Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

274results about "Magnetic film to substrate application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

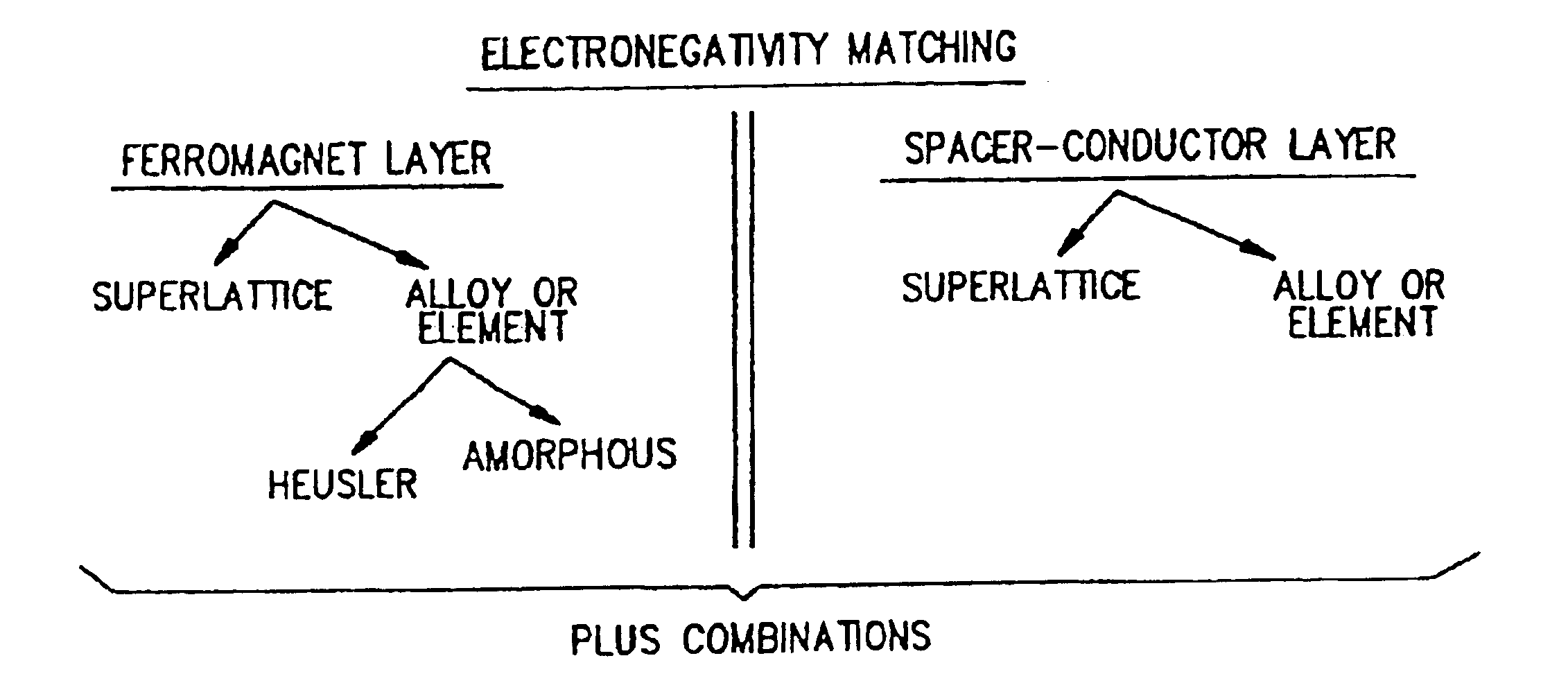

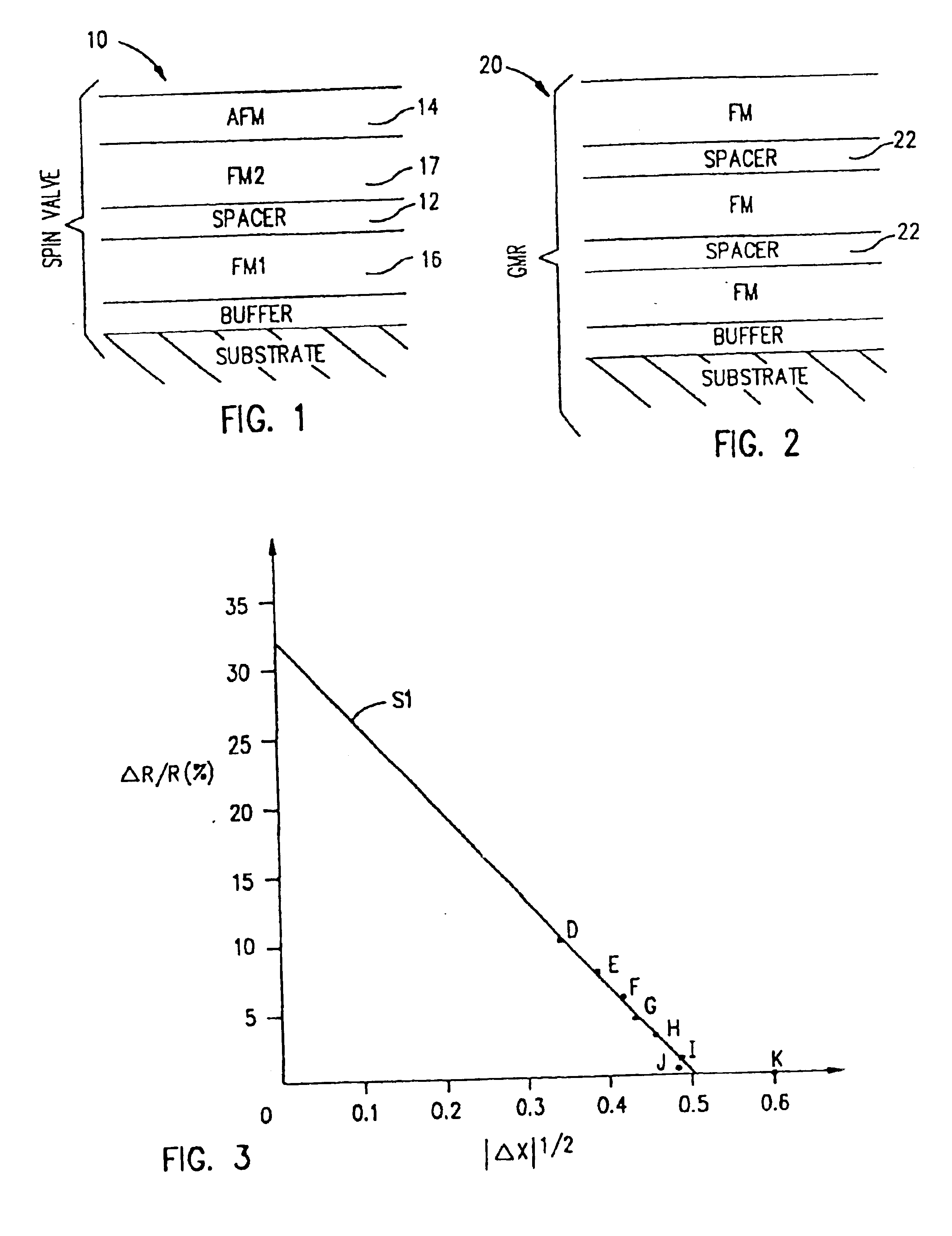

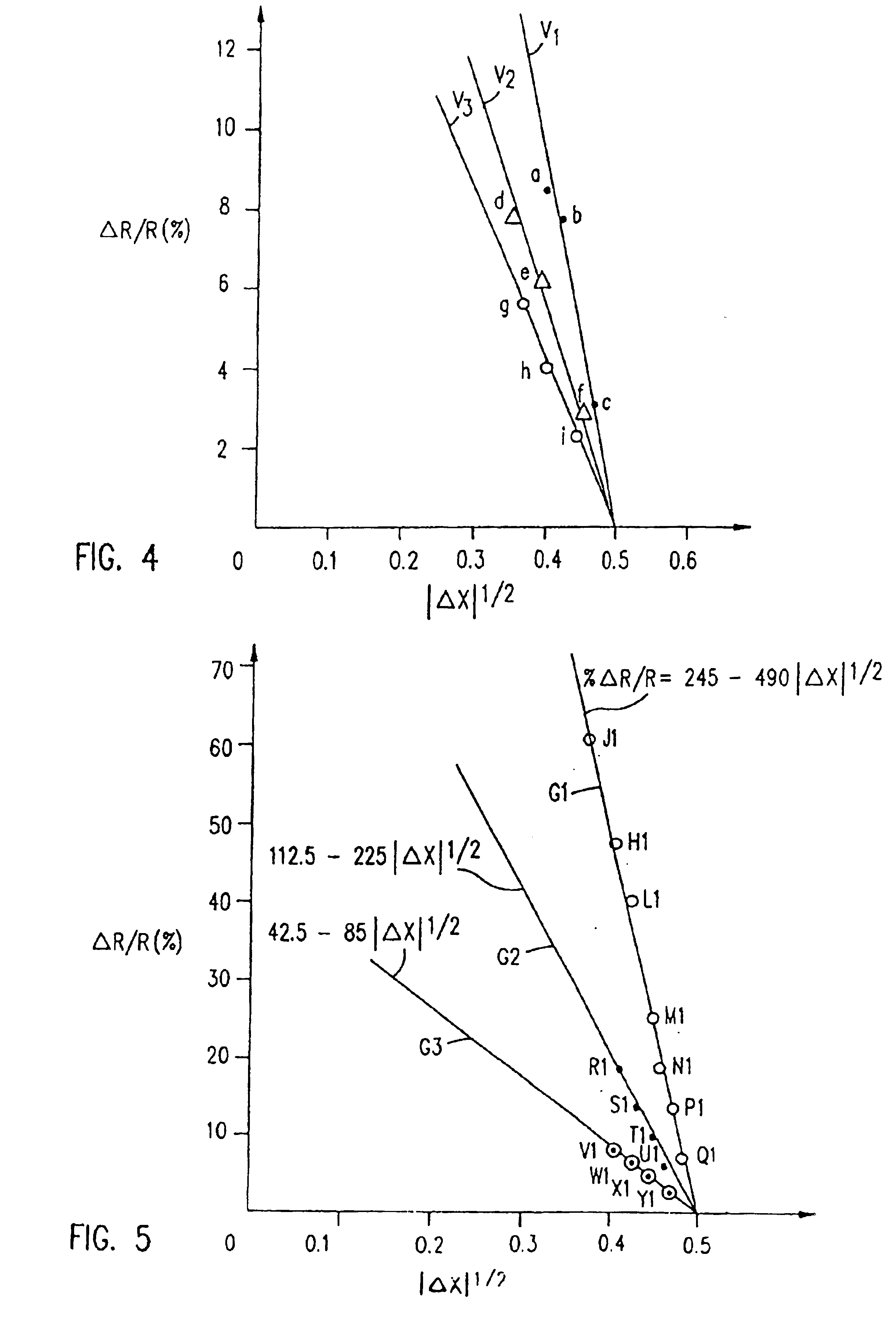

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

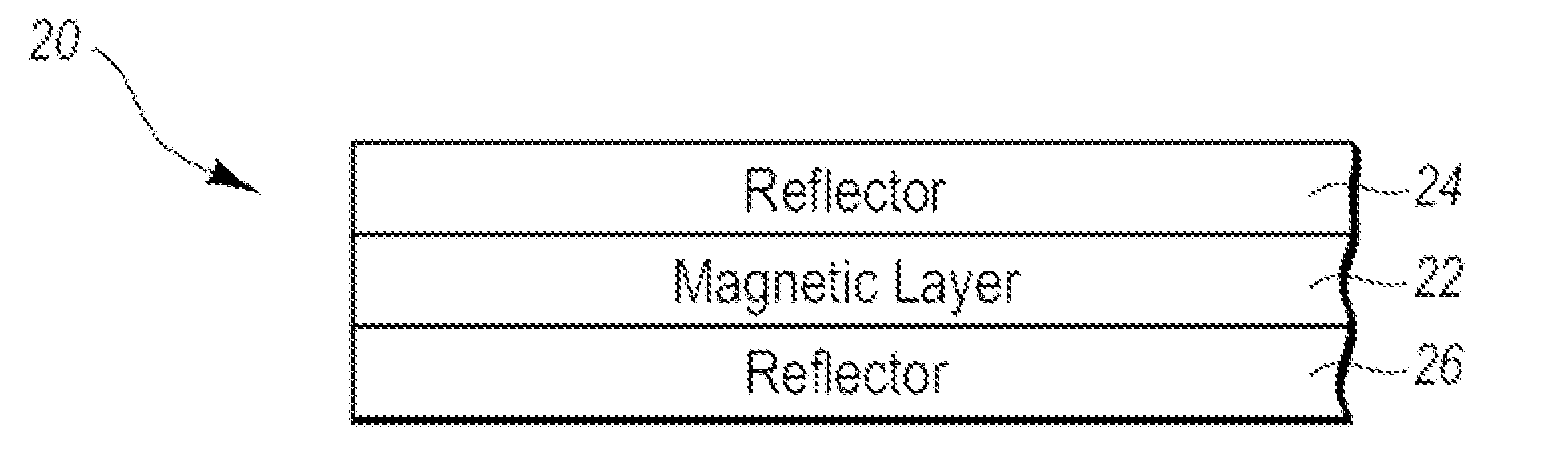

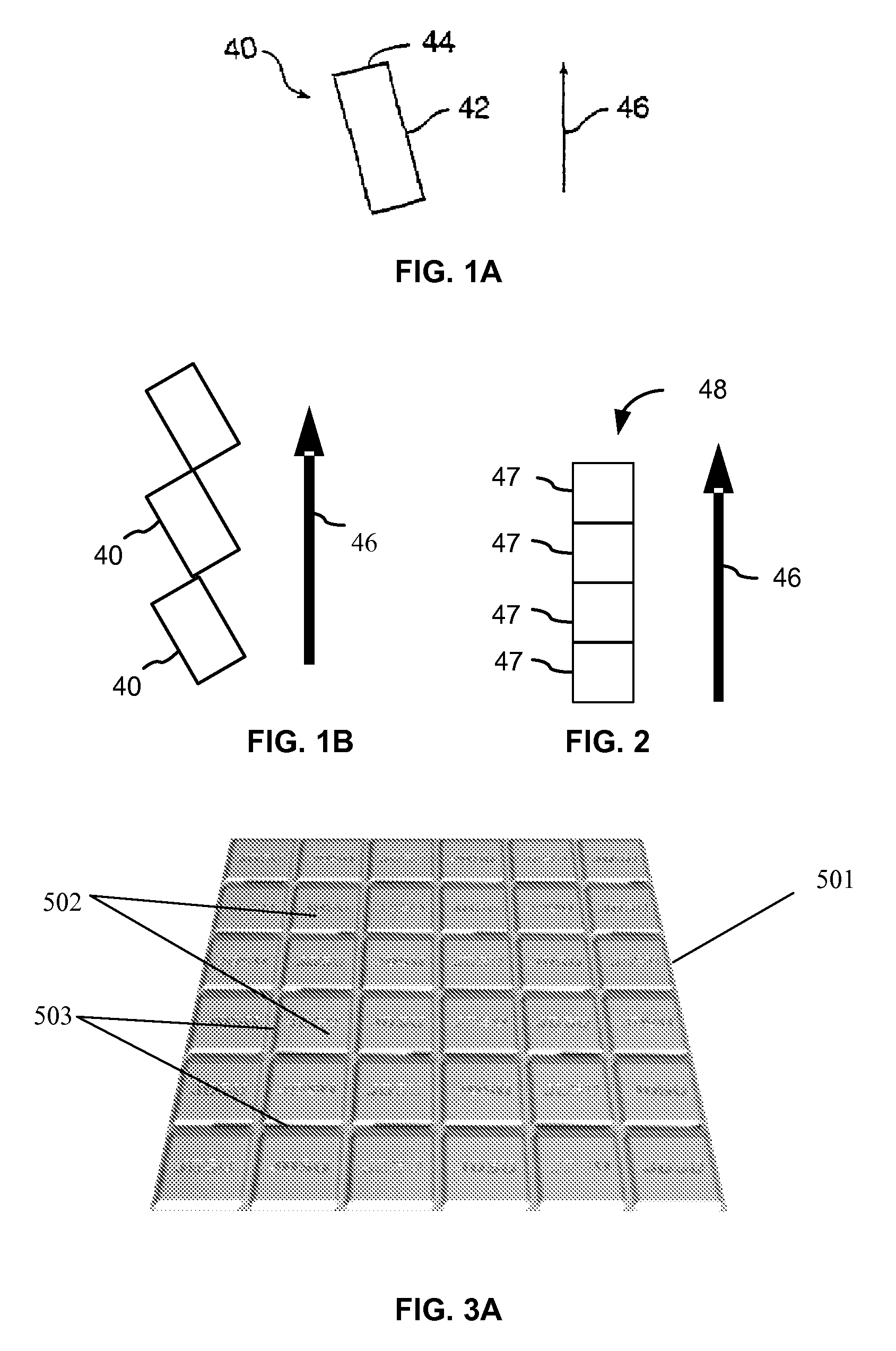

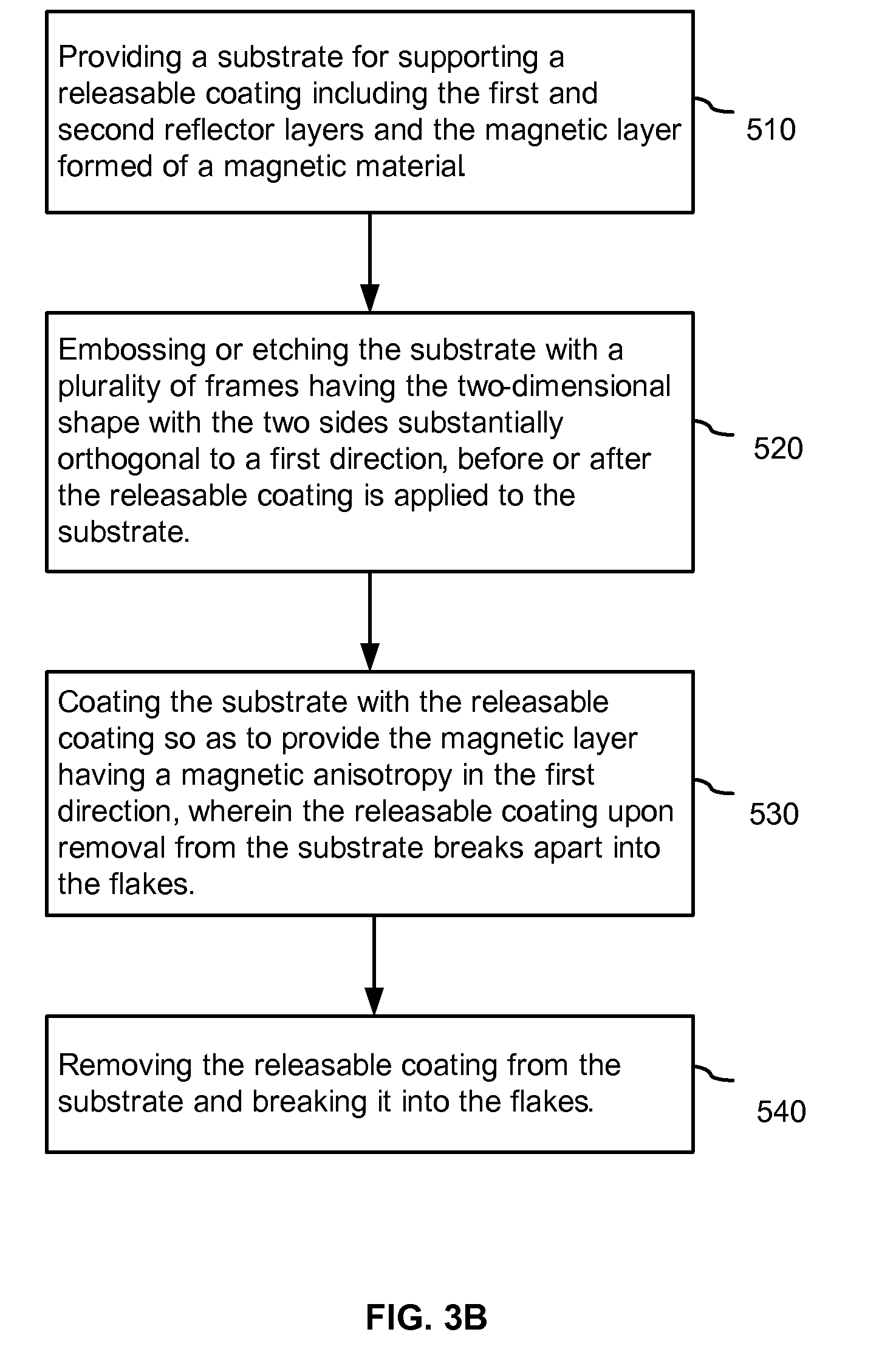

Anisotropic Magnetic Flakes

ActiveUS20090072185A1Cost effectiveMaterial nanotechnologyDecorative surface effectsHigh reflectivityMaterials science

The invention relates to anisotropic, reflective, magnetic flakes. In a liquid carrier and under influence of an external magnetic field, the flakes attract to one another side-by-side and form ribbons which provide higher reflectivity to a coating and may be used as a security feature for authentication of an object.

