Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about "Pigment preparation by PVD/CVD methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

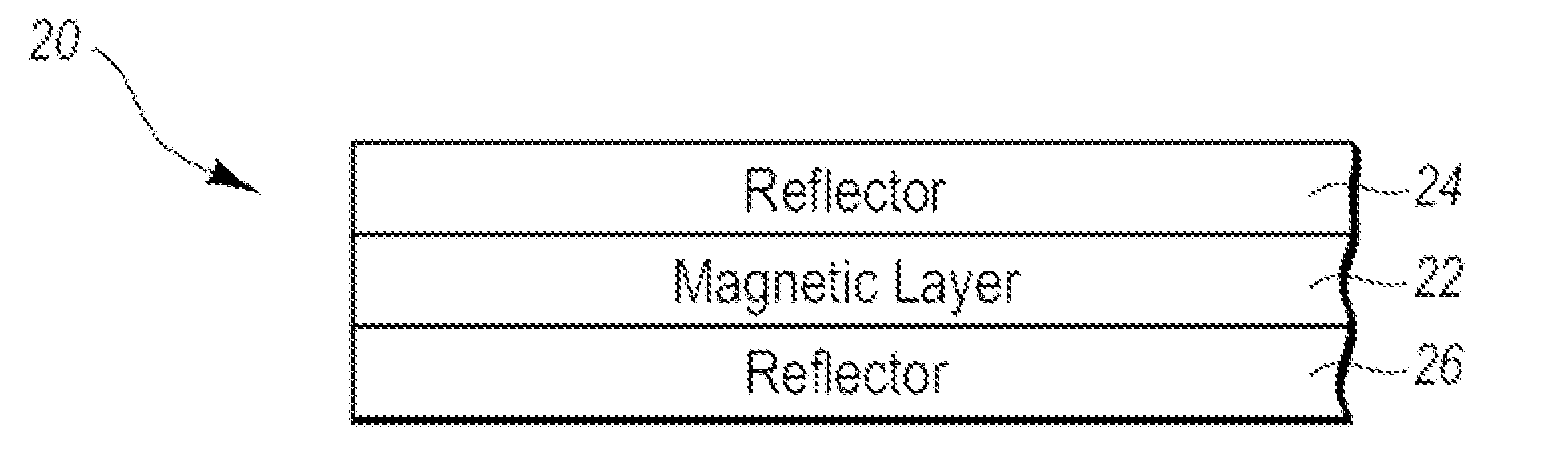

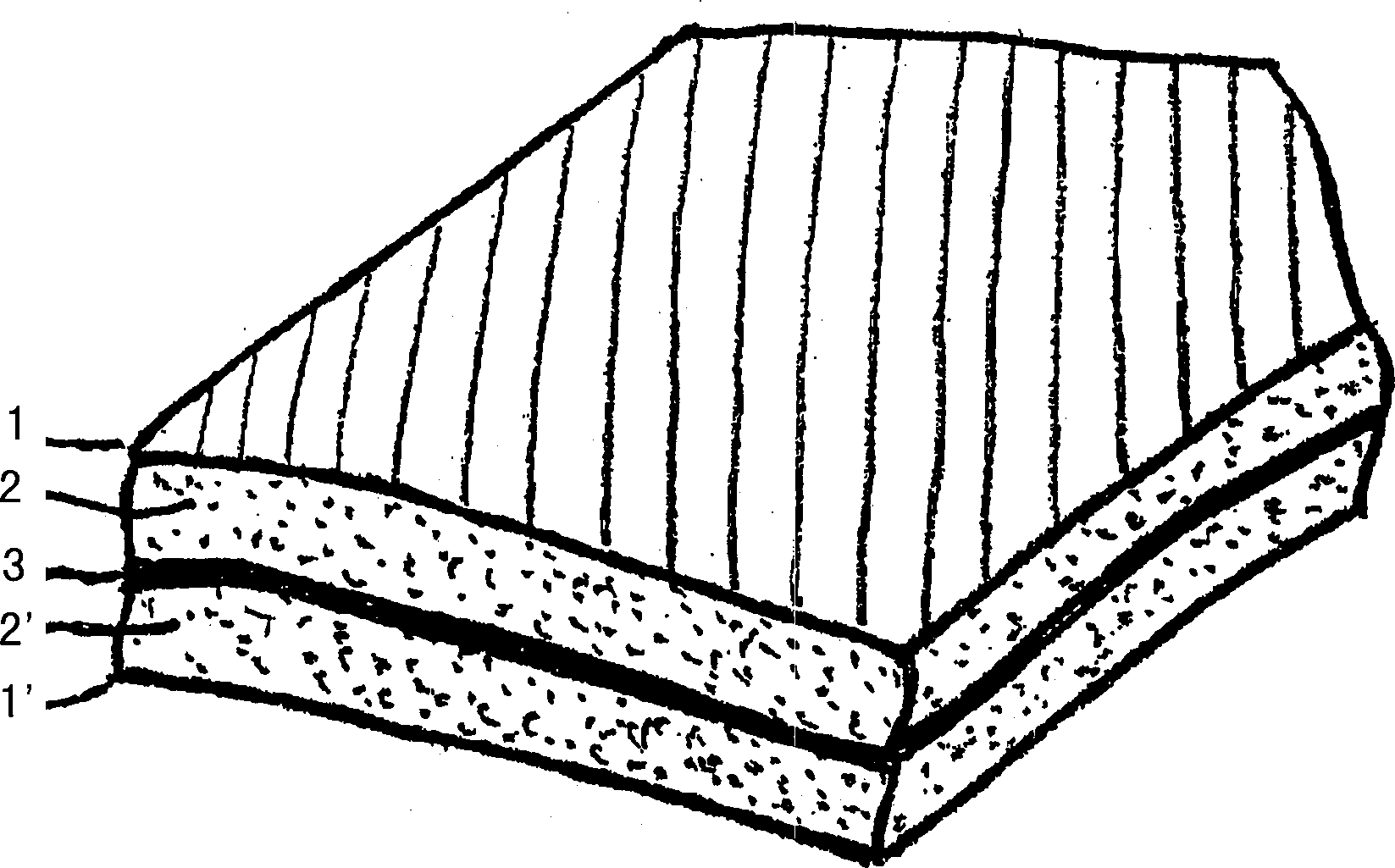

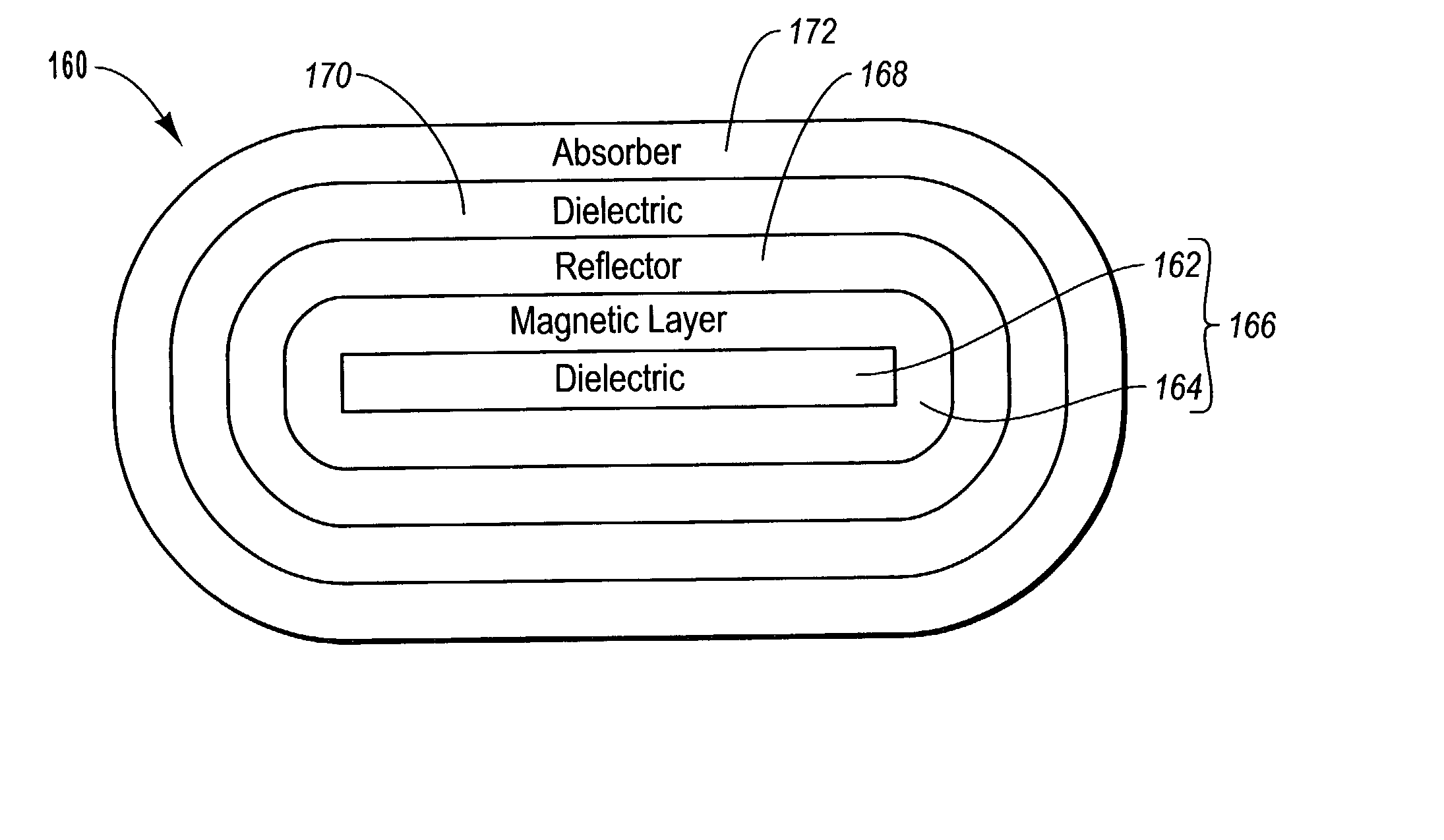

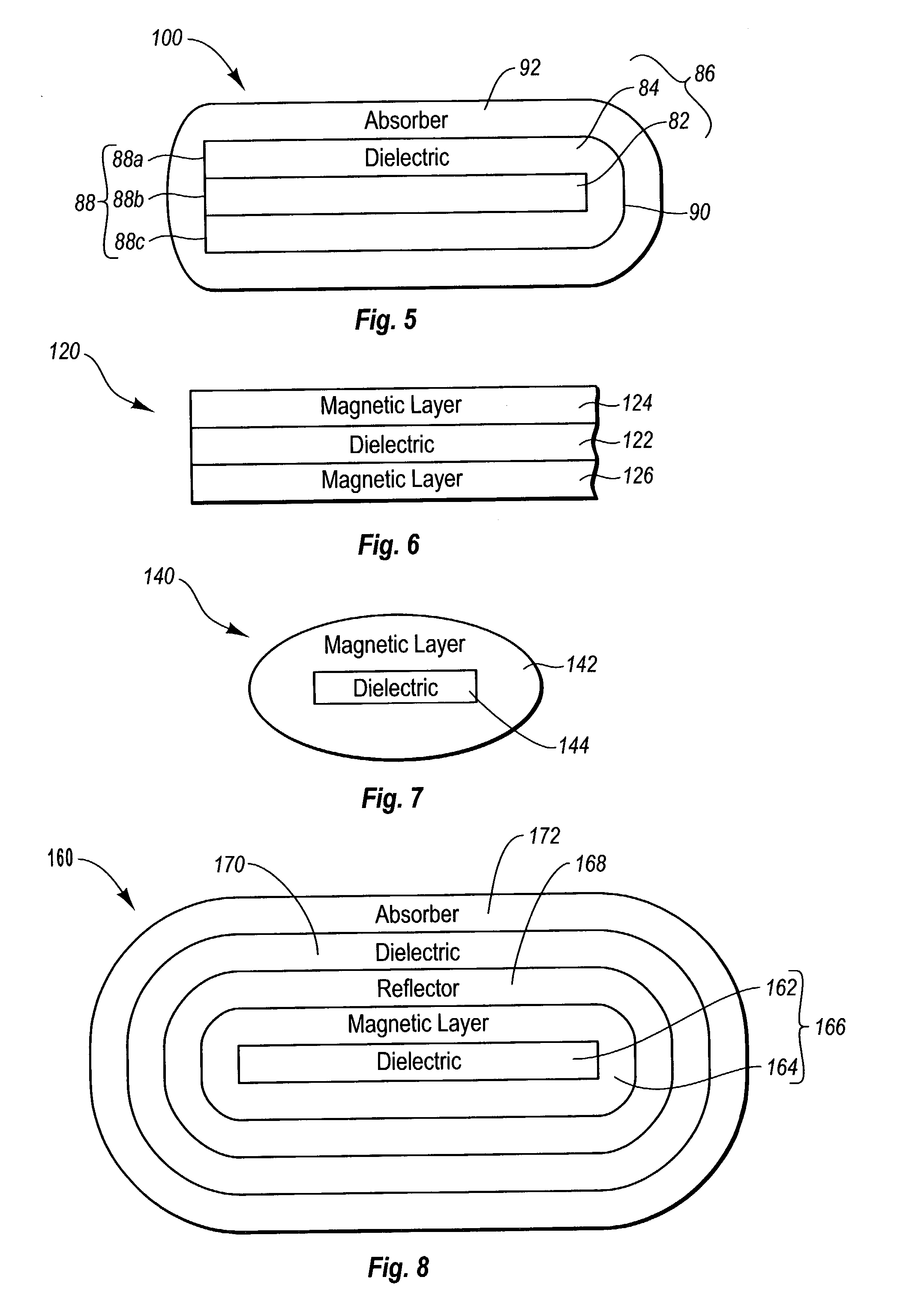

Multi-layered magnetic pigments and foils

InactiveUS20020160194A1High chromaIncreased durabilityPigment preparation by PVD/CVD methodsPattern printingLiquid mediumColor shift

