Manufacturing method for micro-miniature atomic air chamber

A technology of atomic gas chamber and manufacturing method, which is applied to instruments using atomic clocks, etc., can solve the problems of low stress, low optical precision of clear surface, difficult ultra-high vacuum processing, etc., and achieves low force, high optical quality of smooth surface, High air tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

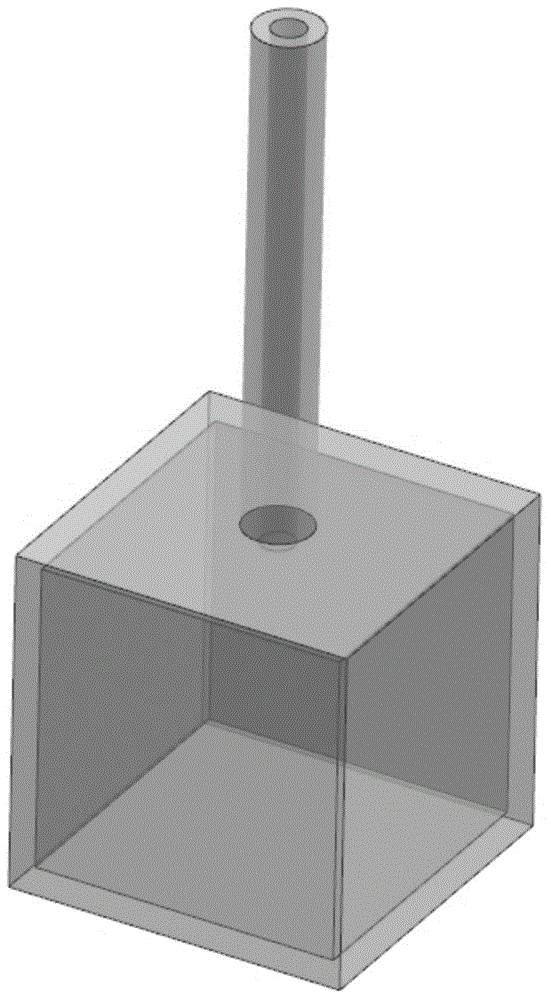

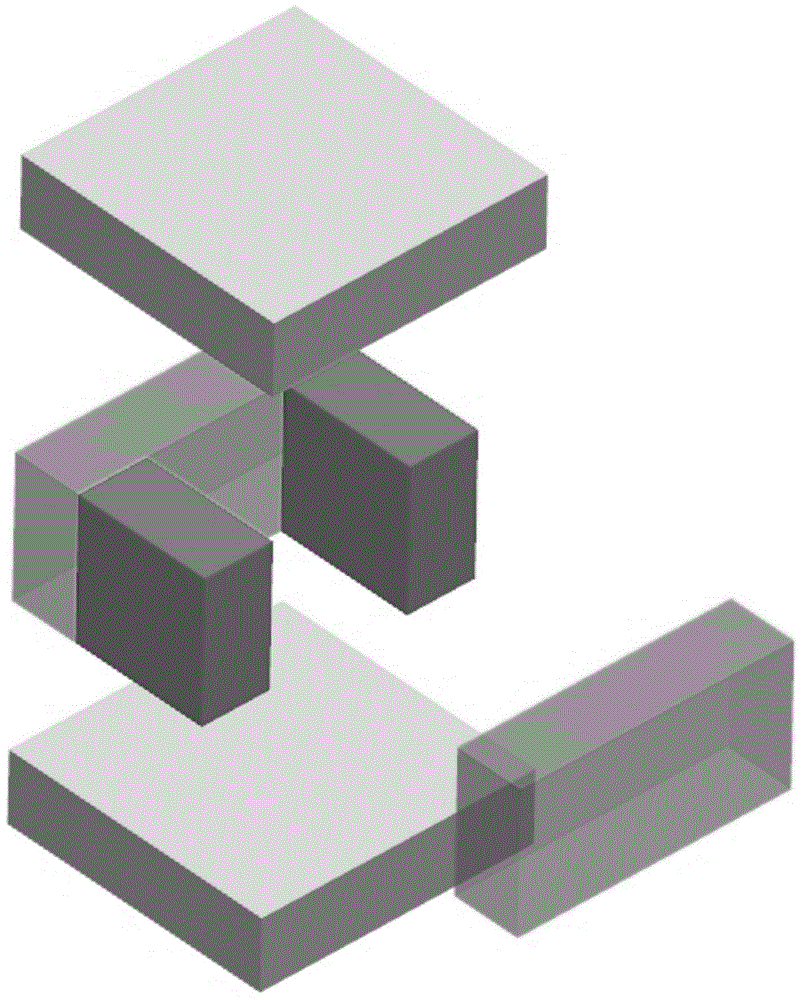

[0024] A manufacturing method of a miniature atomic gas chamber, comprising the following steps:

[0025] Step 1. Material selection and cutting

[0026] Assume that the length, width and height of the external dimensions required by the gas chamber are respectively a, b and h, the definitions of the length, width and height of the external dimensions of the gas chamber can be exchanged arbitrarily in this embodiment, the wall thickness of the gas chamber is l, and the exhaust If the inner diameter of the trachea is d, the plate glass with a thickness of l is selected as the raw material, and the raw plate glass is cut into specifications of a×(h-2l)×l, (b-2l)×(h-2l)×l and a × b × l parts, such as figure 2 As shown, there are at least two parts of each specification, and any specification part is selected, and a hole is opened in the center of half of the selected specification parts. In this embodiment, half of the specifications are selected as a × b × l part size a A thr...

Embodiment 2

[0038] A manufacturing method of a miniature atomic gas chamber, comprising the following steps:

[0039] Step 1. Material selection and cutting

[0040] Assume that the length, width and height of the external dimensions required by the gas chamber are respectively a, b and h, the definitions of the length, width and height of the external dimensions of the gas chamber can be exchanged arbitrarily in this embodiment, the wall thickness of the gas chamber is l, and the exhaust The inner diameter of the trachea is d. Select flat glass with thickness h-2l and l as raw material, cut the raw material flat glass with thickness h-2l into a square frame part with cross-sectional size a×b, height h-2l, and wall thickness l, The raw material flat glass with a thickness l is cut into a bottom part with a dimension specification of a×b×l, and the ratio of the number of the square frame part to the bottom part is 1:2. And make a hole in the center of either side of the box part, or in t...

Embodiment 3

[0052] A manufacturing method of a miniature atomic gas chamber, comprising the following steps:

[0053] Step 1. Material selection and cutting

[0054] Assume that the length, width and height of the external dimensions required by the gas chamber are respectively a, b and h, the definitions of the length, width and height of the external dimensions of the gas chamber can be exchanged arbitrarily in this embodiment, the wall thickness of the gas chamber is l, and the exhaust If the inner diameter of the trachea is d, the flat glass with thickness h-l and l is selected as the raw material, and the raw flat glass is cut into a square box with cross-sectional size a×b, height h-l, wall thickness l and no upper bottom shaped parts, and a bottom part whose size is a×b×l, and the ratio of the number of the square box-shaped parts to the bottom part is 1:1. And open a hole in the center of any side of the square box-shaped part, or the center of the bottom part. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com