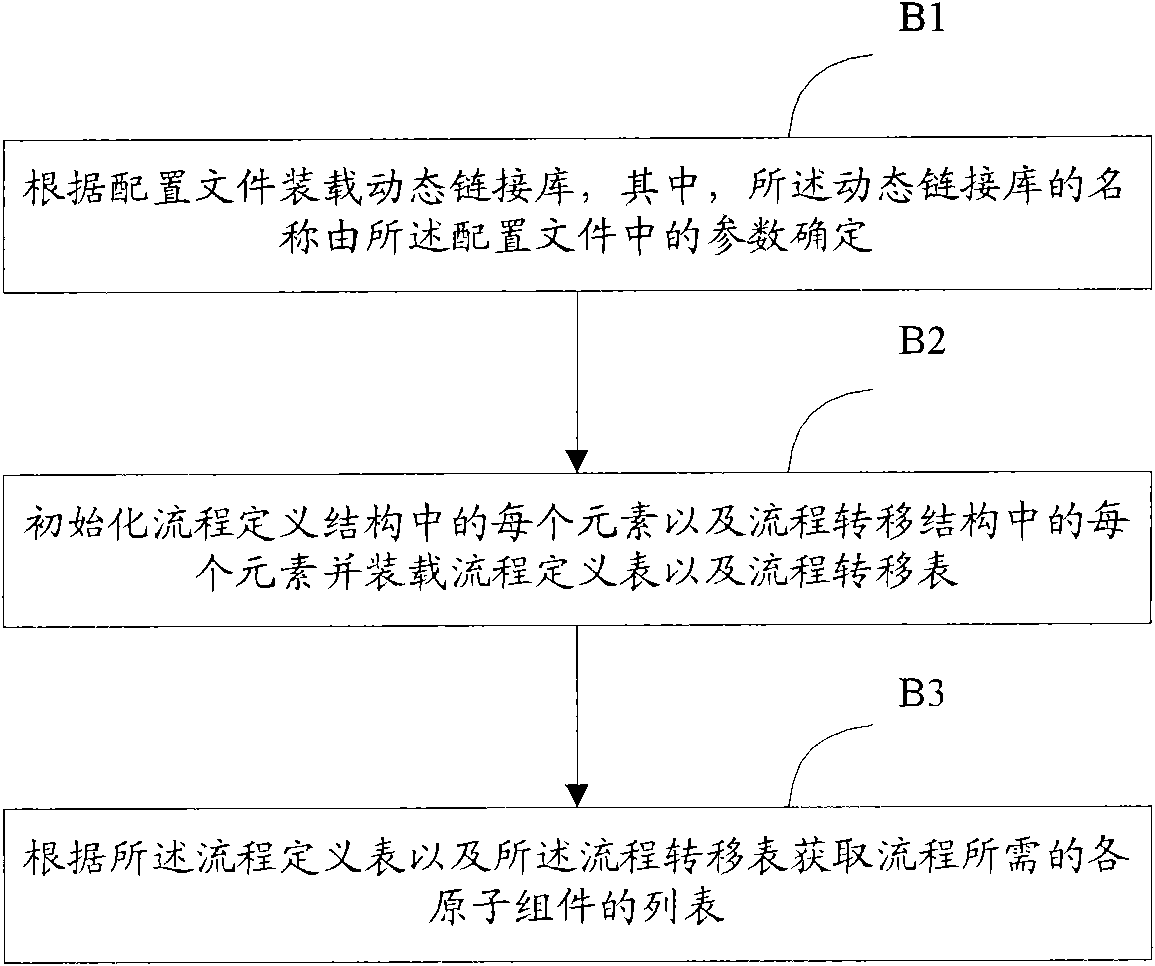

Atomization information processing system and method

InactiveCN102375756AIncrease flexibilityImprove acceleration performanceMultiprogramming arrangementsInformation processingDatabase server

The invention discloses an atomization information processing system and method. The information processing system comprises a configuration device, a process parameter database server, a master controller and a DLL (dynamic link library) server, wherein the configuration device is used for setting and storing configuration files; the process parameter database server is used for setting and storing a process definition table and a process transfer table; the master controller is used for controlling the initialization of the information processing system and the processing of information data; and the DLL server is used for storing a DLL containing an atomic component. By using the atomization information processing system and method disclosed by the invention, the flexibility and expansibility of the information processing system are improved.

Owner:CHINA UNIONPAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com