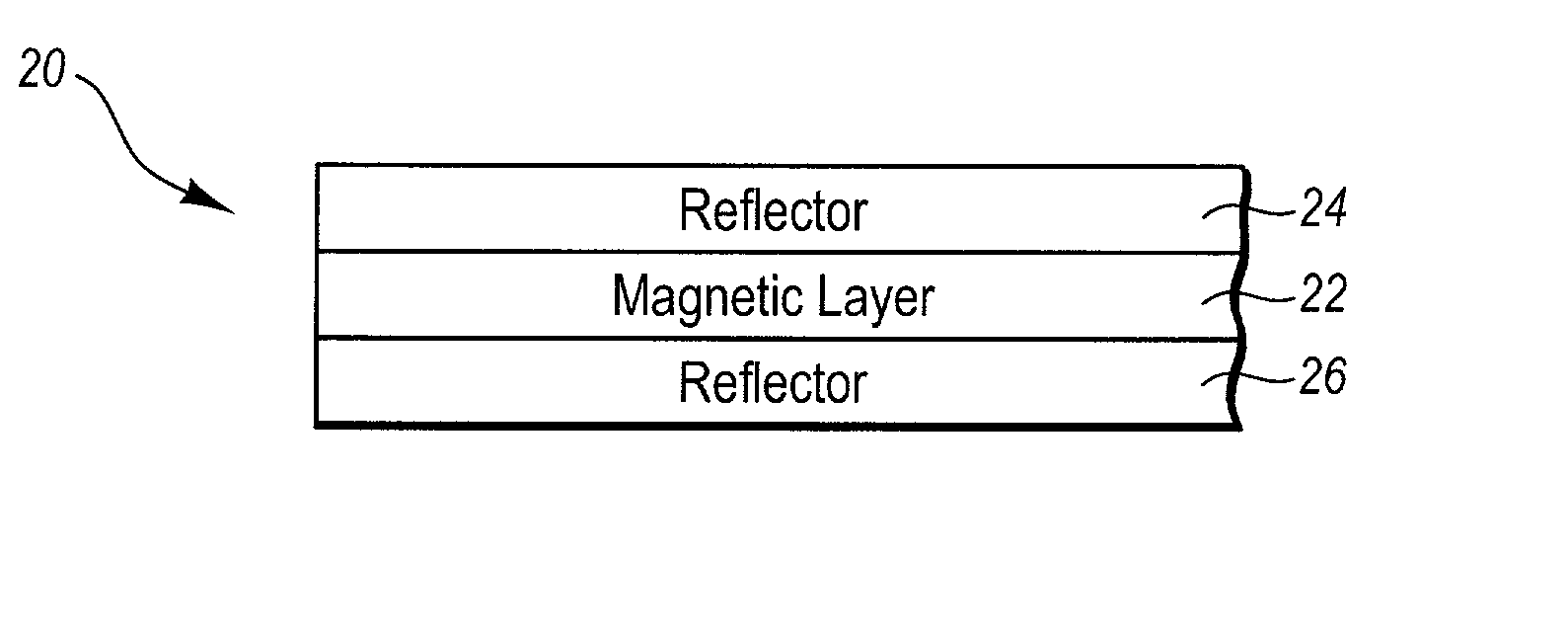

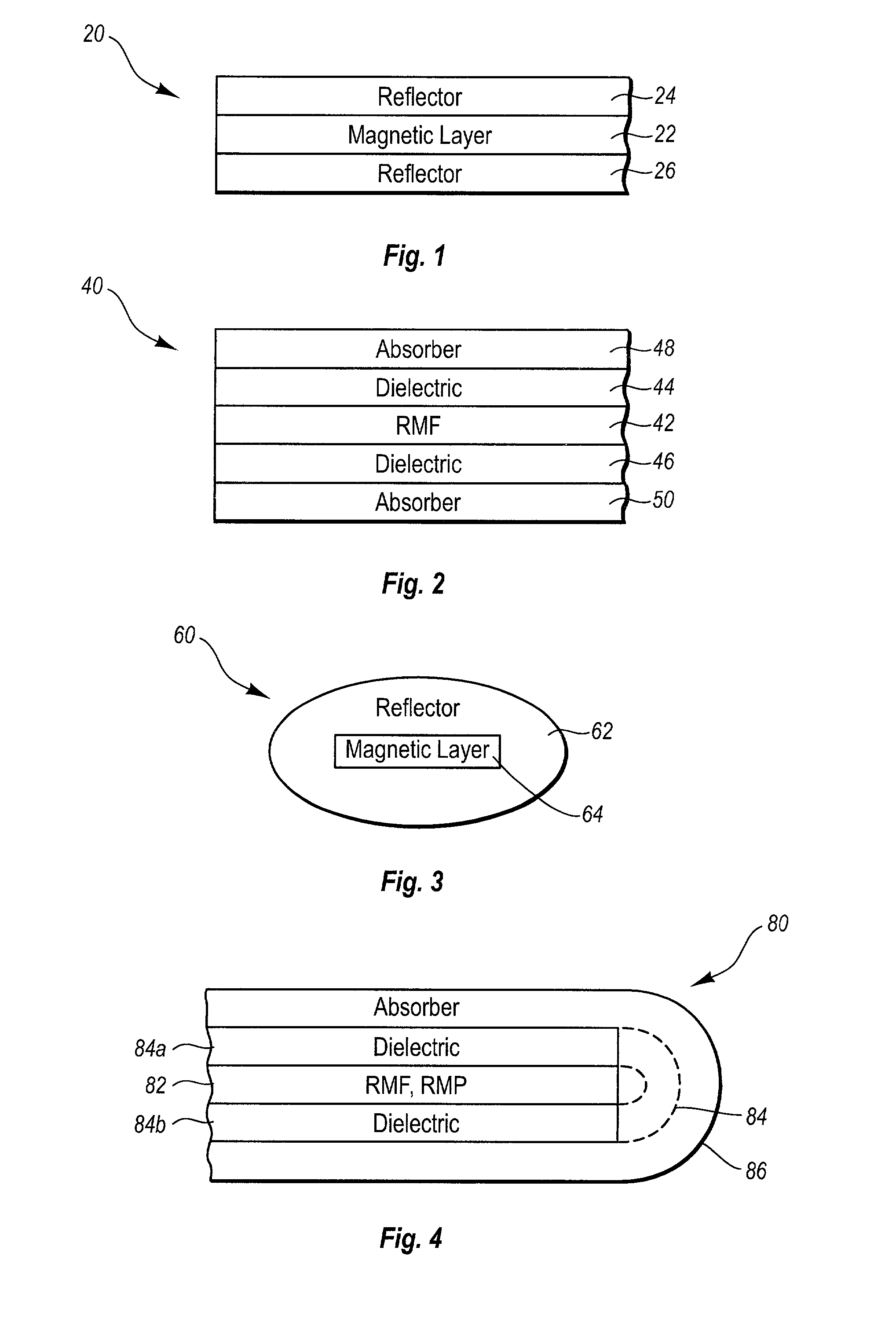

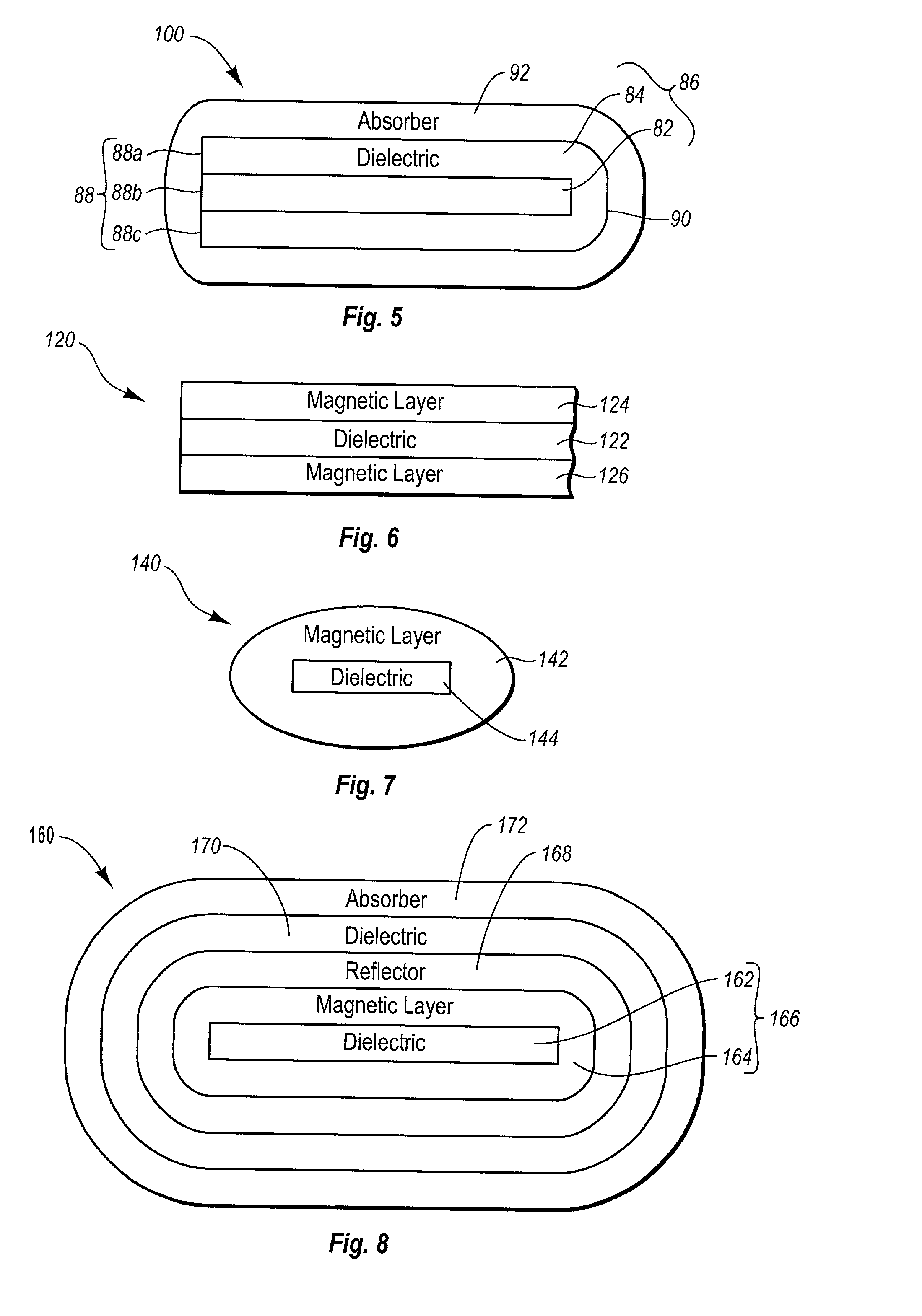

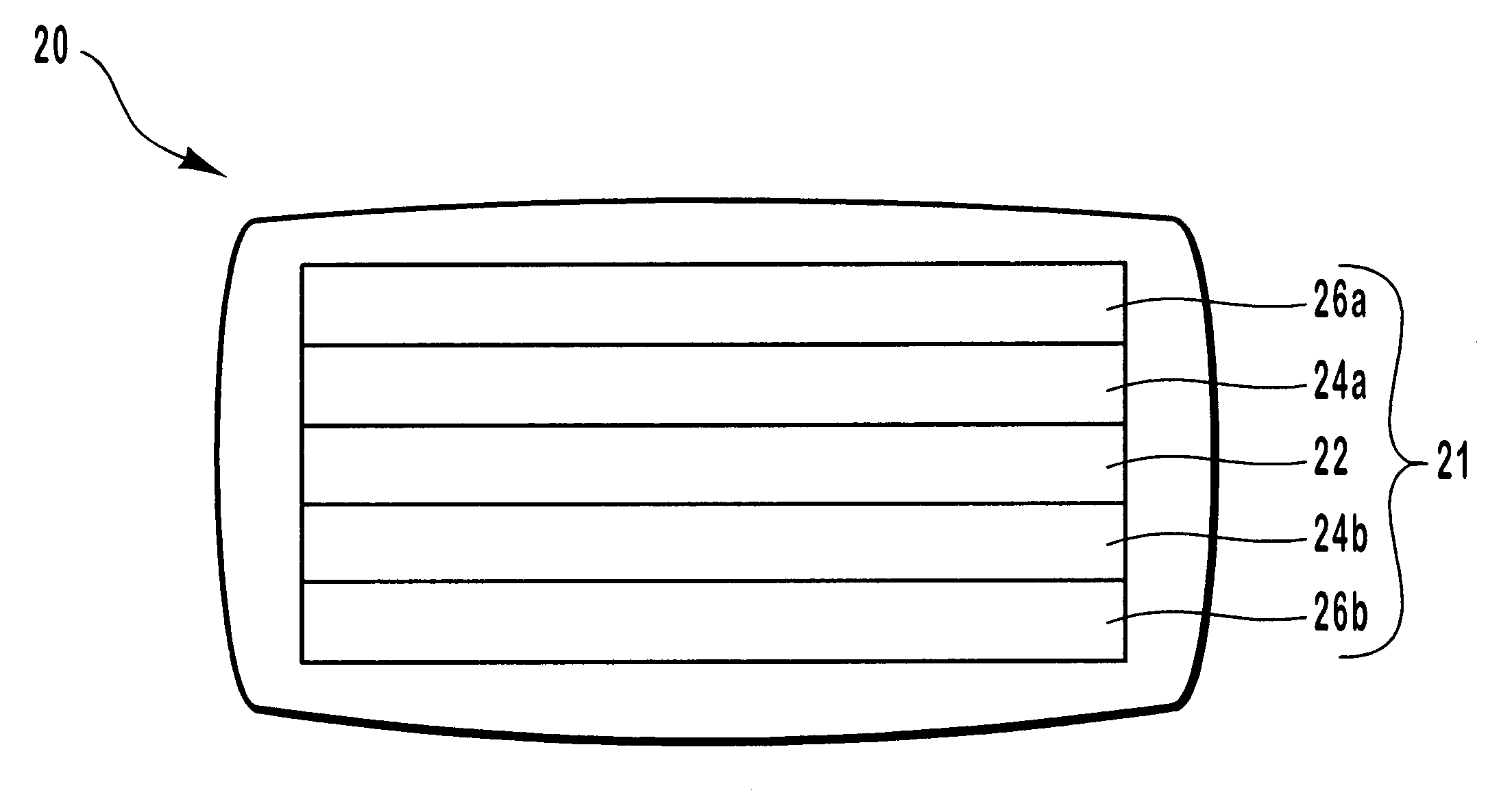

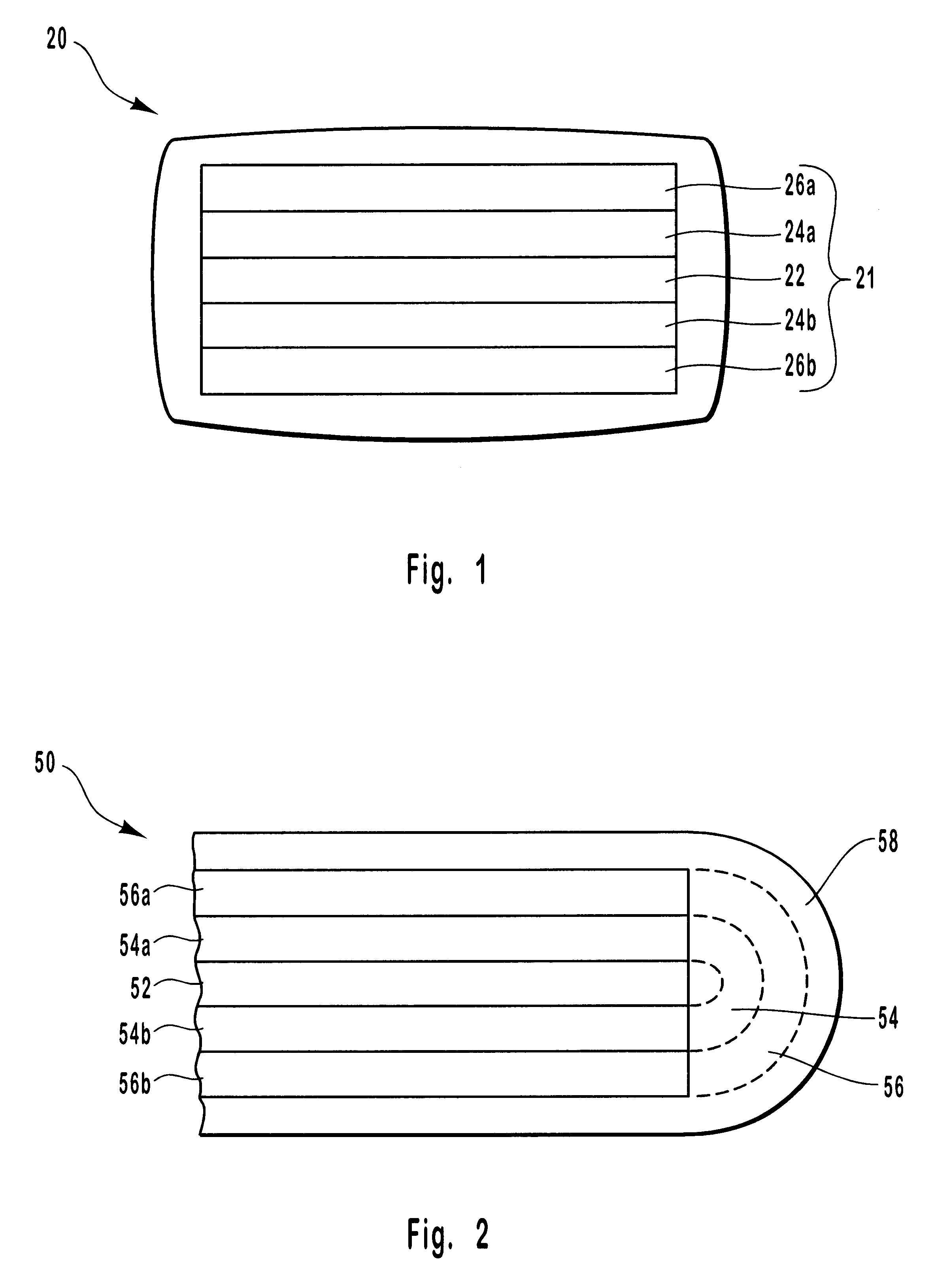

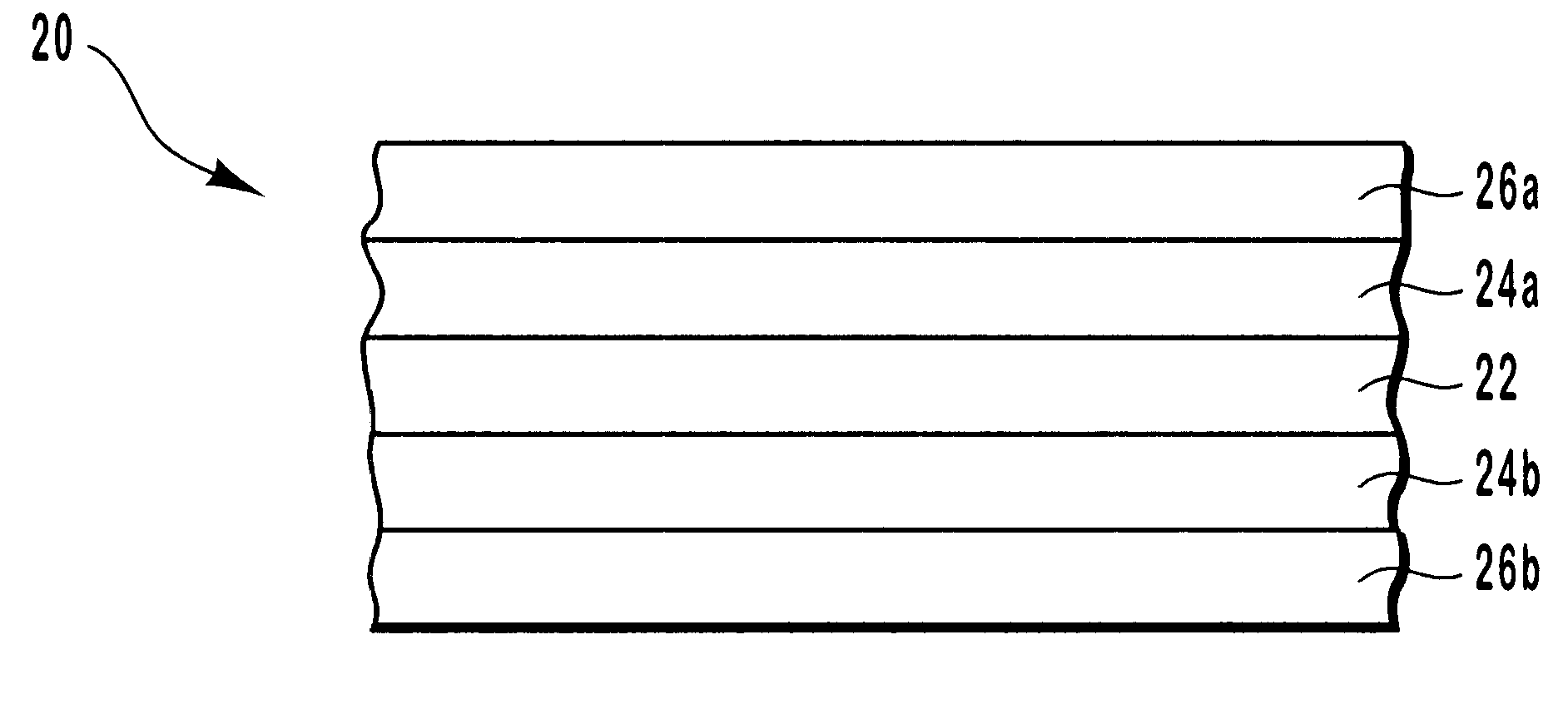

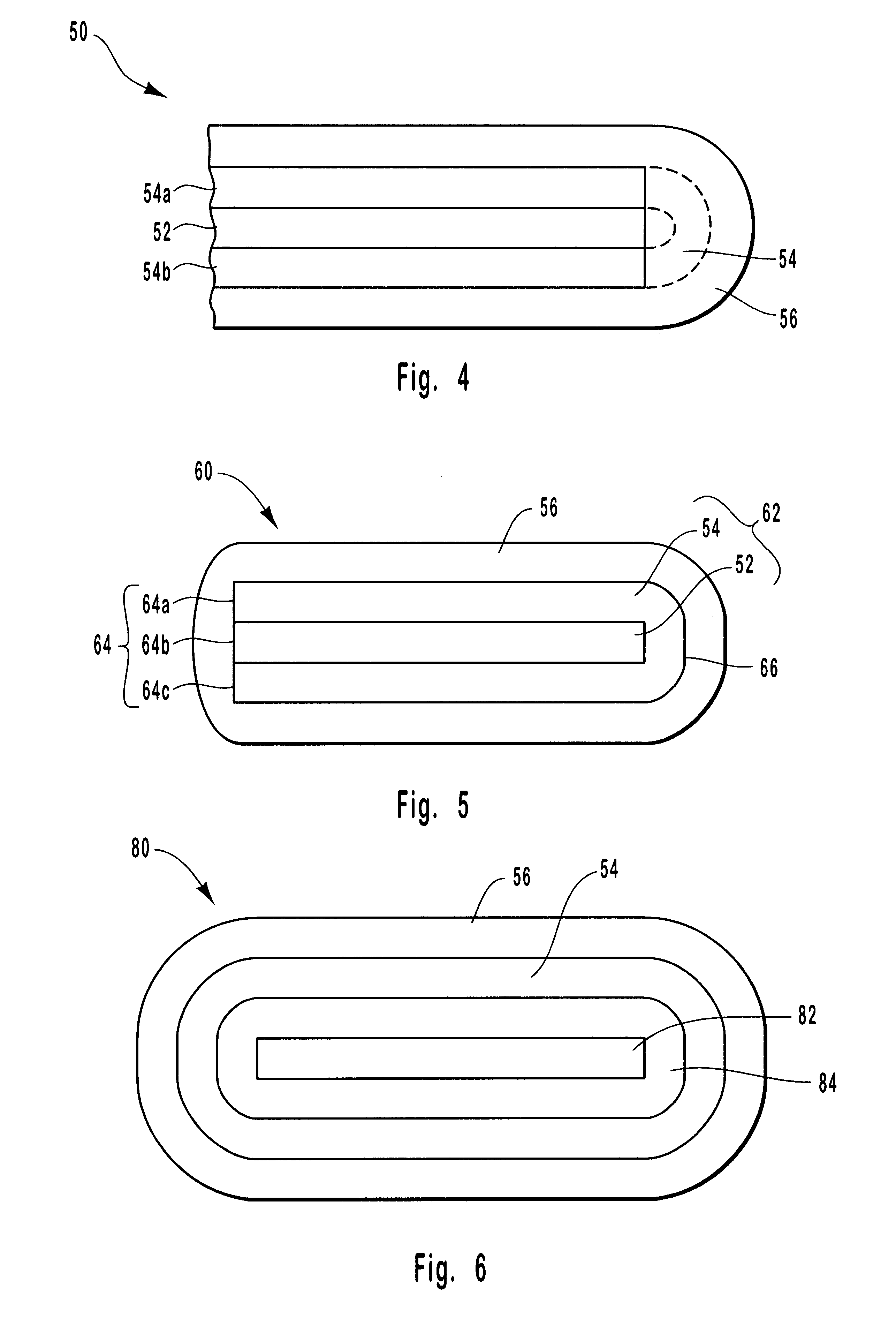

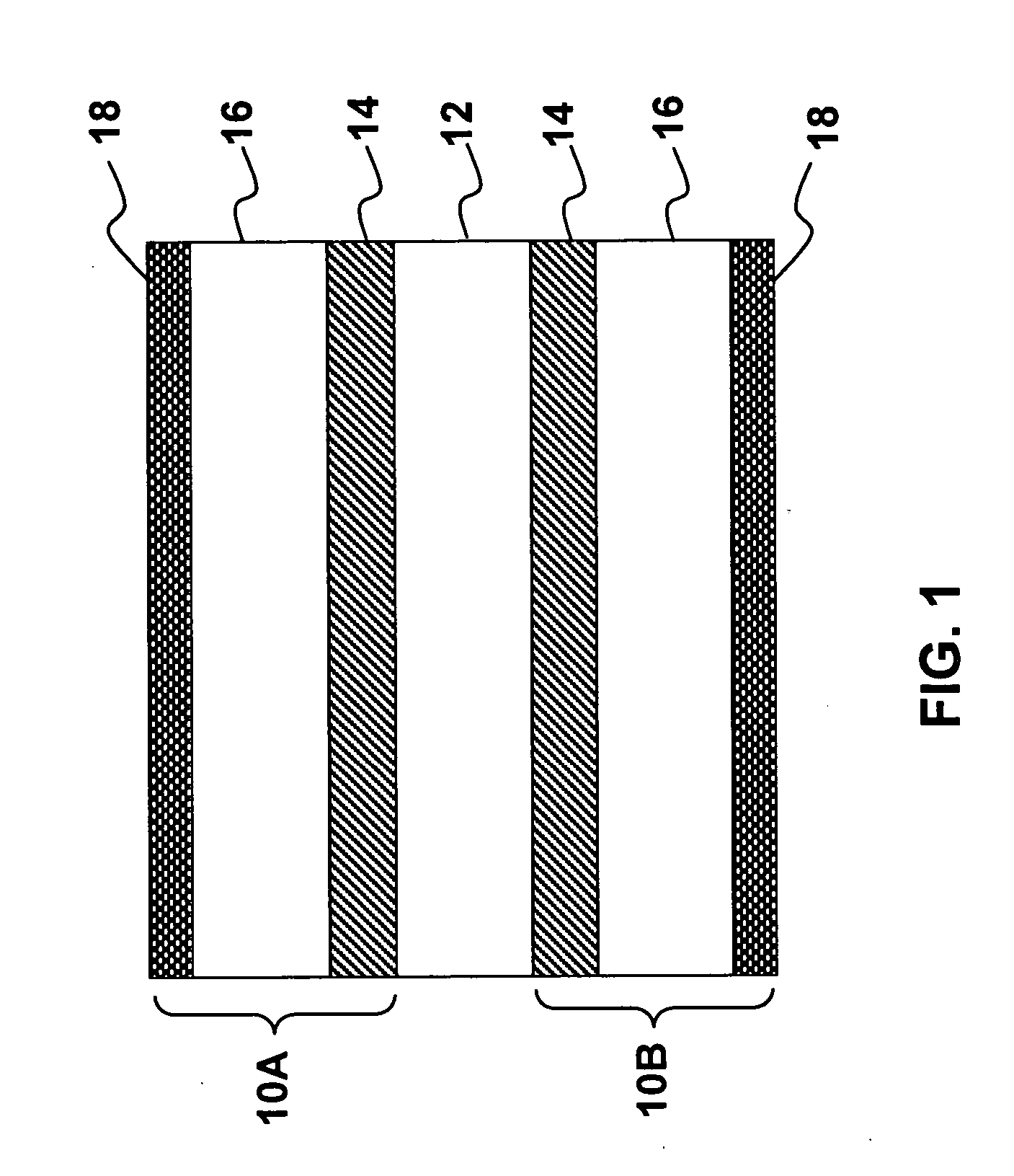

Multilayered magnetic pigment flakes and foils are provided. The pigment flakes can have a symmetrical coating structure on opposing sides of a magnetic core, or can be formed with encapsulating coatings around the magnetic core. The magnetic core can be a magnetic layer between reflector or dielectric layers, a dielectric layer between magnetic layers, or only a magnetic layer. Some embodiments of the pigment flakes and foils exhibit a discrete color shift so as to have distinct colors at differing angles of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:FLEX PRODUCTS INC

