Microwave composite material and preparation method thereof

A composite material and microwave technology, which is applied in the direction of magnetic materials, organic materials/organic magnetic materials, copper organic compounds, etc., can solve problems such as the inability to realize monolithic integrated circuits, low relative permeability, and large dielectric constant. , to achieve the effect of weight reduction, high relative permeability and high relative permittivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

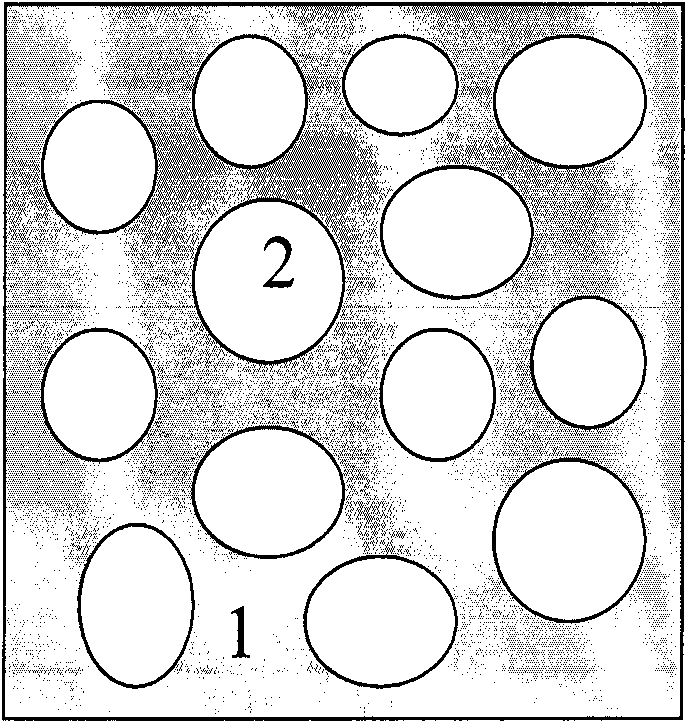

[0040] The present embodiment is a composite film of Fe-Zn-Mn-O and porphyrin zinc grown on a substrate, wherein, there is also a layer of gold thin film between the substrate and the composite film, which is used as a buffer layer to avoid Cracking of the film or substrate caused by the difference in thermal expansion coefficient between the composite film and the substrate. The buffer layer may also be a thin film formed of tantalum, ruthenium, platinum or the like.

[0041] The preparation method of the composite membrane of the present embodiment is as follows:

[0042] (1) Take three raw materials Fe 2 o 3 , ZnO and Mn 3 o 4 , the mass ratio is 9:1:10, the purity of the raw material is higher than 98%; deionized water is added to the raw material, and the raw material is put into a ball mill to grind for 60 minutes. After drying, pre-fire at 800°C for 3 hours. and then doped with an appropriate amount of SiO 2 , ZrO 2 and CaCO 3 Put it into a ball mill and grind ...

