NaAlH4-titanium-vanadium base solid solution hydrogen storage composite material and preparation method thereof

A technology for hydrogen storage materials and solid solutions, which is applied in the production of hydrogen and other directions, can solve the problems affecting the hydrogen absorption and desorption performance of materials, and achieve the effects of simple and easy preparation process, high hydrogen storage capacity, and increased rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

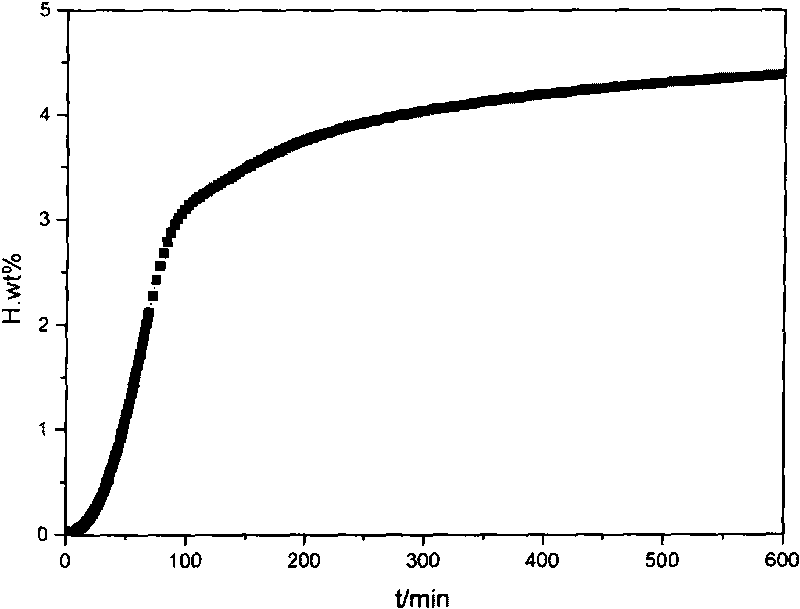

[0021] In a glove box protected by high-purity argon (purity greater than 99.95%), 5mol% of Ti with an average particle size of less than 50μm 30 Cr 25.5 V 40 Fe 4.5 Alloy powder with 95mol% NaAlH 4 The material is mechanically ground and mixed in an agate mortar for 30 minutes, and then put into a stainless steel ball mill tank, and a stainless steel ball with a diameter of 8-10 mm is filled into the tank according to the ball weight ratio of 10:1. After the stainless steel ball mill tank is sealed, The tank is filled with 5.0 MPa hydrogen with a purity of> 99.99%, and then ball milled for 10 hours under the process of a planetary ball mill (300 revolutions / min, 600 revolutions / min). The hydrogen storage test results show that the composite hydrogen storage material can reversibly release 2.0 wt% of hydrogen within 1 h at 150°C, and the total amount of hydrogen released is 4.4 wt%. The kinetic curve of hydrogen release at 150°C and 0.1MPa for the composite is as figure 1 Shown....