Color-shifting pigments and foils with luminescent coatings

InactiveUS6565770B1Improve thermal stabilityImprove mechanical stabilityMaterial nanotechnologyLiquid surface applicatorsLiquid mediumColor shift

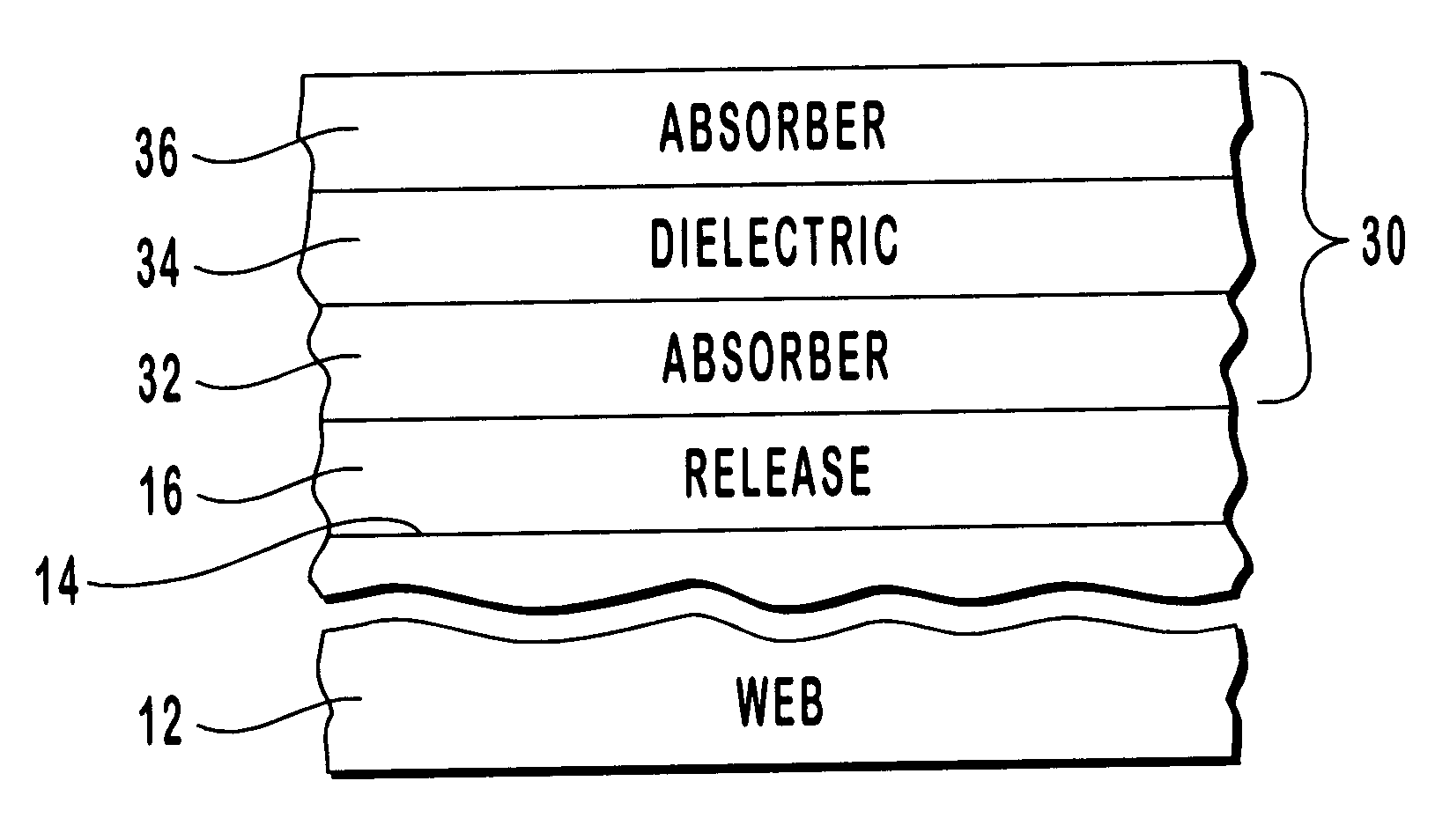

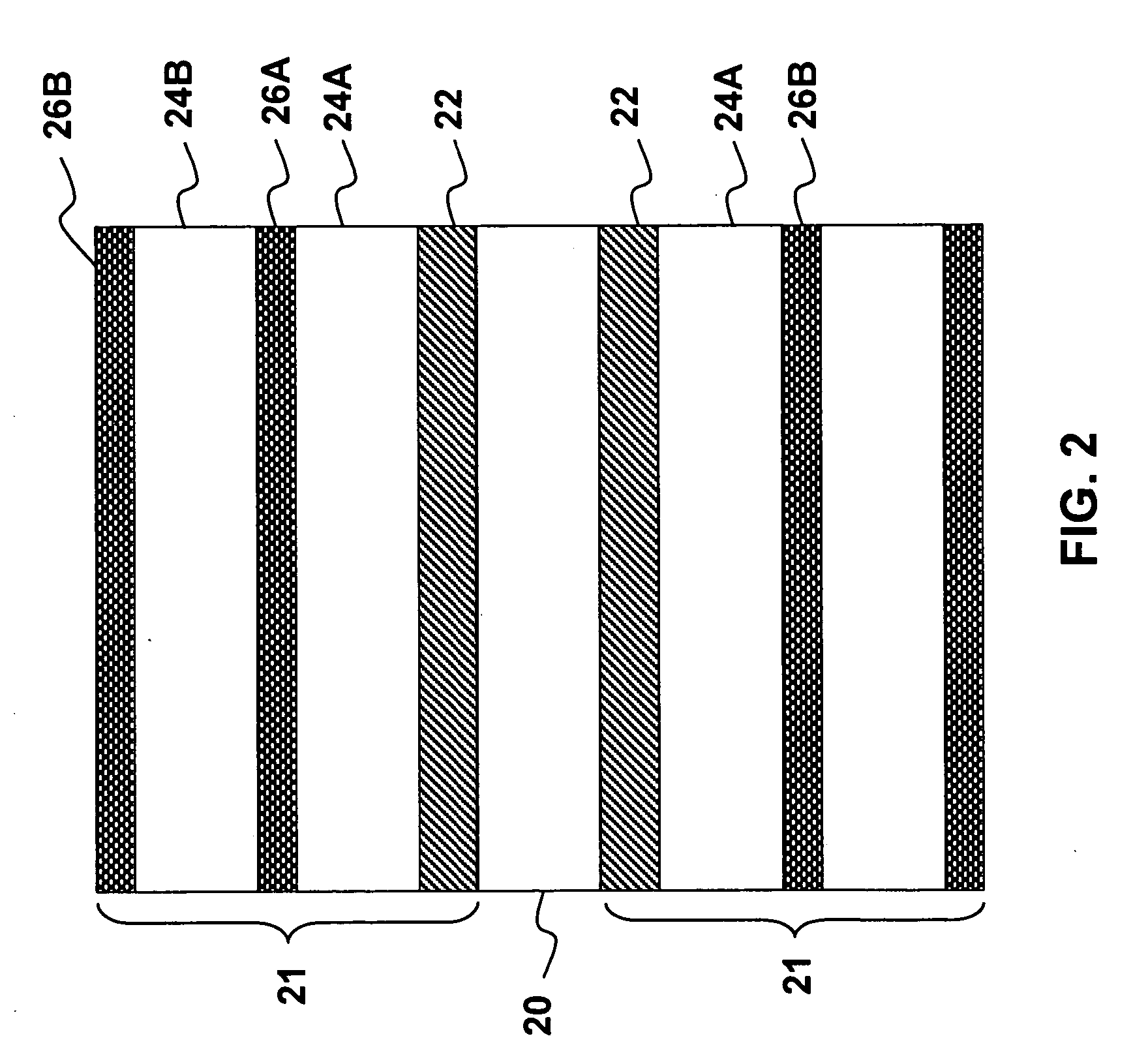

Interference pigment flakes and foils are provided which have luminescent and color-shifting properties. A luminescent material coating structure is provided which partially covers or encapsulates a color-shifting pigment flake, or covers the outer surface of a foil. The pigment flakes can have a symmetrical coating structure on opposing sides of a core layer, can have an asymmetrical coating structure with all of the layers on one side of the core layer, or can be formed with encapsulating coatings around the core layer. The coating structure of the flakes and foils includes a core layer, a dielectric layer overlying the core layer, and an absorber layer overlying the dielectric layer. The luminescent pigment flakes and foils exhibit a discrete color shift so as to have a first color at a first angle of incident light or viewing and a second color different from the first color at a second angle of incident light or viewing. The luminescent pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant materials for subsequent application to objects or papers. The luminescent foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

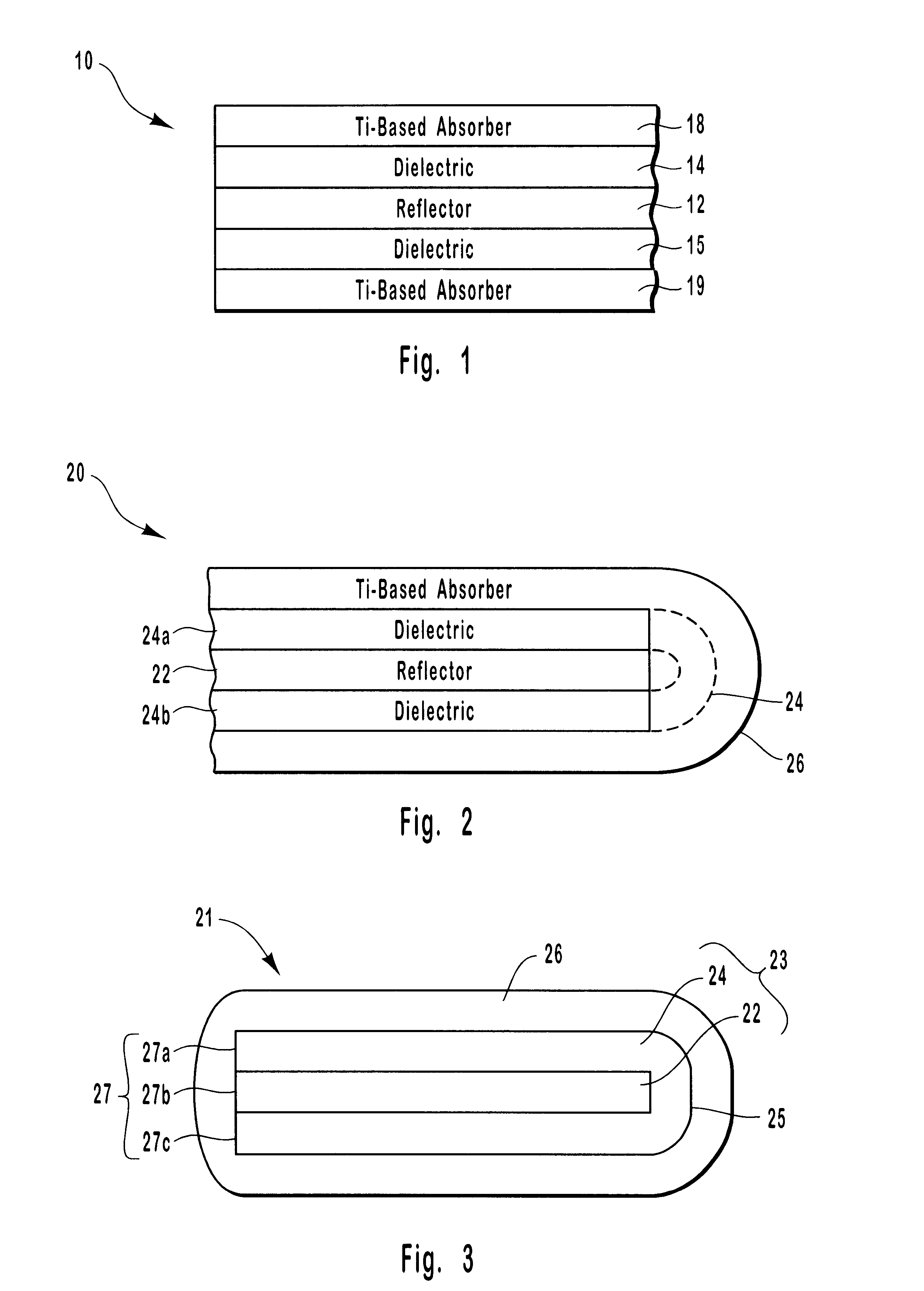

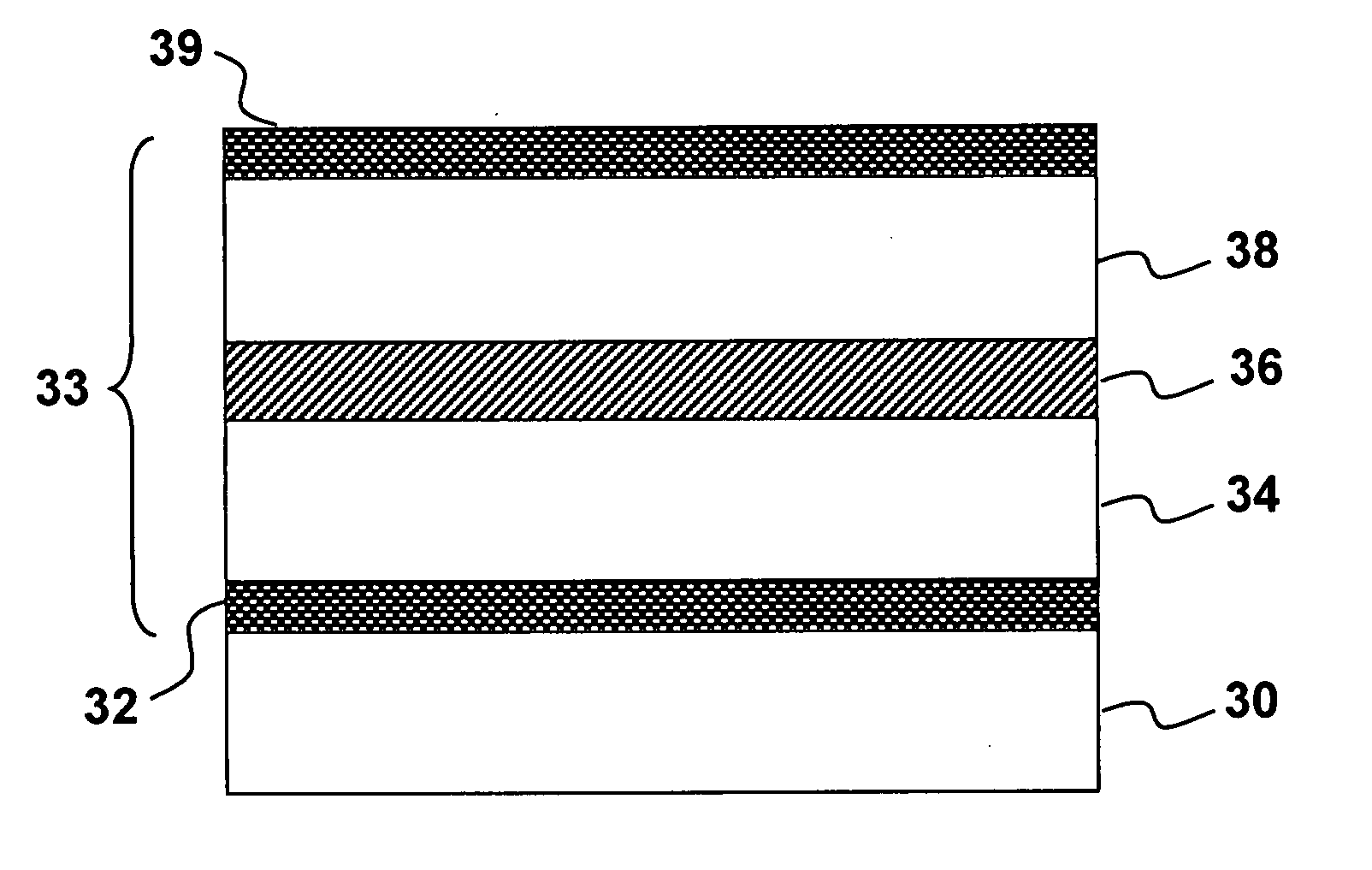

Bright metal flake based pigments

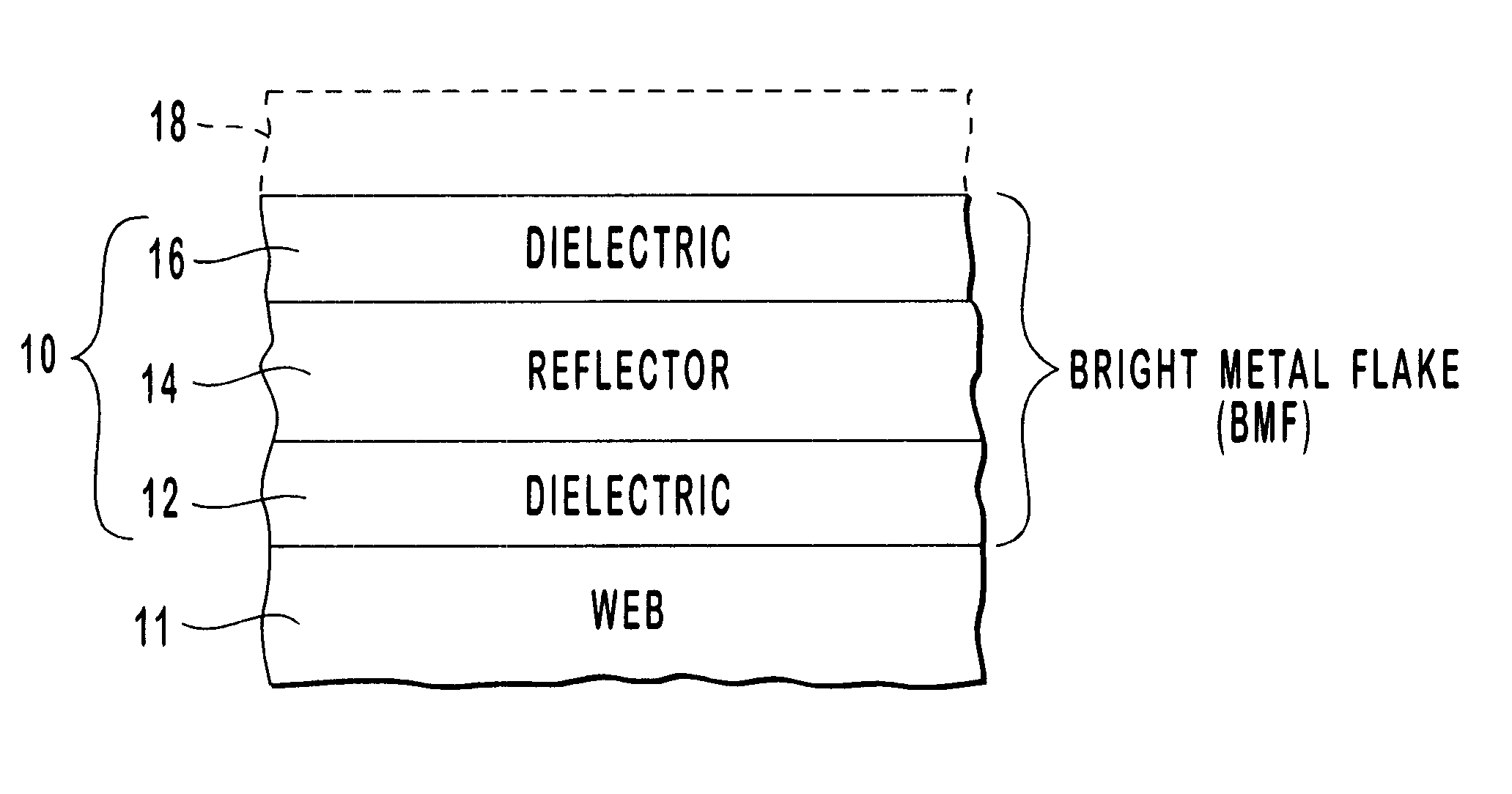

InactiveUS6150022AGood specular reflectance characteristicPigment preparation by PVD/CVD methodsSynthetic resin layered productsDielectricReflectivity

