Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214 results about "Magnetosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A magnetosphere is a region of space surrounding an astronomical object in which charged particles are manipulated or affected by that object's magnetic field. It is created by a planet having an active interior dynamo.

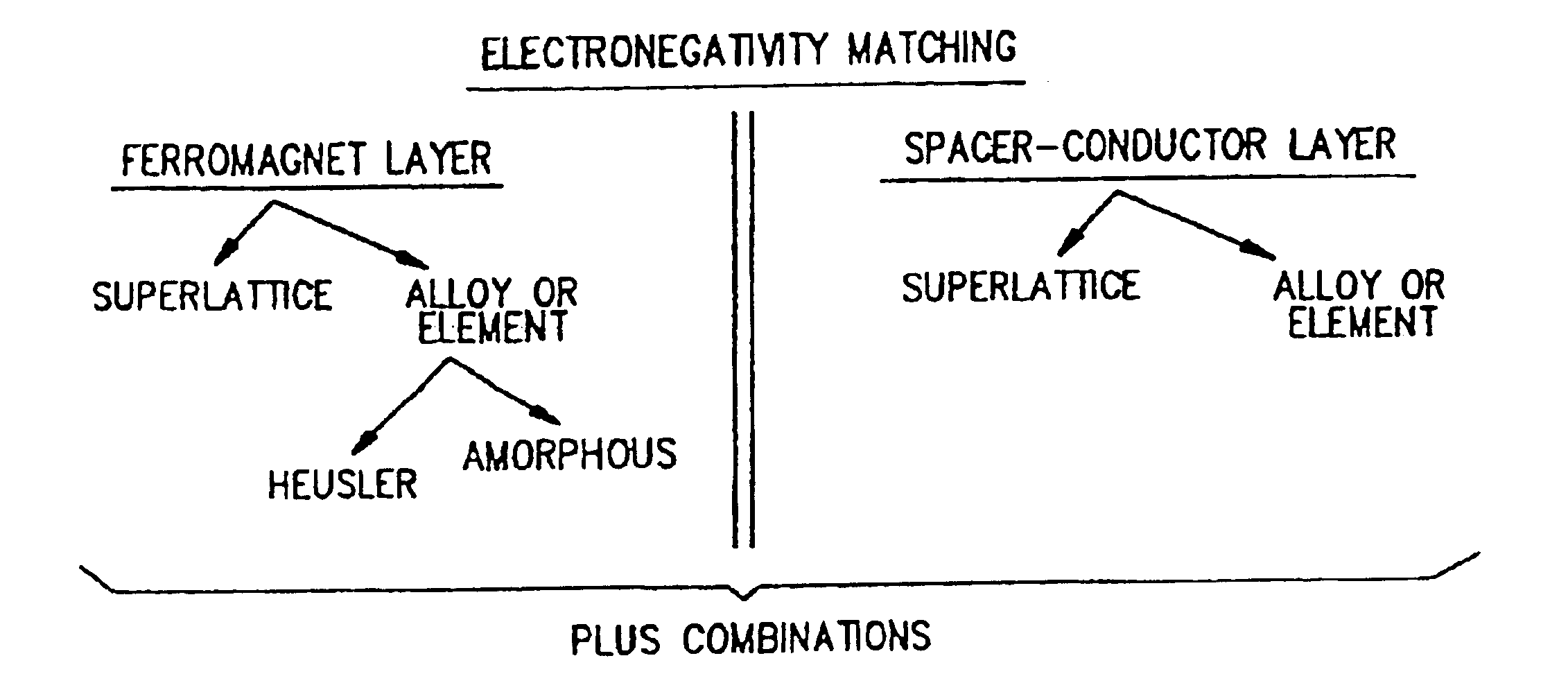

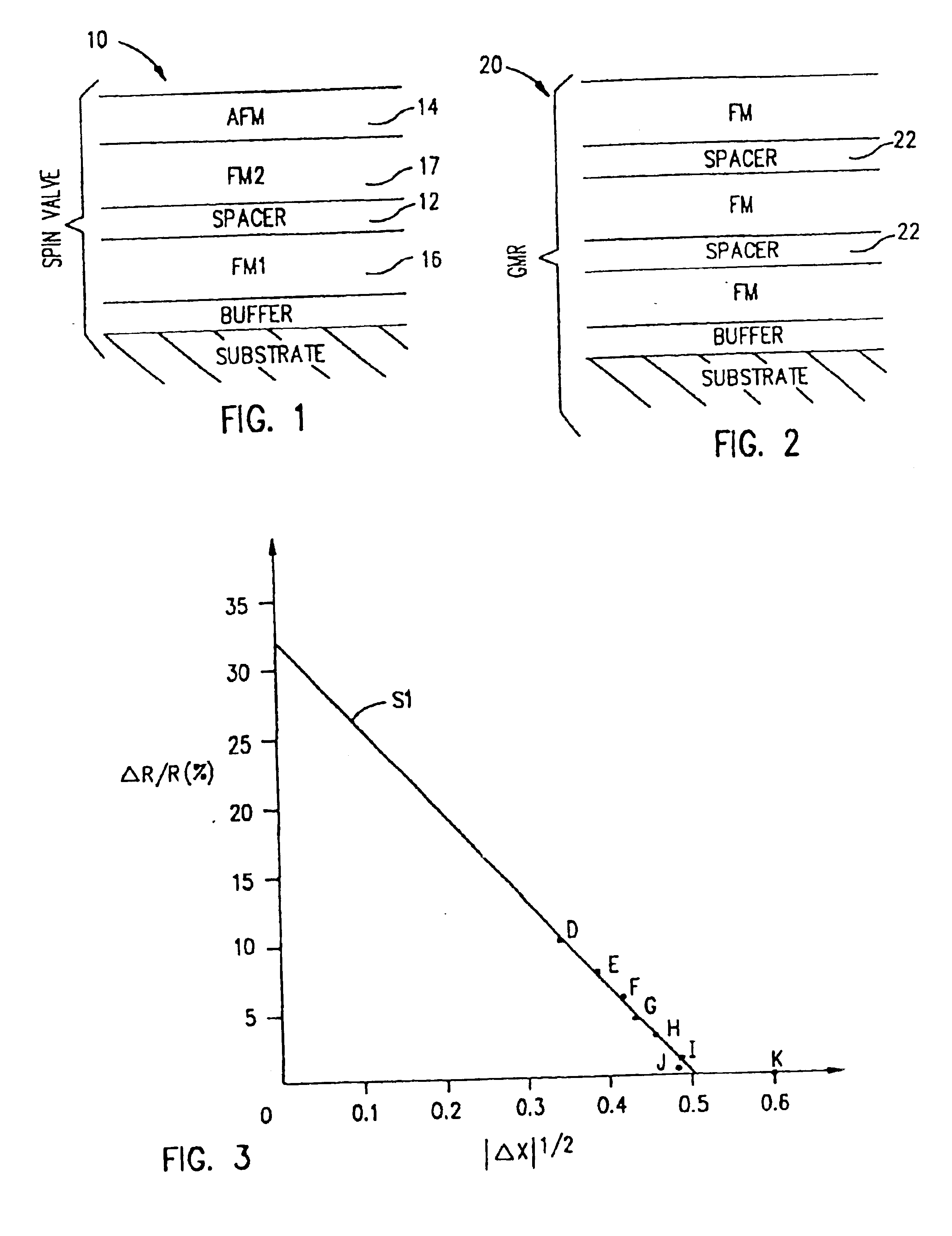

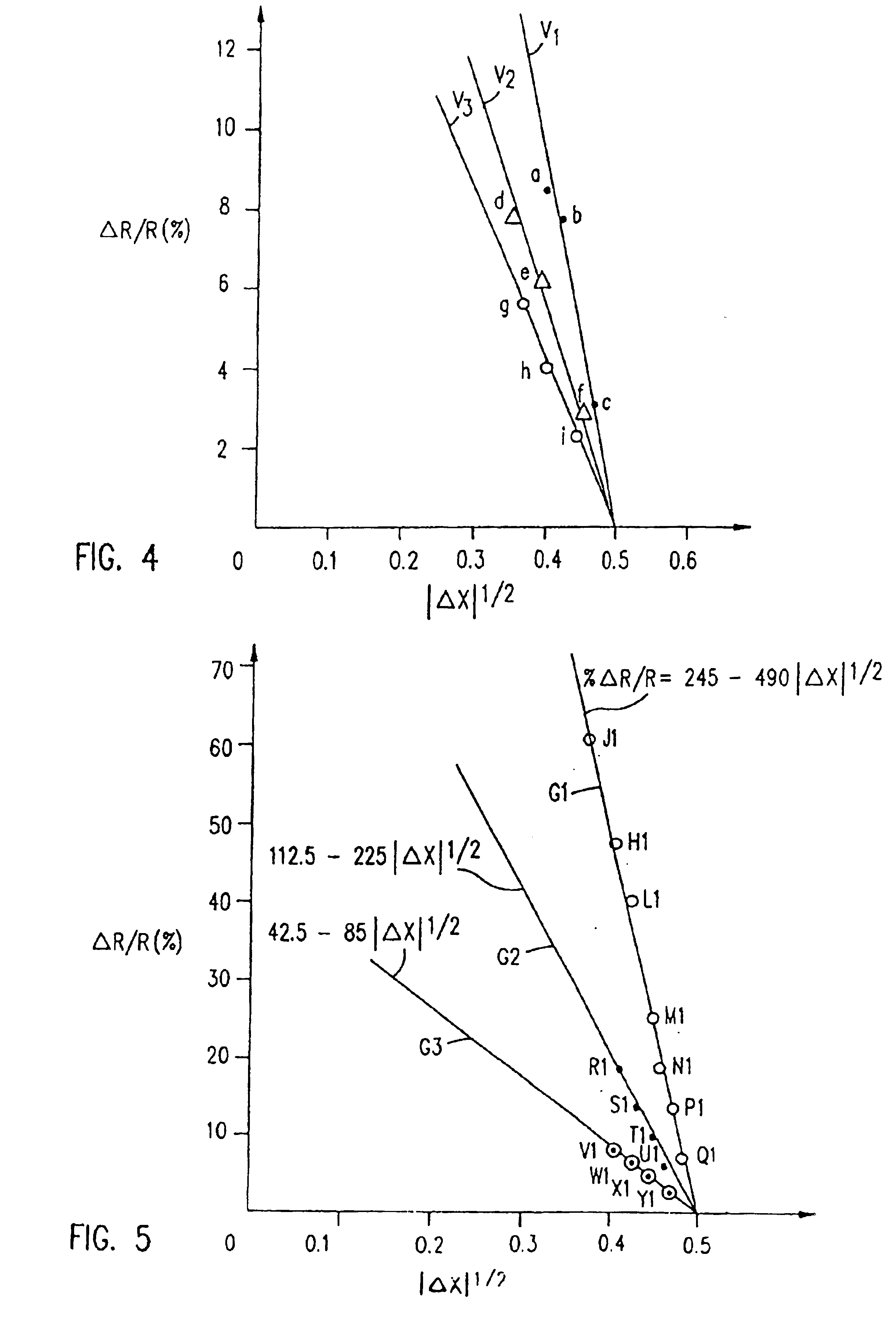

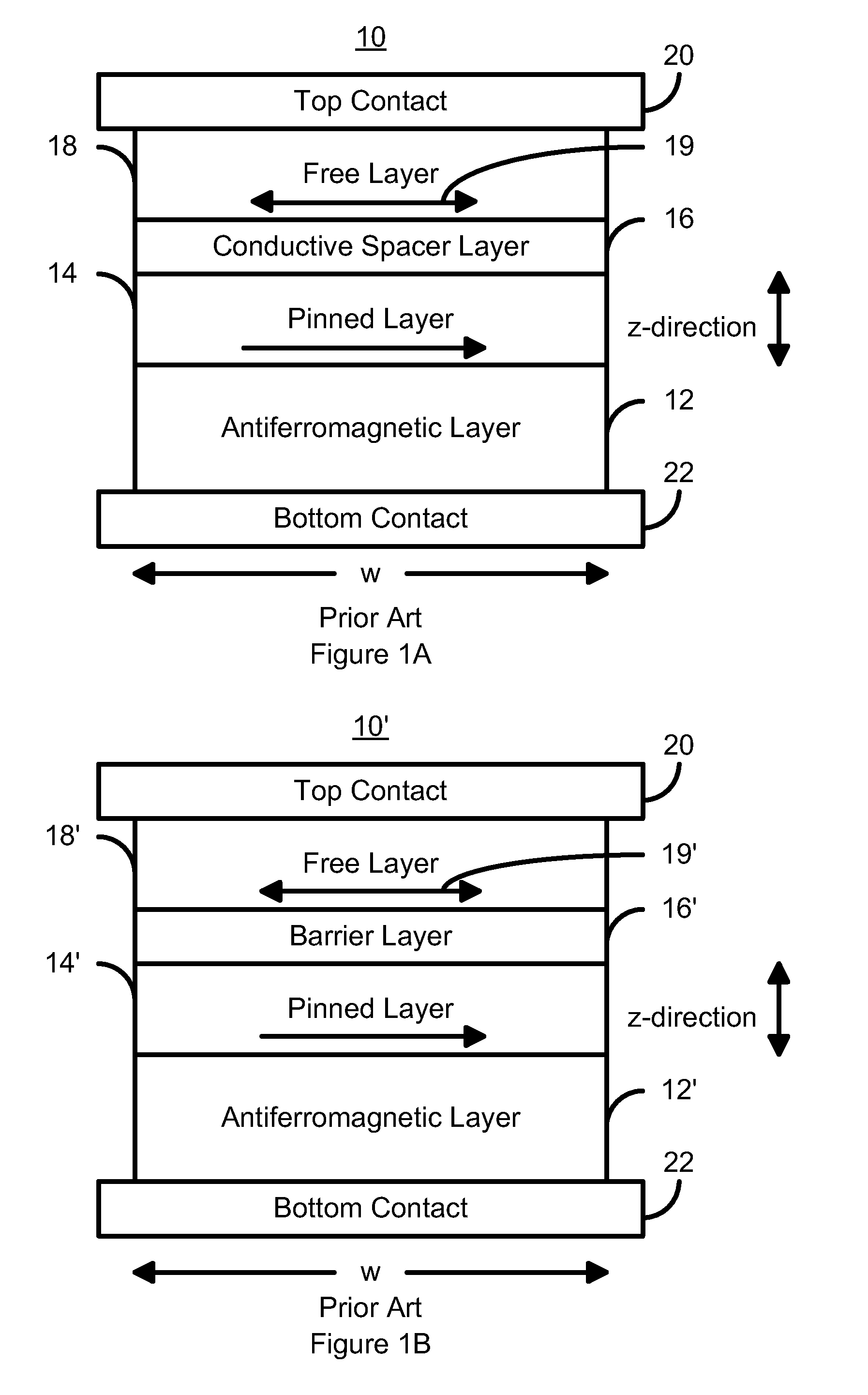

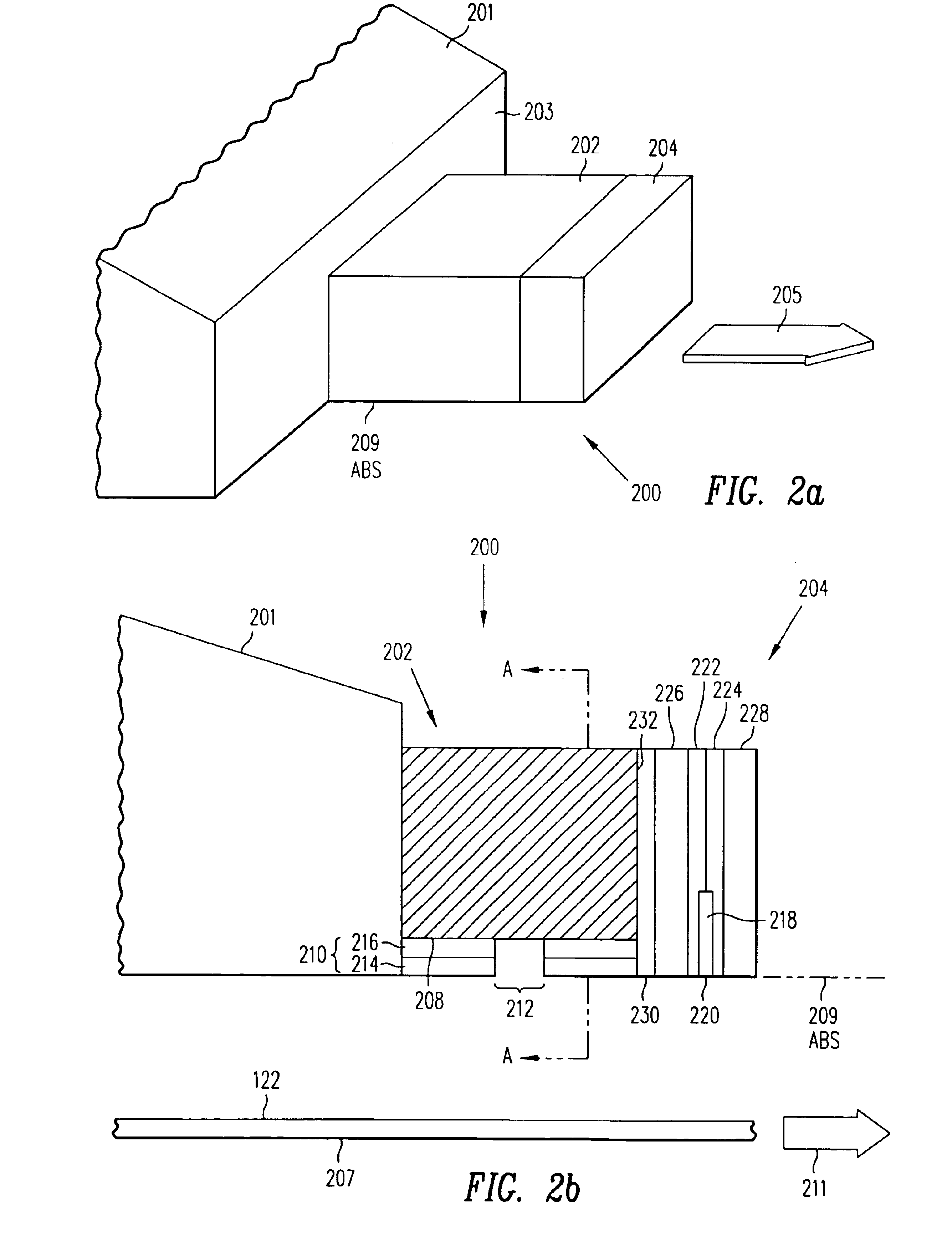

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

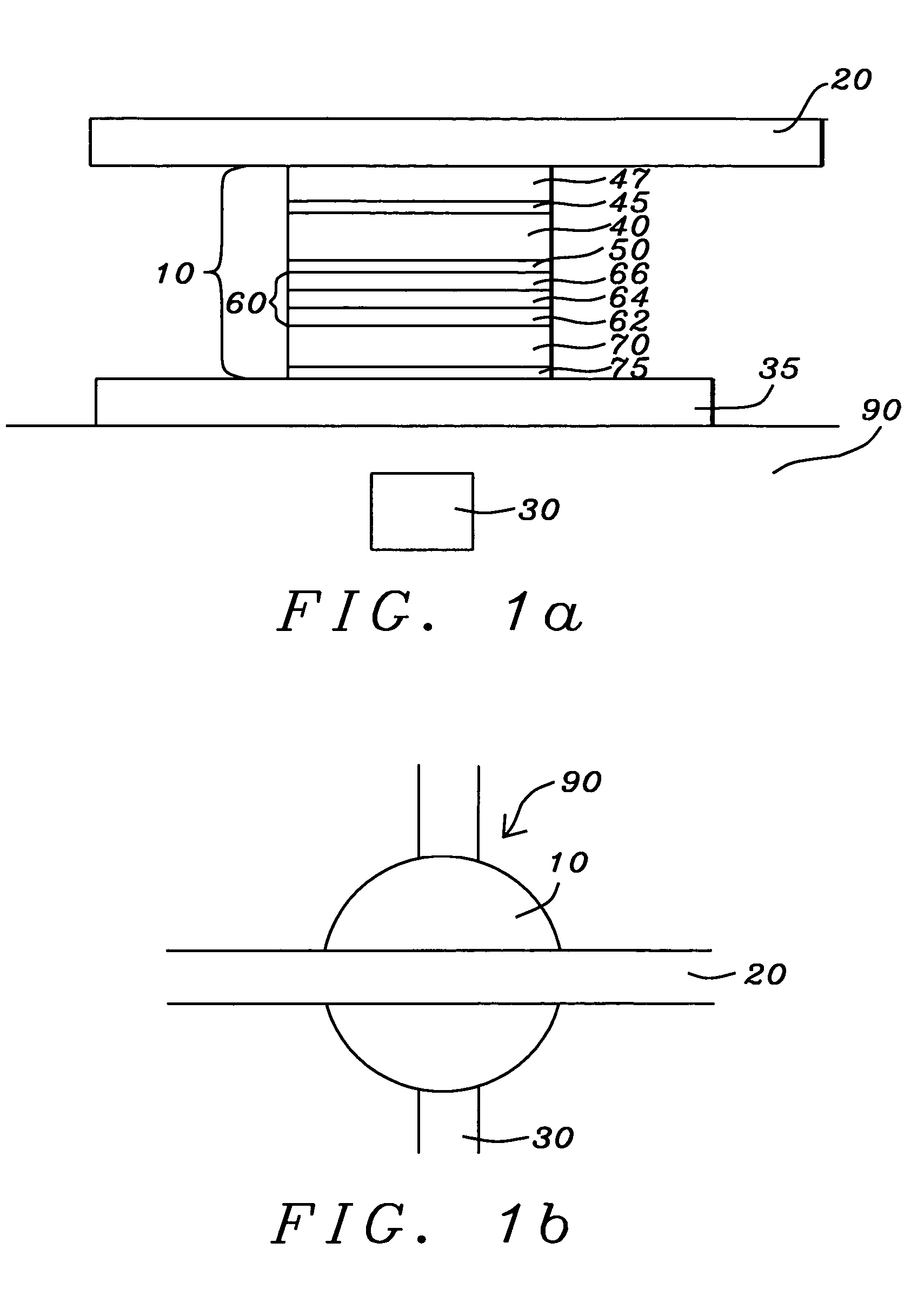

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

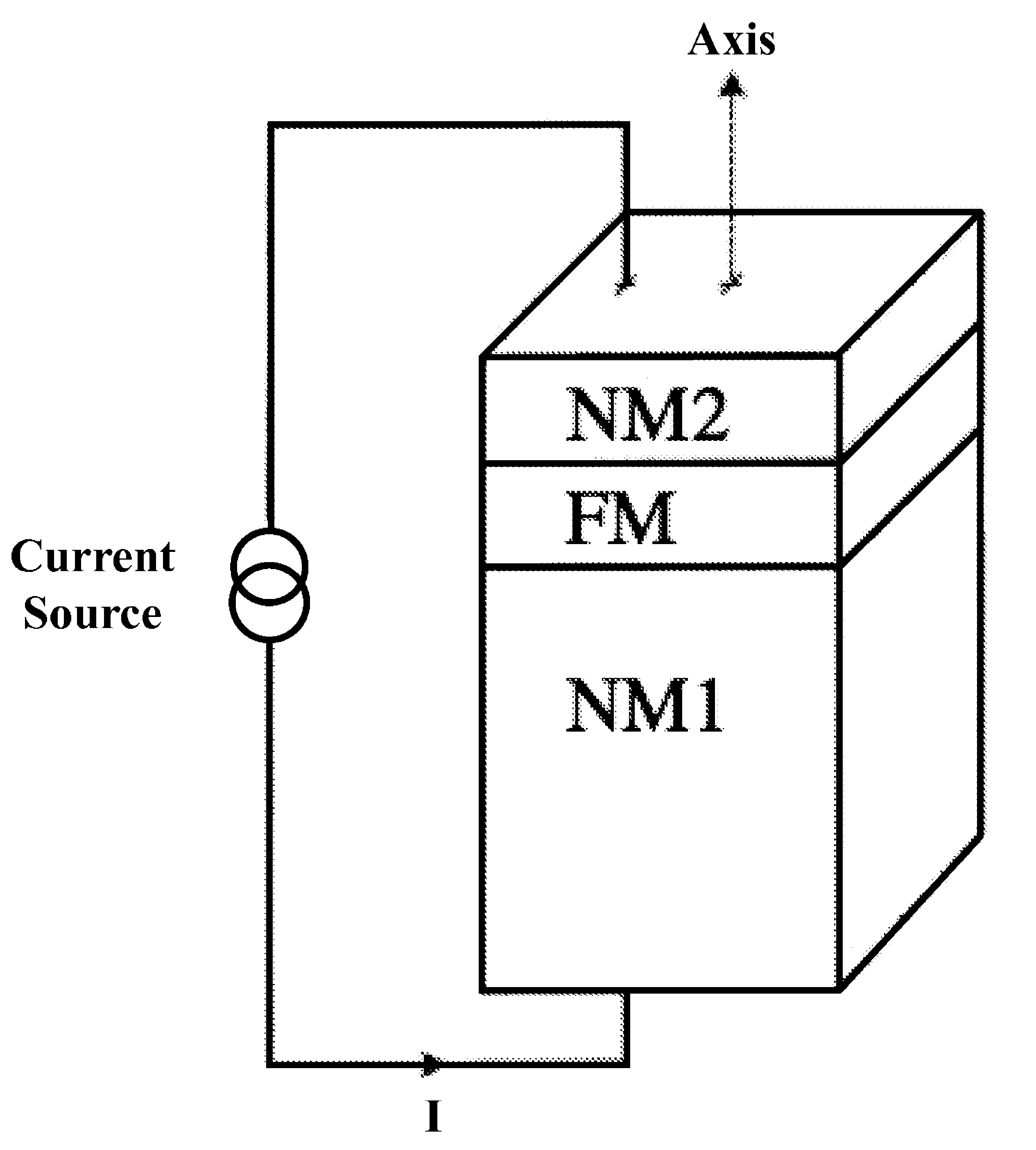

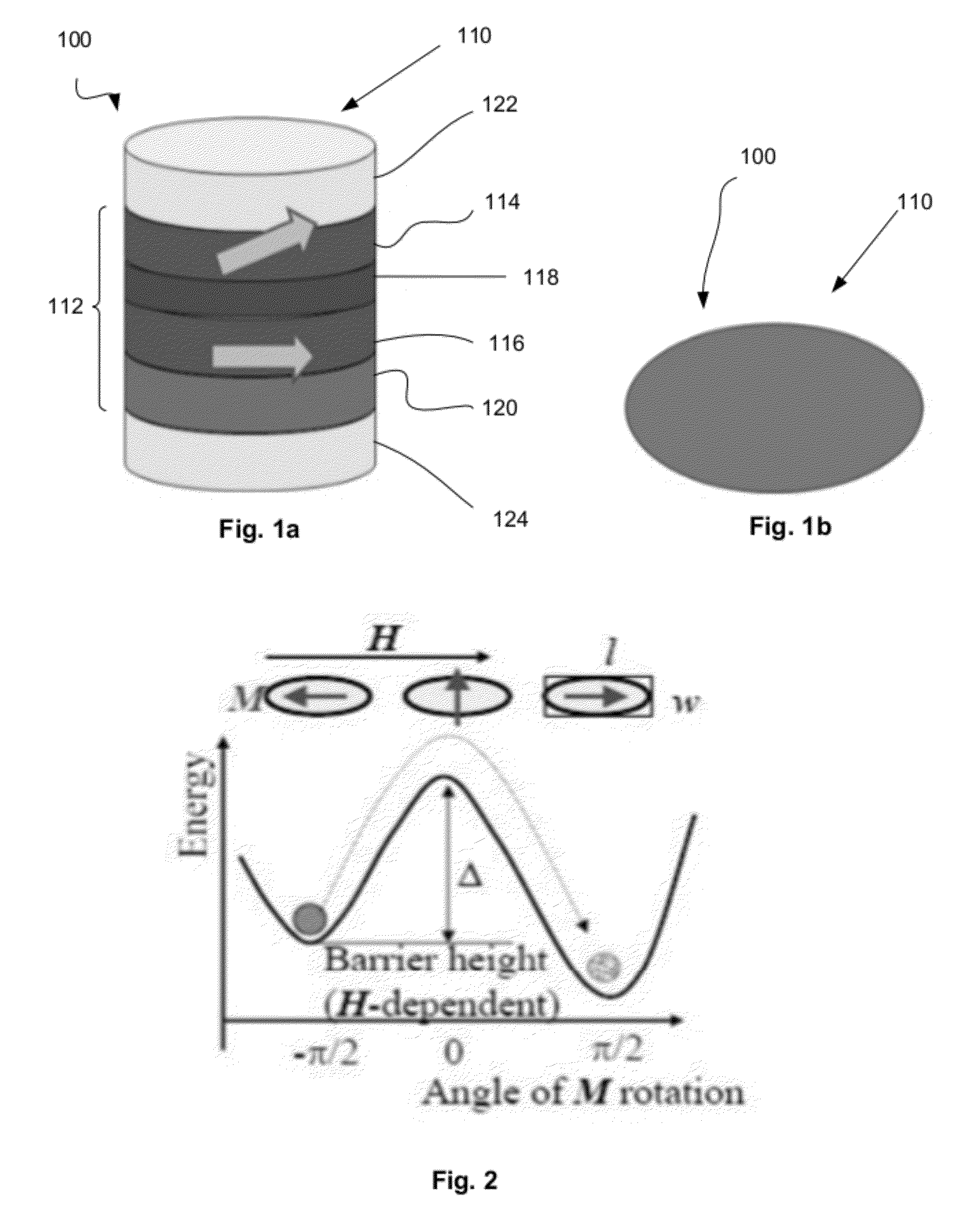

Electronic devices based on current induced magnetization dynamics in single magnetic layers

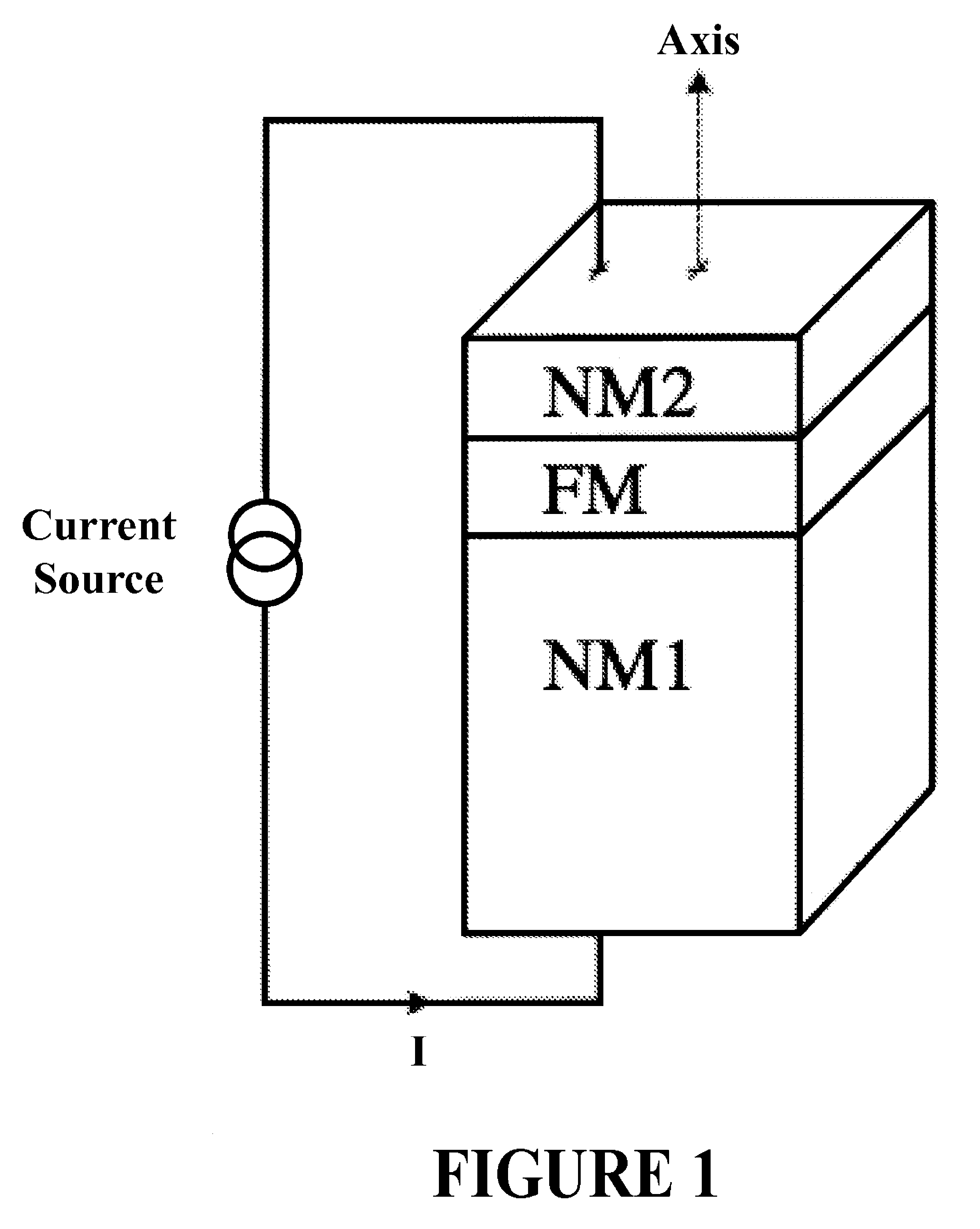

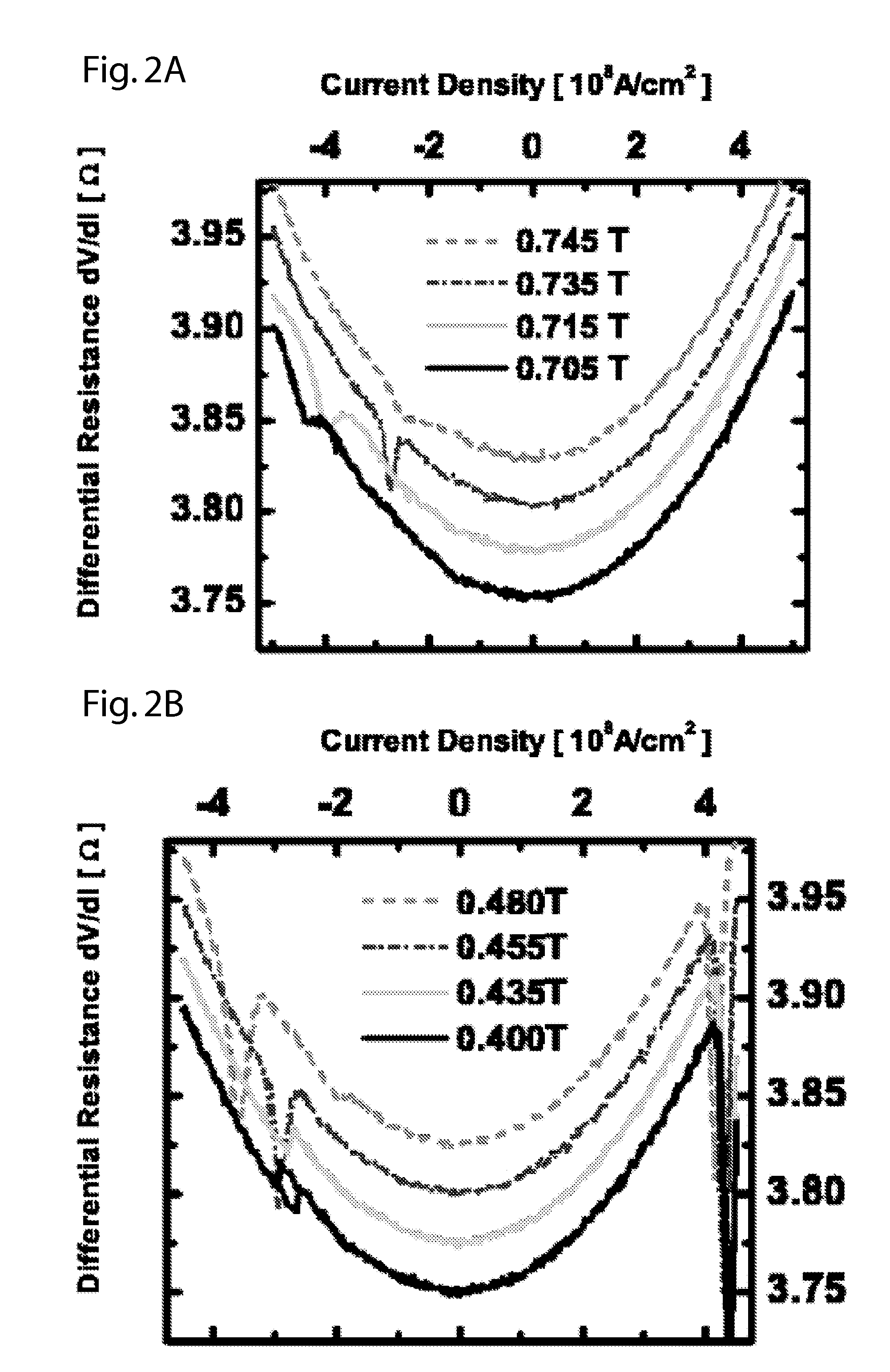

InactiveUS7986544B2Magnetic-field-controlled resistorsDigital storageInformation processingMagnetization dynamics

The present invention generally relates to magnetic devices used in memory and information processing applications, such as giant magneto-resistance (GMR) devices and tunneling magneto-resistance devices. More specifically, the present invention is directed to a single ferromagnetic layer device in which an electrical current is used to control and change magnetic configurations as well as induce high frequency magnetization dynamics. The magnetic layer includes full spin-polarized magnetic material, which may also have non-uniform magnetization. The non-uniform magnetization is achieved by varying the shape or roughness of the magnetic material. The present invention may be used in memory cells, as well as high frequency electronics, such as compact microwave sources, detectors, mixers and phase shifters.

