Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

234results about "Particle application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

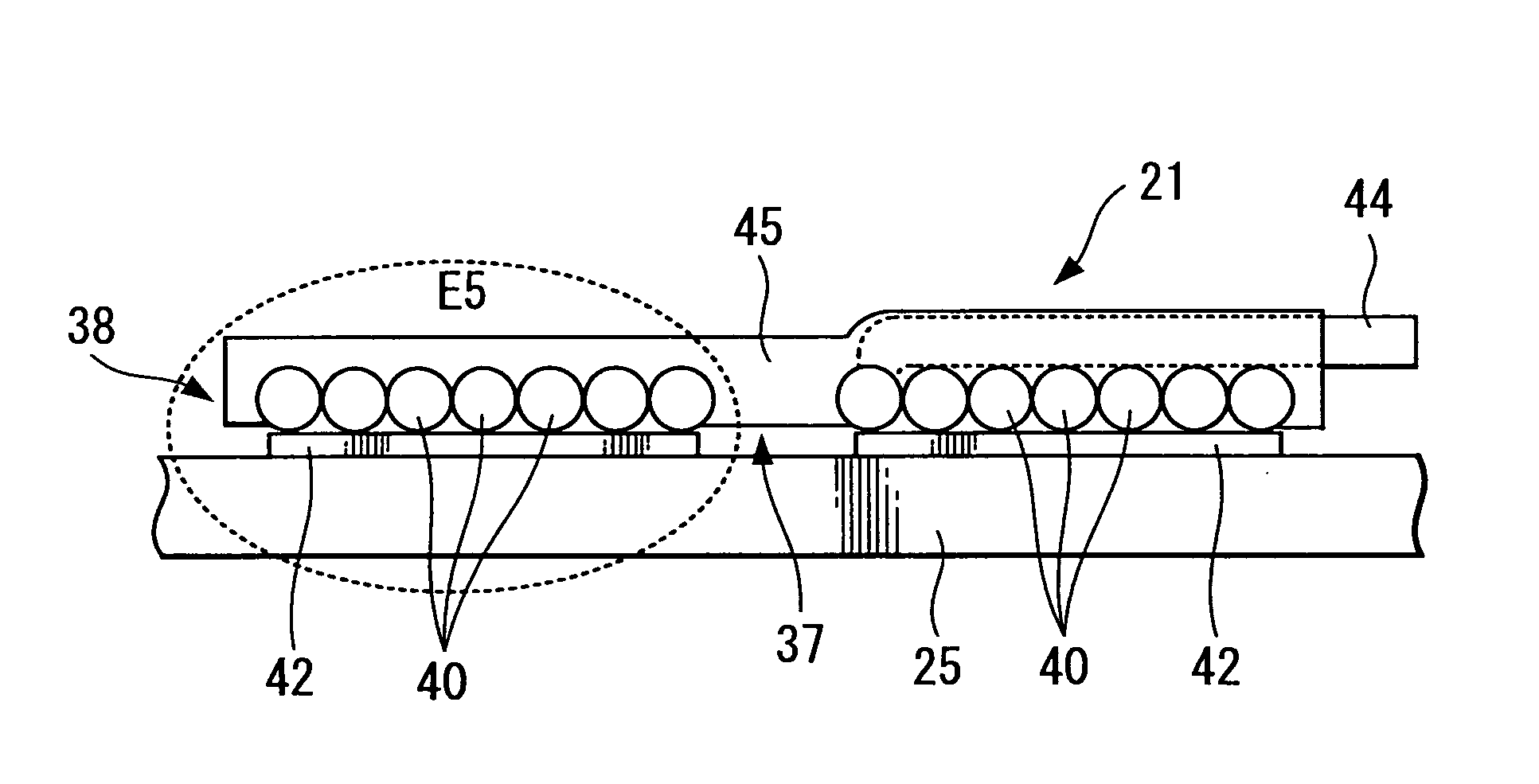

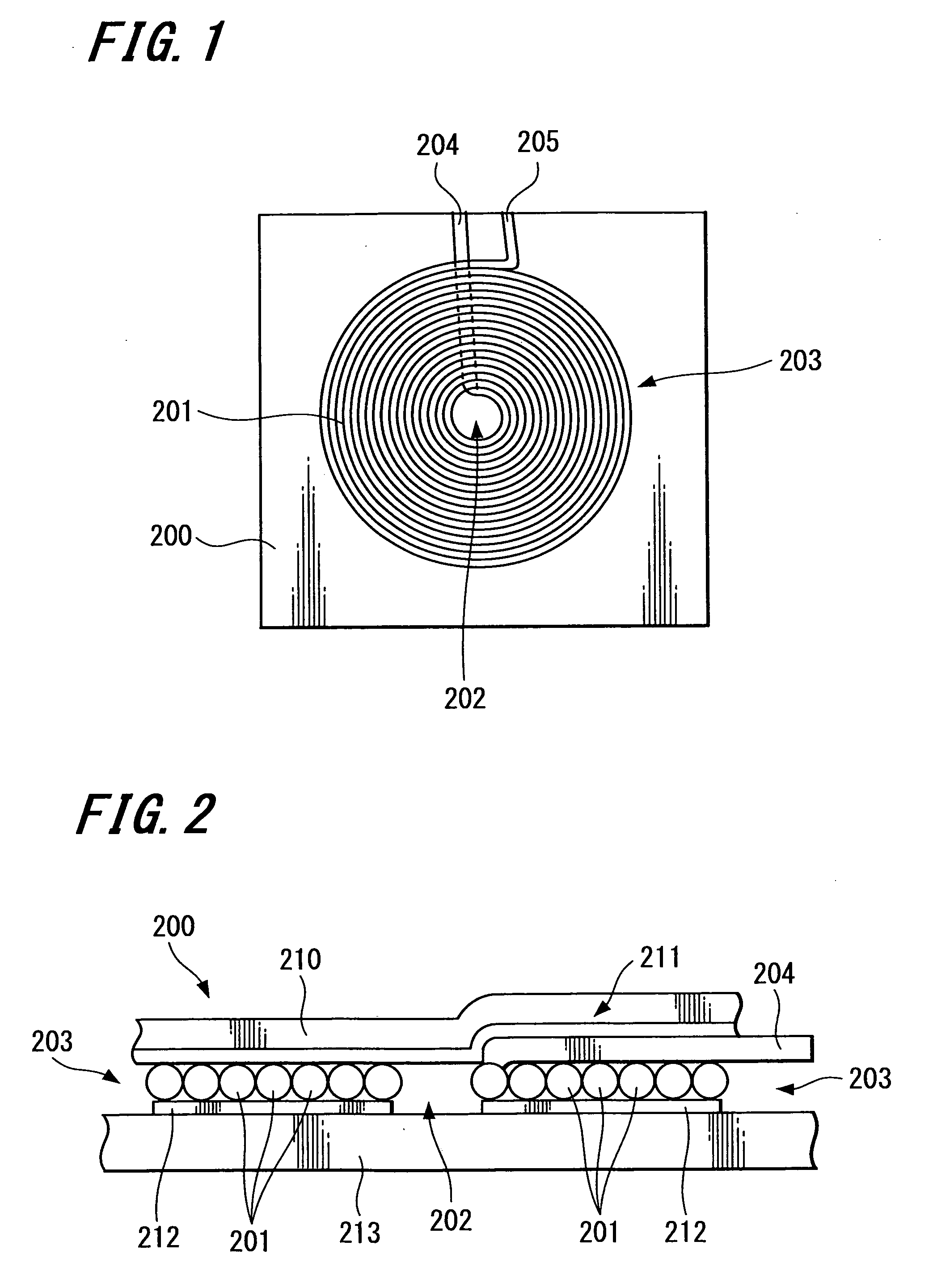