Owner:VIAVI SOLUTIONS INC

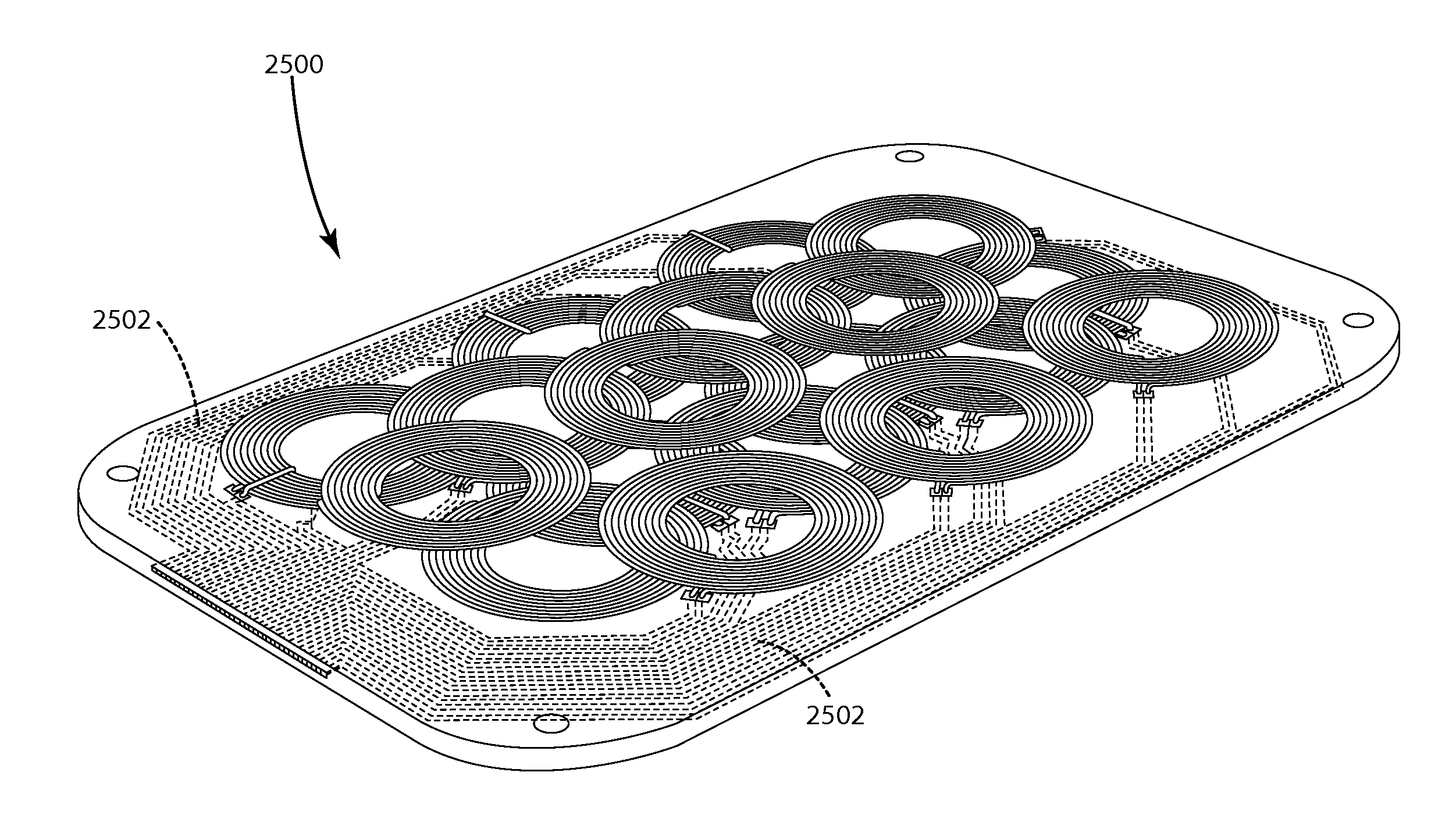

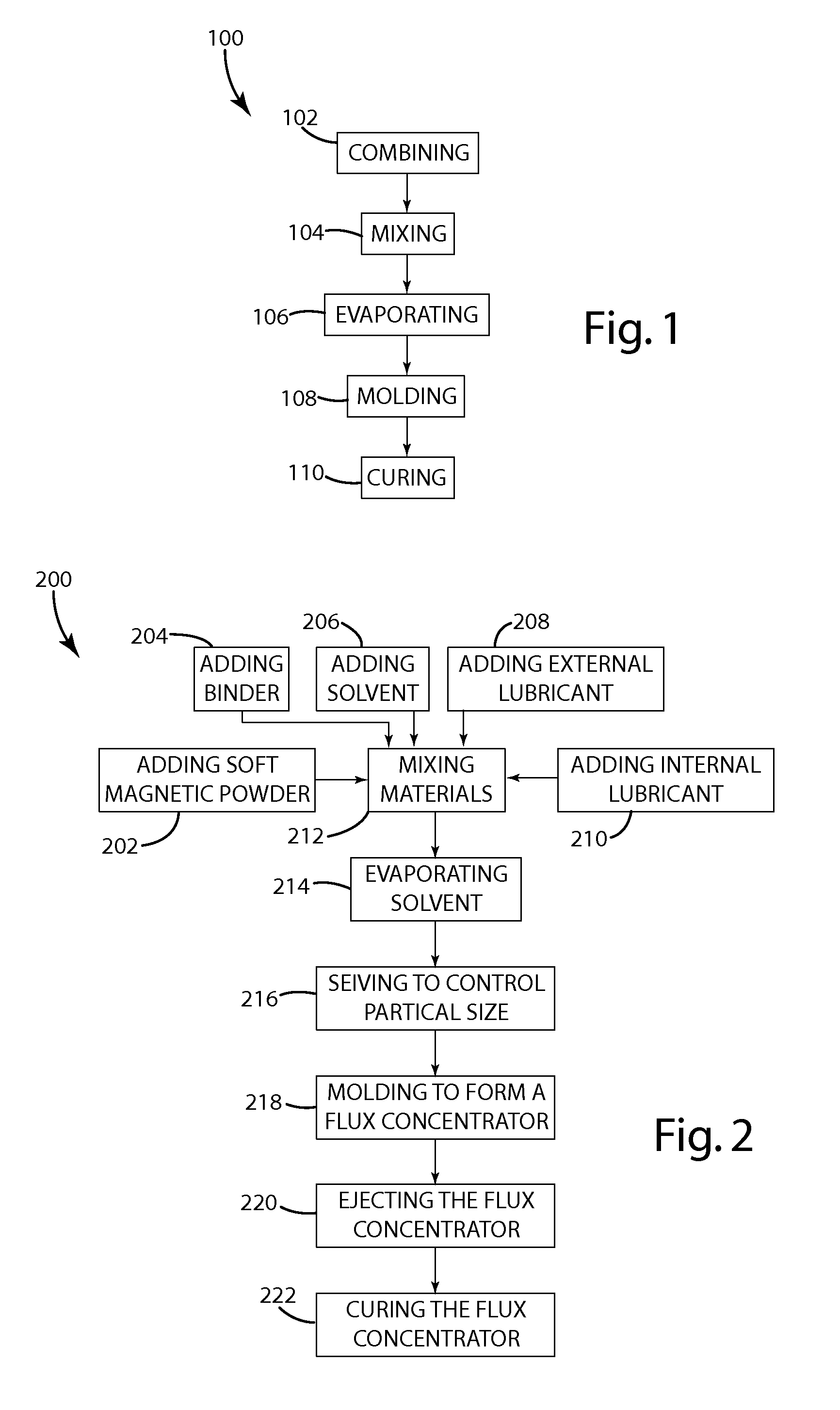

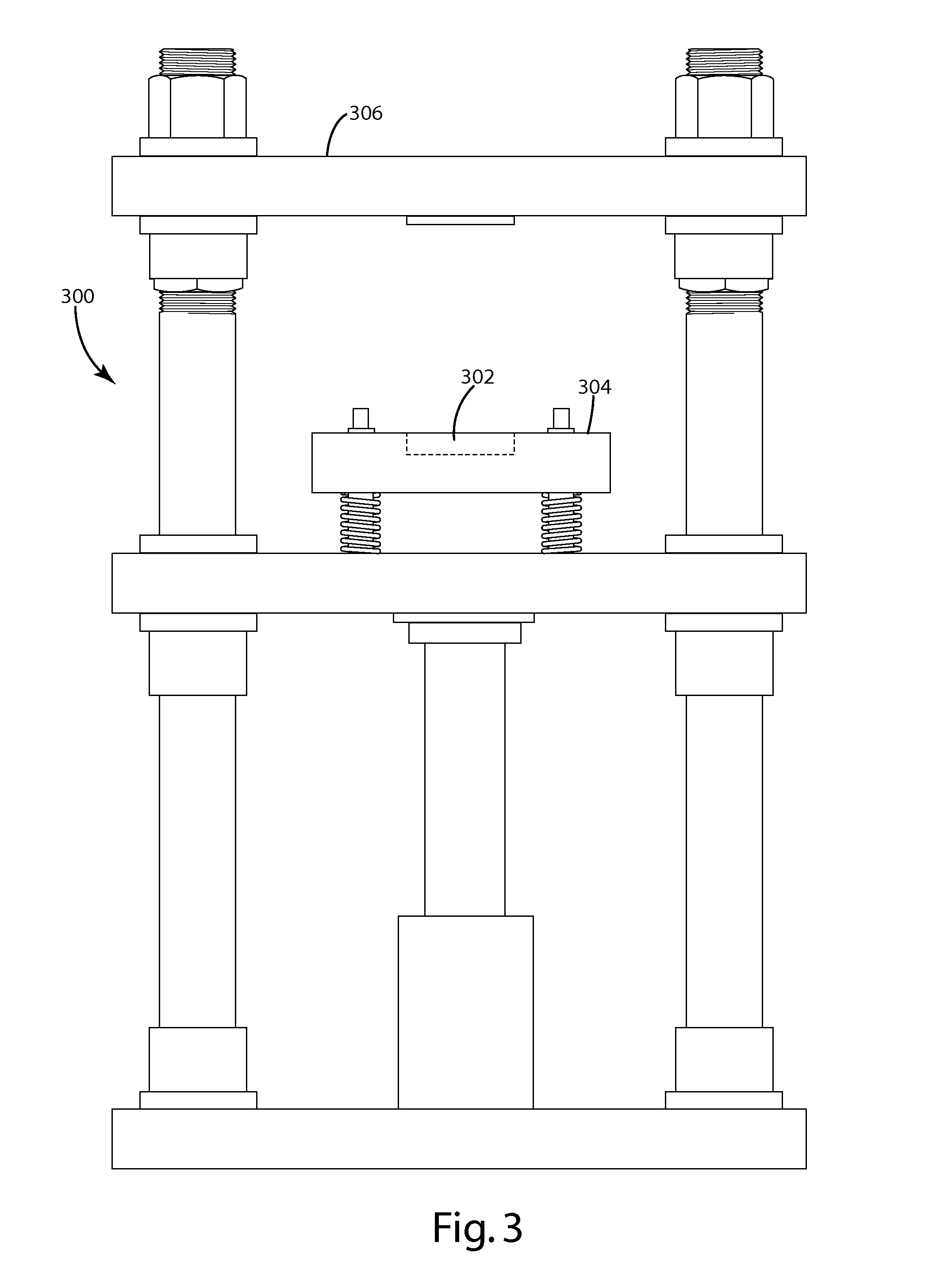

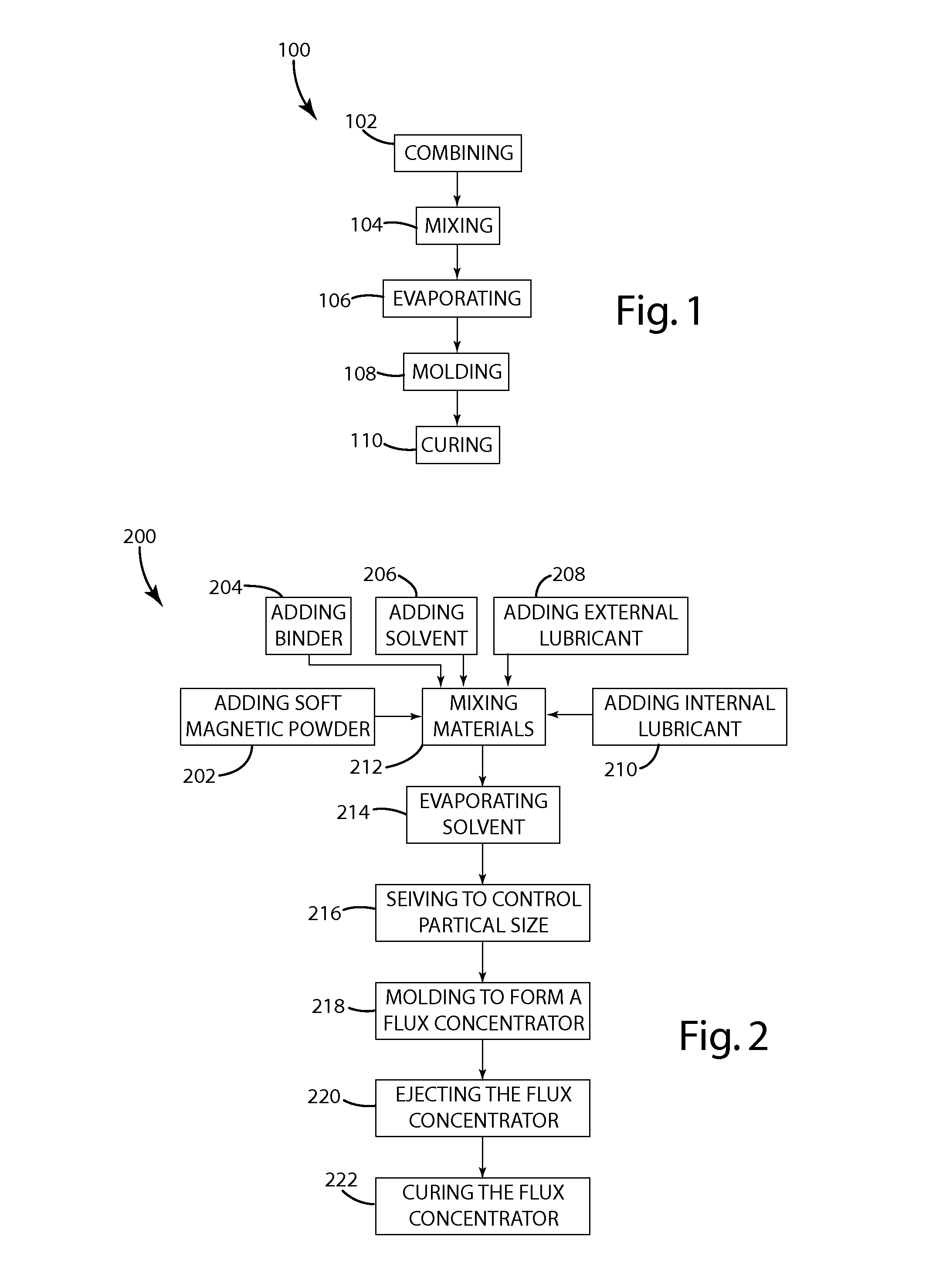

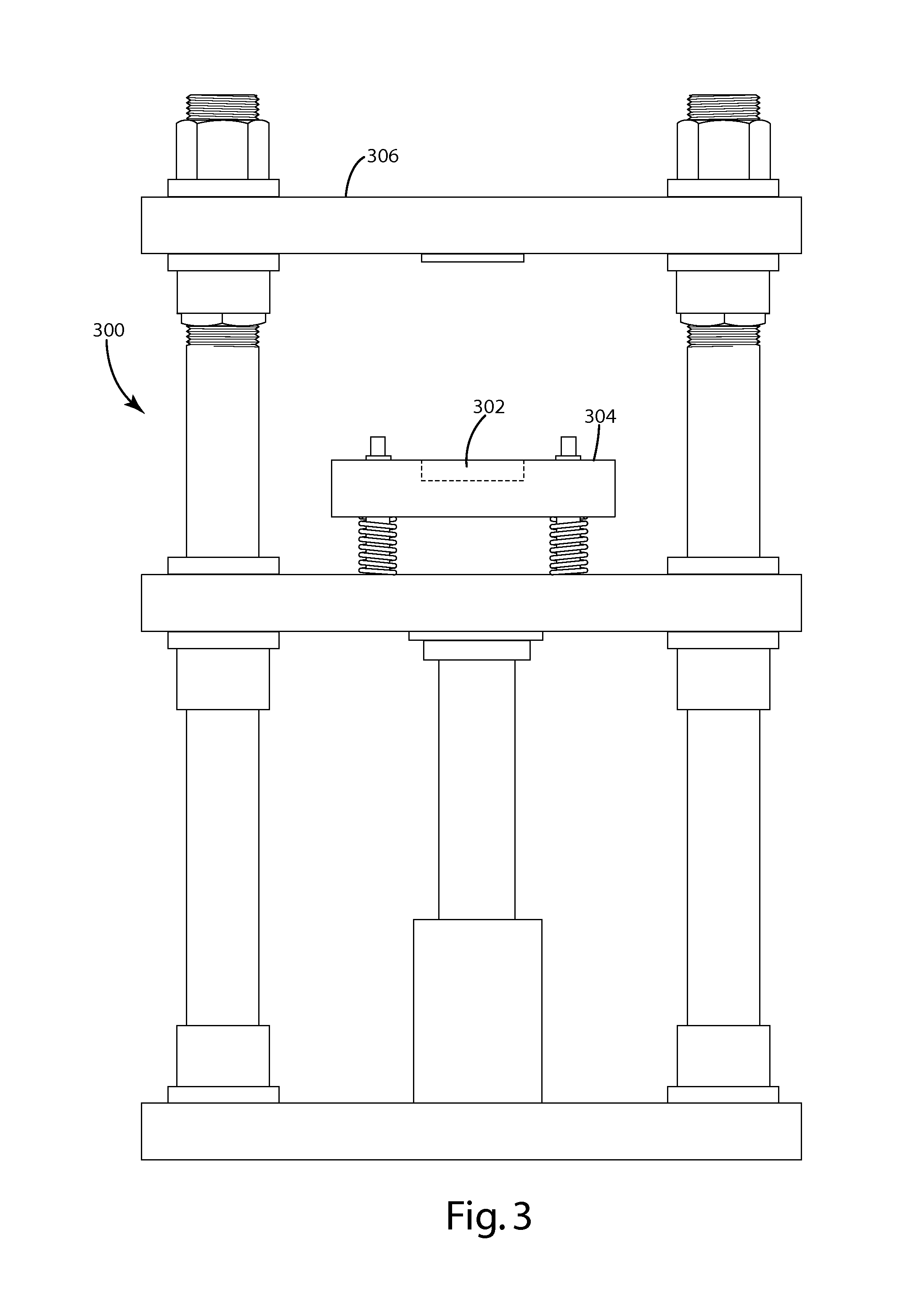

Flux concentrator and method of making a magnetic flux concentrator

ActiveUS20110050382A1Fewer eddy currents formingSuitable characteristicElectromagnetic wave systemTransformersMagnetic fluxLubricant

A flux concentrator and method for manufacturing a flux concentrator is provided. The method can include combining powdered soft magnetic material, a binder, a solvent, a internal lubricant; mixing the materials to create a mixture, evaporating the solvent from the mixture, molding the mixture to form a flux concentrator, and curing the flux concentrator. The flux concentrator may be laminated and broken into multiple pieces, which makes the flux concentrator more flexible. Breaking the flux concentrator does not significantly affect the magnetic properties. Since the permeability of the binder is very similar to that of air, adding tiny air gaps between the fractions is not significantly different than adding more binder.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Flux concentrator and method of making a magnetic flux concentrator

ActiveUS8692639B2Fewer eddy currents formingSuitable characteristicTransformersTransformers/inductances coils/windings/connectionsSolventMagnetic flux

A flux concentrator and method for manufacturing a flux concentrator is provided. The method can include combining powdered soft magnetic material, a binder, a solvent, a internal lubricant; mixing the materials to create a mixture, evaporating the solvent from the mixture, molding the mixture to form a flux concentrator, and curing the flux concentrator. The flux concentrator may be laminated and broken into multiple pieces, which makes the flux concentrator more flexible. Breaking the flux concentrator does not significantly affect the magnetic properties. Since the permeability of the binder is very similar to that of air, adding tiny air gaps between the fractions is not significantly different than adding more binder.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

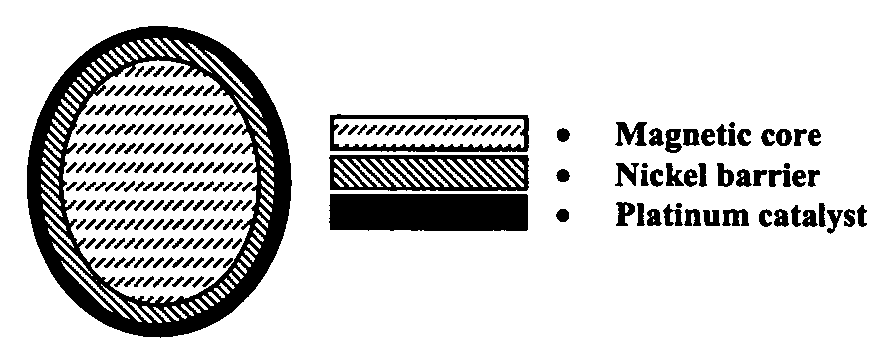

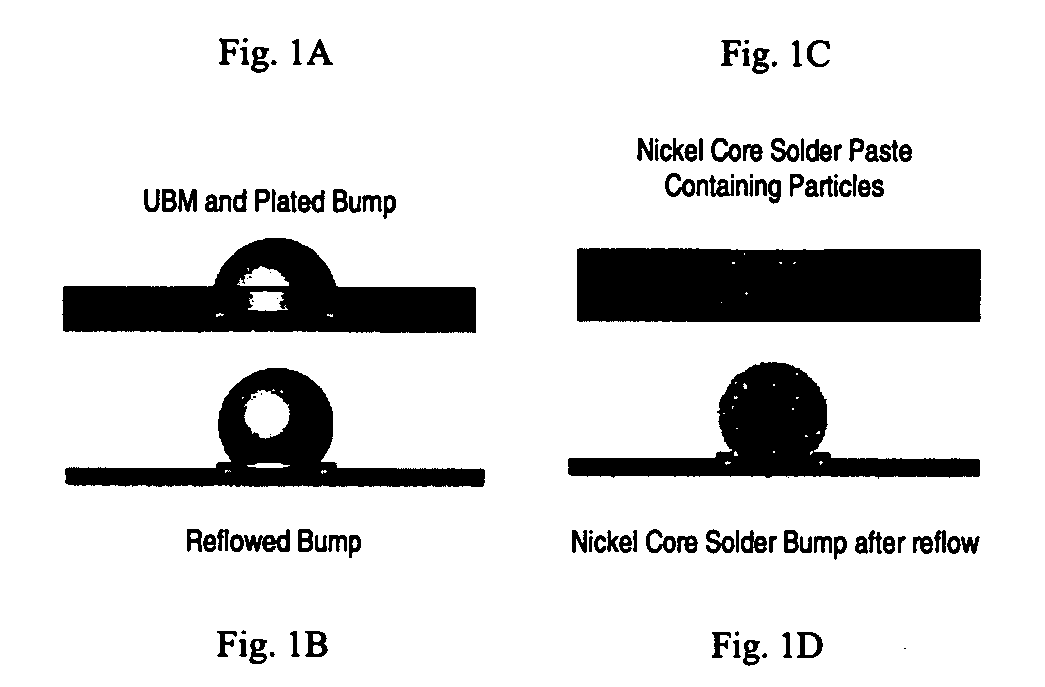

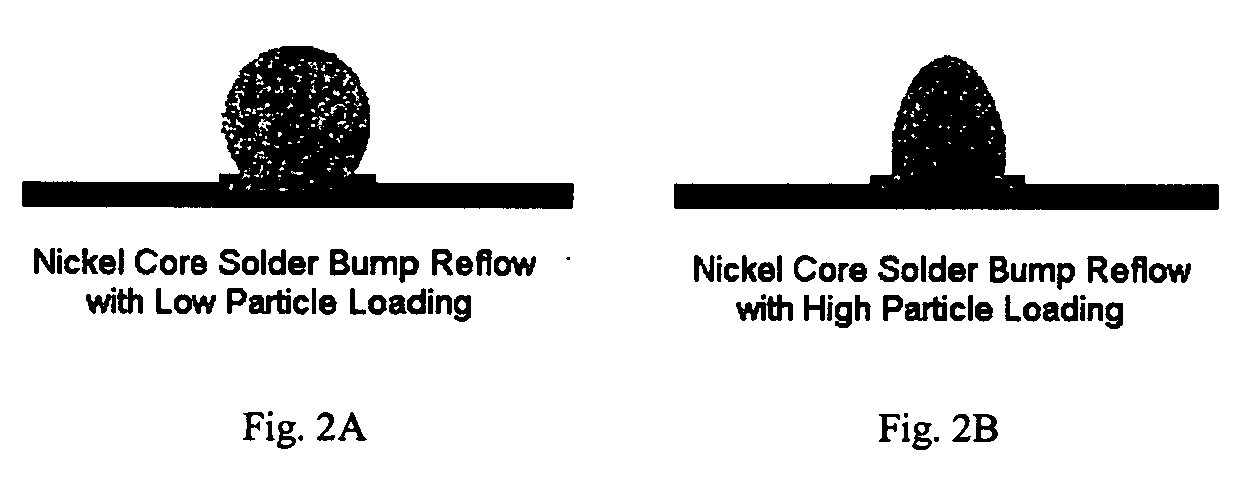

Coated and magnetic particles and applications thereof

InactiveUS20040115340A1Easy to controlImprove catalytic performanceNon-insulated conductorsVolume/mass flow measurementAlloyMaterials science

A method of using coated and / or magnetic particles to deposit structures including solder joints, bumps, vias, bond rings, and the like. The particles may be coated with a solderable material. For solder joints, after reflow the solder material may comprise unmelted particles in a matrix, thereby increasing the strength of the joint and decreasing the pitch of an array of joints. The particle and coating may form a higher melting point alloy, permitting multiple subsequent reflow steps. The particles and / or the coating may be magnetic. External magnetic fields may be applied during deposition to precisely control the particle loading and deposition location. Elements with incompatible electropotentials may thereby be electrodeposited in a single step. Using such fields permits the fill of high aspect ratio structures such as vias without requiring complete seed metallization of the structure. Also, a catalyst consisting of a magnetic particle coated with a catalytic material, optionally including an intermediate layer.