Embodiment 2

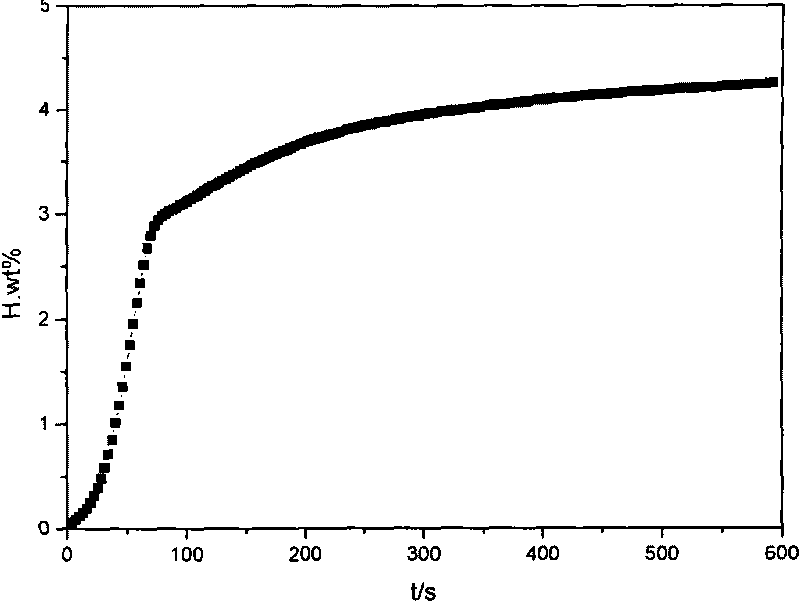

[0023] In a glove box protected by high-purity argon (purity greater than 99.95%), 10mol% of Ti with an average particle size of less than 50μm 40 Cr 30 V 25 Fe 5 Alloy powder with 90mol% NaAlH 4 Material, mechanically grind and mix in an agate mortar for 30 minutes, put it into a stainless steel ball mill tank, and fill the tank with stainless steel balls with a diameter of 8-10mm according to the ball weight ratio of 20:1. After the stainless steel ball mill tank is sealed, The tank is filled with hydrogen with a purity of >99.99% of 0.5MPa, and then ball milled for 5 hours under the process of a planetary ball mill (300 revolutions / min, 600 revolutions / min). The hydrogen storage test results show that the composite hydrogen storage material can reversibly release 2.5 wt% of hydrogen within 1 h at 150°C, and the total amount of hydrogen released is 4.1 wt%. The kinetic curve of hydrogen release at 150°C and 0.1MPa for the composite is as figure 2 Shown.

Embodiment 3

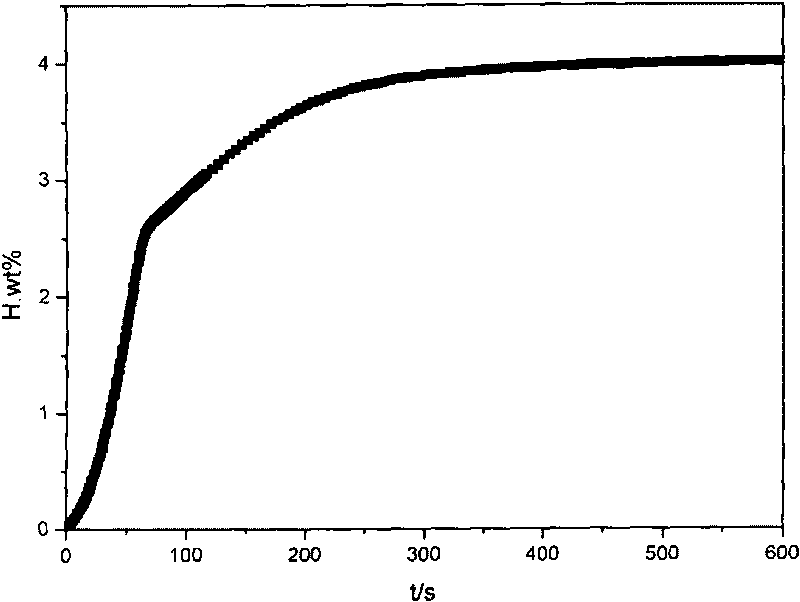

[0025] In a glove box protected by high-purity argon (purity greater than 99.95%), 30 mol% of Ti with an average particle size of less than 50 μm 35 Cr 35 V 30 Fe 0 Alloy powder with 70mol% NaAlH 4 Material, mechanically grind and mix in an agate mortar for 30 minutes, put it into a stainless steel ball mill tank, and fill the tank with stainless steel balls with a diameter of 8-10mm according to the ball weight ratio of 5:1. After the stainless steel ball mill tank is sealed, The tank is filled with hydrogen with a purity of >99.99% of 1.5MPa, and then ball milled for 20 hours under the process of a planetary ball mill (300 revolutions per minute, 600 revolutions per minute). The hydrogen storage test results show that the composite hydrogen storage material can reversibly release 2.6wt% of hydrogen within 1h at 150°C, and the total hydrogen release is 4.0wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com