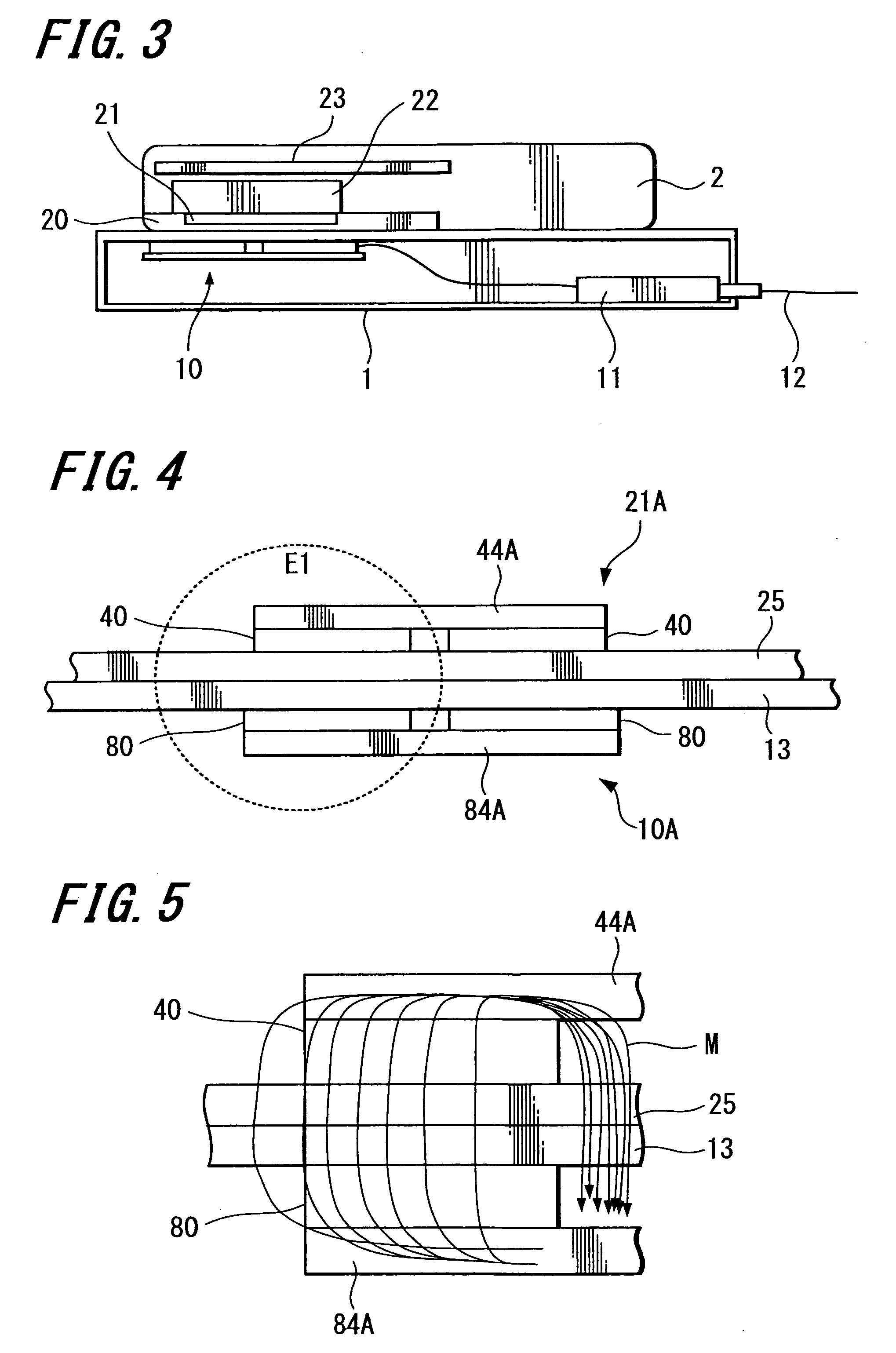

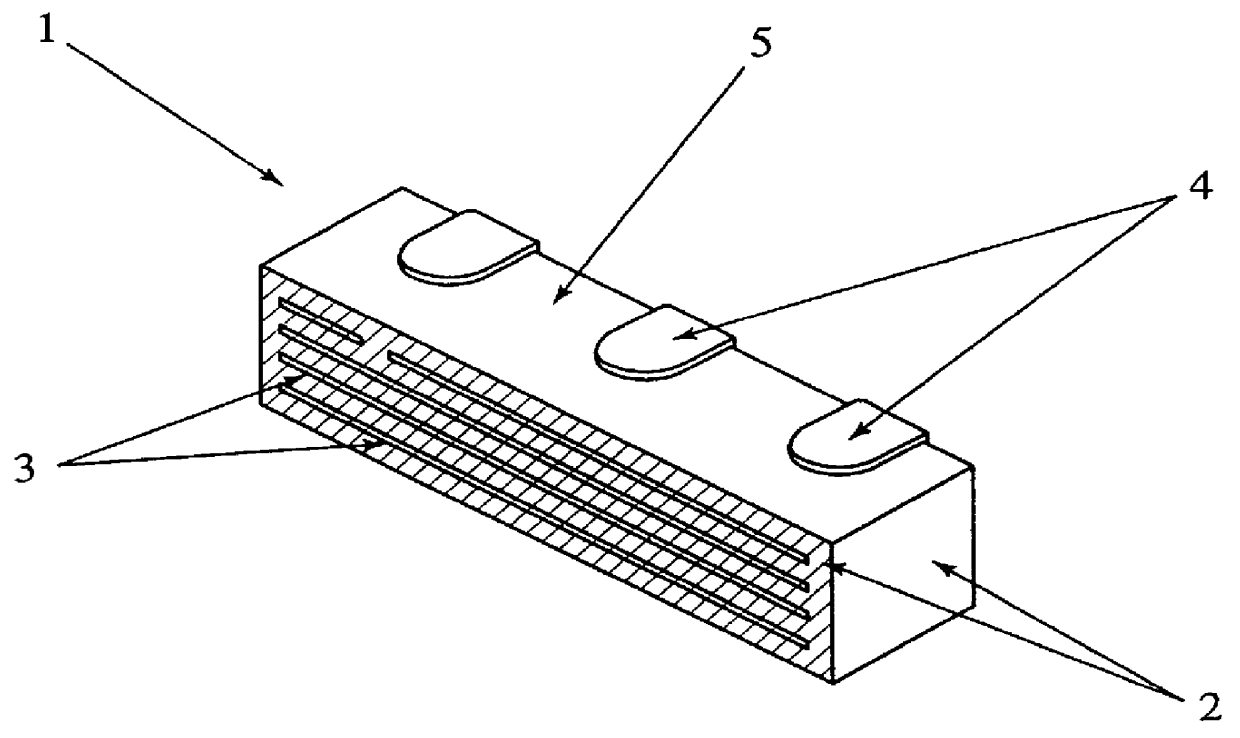

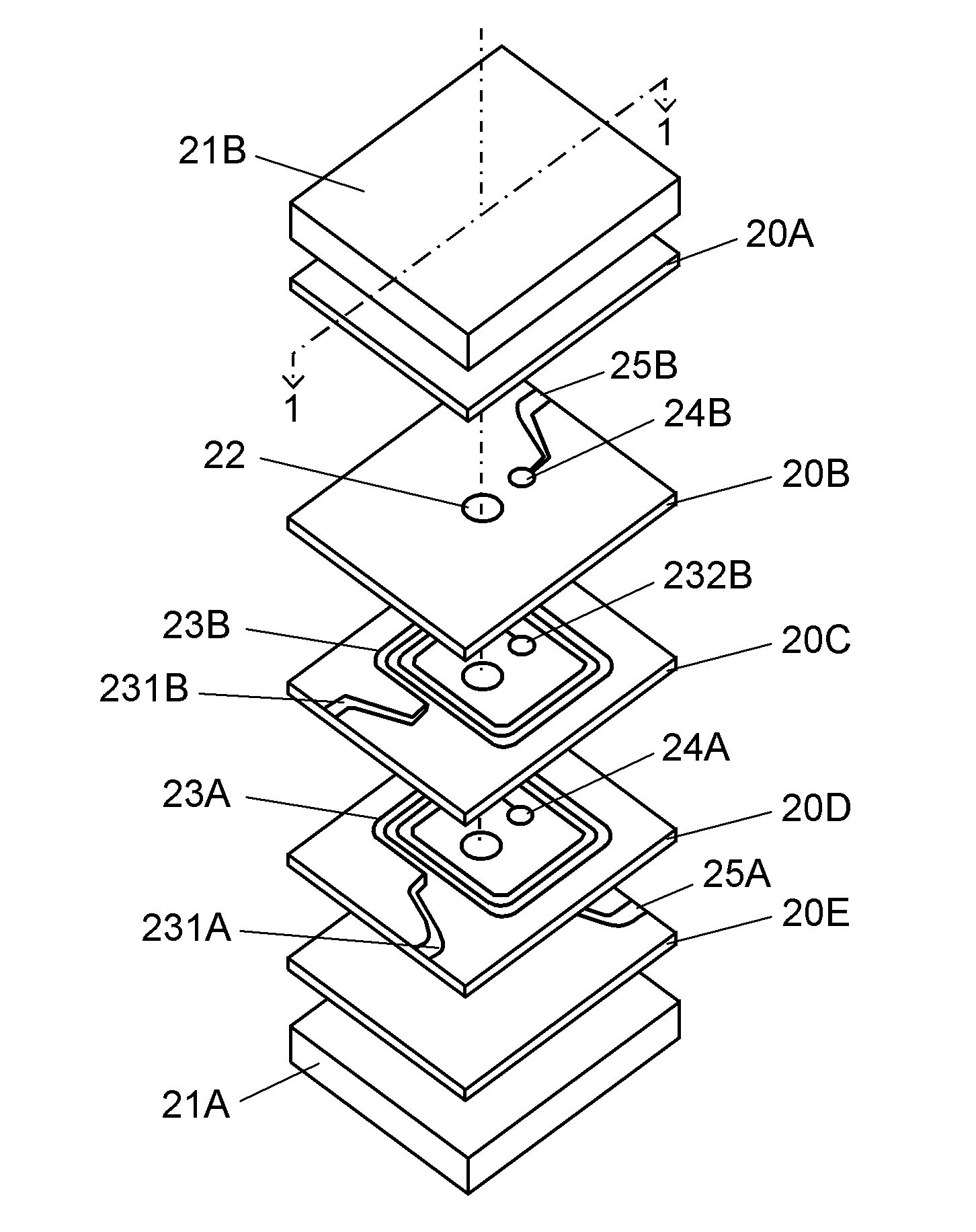

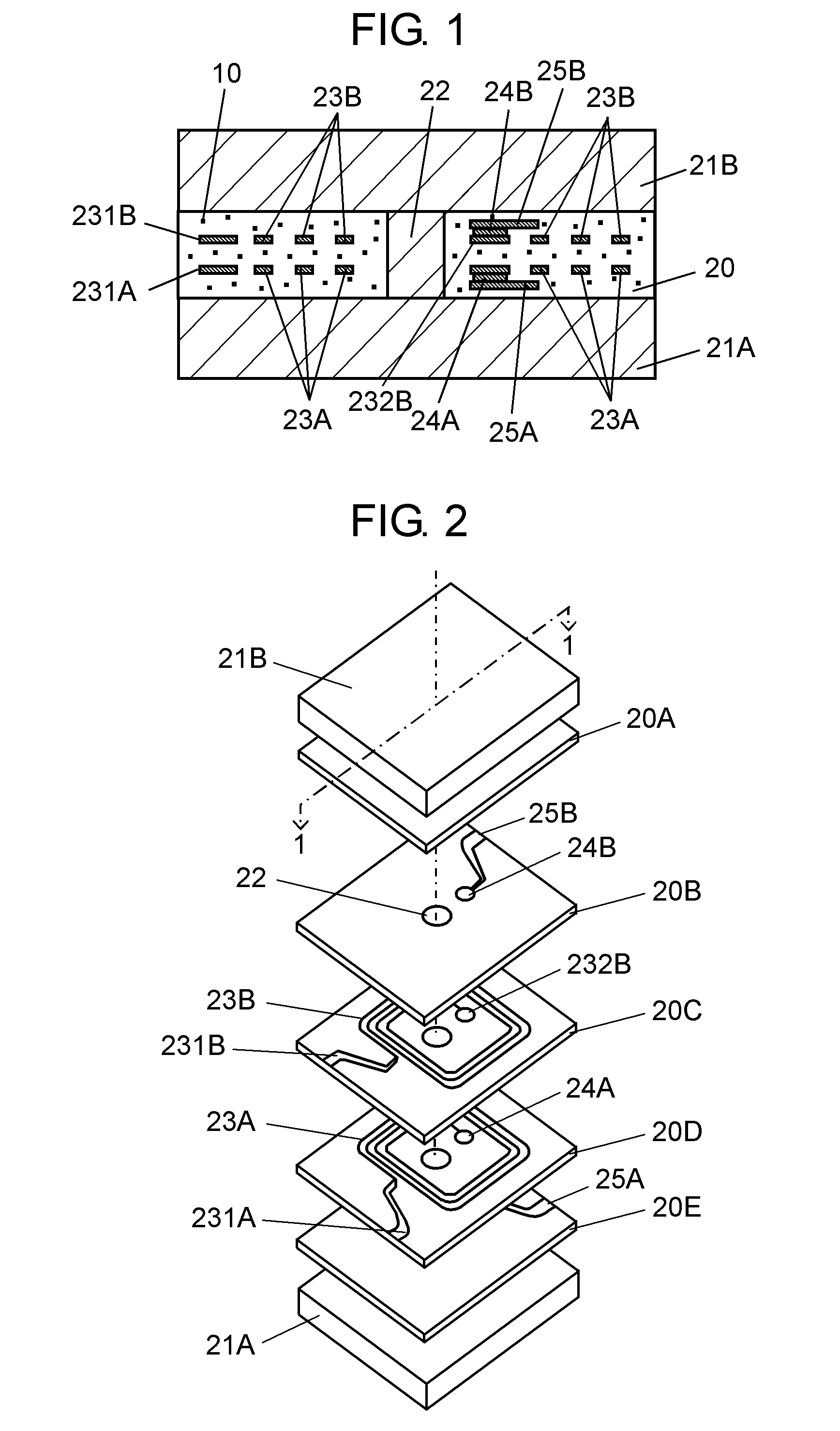

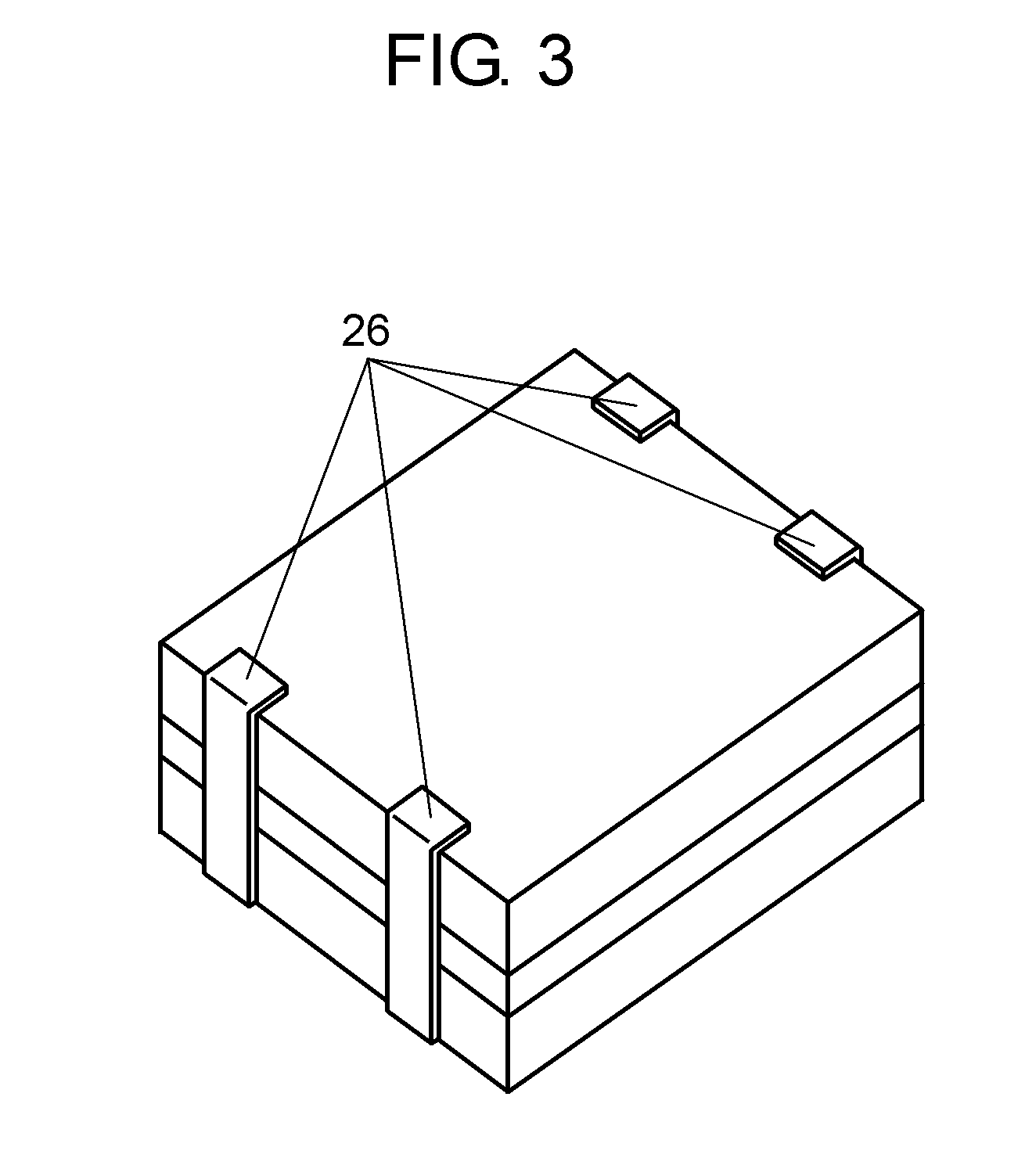

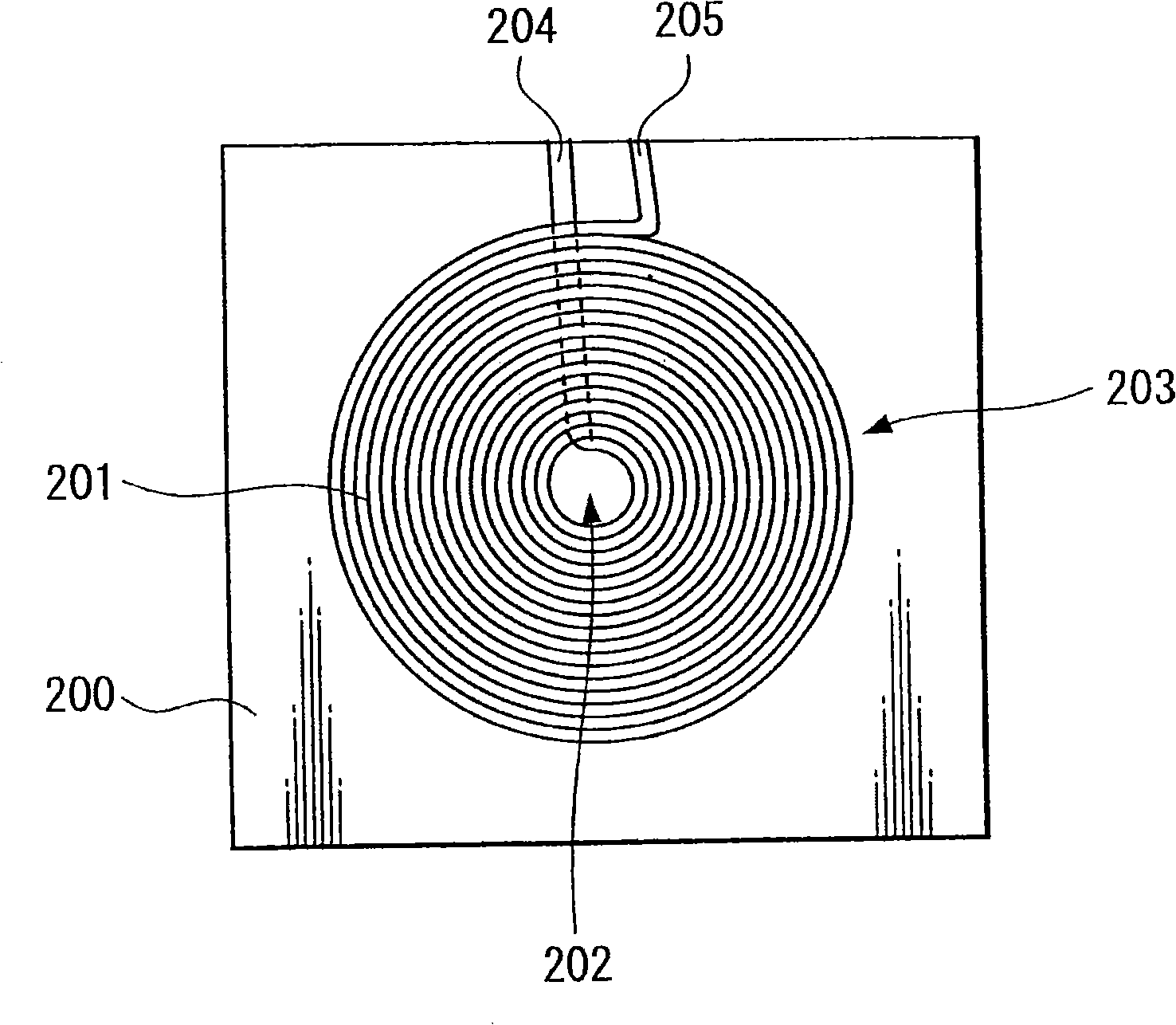