Owner:SURFECT TECH

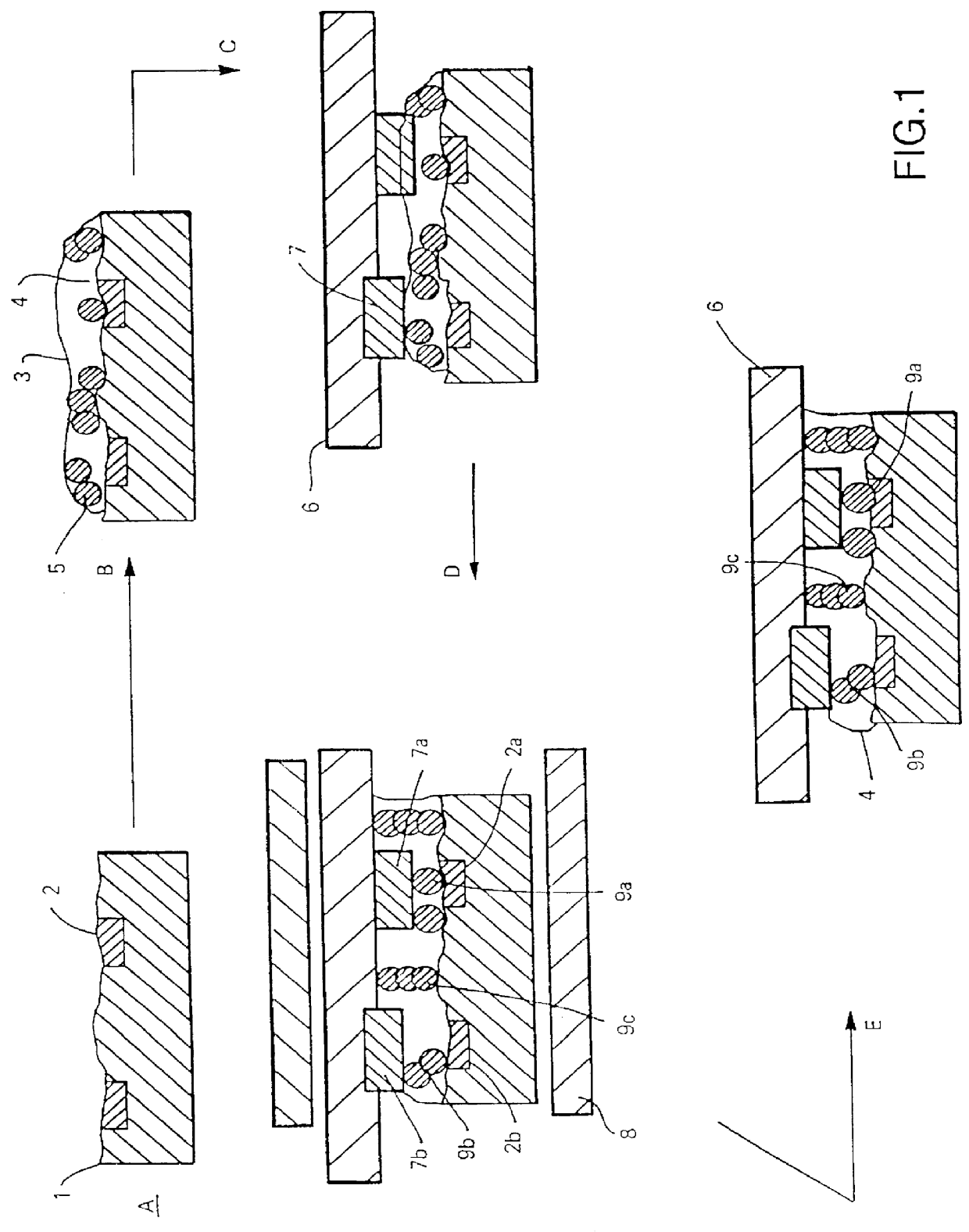

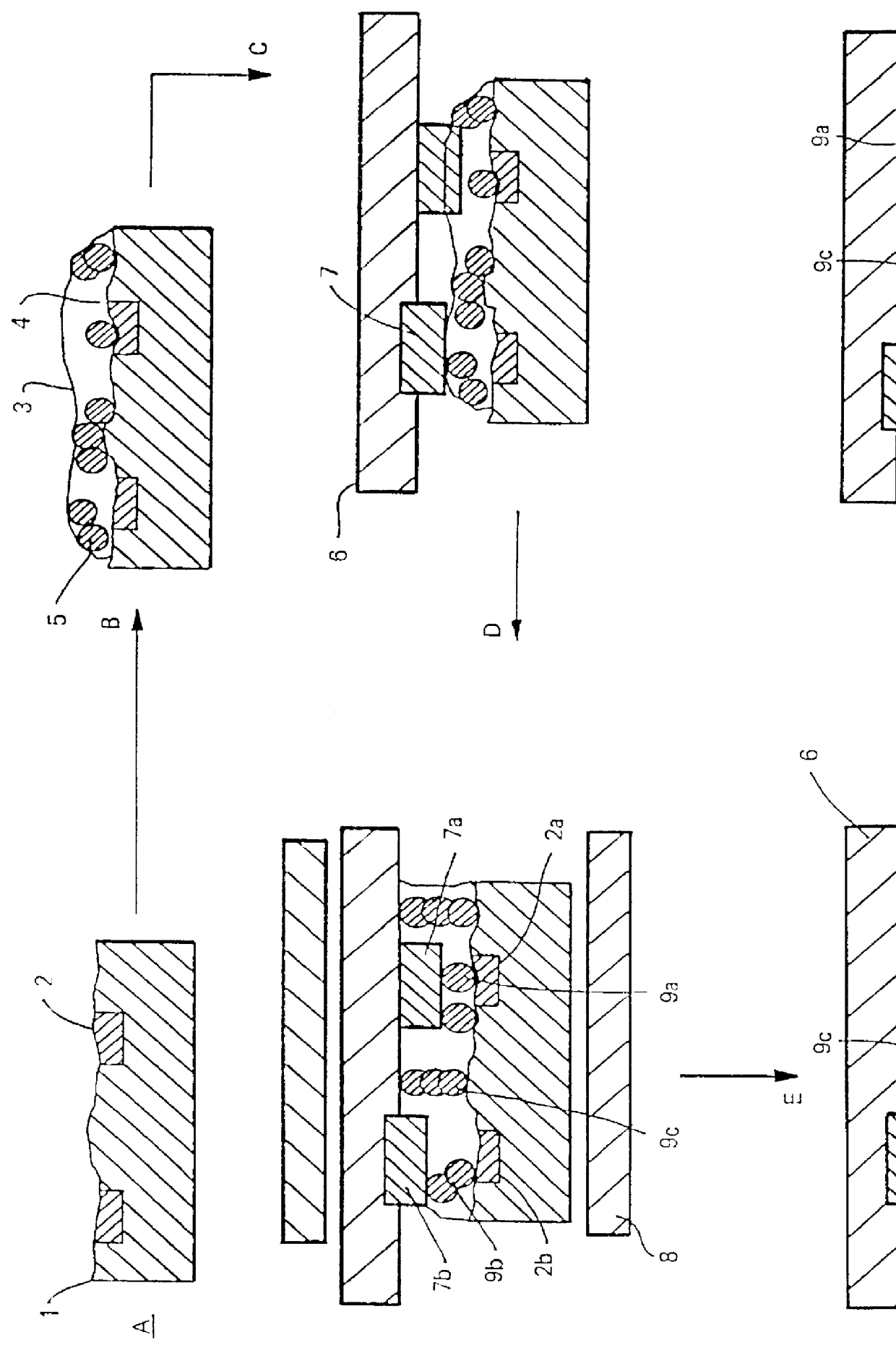

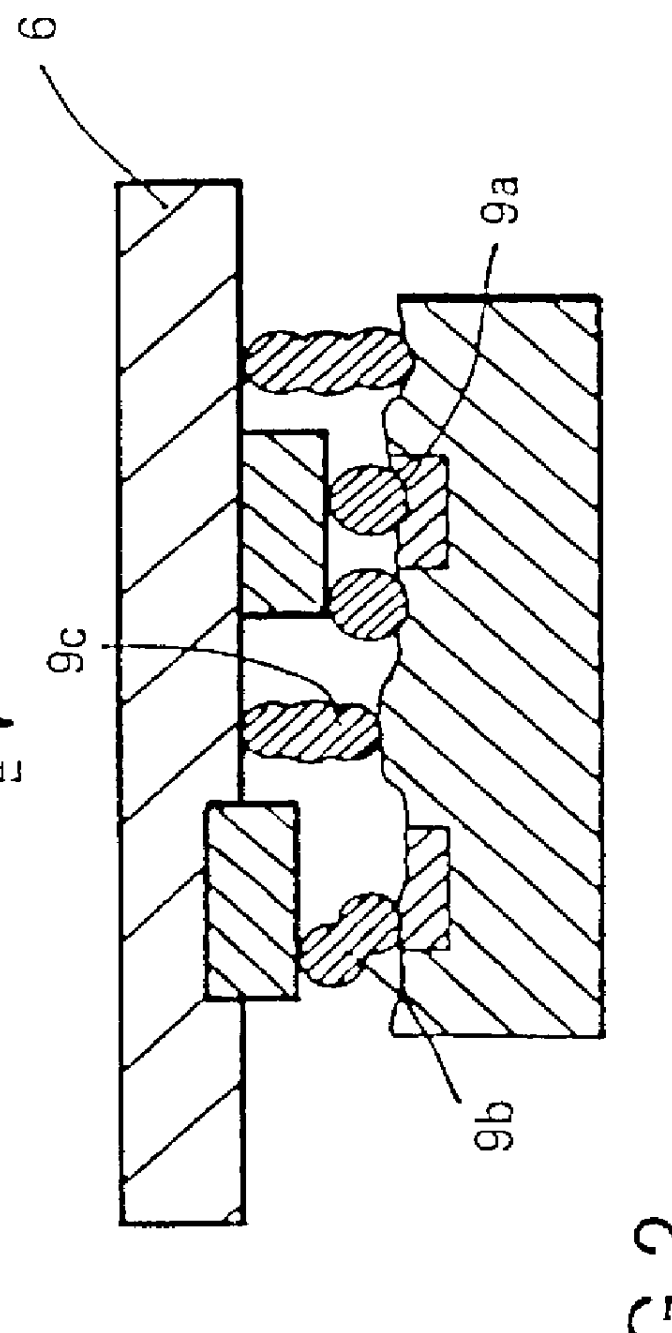

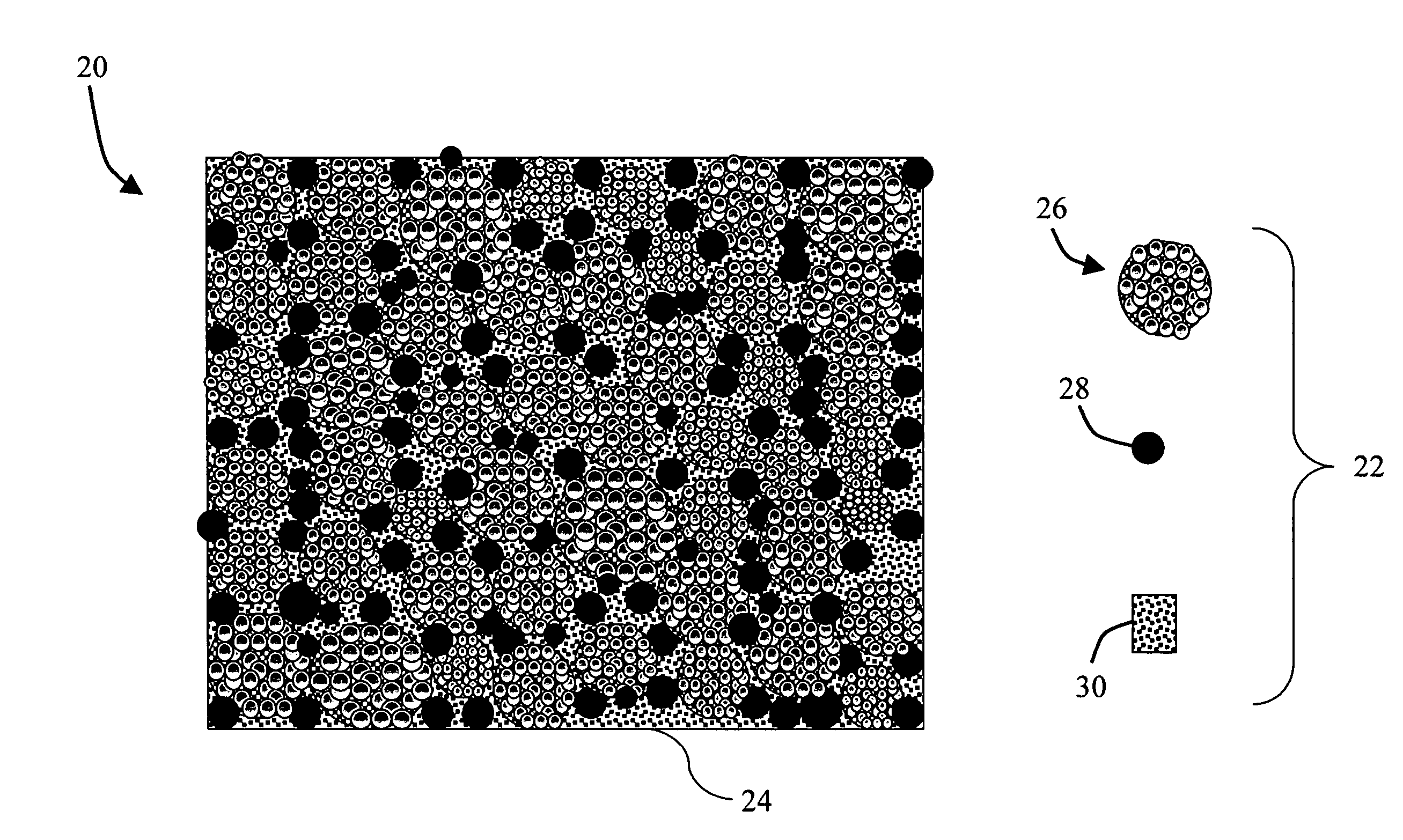

Compositions and method for providing anisotropic conductive pathways and bonds between two sets of conductors

InactiveUS6110399ASimple processImprove electrical contact reliabilityNon-insulated conductorsNon-macromolecular adhesive additivesRegular patternElectrical conductor

The invention provides a composition (3) comprising: (i) a ferrofluid comprising a colloidal suspension (4) of ferromagnetic particles in a non-magnetic carrier liquid, and (ii) a plurality of electrically-conductive particles (5) having substantially uniform sizes and shapes, dispersed in the ferrofluid. Various types of substantially non-magnetic electrically-conductive particles (5) are described. Application of a substantially uniform magnetic field by magnet means (8) to the composition (3) causes the electrically-conductive particles (5) to form a regular pattern (9). The composition is used for providing anisotropic conductive pathways (9a, 9b) between two sets of conductors (2a, 2b; 7a, 7b) in the electronics industry. The composition may be a curable adhesive composition which bonds the conductors. Alternatively or in addition the electrically-conductive particles may have a latent adhesive property e.g. the particles may be solder particles. The ferrofluid may be a colloidal suspension of ferromagnetic particles in a liquid monomer.

Owner:LOCTITE (R&D) LIMITED

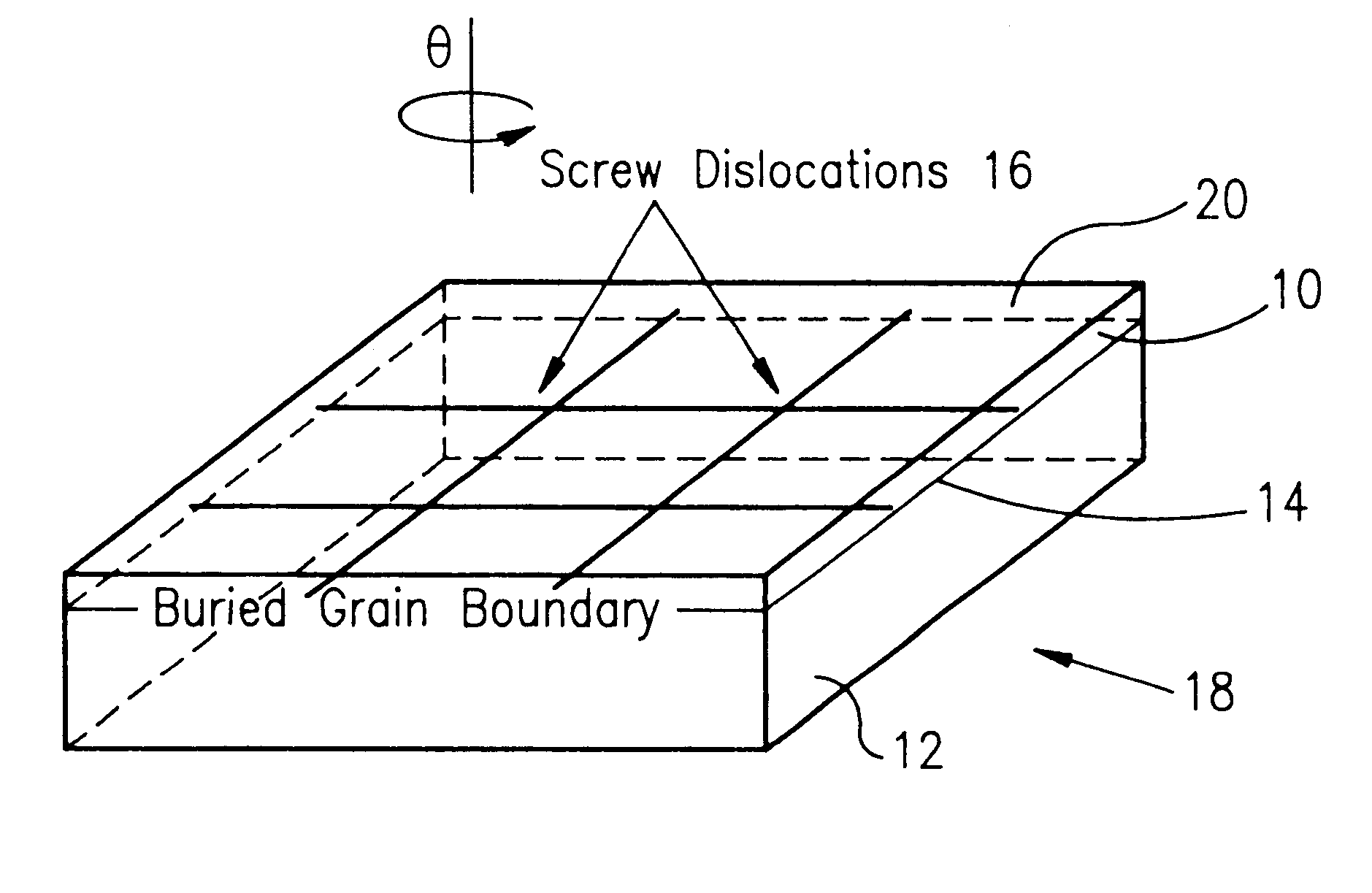

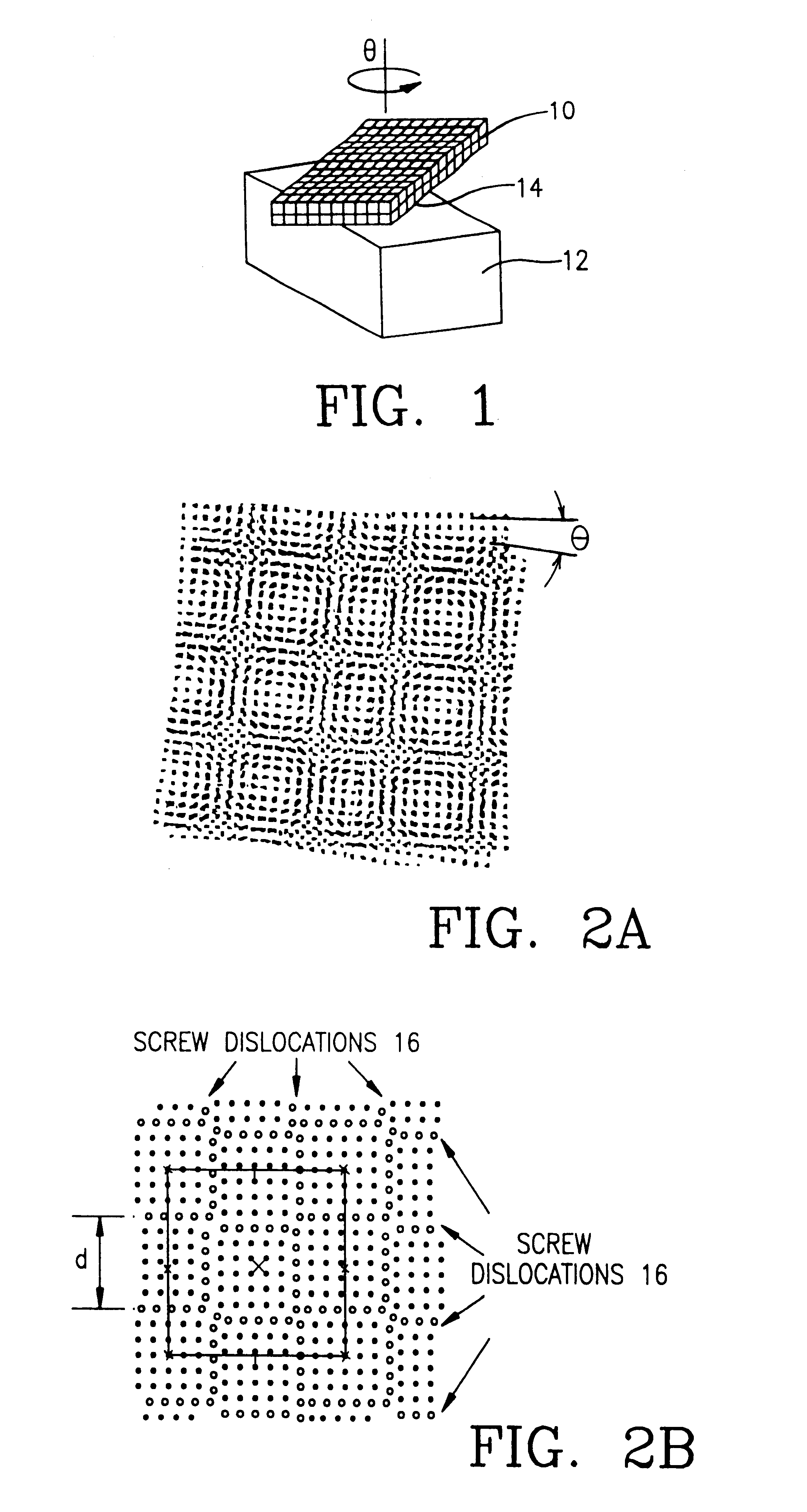

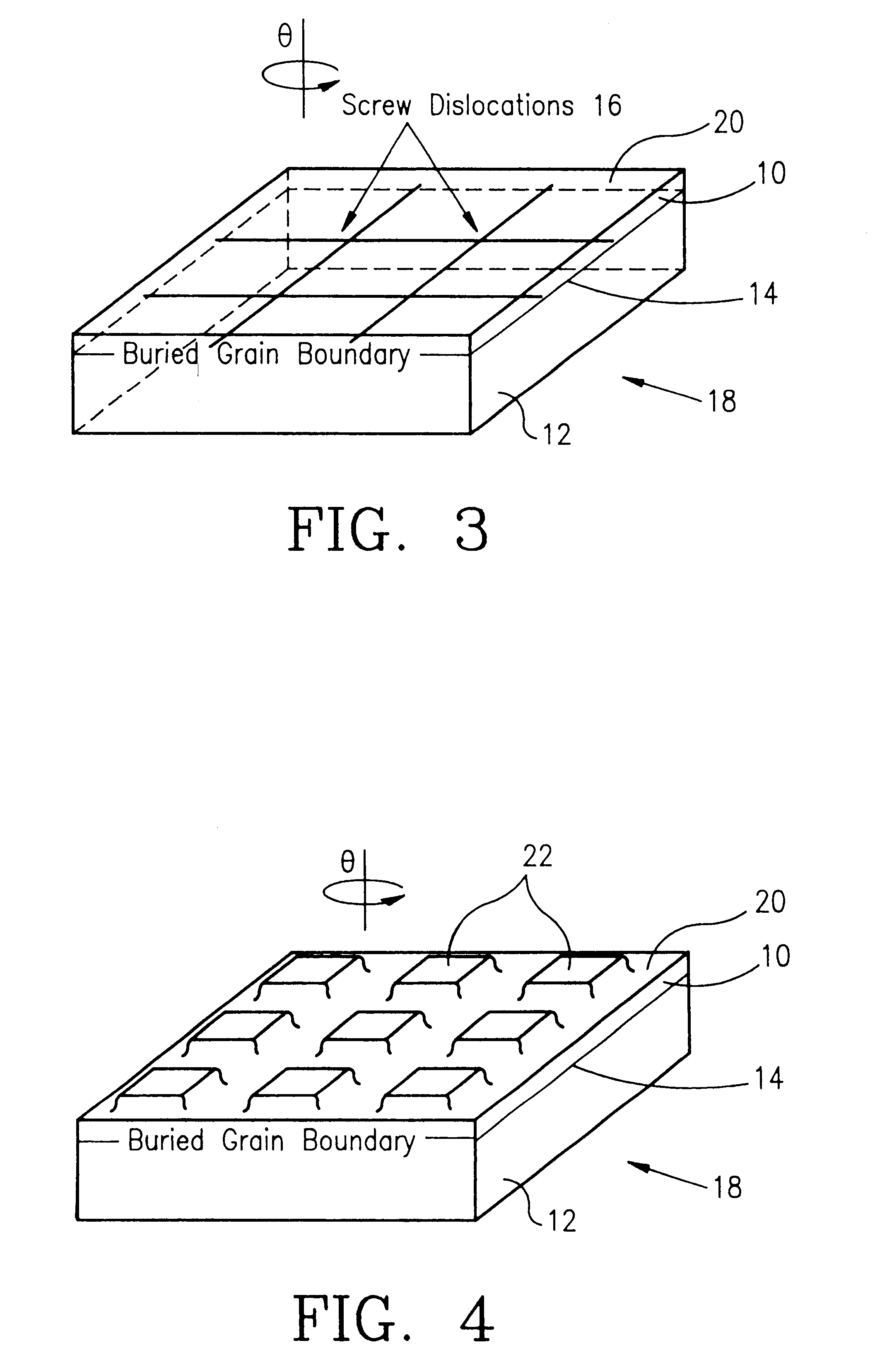

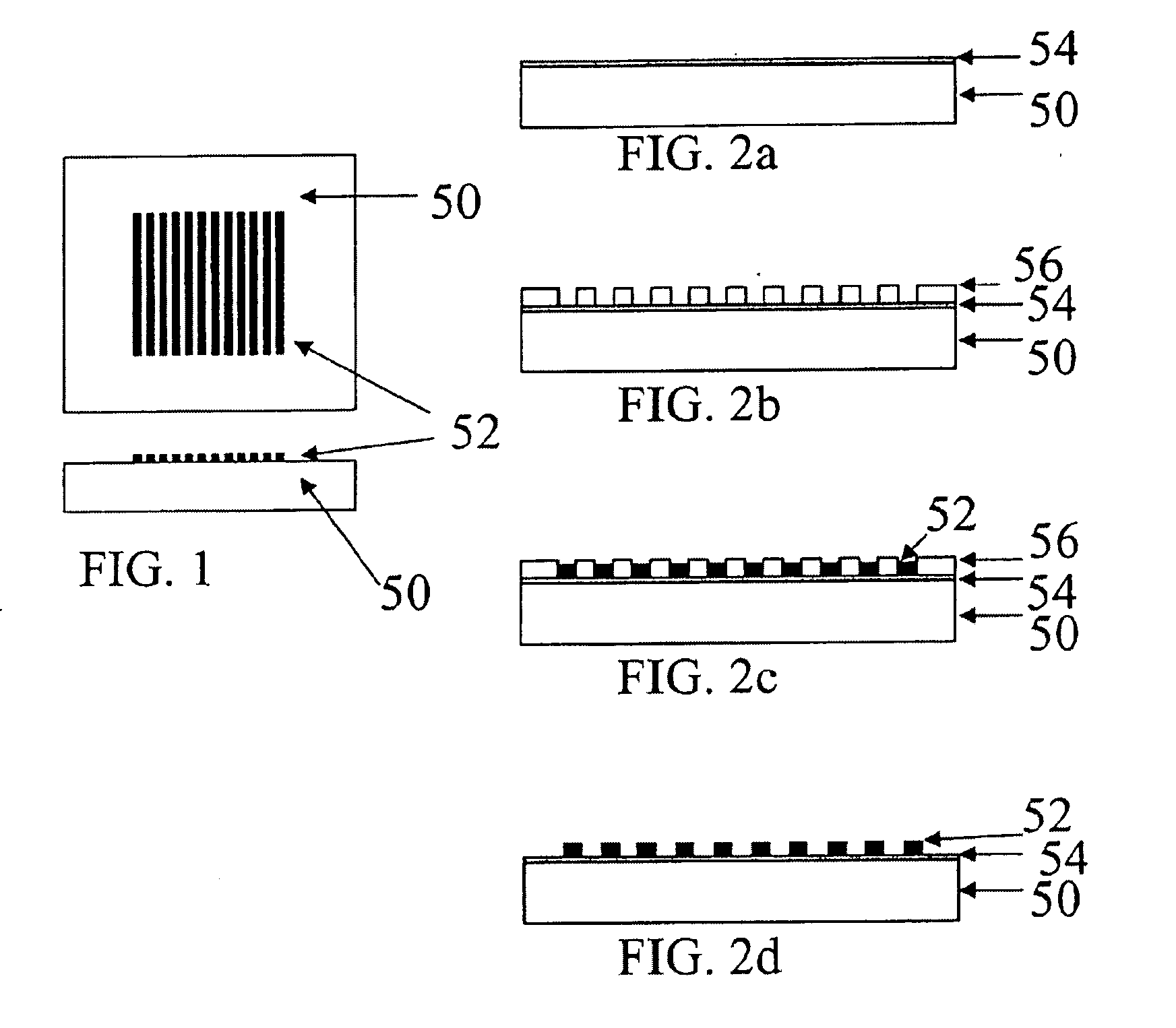

Fabrication of periodic surface structures with nanometer-scale spacings

The periodic stress and strain fields produced by a pure twist grain boundary between two single crystals bonded together in the form of a bicrystal are used to fabricate a two-dimensional surface topography with controllable, nanometer-scale feature spacings (e.g., from 50 nanometers down to 1.5 nanometers). The spacing of the features is controlled by the misorientation angle used during crystal bonding. One of the crystals is selected to be thin, on the order of 5-100 nanometers. A buried periodic array of screw dislocations is formed at the twist grain boundary. To bring the buried periodicity to the surface, the thin single crystal is etched to reveal an array of raised elements, such as pyramids, that have nanometer-scale dimensions. The process can be employed with numerous materials, such as gold, silicon and sapphire. In addition, the process can be used with different materials for each crystal such that a periodic array of misfit dislocations is formed at the interface between the two crystals.