Owner:NEW YORK UNIV

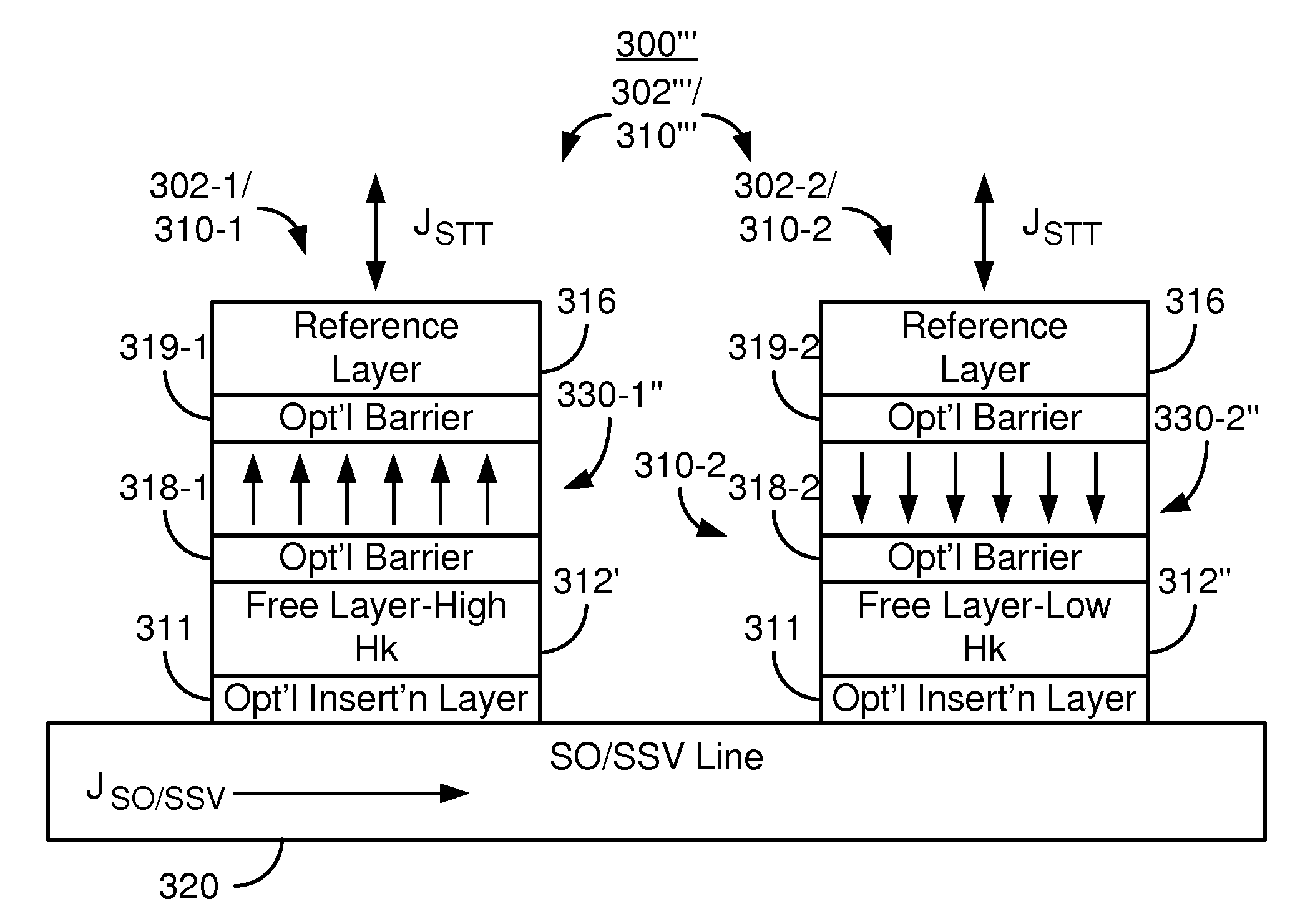

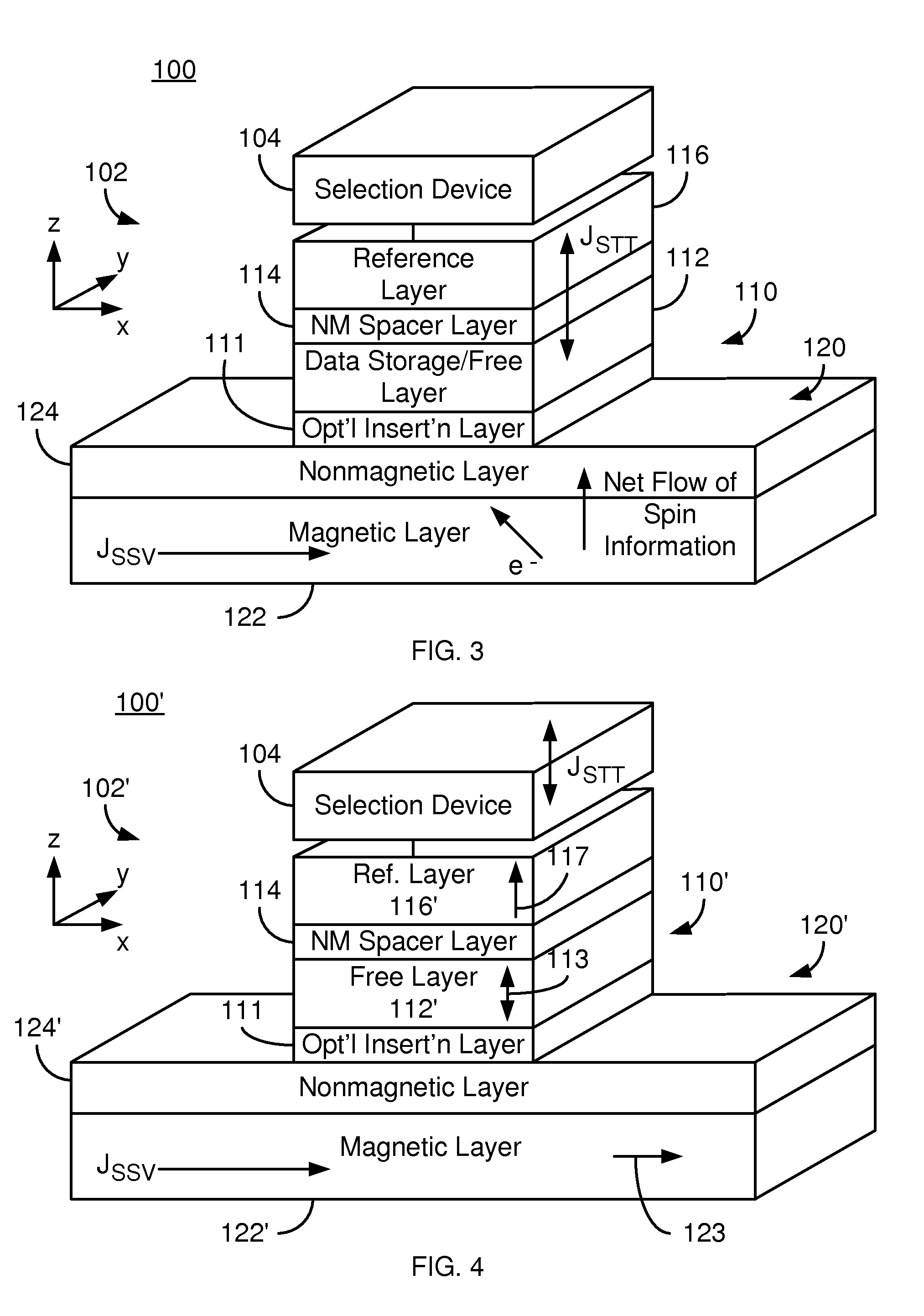

Method and system for providing magnetic memories switchable using spin accumulation and selectable using magnetoelectric devices

A magnetic memory is described. In one aspect, the magnetic memory includes magnetic junctions and at least one semi-spin valve (SSV) line adjacent to the magnetic junctions. Each magnetic junction includes a magnetic free layer. The SSV line(s) include a ferromagnetic layer and a nonmagnetic layer between the ferromagnetic layer and the magnetic junctions. The SSV line(s) are configured to exert a spin accumulation induced torque on at least a portion of the magnetic junctions due to an accumulation of spin polarized current carriers from a current that is substantially in-plane. The free layer is configured to be written using at least the spin accumulation induced torque. In another aspect, the magnetic memory includes magnetic memory cells and at least one spin torque (ST) line that is analogous to the SSV line. Each magnetic memory cell includes magnetic junction(s) analogous to those above and magnetoelectric selection device(s).

Owner:SAMSUNG ELECTRONICS CO LTD

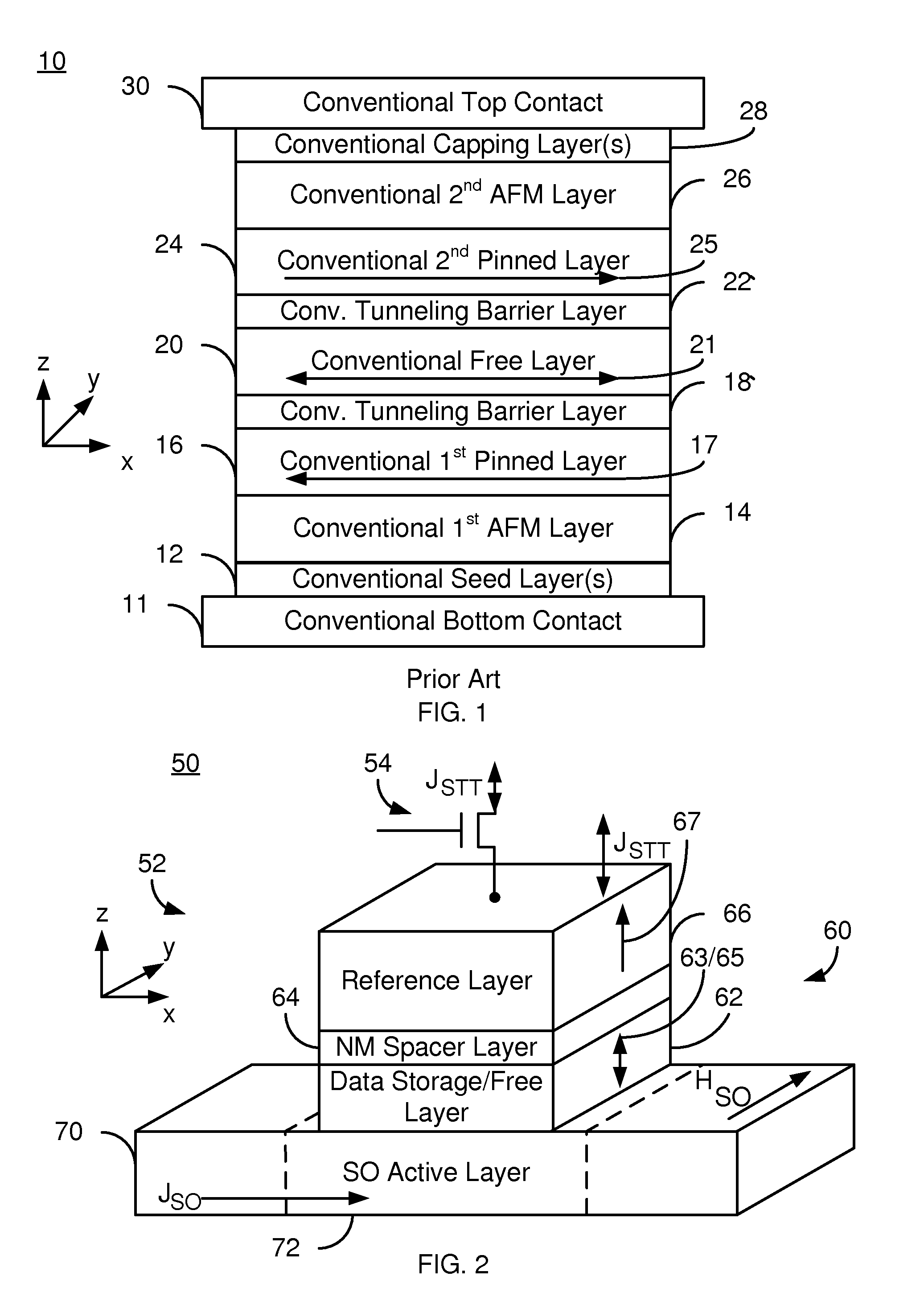

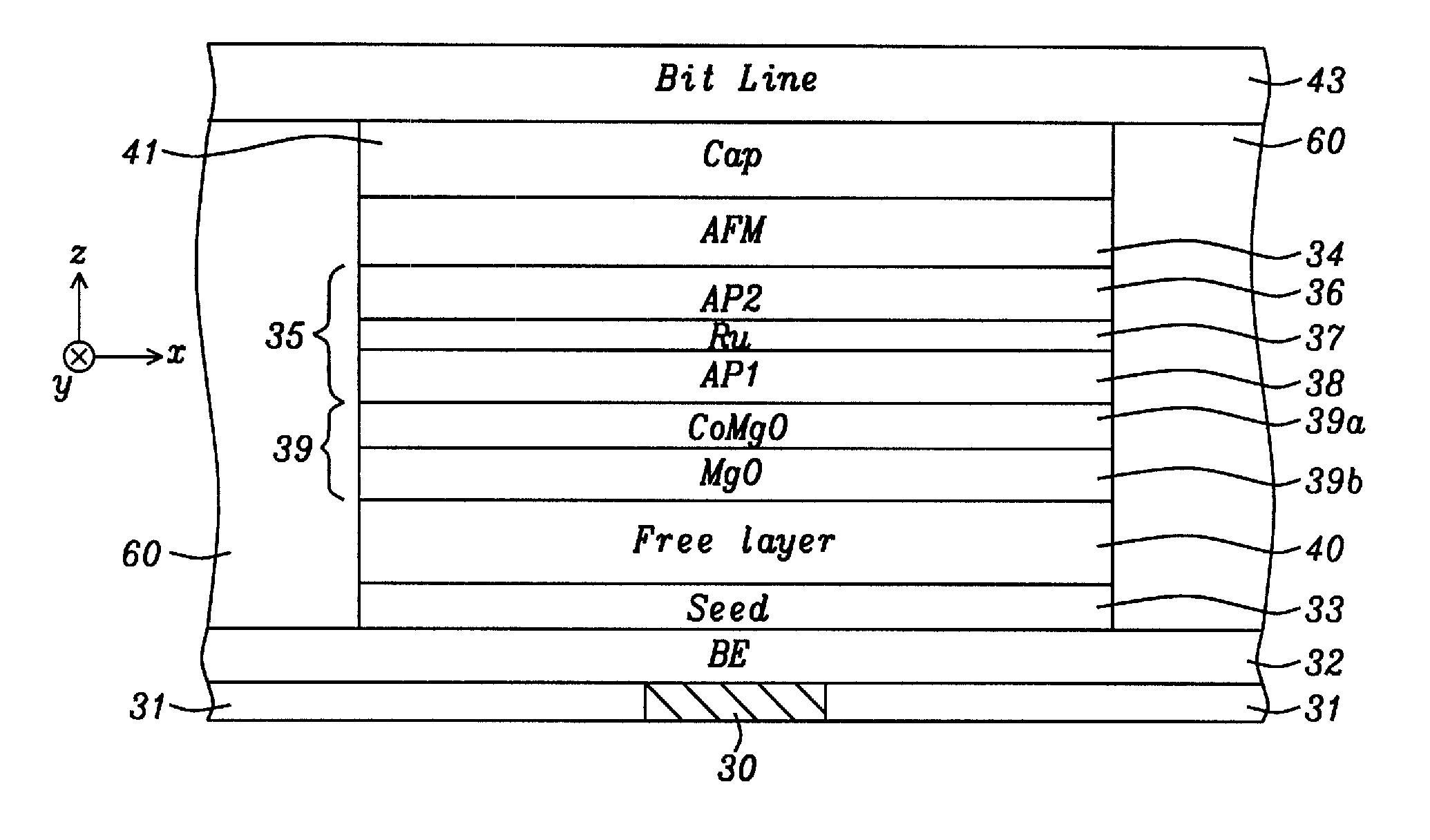

Spin torque transfer magnetic tunnel junction fabricated with a composite tunneling barrier layer

ActiveUS8823118B2Improve performanceHigh densityMagnetic-field-controlled resistorsSolid-state devicesIn planeSpins

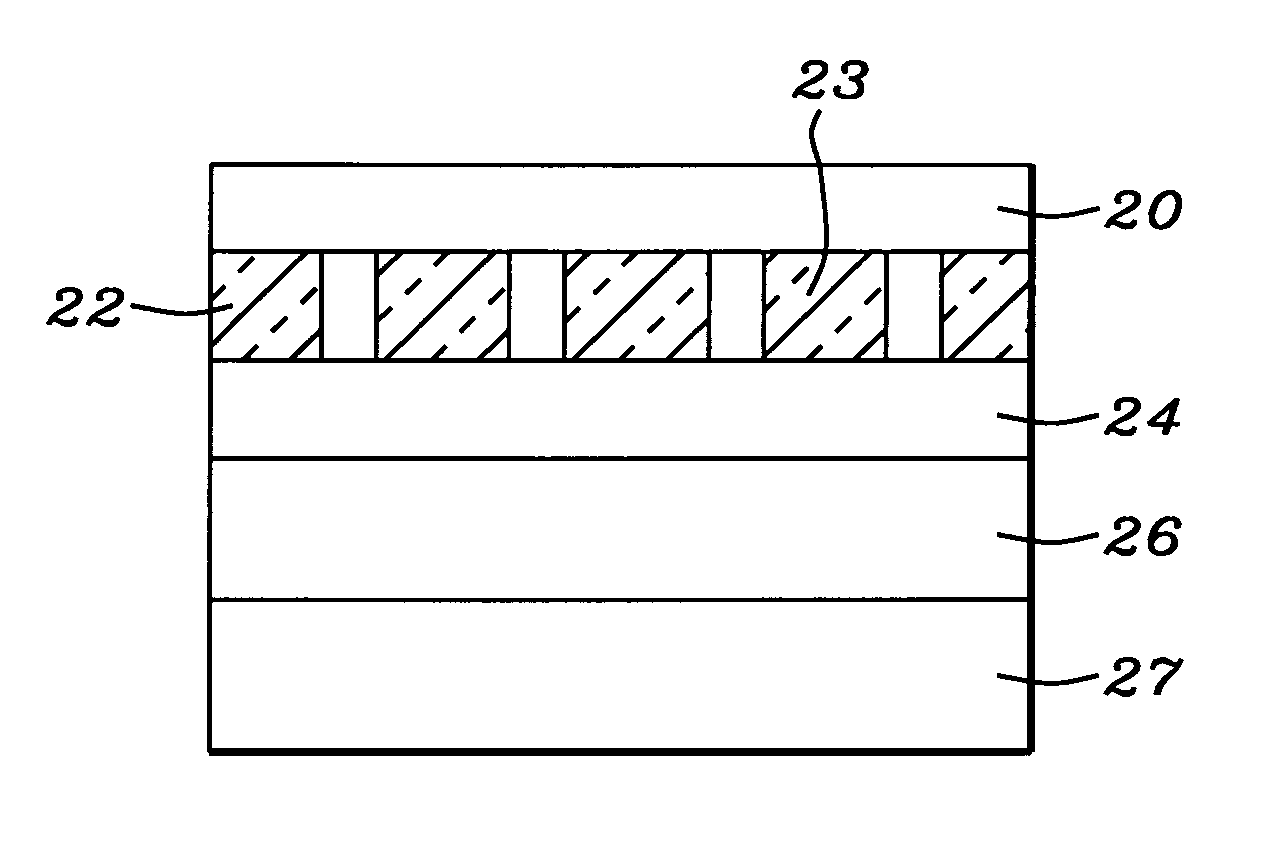

A STT-RAM MTJ is disclosed with a composite tunnel barrier comprised of a CoMgO layer that contacts a pinned layer and a MgO layer which contacts a free layer. A CoMg layer with a Co content between 20 and 40 atomic % is deposited on the pinned layer and is then oxidized to produce Co nanoconstrictions within a MgO insulator matrix. The nanoconstrictions control electromigration of Co into an adjoining MgO layer. The free layer may comprise a nanocurrent channel (NCC) layer such as FeSiO or a moment dilution layer such as Ta between two ferromagnetic layers. Furthermore, a second CoMgO layer or a CoMgO / MgO composite may serve as a perpendicular Hk enhancing layer formed between the free layer and a cap layer. One or both of the pinned layer and free layer may exhibit in-plane anisotropy or perpendicular magnetic anisotropy.

Owner:TAIWAN SEMICON MFG CO LTD

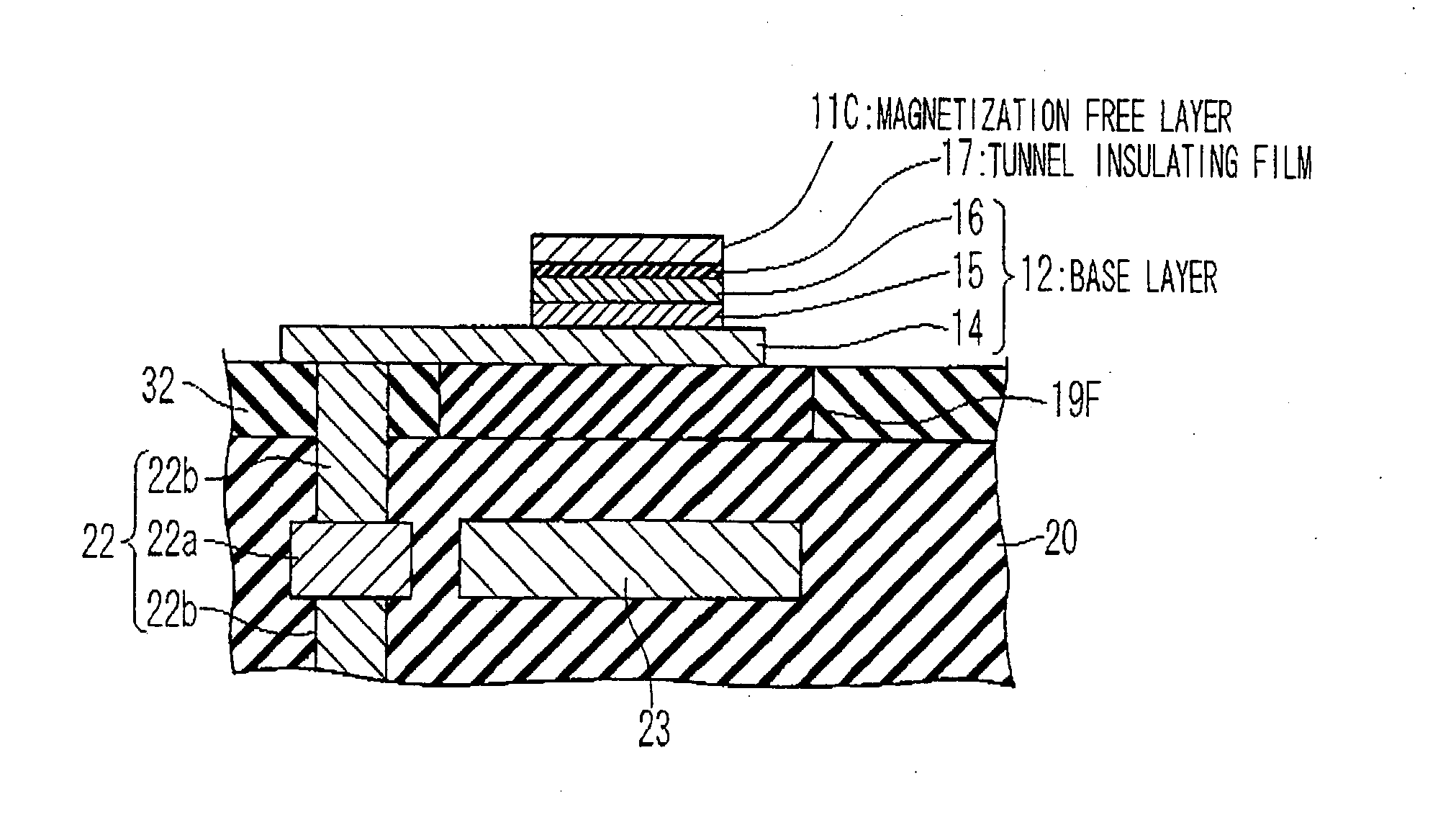

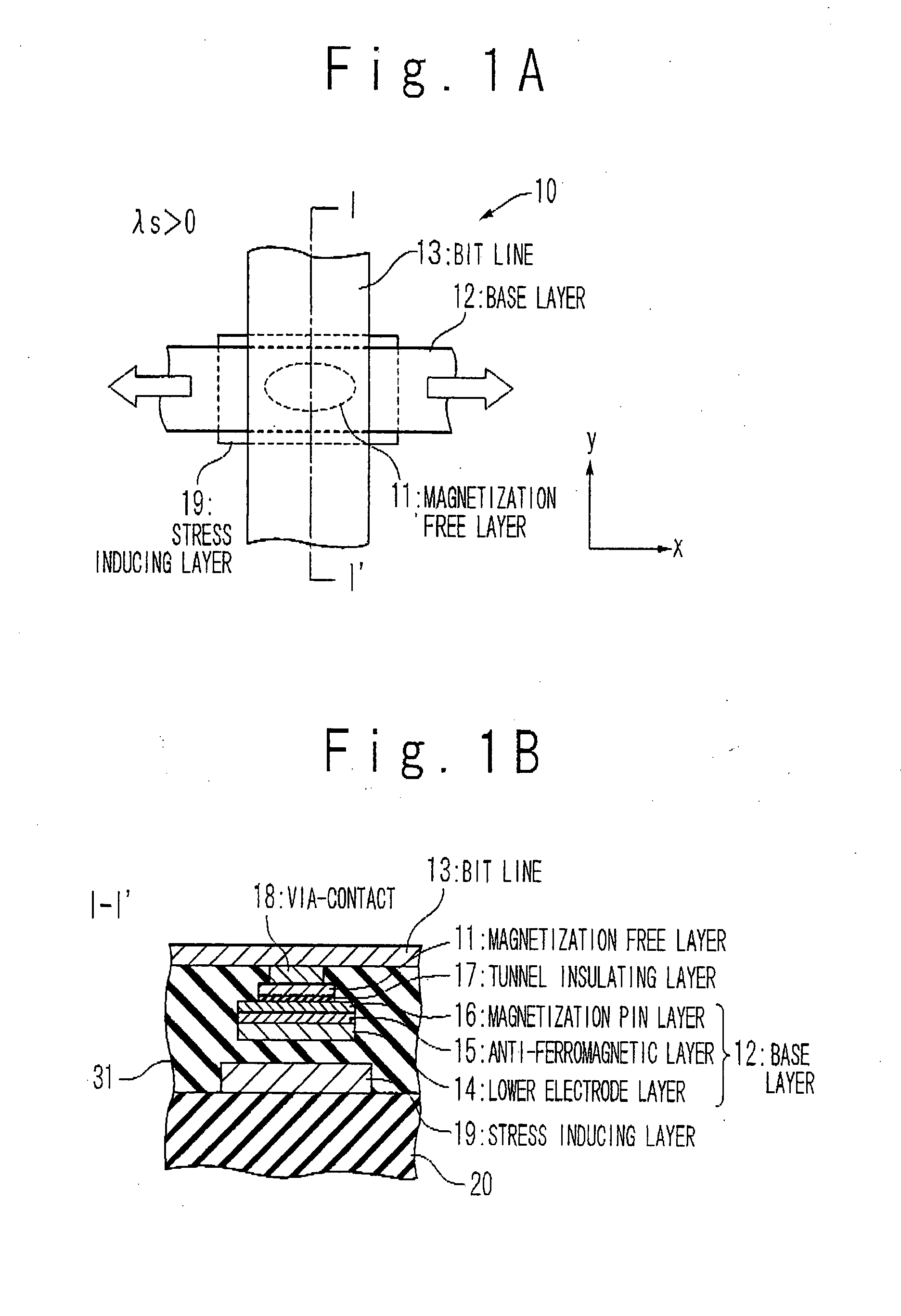

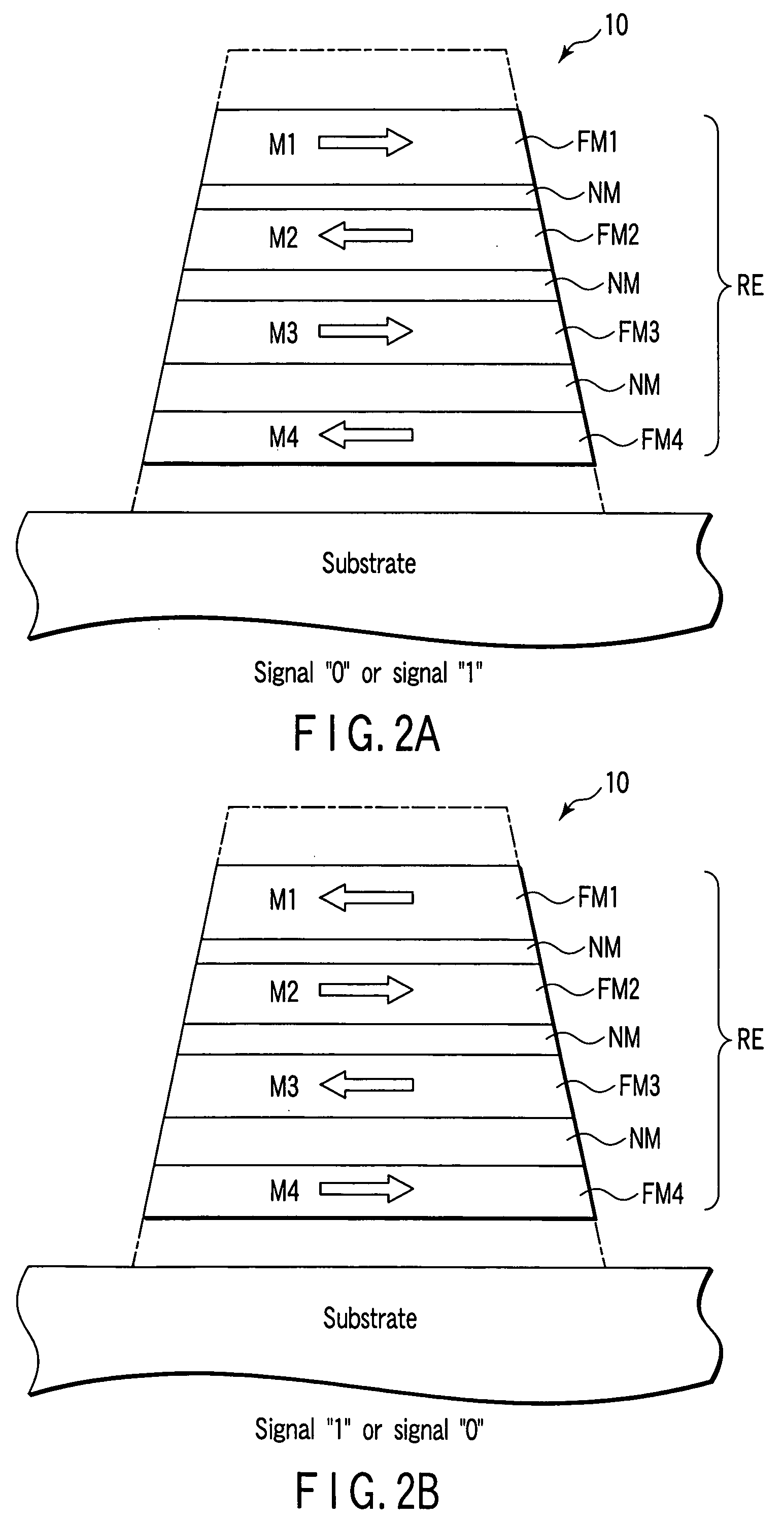

Magnetic Memory and Manufacturing Method For the Same

ActiveUS20080164502A1Suppress mutationReduce variationMagnetic-field-controlled resistorsSolid-state devicesStress inducedMagnetic anisotropy

The present invention to provide a new technique to reduce a variation in switching field of a magnetization free layer in a magnetic memory. The magnetic memory according to the present invention includes a magnetization free layer including a ferromagnetic layer having a shape magnetic anisotropy in a first direction and a magnetic strain constant is positive; and a stress inducing structure configured to apply a tensile stress to said magnetization free layer in a same direction as the first direction.