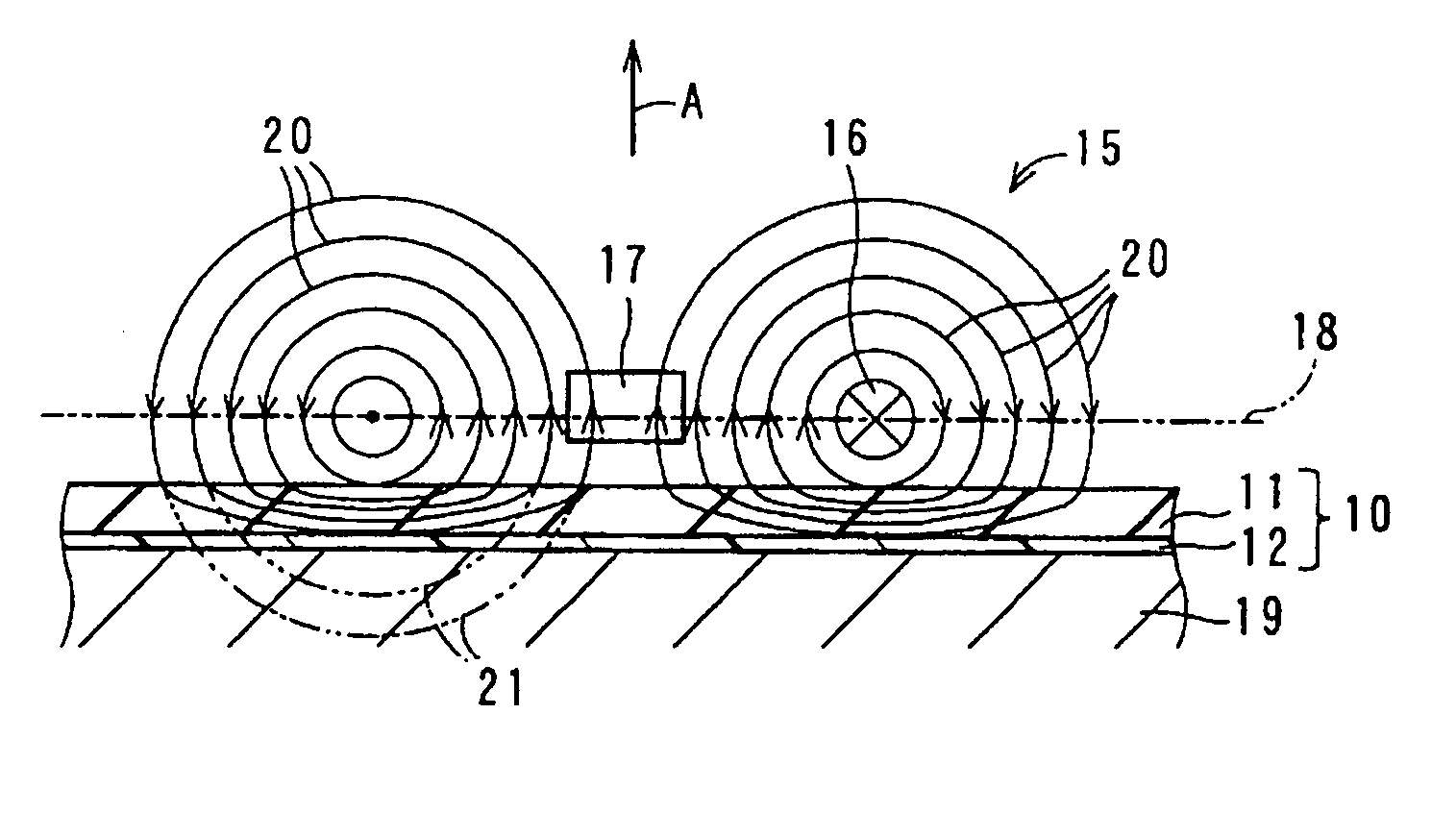

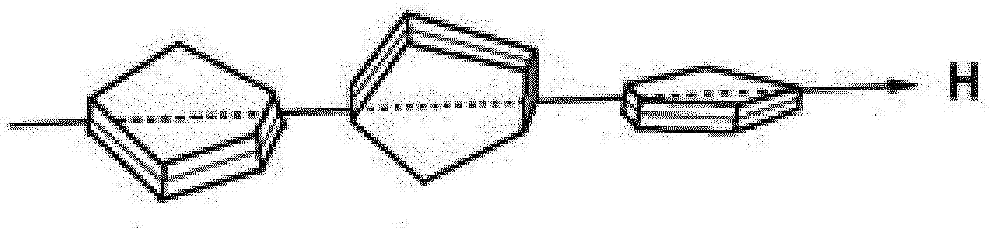

Noncontact power-transmission coil, portable terminal and terminal charging device, planar coil magnetic layer formation device, and magnetic layer formation method