Embodiment 2

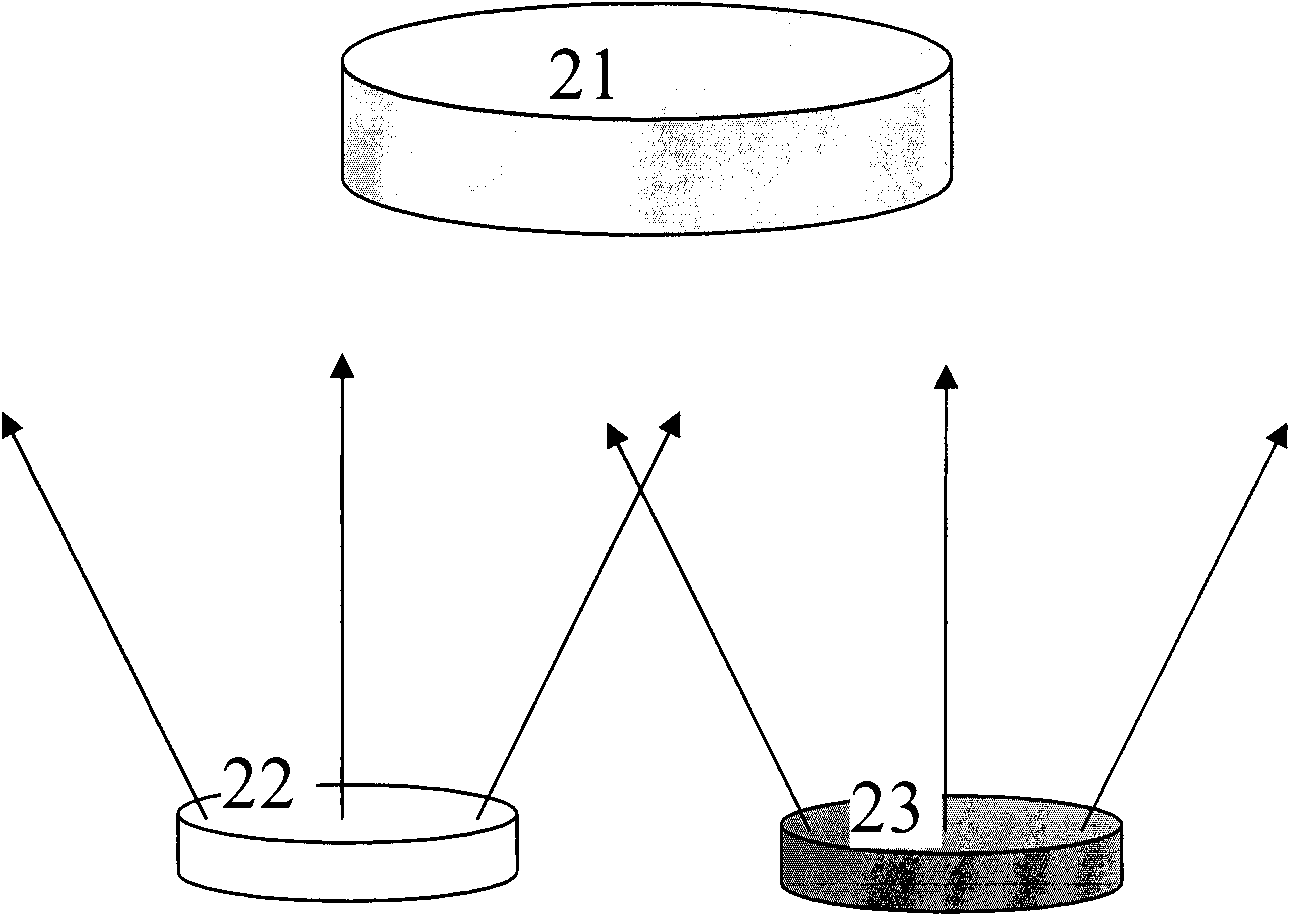

[0049] This embodiment is a composite film of magnetic alloy NiFe nanoparticles and melamine powder. The preparation method is as follows:

[0050] (1) The magnetic alloy NiFe nanoparticles and melamine powder purchased on the market are fully stirred according to the mass ratio of 1: 8, mixed uniformly, and pre-pressed, and then in 10 -4 Sintering at 80° C. for 2 hours in a vacuum environment of Pa to obtain a mixed target.

[0051] (2) using the electron beam evaporation method to grow a 10nm gold film on the Si substrate;

[0052] (3) The mixed target material prepared in (1) was grown by electron beam evaporation method, and a 500nm composite film was grown, wherein the magnetic metal NiFe existed in the form of particles with a diameter of about 100nm.

