Novel La-Mg-Ni-series hydrogen storage alloy

A hydrogen storage alloy and alloy technology, which is applied in the field of nickel-hydrogen battery negative electrode hydrogen storage materials and La-Mg-Ni hydrogen storage alloys, can solve the problem of not meeting the requirements of commercial nickel-hydrogen batteries, poor electrode cycle stability, and hindering commercial use. problems such as chemical application, to achieve the effect of improving hydrogen storage capacity and cycle stability, increasing cycle stability, and slowing down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. The design alloy composition is La 0.55 PR 0.05 Nd 0.15 Mg 0.25 Ni 3.5 (Co 0.5 al 0.5 ) 0.1

[0023] B. Proportioning each elemental element with a purity of more than 99% according to the molar percentage;

[0024] C. Prepare the alloy designed in step A by magnetic levitation melting. Put all the raw materials into the crucible together, and pass 1×10 into the melting crucible 5 Pa argon, smelting by slowly increasing the smelting power, the smelting power range is 20-2500KW, the smelting time is 2-5min, and the alloy is turned over and remelted 3-4 times during the alloy smelting process to ensure that the alloy composition is uniform. The smelted alloy ingot is polished with sandpaper to remove the surface oxide layer, and then the alloy is mechanically ground and pulverized through a 200-mesh sieve for later use.

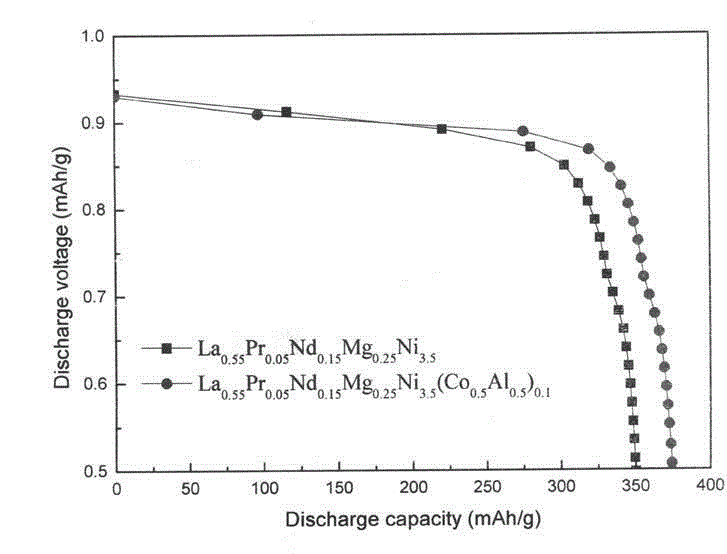

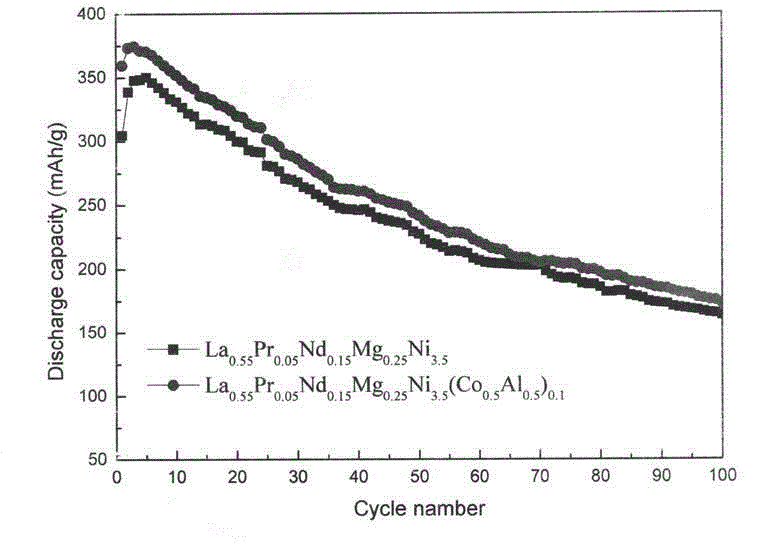

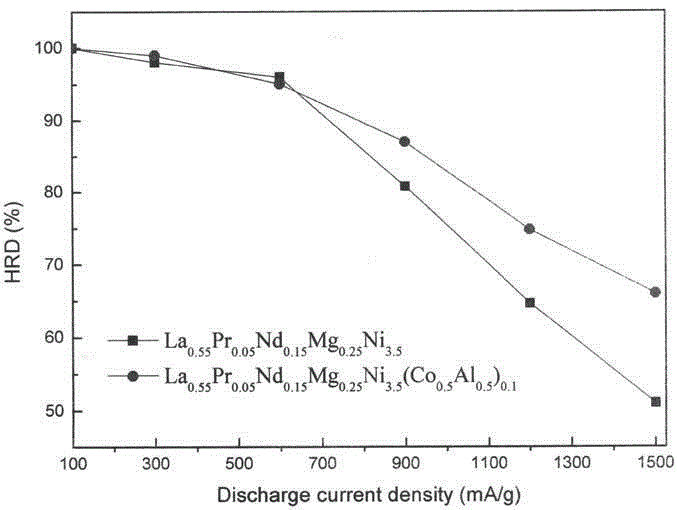

[0025] The electrochemical performance of the alloy electrode was tested by the open three-electrode method. Mix 0.3 g of the prepared hyd...

Embodiment 2

[0027] A. The design alloy composition is La 0.55 PR 0.05 Nd 0.15 Mg 0.25 Ni 3.5 (Co 0.5 al 0.5 ) 0.3

[0028] B. Prepare the alloy designed in step A by magnetic levitation melting. Put all the raw materials into the crucible together, and pass 1×10 into the melting crucible 5 Pa argon, smelting by slowly increasing the smelting power, the smelting power range is 20-2500KW, the smelting time is 2-5min, and the alloy is turned over and remelted 3-4 times during the alloy smelting process to ensure that the alloy composition is uniform. The smelted alloy ingot is polished with sandpaper to remove the surface oxide layer, and then the alloy is mechanically ground and pulverized through a 200-mesh sieve for later use.

[0029] The electrochemical performance of the alloy electrode was tested by the open three-electrode method. Mix 0.3 g of the prepared hydrogen storage alloy powder with 1.2 g of nickel hydroxy powder in a mass ratio of 1:4, and press it into a negative ...

Embodiment 3

[0031] A. The design alloy composition is La 0.55 PR 0.05 Nd 0.15 Mg 0.25 Ni 3.5 (Co 0.5 Al 0.5 ) 0.5

[0032] B. Proportioning each elemental element with a purity of more than 99% according to the molar percentage;

[0033] C. Prepare the alloy designed in step A by magnetic levitation melting. Put all the raw materials into the crucible together, and pass 1×10 into the melting crucible 5 Pa argon, smelting by slowly increasing the smelting power, the smelting power range is 20-2500KW, the smelting time is 2-5min, and the alloy is turned over and remelted 3-4 times during the alloy smelting process to ensure that the alloy composition is uniform. The smelted alloy ingot is polished with sandpaper to remove the surface oxide layer, and then the alloy is mechanically ground and pulverized through a 200-mesh sieve for later use.

[0034] The electrochemical performance of the alloy electrode was tested by the open three-electrode method. Mix 0.3 g of the prepared hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com