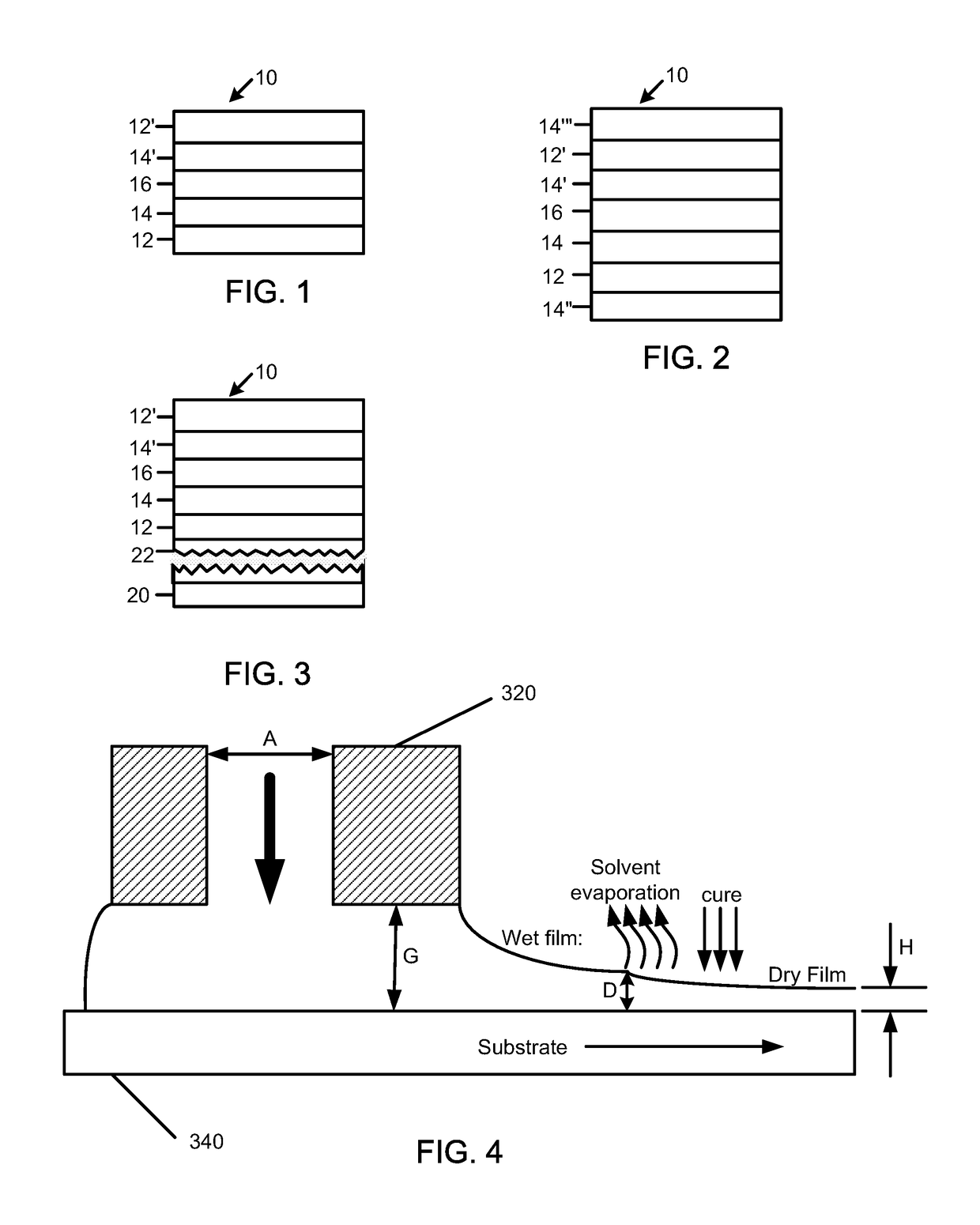

A flake-based pigment is provided having improved specular reflectance characteristics in the visible wavelength range. The flake-based pigment has a plurality of core flake sections each formed of a central reflector layer and dielectric support layers on opposing sides of the reflector layer. The resulting core flake section is a very thin three-layered structure that exhibits a uniaxial compressive strength much greater than a corresponding uniaxial tensile strength. This structure provides the benefits of rigidity and brittle fracture during manufacturing and application processes, which ultimately provides favorable planar and specular reflectance characteristics for the pigment in the visible wavelength range. A variety of outer coating layers can be formed around the core flake sections, such as various dielectric and absorber layers having thicknesses dependent upon the desired optical characteristics of the pigment.

Owner:JDS UNIPHASE CORP

Luminescent pigments and foils with color-shifting properties

InactiveUS6572784B1Improve thermal stabilityImprove mechanical stabilityMaterial nanotechnologyLiquid surface applicatorsLiquid mediumColor shift

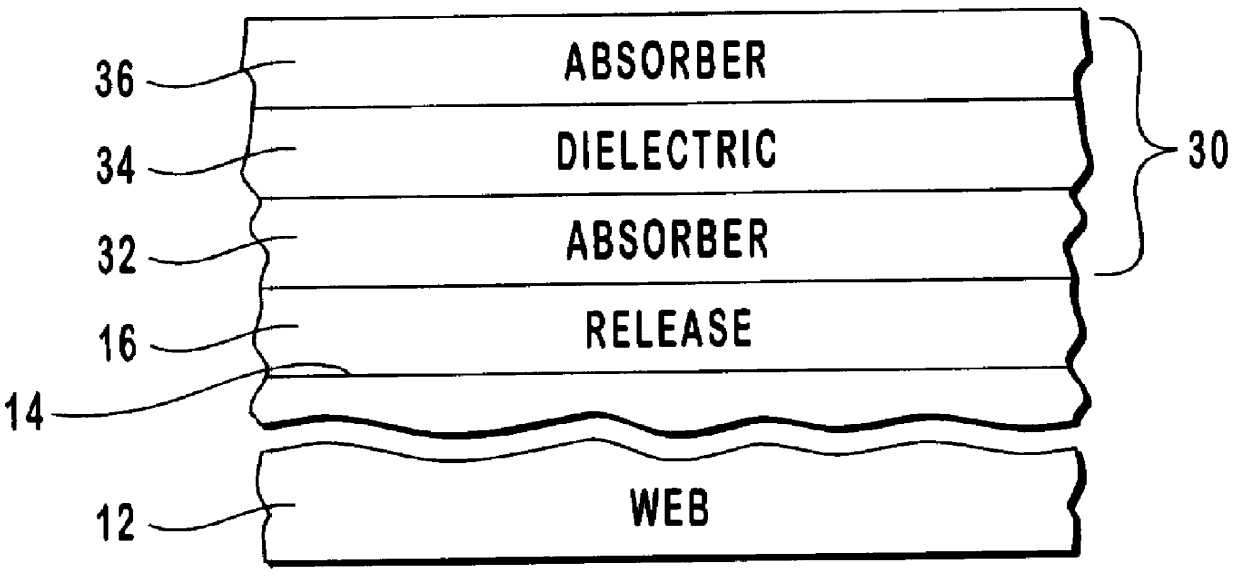

Interference pigment flakes and foils are provided which have luminescent and color-shifting properties. The pigment flakes can have a symmetrical coating structure on opposing sides of a core layer, can have an asymmetrical coating structure with all of the layers on one side of the core layer, or can be formed with encapsulating coatings around the core layer. The coating structure of the flakes and foils includes a core layer, a dielectric layer overlying the core layer, and an absorber layer overlying the dielectric layer. A luminescent material is incorporated into the flakes or foils as a separate layer or as at least part of one or more of the other layers. The pigment flakes and foils exhibit a discrete color shift so as to have a first color at a first angle of incident light or viewing and a second color different from the first color at a second angle of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant materials for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

Color shifting thin film pigments

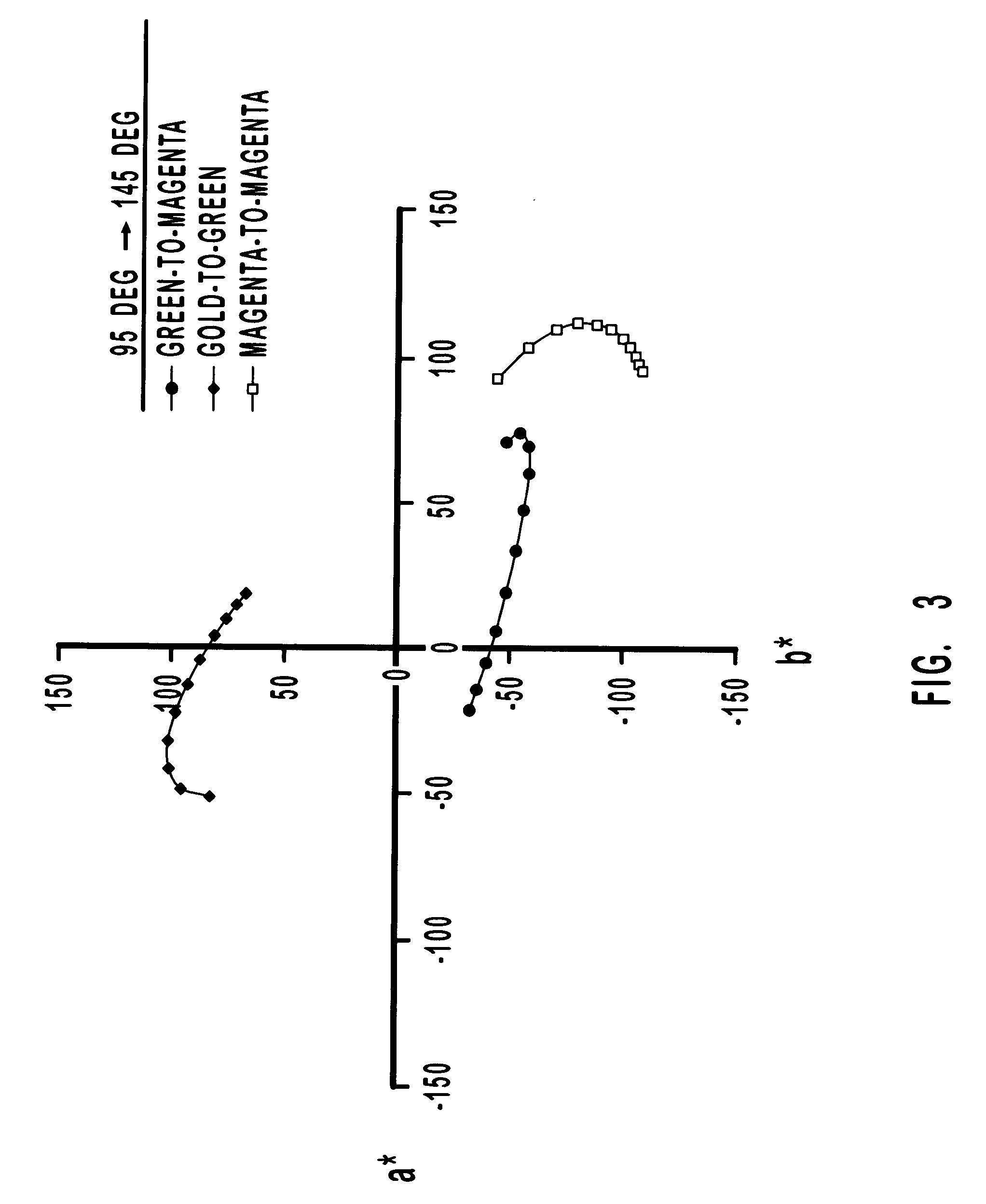

InactiveUS6157489AHigh chromaIncreased durabilityPigment preparation by PVD/CVD methodsCoatingsLiquid mediumColor shift

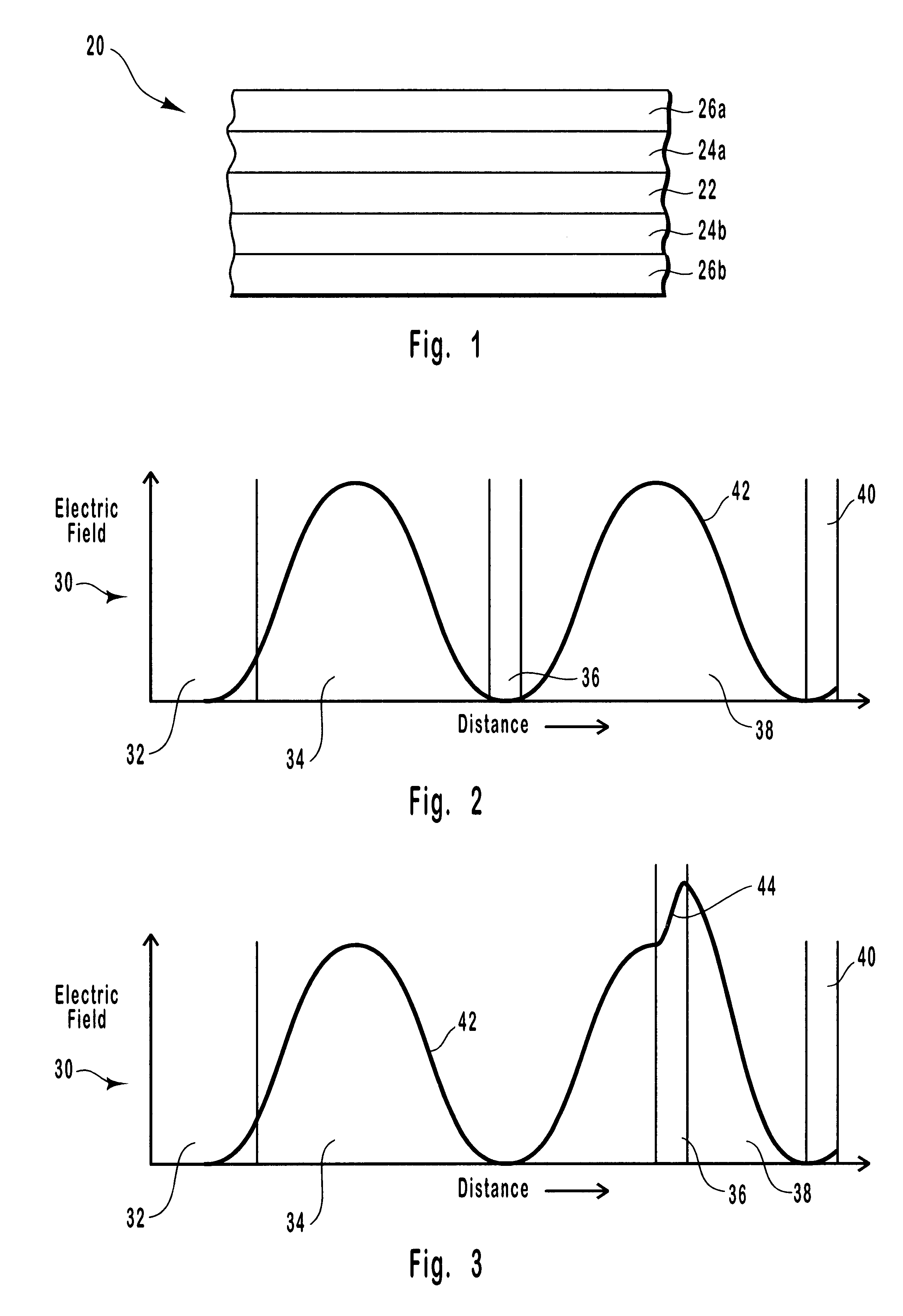

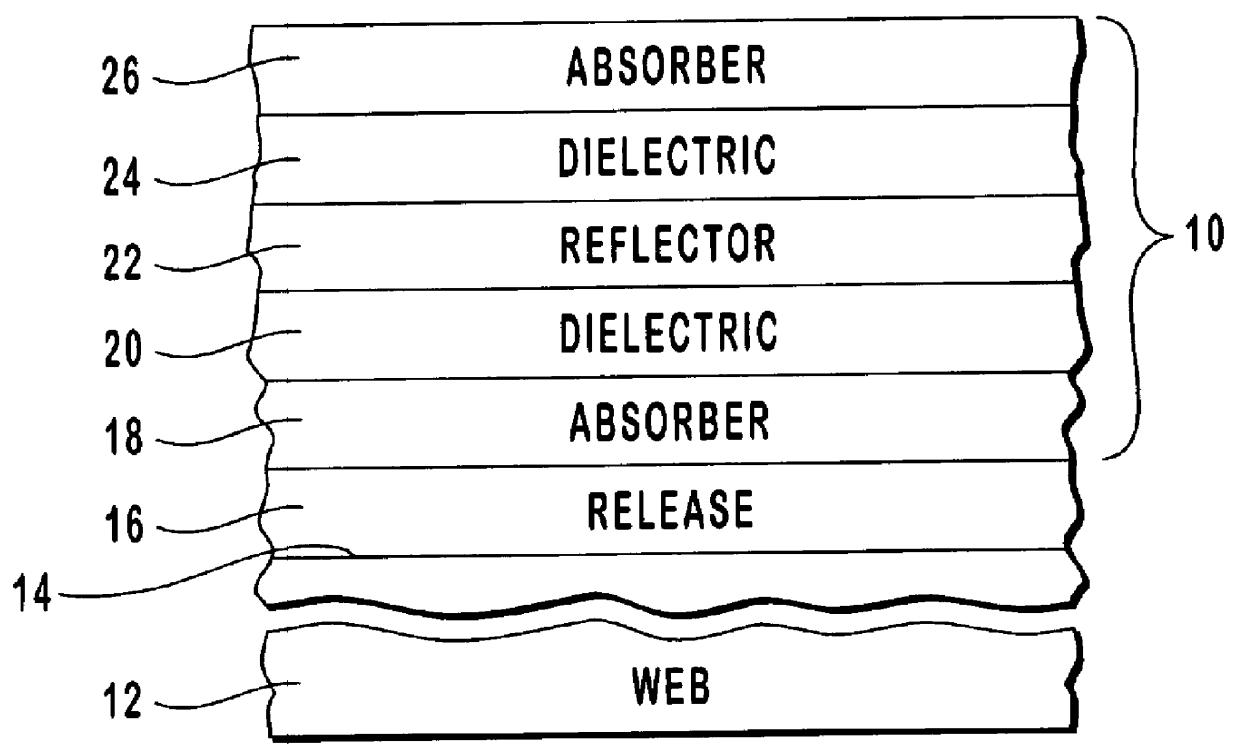

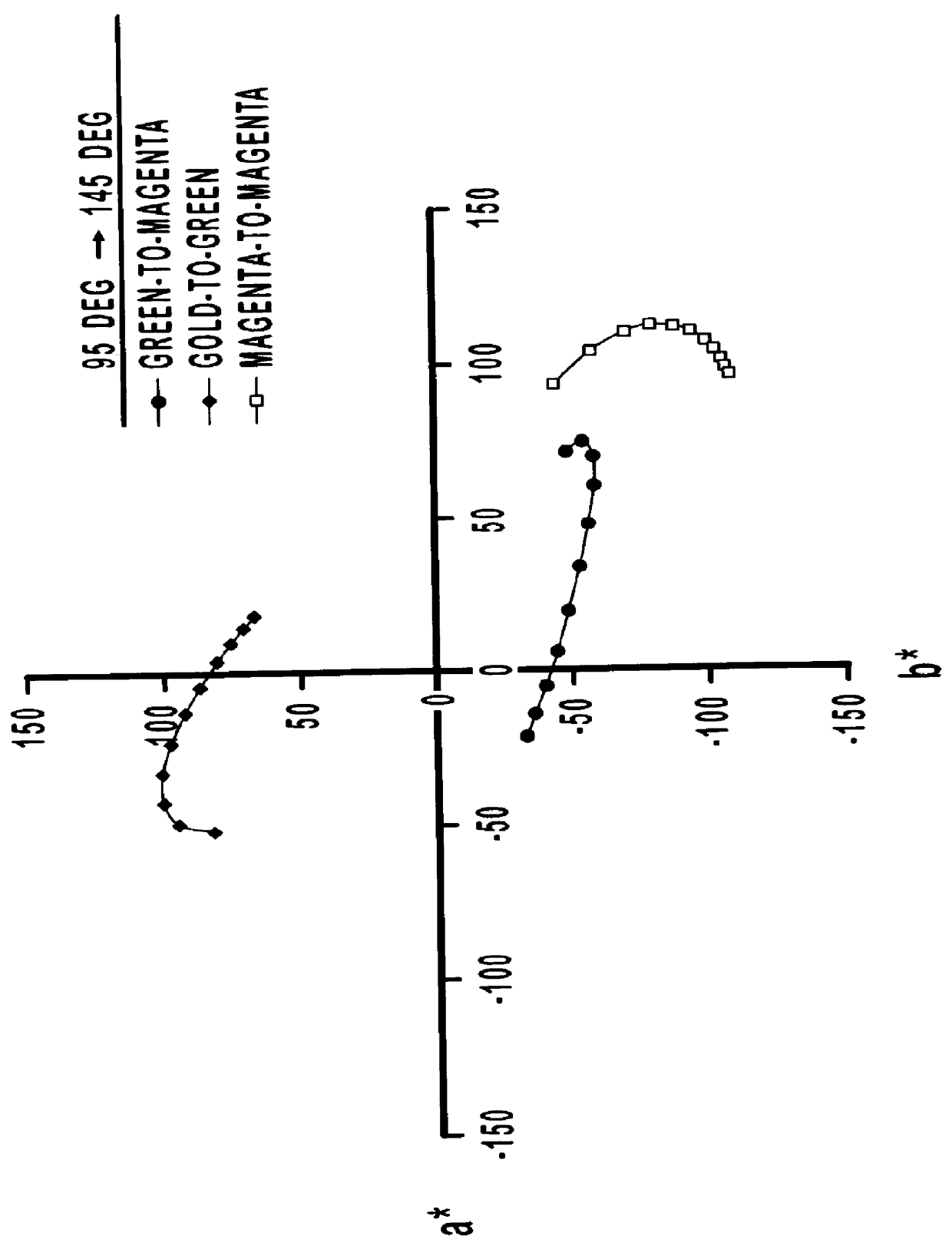

A color shifting multilayer interference film is provided which may be used to produce flakes for use in colorants having color shifting properties. The flakes can be interspersed into liquid media such as paints or inks which can subsequently be applied to objects or papers to achieve color variations upon shifts in angle of incident light or upon shifts in viewing angle. A five layer design of the interference film includes a first absorber layer, a first dielectric layer on the first absorber layer, a reflector layer on the first dielectric layer, a second dielectric layer on the reflector layer, and a second absorber layer on the second dielectric layer. The first and second dielectric layers are formed to have an optical thickness at a design wavelength that provides a color shift as the angle of incident light or viewing changes.