Owner:NEC CORP

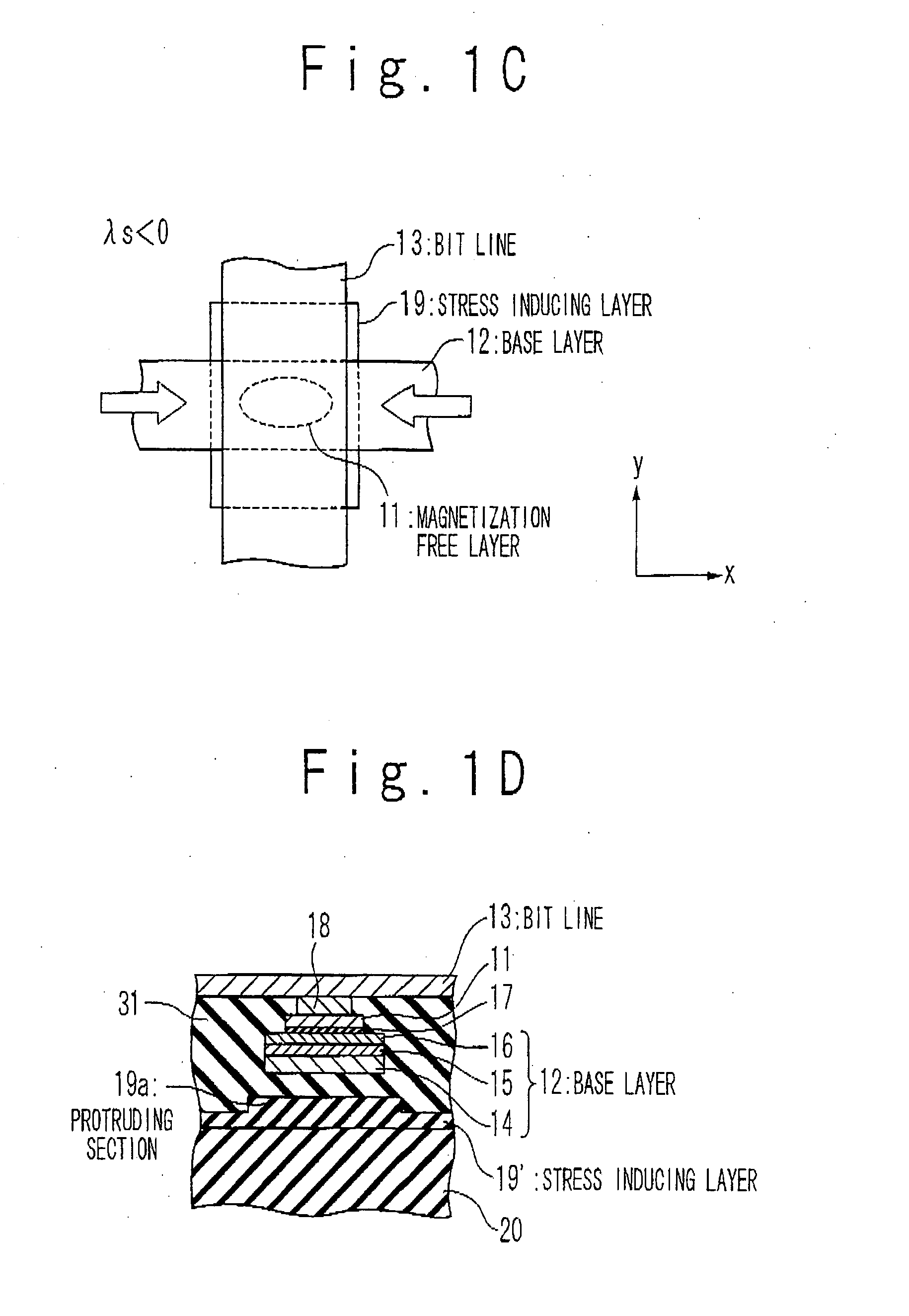

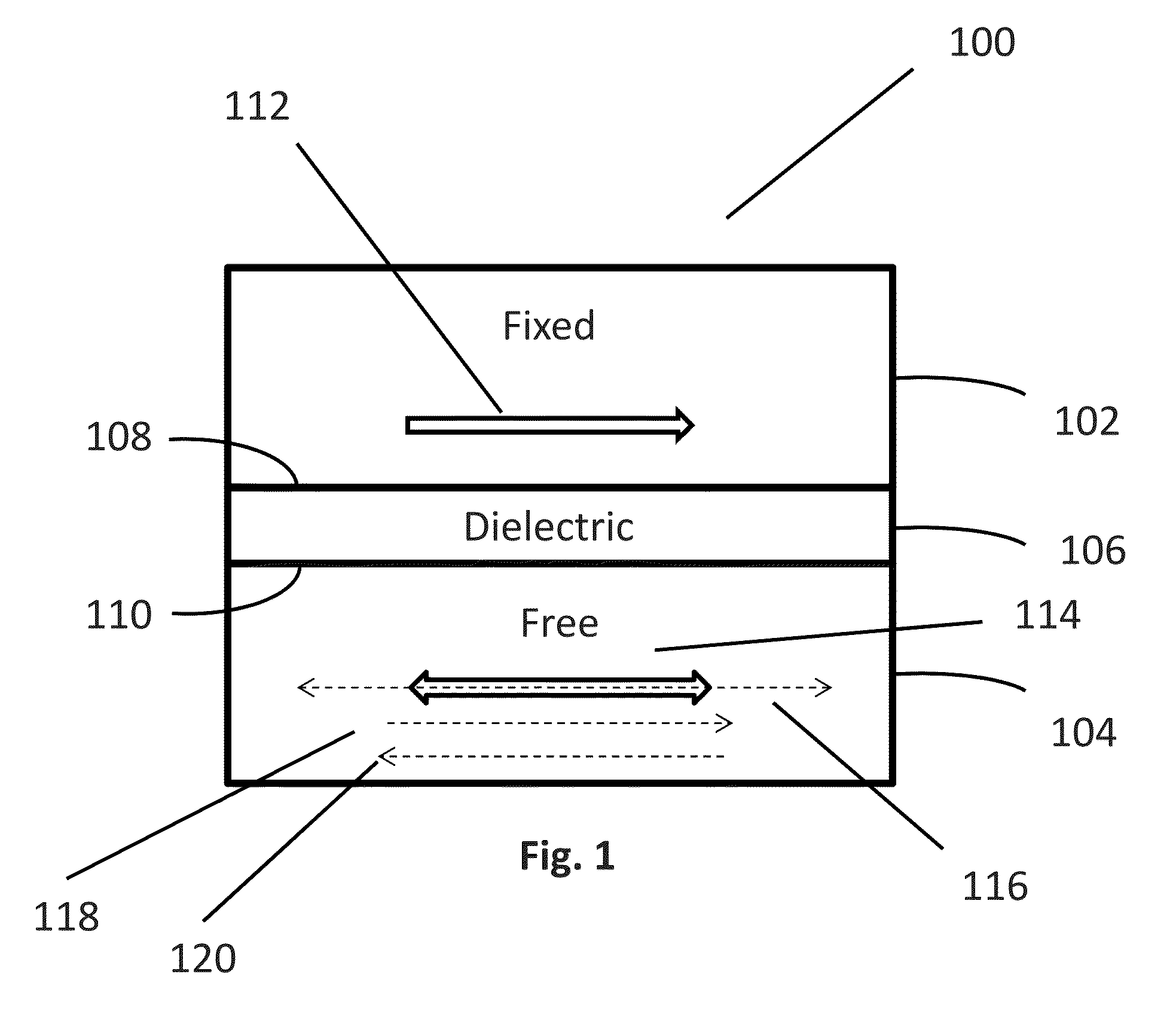

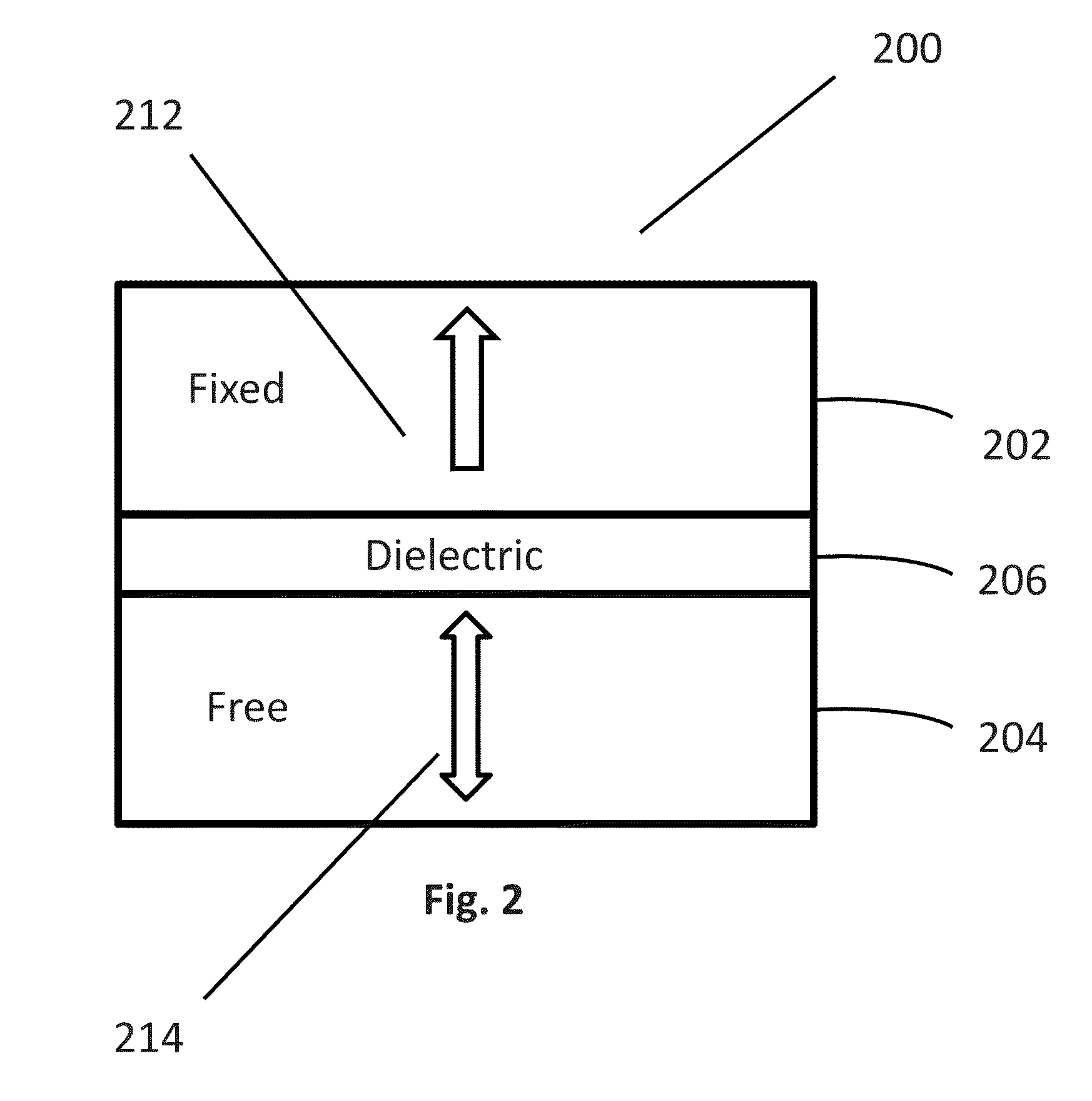

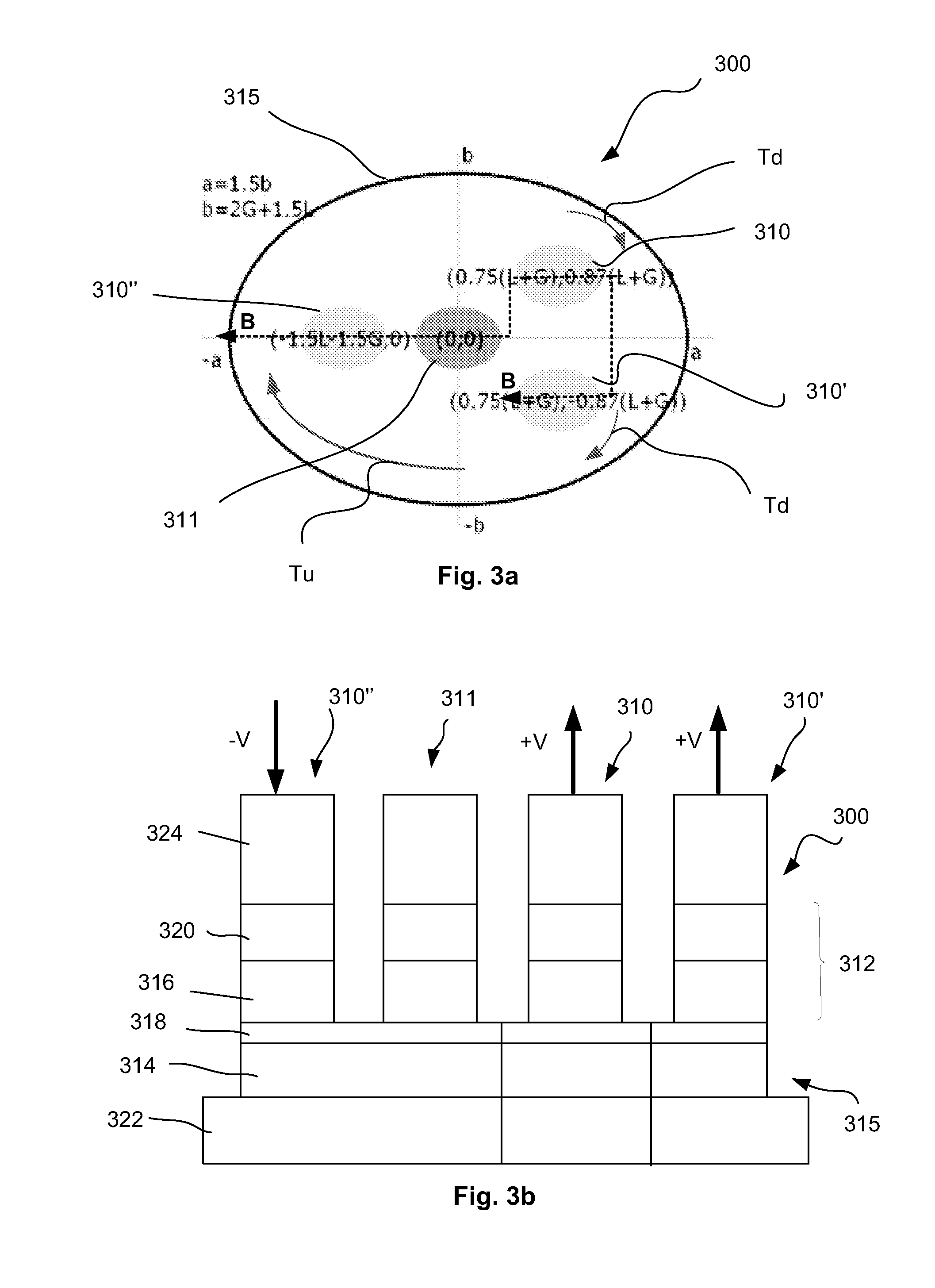

Systems and methods for implementing magnetoelectric junctions having improved read-write characteristics

ActiveUS20140124882A1Low coercivityGalvano-magnetic material selectionGalvano-magnetic device detailsMagnetic anisotropyPotential difference

Embodiments of the invention implement MEJs having improved read-write characteristics. In one embodiment, an MEJ includes: ferromagnetic fixed and free layers, a dielectric layer interposed between the ferromagnetic layers, and an additional dielectric layer proximate the free layer, where the fixed layer is magnetically polarized in a first direction, where the free layer has a first easy axis that is aligned with the first direction, and where the MEJ is configured such that when subject to a potential difference, the magnetic anisotropy of the free layer is altered such that the relative strength of the magnetic anisotropy along a second easy axis that is orthogonal to the first easy axis, compared to the strength of the magnetic anisotropy along the first easy axis, is magnified during the application of the potential difference, where the extent of the magnification is enhanced by the presence of the additional layer.

Owner:RGT UNIV OF CALIFORNIA

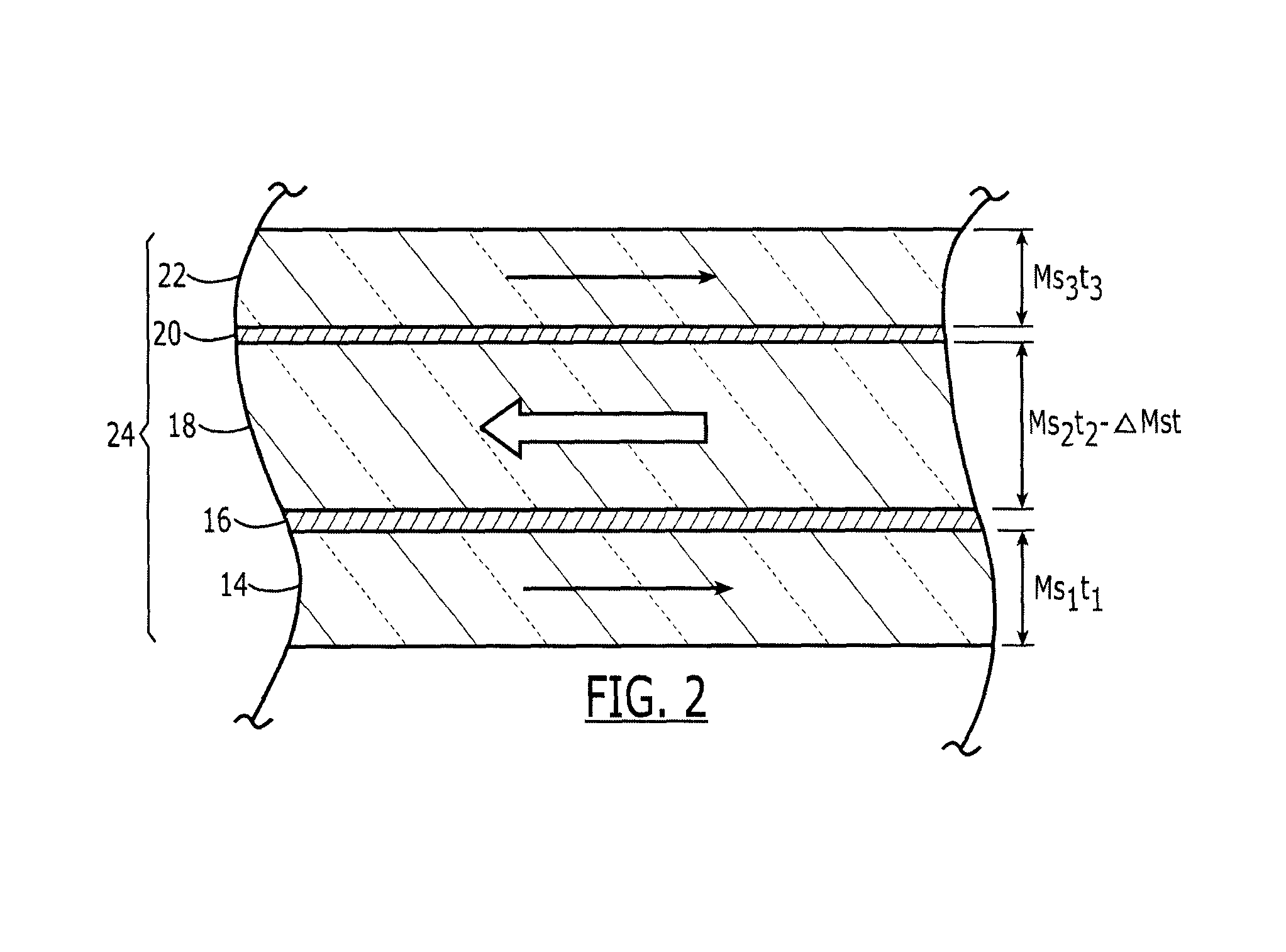

Perpendicular magnetic recording medium with single domain exchange-coupled soft magnetic underlayer and device incorporating same

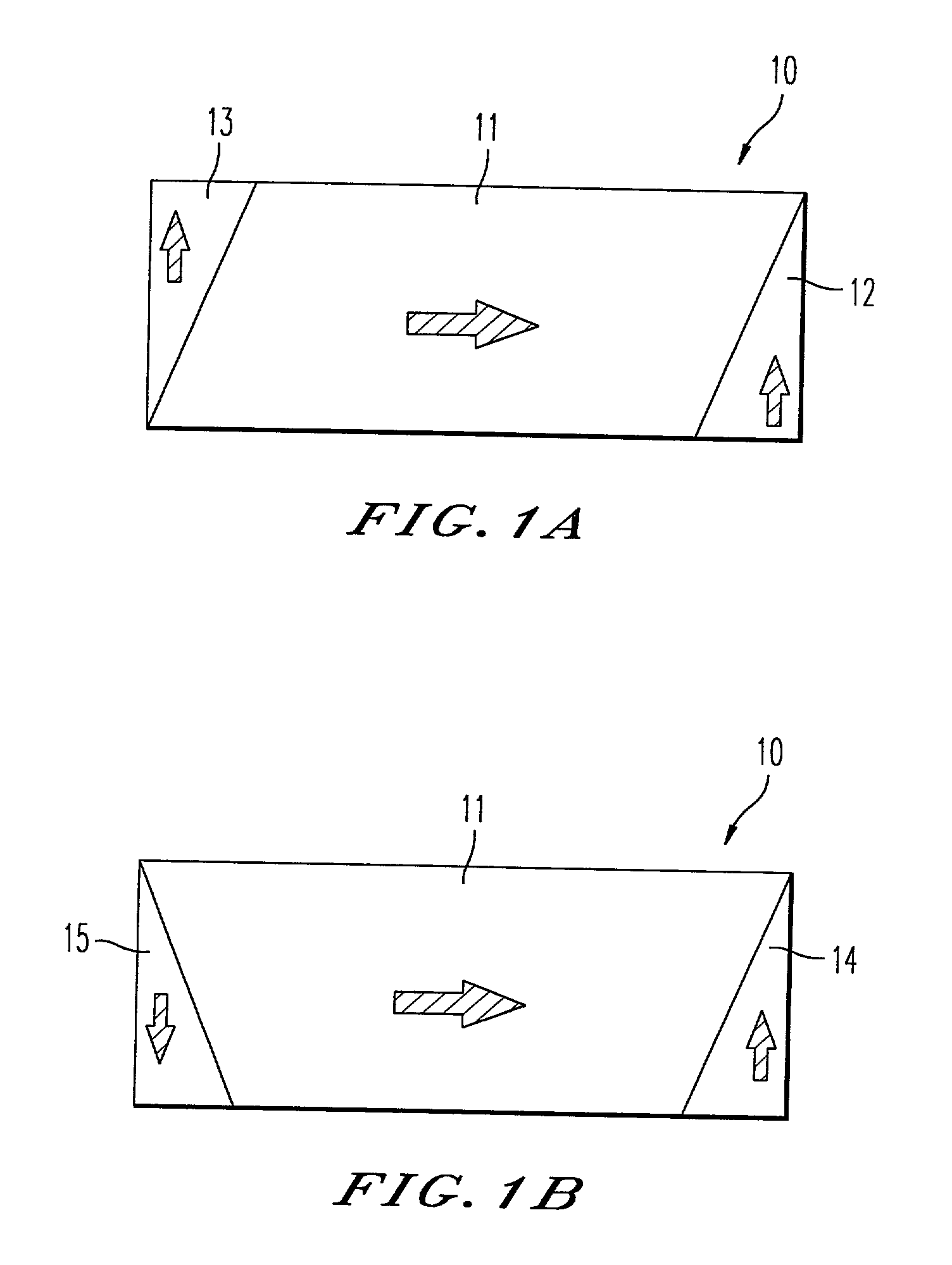

InactiveUS8597723B1Improve performanceRobustnessMagnetic field orientationRecord information storageMagnetizationRadial field

A perpendicular magnetic recording disk having a single domain exchange-coupled laminated soft magnetic underlayer (SUL) is disclosed. The SUL is a combination synthetic anti-parallel coupled SUL structure, which has the product (Mst) of saturation magnetization and film thickness of the middle ferromagnetic layer less than the sum of the Mst of the bottom and top ferromagnetic layers. Subjected to a post radial field reset process, this SUL provides single domain state. Moreover, both robustness of stray fields and low permeability are obtained while keeping excellent corrosion resistance and cost effective manufacturability.