Owner:CORNELL RES FOUNDATION INC

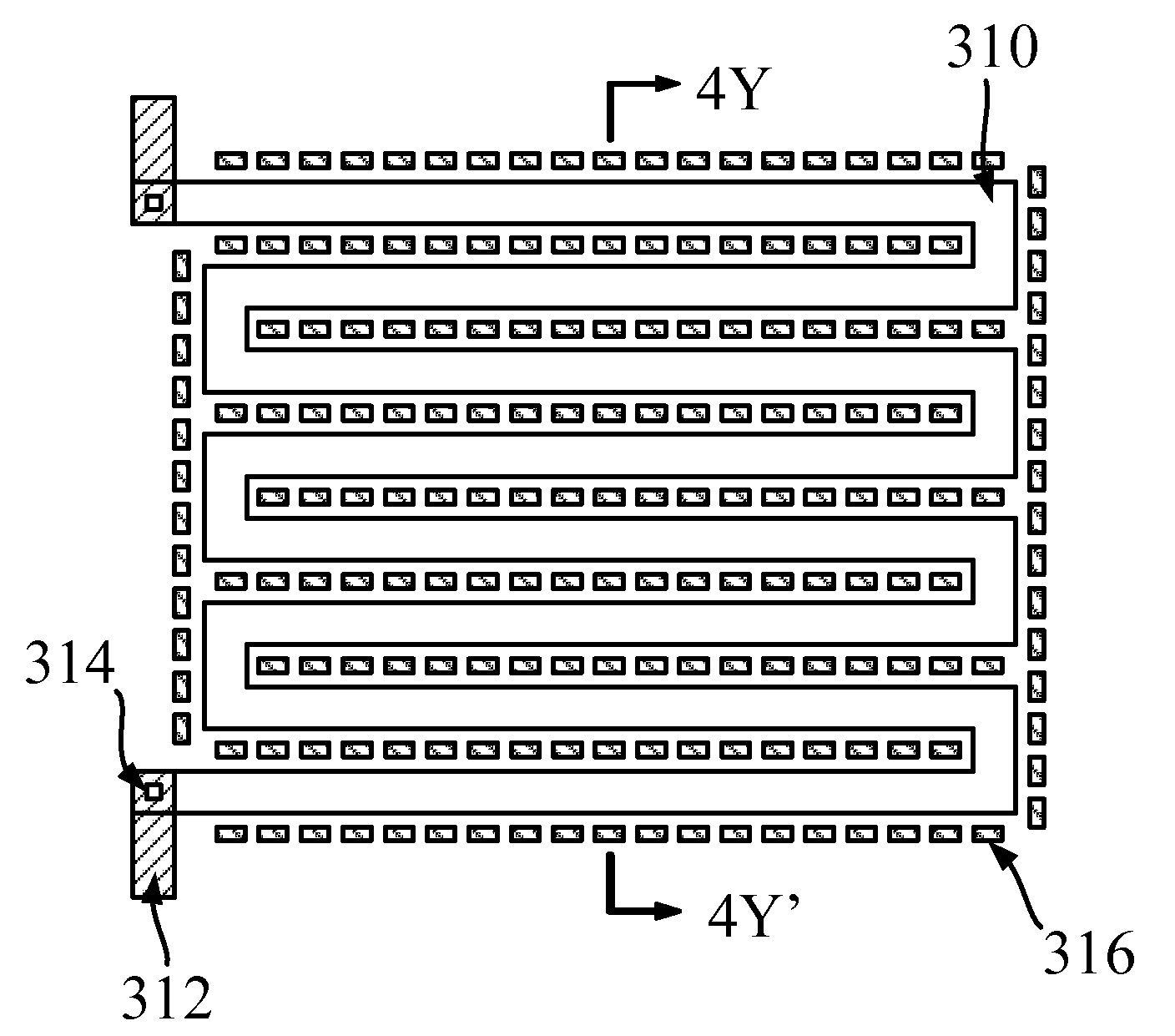

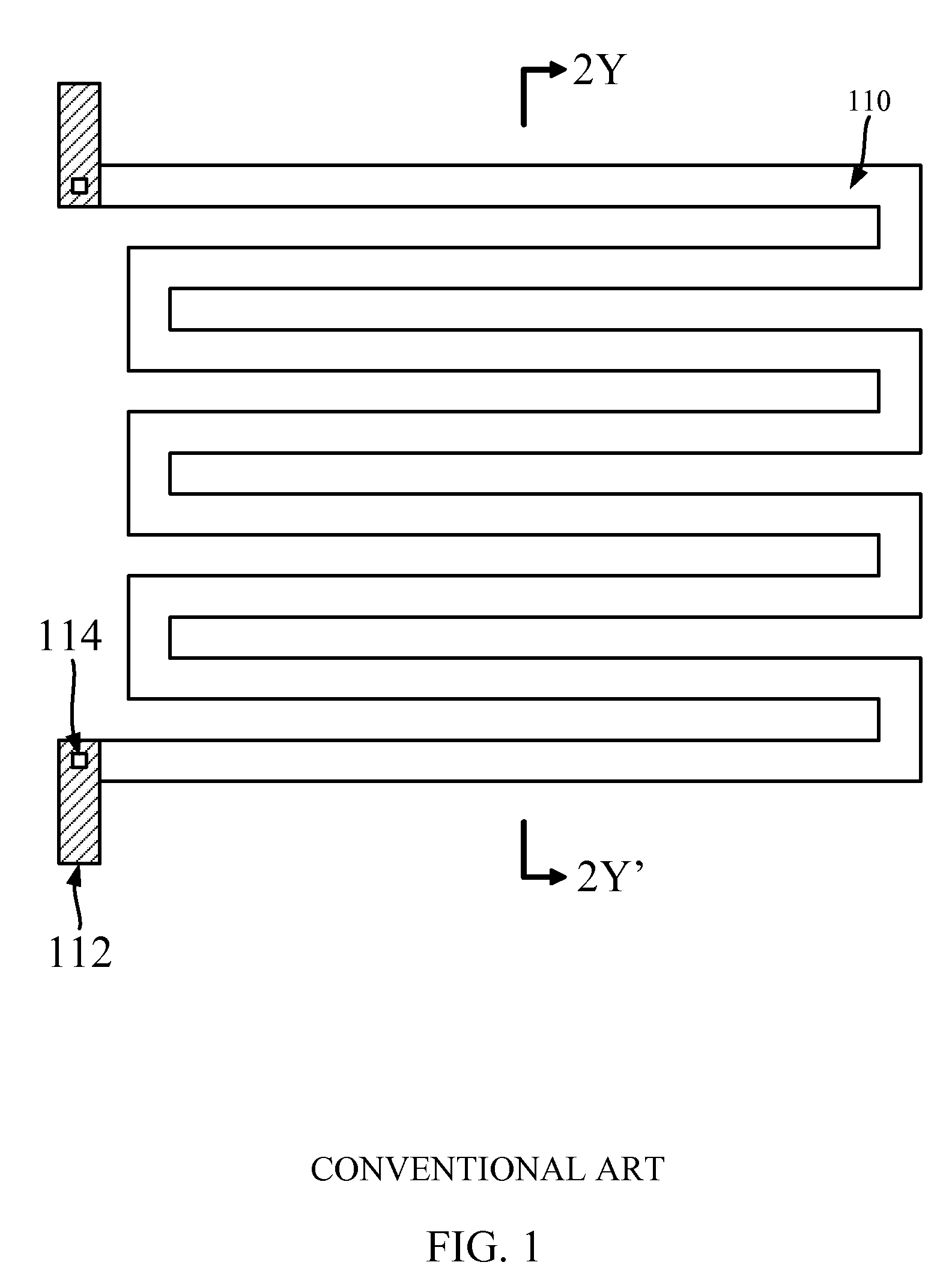

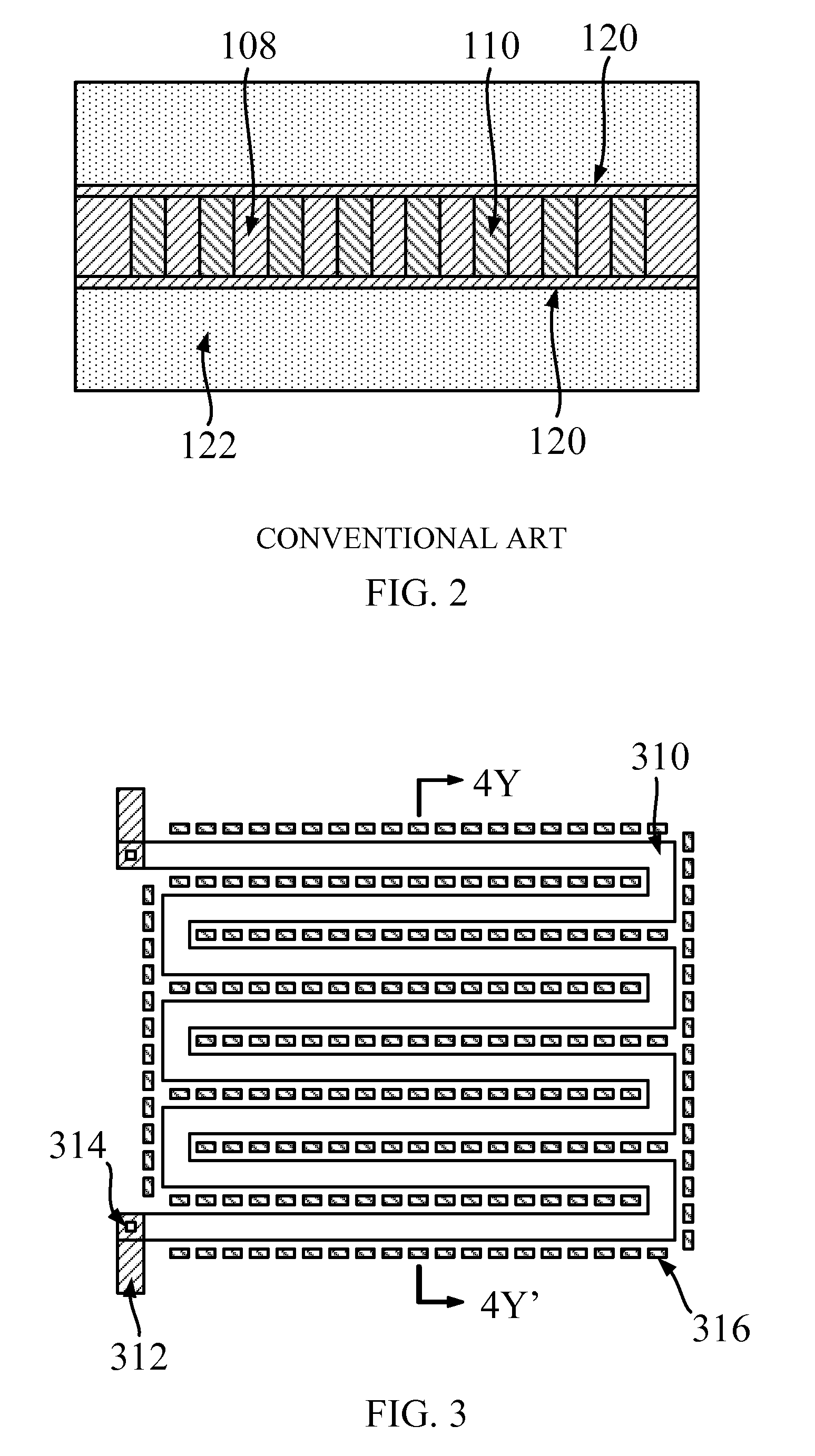

Wireless power receiver and method of manufacturing the same

ActiveUS20130249302A1Reduce thicknessFacilitate communicationNear-field transmissionBatteries circuit arrangementsElectric powerTelecommunications

Owner:SCRAMOGE TECH LTD

Magnetic Film Enhanced Inductor

ActiveUS20100225435A1Decorative surface effectsSemiconductor/solid-state device detailsEngineeringInductor

An integrated magnetic film enhanced inductor and a method of forming an integrated magnetic film enhanced inductor are disclosed. The integrated magnetic film enhanced inductor includes an inductor metal having a first portion and a second portion, a top metal or bottom metal coupled to the inductor metal, and an isolation film disposed one of in, on, and adjacent to at least one of the first portion and the second portion of the inductor metal. The isolation film includes a magnetic material, such as a magnetic film.

Owner:QUALCOMM INC

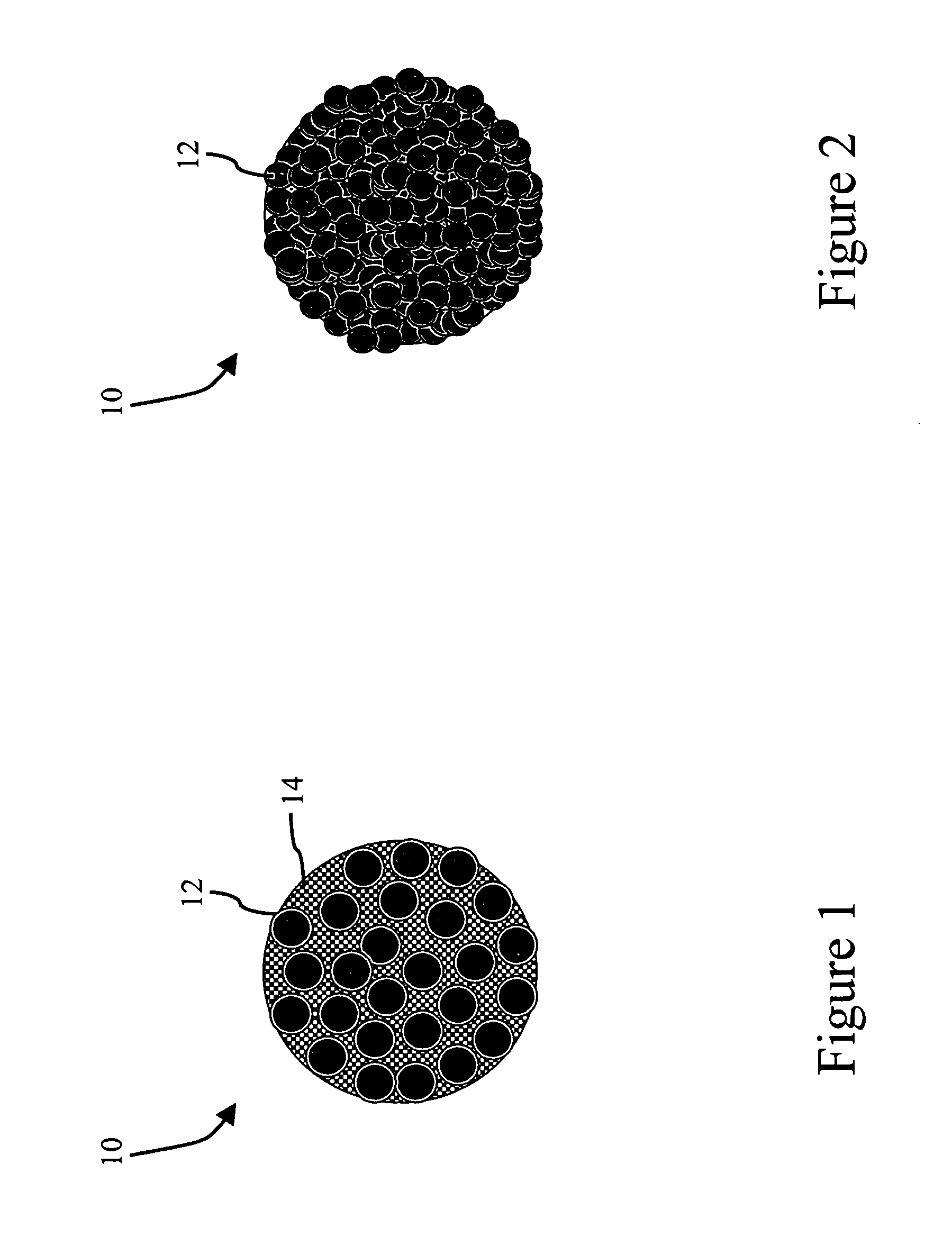

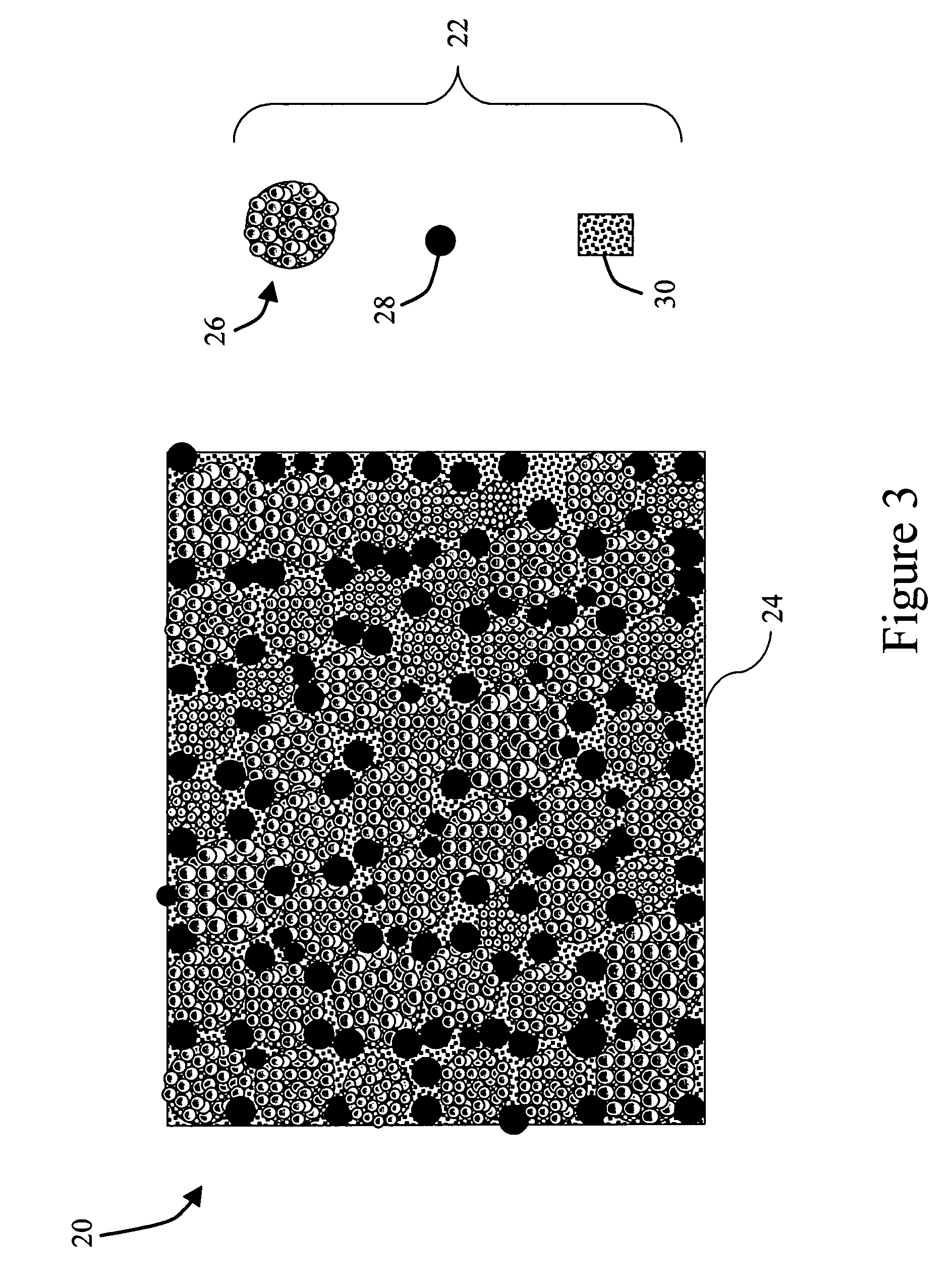

Magnetic composites and methods of making and using

Disclosed herein is a magnetic paste that generally includes a magnetic component and a liquid organic component. The magnetic component includes a plurality of discrete nanoparticles, a plurality of nanoparticle-containing assemblies, or both. Magnetic devices can be formed from the magnetic paste. Methods of making and using the magnetic paste are also described.