Owner:VIAVI SOLUTIONS INC

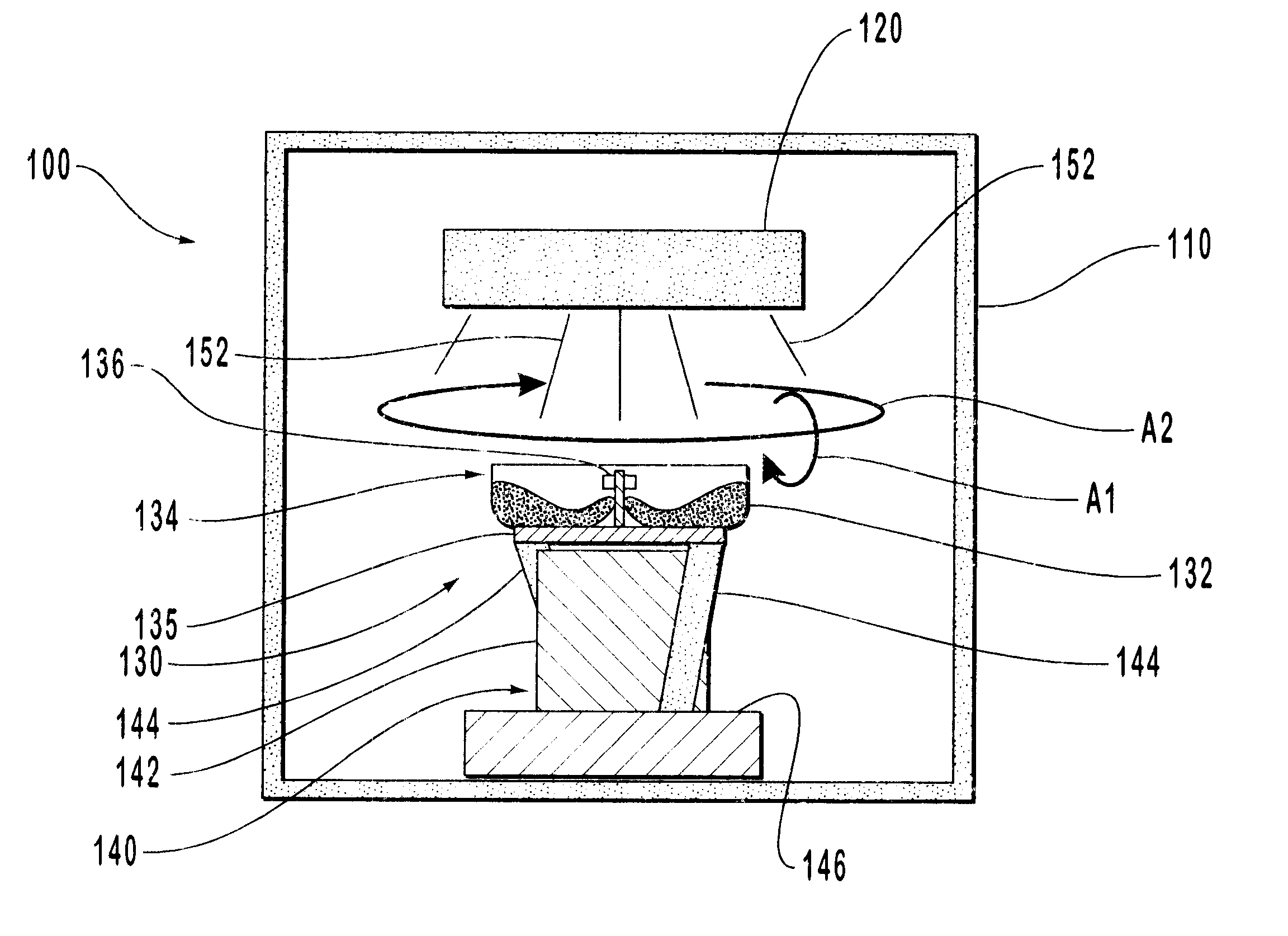

Methods and apparatus for producing enhanced interference pigments

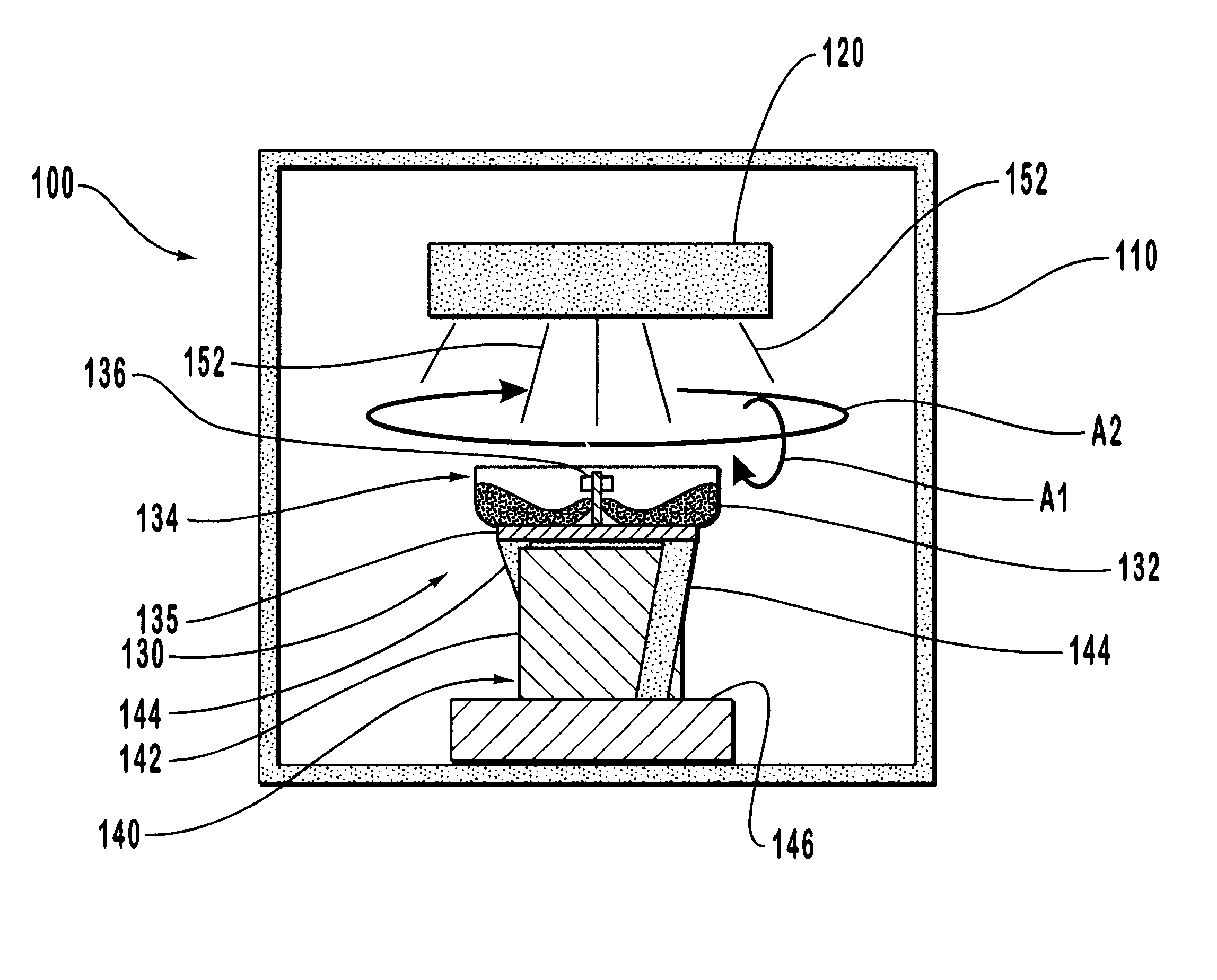

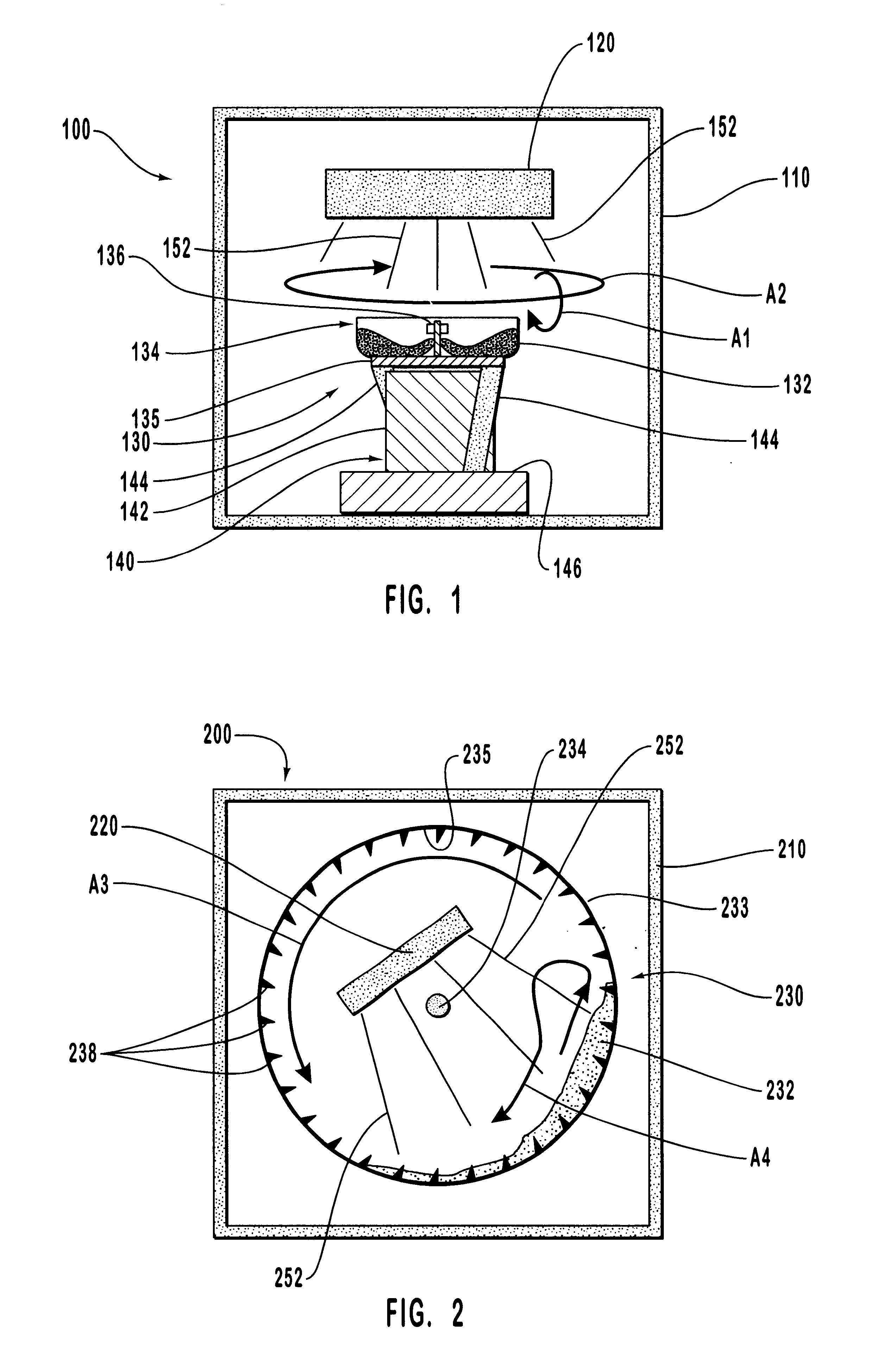

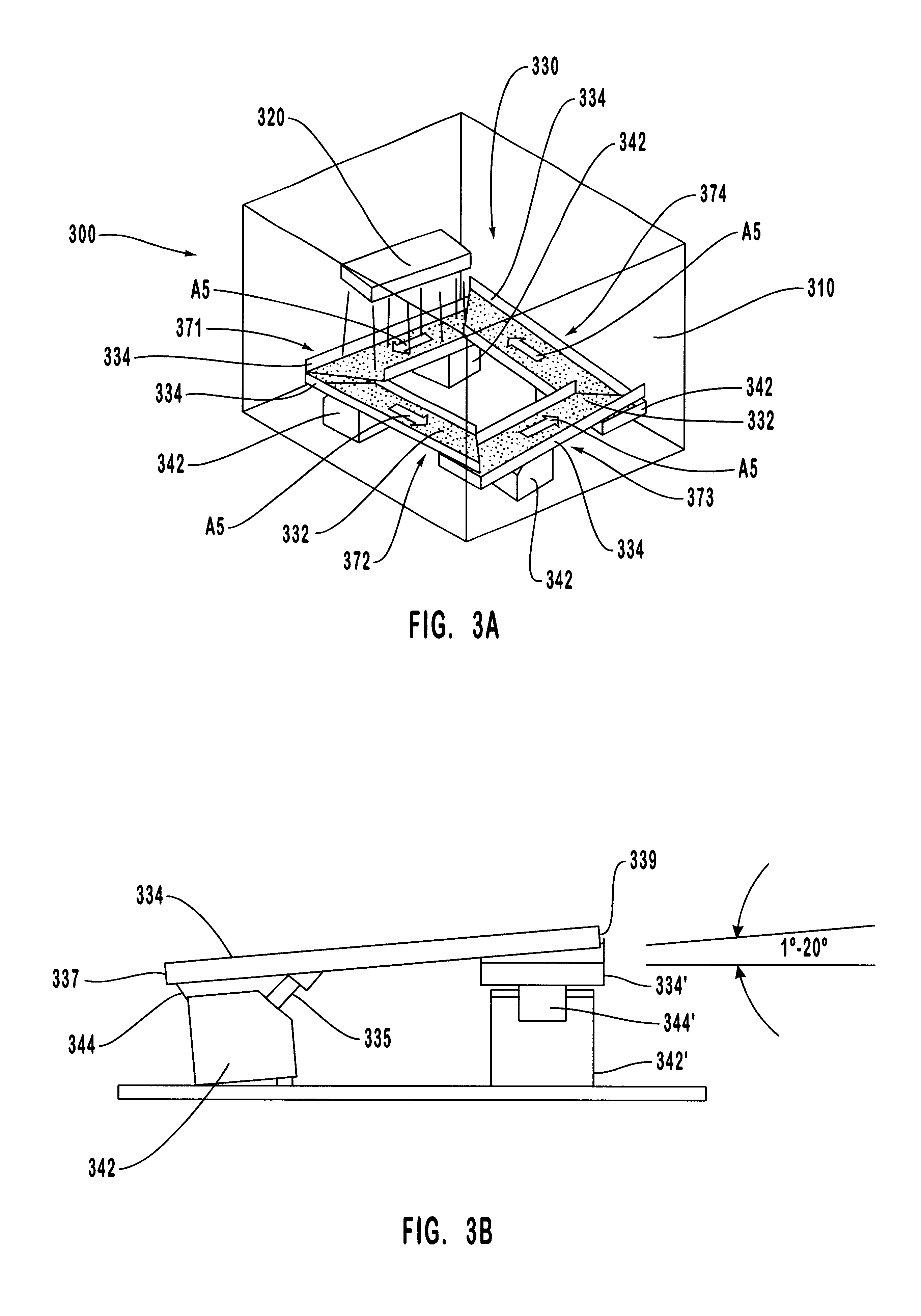

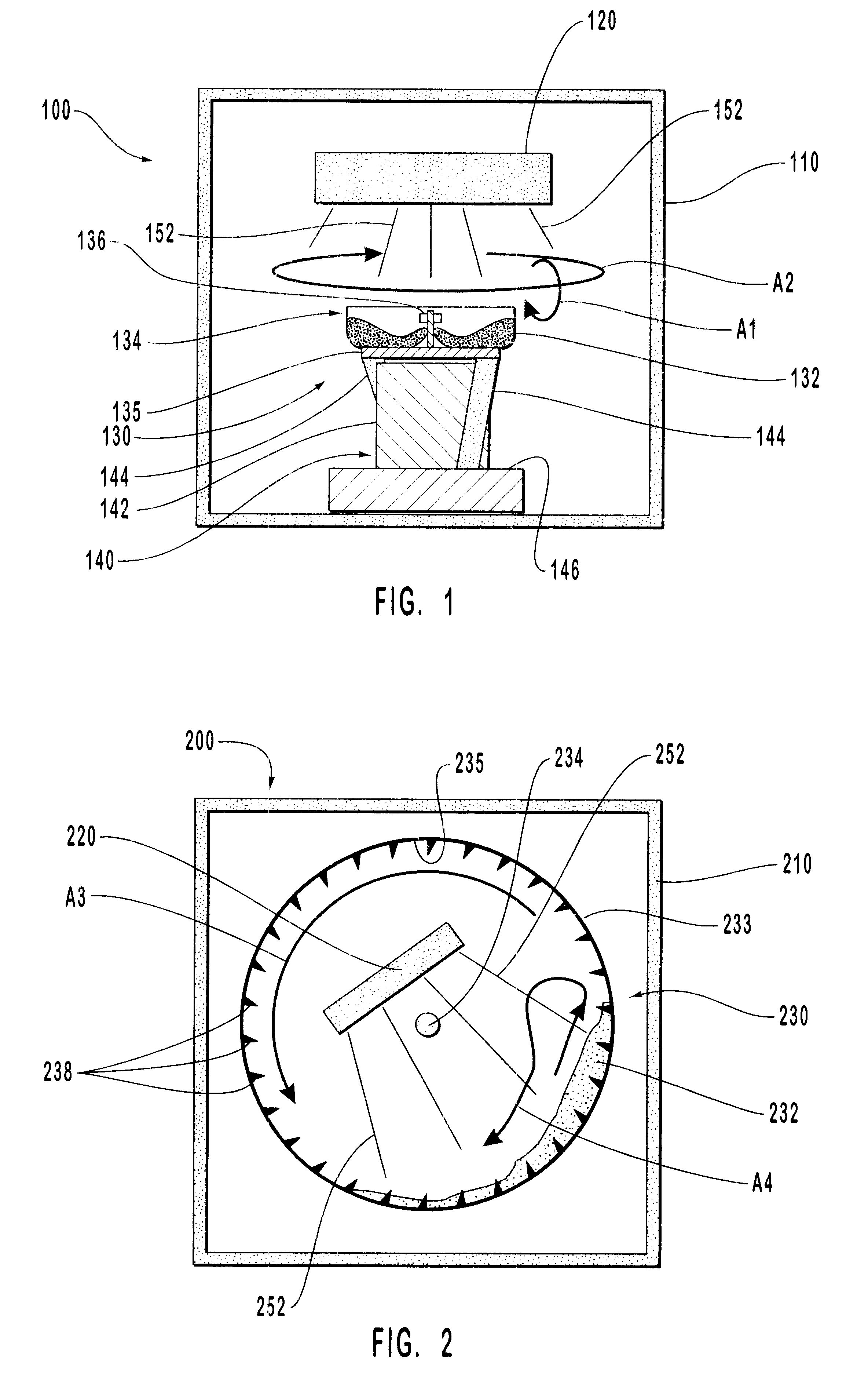

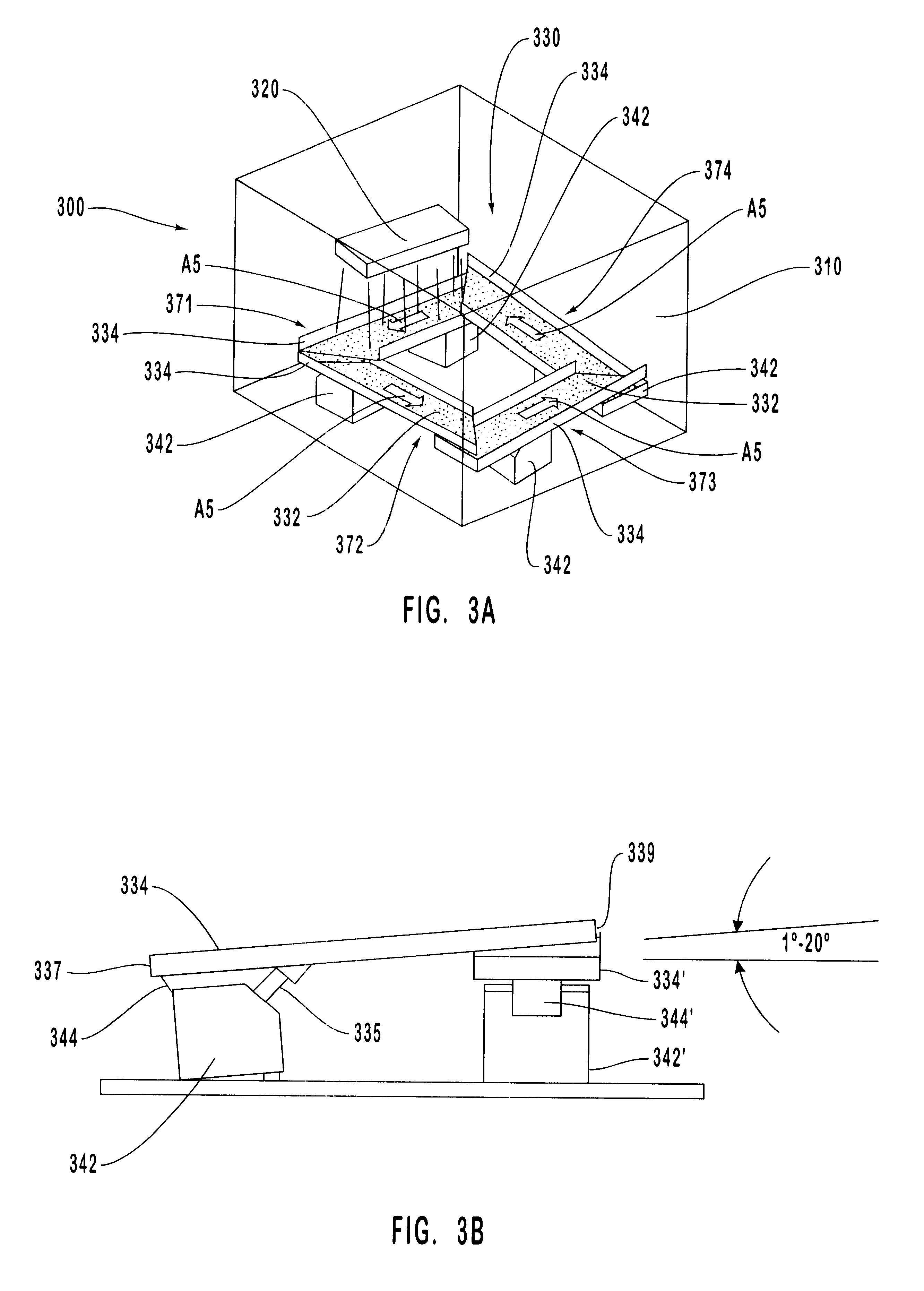

InactiveUS6241858B1Interference be notGood effectElectric discharge heatingPigment preparation by PVD/CVD methodsGas phaseVaporization

Methods and apparatus are provided for uniformly depositing a coating material from a vaporization source onto a powdered substrate material to form a thin coalescence film of the coating material that smoothly replicates the surface microstructure of the substrate material. The coating material is uniformly deposited on the substrate material to form optical interference pigment particles. The thin film enhances the hiding power and color gamut of the substrate material. Physical vapor deposition processes are used for depositing the film on the substrate material. The apparatus and systems employed in forming the coated particles utilize vibrating bed coaters, vibrating conveyor coaters, or coating towers. These allow the powdered substrate material to be uniformly exposed to the coating material vapor during the coating process.

Owner:JDS UNIPHASE CORP

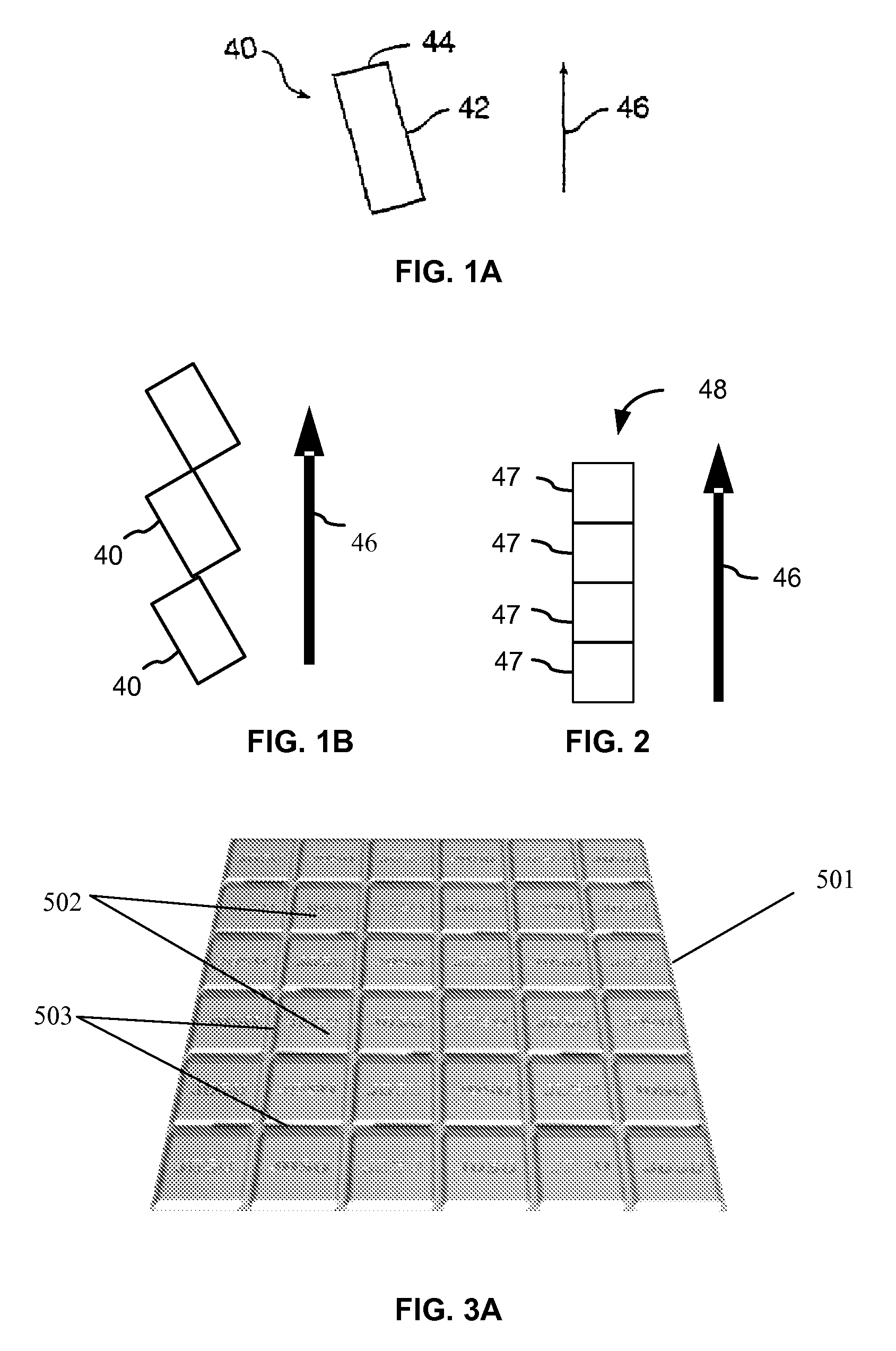

Anisotropic Magnetic Flakes

ActiveUS20090072185A1Cost effectiveMaterial nanotechnologyDecorative surface effectsHigh reflectivityMaterials science