ActiveUS20080164844A1Efficiently formedImprove efficiencyCircuit authenticationTransformers/inductances coils/windings/connectionsElectric power transmissionElectrical conductor

Owner:SONY MOBILE COMM INC +1

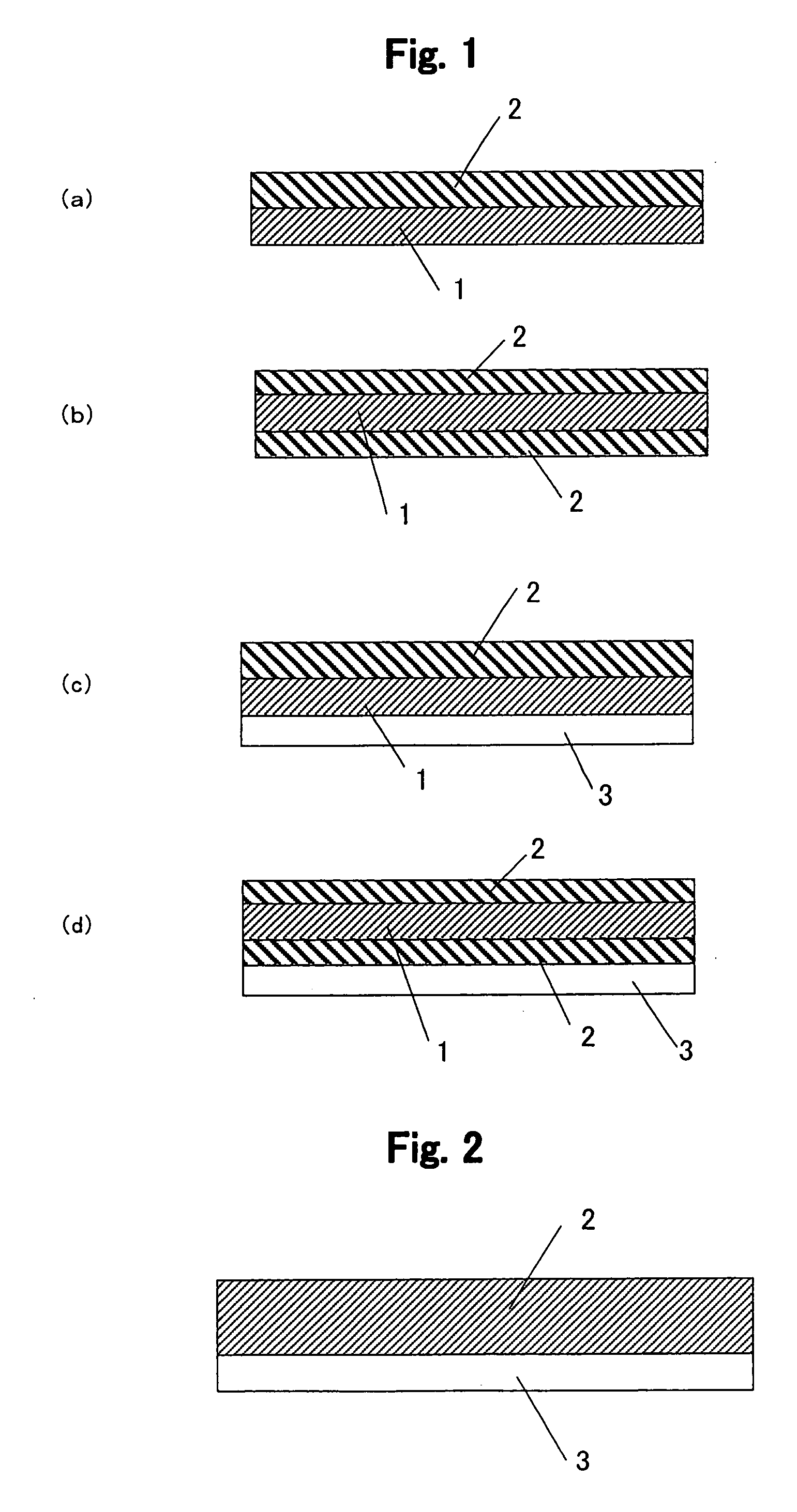

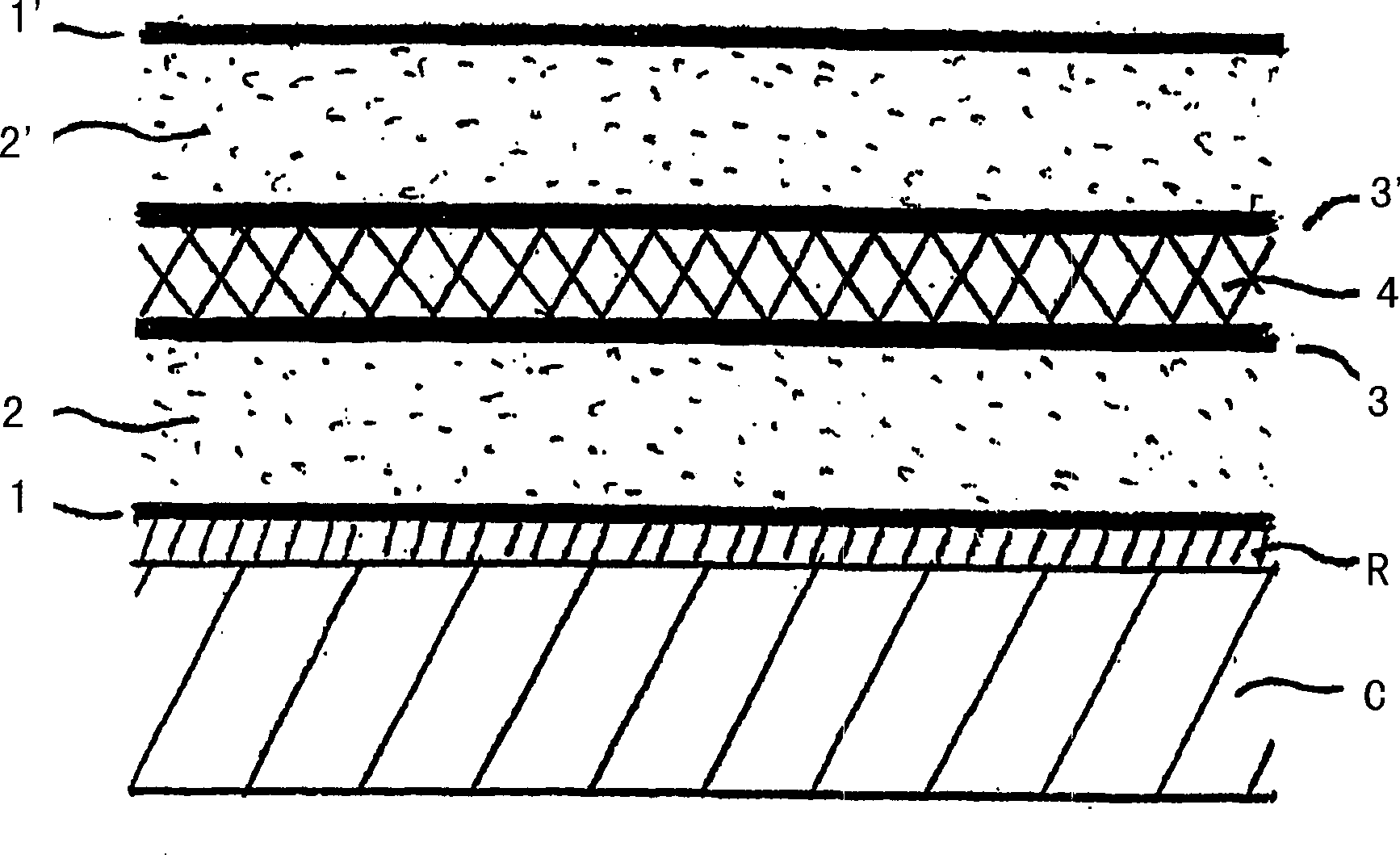

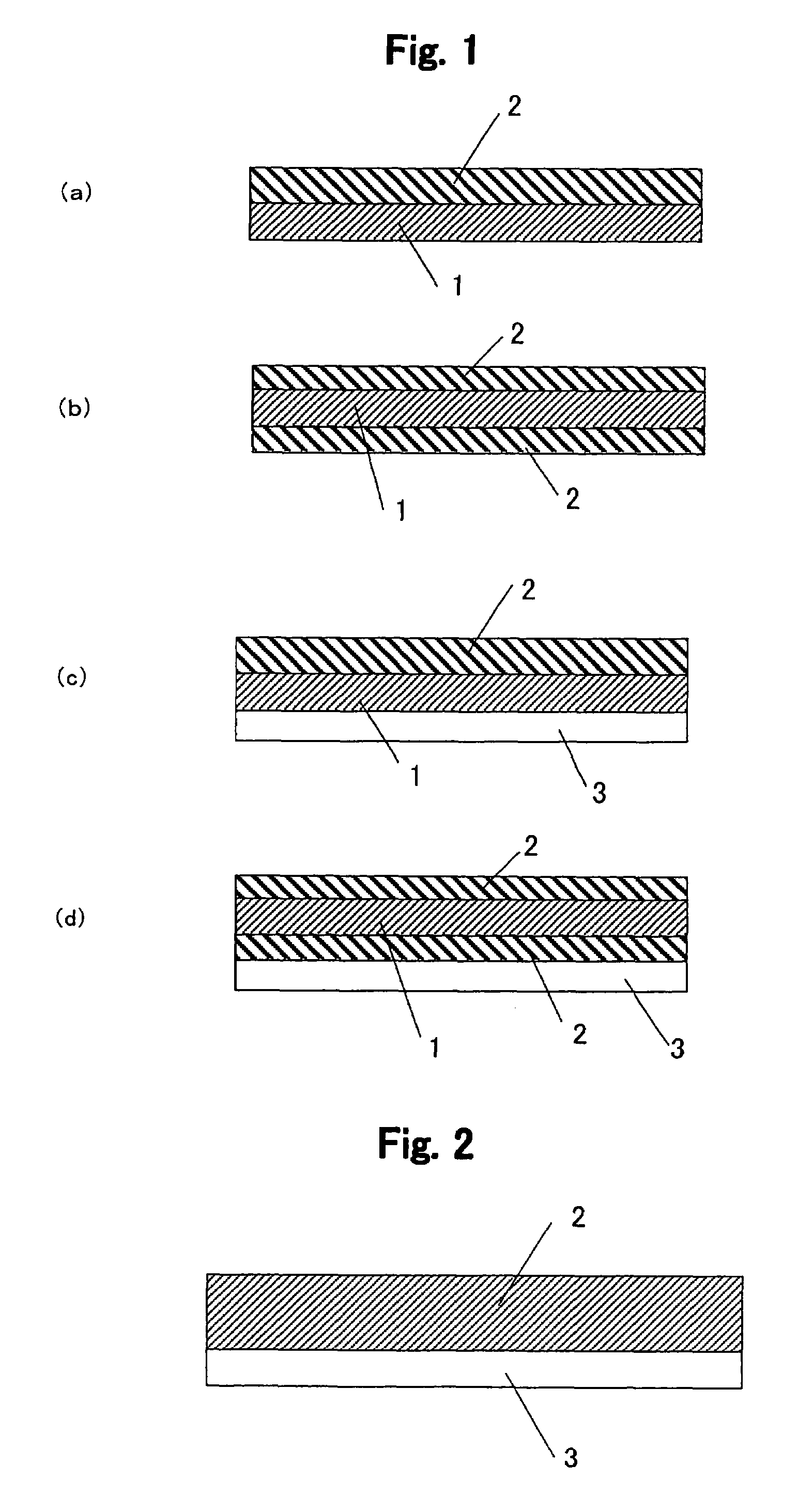

Electromagnetic Interference Suppressor, Antenna Device and Electronic Information Transmitting Apparatus