Owner:INFRAMAT CORPORATION

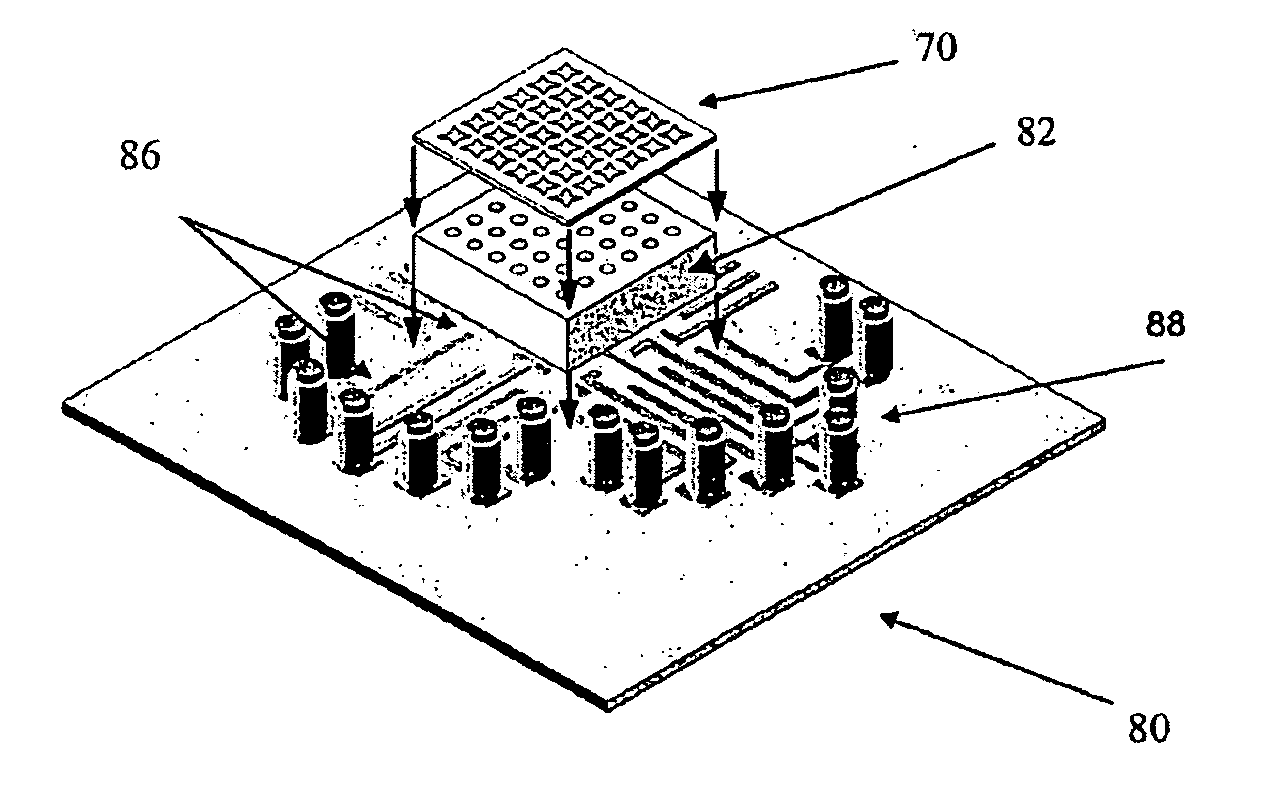

Magnetic bead-based arrays

InactiveUS20080187472A1Easy to separateEasy to replaceSequential/parallel process reactionsFlow mixersFluorescenceMagnetic bead

The present invention relates to magnetic particle separators using micromachined magnetic arrays and more particularly, to magnetic particle separators or manipulators using controlled magnetization on micromachined magnetic arrays for the separation of cells and other biological materials. The present invention also pertains to using such devices for the separation and analysis of biological materials for immunoassays, DNA sequencing, protein analysis, and biochemical detection applications. The present invention can also be viewed as a novel method for fabricating fully integrated permanent magnet components within any microelectromechanical system (“MEMS”) structures. The present invention also provides a magnetic particle separation and manipulation system for rapid separation and accurate manipulation of magnetic particles in two-dimensional electromagnetic arrays, which utilize high throughput biological analyses. A disposable cartridge can be produced in low cost using a low cost substrate such as plastic or other polymer, glass, or metal. Magnetic flux is generated by conventional or micromachined electromagnets a platform system consisting of magnetic flux sources, magnetic flux guidance, and a microprocessor control interface. By controlling direction of electric currents into inductors on the platform system, arbitrary magnetic poles can be generated on Permalloy structures of the cartridge to separate and manipulate magnetic particles. The magnetic particle separator and manipulator in the present invention can be easily combined with automated detection systems such as a fluorescent monitoring system.

Owner:AHN CHONG H +2

Current-perpendicular-to-plane magnetoresistive sensor with free layer stabilized against vortex magnetic domains generated by the sense current

InactiveUS20050174701A1Magnetic measurementsMagnetic-field-controlled resistorsMagnetosphereMagnetic domain

A current-perpendicular-to-the-plane (CPP) magnetoresistive sensor has additional layers for stabilizing the free layer against sense-current-generated magnetic fields. A ferromagnetic stabilizing layer is spaced from the free layer by a spacer layer and is exchange coupled with a second antiferromagnetic layer, the first antiferromagnetic layer being the conventional one for pinning the pinned layer in the CPP sensor. The stabilizing layer is in a vortex or other non-longitudinal magnetization pattern that is fixed by exchange coupling with the second antiferromagnetic layer. The stabilizing layer is also ferromagnetically coupled to the free layer across the spacer layer so that in the absence of both a sense current and an external magnetic field, the free and stabilization layers have similarly shaped vortex or other non-longitudinal magnetization patterns. The sense current generates a vortex magnetic field in the free layer opposite to the fixed vortex magnetization pattern in the stabilizing layer and essentially erases the effect of the vortex magnetization pattern in the free layer.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

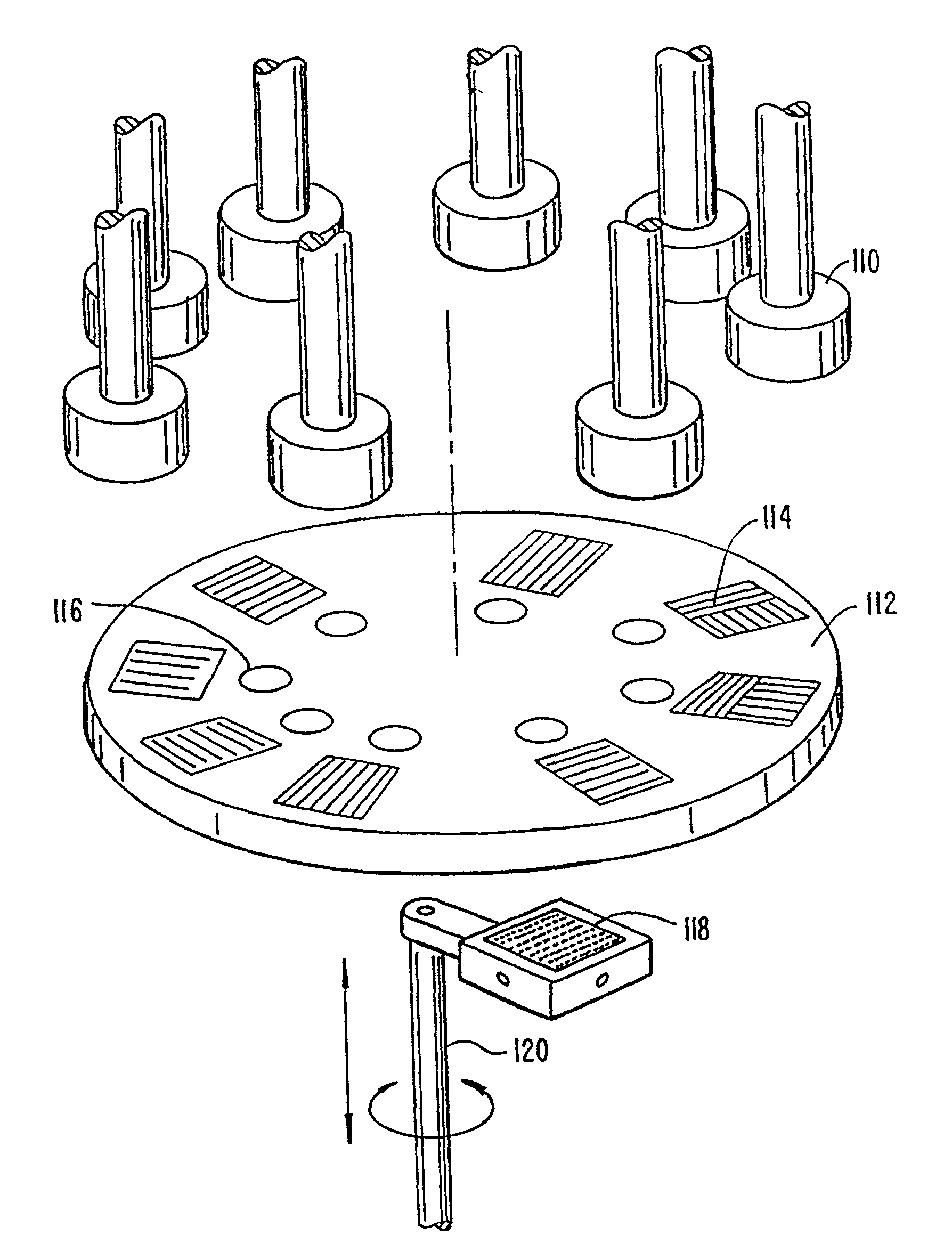

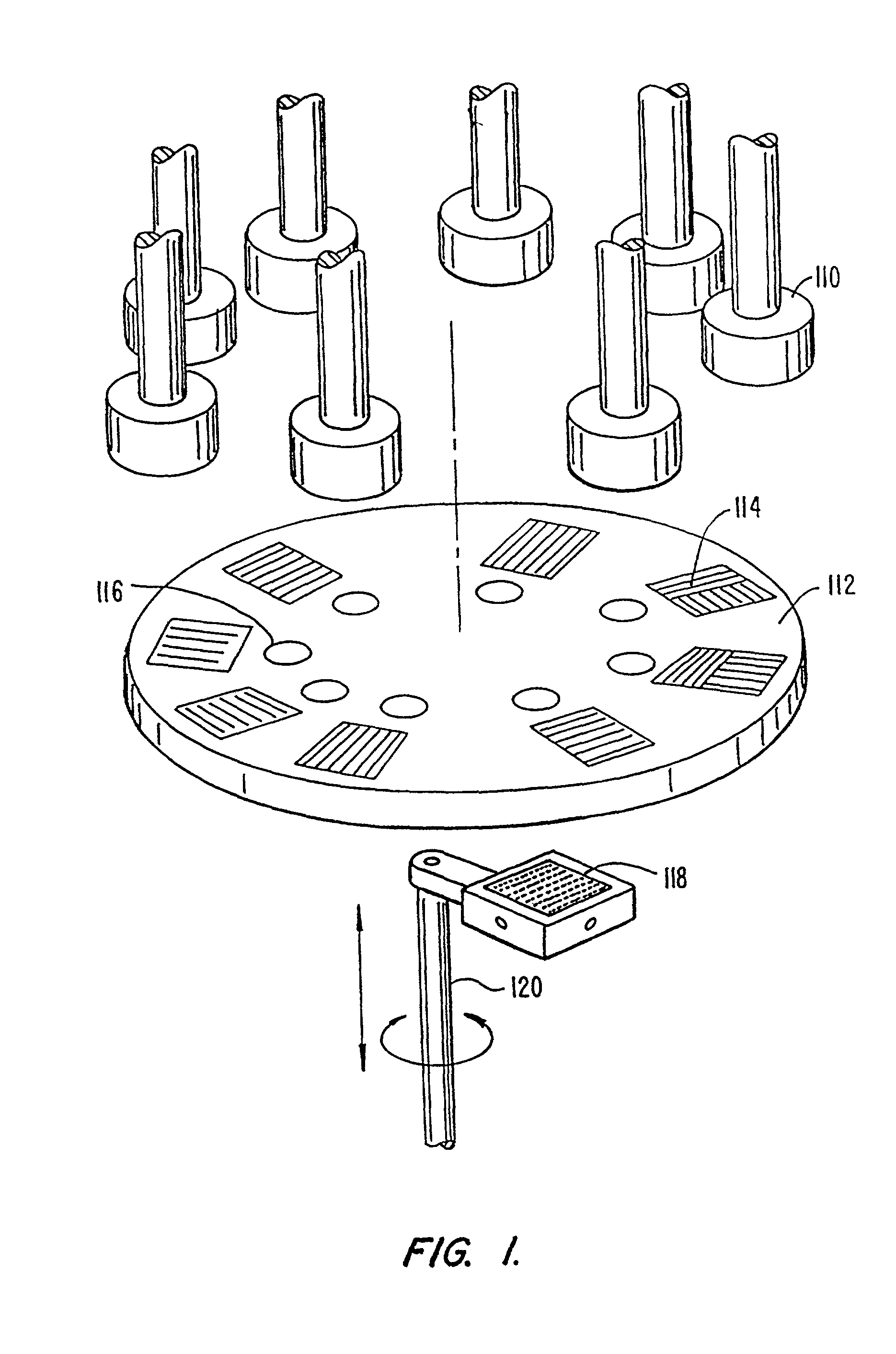

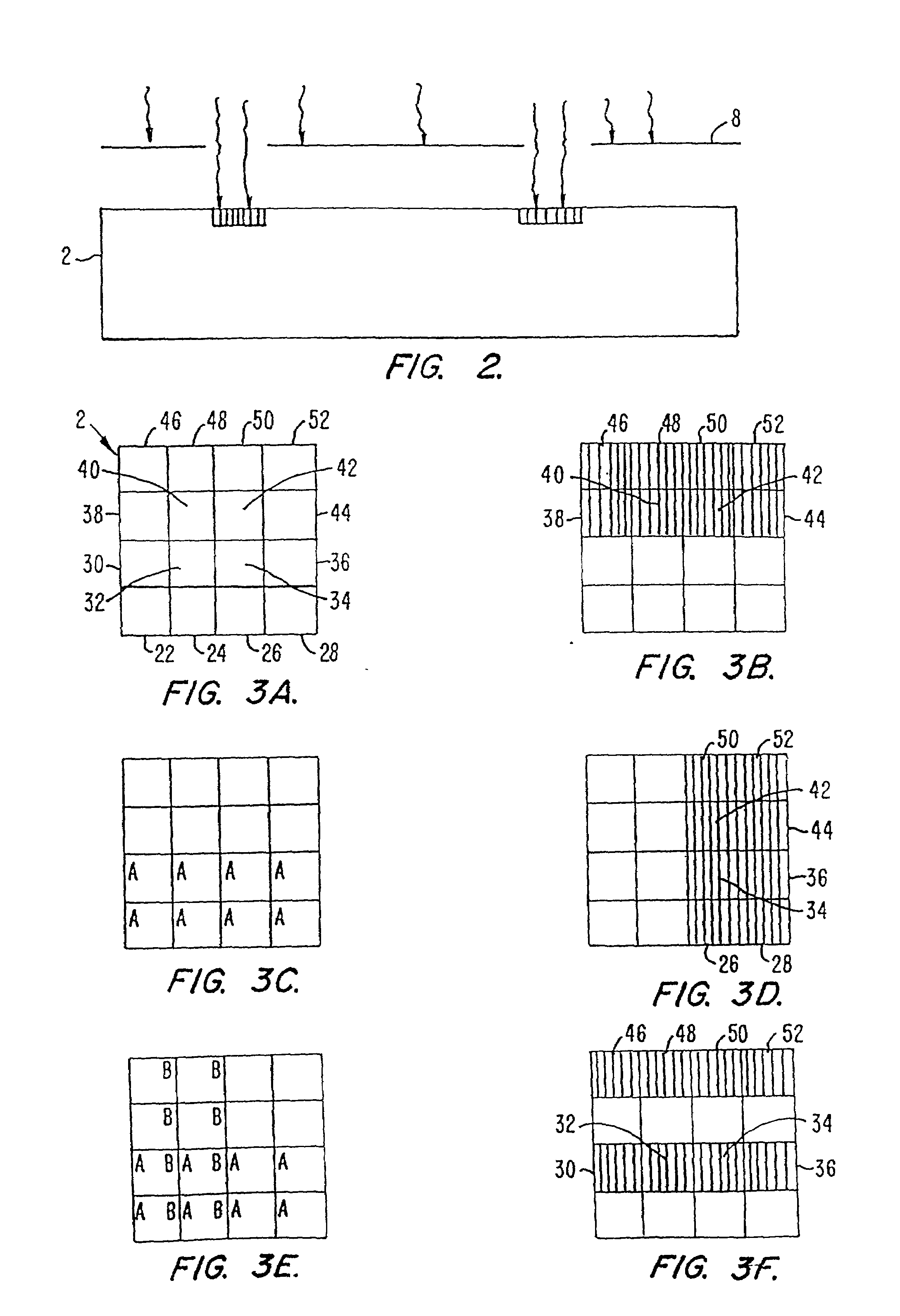

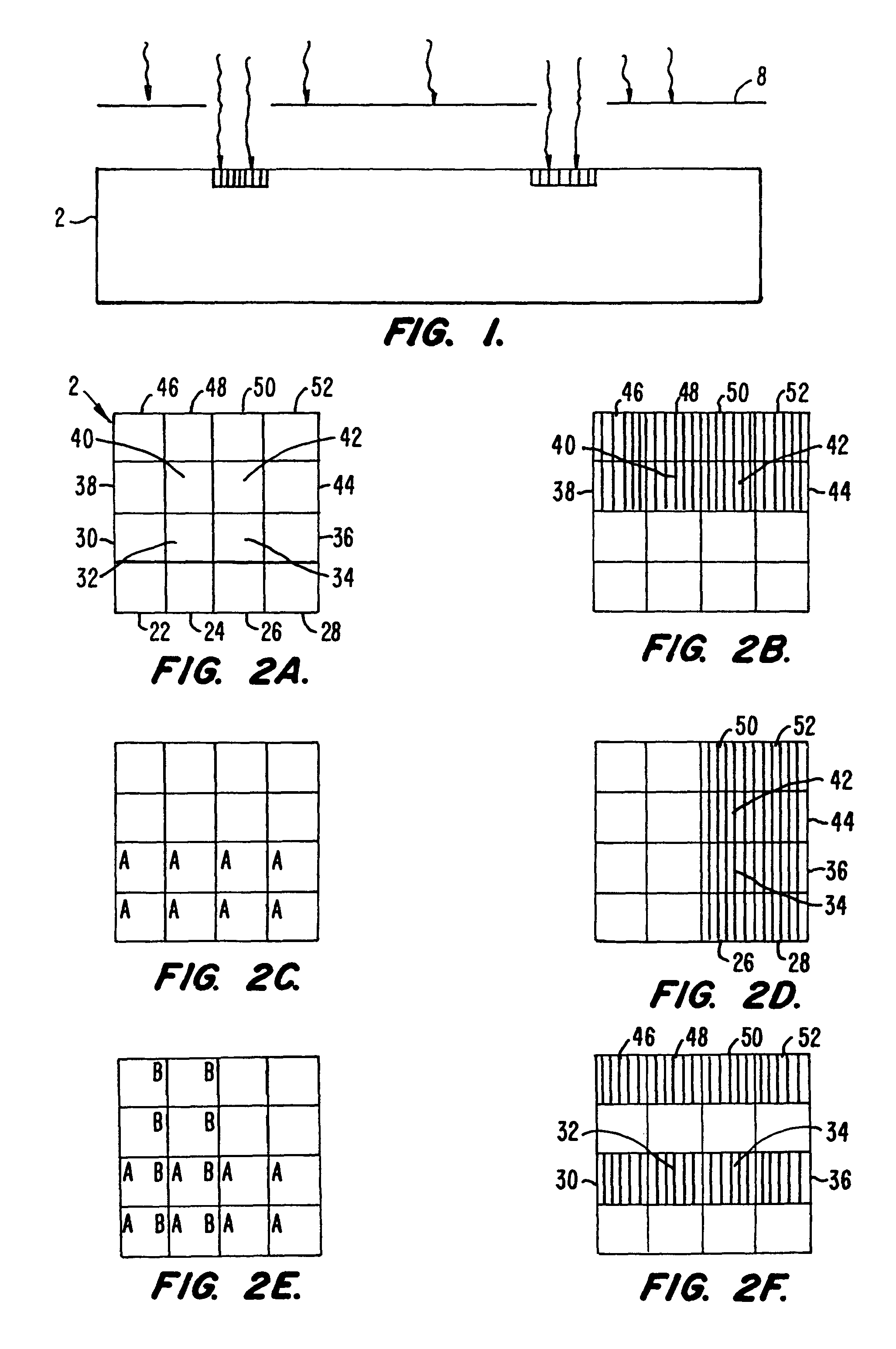

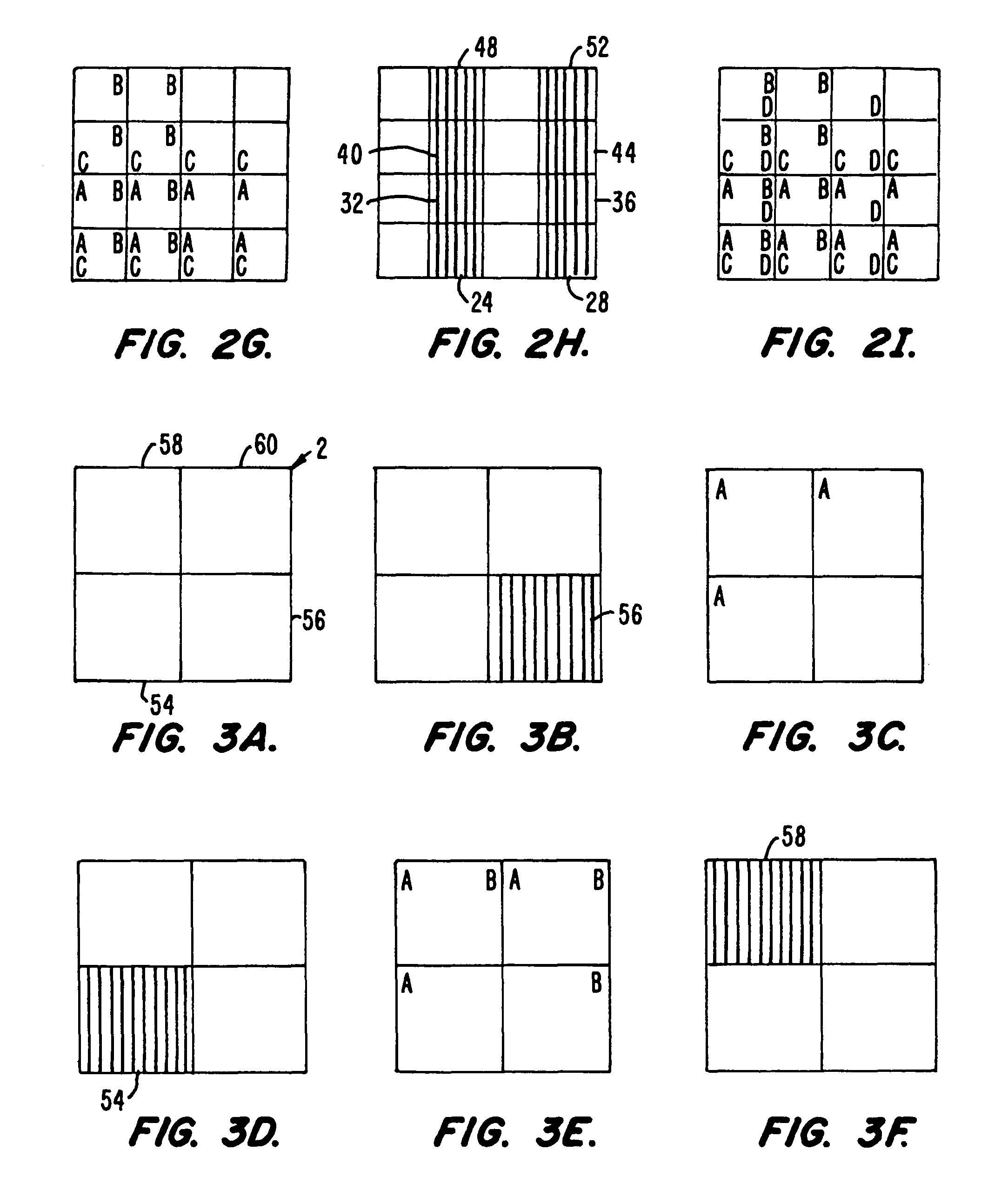

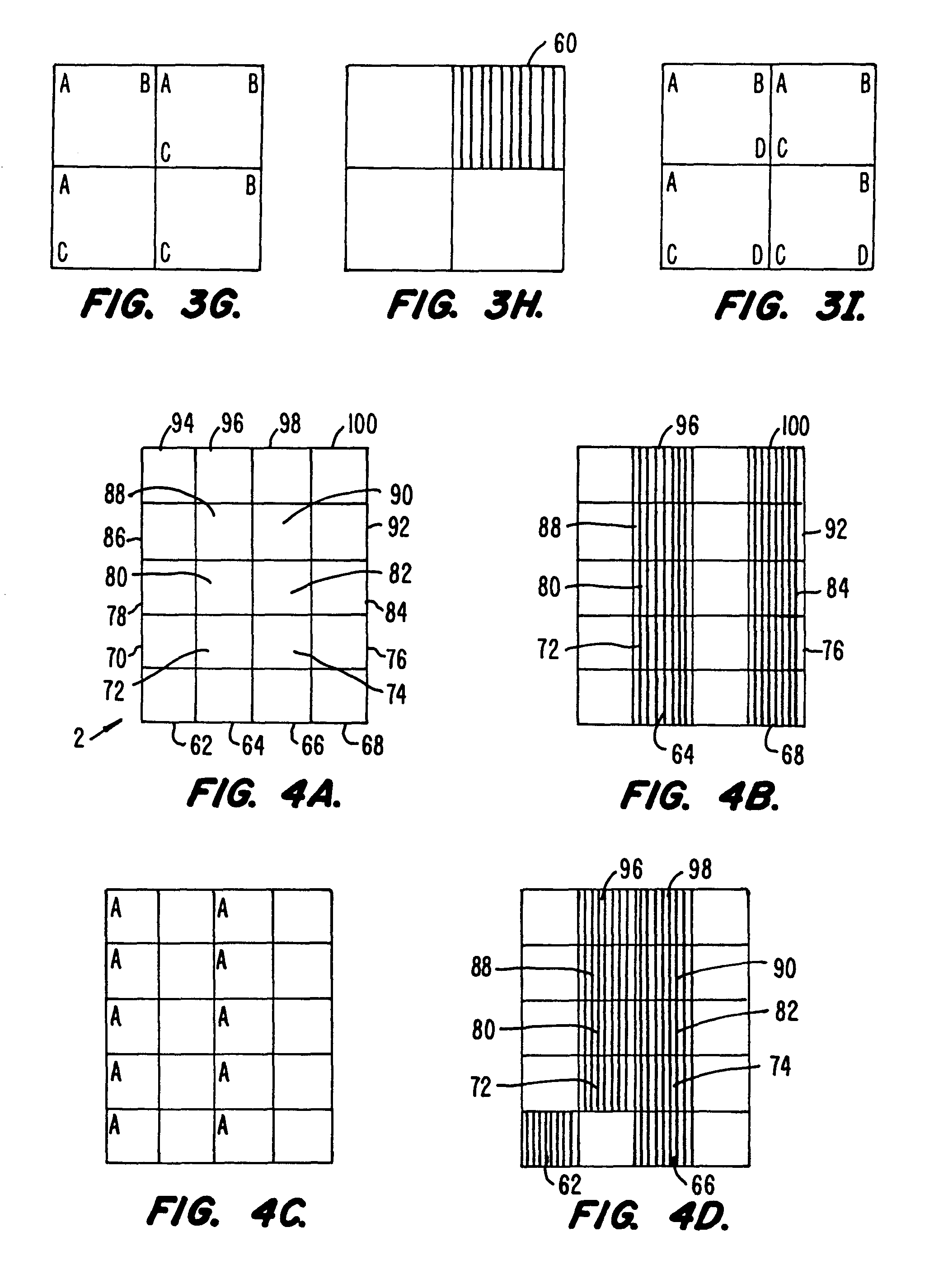

Combinatorial synthesis and screening of non-biological polymers

Methods and apparatus for the preparation and use of a substrate having an array of diverse materials in predefined regions thereon. A substrate having an array of diverse materials thereon is generally prepared by delivering components of materials to predefined regions on a substrate, and simultaneously reacting the components to form at least two materials. Materials which can be prepared using the methods and apparatus of the present invention include, for example, covalent network solids, ionic solids and molecular solids. More particularly, materials which can be prepared using the methods and apparatus of the present invention include, for example, inorganic materials, intermetallic materials, metal alloys, ceramic materials, organic materials, organometallic materials, non-biological organic polymers, composite materials (e.g., inorganic composites, organic composites, or combinations thereof), etc. Once prepared, these materials can be screened for useful properties including, for example, electrical, thermal, mechanical, morphological, optical, magnetic, chemical, or other properties. Thus, the present invention provides methods for the parallel synthesis and analysis of novel materials having useful properties.

