Coated and magnetic particles and applications thereof

a technology of magnetic particles and coatings, applied in the field of magnetic or non-magnetic particles, can solve the problems of high cost of ownership, severe limitations on bump height, and inconvenient use of solder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

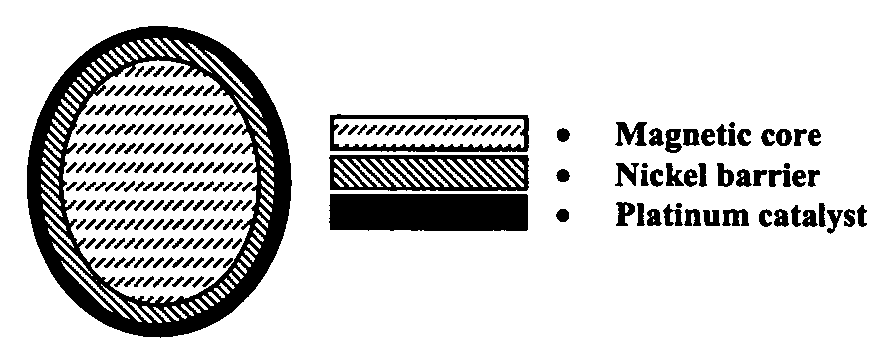

[0062] Magnetic Core Catalyst Particles

[0063] An example of the use of coated magnetic core powders is in the manufacture of electrocatalyst materials for applications including, but not limited to, fuel cells. Not only does the use of magnetic core powders improve manufacturability of the device, it enhances its efficiency as well. The present invention comprises coating a magnetic particle, preferably Ni, with a catalytic material, preferably a metal, and preferably platinum. Optionally, other elements such as ruthenium may be added to the surface, either entirely encapsulating the particle or partially coating the surface, to tailor the catalyst's mechanical, electrochemical, electronic, and / or magnetic properties. The partial coatings may comprise isolated islands of the additional element. The ruthenium may optionally be oxidized.

[0064] The use of a magnetic material in catalyst electrodes results in improved catalytic properties. The magnetic moment of the core particles impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com