InactiveUS20070252771A1High densitySuperior electromagnetic interference suppressing effectMagnetic/electric field screeningLayered productsElastomerVitrification

An electromagnetic interference suppressor of substantially unpressurized sheet form is obtained by applying and drying a magnetic paint, and comprises 30 to 80% by volume of soft magnetic powder and 20 to 70% by volume of a binder. The binder is an elastomer or a resin that a glass transition point and / or a softening point is 50° C. or more and a storage modulus (E′) is 107 Pa (JIS K 7244-1) or more in a state containing neither solvent nor filler at room temperature. This electromagnetic interference suppressor exerts a superior electromagnetic interference suppressing effect.

Owner:NITTA CORP

High density magnetic recording compositions and processes thereof

InactiveUS6451220B1NanomagnetismMagnetic materials for record carriersHigh densityCobalt ferrite nanoparticles

A magnetic composition comprised of cobalt ferrite nanoparticles dispersed in an ionic exchange resin.

Owner:XEROX CORP

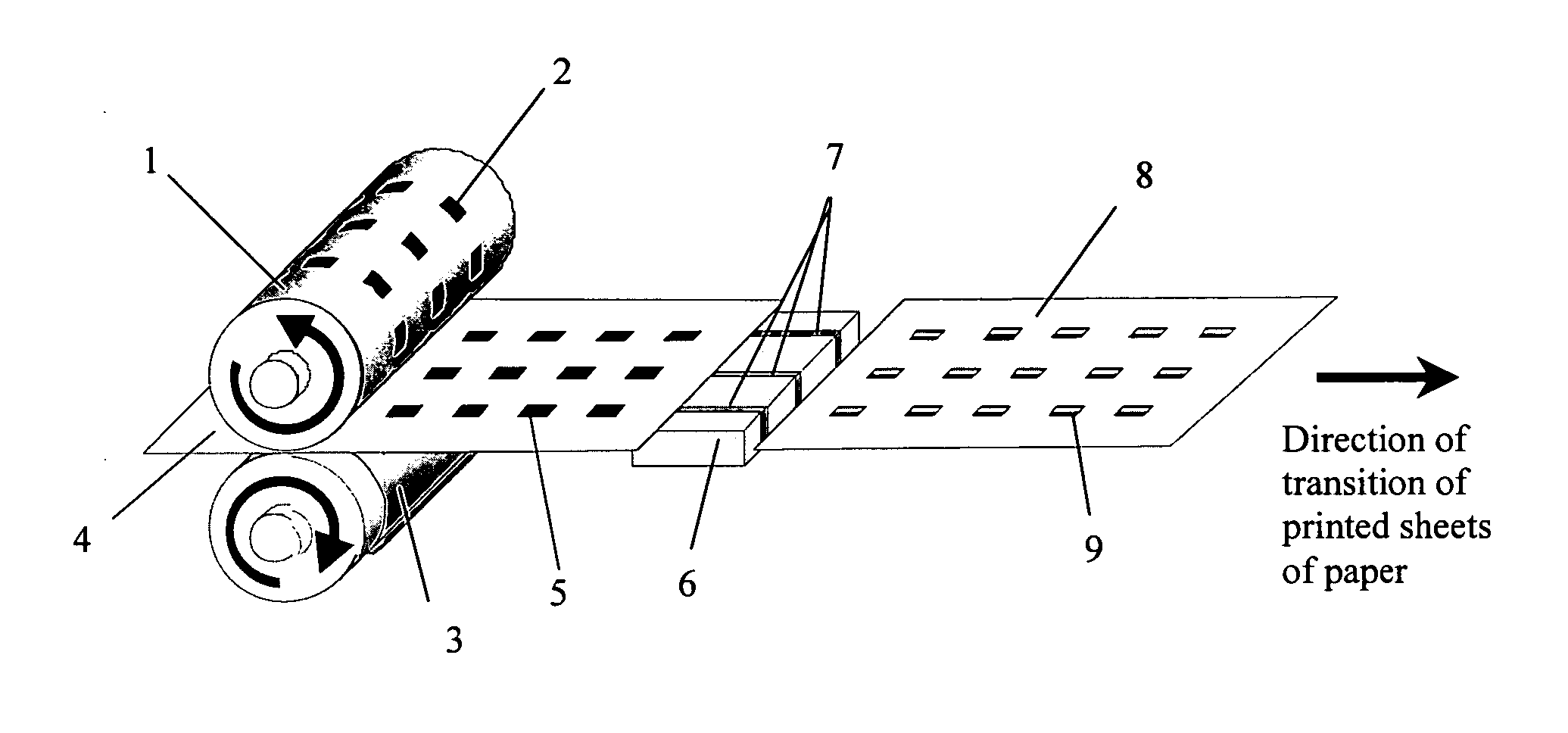

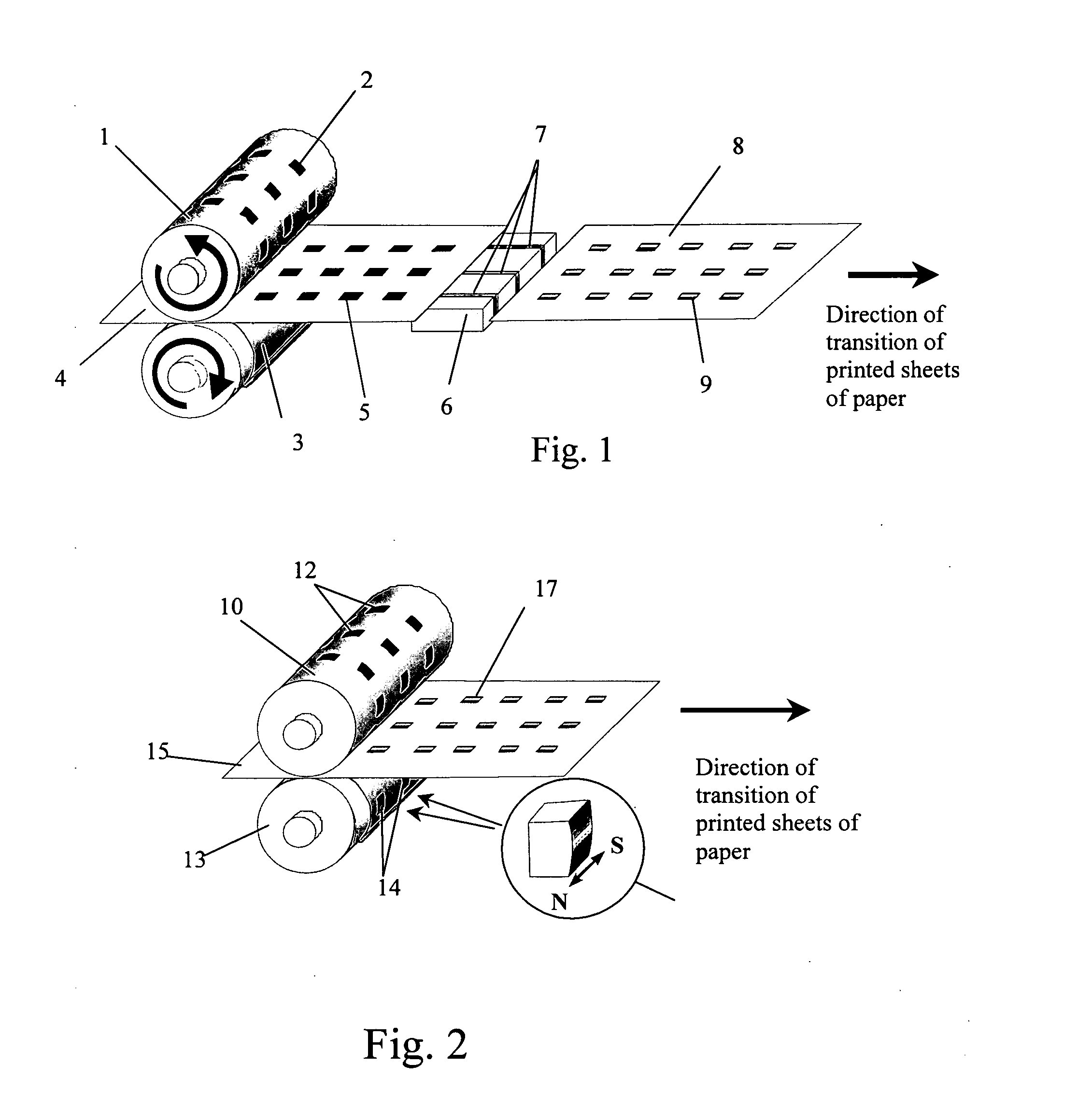

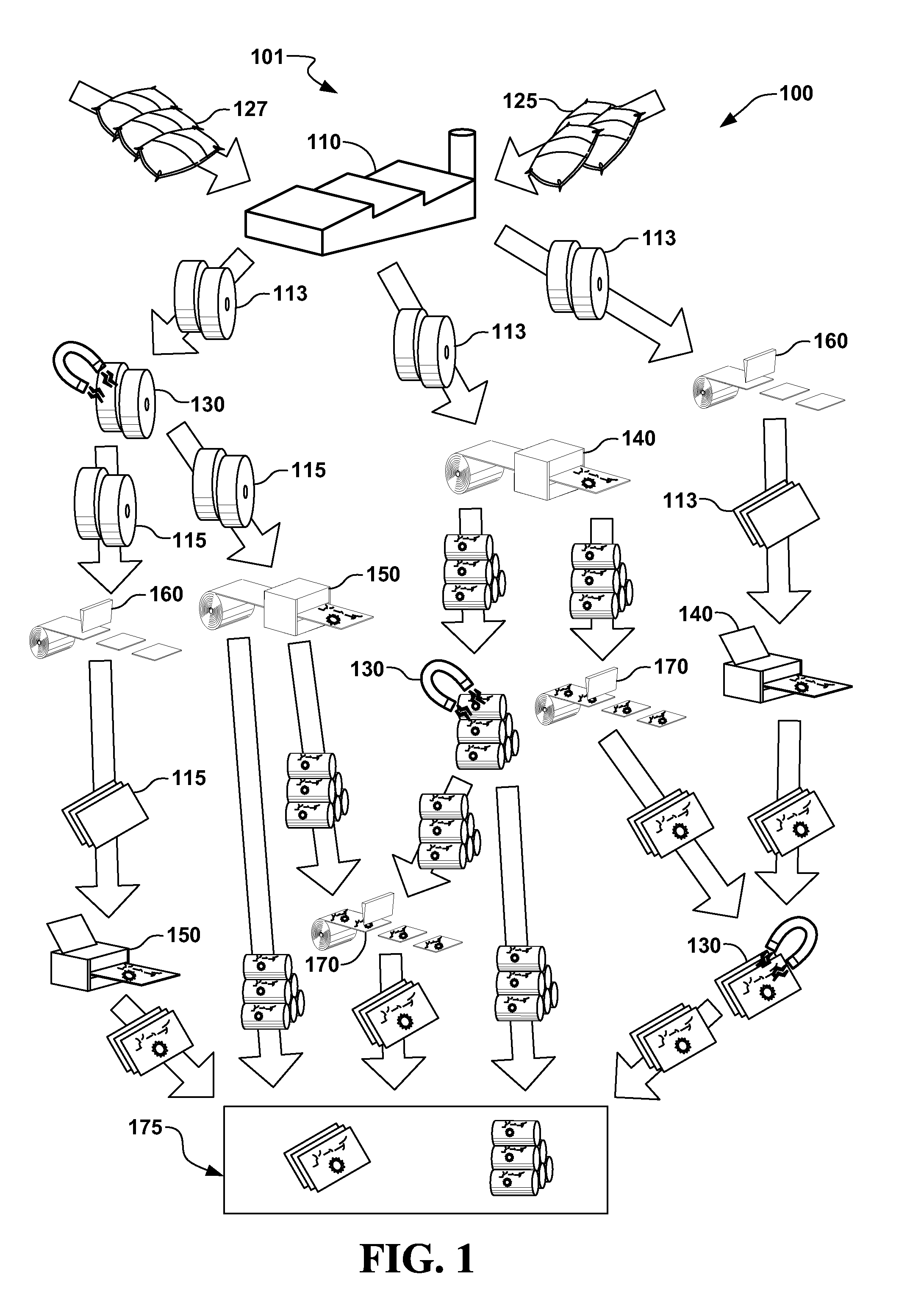

Alignment of paste-like ink having magnetic particles therein, and the printing of optical effects