Owner:INTERMOLECULAR

Anisotropic magnetic flakes

ActiveUS9662925B2Cost effectiveMaterial nanotechnologyDecorative surface effectsHigh reflectivityMaterials science

The invention relates to anisotropic, reflective, magnetic flakes. In a liquid carrier and under influence of an external magnetic field, the flakes attract to one another side-by-side and form ribbons which provide higher reflectivity to a coating and may be used as a security feature for authentication of an object.

Owner:VIAVI SOLUTIONS INC

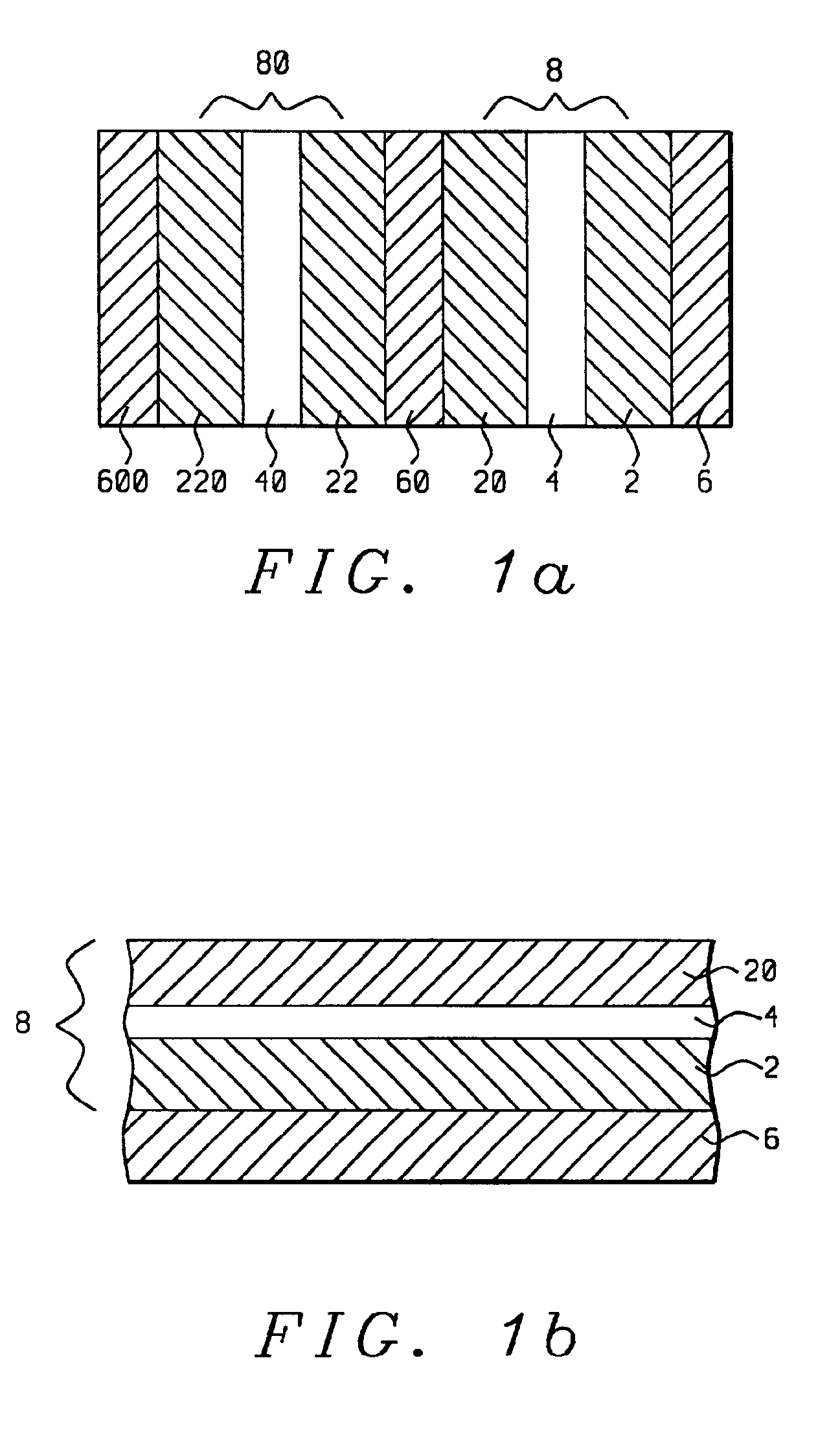

Multilayered structures comprising magnetic nano-oxide layers for current perpindicular to plane GMR heads

InactiveUS6888703B2Enhanced magnetoresistive propertiesNanomagnetismNanoinformaticsElectrical resistance and conductanceEngineering

Nano-oxide based current-perpendicular-to-plane (CPP) magnetoresistive (MR) sensor stacks are provided, together with methods for forming such stacks. Such stacks have increased resistance and enhanced magnetoresistive properties relative to CPP stacks made entirely of metallic layers. Said enhanced properties are provided by the insertion of magnetic nano-oxide layers between ferromagnetic layers and non-magnetic spacer layers, whereby said nano-oxide layers increase resistance and exhibit spin filtering properties. CPP sensor stacks of various types are provided, all having nano-oxide layers formed therein, including the spin-valve type and the synthetic antiferromagnetic pinned layer spin-valve type. Said stacks can also be formed upon each other to provide laminated stacks of different types.

Owner:HEADWAY TECH INC

Magnetic etching process, especially for magnetic or magnetooptic recording

Process for writing on a material, in which said material is irradiated by means of a beam of light ions, such as for example He<+> ions, said beam of light ions having an energy of the order of or less than a hundred keV, wherein this material comprises a plurality of superposed thin-layers, at least one of said thin layers being magnetic and in that one or more regions having sizes of the order of 1 micrometer or less are irradiated, the irradiation dose being controlled so as to be a few 10<16 >ions / cm<2 >or less, the irradiation modifying the composition of atomic planes in the material at one or more interfaces between two layers of the latter.

Owner:CENT NAT DE LA RECHERCHE SCI

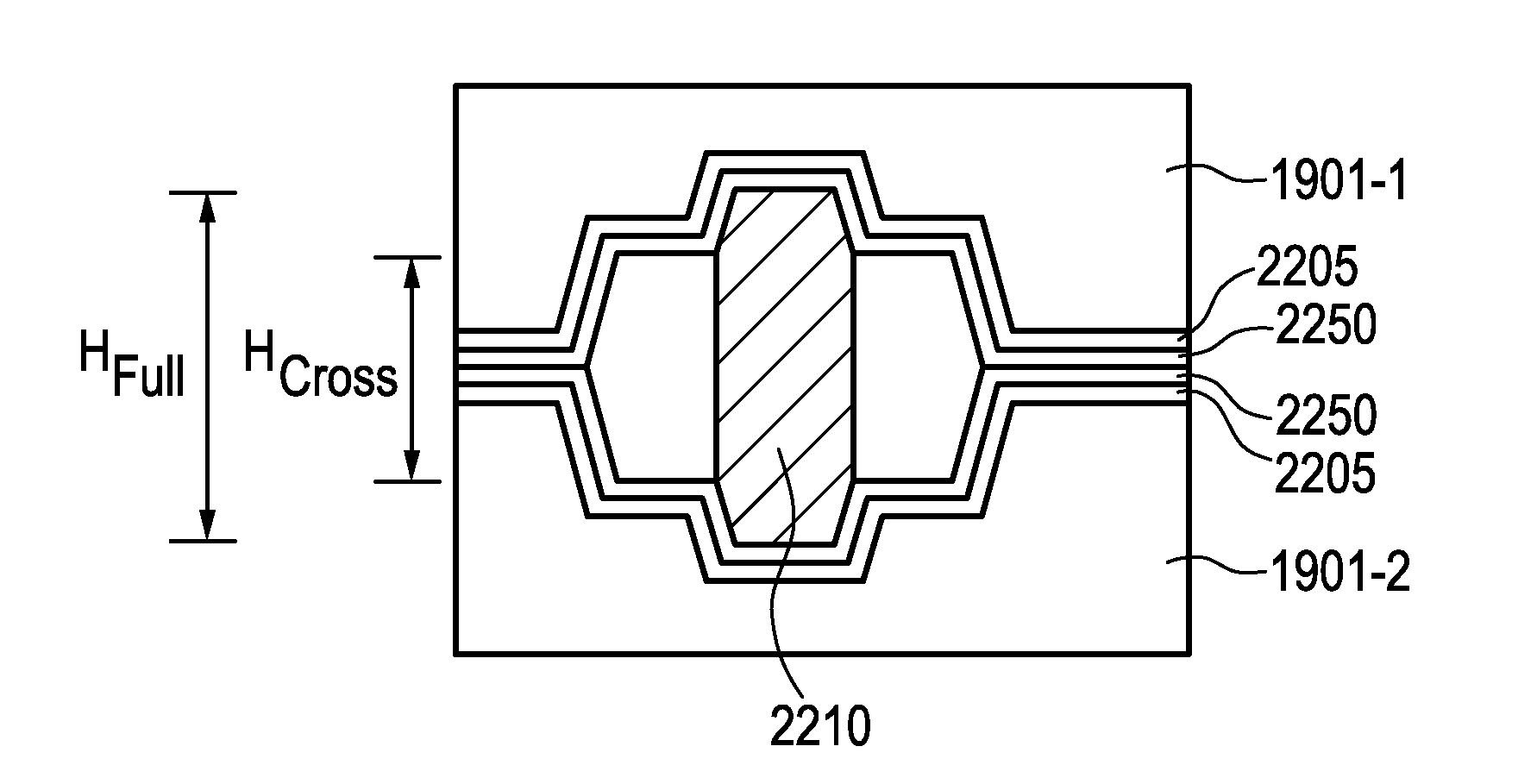

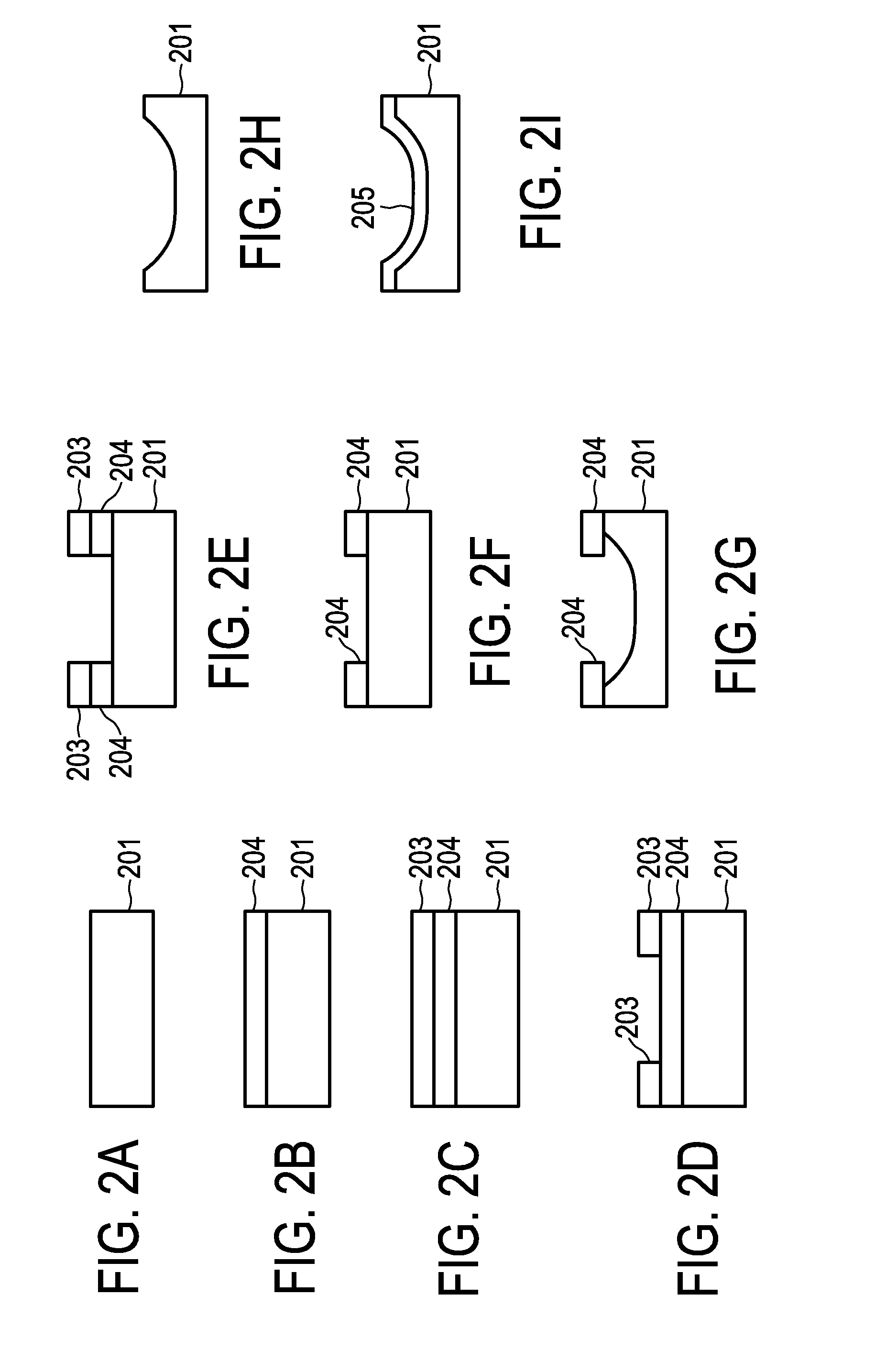

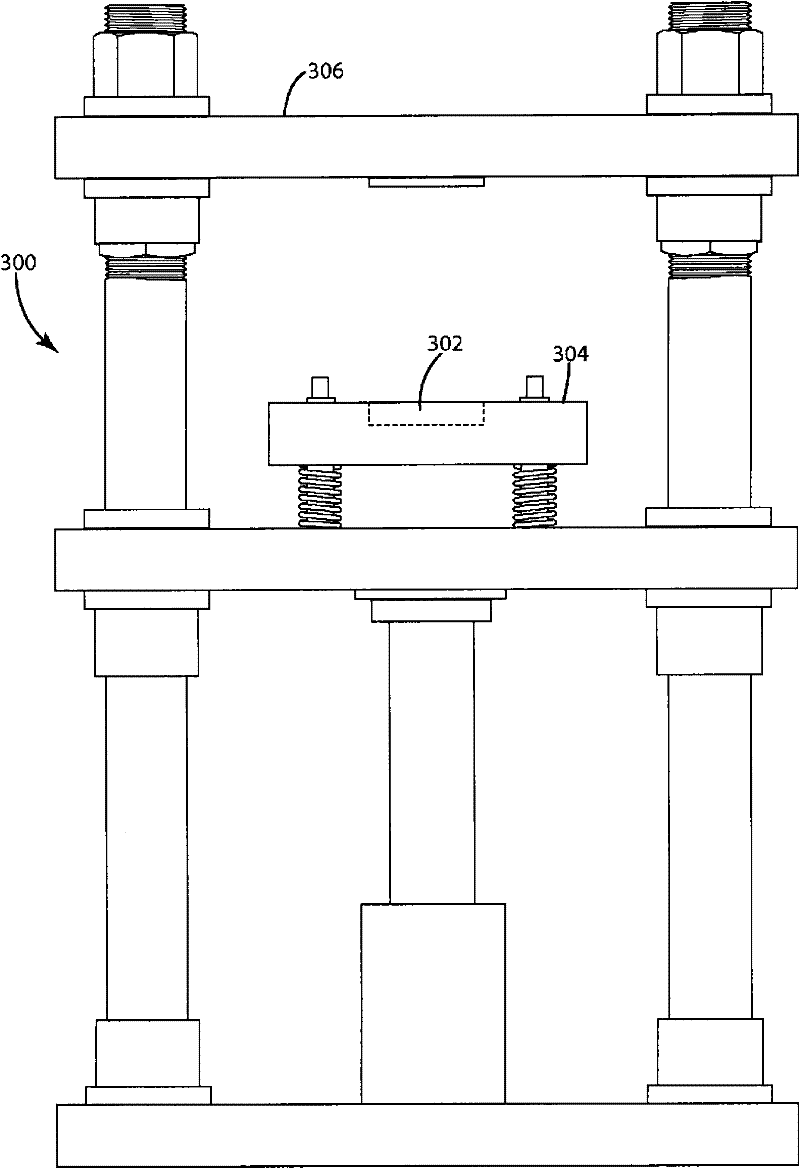

Precision batch production method for manufacturing ferrite rods

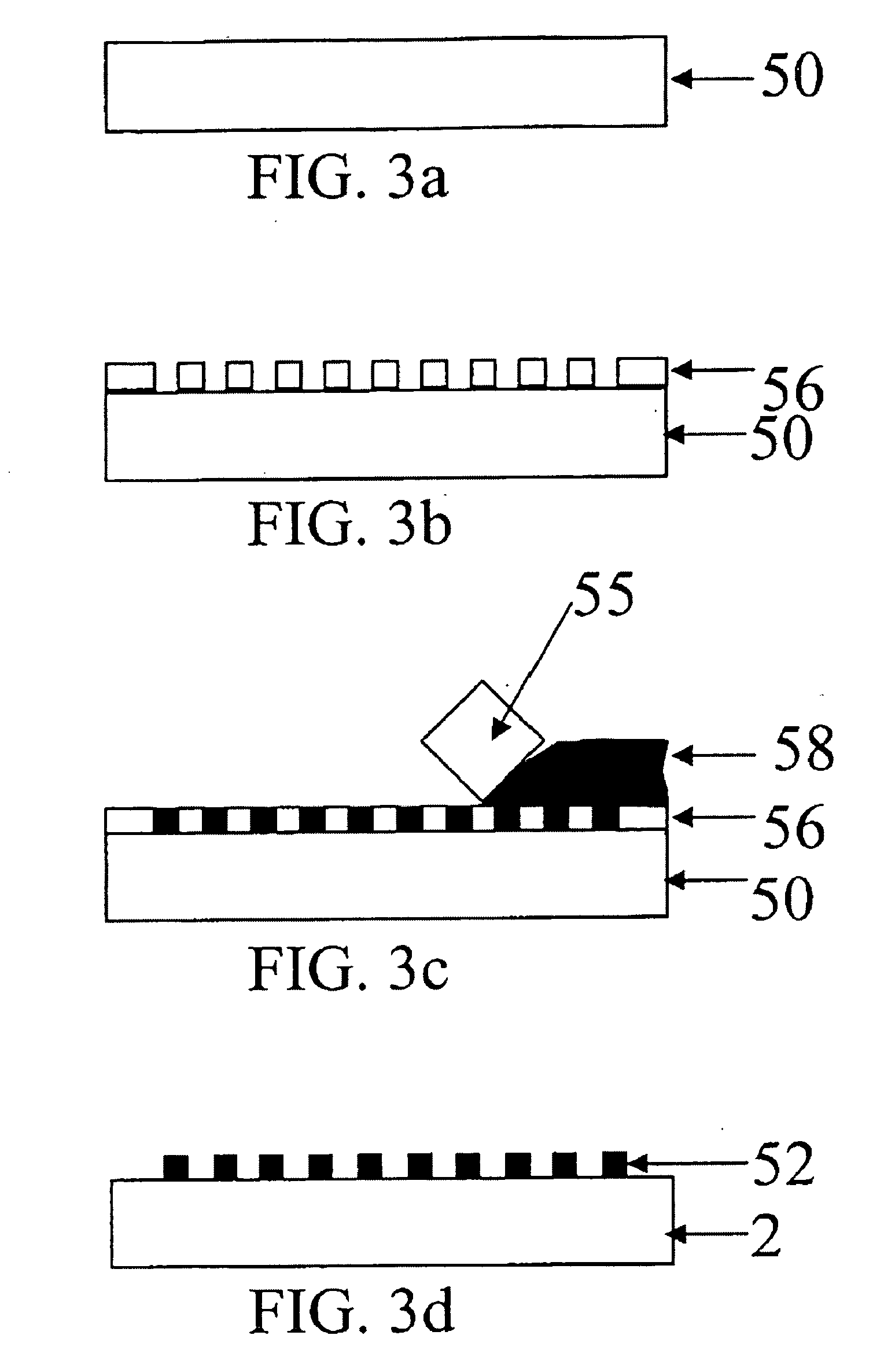

InactiveUS20160254579A1Optimize layoutReduce decreaseSemiconductor/solid-state device manufacturingConductive/insulating/magnetic material on magnetic film applicationCrystallographyFerrite layer

The present invention relates to a method of manufacturing a ferrite rod. The method comprises etching cavities into two semiconductor substrates and depositing ferrite layers into the cavities. The semiconductor substrates are attached to each other such that the ferriote layers form a ferrite rod. The present invention employs conventional photolithography and bulk isotropic micromachining of semiconductor wafers to precisely and repeatably form a template or mould, into which magnetic material can be deposited to form a Faraday rotation or phase-shifting element.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Flux concentrator and method of making a magnetic flux concentrator

ActiveCN102598168ARealize the outlineReduce exposureTransformersTransformers/inductances casingsSolventMagnetic flux

A flux concentrator and method for manufacturing a flux concentrator is provided. The method can include combining powdered soft magnetic material, a binder, a solvent, a internal lubricant; mixing the materials to create a mixture, evaporating the solvent from the mixture, molding the mixture to form a flux concentrator, and curing the flux concentrator. The flux concentrator may be laminated and broken into multiple pieces, which makes the flux concentrator more flexible. Breaking the flux concentrator does not significantly affect the magnetic properties. Since the permeability of the binder is very similar to that of air, adding tiny air gaps between the fractions is not significantly different than adding more binder.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

