Magnetic thin film interference device or pigment and method of making it, printing ink or coating composition containing said magnetic thin fim interference device

A technology of magnetic films and magnetic materials, applied in the application of magnetic films to substrates, magnetic coatings, preparation of dyed pigments by PVD/CVD method, etc. Wide variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

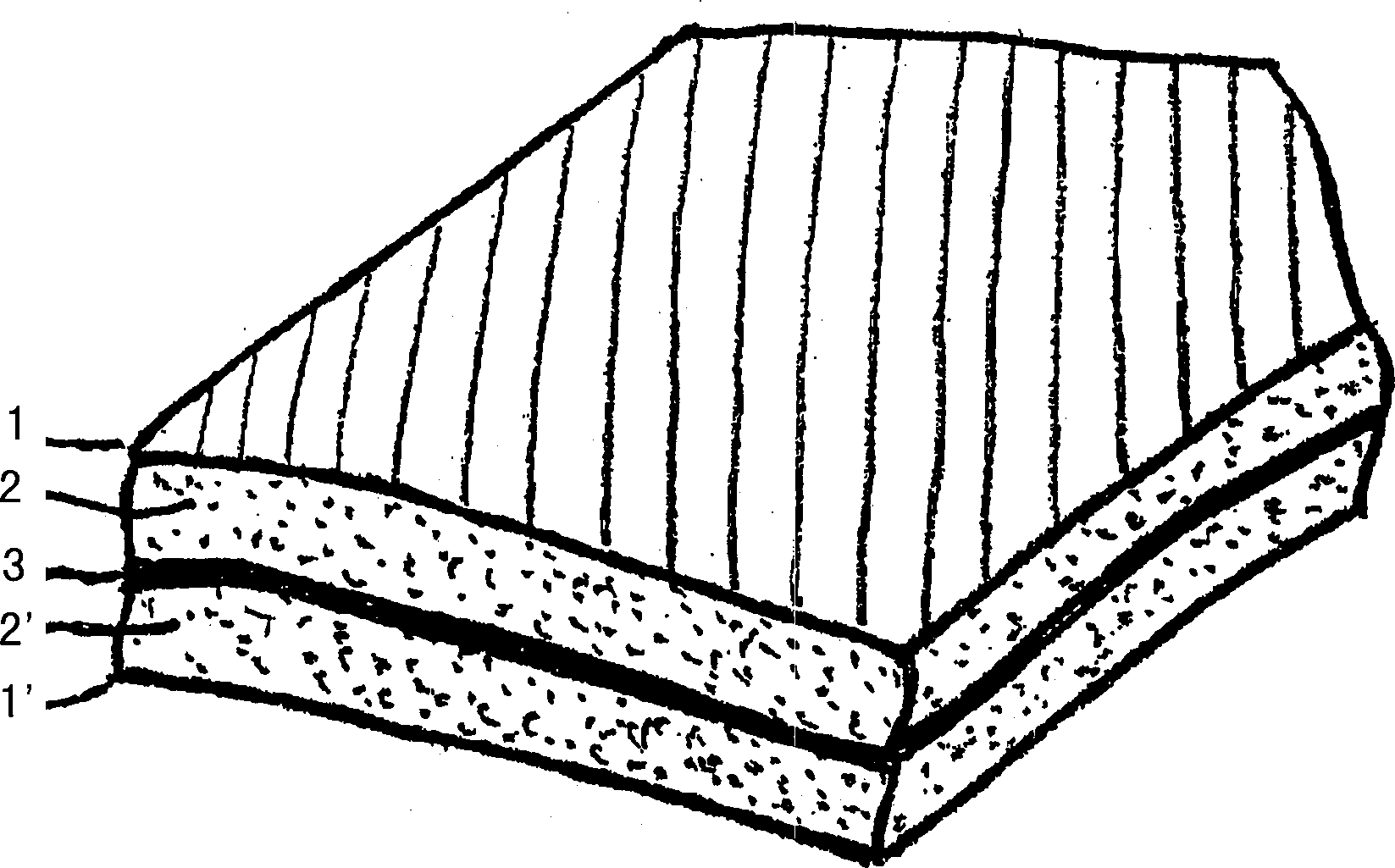

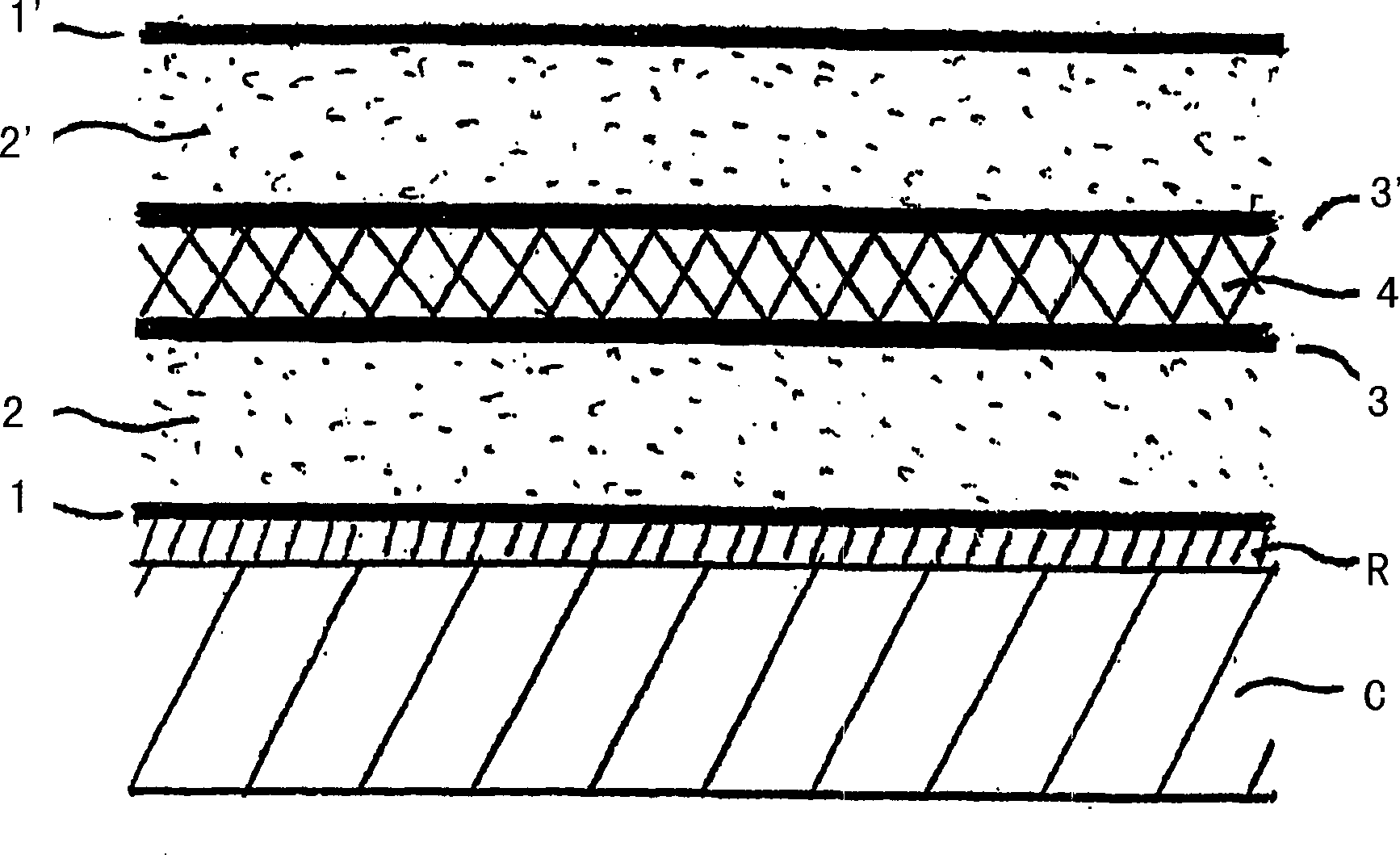

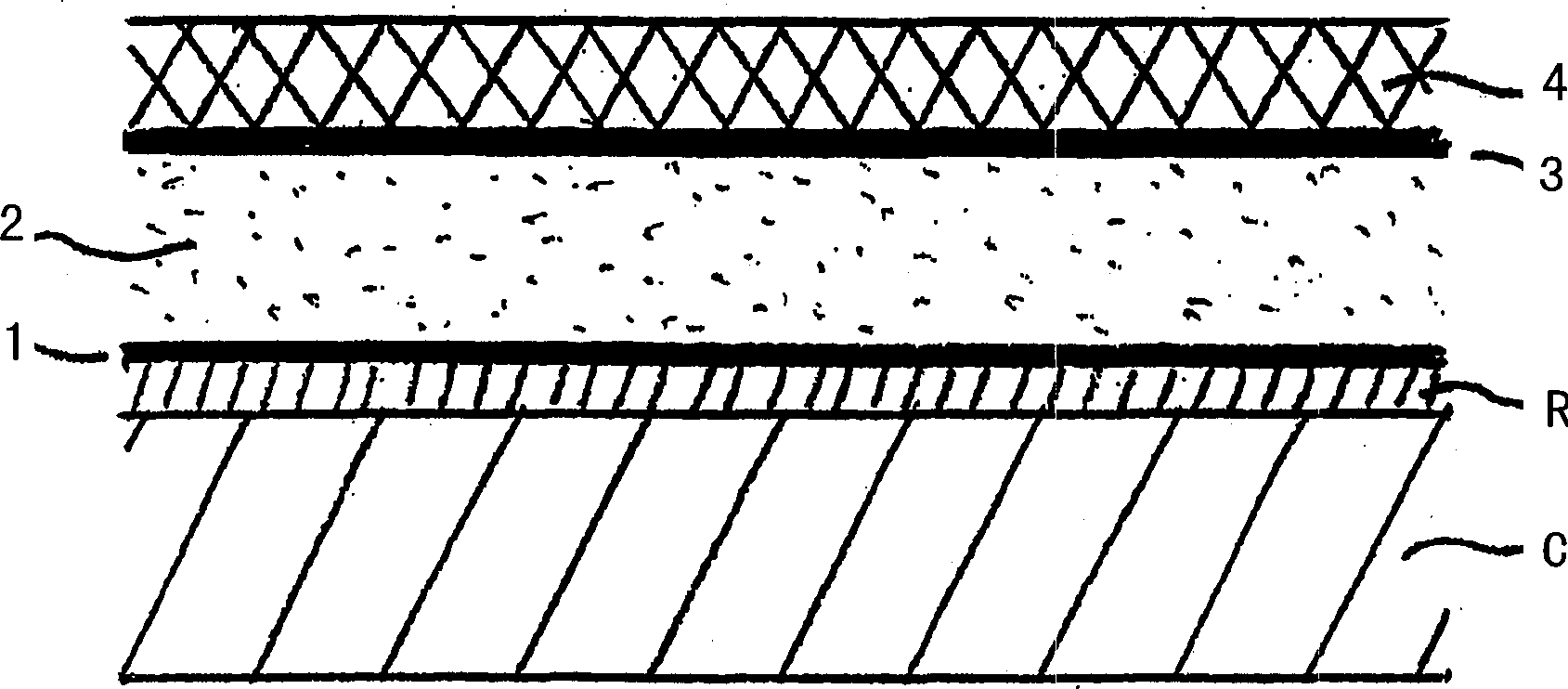

[0038] exist figure 2 In the first preferred embodiment of the magnetic OVP shown, a layer 4 of magnetic material is included between two total reflector layers 3, 3' of the OVP stack. In order to provide the best optical and magnetic interaction conditions, the optical interaction is done using the "standard" OVP layer sequence - chromium / magnesium fluoride / aluminum. In order to accommodate the magnetic function inside it in the form of any desired additional layer of magnetic elements, alloys or compounds, the aluminum layer is "divided in two".

[0039] On the carrier foil C coated with a release agent R, a first chromium absorber layer 1 is deposited, followed by a first magnesium fluoride dielectric material layer 2 and a first aluminum reflector layer 3 . A magnetic material layer 4 of magnetic material is then deposited, followed by a second aluminum reflector layer 3'. Then deposit a second magnesium fluoride dielectric material layer 2' and a second chromium absorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com