A method and apparatus is provided for printing using paste like inks such as those used in intaglio printing, wherein the inks include specialty flakes such as thin film optically variable flakes, or diffractive flakes. The invention discloses an apparatus having an energy source such as a heat source for temporarily lessening the viscosity of the ink during alignment of the flakes within the ink.

Owner:VIAVI SOLUTIONS INC

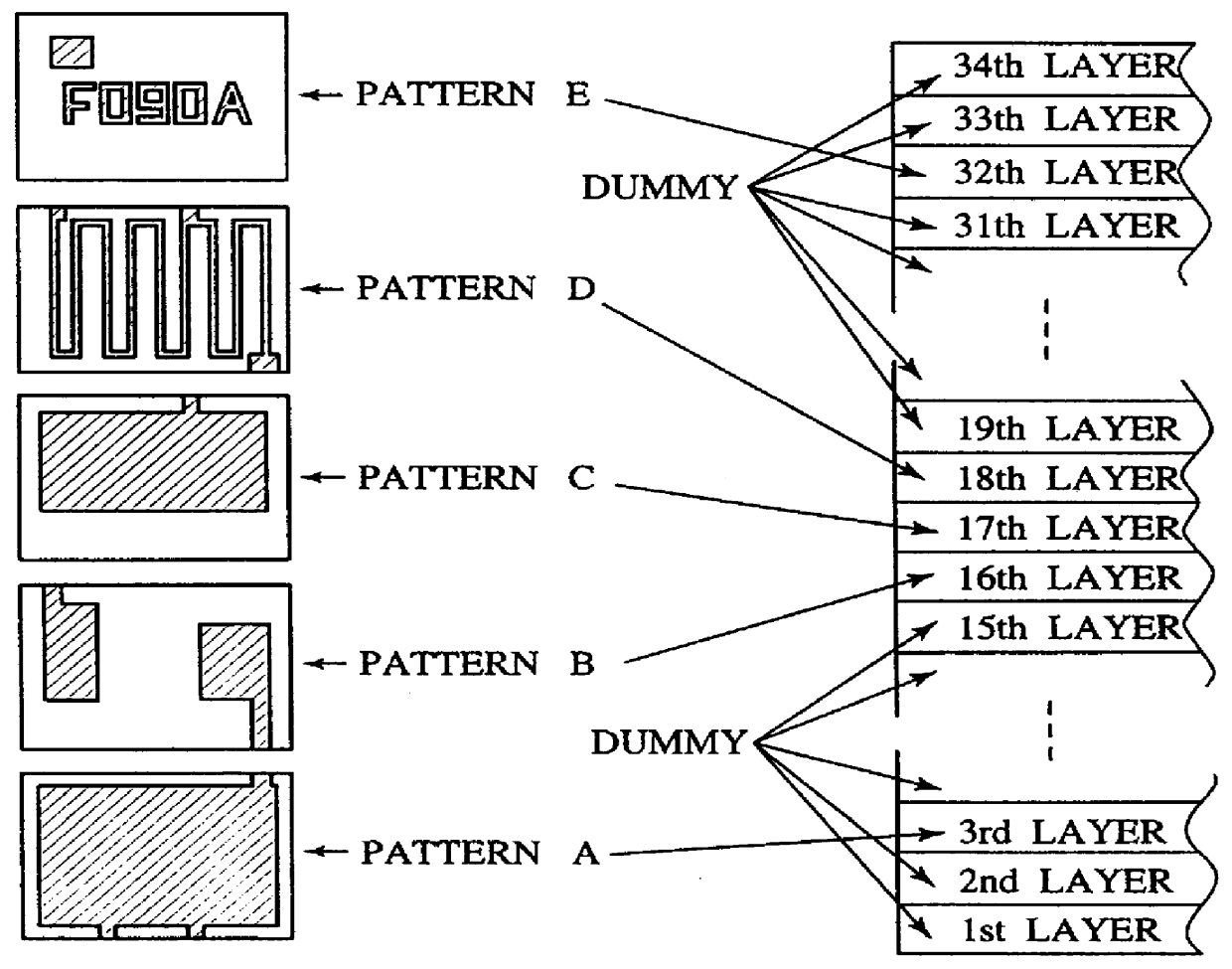

Multilayered electronic part with minimum silver diffusion

InactiveUS6045893AExcellent electrical propertiesIncrease brightnessSemiconductor/solid-state device detailsSolid-state devicesMetallurgyElectron

A multilayered electronic part with minimized silver diffusion into ceramic body. The multilayered electronic part is produced by sintering a green ceramic body of a plurality of ceramic layers comprising a main phase and a grain boundary phase, at least one of the ceramic layers being printed thereon Ag-containing internal electrode patterns which may serve as markers for indicating several information such as a production number, a name of manufacturer, a kind of circuit, etc. By the production method of the invention, the diffusion of Ag in the internal electrode patterns into the ceramic body is effectively prevented to avoid the deterioration of the electrical characteristics as well as to avoid the blackening of the ceramic to ensure a high lightness of the ceramic body which enhances the reliability of the visual identification and distinguishability of the markers.