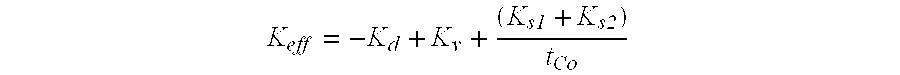

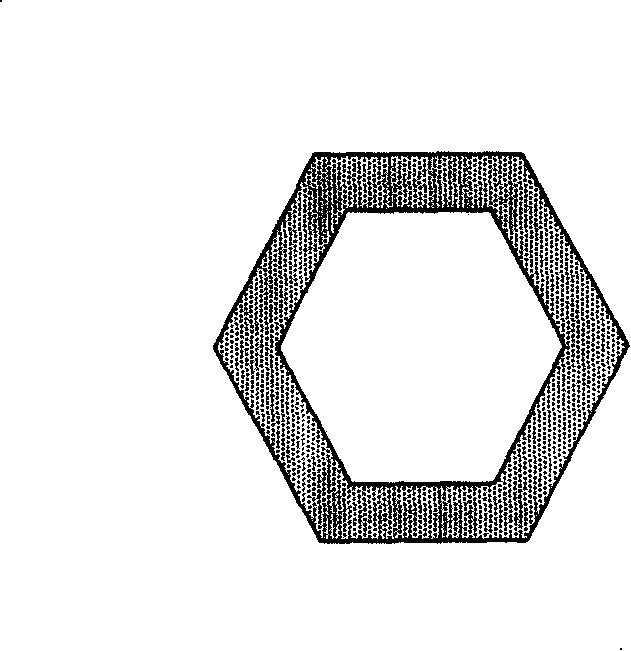

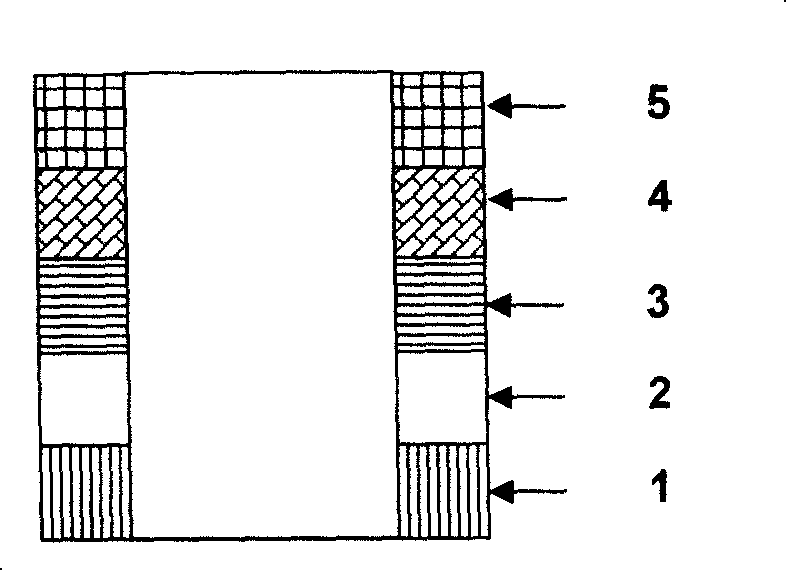

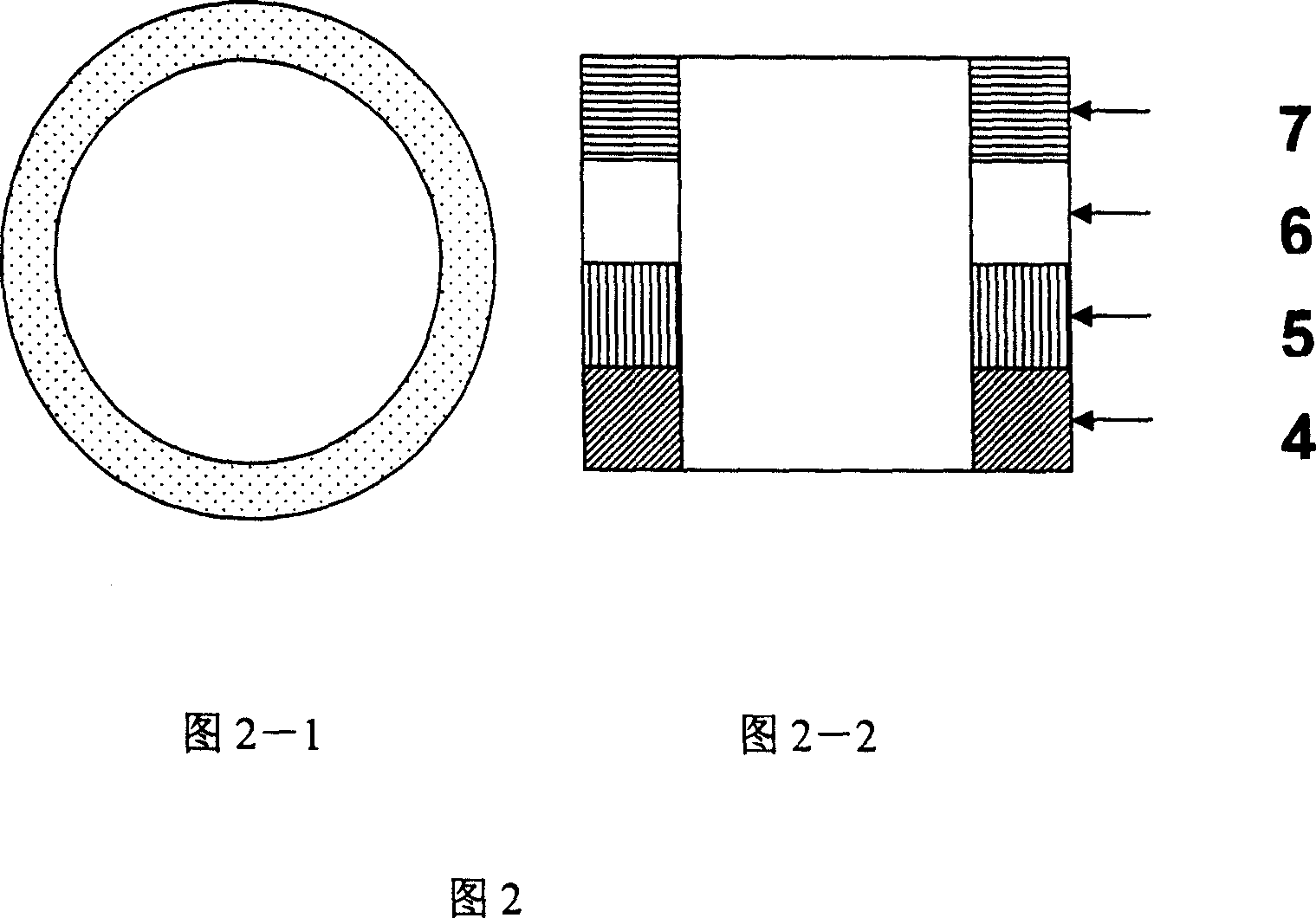

Magnetic multilayer film with geometrical shape and preparation method and application thereof

ActiveCN101221849AEasy to controlEasy to driveRecord information storageMagnetic film to substrate applicationMagnetic storageRandom access memory

The invention relates to a magnetic multiplayer film with geometric shape, comprising all layers of a magnetic multiplayer film unit deposited on a substrate, wherein the cross section of the magnetic multiplayer film unit is polygonal closing ring shaped, magnetic moments or magnetic fluxes of film layers with ferromagnetism in the magnetic multiplayer film unit become in a clockwise or counter clockwise closing state; the invention also comprises a metal core arranged on the geometric center of the polygonal closed ring shaped magnetic multiplayer film, wherein the cross section of the metal core is a corresponding polygon; the invention also relates to a magnetic storage made of the magnetic multiplayer film which comprises(or does not comprise) the metal core; in the invention, the closing shape magnetic multiplayer film is prepared based on the micro processing method; the closing with(or without) metal core polygonal closing ring shaped magnetic multiplayer film is widely applicable to devices which takes the magnetic multiplayer film such as magnetic random access memory, computer magnetic reading head, magneto-dependent sensor, magnetic logic device and self-rotation transistor, etc. as the core.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

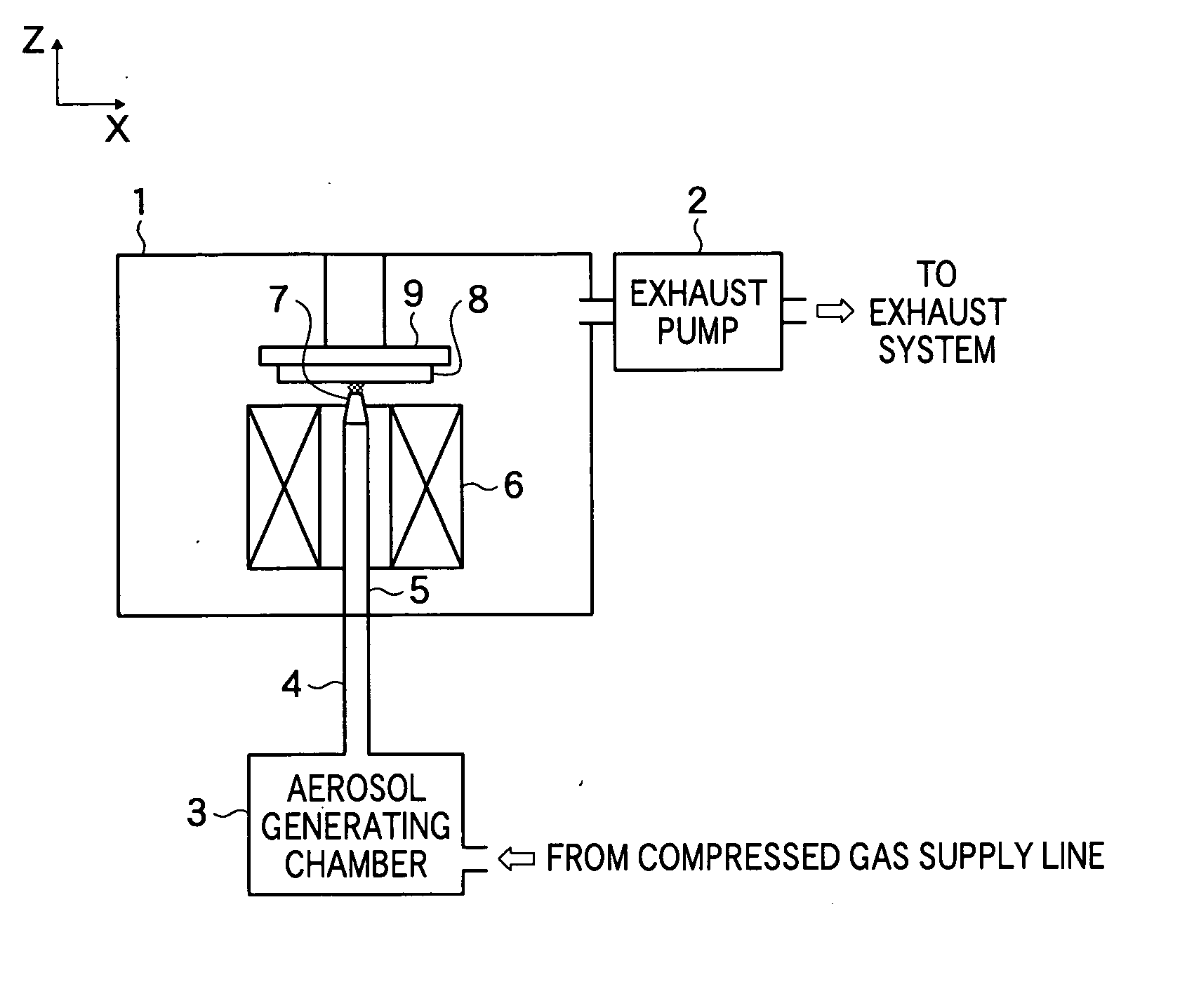

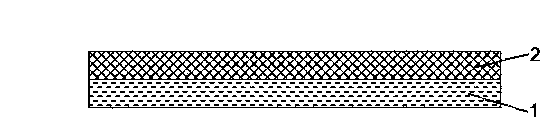

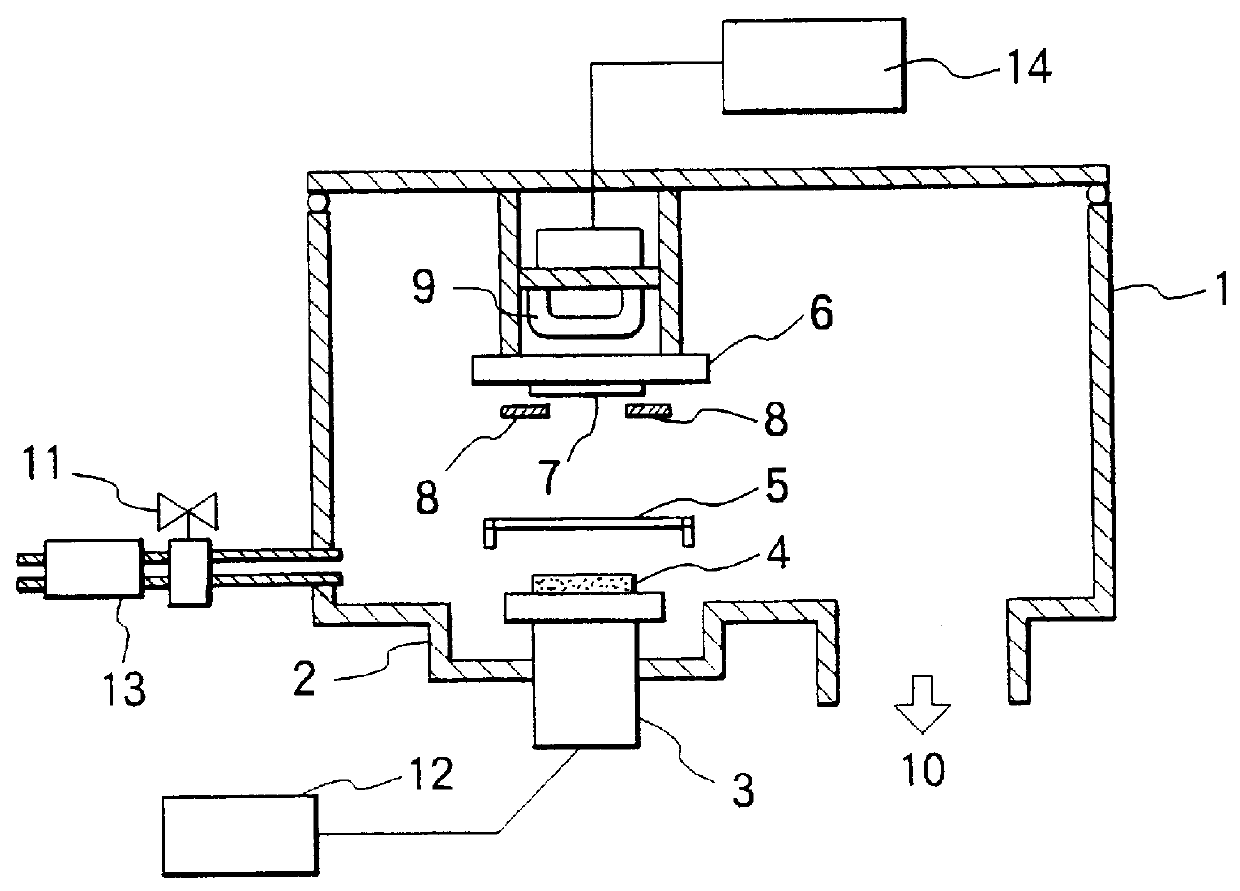

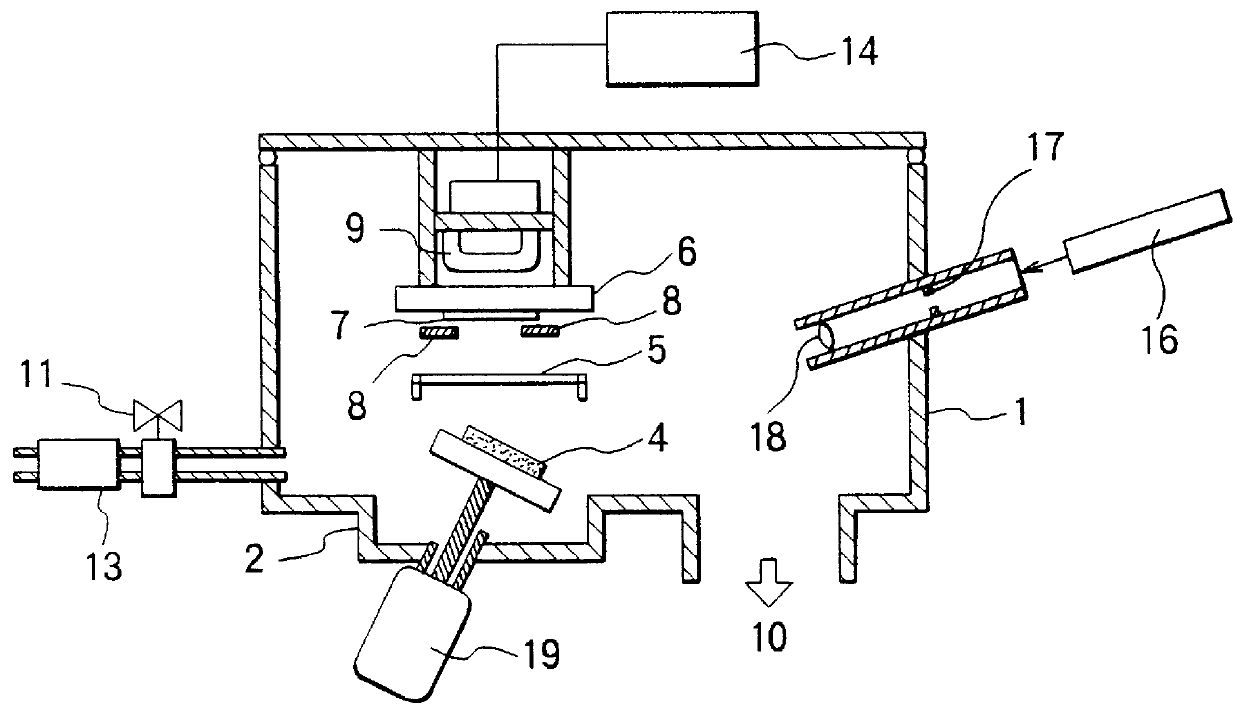

Film forming method and film forming apparatus

InactiveUS20060068105A1Improve propertiesIncrease valuePretreated surfacesMagnetic film to substrate applicationProperty valueCrystal orientation

A film forming apparatus by which property values in a film formed by the AD method can be improved. The film forming apparatus includes: a chamber having a substrate stage for holding a substrate on which a film is to be formed; an aerosol generating unit for generating an aerosol by dispersing a raw material powder into a gas; a magnetic field applying device for applying a magnetic field to a flow path of the aerosol generated by the aerosol generating unit so as to orient crystal orientation in the raw material powder in an aerosol state; and an injection nozzle for spraying the aerosol applied with the magnetic field by the magnetic field applying device to the substrate so as to deposit the raw material powder, in which the crystal orientation is oriented, on the substrate.

Owner:FUJIFILM CORP +1

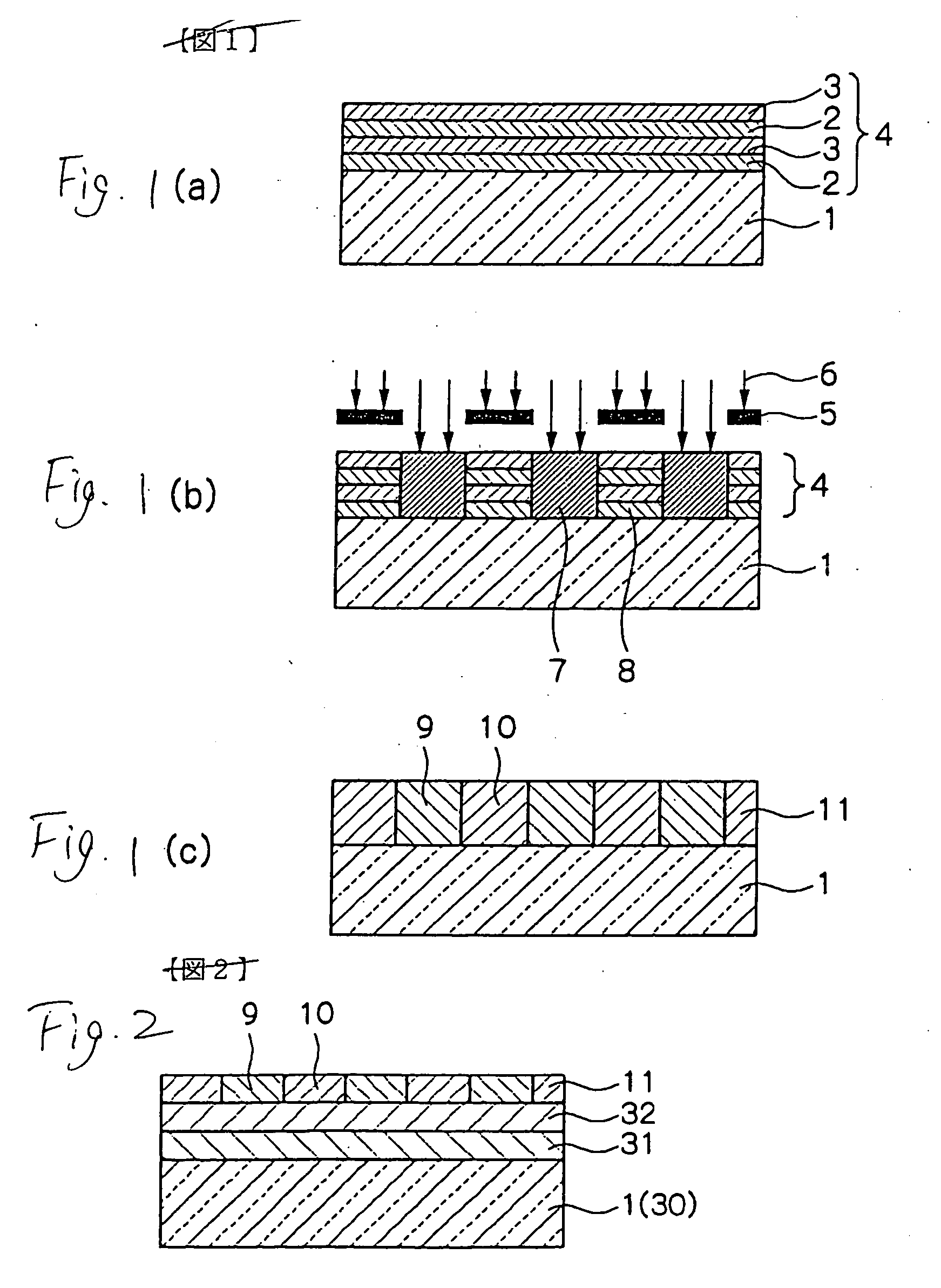

Magnetic film forming method, magnetic pattern forming method and magnetic recording medium manufacturing method

InactiveUS20050220990A1Reduce manufacturing costHigh magnetic anisotropyVacuum evaporation coatingSputtering coatingHeat treatedRecording media

An Ag ion 6 is locally implanted into a thin film 4 containing, as main components, at least one of Fe and Co and at least one of Pd and Pt and a heat treatment is then carried out, and a portion 7 into which the Ag ion 6 is implanted becomes a portion 9 having a large coercive force and a portion 8 into which the Ag ion 6 is not locally implanted becomes a portion 10 having a small coercive force.