The invention relates to anisotropic, reflective, magnetic flakes. In a liquid carrier and under influence of an external magnetic field, the flakes attract to one another side-by-side and form ribbons which provide higher reflectivity to a coating and may be used as a security feature for authentication of an object.

Owner:VIAVI SOLUTIONS INC

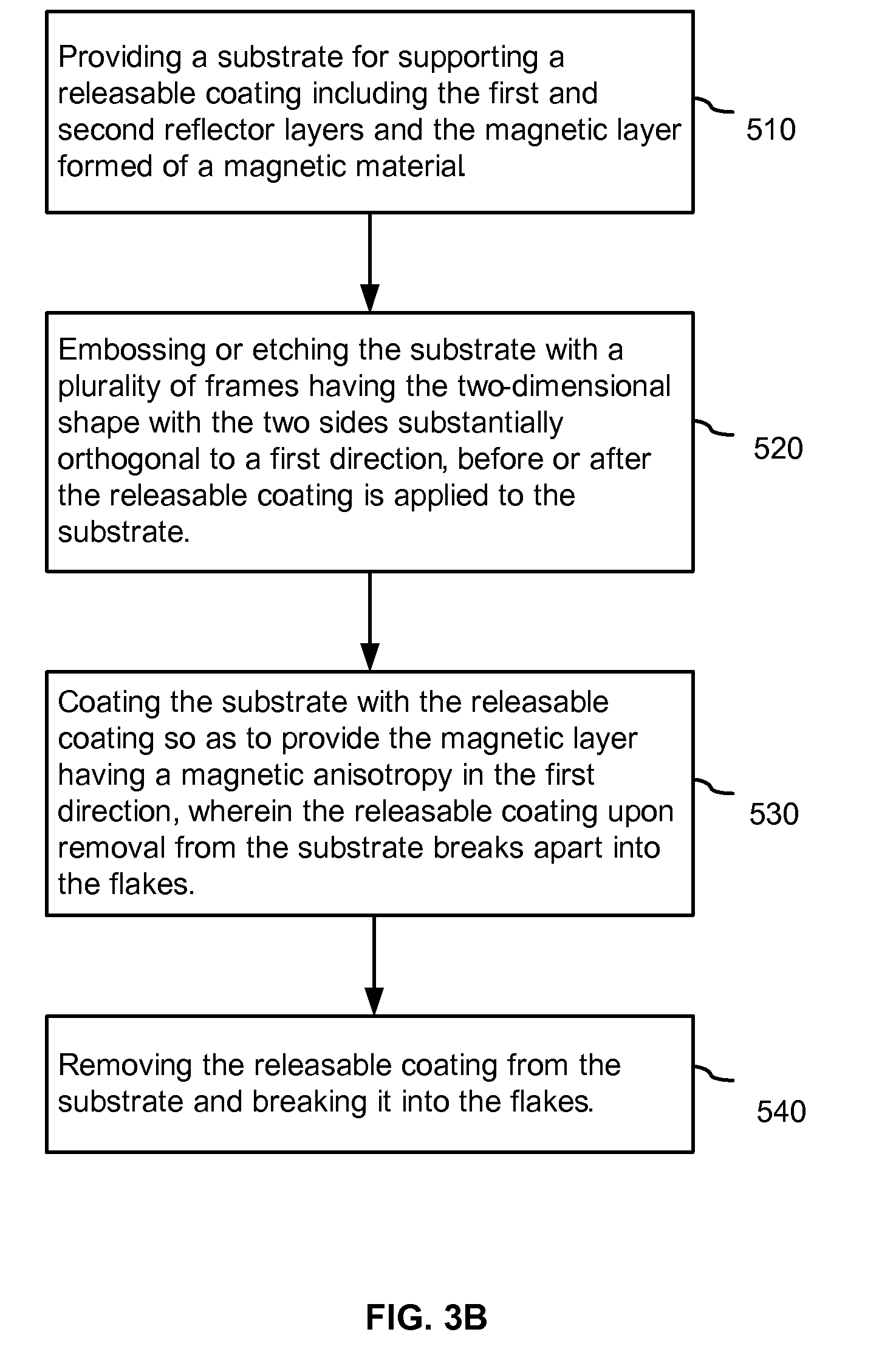

Provision of frames or borders around opaque flakes for covert security applications

InactiveUS20060035080A1Reduce concentrationPigment preparation by PVD/CVD methodsPencil leadsEngineeringMagnification

Opaque flakes, such as pigment or bright flake used in paints and inks, have a selected shape and / or other indicia to provide a covert security feature to an object. In some embodiments the composition includes base pigment, and the opaque covert flakes match the visual characteristics of the base pigment. In another embodiment, opaque covert flakes are mixed in the carrier with base pigment at a concentration sufficient to avoid changing the appearance of the composition. In another embodiment, opaque covert flakes are mixed in a clear or tinted varnish base that can be applied over an existing security feature. Shaped opaque covert flakes are not readily detectable by causal observation, but in some embodiments are easily seen at 50× magnification. In manufacturing the flakes a sheet of embossed frames are provided having symbols or indicia within; upon removing a coating from the sheet the coating material tends to break along frame lines and the resulting flakes are substantially uniform in size.

Owner:VIAVI SOLUTIONS INC

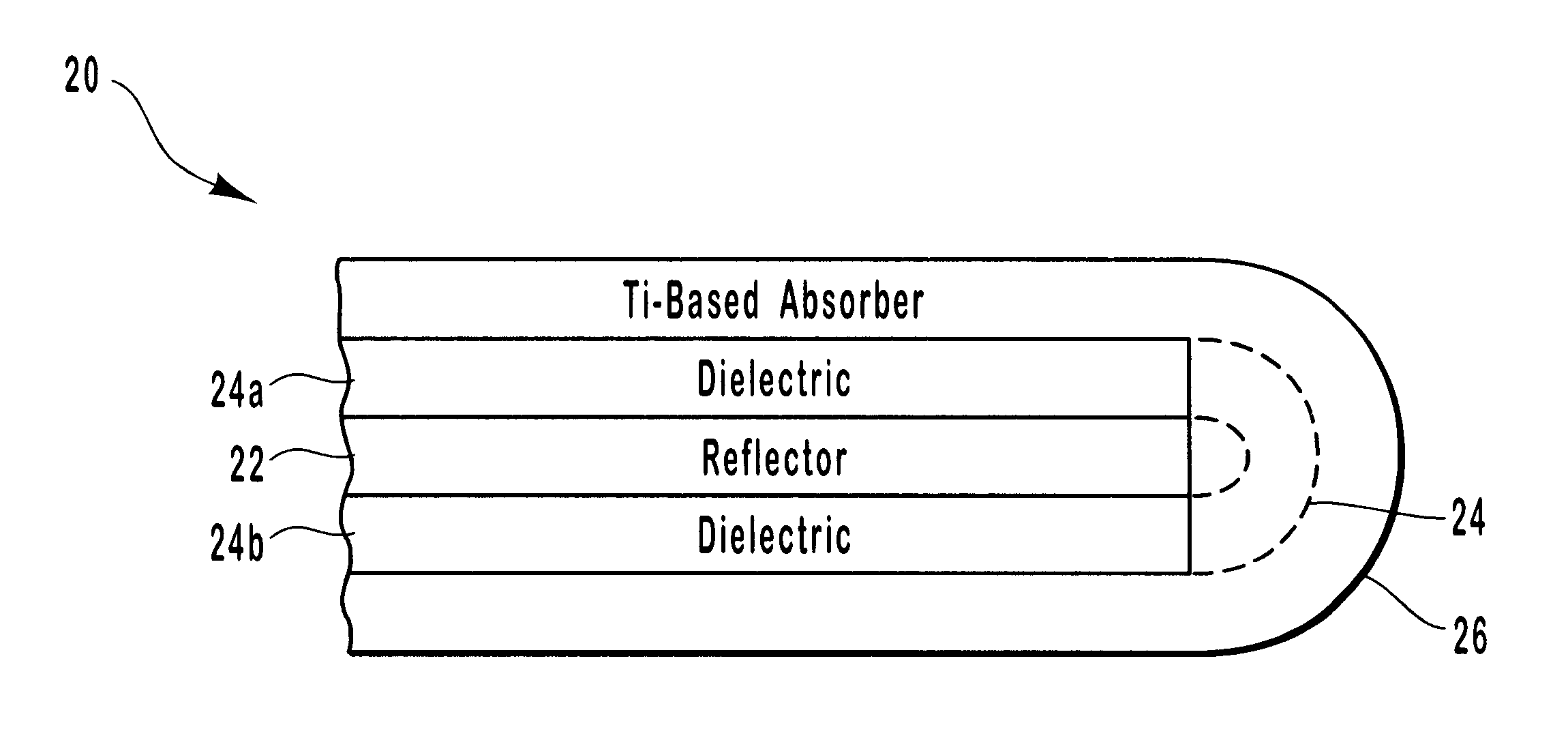

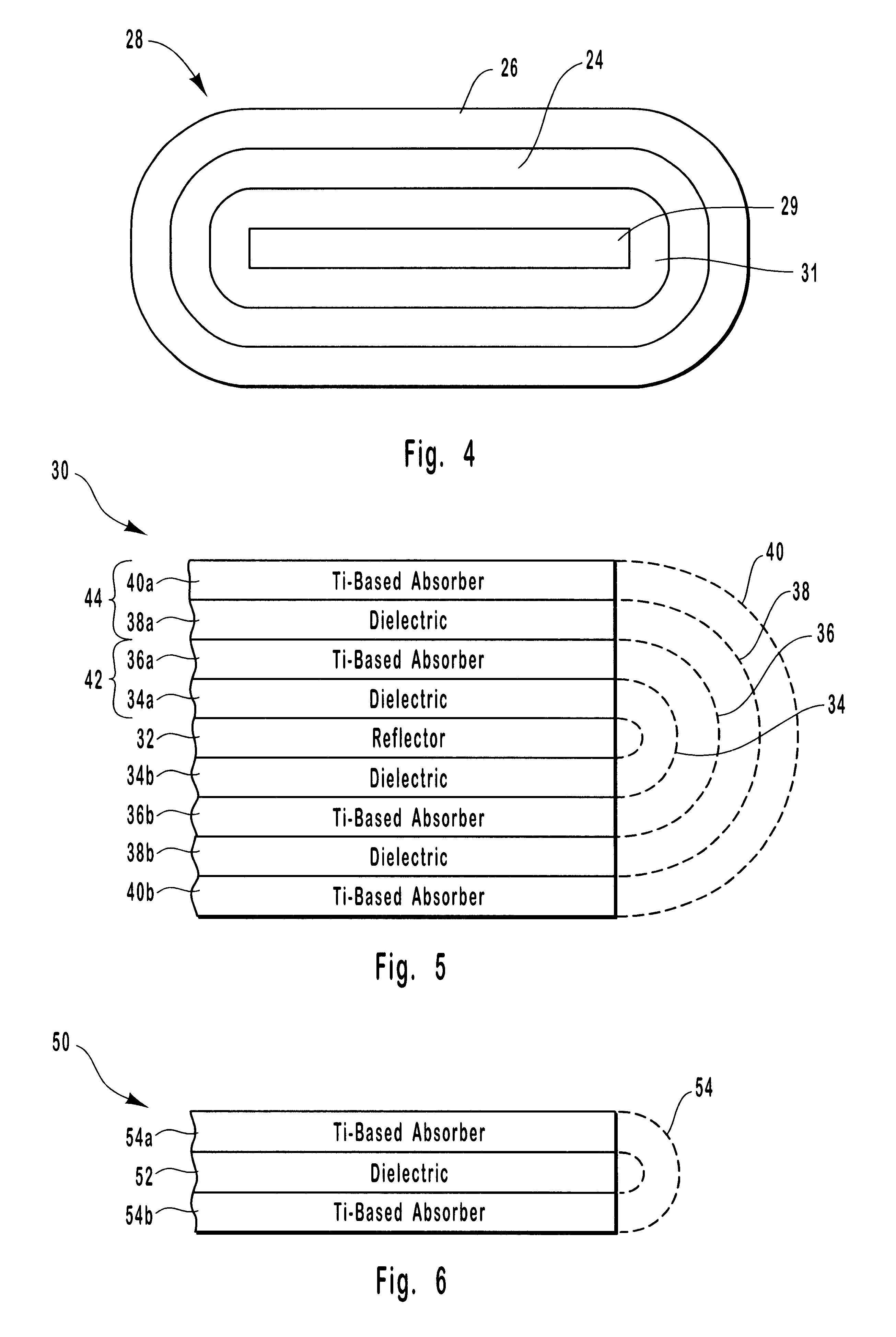

Titanium-containing interference pigments and foils with color shifting properties