Owner:WD MEDIA

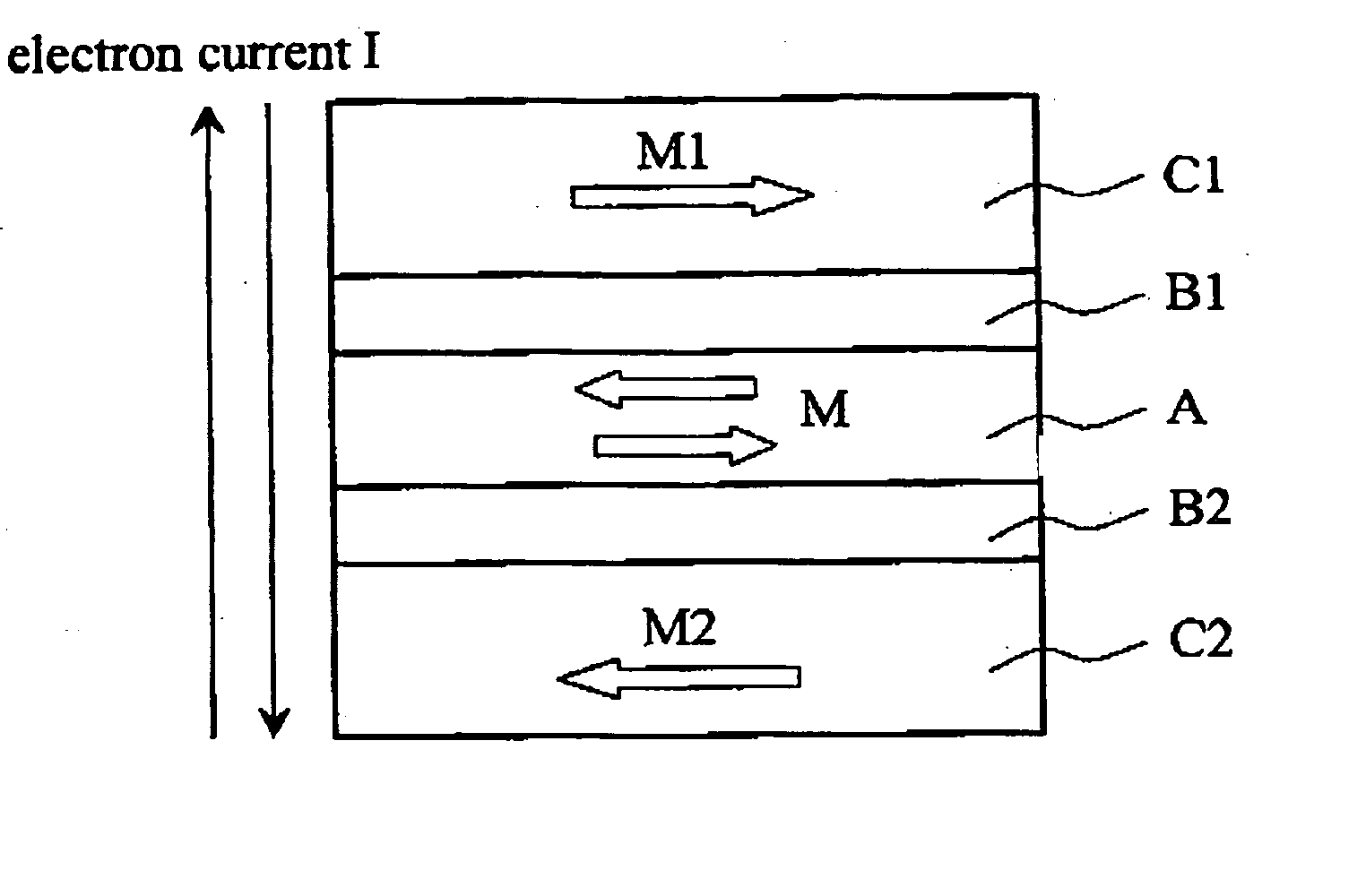

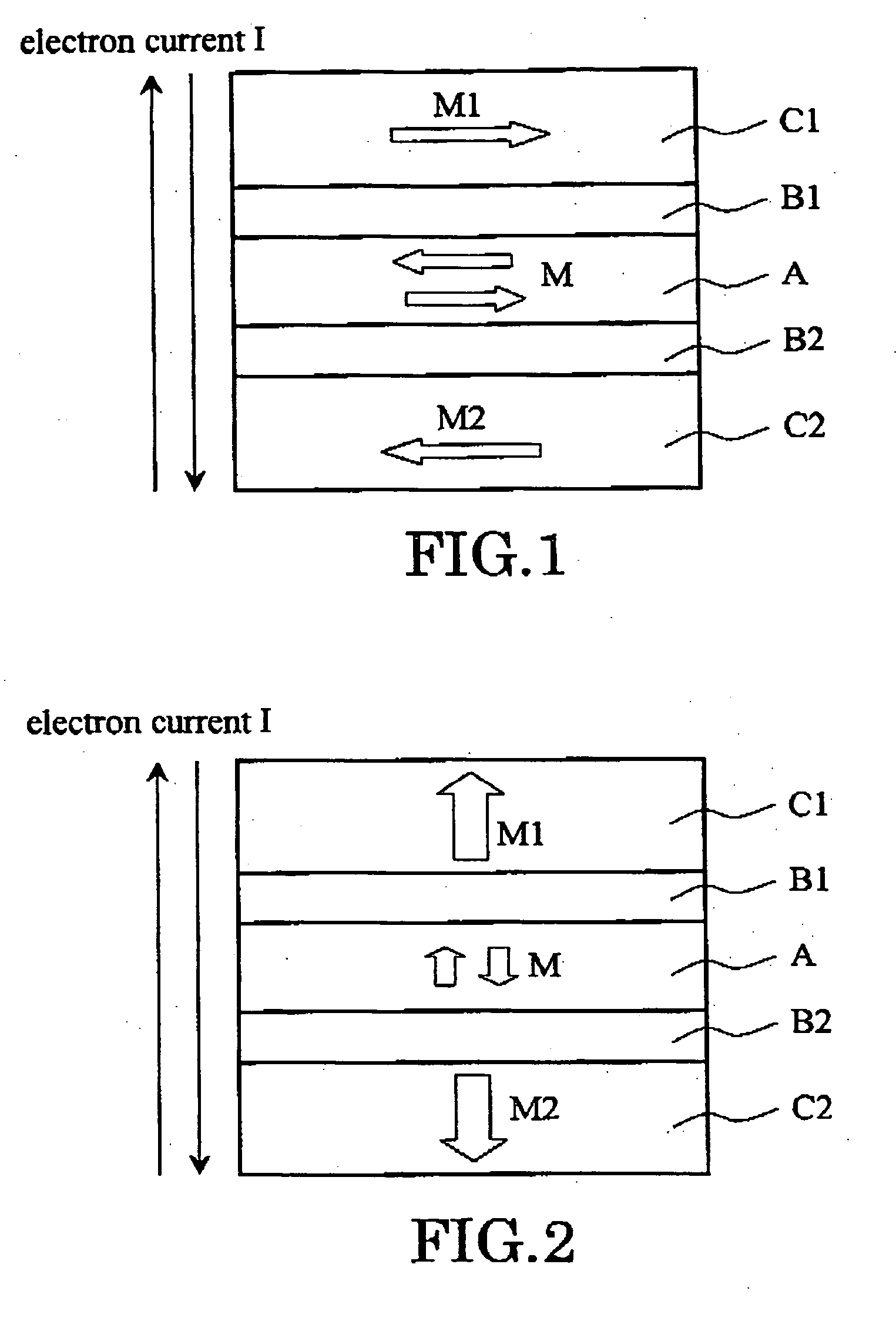

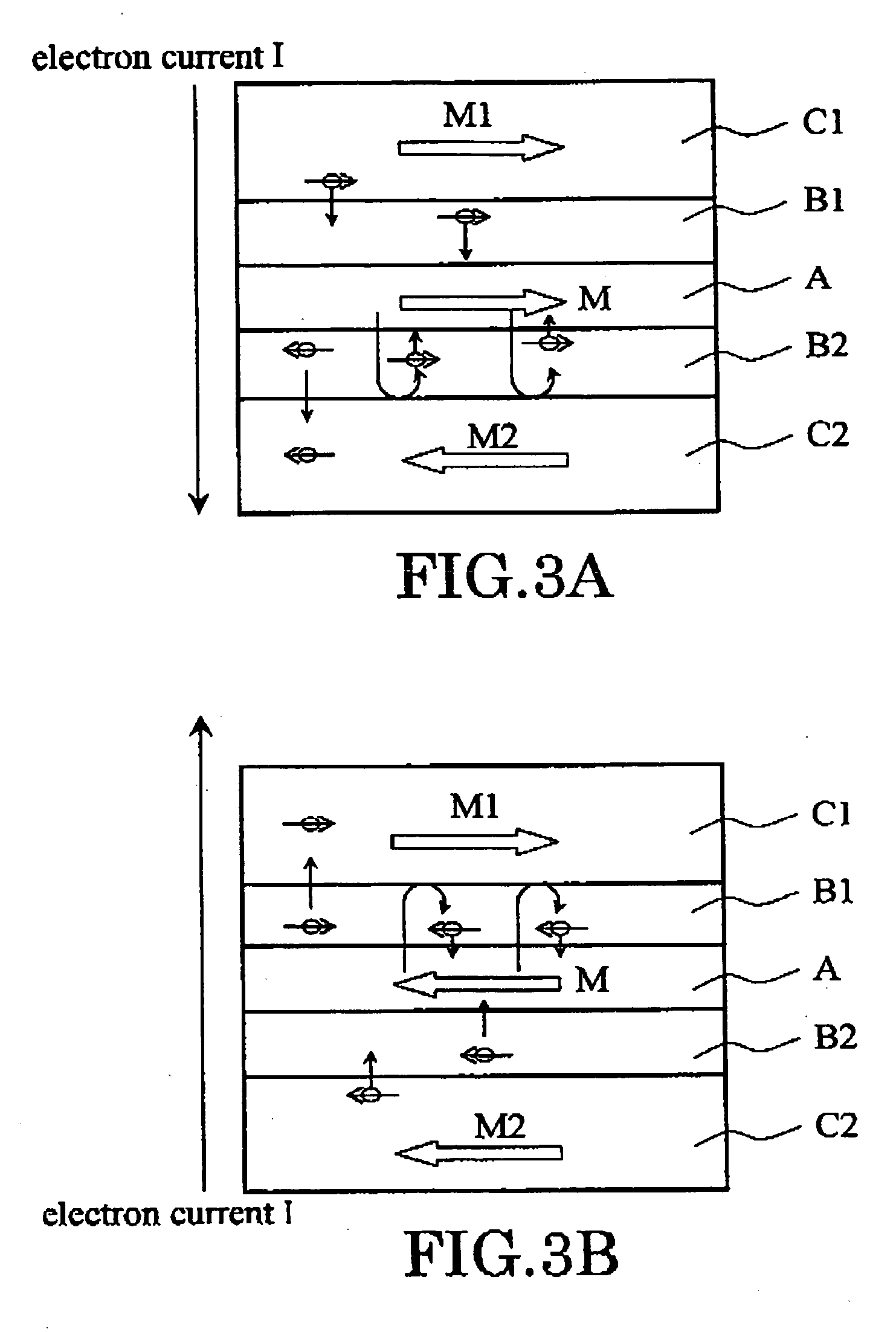

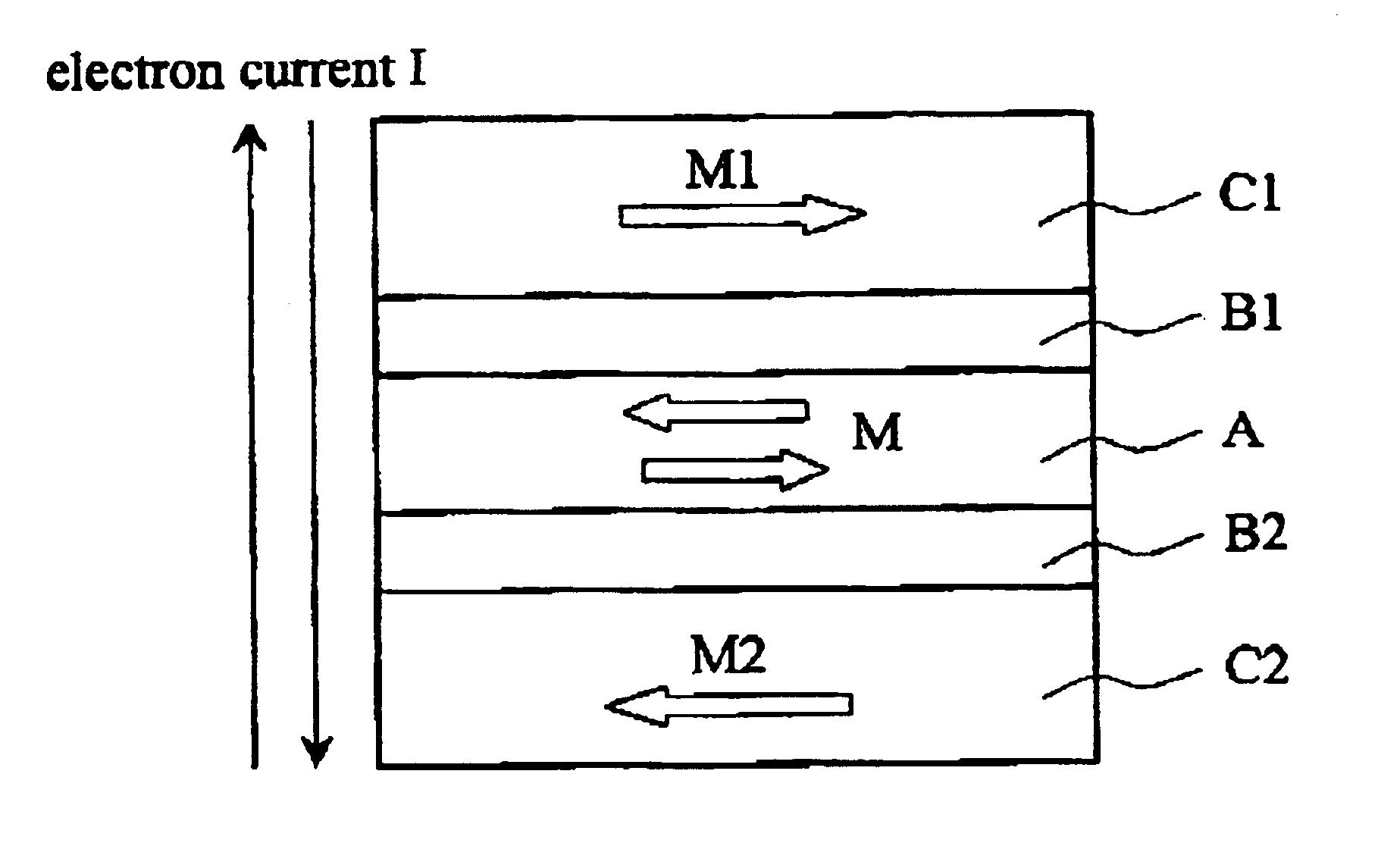

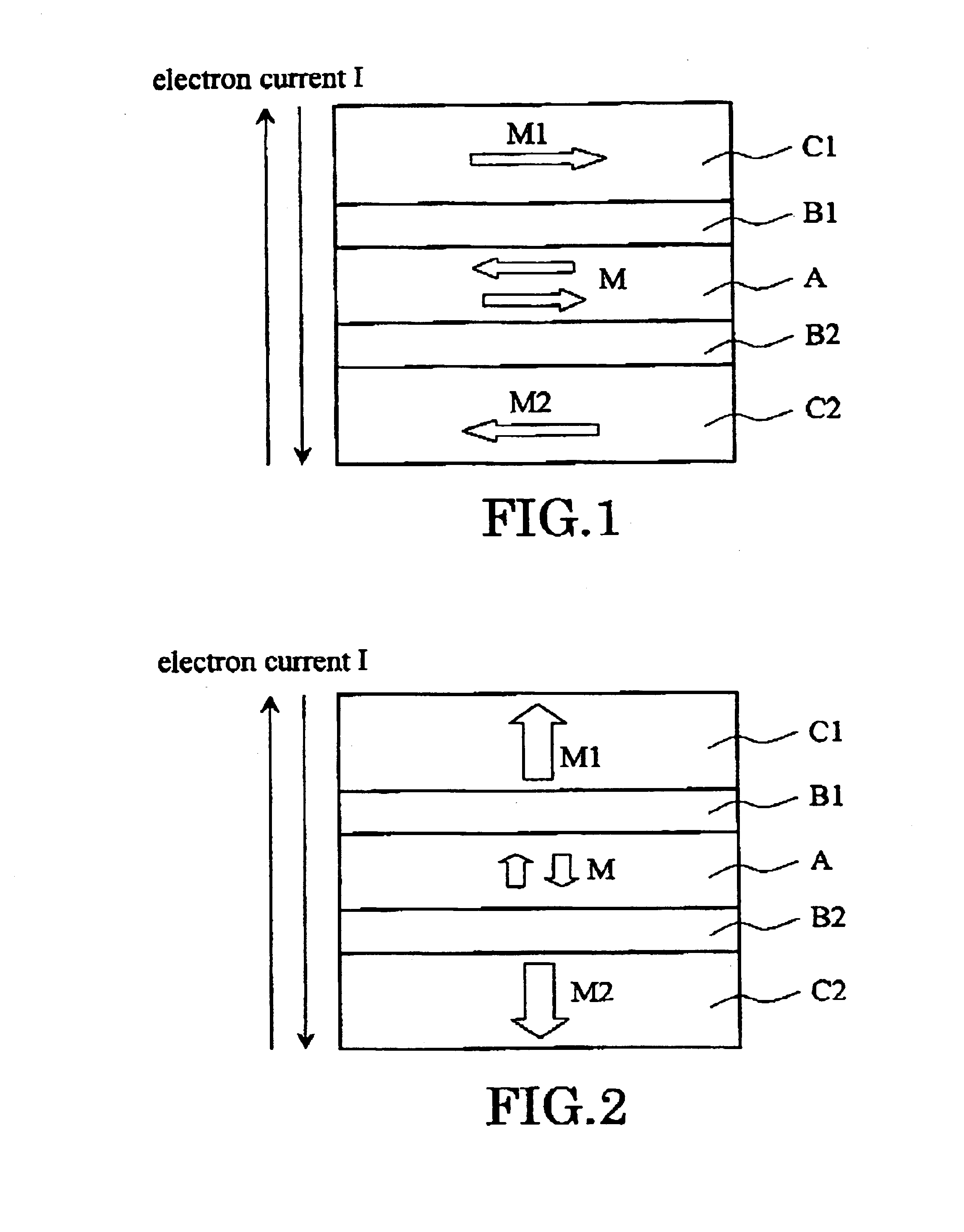

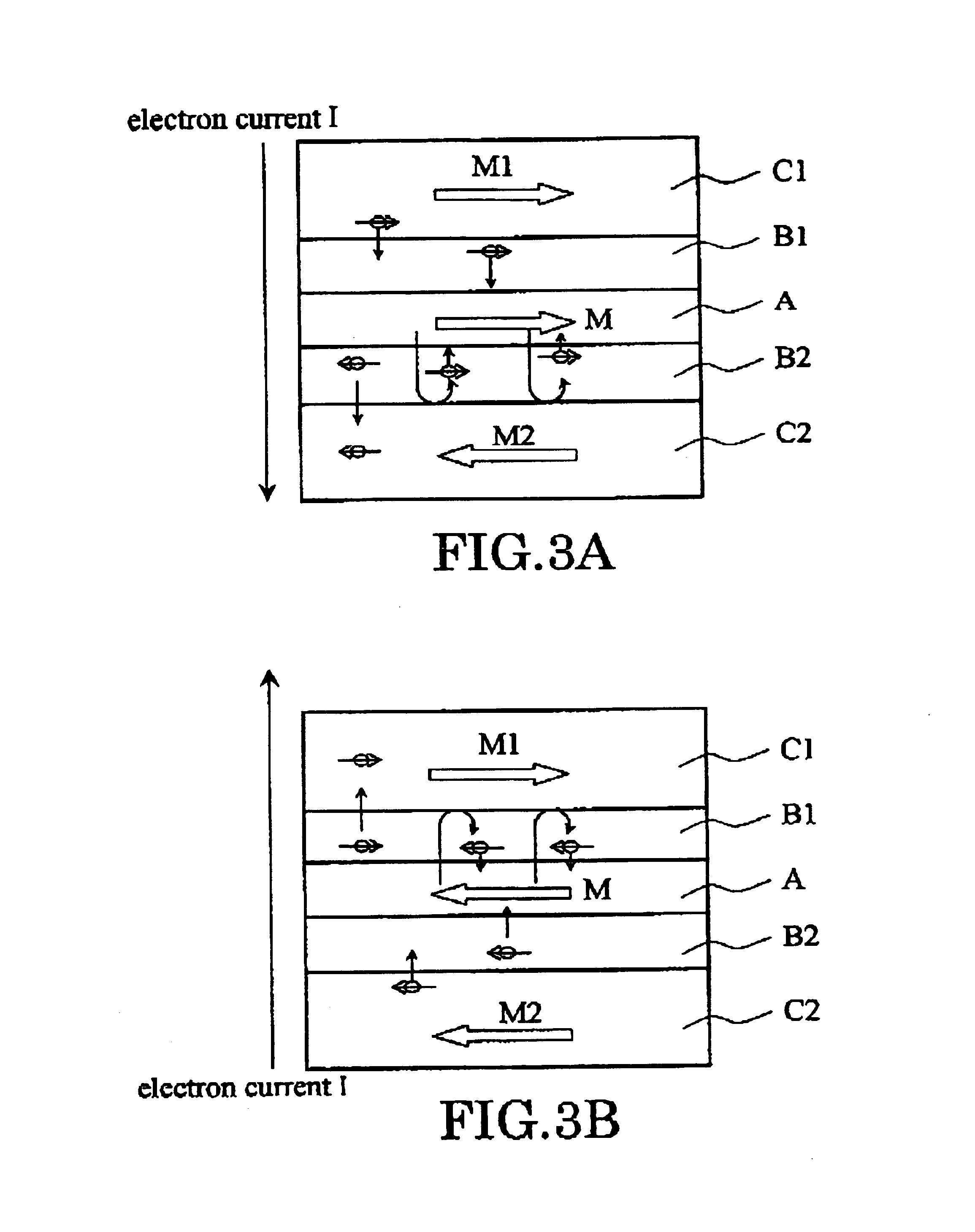

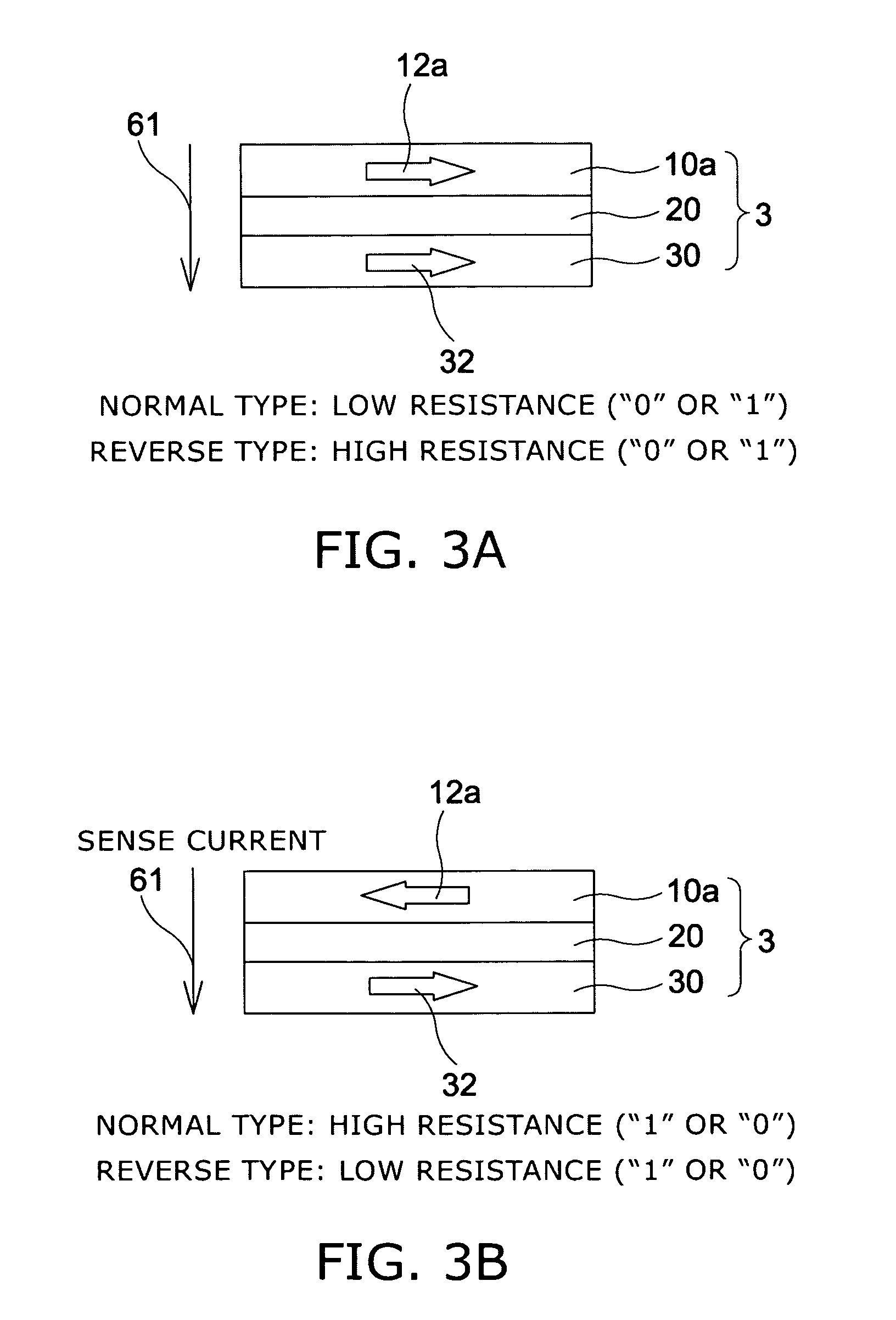

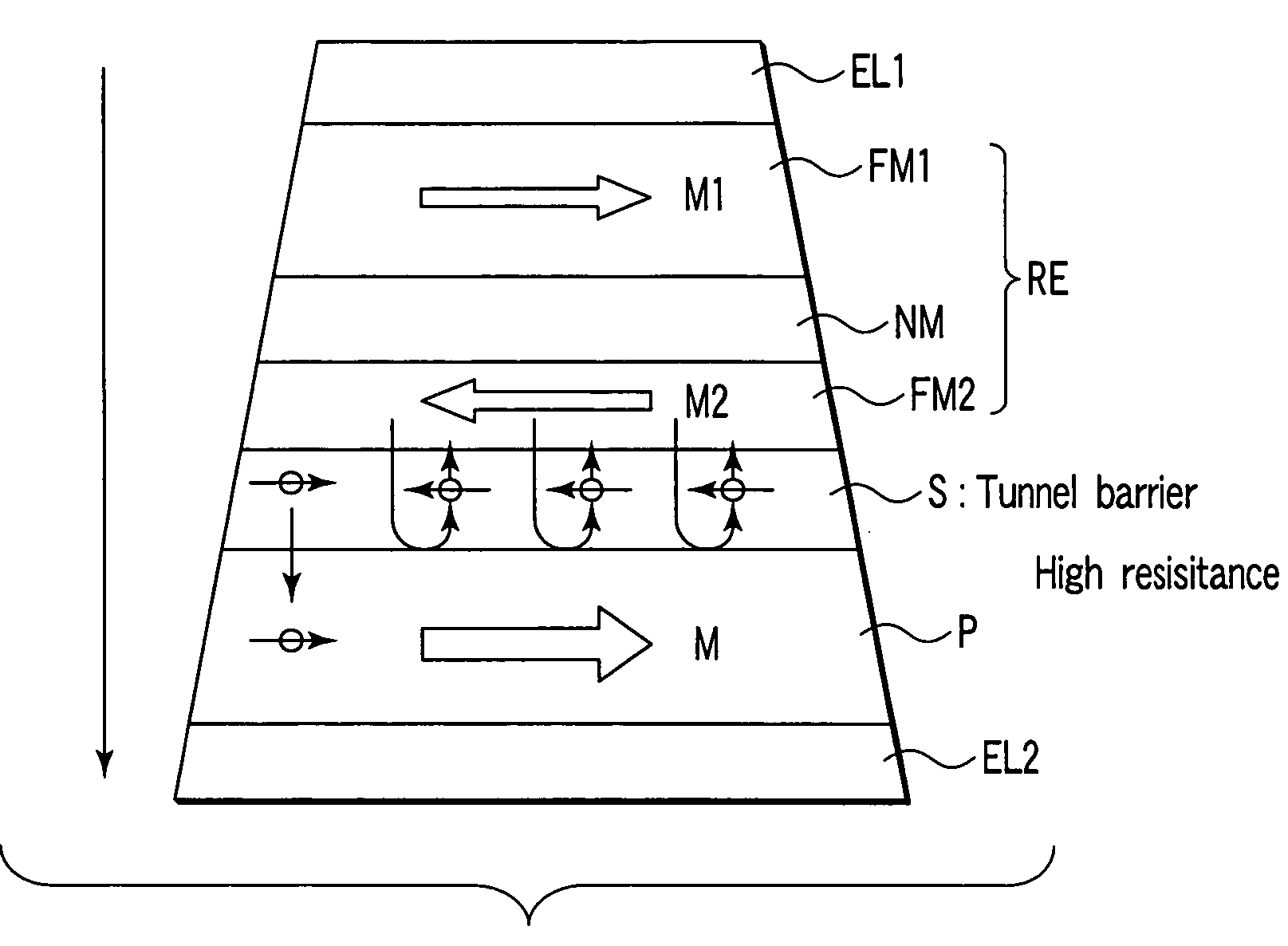

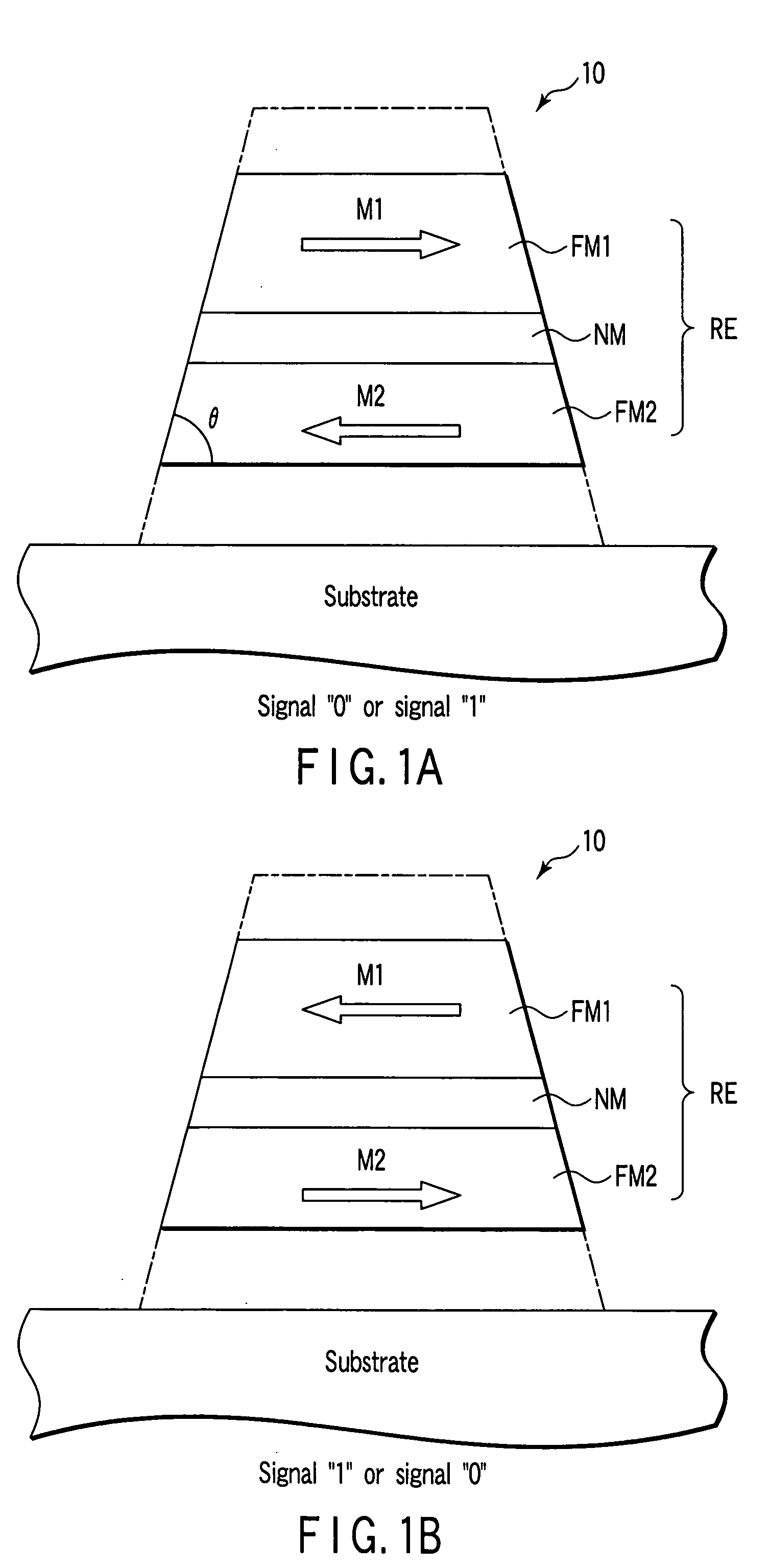

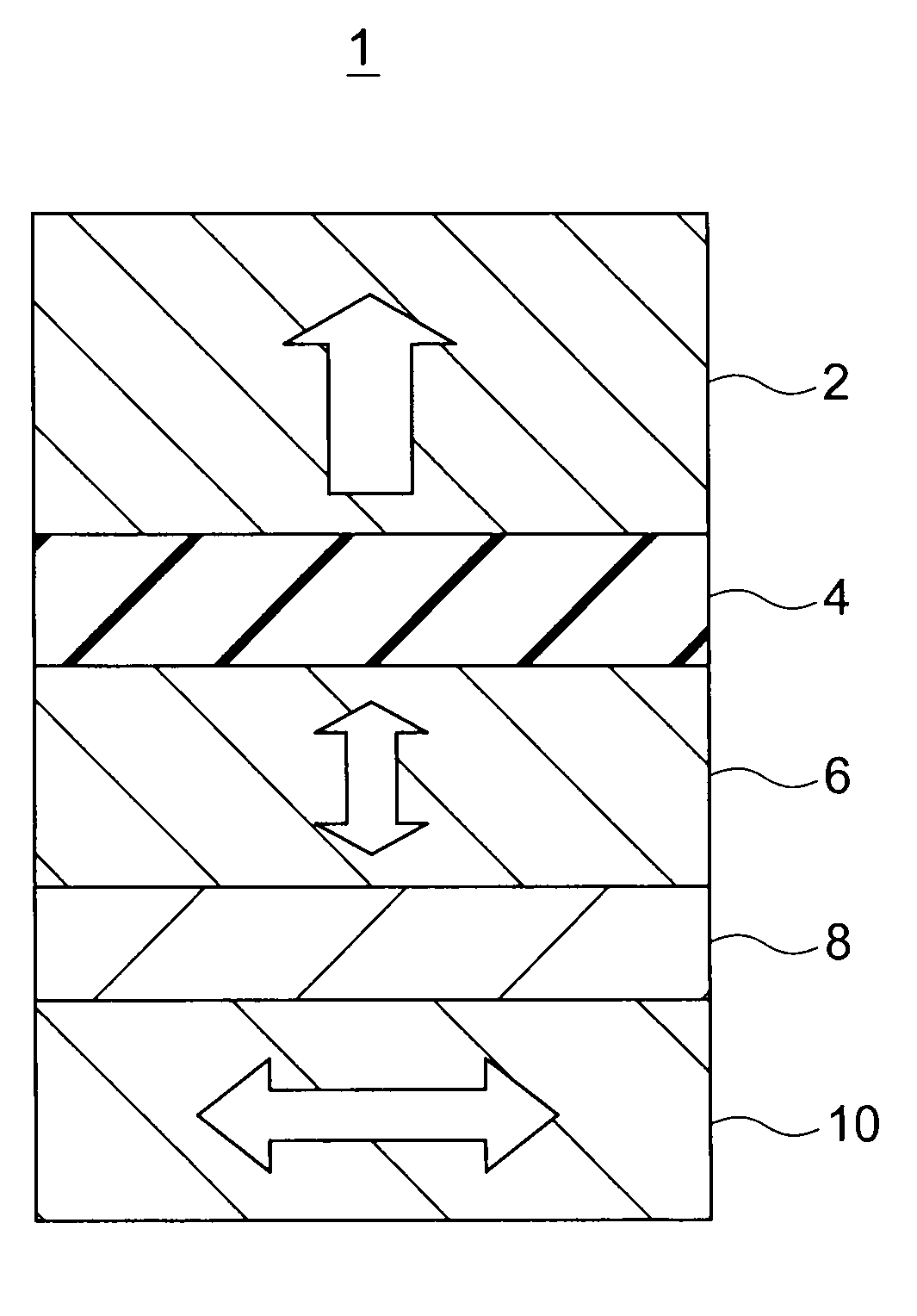

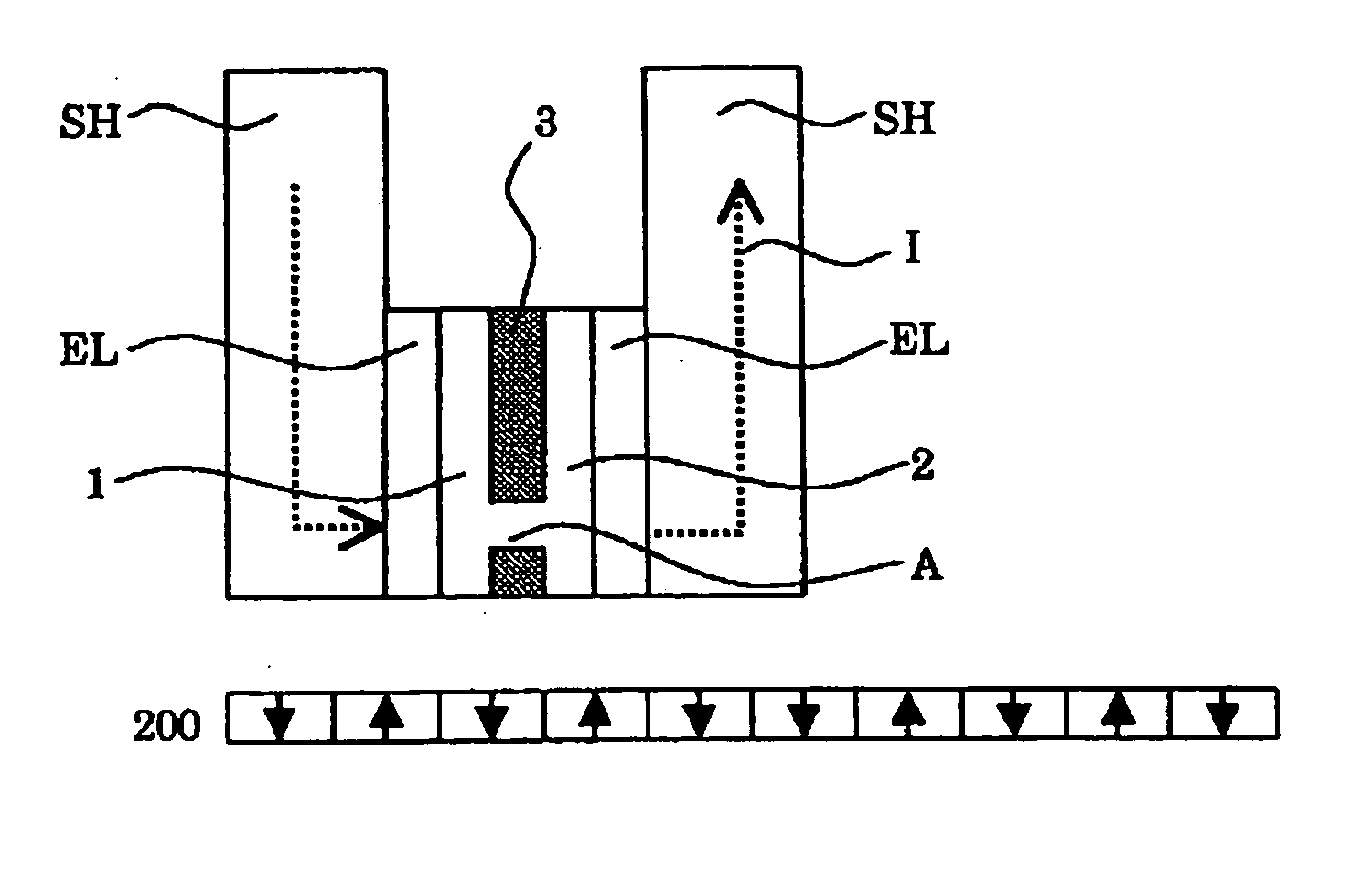

Magnetic cell and magnetic memory

ActiveUS20040165425A1Magnetic-field-controlled resistorsSolid-state devicesInter layerElectrical battery

A magnetic cell comprises: a first ferromagnetic layer whose magnetization is substantially fixed in a first direction; a second ferromagnetic layer whose magnetization is substantially fixed in a second direction opposite to the first direction; a third ferromagnetic layer provided between the first and the second ferromagnetic layers, a direction of magnetization of the third ferromagnetic layer being variable; a first intermediate layer provided between the first and the third ferromagnetic layers; and a second intermediate layer provided between the second and the third ferromagnetic layers. The direction of magnetization of the third ferromagnetic layer can be determined under an influence of spin-polarized electrons upon the third ferromagnetic layer by passing a current between the first and the second ferromagnetic layers.

Owner:KIOXIA CORP

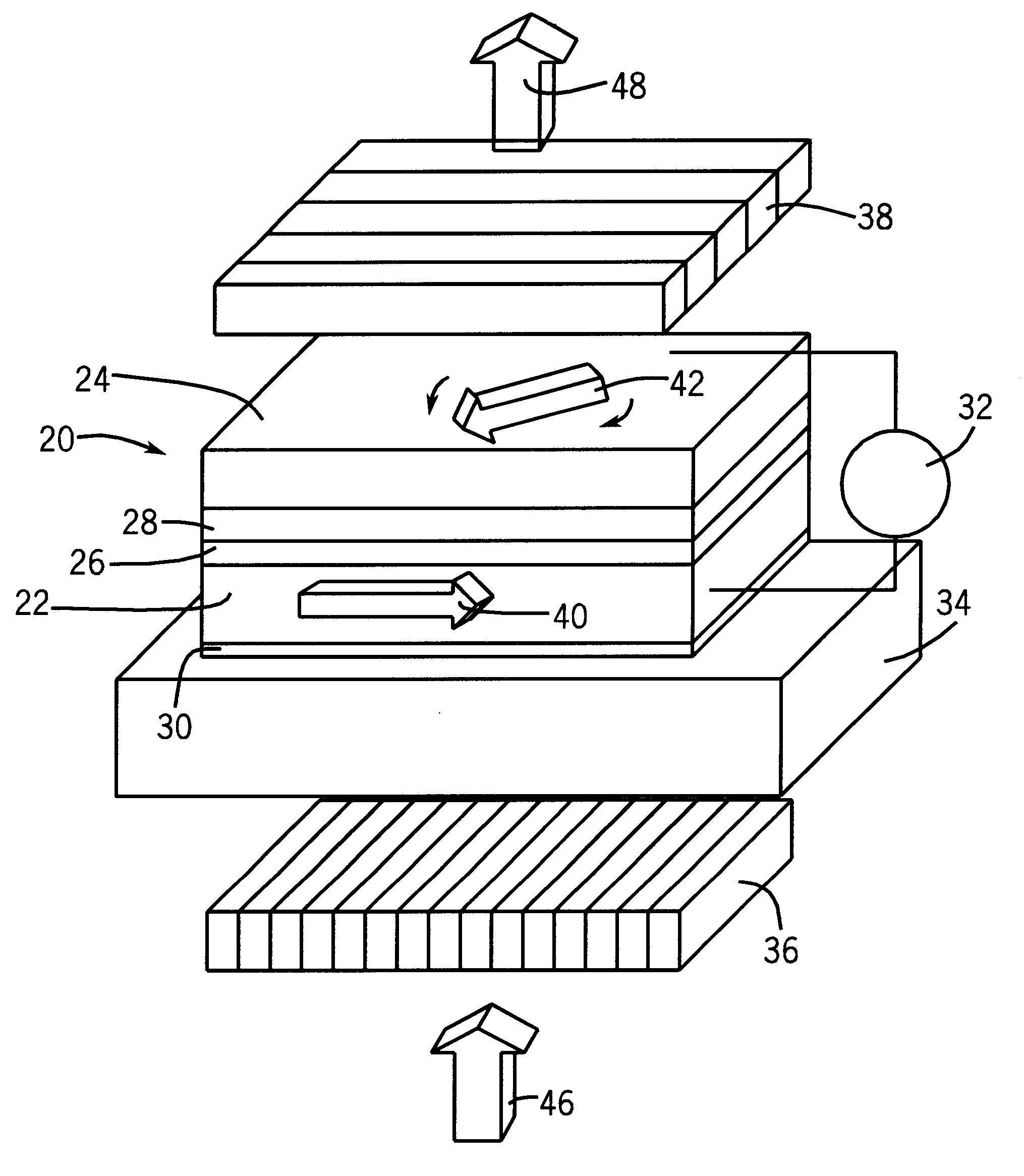

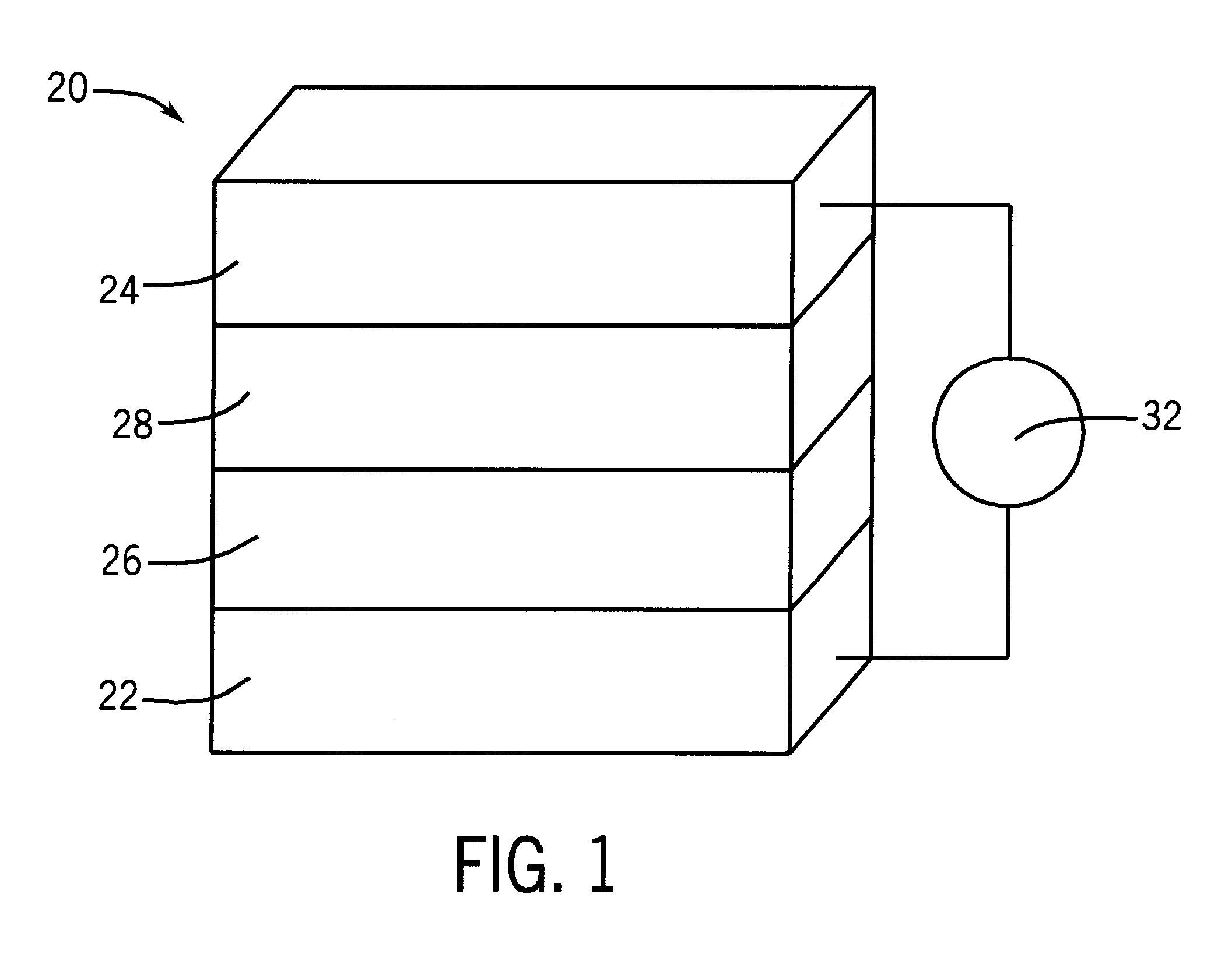

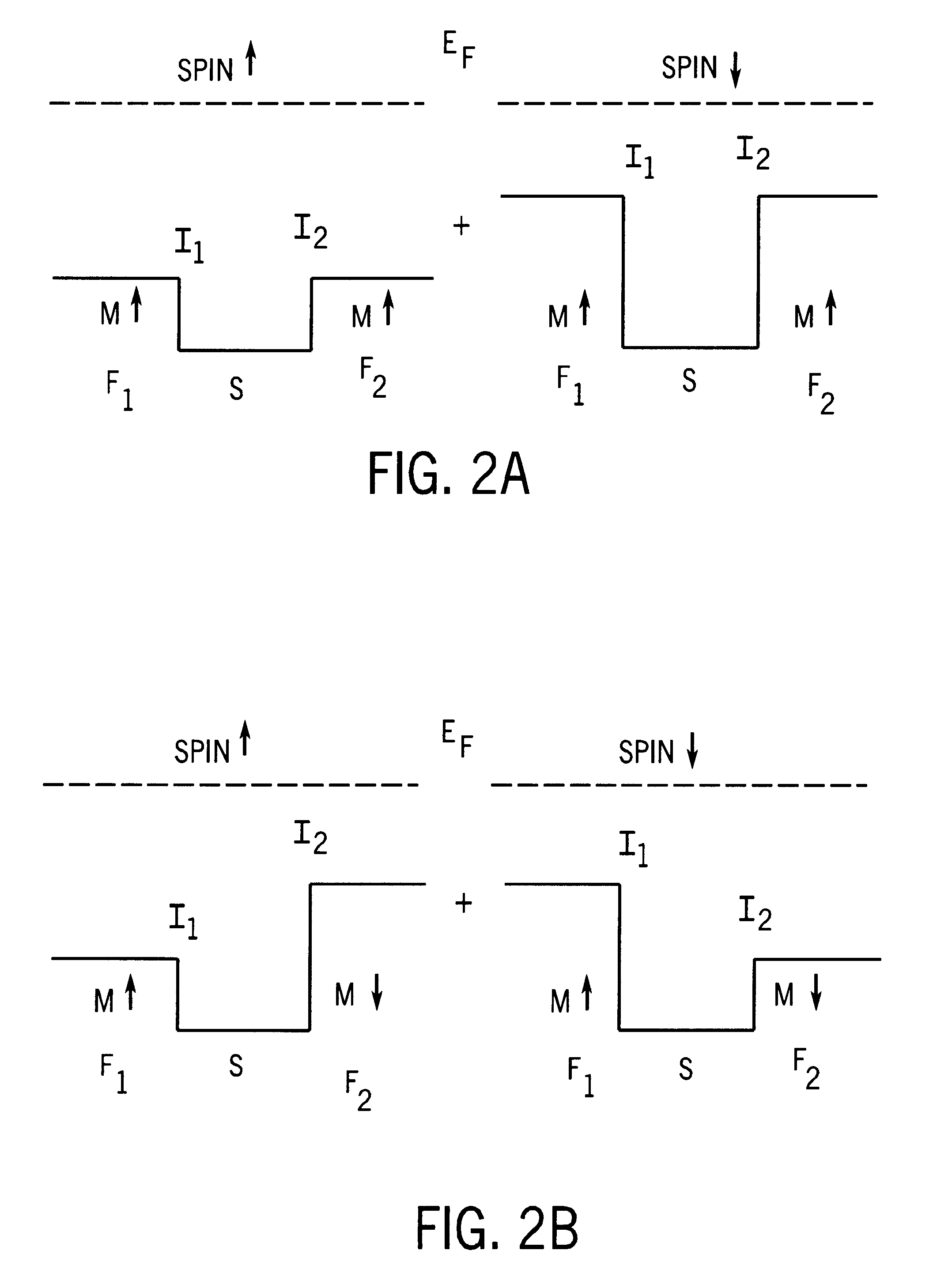

Control of magnetic direction in multi-layer ferromagnetic devices by bias voltage

A system for controlling the direction of magnetization of materials comprising a ferromagnetic device with first and second ferromagnetic layers. The ferromagnetic layers are disposed such that they combine to form an interlayer with exchange coupling. An insulating layer and a spacer layer are located between the first and second ferromagnetic layers. A direct bias voltage is applied to the interlayer exchange coupling, causing the direction of magnetization of the second ferromagnetic layer to change. This change of magnetization direction occurs in the absence of any applied external magnetic field.