Owner:TDK CORPARATION

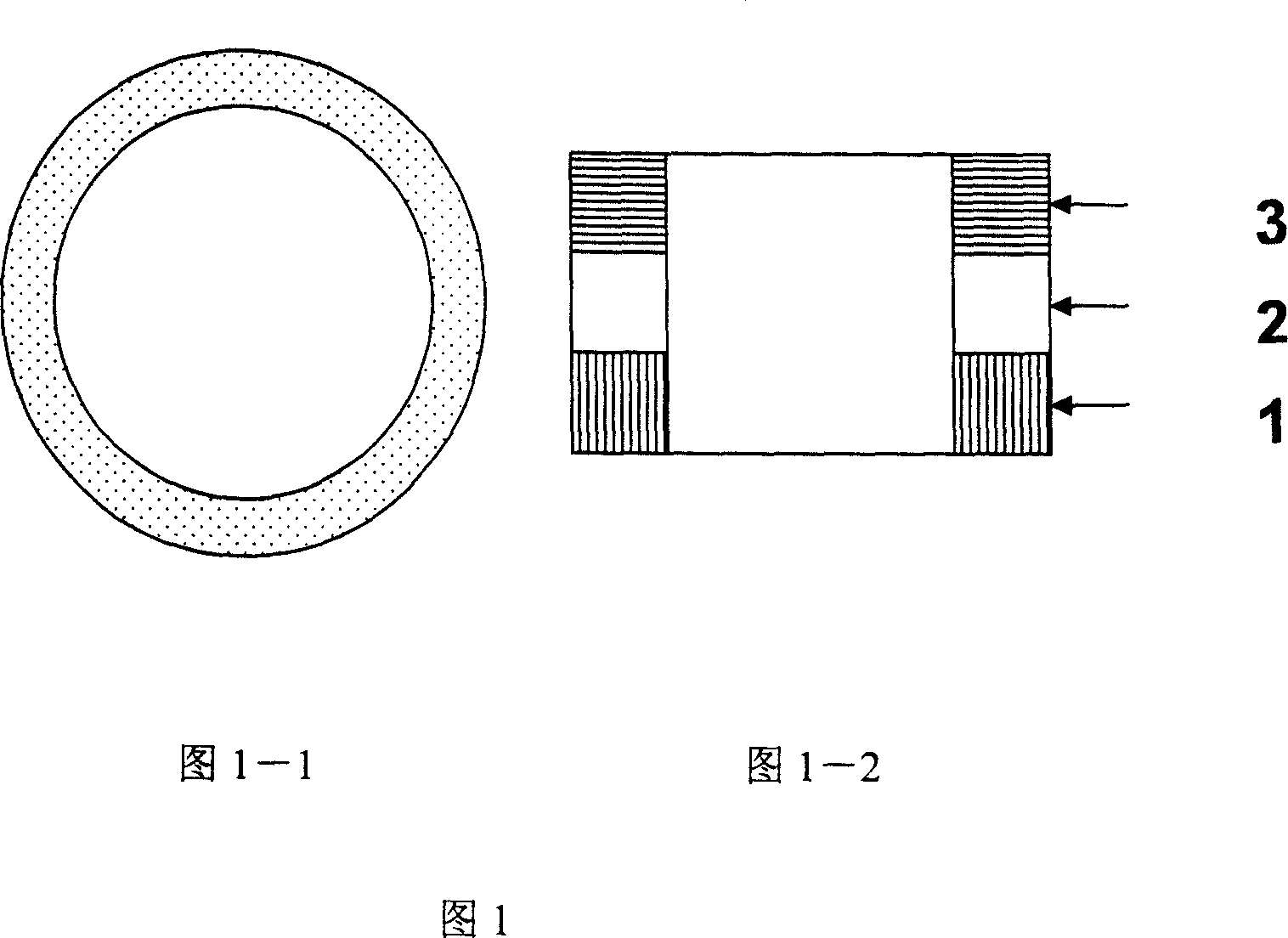

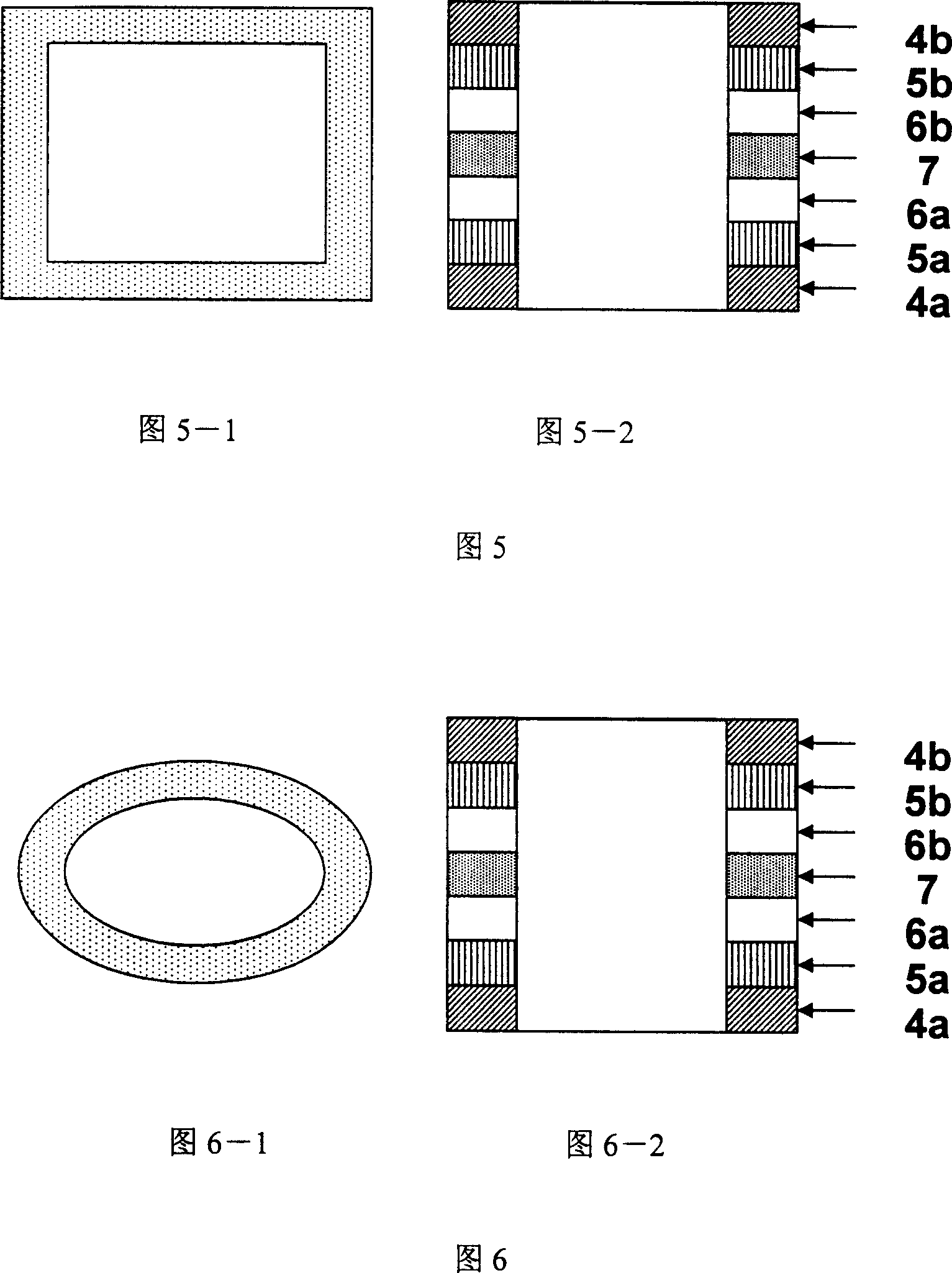

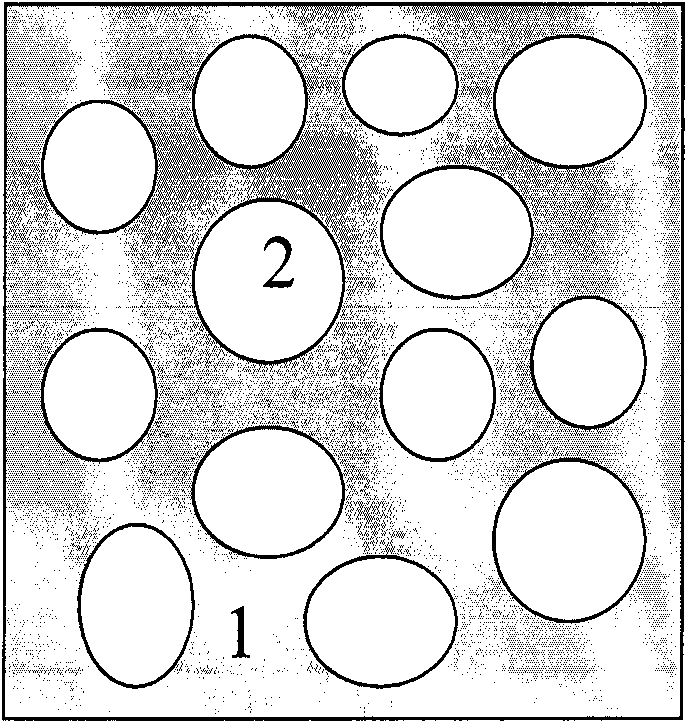

Ring-shaped magnetic multi-layer film and method for making same and use

ActiveCN1992104AImprove performanceThe magnetization state is not easy to changeMagnetic-field-controlled resistorsManufacture of flux-sensitive headsNanoparticleRandom access memory

This invention relates to a circular magnetic multi-layer membrane, which characterized with: the cross section of the said magnetic multi-layer membrane takes on the closed circle shape, the circle's inner diameter being 10~100000nm, outer diameter being 20~200000nm. In accordance with the classification of the forming materials, the magnetic multi-layer membrane of the invention includes the circular magnetic multi-layer membrane without pinning and the circular magnetic multi-layer membrane with pinning, and it can be prepared through micro-processing method or insulator micron, submicron or nano-particles masking method. The circular magnetic multi-layer membrane of the invention has no fading magnetic field, weak shape anisotropy, and it can be widely used in various devices with the core of magnetic multi-layer membrane, such as magnetic random access memory, computer magnetic heads, magnetic-sensing sensors, etc.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Combinatorial synthesis of inorganic or composite materials

InactiveUS7767627B1Improve responseEvenly distributedSequential/parallel process reactionsLibrary screeningMolecular solidAlloy

Methods and apparatus for the preparation and use of a substrate having an array of diverse materials in predefined regions thereon. A substrate having an array of diverse materials thereon is generally prepared by delivering components of materials to predefined regions on a substrate, and simultaneously reacting the components to form at least two materials or, alternatively, allowing the components to interact to form at least two different materials. Materials which can be prepared using the methods and apparatus of the present invention include, for example, covalent network solids, ionic solids and molecular solids. More particularly, materials which can be prepared using the methods and apparatus of the present invention include, for example, inorganic materials, intermetallic materials, metal alloys, ceramic materials, organic materials, organometallic materials, nonbiological organic polymers, composite materials (e.g., inorganic composites, organic composites, or combinations thereof), etc. Once prepared, these materials can be screened for useful properties including, for example, electrical, thermal, mechanical, morphological, optical, magnetic, chemical, or other properties. Thus, the present invention provides methods for the parallel synthesis and analysis of novel materials having useful properties.

Owner:RGT UNIV OF CALIFORNIA +1

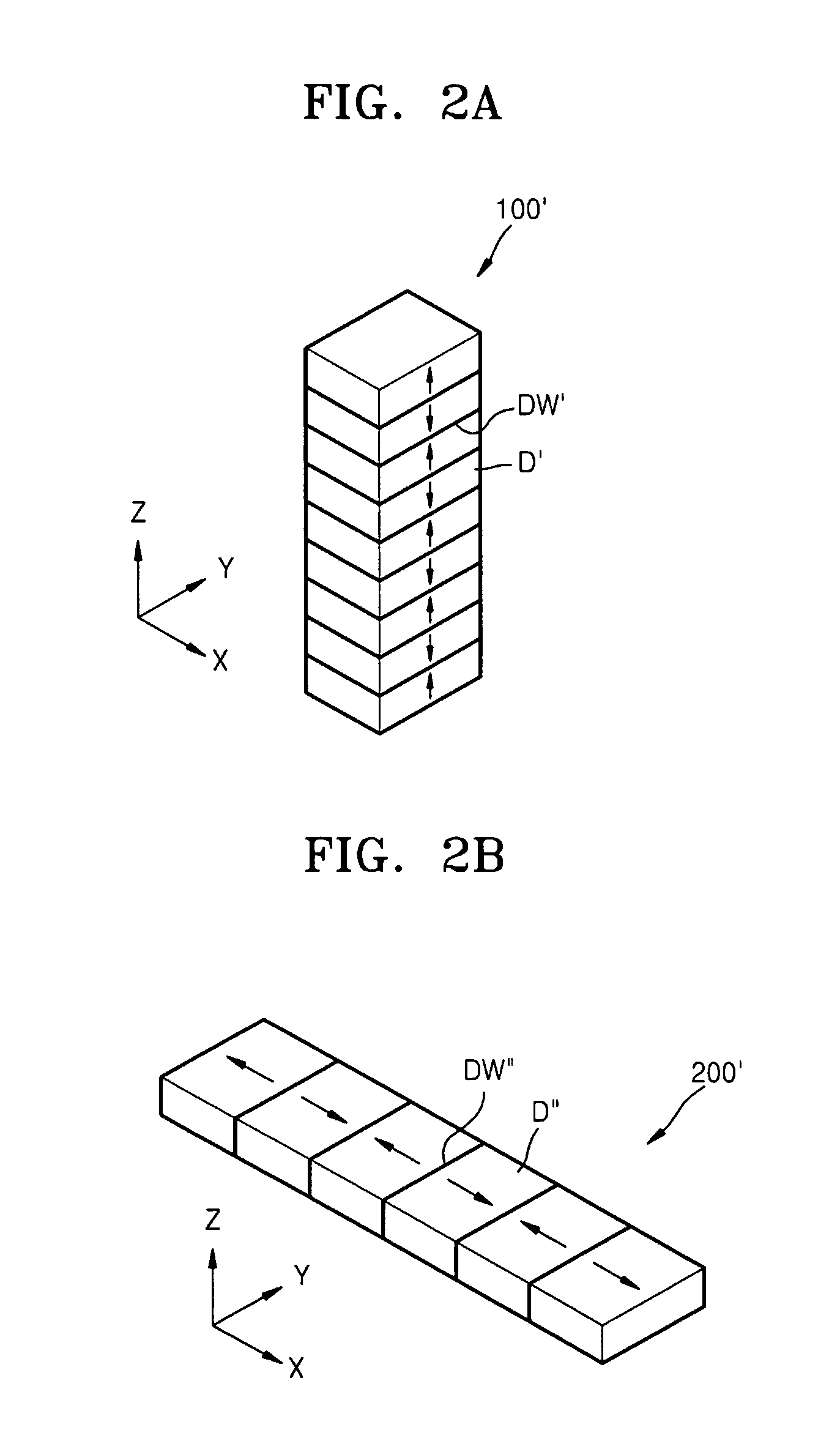

Magnetic layer, method of forming the magnetic layer, information storage device including the magnetic layer, and method of manufacturing the information storage device

InactiveUS20090097365A1Large storage capacityReduce power consumptionCombination recordingNanotechMagnetic layerInformation storage

Provided are a magnetic layer, a method of forming the magnetic layer, an information storage device, and a method of manufacturing the information storage device. The information storage device may include a magnetic track having a plurality of magnetic domains, a current supply element connected to the magnetic layer and a reading / writing element. The magnetic track includes a hard magnetic track, and the hard magnetic track has a magnetization easy-axis extending in a direction parallel to a width of the hard magnetic track.

Owner:SAMSUNG ELECTRONICS CO LTD

Soft-magnetic composite film and manufacturing method and application of soft-magnetic composite film in electronic equipment

InactiveCN104134513APromote absorptionImprove permeabilityMagnetic/electric field screeningInorganic material magnetismComposite filmAdhesive

The present invention provides a soft magnetic composite film for absorbing near-field electromagnetic waves, a soft magnetic composite film adhesive tape, a manufacturing method and the use thereof in electronic devices for absorbing near-field electromagnetic noises. The soft magnetic composite film can solve the problems existing in the prior art that a composite film has a low magnetic conductivity at 2-3 GHz and shows poor absorption effect of near-field electromagnetic noise, but it cannot effectively solve the problem that the signal transmission quality of an electronic device is low. The technical solution is a soft magnetic composite film. The soft magnetic composite film comprises: a, a sheet Fe-Ni soft magnetic alloy powder in which 45%-60% Fe and 40%-55% Ni by mass fraction are comprised; b, sheet Fe-Ni soft magnetic alloy powder and an organic bonding material are mixed and formed into a soft magnetic composite film, wherein the volume fraction of the sheet Fe-Ni soft magnetic alloy powder accounts for 31% to 73% of the total volume of the soft magnetic composite film material. The present invention has a high magnetic conductivity at 1-5 GHz, particularly between 2 and 3GHz, enabling high frequency near-field electromagnetic noise to be absorbed by the magnetic composite film more easily.

Owner:杨立章

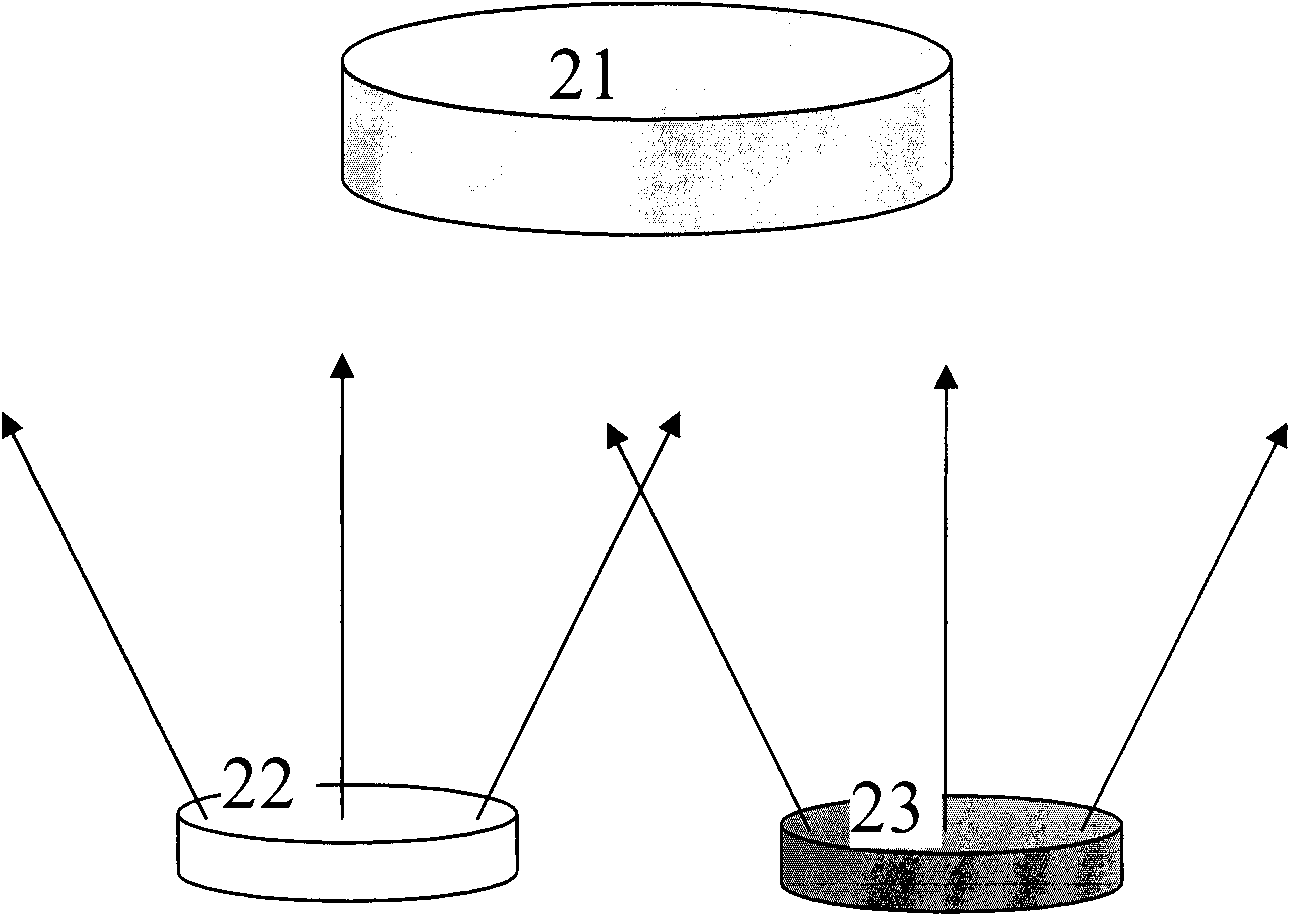

Titanium dioxide cobalt magnetic film and its manufacturing method

InactiveUS20030091500A1High catalytic activitySoldering apparatusVacuum evaporation coatingSemiconductor materialsMagnetization

A titanium dioxide.cobalt magnetic film is provided that is useful to make up a photocatalyst having high catalytic capability, a semiconductor material having an optical, an electrical and a magnetic function all in combination, and a transparent magnet. The titanium dioxide.cobalt magnetic film has a composition expressed by chemical formula: Ti1-xCoxO2 where 0<x<=0.3, wherein a Ti atom at its lattice position is replaced with a Co atom, and the magnetic film is a film epitaxially grown on a single crystal substrate. The magnetic film has either anatase or rutile crystalline structure, has its band gap energy varying in a range between 3.13 eV and 3.33 eV according to the concentration of Co atoms replaced for Ti atoms at their lattice positions, is capable of retaining its magnetization even at a temperature higher than a room temperature, and is also transparent to a visible light. I the manufacture of the titanium dioxide.cobalt magnetic film, a target having TiO2 and Co mixed together at a selected mixing ratio is prepared, placed in a vacuum chamber provided with an atmosphere with a selected oxygen pressure therein, and irradiated in the vacuum chamber with a selected laser light under selected irradiating conditions to cause TiO2 and Co to evaporate from the target and a layer of TiO2.Co to grow in a single crystal substrate that is heated in the vacuum chamber.

Owner:JAPAN SCI & TECH CORP

Close-shaped magnetic multi-layer film and preparation method and use thereof

InactiveCN101000821AImprove performanceThe magnetization state is not easy to changeMagnetic-field-controlled resistorsManufacture of flux-sensitive headsRandom access memoryElectrical and Electronics engineering

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Thin film magnet, cylindrical ferromagnetic thin film and production method thereof

InactiveUSRE36517E1Improve magnetic propertiesSmall sizeFixed microstructural devicesVolume/mass flow measurementPerpendicular magnetizationGas phase

A thin film magnet and a cylindrical ferromagnetic thin film having a high maximum energy product (greater than 120 kJ / m3) and thus suitable for use in miniature high performance devices are provided. The thin film magnet is produced by means of physical vapor deposition. The thin film magnet is an (Nd1-xRx)yM1-y-zBz alloy having a ferromagnetic compound of the Nd2Fe14B type as its main phase, wherein R is Tb, Ho, and Dy and M is Fe metal or an Fe-based alloy including at least one of Co and Ni, 0.04< / =x< / =0.10,0.11< / =y< / =0.15, and 0.08< / =z< / =0.15. A perpendicular magnetization film having such a composition is deposited on the side wall of a substrate in the columnar (or cylindrical) form thereby obtaining a cylindrical ferromagnetic thin film having radial anisotropy.

Owner:MITSUBISHI ELECTRIC CORP

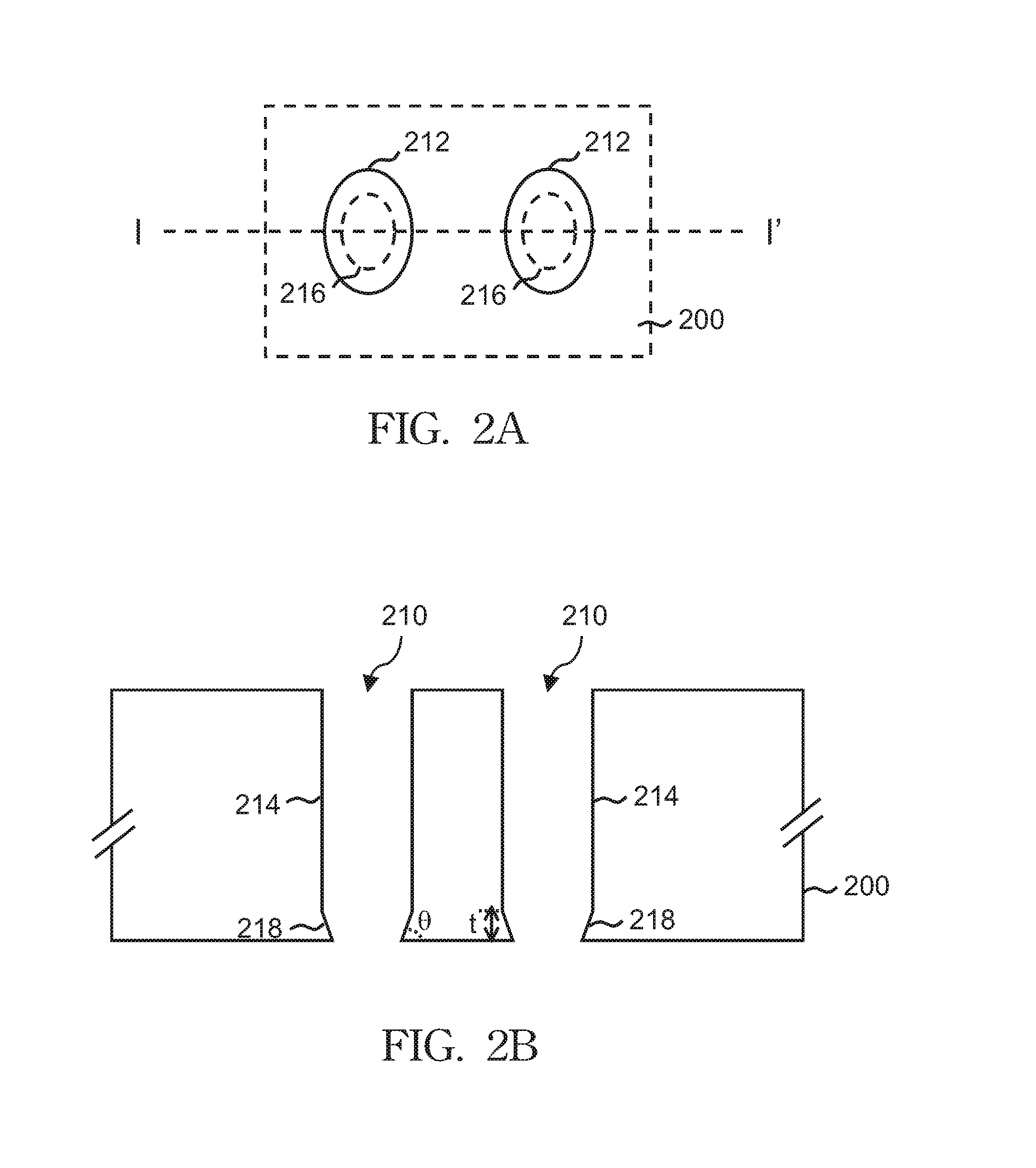

Method of embedding magnetic component in substrate

ActiveUS20130104365A1Increase ratingsIncrease the areaPrinted circuit aspectsMagnetic film to substrate applicationEngineeringMagnetic components

A method of embedding a magnetic component in a substrate is disclosed. Holes are formed in a substrate by mechanically drilling. Each of the holes includes a top opening, a bottom and sidewall, wherein an area of the top opening is larger than that of the bottom. The sidewall extends from the top opening vertically downwards to a predetermined depth, and then is slanted inwardly to the bottom to form a sloped sidewall at the bottom of the hole. A predetermined region is defined along a portion of an edge of the top opening, and a portion of the substrate material under the predetermined region is removed by routing to form a component accommodation trench with a portion of the sloped sidewall at the bottom. Then, a magnetic component is placed into the component accommodation trench.

Owner:TRIPOD TECHNOLOGY CORPORATION

Microwave composite material and preparation method thereof

InactiveCN101847479AHigh resistivityHigh saturation magnetizationCopper organic compoundsOrganic/organic-metallic materials magnetismHigh resistivityCritical dimension

The invention provides a microwave composite material which is compounded from nano magnets made of ferromagnetic materials and organic materials, wherein the nano magnets are distributed in the organic materials, the size of the nano magnets made of the ferromagnetic materials is greater than the room-temperature superparamagnetic critical dimension of the ferromagnetic materials, and the resistivity of the organic material is greater than 1 ohm. cm. The invention also correspondingly provides multiple methods for preparing the microwave composite material. The microwave composite material has the characteristics of high resistivity and high saturated magnetic intensity, has good flexibility and certain elasticity, and is beneficial to the miniaturization and portability of devices. Besides, the preparation process of the microwave composite material can be compatible with the conventional semiconductor process, and realizes the integral monolithic integrated circuit.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com