InactiveUS6569529B1High chromaIncreased durabilityPigment preparation by PVD/CVD methodsRecord information storageColor shiftLiquid medium

Interference pigment flakes and foils are provided which have color shifting properties. The pigment flakes can have a symmetrical coating structure on opposing sides of a reflector layer, can have an asymmetrical coating structure with all of the layers on one side of the reflector layer, or can be formed with encapsulating coatings around a core reflector layer. The coating structure of the flakes and foils includes a reflector layer, a dielectric layer on the reflector layer, and a titanium-containing absorber layer on the dielectric layer. The pigment flakes and foils exhibit a discrete color shift so as to have a first color at a first angle of incident light or viewing and a second color different from the first color at a second angle of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

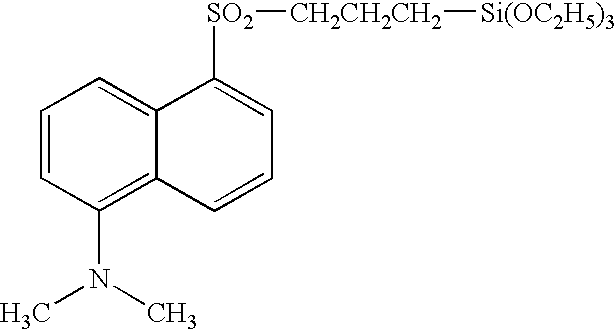

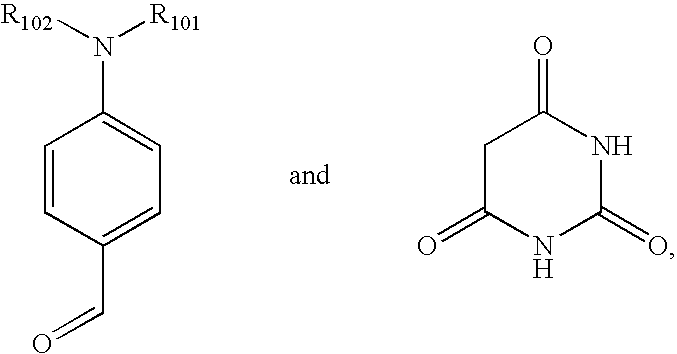

Composite pigment original, composite pigment, process for producing ink composition, and ink composition

InactiveUS7303619B2Avoid reactionLong-term storability is remarkably enhancedPigment preparation by PVD/CVD methodsInksSilicon oxideSubstrate surface

The present invention provides a composite pigment original having a structure comprising a resin layer and a pigment layer sequentially stacked on a sheet-shaped substrate surface, the pigment layer having a structure that at least a silicon oxide layer, a metal or metal compound layer and a silicon oxide layer are sequentially stacked. Furthermore, a composite pigment obtained from the composite pigment original, a process for producing an ink composition using the composite pigment original, and an ink composition obtained by the production process are disclosed.

Owner:SEIKO EPSON CORP

Methods for producing enhanced interference pigments

InactiveUS6524381B1Enhancement in electron generation rateIncrease deposition rateElectric discharge heatingPigment preparation by PVD/CVD methodsGas phaseVaporization

Methods and apparatus are provided for uniformly depositing a coating material from a vaporization source onto a powdered substrate material to form a thin coalescence film of the coating material that smoothly replicates the surface microstructure of the substrate material. The coating material is uniformly deposited on the substrate material to form optical interference pigment particles. The thin film enhances the hiding power and color gamut of the substrate material. Physical vapor deposition processes are used for depositing the film on the substrate material. The apparatus and systems employed in forming the coated particles utilize vibrating bed coaters, vibrating conveyor coaters, or coating towers. These allow the powdered substrate material to be uniformly exposed to the coating material vapor during the coating process.

Owner:JDS UNIPHASE CORP

Apparatus and method for producing plane-parallel flakes

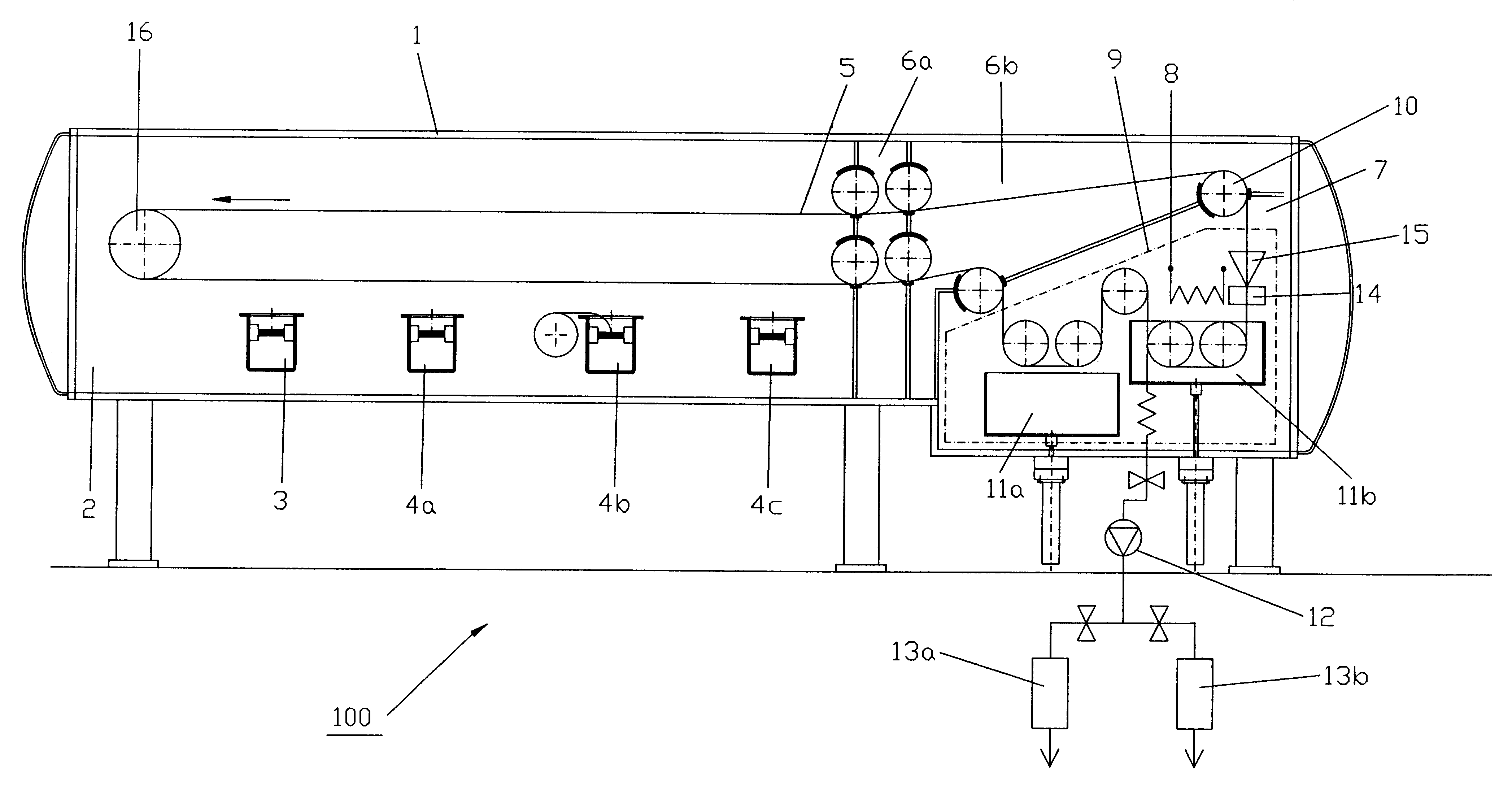

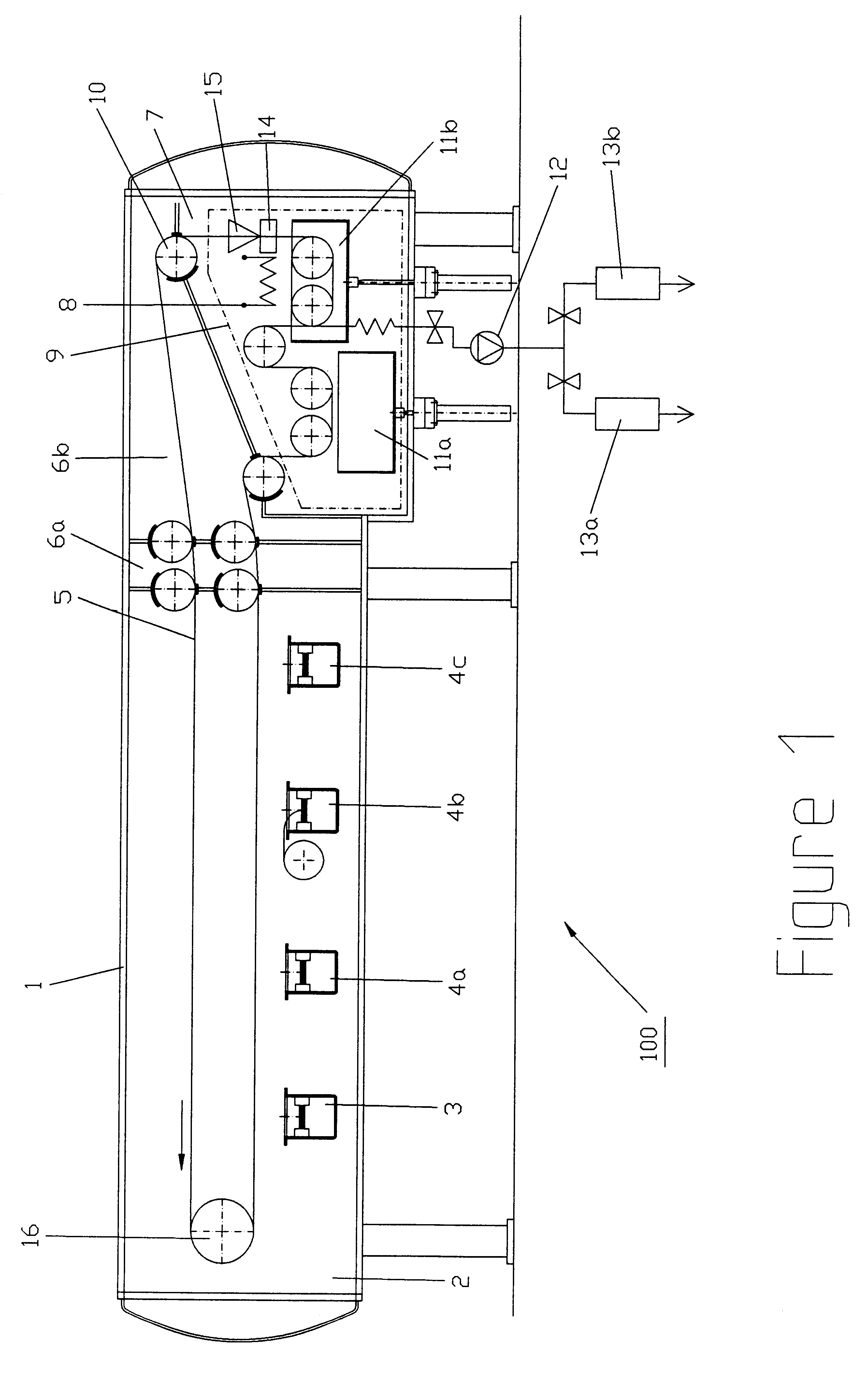

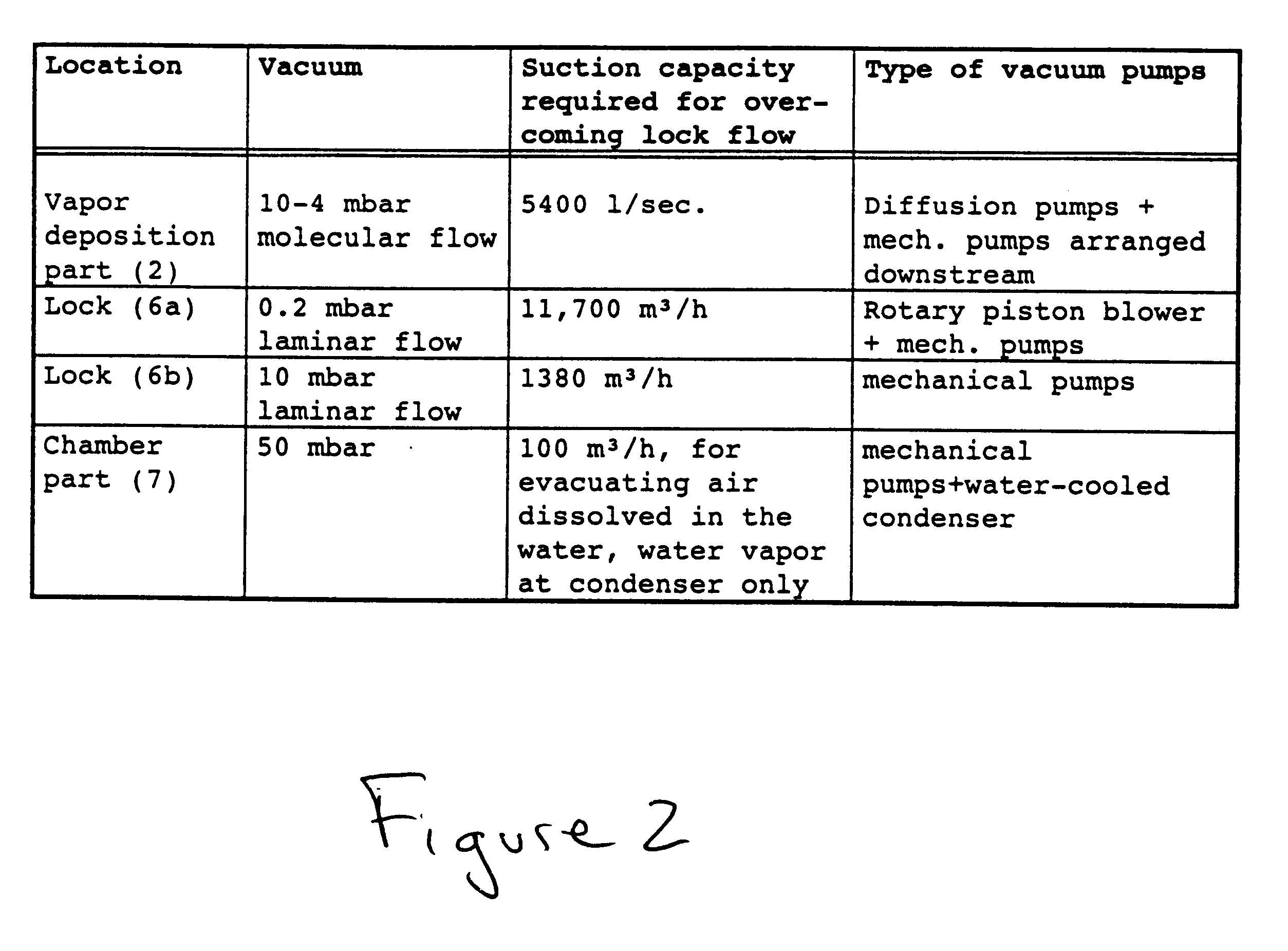

InactiveUS6270840B1Increase productionLow production costTransportation and packagingPigment preparation by PVD/CVD methodsAlcoholFluoride

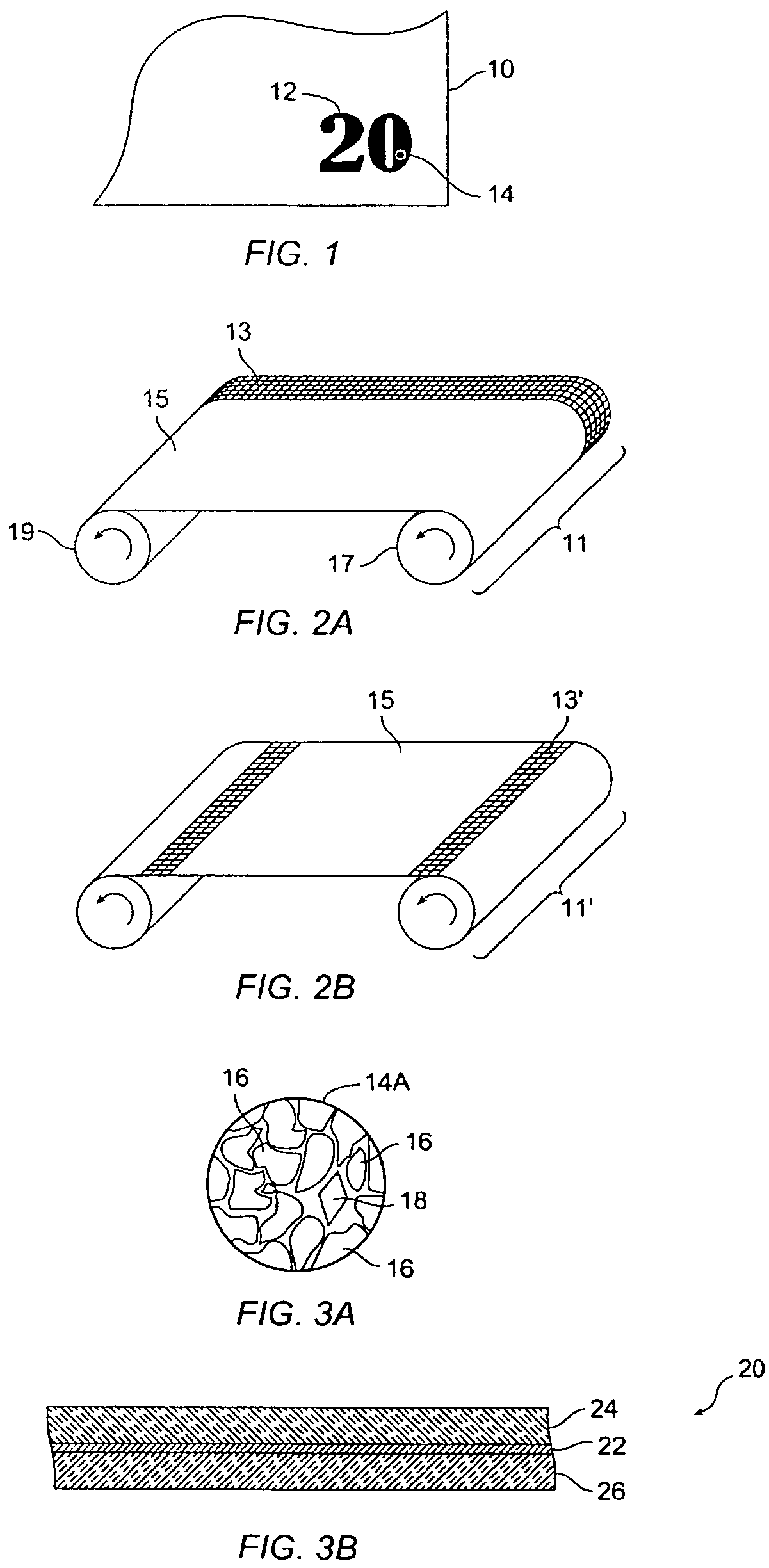

An apparatus and method technique for producing plane-parallel flakes is disclosed. In a preferred embodiment, the present invention is realized through a multi-chamber apparatus for producing plane-parallel flakes from layers vapor deposited in vacuum on an endlessly circulating substrate. The present invention includes the sequential steps of: vapor deposition of a separating agent layer in high vacuum on the endlessly circulating substrate; vapor deposition of one or more layers of metal, oxides, fluorides, and nitrides in high vacuum on the separating agent layer; and stripping the vapor deposited layers from the endlessly circulating substrate under low vacuum. The vapor deposited layers are subsequently present in a separate vacuum stage separated from the vapor deposition chamber by dynamic locks as a suspension of fine flakes in a mixture of solvent. and separating agent. The suspension may continuously or intermittently be transferred out of the separate vacuum stage for further processing. The solvent may be water in a vacuum environment of more than 20 mbar or secondary or tertiary alcohols at more than 0.05 mbar.

Owner:CIBA SPECIALTY CHEM CORP +1

Bright metal flake based pigments

InactiveUS6383638B1Good specular reflectance characteristicPigment preparation by PVD/CVD methodsSynthetic resin layered productsDielectricReflectivity

A flake-based pigment is provided having improved specular reflectance characteristics in the visible wavelength range. The flake-based pigment has a plurality of core flake sections each formed of a central reflector layer and dielectric support layers on opposing sides of the reflector layer. The resulting core flake section is a very thin three-layered structure that exhibits a uniaxial compressive strength much greater than a corresponding uniaxial tensile strength. This structure provides the benefits of rigidity and brittle fracture during manufacturing and application processes, which ultimately provides favorable planar and specular reflectance characteristics for the pigment in the visible wavelength range. A variety of outer coating layers can be formed around the core flake sections, such as various dielectric and absorber layers having thicknesses dependent upon the desired optical characteristics of the pigment.