Owner:UCHICAGO ARGONNE LLC

Magnetic tunneling junction film structure with process determined in-plane magnetic anisotropy

ActiveUS7105372B2Data efficientSmall sizeNanomagnetismMagnetic-field-controlled resistorsIn planeMagnetic anisotropy

A method of forming an MTJ memory cell and / or an array of such cells is provided wherein each such cell has a small circular horizontal cross-section of 1.0 microns or less in diameter and wherein the ferromagnetic free layer of each such cell has a magnetic anisotropy produced by a magnetic coupling with a thin antiferromagnetic layer that is formed on the free layer. The MTJ memory cell so provided is far less sensitive to shape irregularities and edge defects than cells of the prior art.

Owner:HEADWAY TECH INC

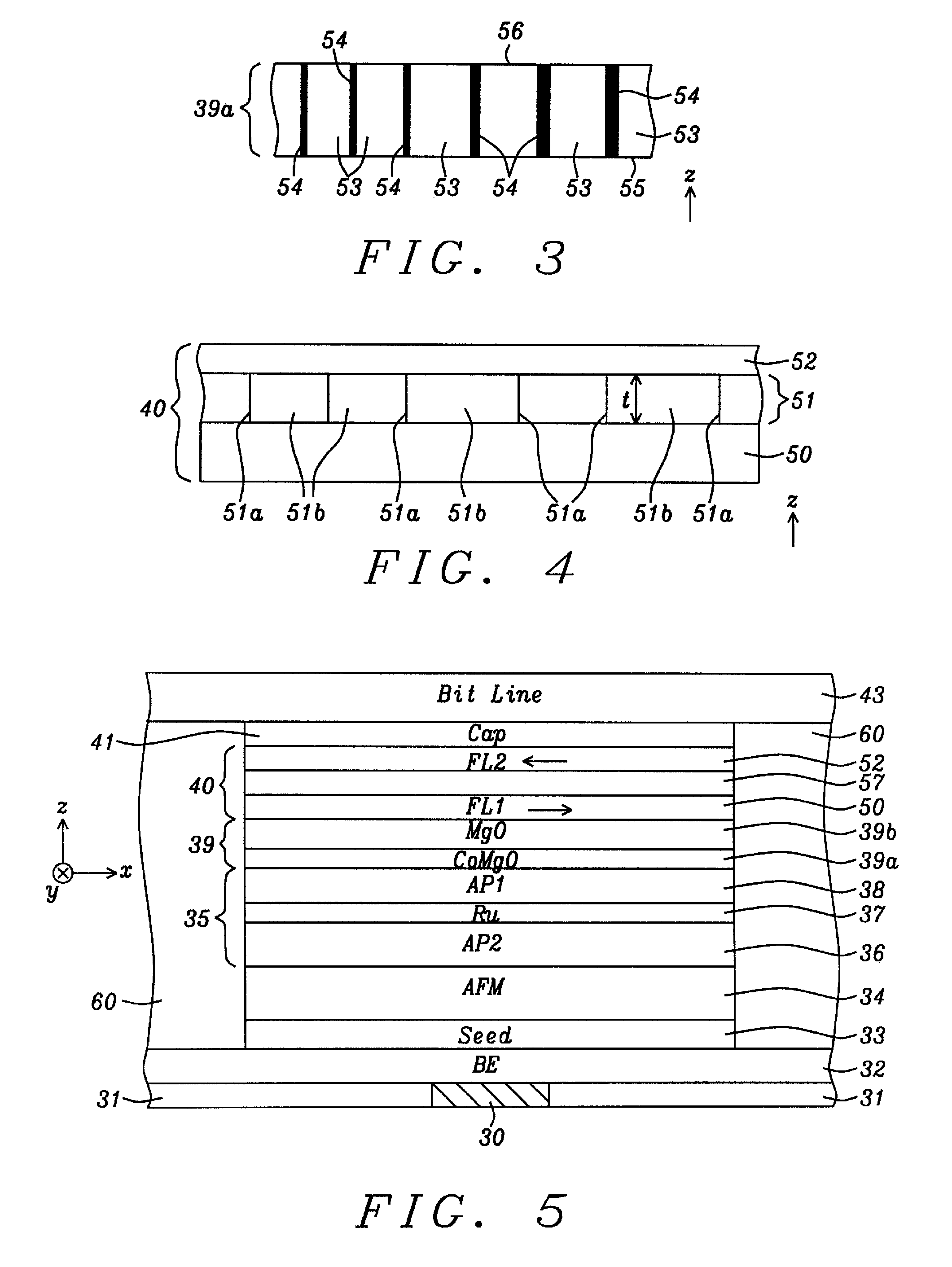

Spin momentum transfer MRAM design

We describe the structure and method of formation of a STT MTJ or GMR MRAM cell element that utilizes transfer of spin torque as a mechanism for changing the magnetization direction of a free layer. The critical current is reduced by constructing the free layer as a lamination comprising two ferromagnetic layers sandwiching a coupling valve layer. When the Curie temperature of the coupling valve layer is above the temperature of the cell, the two ferromagnetic layers are exchange coupled in parallel directions of their magnetization. When the coupling valve layer is above its Curie temperature, it no longer exchange couples the layers and they are magnetostatically coupled. In the exchange coupled configuration, the free layer serves to store data and the cell can be read. In its magnetostatically coupled configuration, the cell can be more easily written upon because one of the layers can assist the spin torque transfer by its magnetostatic coupling. If the free layer is formed as a multi-layered lamination of N periodically repeating combinations of a ferromagnetic layer and a coupling valve layer, the critical current can be reduced by a factor of N.

Owner:TAIWAN SEMICON MFG CO LTD

Magnetic cell and magnetic memory

ActiveUS6956766B2Magnetic-field-controlled resistorsSolid-state devicesInter layerElectrical battery

A magnetic cell comprises: a first ferromagnetic layer whose magnetization is substantially fixed in a first direction; a second ferromagnetic layer whose magnetization is substantially fixed in a second direction opposite to the first direction; a third ferromagnetic layer provided between the first and the second ferromagnetic layers, a direction of magnetization of the third ferromagnetic layer being variable; a first intermediate layer provided between the first and the third ferromagnetic layers; and a second intermediate layer provided between the second and the third ferromagnetic layers. The direction of magnetization of the third ferromagnetic layer can be determined under an influence of spin-polarized electrons upon the third ferromagnetic layer by passing a current between the first and the second ferromagnetic layers.

Owner:KIOXIA CORP

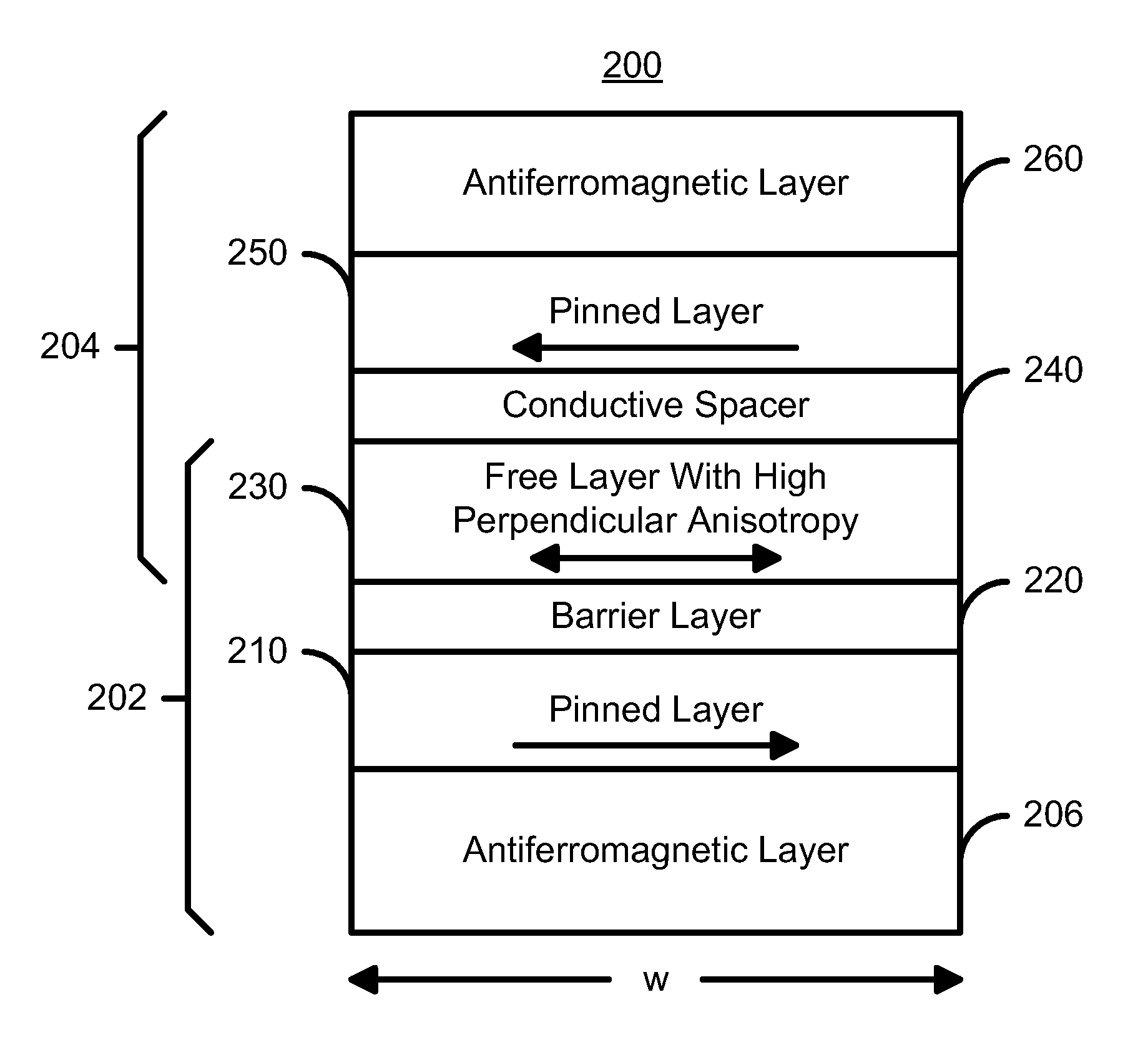

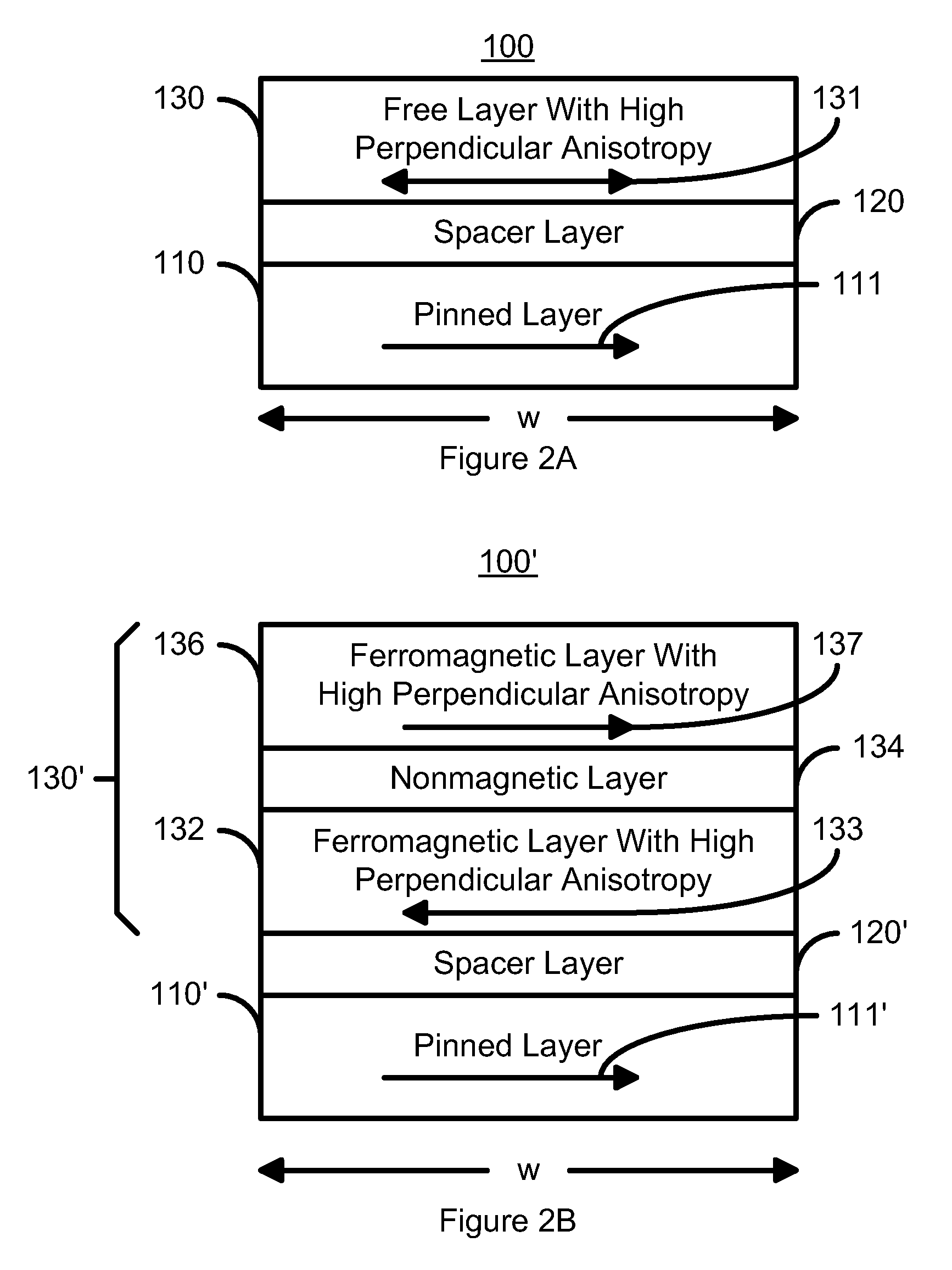

Spin transfer magnetic element with free layers having high perpendicular anisotropy and in-plane equilibrium magnetization

InactiveUS20110140217A1High perpendicular anisotropyNanomagnetismMagnetic measurementsIn planePerpendicular anisotropy

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer includes a first ferromagnetic layer and a second ferromagnetic layer. The second ferromagnetic layer has a very high perpendicular anisotropy and an out-of-plane demagnetization energy. The very high perpendicular anisotropy energy is greater than the out-of-plane demagnetization energy of the second layer.

Owner:GRANDIS

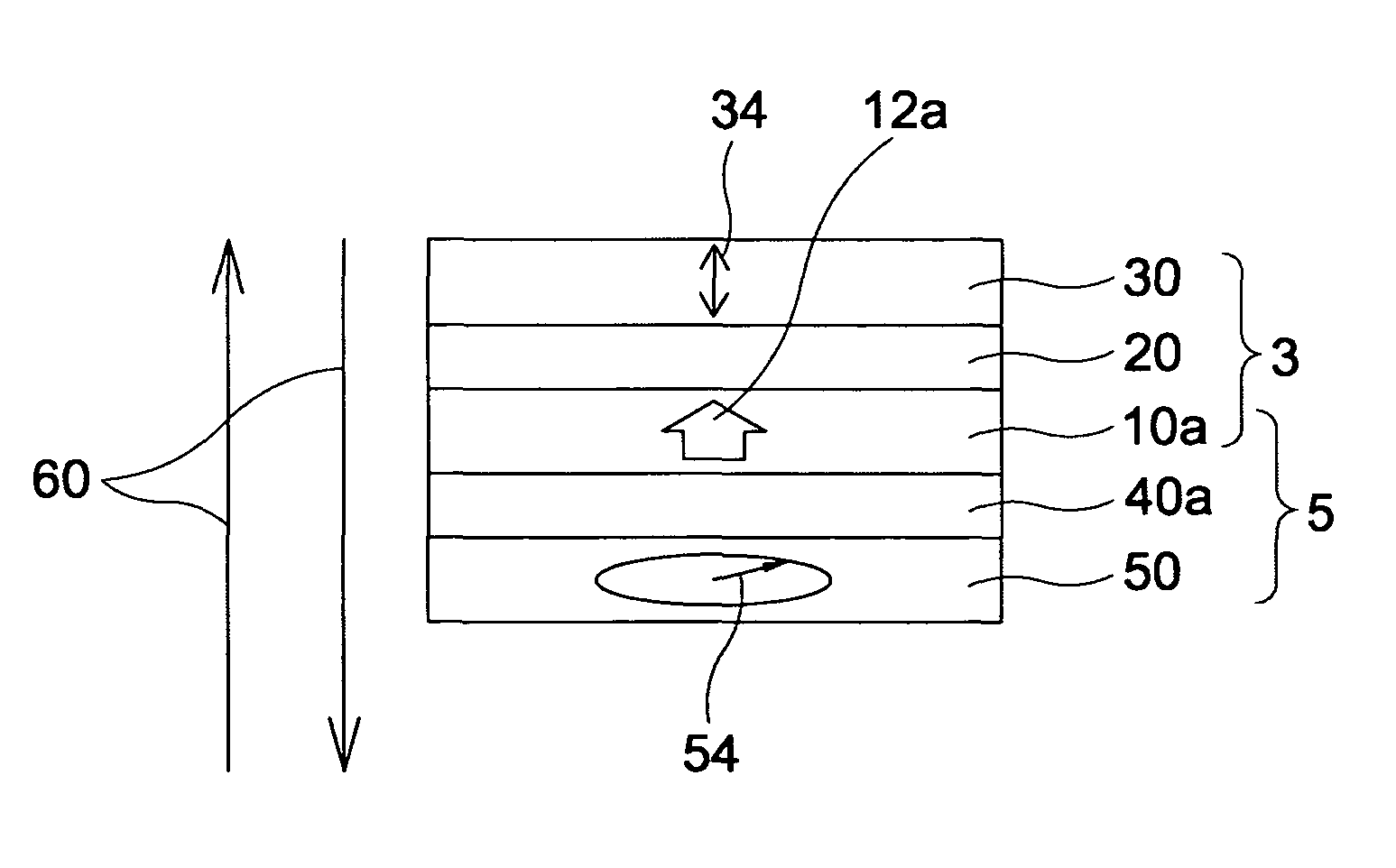

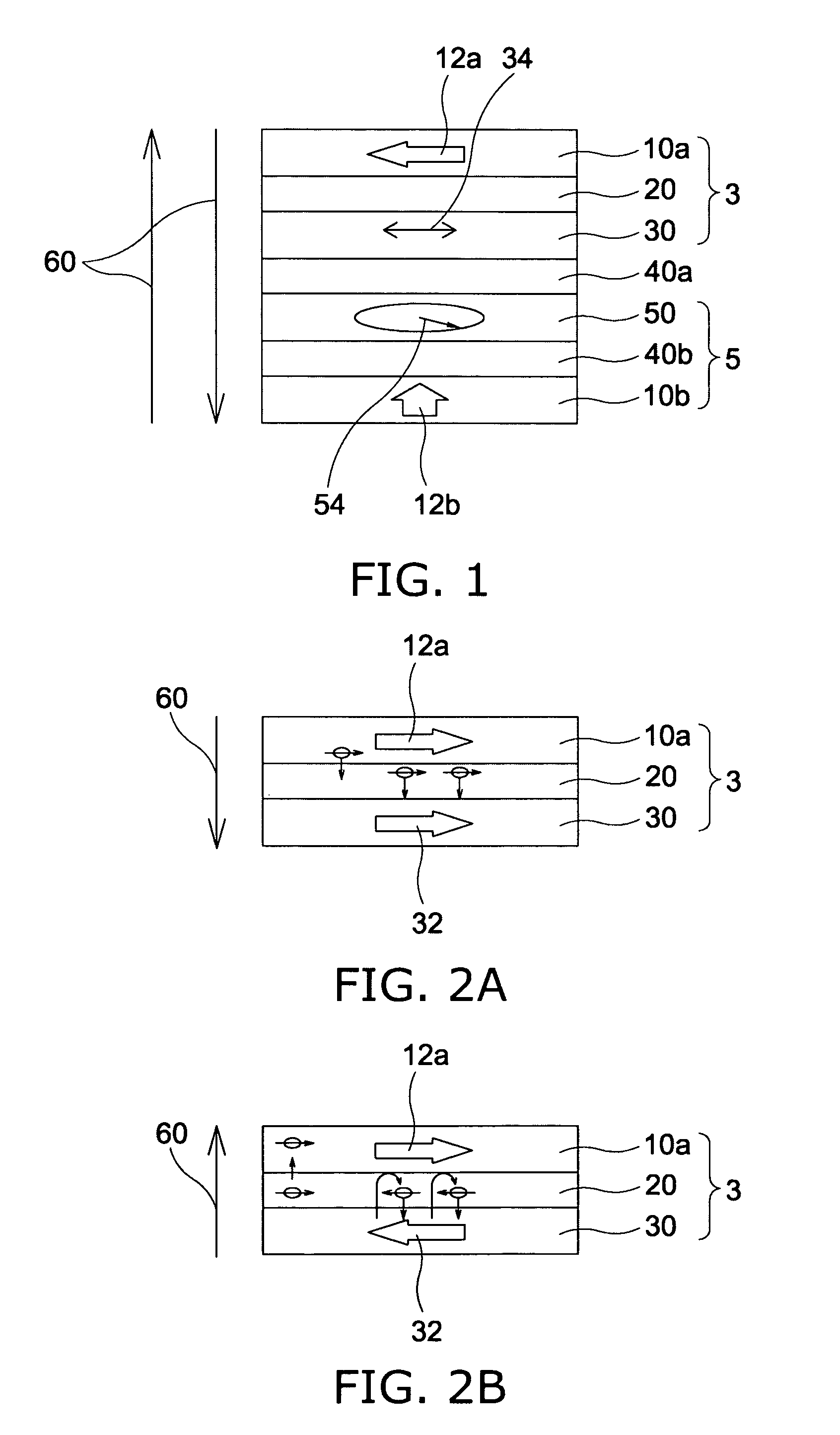

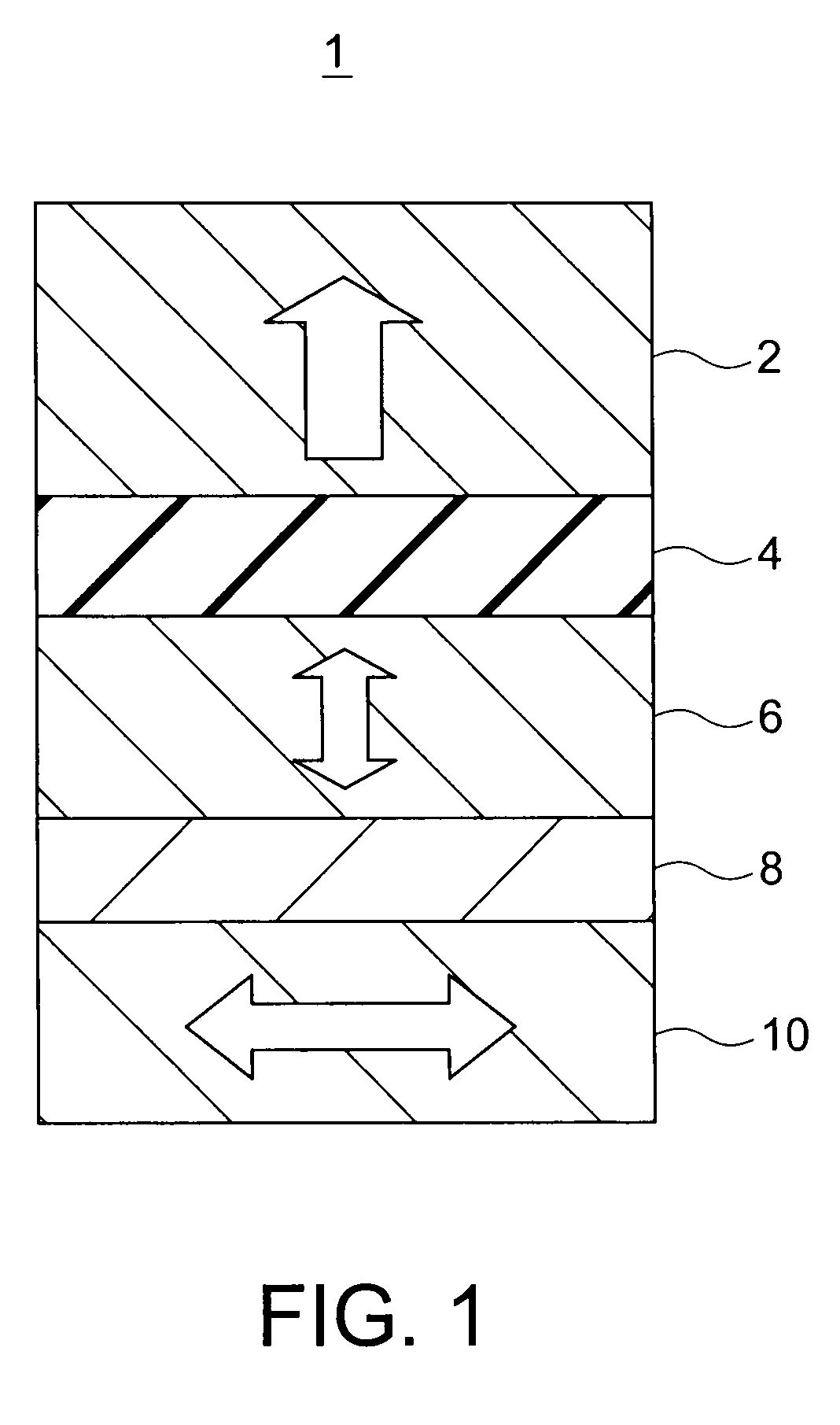

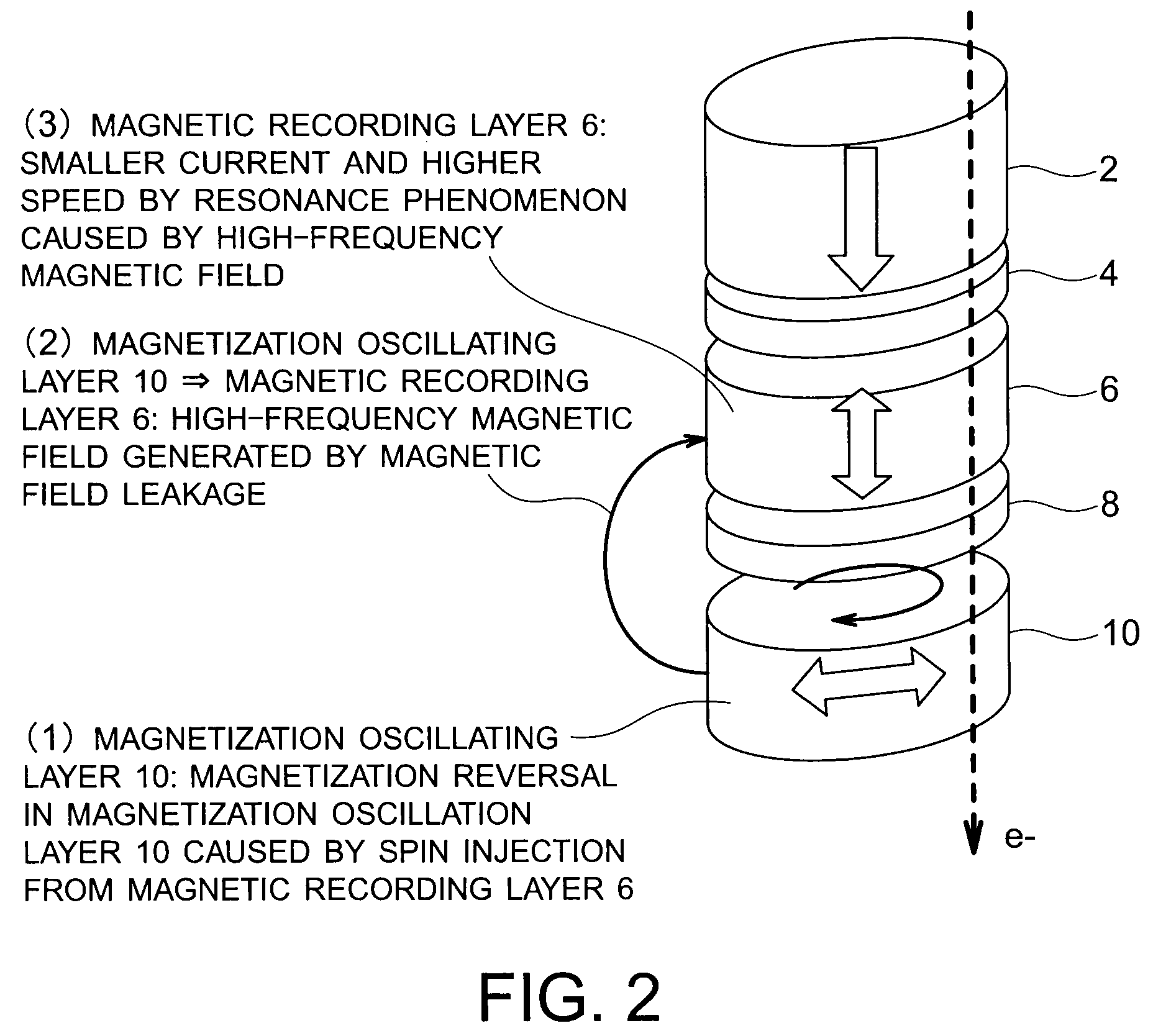

Magnetic recording device and magnetic recording apparatus

InactiveUS8085582B2Record information storageManufacture of flux-sensitive headsFilm planePrecession

A magnetic recording device includes: a laminated body including: a first ferromagnetic layer with a magnetization substantially fixed in a first direction; a second ferromagnetic layer with a variable magnetization direction; a first nonmagnetic layer disposed between the first ferromagnetic layer and the second ferromagnetic layer; and a third ferromagnetic layer with a variable magnetization direction. The magnetization direction of the second ferromagnetic layer is determinable in response to the orientation of a current, by allowing electrons spin-polarized by passing a current in a direction generally perpendicular to the film plane of the layers of the laminated body to act on the second ferromagnetic layer, and by allowing a magnetic field generated by precession of the magnetization of the third ferromagnetic layer to act on the second ferromagnetic layer.

Owner:KK TOSHIBA

Spin torque oscillator having multiple fixed ferromagnetic layers or multiple free ferromagnetic layers

InactiveUS8604886B2Record information storageInductances/transformers/magnets manufactureNanopillarMicrowave

A spin torque oscillator and a method of making same. The spin torque oscillator is configured to generate microwave electrical oscillations without the use of a magnetic field external thereto, the spin torque oscillator having one of a plurality of input nanopillars and a nanopillar having a plurality of free FM layers.