Embodiment 3

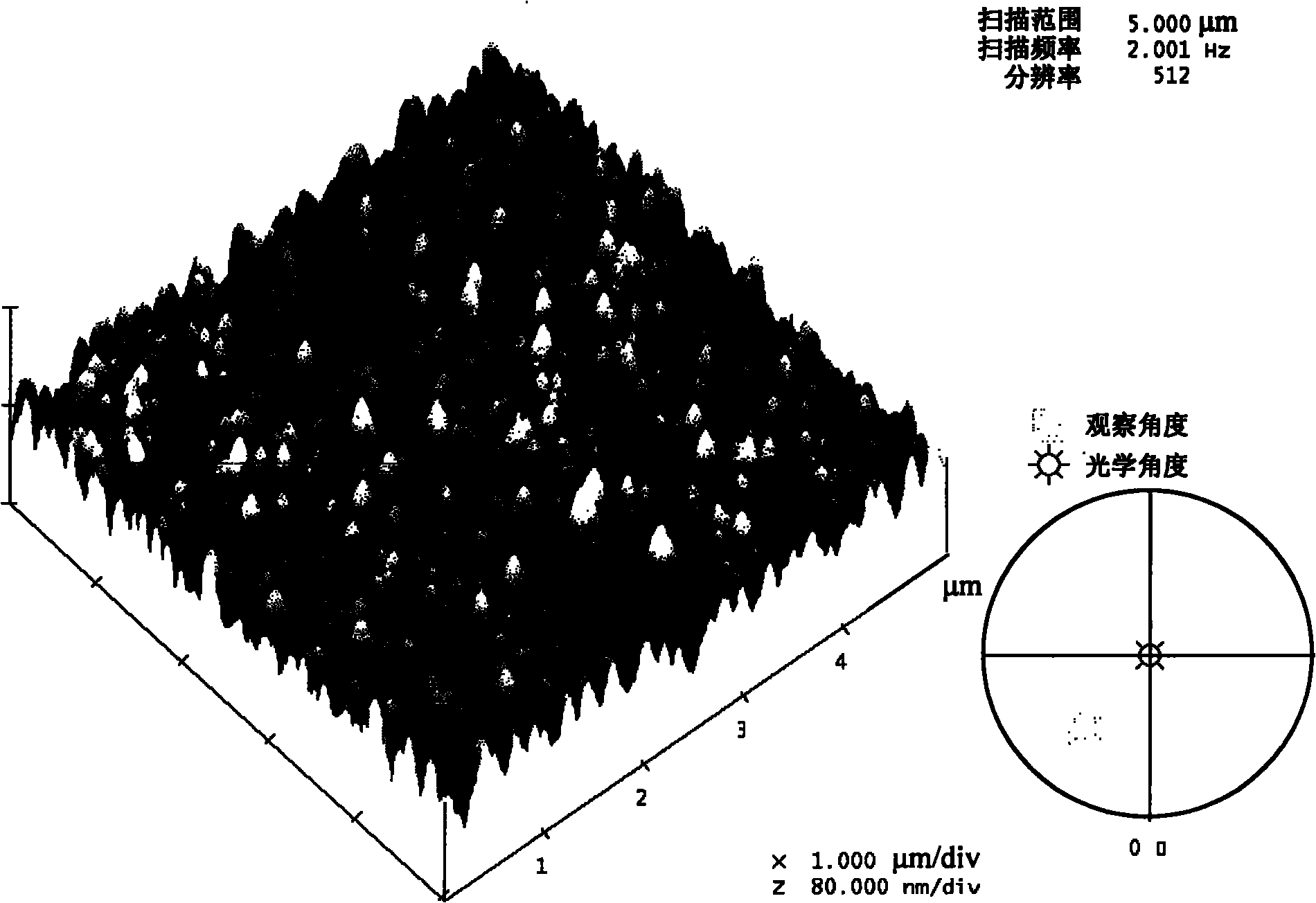

[0054] The present embodiment is a kind of octahydroxyquinoline aluminum (Alq 3 ) and a composite film of magnetic metal powder Co. The preparation method is as follows:

[0055] (1) Thermal evaporation on a thin Cu substrate (thickness about 0.1mm) to obtain a 10nm gold film

[0056] (2) Two kinds of thin films were deposited separately by thermal evaporation method. The organic material octahydroxyquinoline aluminum (Alq 3 ) and magnetic metal powder Co were put into two crucible evaporation boats. The background vacuum is better than 3×10 -4 Under the environment of Pa, the evaporation boat containing the aluminum octahydroxyquinoline and the evaporation boat containing the metal powder Co are heated with an appropriate current at the same time, so as to realize simultaneous coating. The coating speed and film thickness are monitored in real time by a crystal oscillator film thickness tester, and the voltage applied to the evaporation boat is adjusted to control the ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com