Owner:HITACHI METALS LTD

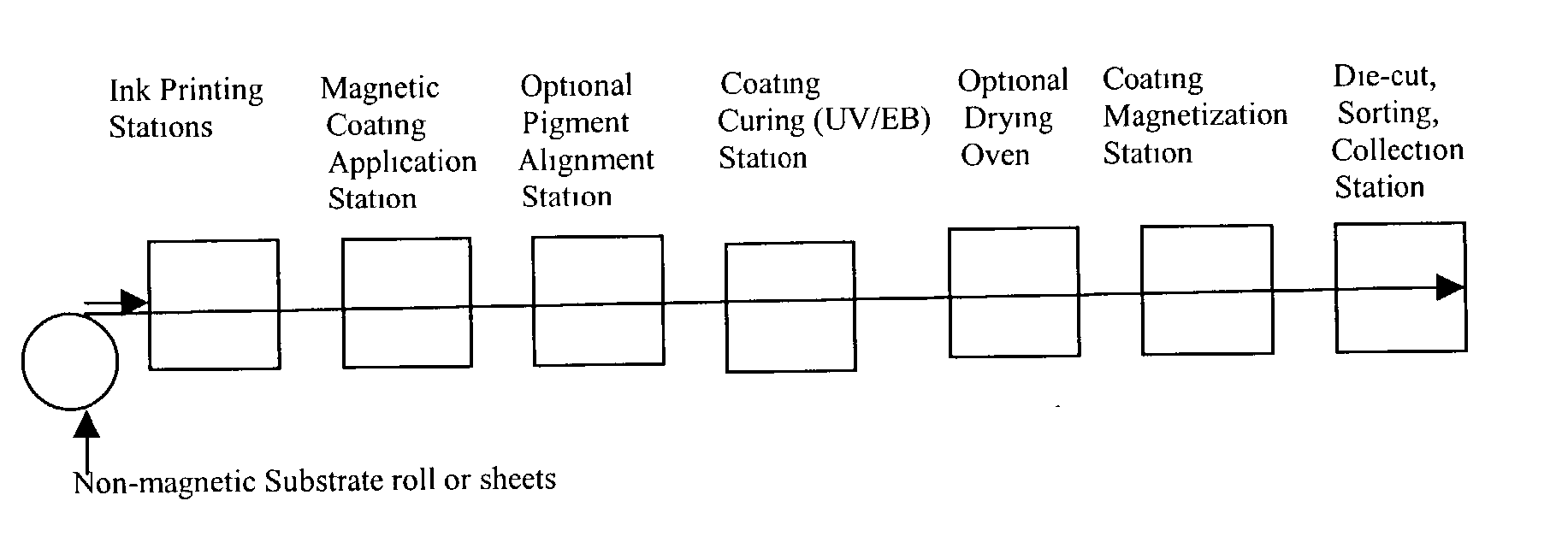

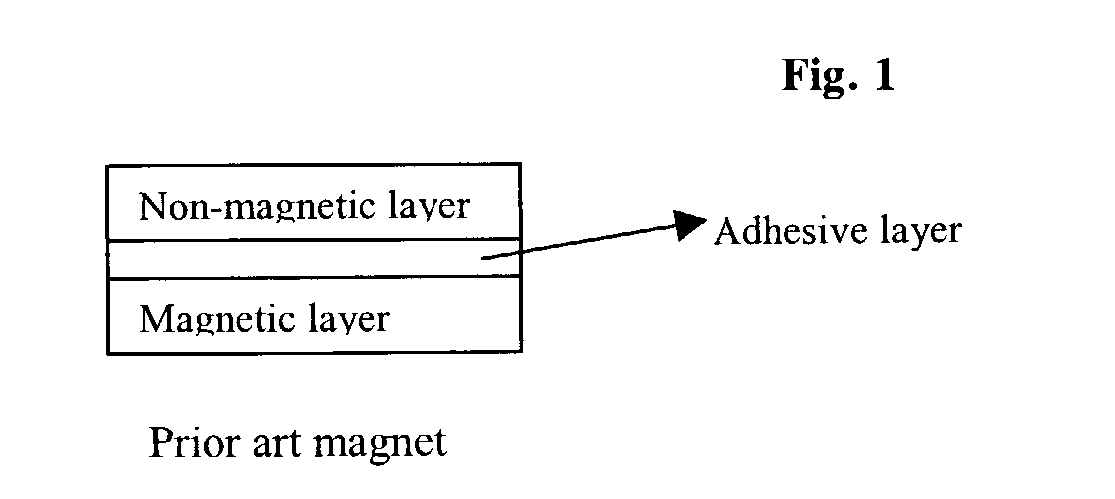

UV/EB cured integrated magnets-composition and method of fabrication

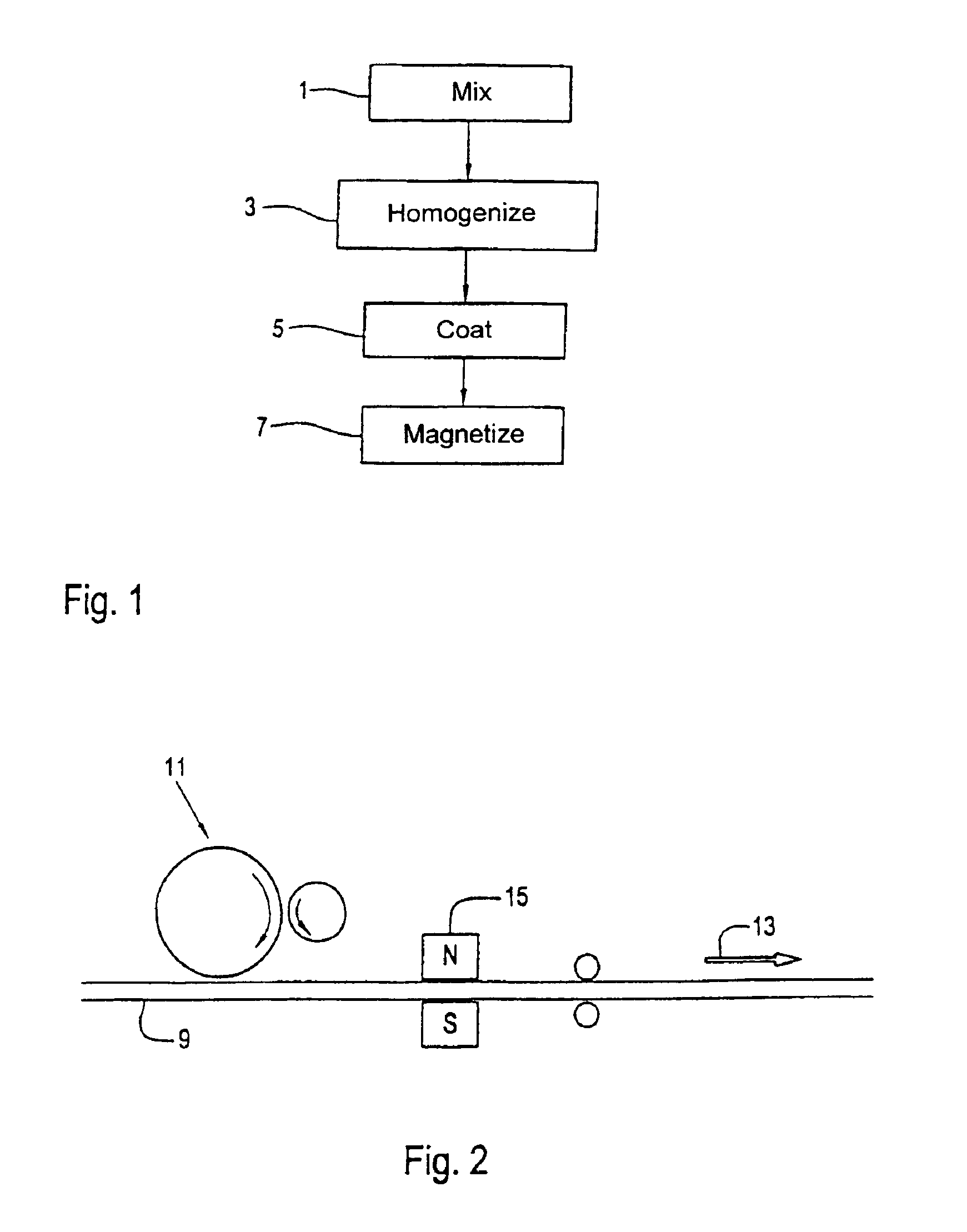

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM +1

Magnetic thin film interference device or pigment and method of making it, printing ink or coating composition containing said magnetic thin fim interference device

InactiveCN1459034ARich varietyExact matchOther printing matterMagnetic paintsPrinting inkMagnetic thin film

The invention discloses magnetic OVP, said pigment consisting of thin-layer flakes having a basic metal-dielectric-metal structure to result in a viewing-angle dependent color appearance, and having, in addition to said viewing-angle dependent color appearance, incorporated magnetic properties, to make them distinguishable from OVP of similar appearance but not having said magnetic properties. The invention discloses as well methods for obtaining such pigments and the use of such pigments as security elements in inks, coatings and articles.

Owner:SICPA HLDG SA

Markable powder and interference pigment containing coatings

According to the present invention, methods of marking in a substrate comprises placing one or more than one magnet adjacent to a substrate while it is being powder coated or after it is powder coated and while the coating is uncured, thereby orienting a magnetic pigment with the magnet having a desired shape to form a desired marking, followed by heating or curing to form a coating film. In another embodiment, the present invention provides marked powder coated substrates in a variety of shapes comprising one or more than one marking formed by orienting a magnetic pigment or interference pigment in a powder coating or by orienting an interference pigment in a liquid coating. In yet another embodiment, the present invention provides markable powder coating compositions comprising magnetic pigments, as well as powder coating compositions comprising interference pigments, such as color shifting pigments.