Owner:INTEL CORP

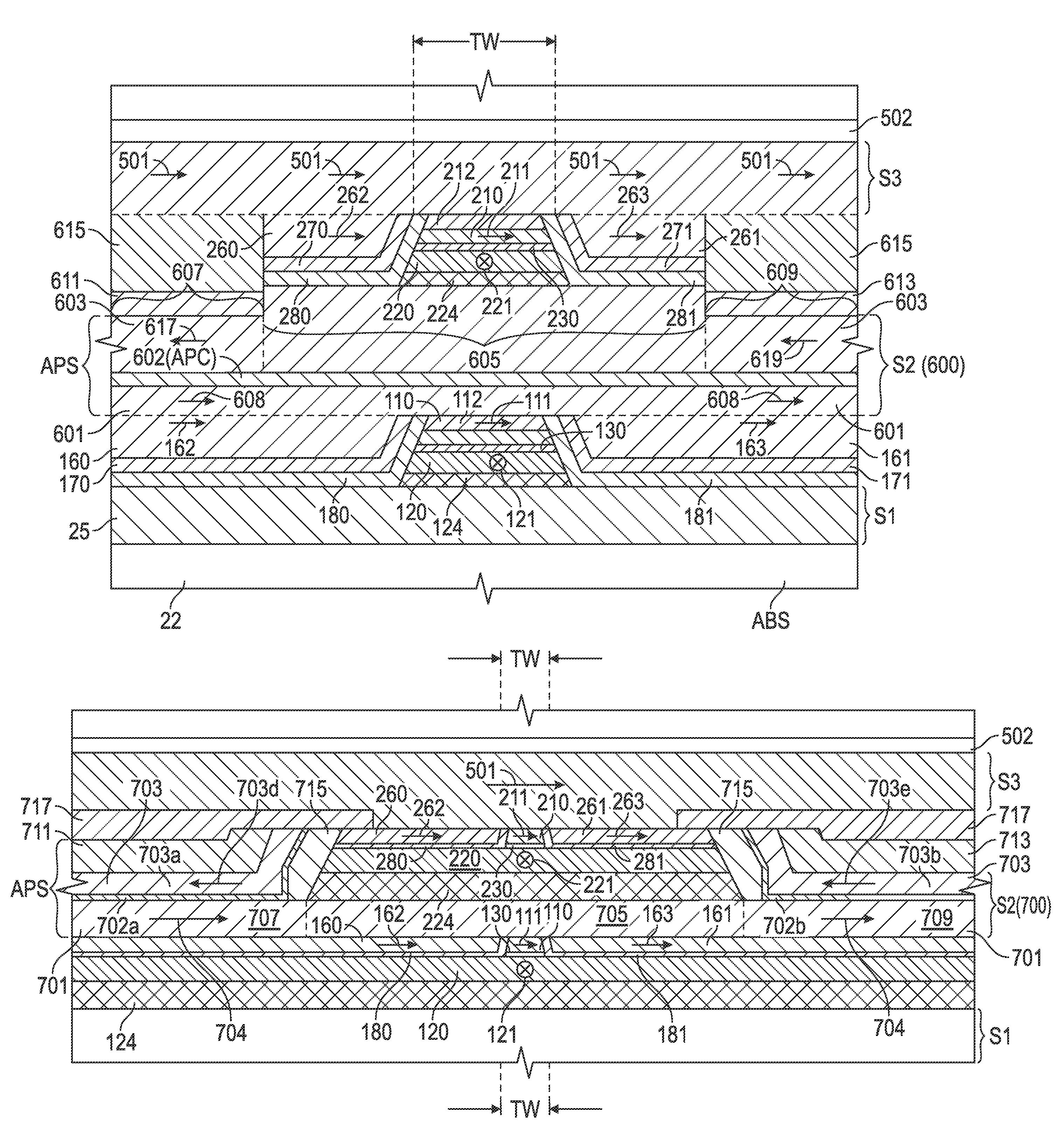

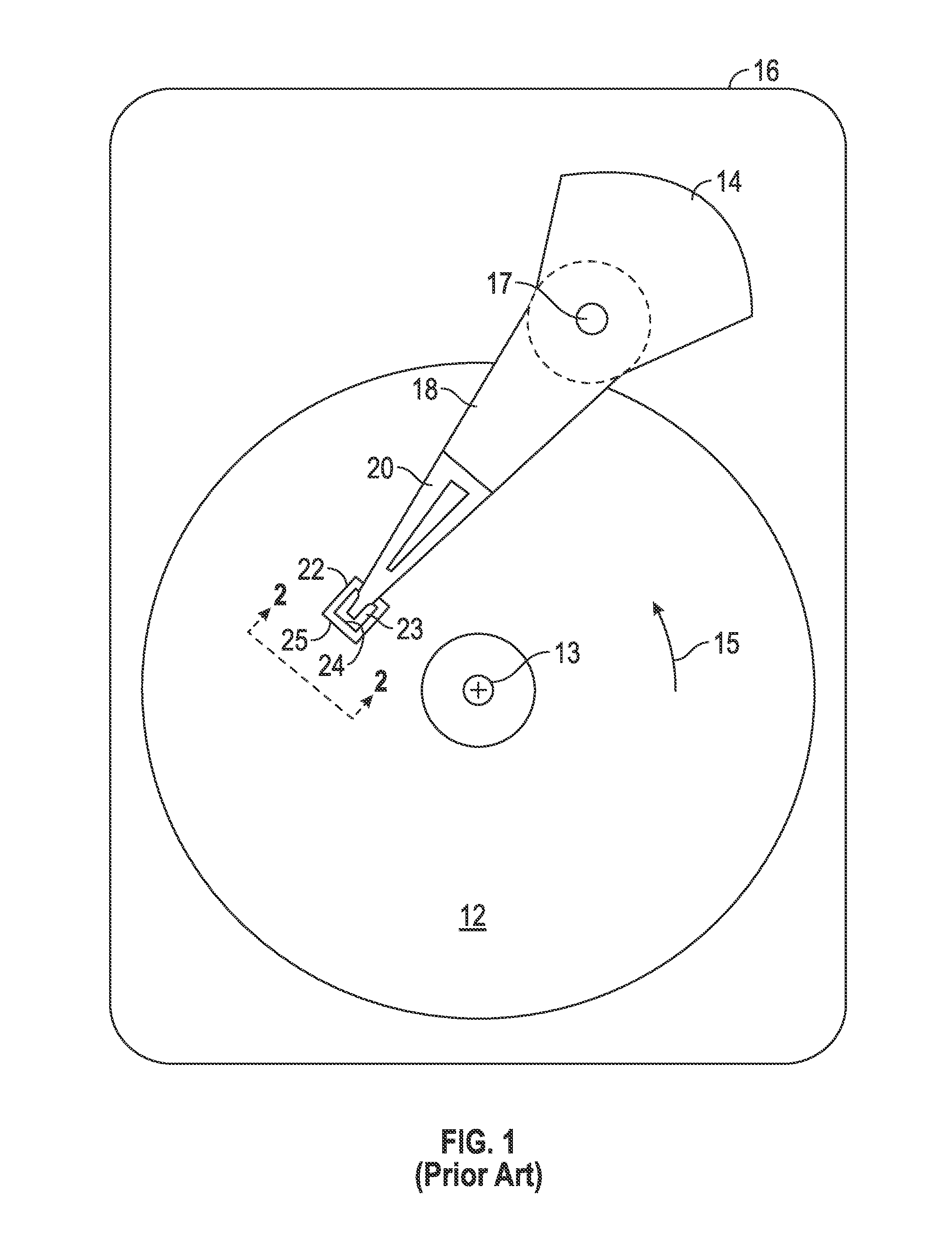

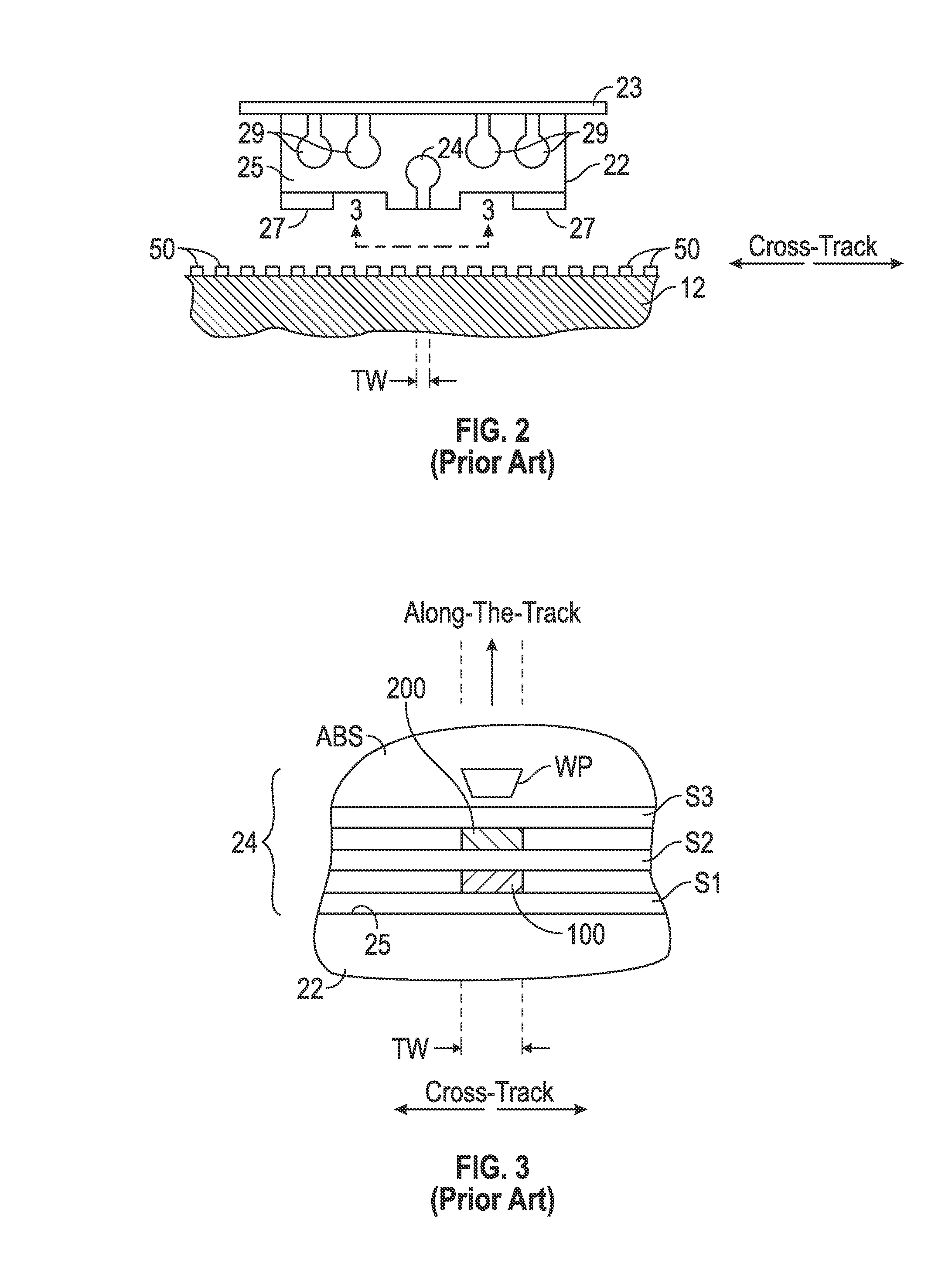

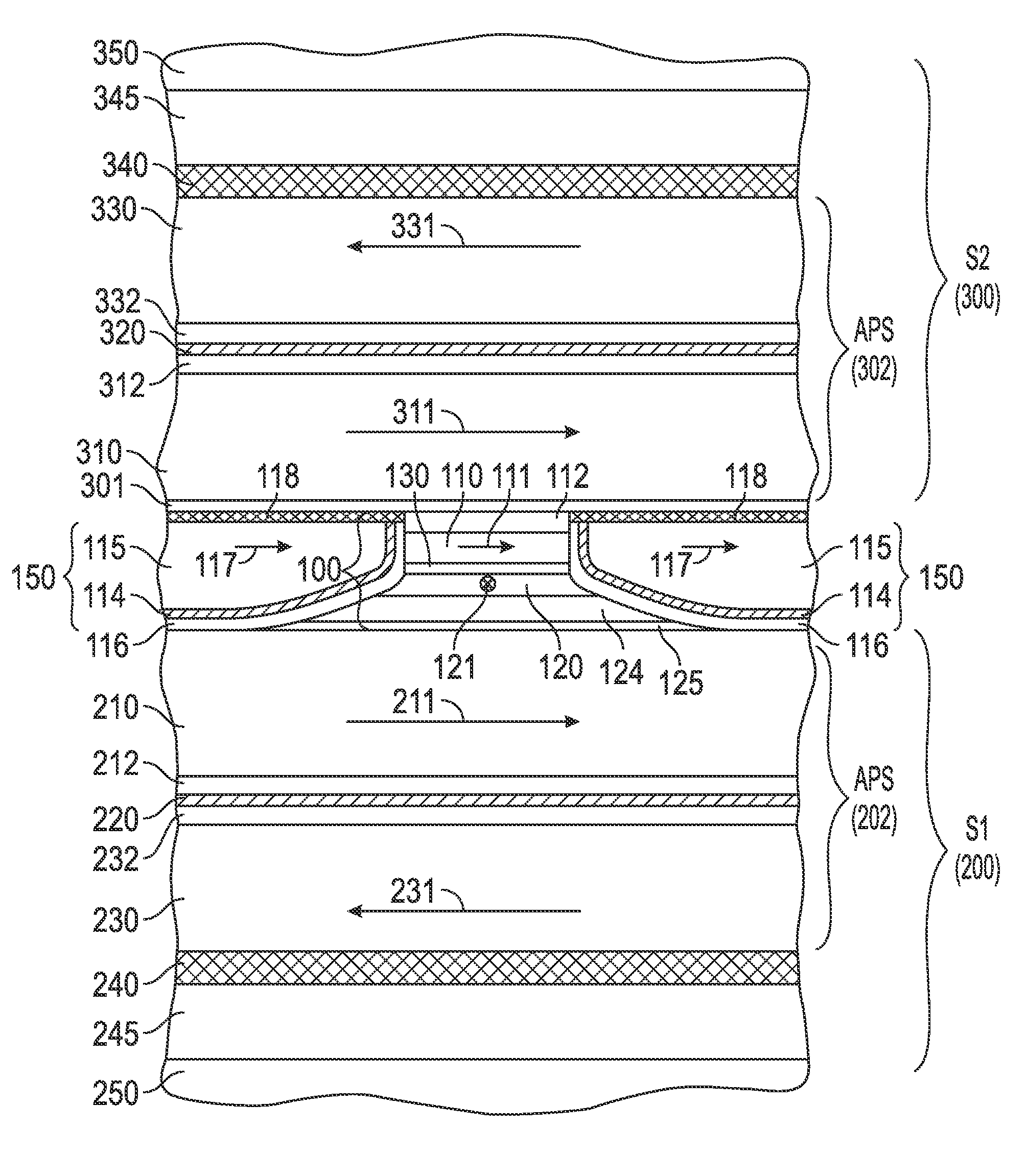

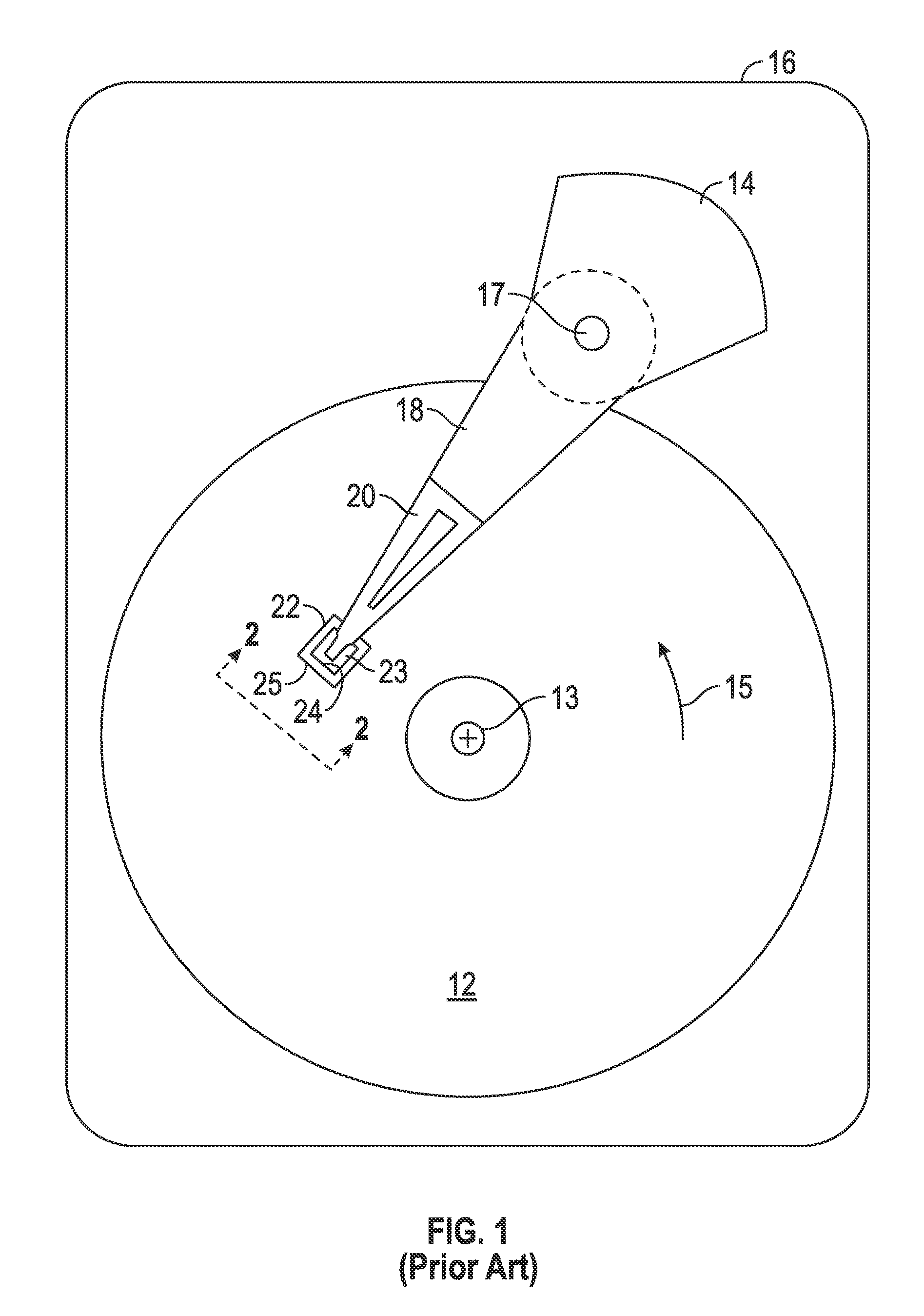

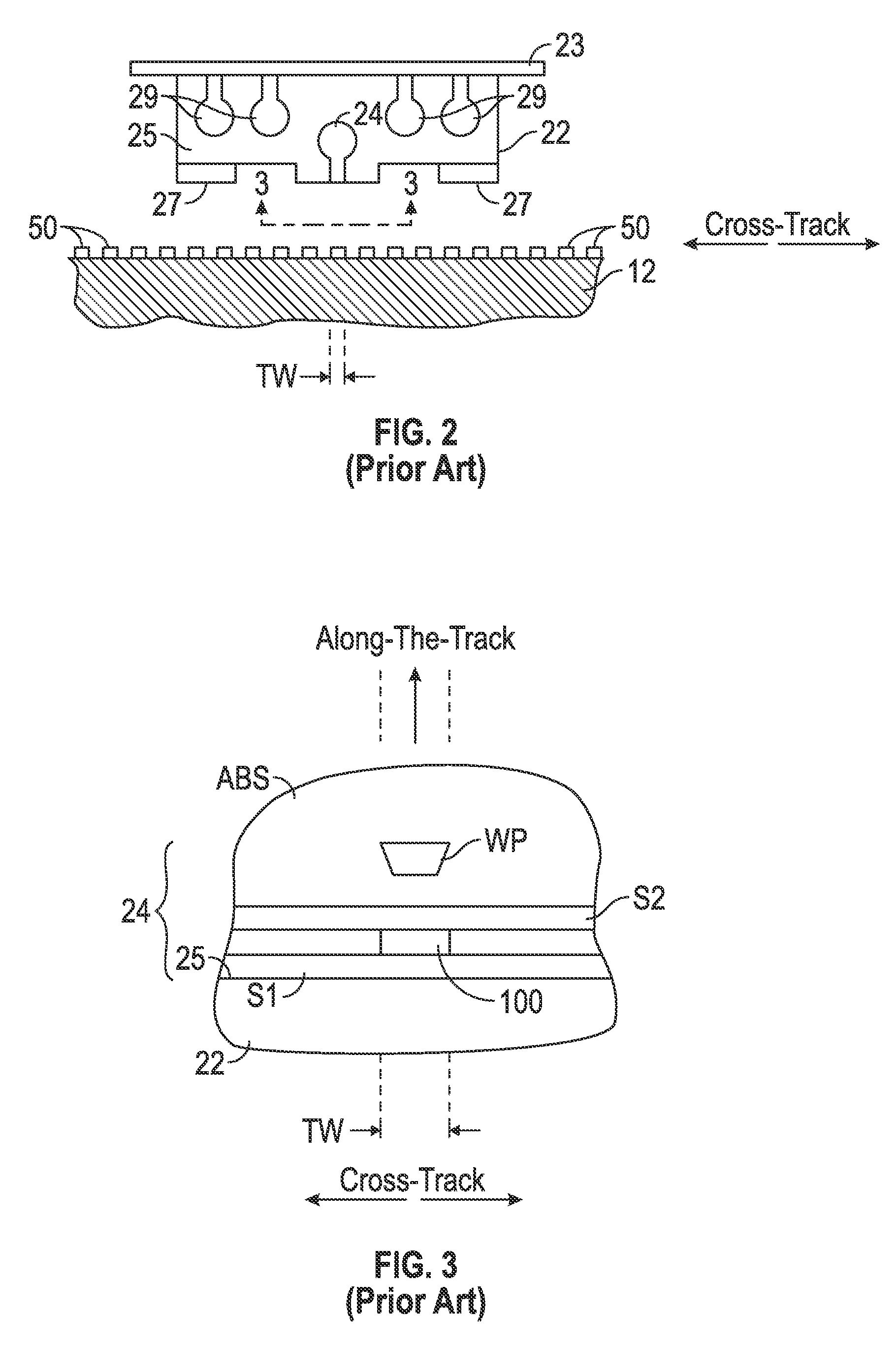

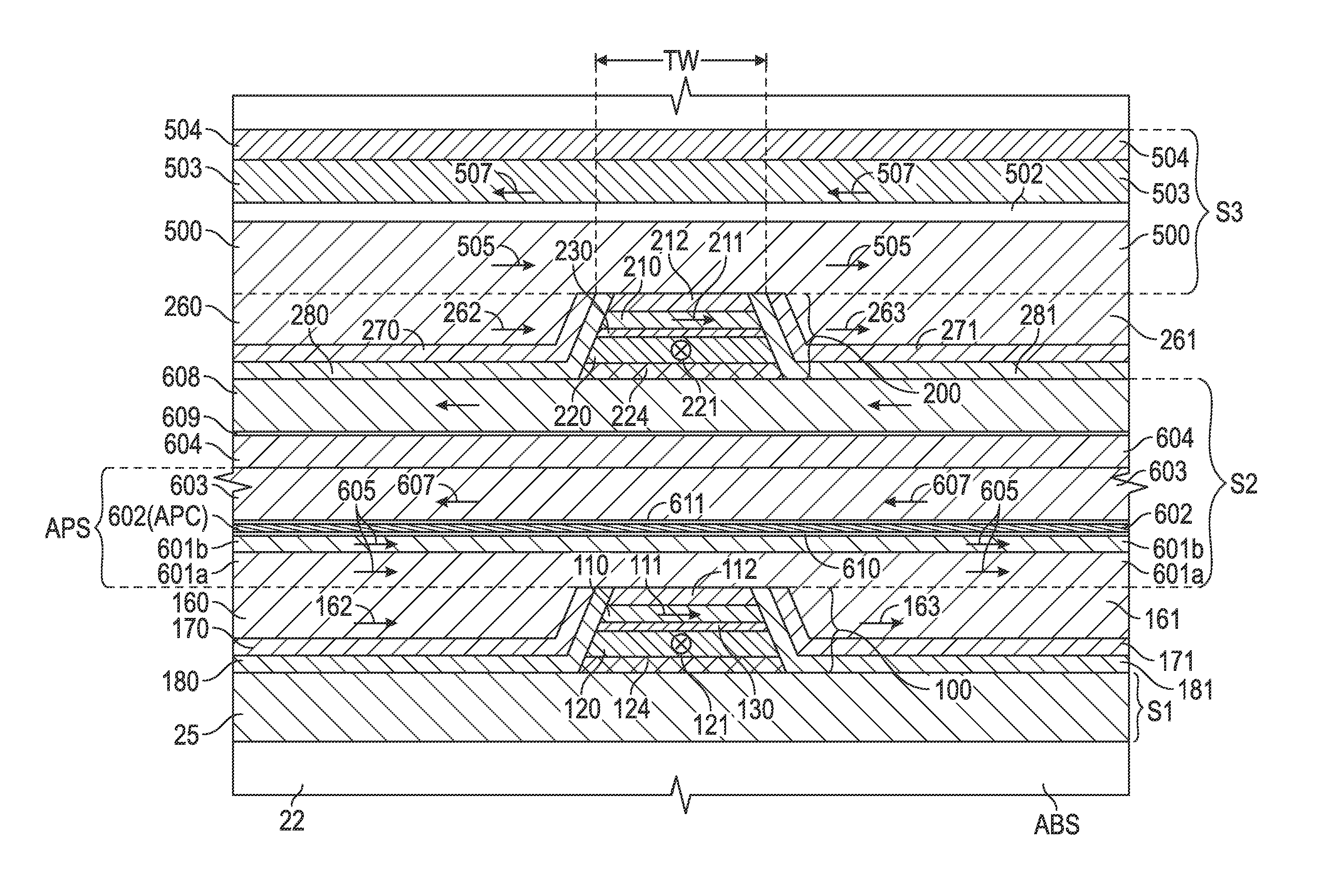

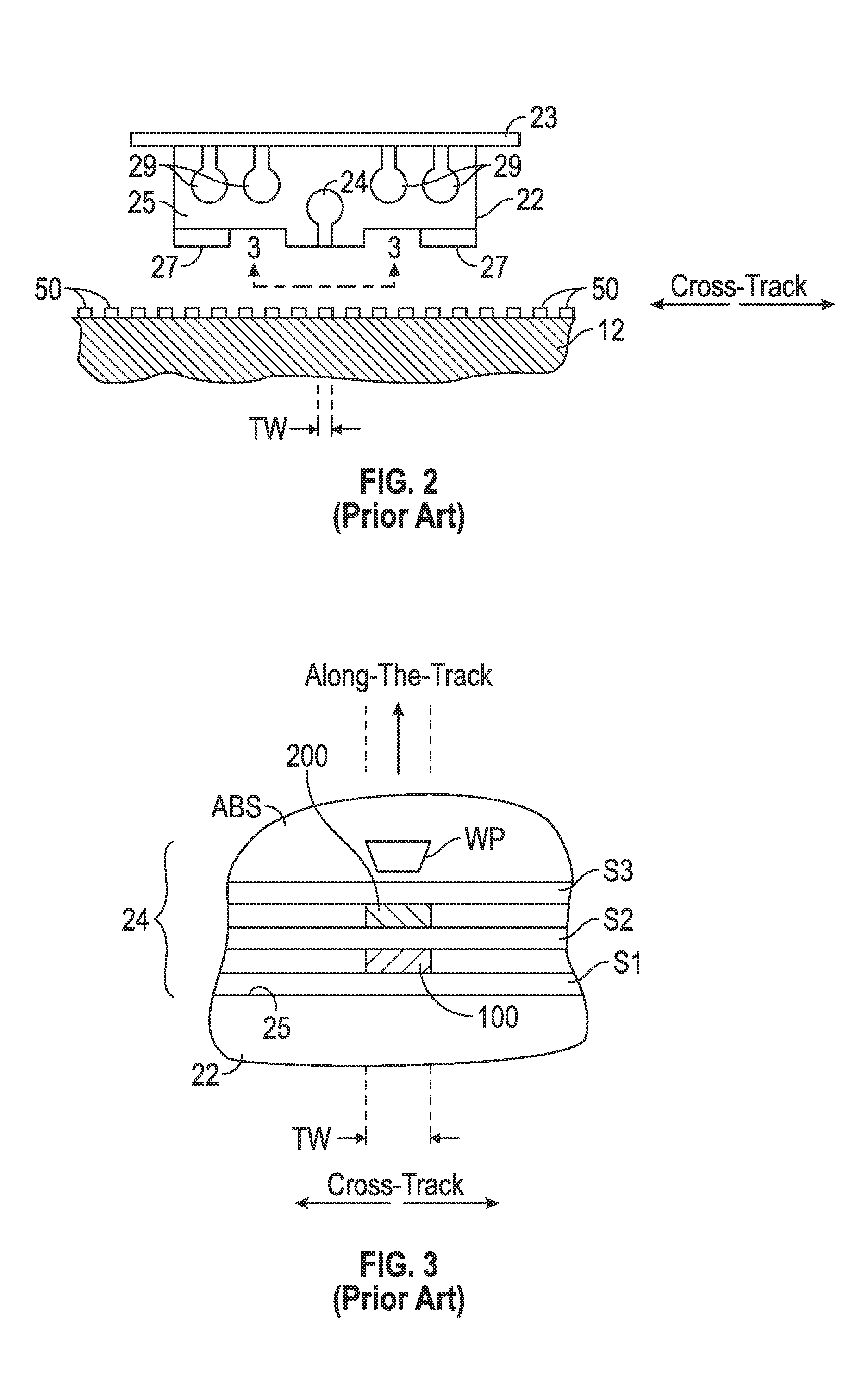

Current-perpendicular-to-the-plane (CPP) magnetoresistive (MR) sensor structure with multiple stacked sensors and improved center shield

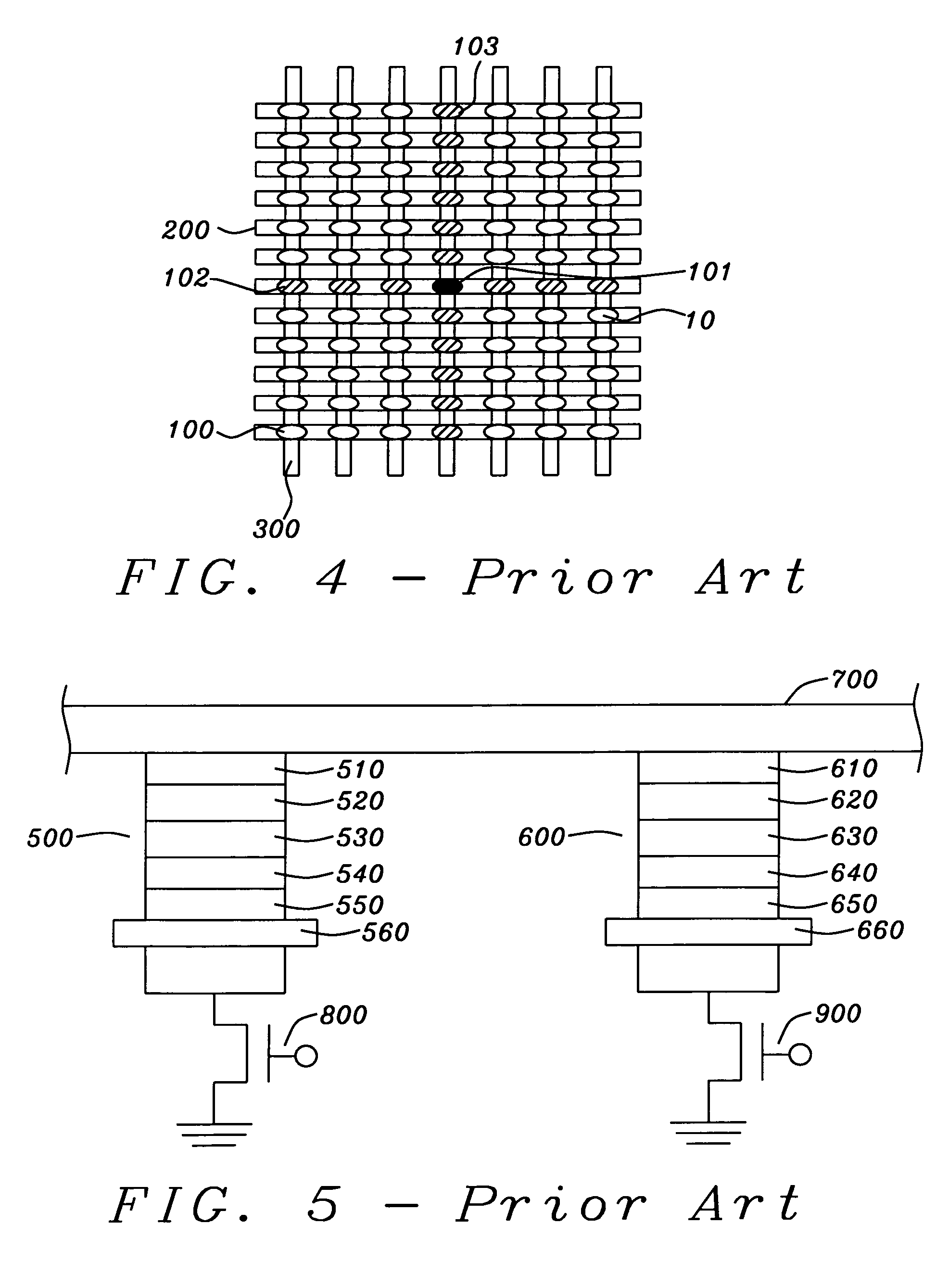

A two-dimensional magnetic recording (TDMR) read head has upper and lower read sensors wherein the lower read sensor has its magnetization biased by side shields of soft magnetic material. The center shield between the lower and upper sensors may be an antiparallel structure (APS) with two ferromagnetic layers separated by an antiparallel coupling (APC) layer. The center shield has a central region and two side regions, but there is no antiferromagnetic (AF) layer in the central region. Instead the two side regions of the upper ferromagnetic layer in the APS are pinned by AF tab layers that are electrically isolated from the upper sensor. The upper ferromagnetic layer and the APC layer in the APS may also be located only in the side regions. The thickness of the center shield can thus be made thinner, which reduces the free layer to free layer spacing.

Owner:WESTERN DIGITAL TECH INC

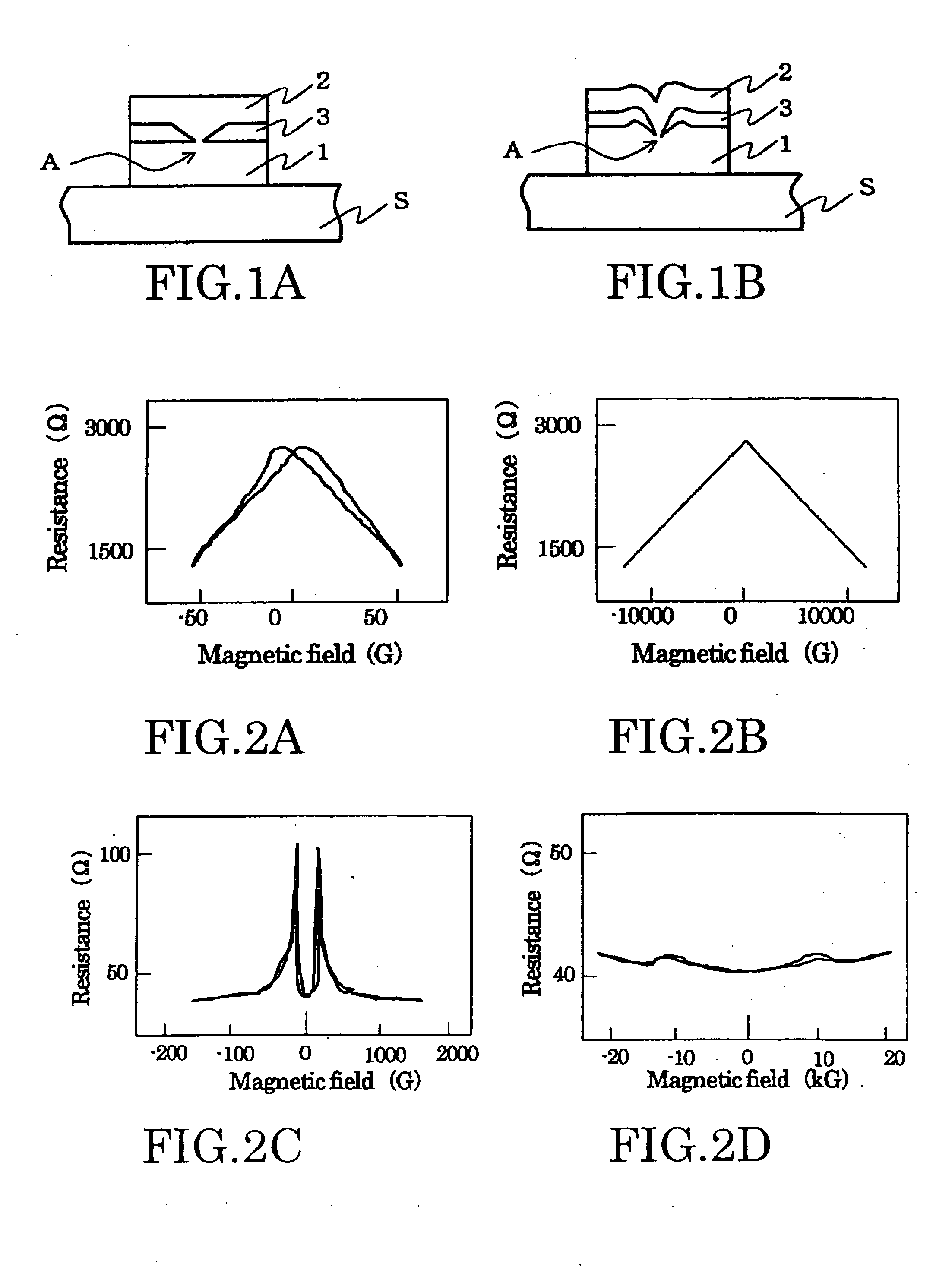

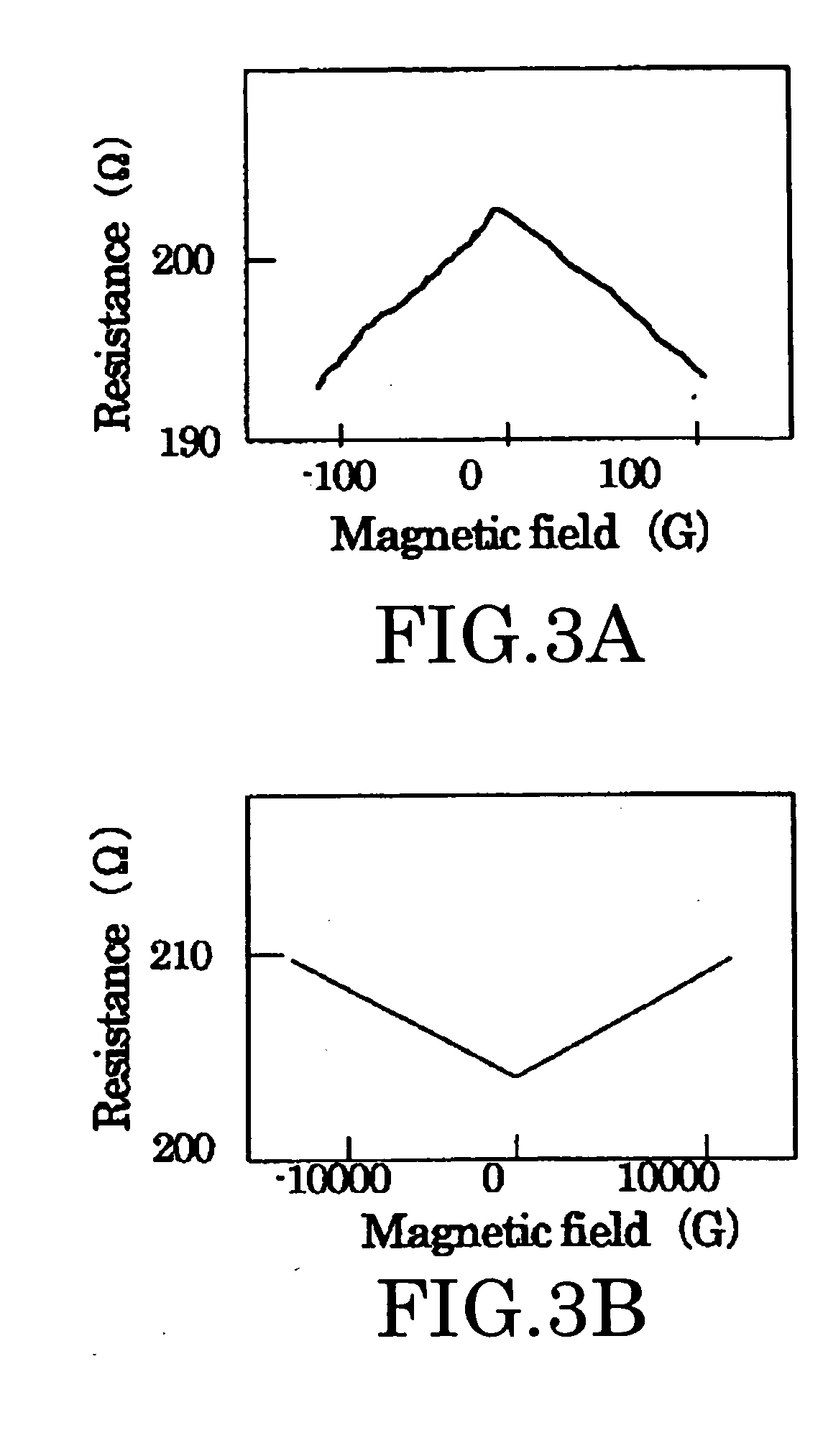

Magneto-resistive element

ActiveUS20050219767A1Magnetic-field-controlled resistorsSolid-state devicesMagnetizationMagnetic reluctance

A magneto-resistive element comprising a free layer having two ferromagnetic layers having a nonmagnetic layer interposed therebetween are coupled with each other in an anti-ferromagnetic manner, a difference between an absolute value of a total of magnetizations of at least one ferromagnetic layer in which the magnetization direction is a first direction and an absolute value of a total of magnetizations of at least one ferromagnetic layer in which the magnetization direction is a second direction which is opposite to the first direction is equal to or smaller than 5×10−15 emu, and planes parallel to a substrate of the ferromagnetic layers are smaller as the planes are distant from the substrate.