Owner:JDS UNIPHASE CORP

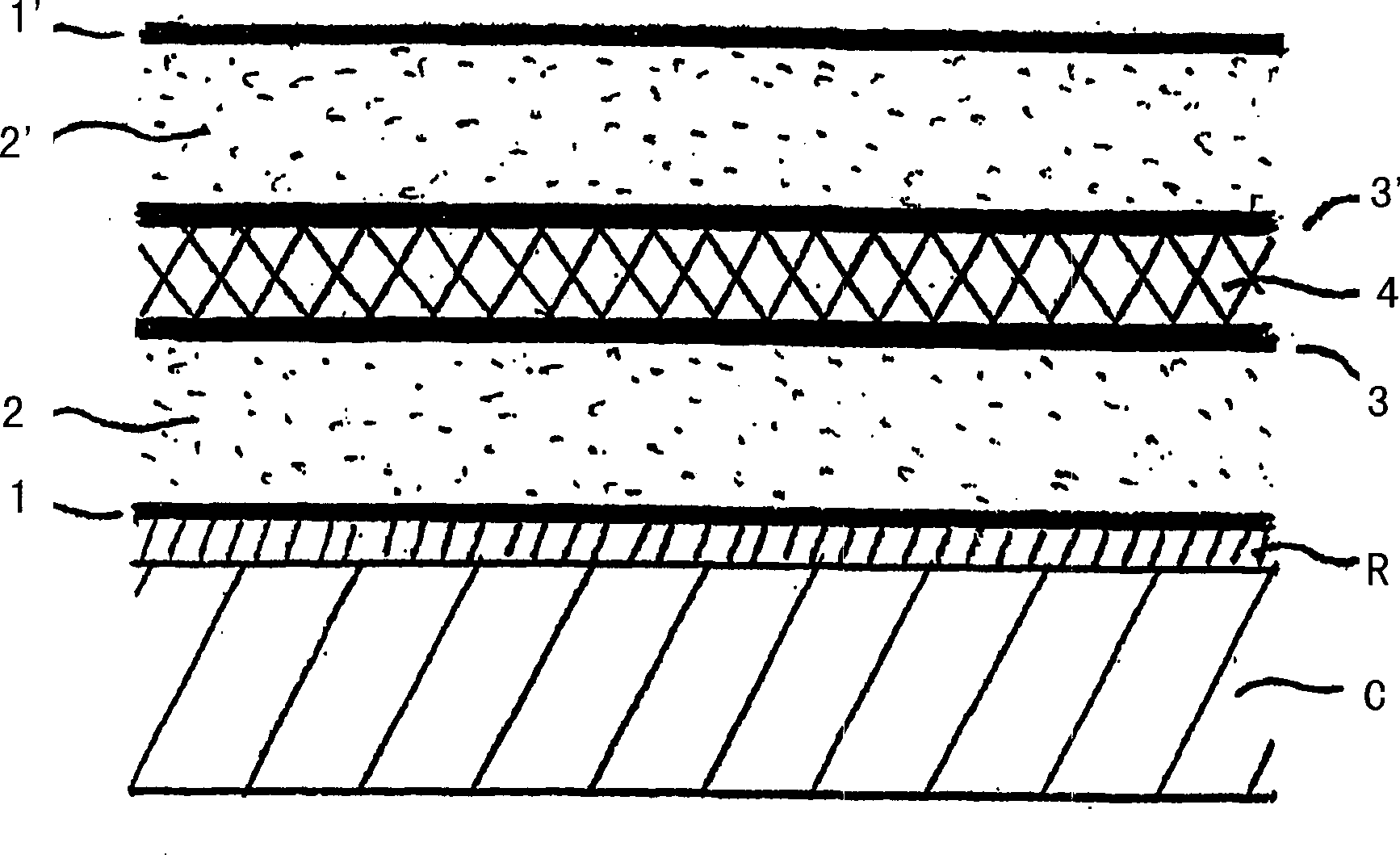

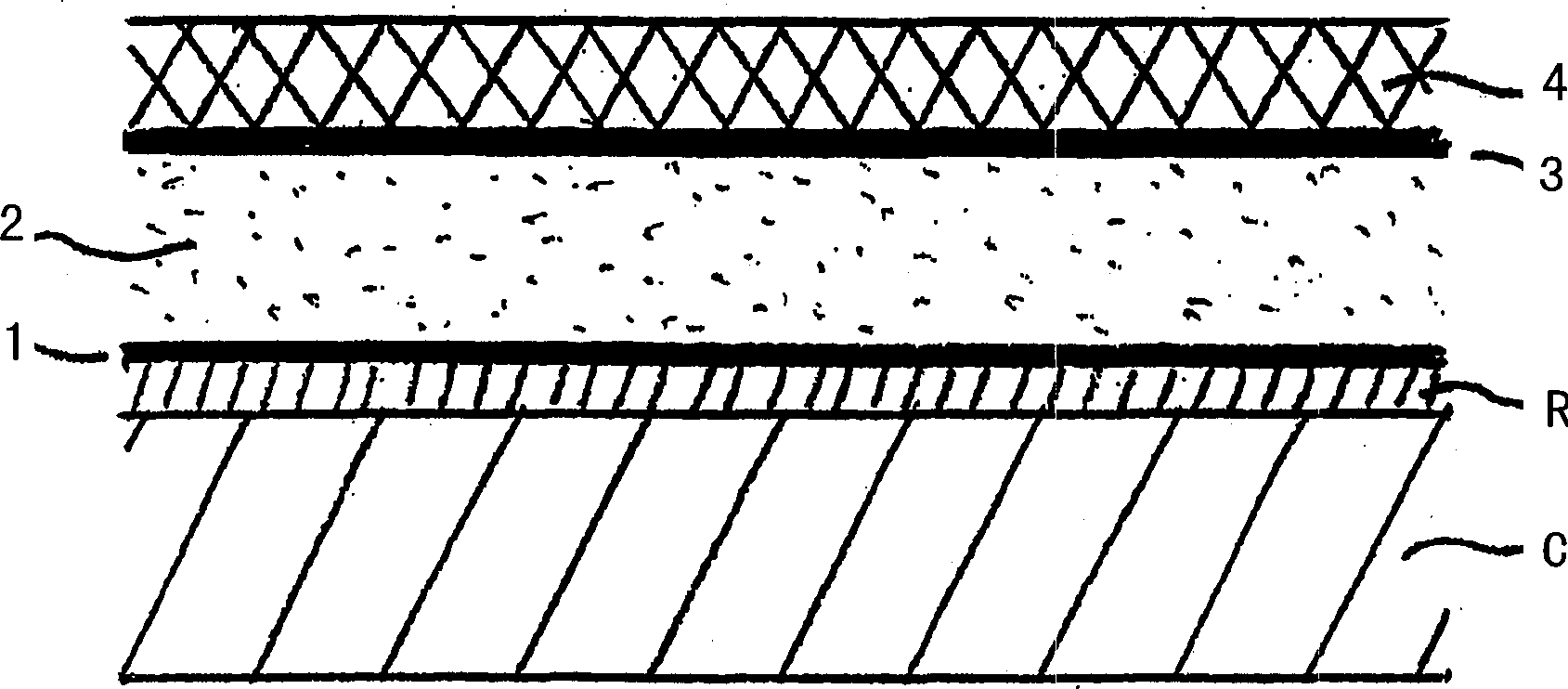

Magnetic thin film interference device or pigment and method of making it, printing ink or coating composition, security document and use of such a magnetic thin film interference device

InactiveUS6875522B2Easy to distinguishGood optical performancePigment preparation by PVD/CVD methodsSoldering apparatusChemistryPrinting ink

The invention discloses magnetic OVP, said pigment consisting of thin-layer flakes having a basic metal-dielectric-metal structure to result in a viewing-angle dependent color appearance, and having, in addition to said viewing-angle dependent color appearance, incorporated magnetic properties, to make them distinguishable from OVP of similar appearance but not having said magnetic properties. The invention discloses as well methods for obtaining such pigments and the use of such pigments as security elements in inks, coatings and articles.

Owner:SICPA HLDG SA

Color shifting thin film pigments

InactiveUS6236510B1Easily and economically utilizedMaximum optical effectPigment preparation by PVD/CVD methodsSynthetic resin layered productsElectricityLiquid medium

Owner:VIAVI SOLUTIONS INC

Process for the preparation of a pigment comprising a core material and at least one dielectric layer

InactiveUS20050013934A1Good absorbance of microwave energyImprove adhesionLiquid surface applicatorsPigment preparation by wet methodsAqueous solutionDielectric layer

The present invention relates to a process for the preparation of a pigment comprising a core material and at least one dielectric layer using microwave deposition of a metal oxide from an aqueous solution of fluorine scavenger onto a core material.

Owner:CIBA SPECIALTY CHEM CORP

Magnetic thin film interference device or pigment and method of making it, printing ink or coating composition containing said magnetic thin fim interference device

InactiveCN1459034ARich varietyExact matchOther printing matterMagnetic paintsPrinting inkMagnetic thin film

The invention discloses magnetic OVP, said pigment consisting of thin-layer flakes having a basic metal-dielectric-metal structure to result in a viewing-angle dependent color appearance, and having, in addition to said viewing-angle dependent color appearance, incorporated magnetic properties, to make them distinguishable from OVP of similar appearance but not having said magnetic properties. The invention discloses as well methods for obtaining such pigments and the use of such pigments as security elements in inks, coatings and articles.

Owner:SICPA HLDG SA

Opaque flake for covert security applications

InactiveUS7241489B2Reduce concentrationPigment preparation by PVD/CVD methodsPattern printingMagnificationEngineering

Opaque flakes, such as pigment or bright flake used in paints and inks, have a selected shape and / or other indicia to provide a covert security feature to an object. In some embodiments the composition includes base pigment, and the opaque covert flakes match the visual characteristics of the base pigment. In another embodiment, opaque covert flakes are mixed in the carrier with base pigment at a concentration sufficient to avoid changing the appearance of the composition. In another embodiment, opaque covert flakes are mixed in a clear or tinted varnish base that can be applied over an existing security feature. Shaped opaque covert flakes are not readily detectable by causal observation, but in some embodiments are easily seen at 100× magnification.

Owner:VIAVI SOLUTIONS INC

Anisotropic magnetic flakes

ActiveUS9662925B2Cost effectiveMaterial nanotechnologyDecorative surface effectsHigh reflectivityMaterials science

The invention relates to anisotropic, reflective, magnetic flakes. In a liquid carrier and under influence of an external magnetic field, the flakes attract to one another side-by-side and form ribbons which provide higher reflectivity to a coating and may be used as a security feature for authentication of an object.

Owner:VIAVI SOLUTIONS INC

Composite pigment original, composite pigment, process for producing ink composition, and ink composition

InactiveUS20050090581A1Avoid reactionLong-term storability is remarkably enhancedPigment preparation by PVD/CVD methodsInksSilicon oxideSubstrate surface

The present invention provides a composite pigment original having a structure comprising a resin layer and a pigment layer sequentially stacked on a sheet-shaped substrate surface, the pigment layer having a structure that at least a silicon oxide layer, a metal or metal compound layer and a silicon oxide layer are sequentially stacked. Furthermore, a composite pigment obtained from the composite pigment original, a process for producing an ink composition using the composite pigment original, and an ink composition obtained by the production process are disclosed.

Owner:SEIKO EPSON CORP

Process for making angstrom scale and high aspect functional platelets

InactiveUS6863851B2Increase capacitanceMaterial nanotechnologyNanostructure manufactureGas phaseSolvent

A process for making functional or decorative flakes or platelets economically and at high production rates comprises applying a multi-layer sandwich of vapor deposited metal and release coats in alternating layers to a rotating chilled drum or suitable carrier medium contained in a vapor deposition chamber. The alternating metallized layers are applied by vapor deposition and the intervening release layers are preferably solvent soluble thermoplastic polymeric materials applied by vapor deposition sources contained in the vapor deposition chamber. The multi-layer sandwich built up in the vacuum chamber is removed from the drum or carrier and treated with a suitable organic solvent to dissolve the release coating from the metal in a stripping process that leaves the metal flakes essentially release coat free. The solvent and dissolved release material are then removed by centrifuging to produce a cake of concentrated flakes which can be air milled and let down in a preferred vehicle and further sized and homogenized for final use in inks, paints or coatings. In one embodiment the finished flakes comprise single-layer thin metal or metal alloy flakes or flakes of inorganic materials, and in another embodiment flakes are coated on both sides with protective polymeric coatings that were applied from suitable vacuum deposition sources or the like contained in the vapor deposition chamber.

Owner:ECKART AMERICA CORP

Multi-layered magnetic pigments and foils

InactiveUS20030143400A1Substantial shift in chroma and hueEasily and economically utilizedPigment preparation by PVD/CVD methodsPattern printingLiquid mediumColor shift

Multilayered magnetic pigment flakes and foils are provided. The pigment flakes can have a symmetrical coating structure on opposing sides of a magnetic core, or can be formed with encapsulating coatings around the magnetic core. The magnetic core can be a magnetic layer between reflector or dielectric layers, a dielectric layer between magnetic layers, or only a magnetic layer. Some embodiments of the pigment flakes and foils exhibit a discrete color shift so as to have distinct colors at differing angles of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

Provision of Frames Or Borders Around Pigment Flakes For Covert Security Applications

Opaque flakes, such as pigment or bright flakes used in paints and inks, have a selected shape and / or other indicia to provide a covert security feature to an object. Shaped opaque covert flakes are not readily detectable by causal observation, but in some embodiments are easily seen at 50× magnification. In manufacturing the flakes a sheet of embossed frames are provided having embossed symbols or indicia within. Upon removing a coating from the embossed sheet the coating material tends to break along frame lines or grooves and the resulting flakes are substantially uniform in size. In order to have the flakes break along frame lines or grooves more readily than along the embossing or grooves defining indicia within a frame, the frames are provided with a deeper groove than indicia grooves. As well a groove having a different shaped profile conducive to breakage can be used for the frame grooves whereas a groove having a profile less conducive to breakage can be used to form the indicia grooves. We have found that the flakes can be further protected from breakage by coating them in a protective coating. This coating may have other features which makes the logo more visible.

Owner:VIAVI SOLUTIONS INC

High chroma optically variable color-shifting glitter

InactiveUS20060228553A1Reduce chippingReduce breakagePigment preparation by PVD/CVD methodsSynthetic resin layered productsGlitterChromaticity

Opaque glitter particles that are uniform in size and shape are disclosed that have an optically variable color with a change in angle of incident light. The glitter particles have an organic substrate and an optical interference structure on one or both sides of the organic substrate. The optical interference design can be a Fabry-Perot structure or can be an optically variable ink.

Owner:JDS UNIPHASE CORP

Titanium-containing interference pigments and foils with color shifting properties

InactiveUS20030203222A1Easily and economically utilizedStable to ultraviolet radiation (UV) exposureAnodisationPigment preparation by PVD/CVD methodsColor shiftLiquid medium

Interference pigment flakes and foils are provided which have color shifting properties. The pigment flakes can have a symmetrical coating structure on opposing sides of a reflector layer, can have an asymmetrical coating structure with all of the layers on one side of the reflector layer, or can be formed with encapsulating coatings around a core reflector layer. The coating structure of the flakes and foils includes a reflector layer, a dielectric layer on the reflector layer, and a titanium-containing absorber layer on the dielectric layer. The pigment flakes and foils exhibit a discrete color shift so as to have a first color at a first angle of incident light or viewing and a second color different from the first color at a second angle of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

Provision of frames or borders around opaque flakes for covert security applications

Opaque flakes, such as pigment or bright flake used in paints and inks, have a selected shape and / or other indicia to provide a covert security feature to an object. In some embodiments the composition includes base pigment, and the opaque covert flakes match the visual characteristics of the base pigment. In another embodiment, opaque covert flakes are mixed in the carrier with base pigment at a concentration sufficient to avoid changing the appearance of the composition. In another embodiment, opaque covert flakes are mixed in a clear or tinted varnish base that can be applied over an existing security feature. Shaped opaque covert flakes are not readily detectable by causal observation, but in some embodiments are easily seen at 50× magnification. In manufacturing the flakes a sheet of embossed frames are provided having symbols or indicia within; upon removing a coating from the sheet the coating material tends to break along frame lines and the resulting flakes are substantially uniform in size.

Owner:VIAVI SOLUTIONS INC

Process for making angstrom scale and high aspect functional platelets

Owner:ECKART AMERICA CORP

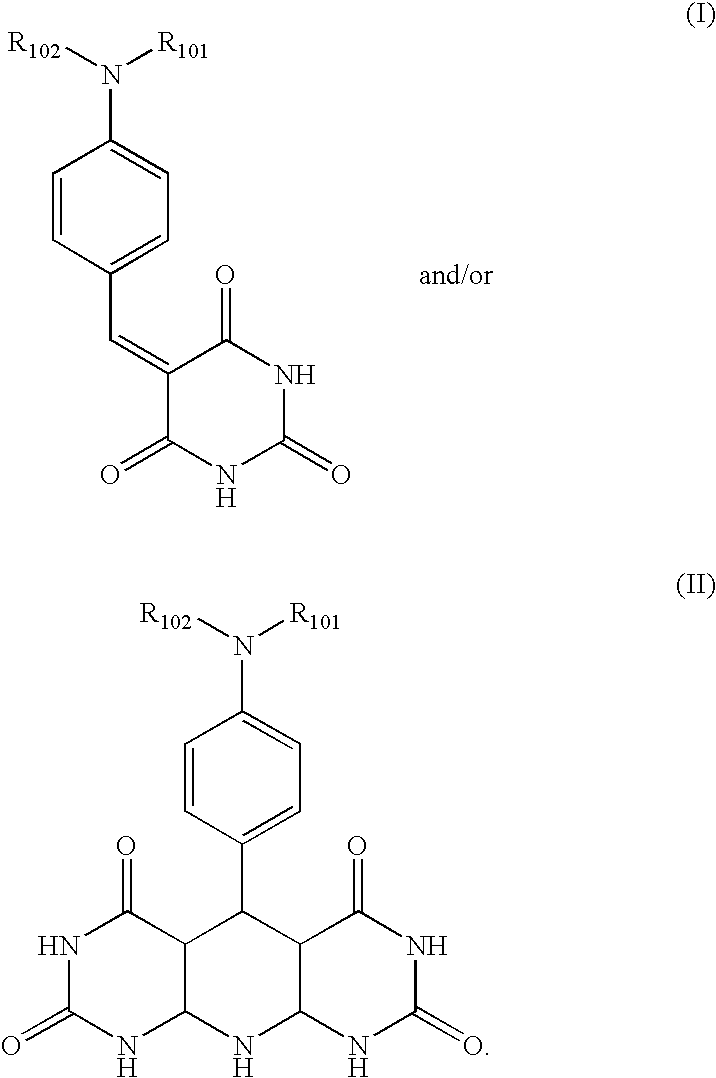

Bright Pigment, Method for Producing the Pigment, and Waterborne Resin Composition Containing the Pigment

A bright pigment of the present invention includes a scaly inorganic base 10, a silver-containing coating 11 that covers the inorganic base 10 and contains silver or a silver alloy, and a yellowing-suppressing coating 2 that covers the inorganic base 10 from outside of the silver-containing coating 11 and contains a metal compound functioning as an oxidizing agent. The metal compound is preferably at least one selected from the group consisting of a hydroxide of metal, an oxide hydrate of metal, and a salt of an oxide hydrate of metal, and the metal is at least one selected from the group consisting of tungsten, molybdenum, bismuth, vanadium, or cerium.

Owner:NIPPON SHEET GLASS CO LTD

Reinforced Glitter

InactiveUS20090081460A1Precise cuttingAvoid curlPigment preparation by PVD/CVD methodsSynthetic resin layered productsLacquerOptoelectronics

The reinforced opaque glitter particles have a substantially uniform shape and size. Each of the particles includes a reflective core supported by a transparent organic substrate and one or more robustness-improving layers for providing rigidity to the particle. Optionally, the particles have lacquer layers at a surface of the particle. One example of a robustness-improving layer is an inorganic transparent protective layer having a thickness of at least 20 nm adjacent directly to the aluminum layer. Another example is an adhesion promoting layer directly adjacent to the transparent organic substrate.

Owner:JDS UNIPHASE CORP

High chroma flakes

An article including a reflector having a first surface and a second surface opposite the first surface; a first selective light modulator layer external to the first surface of the reflector; a second selective light modulator layer external to the second surface of the reflector; a first absorber layer external to the first selective light modulator layer; and a second absorber layer external to the second selective light modulator layer; wherein each of the first and second selective light modulator layers include a host material is disclosed herein. Methods of making the article are also disclosed.

Owner:VIAVI SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com