Owner:KIOXIA CORP

Current-perpendicular-to-the-plane (CPP) magnetoresistive (MR) sensor having a top shield with an antiparallel structure

ActiveUS8638530B1Improved top shield structureInduce noiseNanoinformaticsRecord information storageMagnetizationEngineering

A current-perpendicular-to-the-plane magnetoresistive sensor structure includes at least an improved top shield structure and optionally also a similar bottom shield structure. The top shield structure includes an antiparallel structure (APS) of two ferromagnetic films and a nonmagnetic antiparallel coupling (APC) film between them. The APC film induces antiferromagnetic (AF) coupling between the two ferromagnetic films so that they have their respective magnetizations oriented antiparallel. An important aspect of the APS is that there is no antiferromagnetic layer adjacent the upper ferromagnetic film, so that the upper ferromagnetic film does not have its magnetization pinned by an antiferromagnetic layer. An electroplated shield layer is formed above the APS. A nonmagnetic decoupling layer is located between the APS and the electroplated shield layer to prevent domain wall movement in the electroplated shield from transferring to the ferromagnetic layers in the APS and thus possibly induce noise in the sensor.

Owner:WESTERN DIGITAL TECH INC

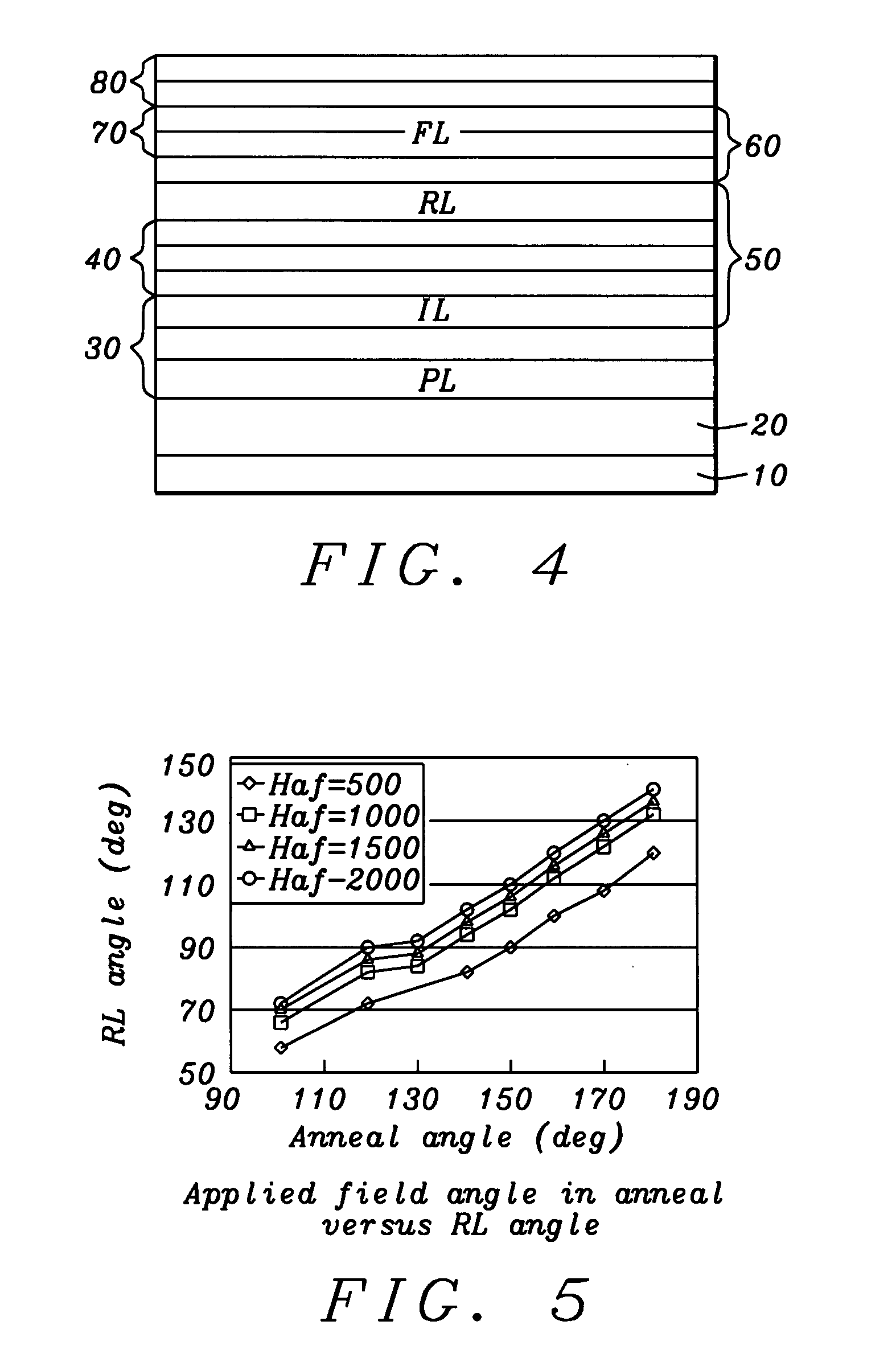

Current-perpendicular-to-the-plane (CPP) magnetoresistive (MR) sensor structure with multiple stacked sensors and center shield with CoFeB insertion layer

ActiveUS8873204B1Improve smoothnessRecord information storageManufacture of flux-sensitive headsCouplingAlloy

A two-dimensional magnetic recording (TDMR) read head structure has the lower read sensor free layer magnetization biased by side shields of soft magnetic material. A center shield between the lower and upper sensors is an antiparallel coupled magnetic structure, i.e., first and second ferromagnetic layers separated by an antiparallel coupling (APC) layer. The first ferromagnetic layer is ferromagnetically exchange coupled to the side shields of the lower sensor to stabilize the magnetization of the lower sensor's free layer. The first ferromagnetic layer of the center shield is a multilayer of a lower NiFe layer and an upper CoFeB alloy layer inserted below the APC layer. The CoFeB alloy insertion layer increases the antiparallel coupling of the first and second ferromagnetic layers of the center shield after two orthogonal anneals so that the magnetization of the first ferromagnetic layer is aligned parallel to the air-bearing surface (ABS) of the TDMR structure.

Owner:WESTERN DIGITAL TECH INC

Magnetoresistance effect element and magnetic random access memory

ActiveUS8014193B2Minimise currentHigh-speed writingMagnetic-field-controlled resistorsSolid-state devicesStatic random-access memoryMicrowave

Owner:KIOXIA CORP

Thermally assisted magnetic recording system and method of writing using magnetic and thermal gradients

InactiveUS6950260B2Avoid thermal instabilityRapid coolingCombination recordingRecord information storageMagnetic field gradientMagnetic media

A magnetic recording system is provided having a write head employing a combination of magnetic write field gradient and thermal gradient to write data on a ‘thermal spring’ magnetic recording media. The write head comprises a magnetic element using a write current to induce a magnetic write field at the magnetic media and a thermal element using a very small aperture laser to heat a portion of the media. The thermal spring magnetic media comprises [comprises] first and second stacks providing two exchange coupled ferromagnetic layers having different Curie temperatures [The first stack has a high magneto-crystalline anisotropy, a relatively low saturation magnetization and a low Curie temperature.] [The second stack has a relatively low magneto-crystalline anisotropy, a high saturation magnetization and a high Curie temperature.] The magnetic field gradient and the thermal gradient are arranged to substantially overlap at the trailing edge of the heated portion of the magnetic media allowing data at high density with high thermal stability to be recorded on the rapidly cooling thermal spring magnetic recording media.

Owner:WESTERN DIGITAL TECH INC

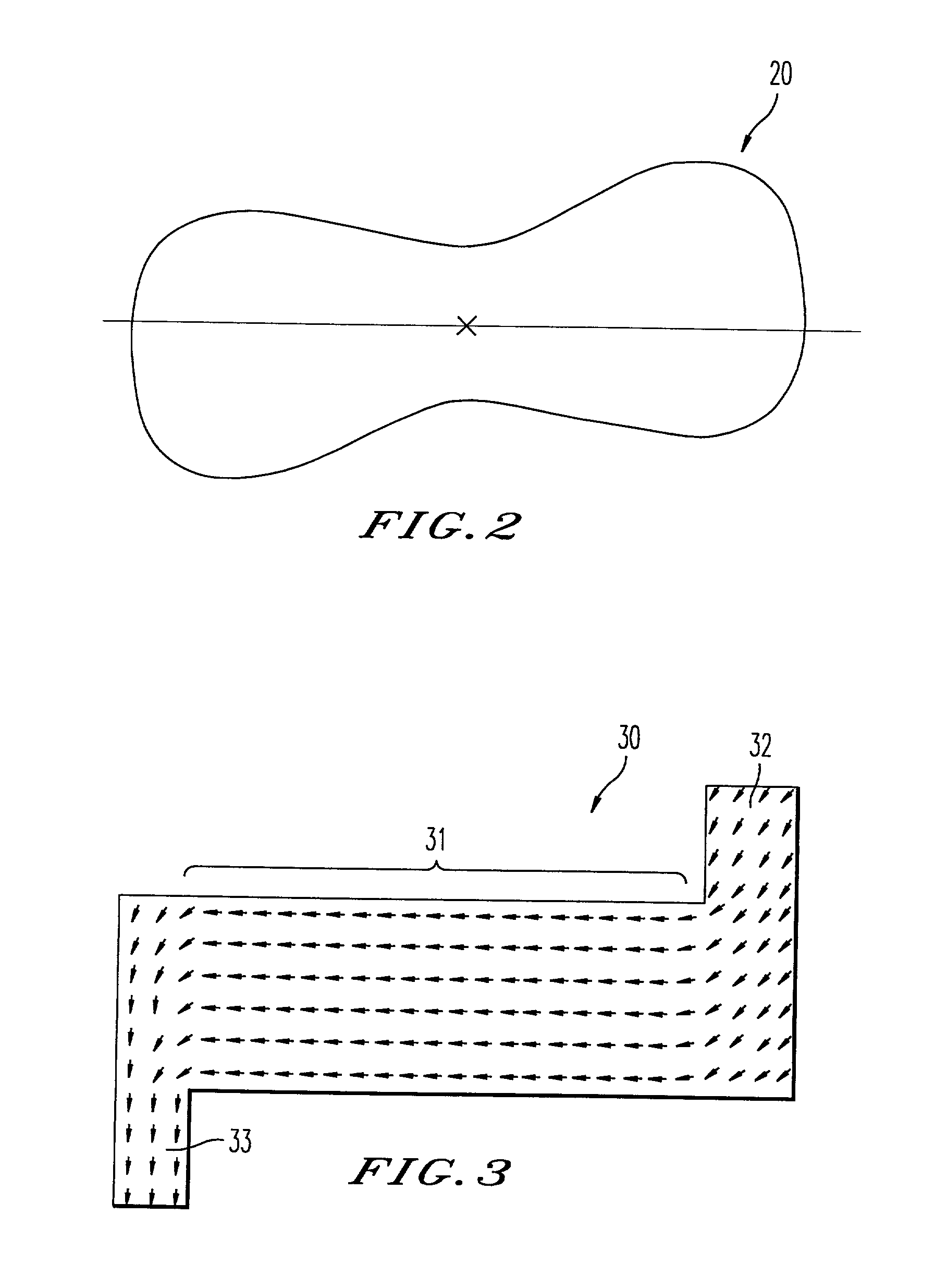

Current-perpendicular-to-plane magnetoresistive sensor with free layer stabilized against vortex magnetic domains generated by the sense current

InactiveUS20050174701A1Magnetic measurementsMagnetic-field-controlled resistorsMagnetosphereMagnetic domain

A current-perpendicular-to-the-plane (CPP) magnetoresistive sensor has additional layers for stabilizing the free layer against sense-current-generated magnetic fields. A ferromagnetic stabilizing layer is spaced from the free layer by a spacer layer and is exchange coupled with a second antiferromagnetic layer, the first antiferromagnetic layer being the conventional one for pinning the pinned layer in the CPP sensor. The stabilizing layer is in a vortex or other non-longitudinal magnetization pattern that is fixed by exchange coupling with the second antiferromagnetic layer. The stabilizing layer is also ferromagnetically coupled to the free layer across the spacer layer so that in the absence of both a sense current and an external magnetic field, the free and stabilization layers have similarly shaped vortex or other non-longitudinal magnetization patterns. The sense current generates a vortex magnetic field in the free layer opposite to the fixed vortex magnetization pattern in the stabilizing layer and essentially erases the effect of the vortex magnetization pattern in the free layer.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Magnetoresistance effect element, its manufacturing method, magnetic reproducing element and magnetic memory

A magnetoresistance effect element includes a first ferromagnetic layer (1), insulating layer (3) overlying the first ferromagnetic layer, and second ferromagnetic layer (2) overlying the insulating layer. The insulating layer has formed a through hole (A) having an opening width not larger than 20 nm, and the first and second ferromagnetic layers are connected to each other via the through hole.

Owner:KK TOSHIBA

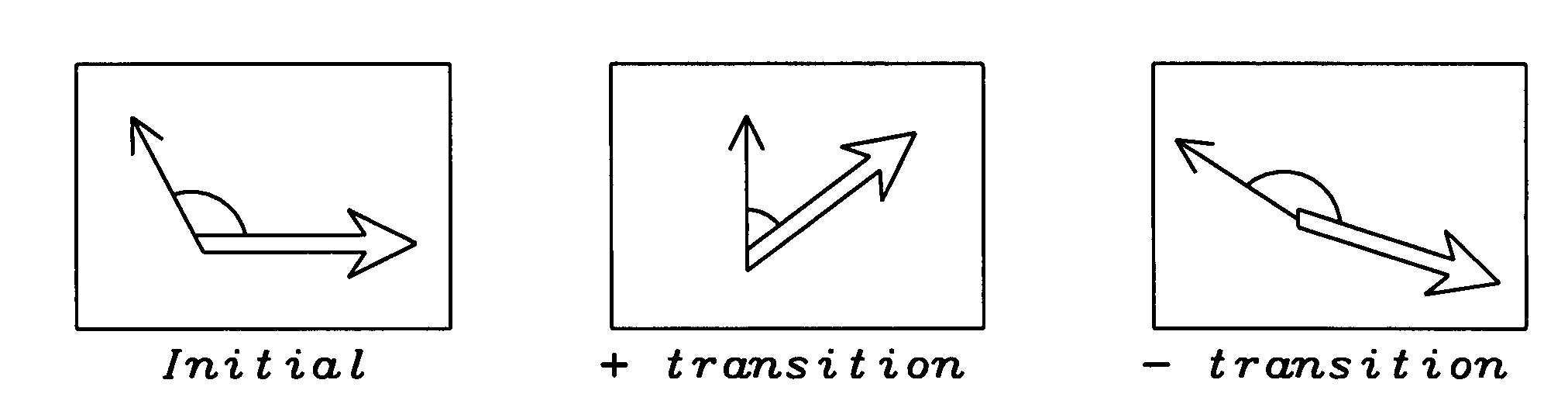

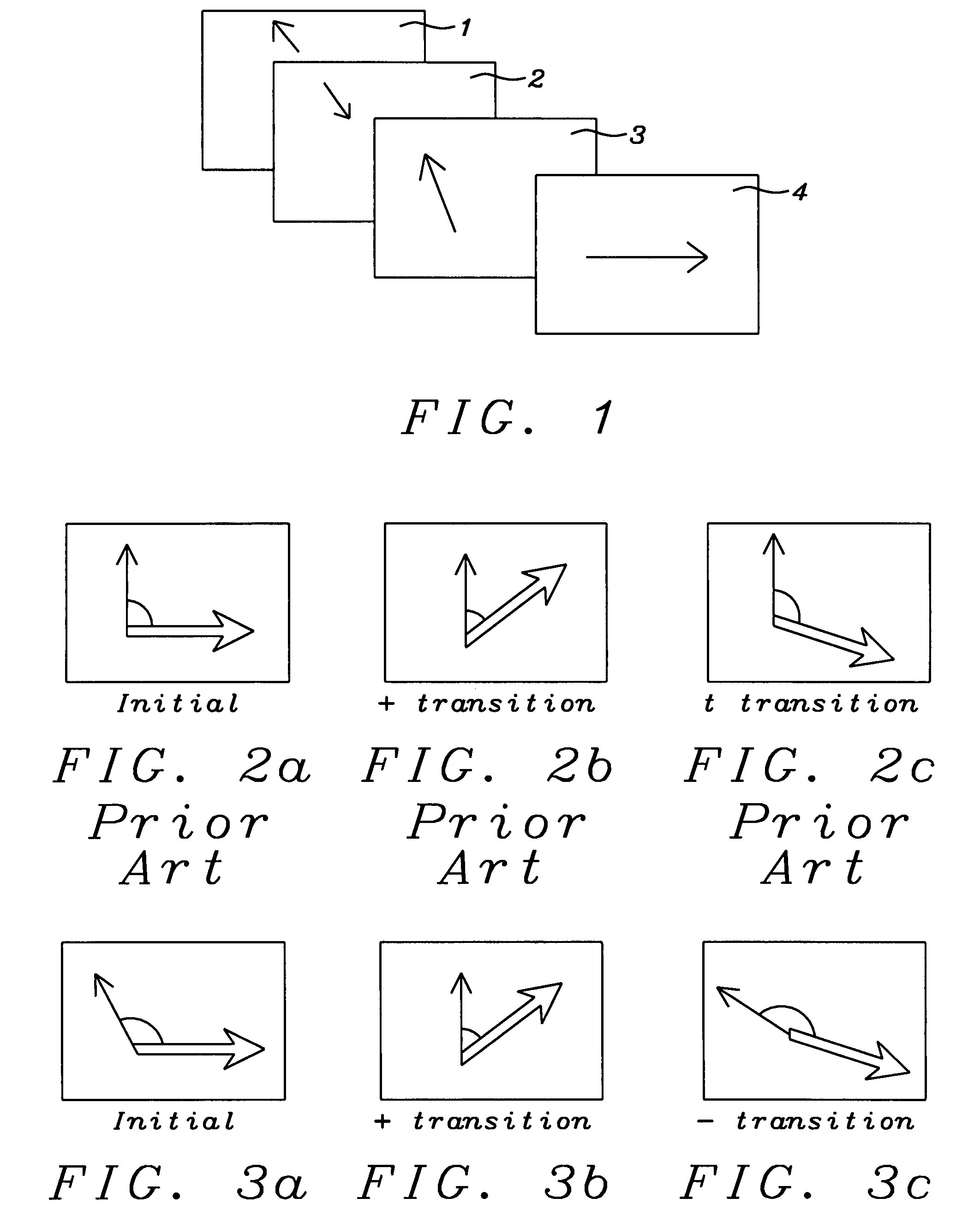

GMR sensor having a reference layer with movable magnetization

ActiveUS7345854B2High sensitivityLow limitRecord information storageManufacture of flux-sensitive headsInter layerCoupling

A method for fabricating a spin-valve GMR sensor having a reference layer with a magnetic moment that moves in an opposite direction to that of the free layer in the presence of external magnetic field transitions. The reference layer is a part of a three ferromagnetic layer structure, including pinned, intermediate and reference layers, that when the layers are taken pairwise and separated by spacer layers, includes a strongly exchange coupled synthetic ferrimagnetic pinned and intermediate layer pair and a weakly exchange coupled synthetic ferrimagnetic intermediate and reference layer pair. The reference layer, because of its weak coupling to the intermediate layer, has a magnetic moment that is free to move. During sensor operation, the reference layer and free layer move in opposite directions under the influence of external magnetic field transitions The novel three layer structure provides a sensor of increased sensitivity for a given track width.

Owner:HEADWAY TECH INC

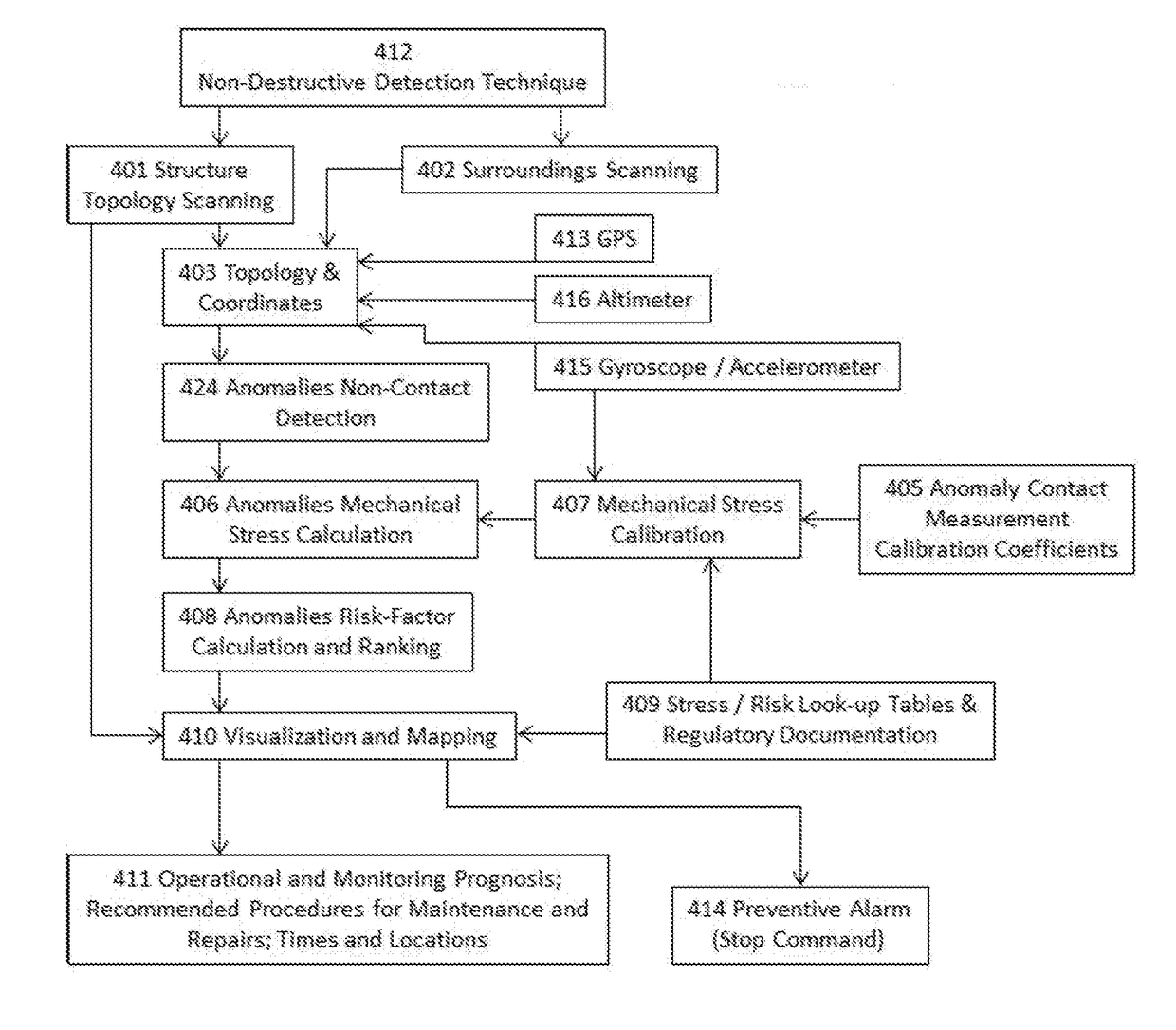

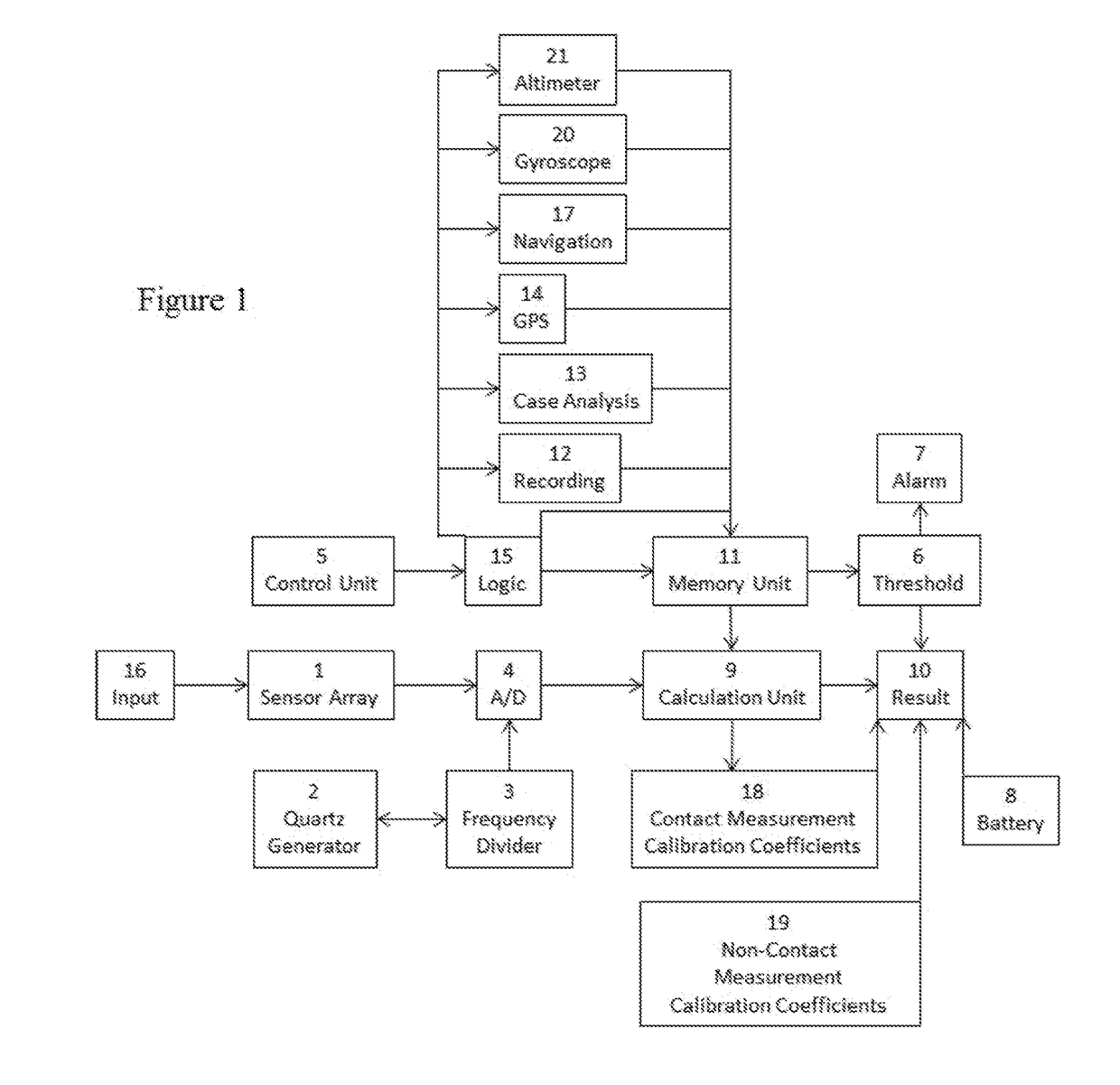

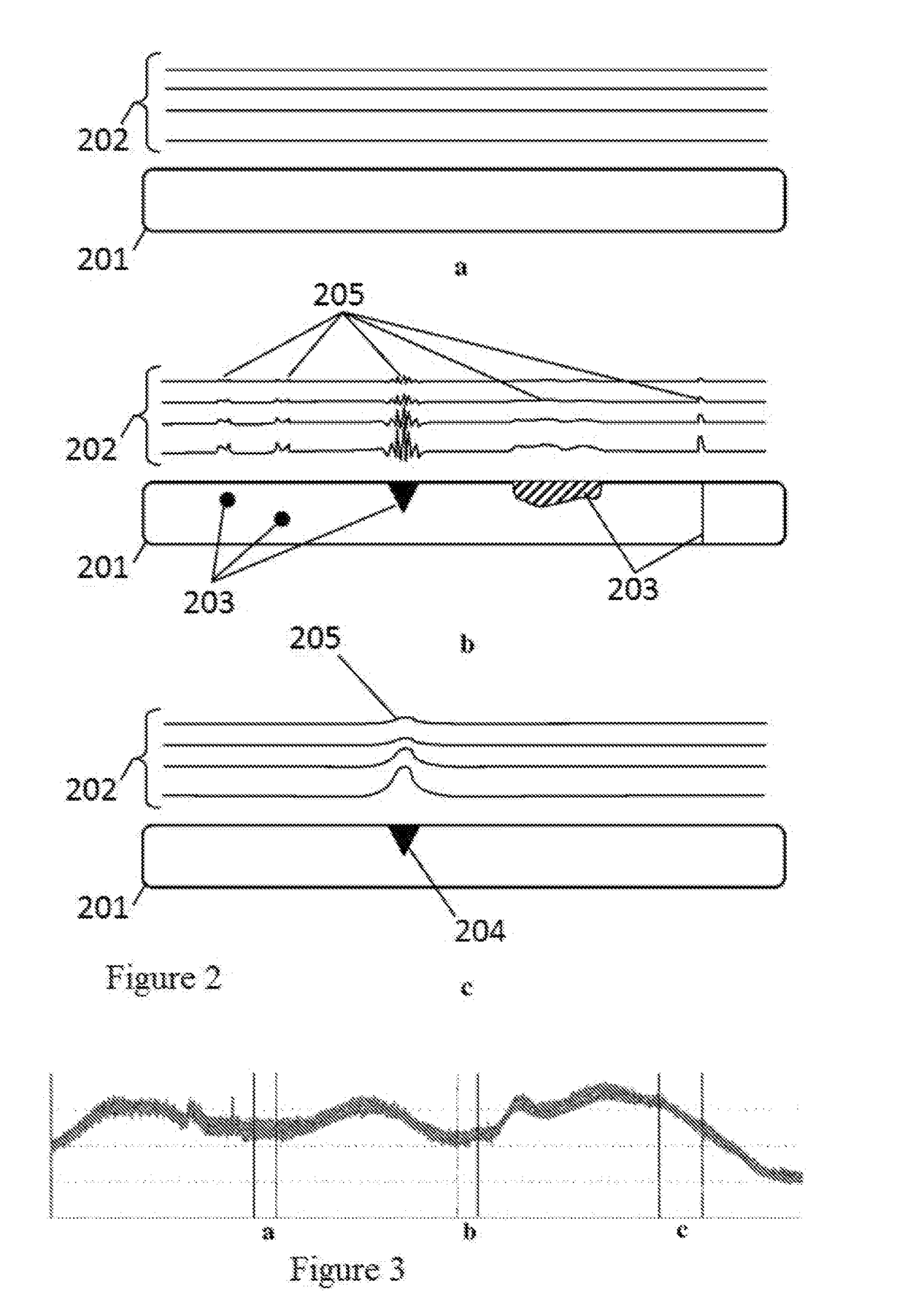

Non-destructive system and method for detecting structural defects

ActiveUS20170122909A1Stable positionImprove accuracyForce measurement by measuring magnetic property varationUnmanned aerial vehiclesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device can determine the position of the defect or stress including depth information. The device includes registration means that optimized for use with metallic structures of various types, shapes, and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in roiled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, bridges, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

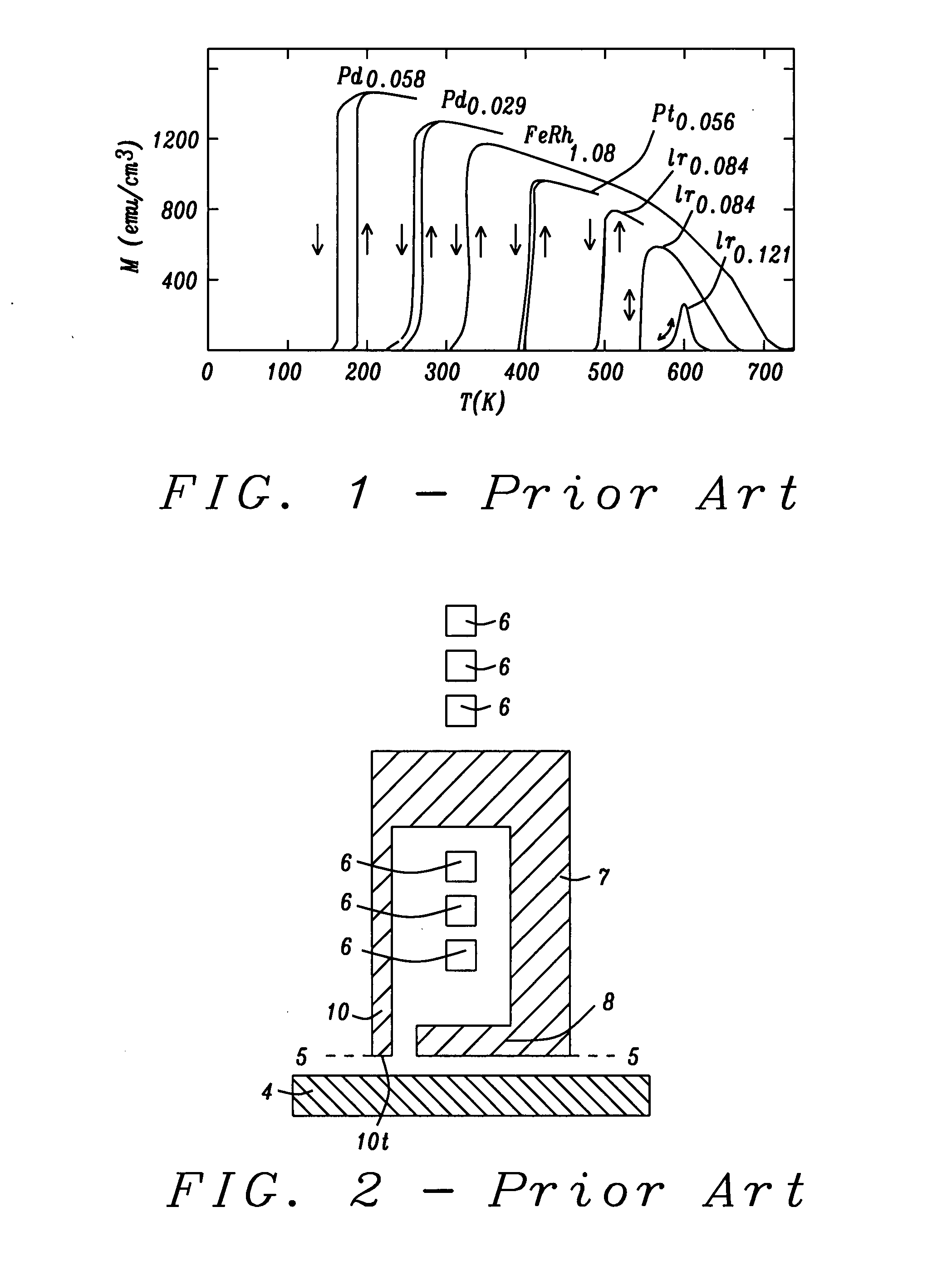

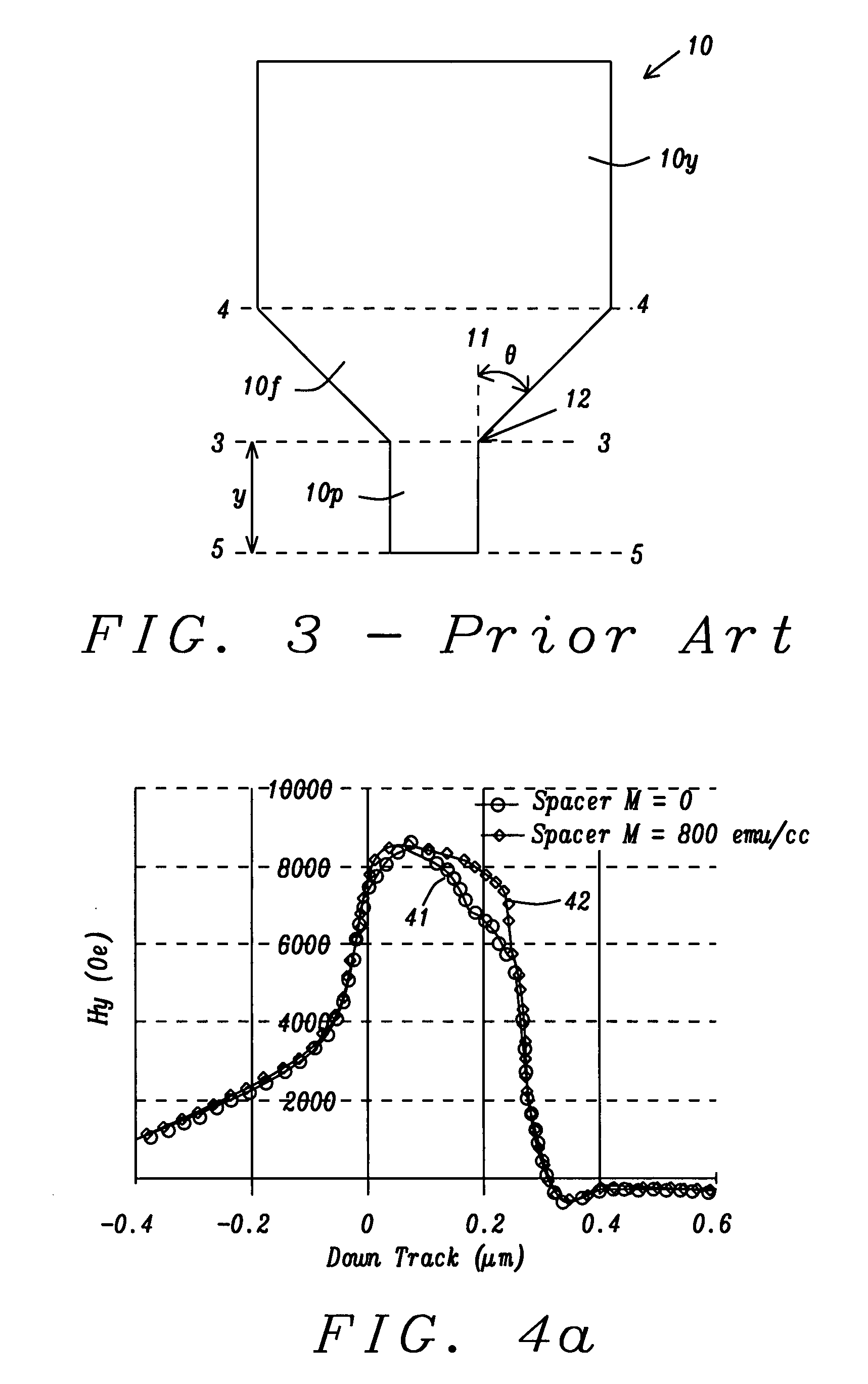

Perpendicular magnetic recording head laminated with AFM-FM phase change material

InactiveUS20090052092A1Decreasing remanenceMinimize pole erasureRecord information storageManufacture of flux-sensitive headsAlloyPhase-change material

A PMR writer is disclosed that minimizes pole erasure during non-writing and maximize write field during writing through an AFM-FM phase change material that is in an AFM state during non-writing and switches to a FM state by heating during writing. The main pole layer including the write pole may be comprised of a laminated structure having a plurality of “n” ferromagnetic layers and “n-1” AFM-FM phase change material layers arranged in an alternating manner. The AFM-FM phase change material is preferably a FeRh or FeRhX alloy (X=Pt, Pd, or Ir) having a Rh content >35 atomic %. AFM-FM phase change material may also be used as a flux gate to prevent yoke flux from leaking into the write pole tip. Heating for the AFM to FM transition is provided by write coils and / or a coil located near the AFM-FM phase change material to enable faster transition times.

Owner:HEADWAY TECH INC

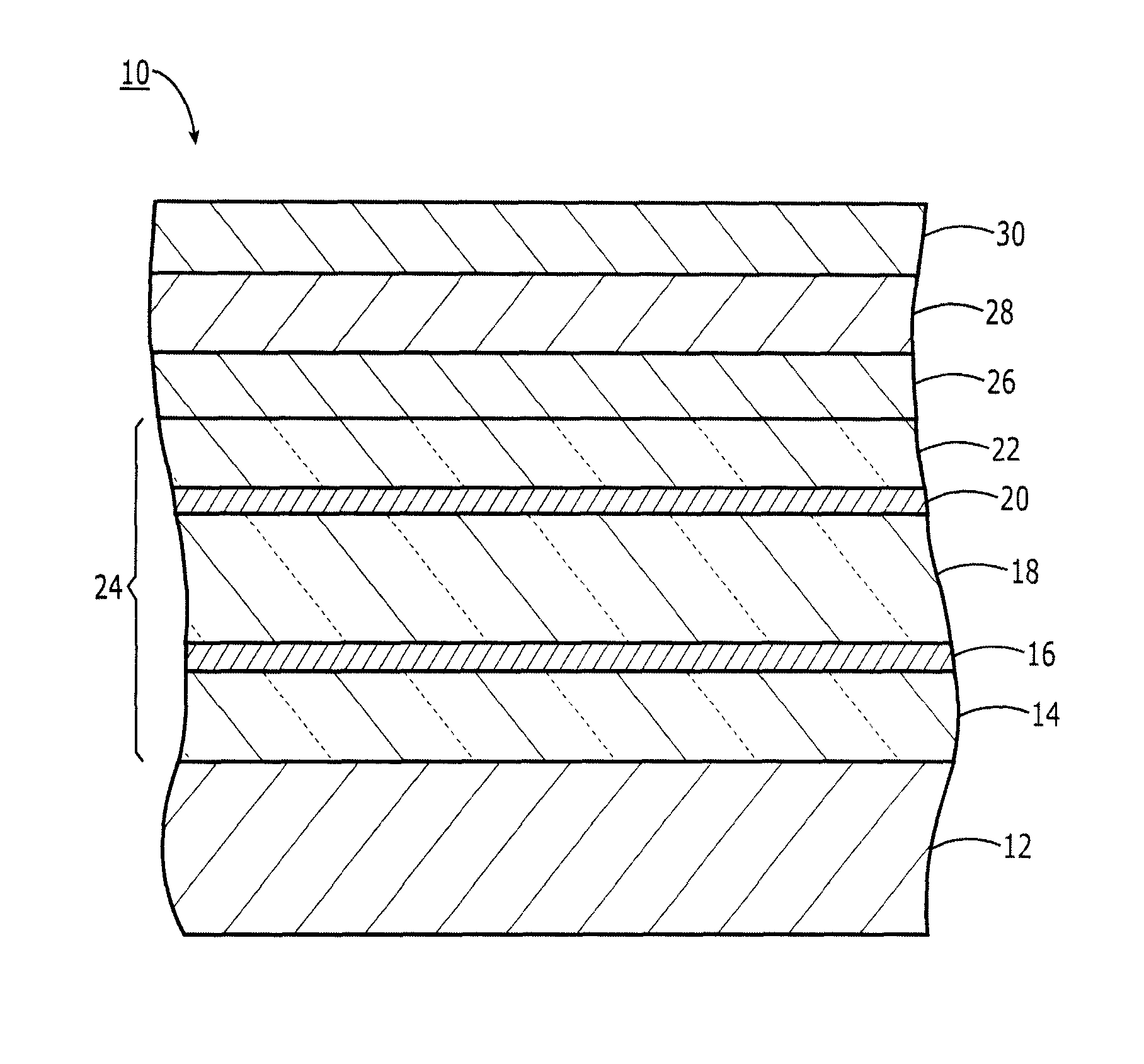

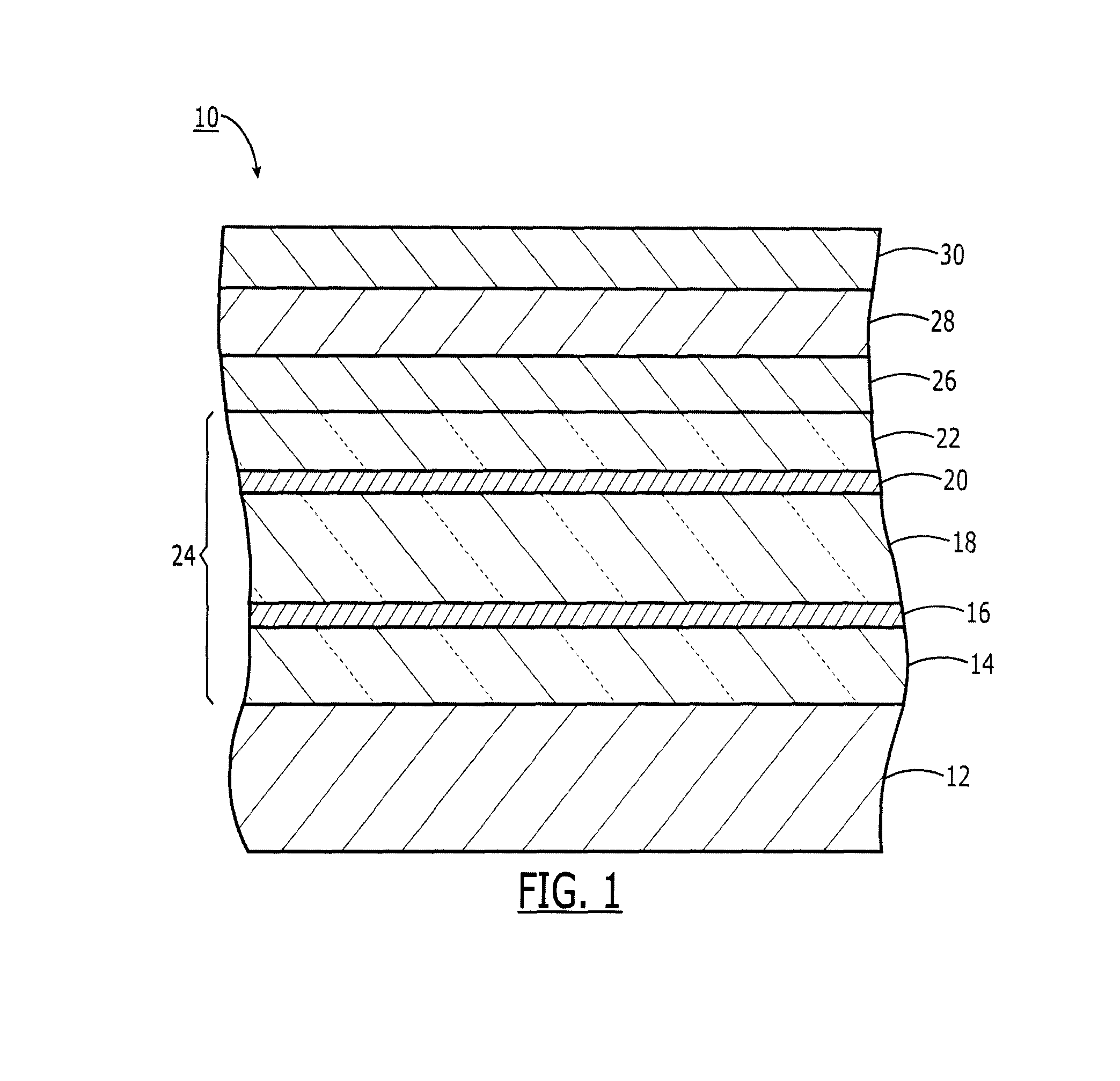

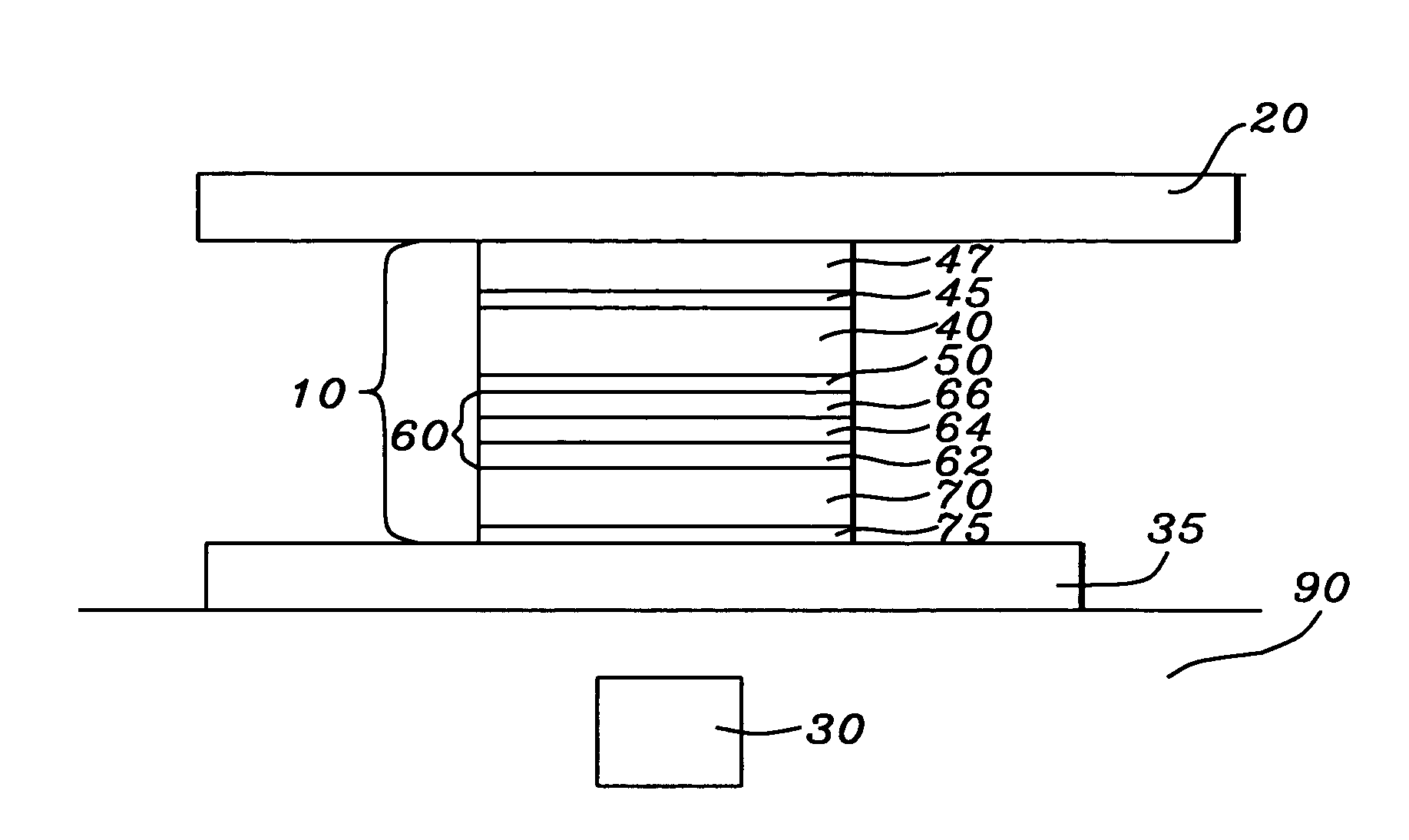

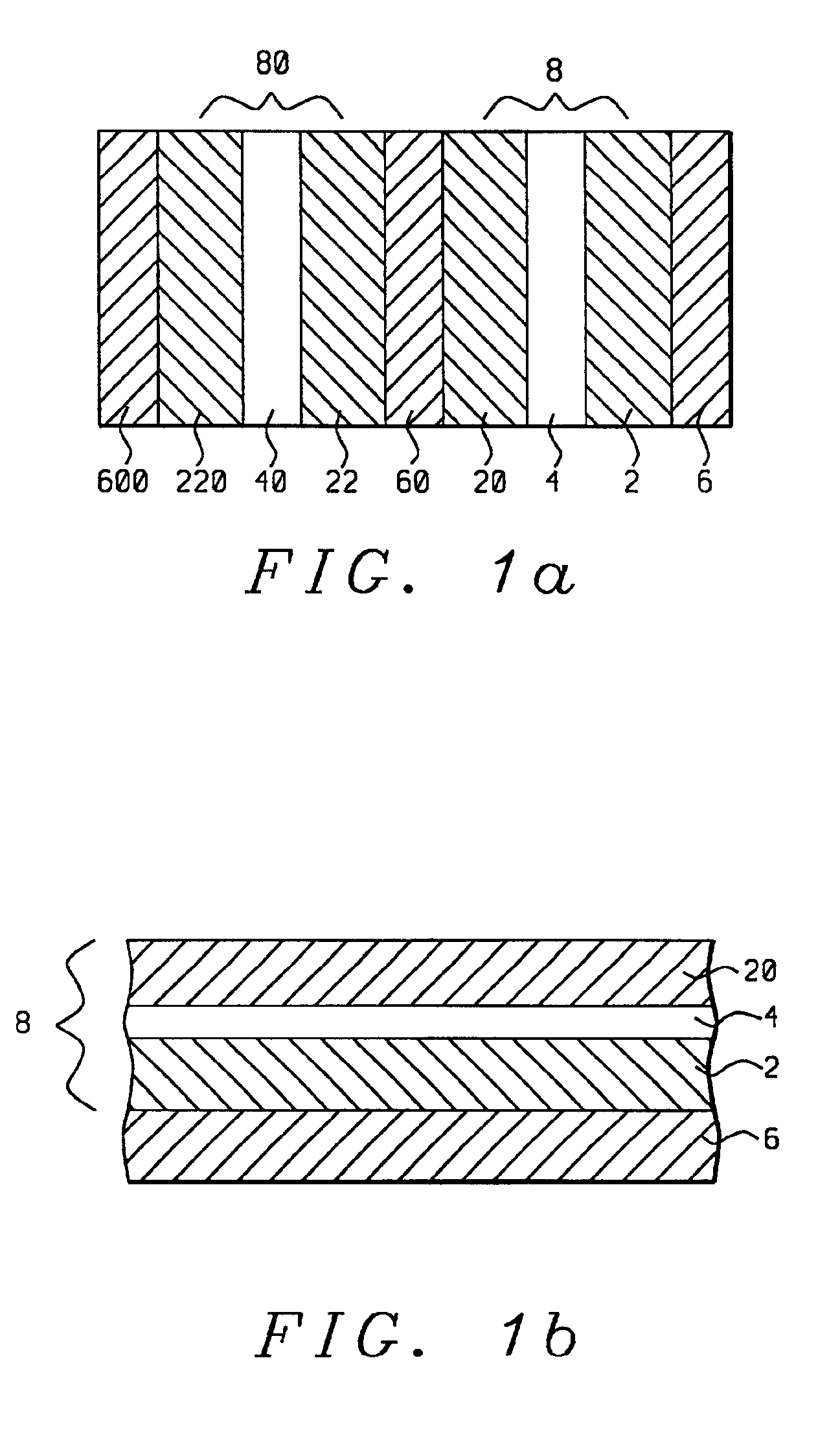

Multilayered structures comprising magnetic nano-oxide layers for current perpindicular to plane GMR heads

InactiveUS6888703B2Enhanced magnetoresistive propertiesNanomagnetismNanoinformaticsElectrical resistance and conductanceEngineering

Nano-oxide based current-perpendicular-to-plane (CPP) magnetoresistive (MR) sensor stacks are provided, together with methods for forming such stacks. Such stacks have increased resistance and enhanced magnetoresistive properties relative to CPP stacks made entirely of metallic layers. Said enhanced properties are provided by the insertion of magnetic nano-oxide layers between ferromagnetic layers and non-magnetic spacer layers, whereby said nano-oxide layers increase resistance and exhibit spin filtering properties. CPP sensor stacks of various types are provided, all having nano-oxide layers formed therein, including the spin-valve type and the synthetic antiferromagnetic pinned layer spin-valve type. Said stacks can also be formed upon each other to provide laminated stacks of different types.

Owner:HEADWAY TECH INC

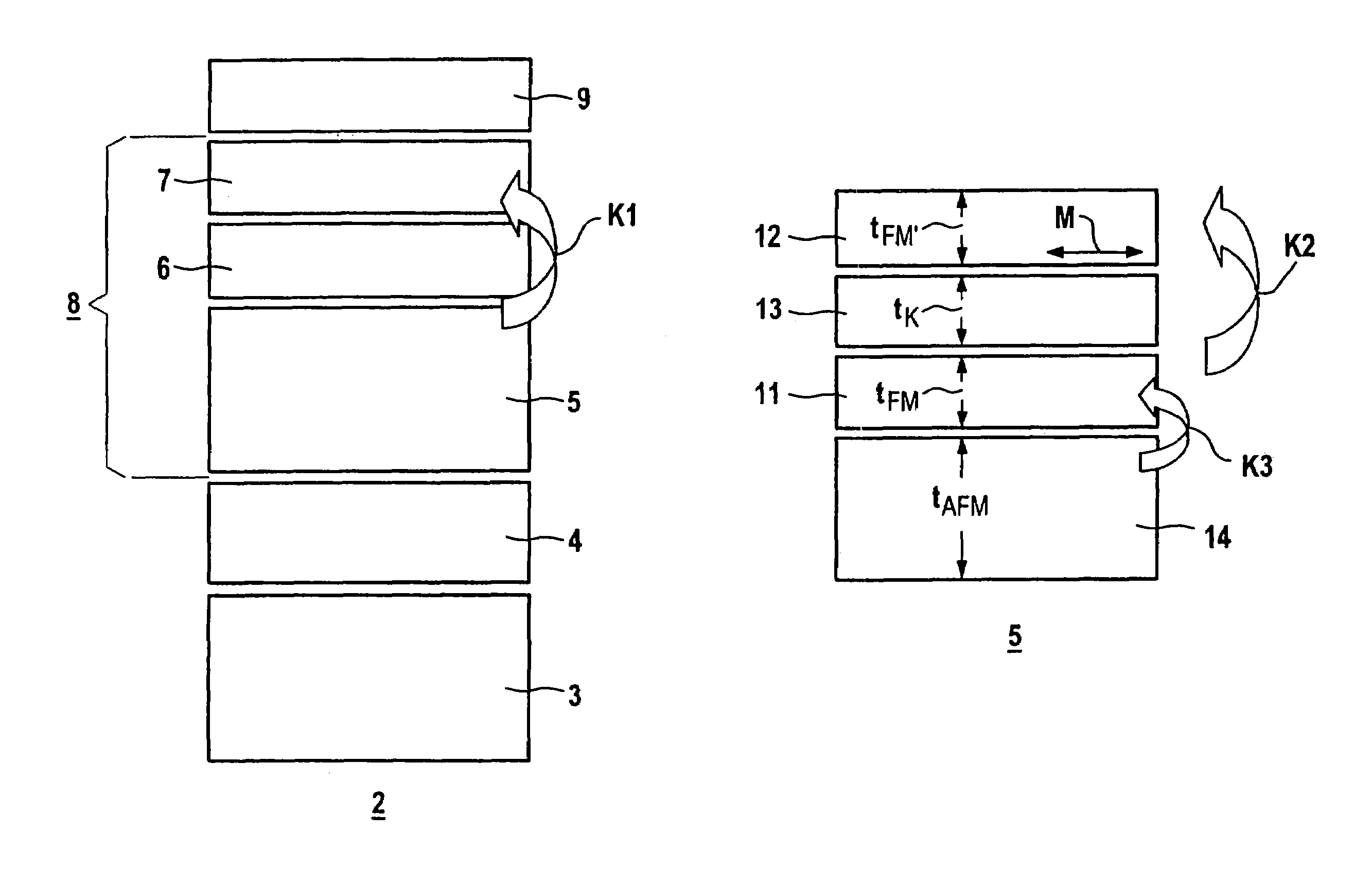

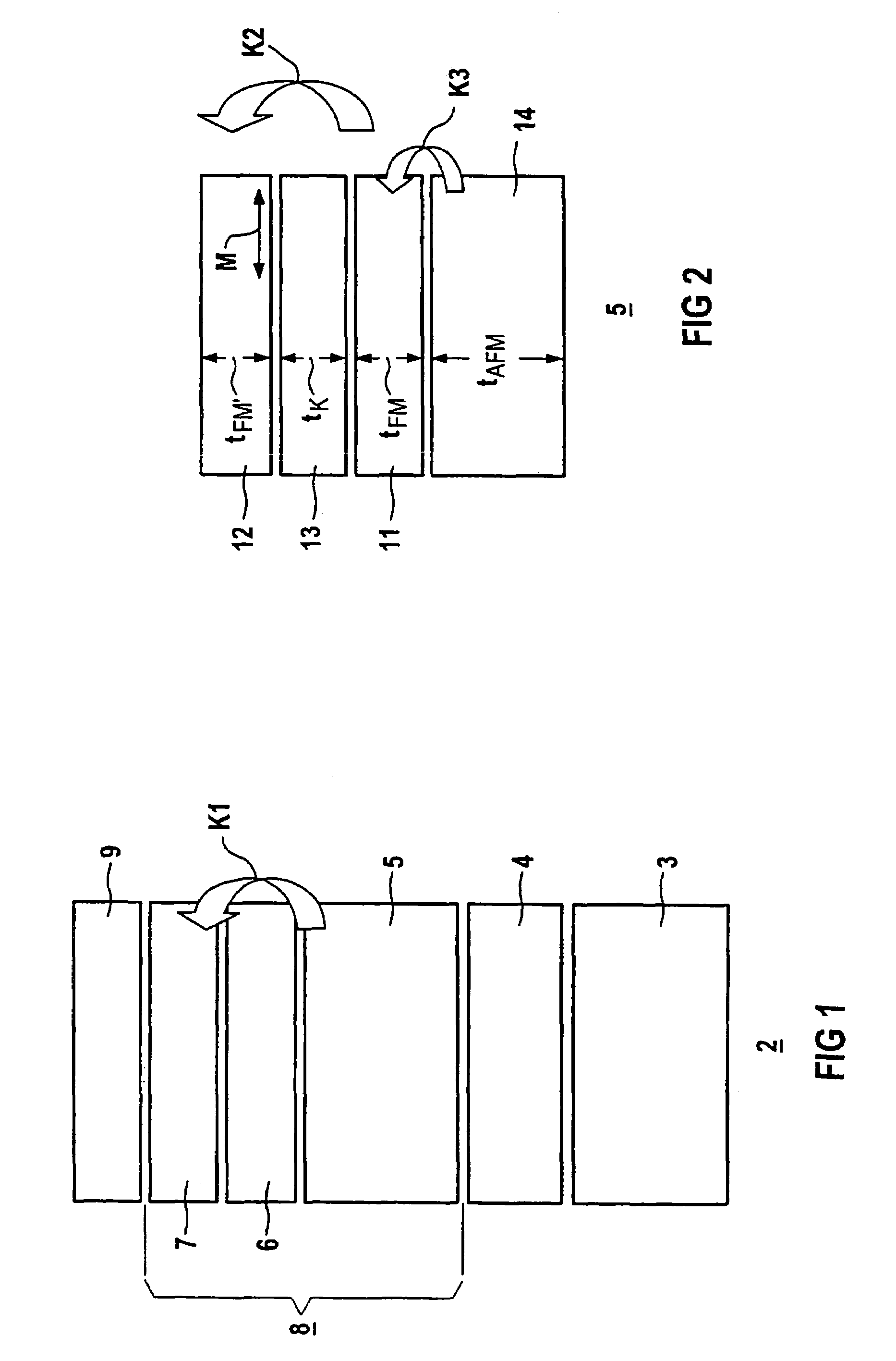

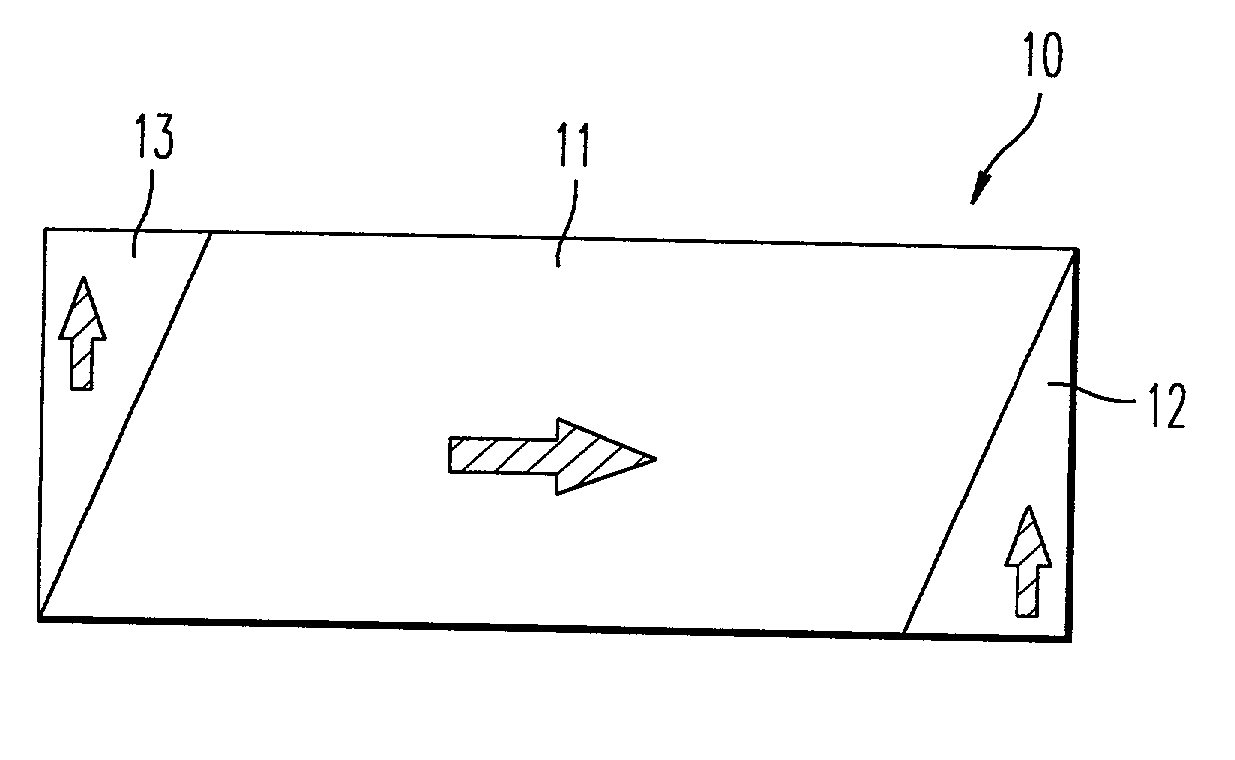

Layer system having an increased magnetoresistive effect and use of the same, wherein a first layer of an artificial antiferromagnet has a relatively low cobalt content

InactiveUS6970333B2Good flexibilityReduce contentNanomagnetismMagnetic measurementsPartial systemAntiferromagnetic coupling

The layer system having an increased magnetoresistive effect contains at least one soft magnetic detection layer, a non-magnetic decoupling layer, which rests on the detection layer, and a layer partial system, which is located at a distance due to the decoupling layer, forms an artificial antiferromagnet, and which is decoupled from the detection layer. This partial system comprises a first ferromagnetic and a second ferromagnetic layer. The first ferromagnetic layer should be antiferromagnetically coupled (K2) to the second ferromagnetic layer via a non-magnetic coupling layer. In addition, the side of the first ferromagnetic layer facing away from the coupling layer should be provided with an antiferromagnetic additional layer and be exchange-coupled (K3) thereto and, in addition, should have a material composition that differs from the second ferromagnetic layer.

Owner:SIEMENS AG

Perpendicular magnetic recording head laminated with AFM-FM phase change material

InactiveUS8004794B2Decreasing remanenceMinimize pole erasureRecord information storageManufacture of flux-sensitive headsEngineeringAlloy

Owner:HEADWAY TECH INC

Magnetoresistance effect device, method of manufacturing the same, magnetic memory apparatus, personal digital assistance, and magnetic reproducing head, and magnetic information reproducing apparatus

InactiveUS20020130339A1Simple highly productive manufacturing methodControllability lostNanomagnetismMagnetic measurementsMagnetic stabilityRandom access memory

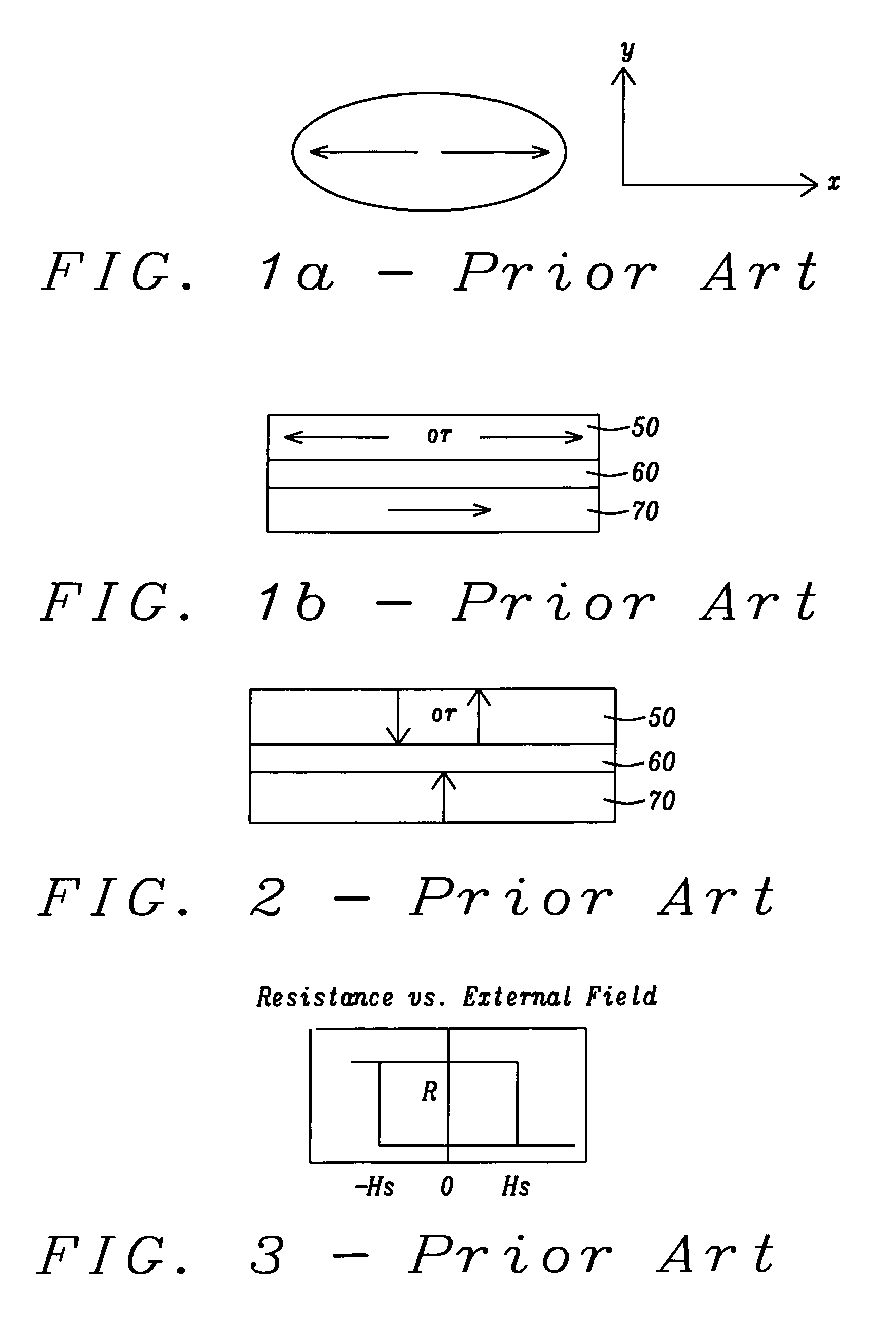

Magnetoresistance effect devices for attaining magnetically stability and for reducing a switching magnetic field. One of the ferromagnetic layers of the magnetoresistance effect device has a plane shape in which a width of an end portions is wider than a center portion sandwiched by two end portions. The end portions are not symmetrical with respect to an easy magnetization axis or longer axis of the plane shape of ferromagnetic material layer, but are substantially rotationally symmetrical with a center of the plane shape as a pivot. The plane shape may have an S-shape where its magnetic domain is stabilized and the switching magnetic field is reduced. The manufacturing method uses two linear mask patterns intersecting with each other to form sharp corners of a ferromagnetic tunnel junction. An electron beam (EB) drawing may be used to form the S-shape plane. The magnetoresistance effect devices may be used in a magnetic memory apparatus, such as a random access memory, a personal digital assistance, a magnetic reproducing head, and a magnetic information reproducing apparatus.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com