Owner:HOFFMANN RENE CHRISTOPHEROUS +2

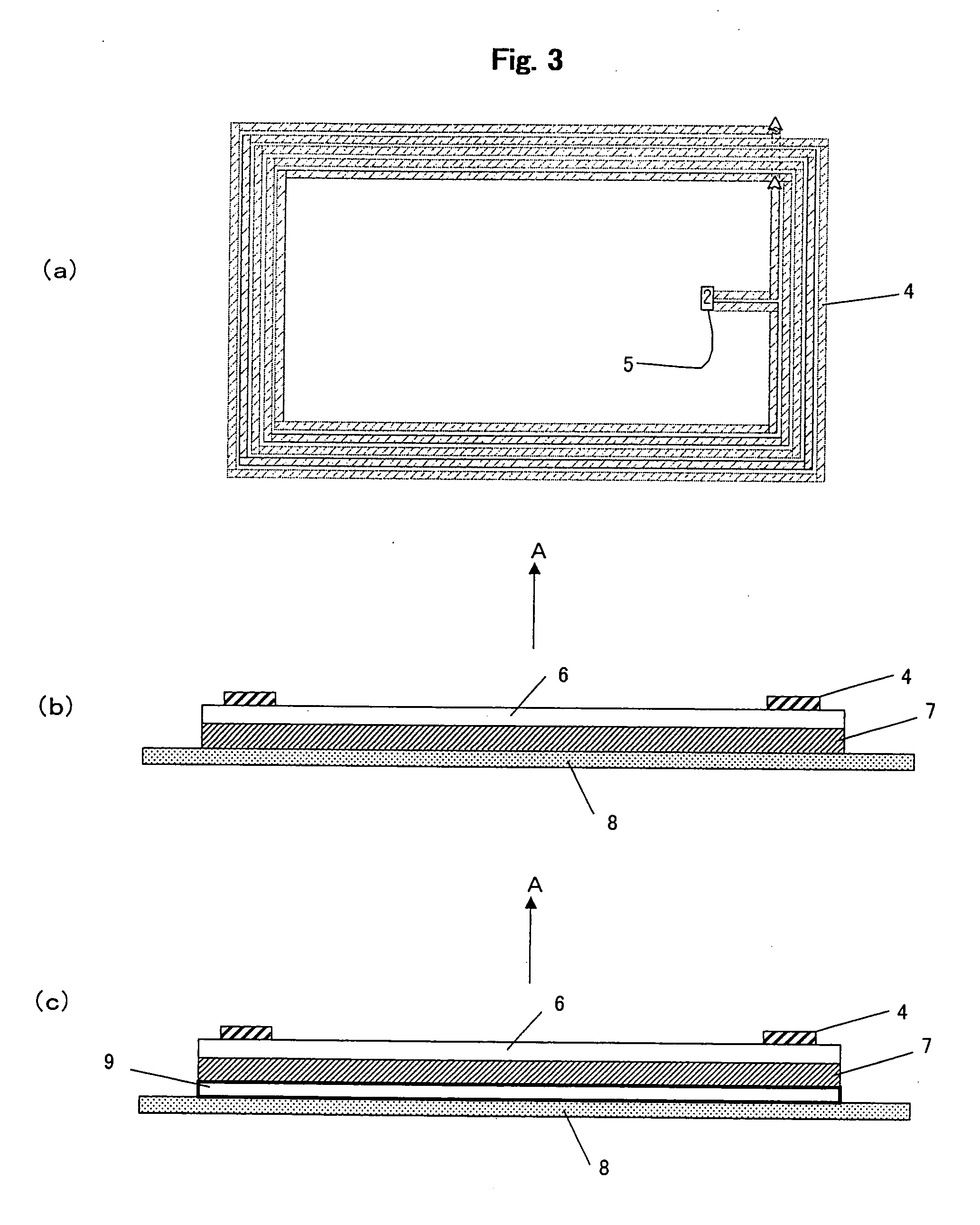

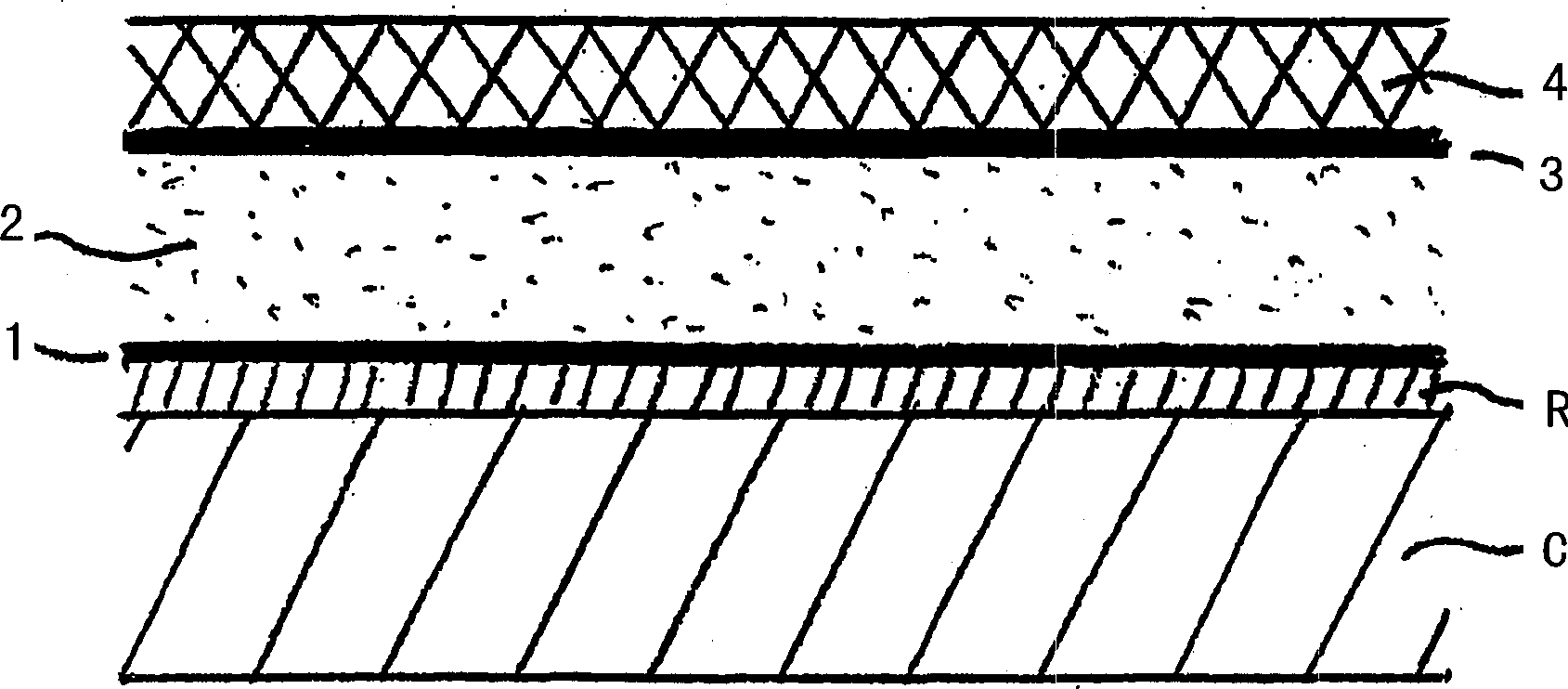

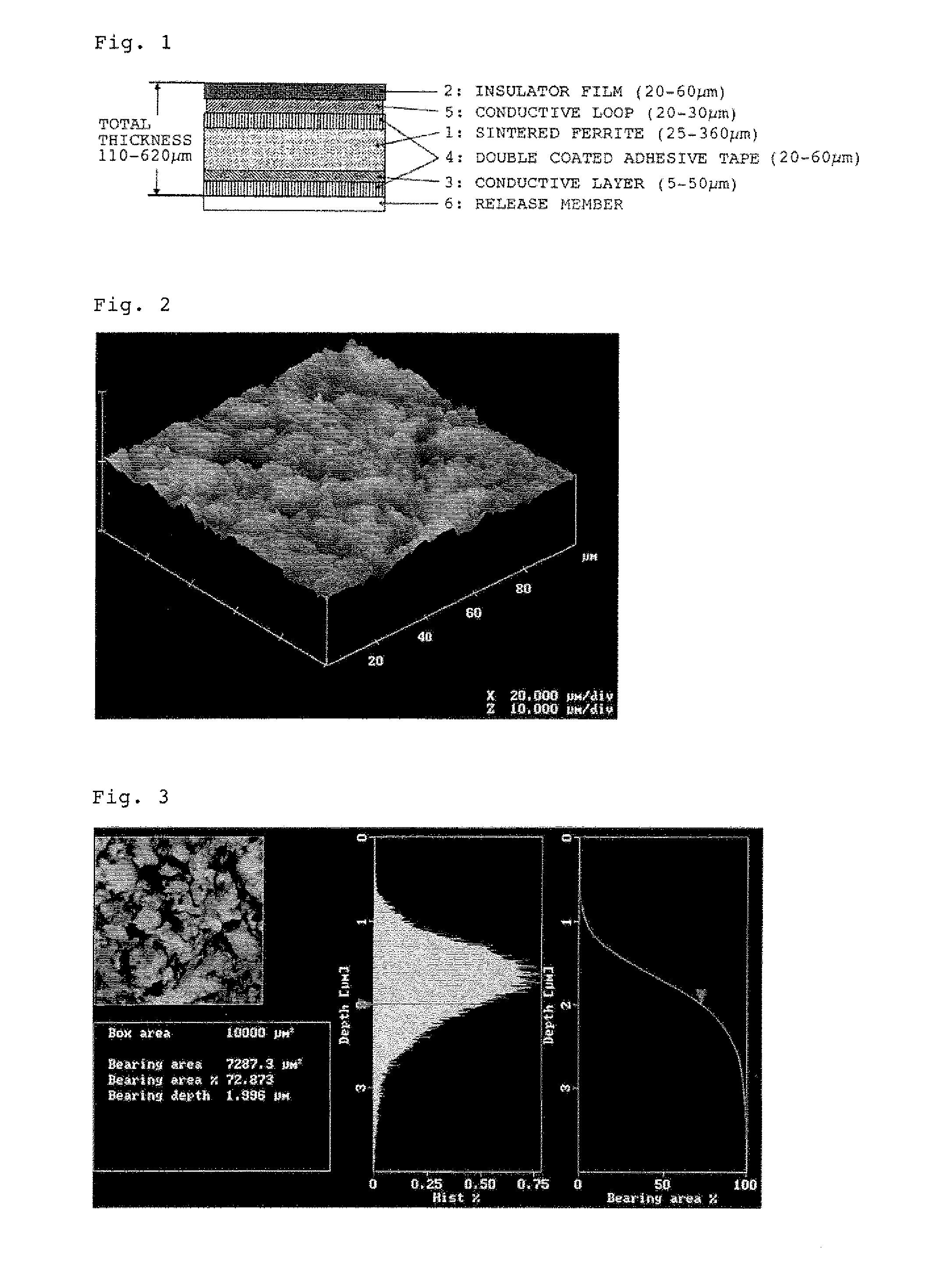

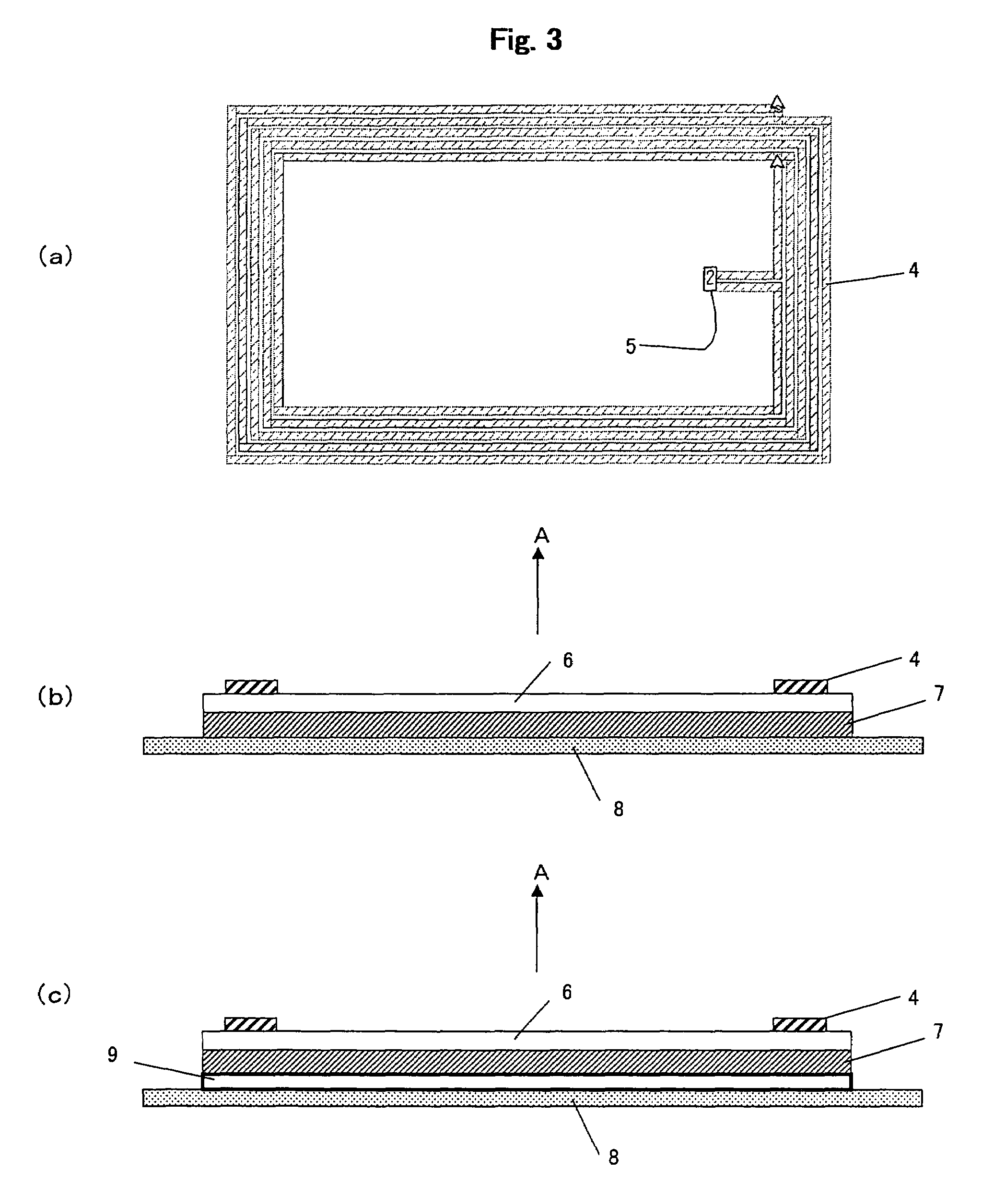

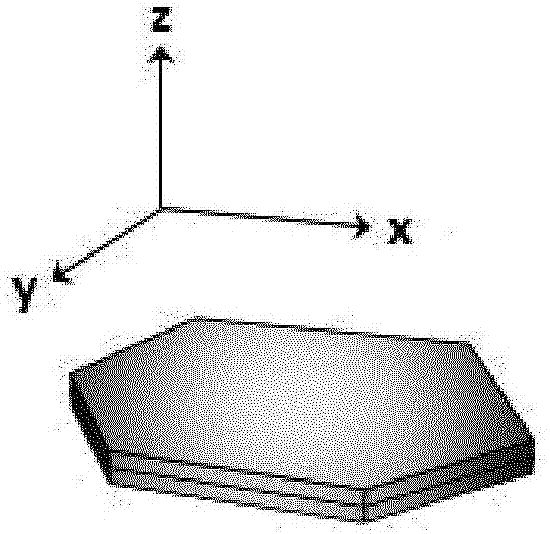

Molded ferrite sheet, sintered ferrite substrate and antenna module

ActiveUS20080224937A1Eliminate procedureReduce instabilityLoop antennas with ferromagnetic coreAntenna supports/mountingsOccupancy rateFerrite substrate

The present invention relates to a molded ferrite sheet having opposing surfaces and a thickness in a range of 30 μm to 430 μm, at least one surface of said opposing surfaces having the following surface roughness characteristics (a) to (c):(a) a center line average roughness is in a range of 170 nm to 800 nm,(b) a maximum height is in a range of 3 μm to 10 μm, and(c) an area occupancy rate of cross-sectional area taken along a horizontal plane at a depth of 50% of the maximum height in a square of side 100 μm is in a range of 10 to 80%.

Owner:TODA IND

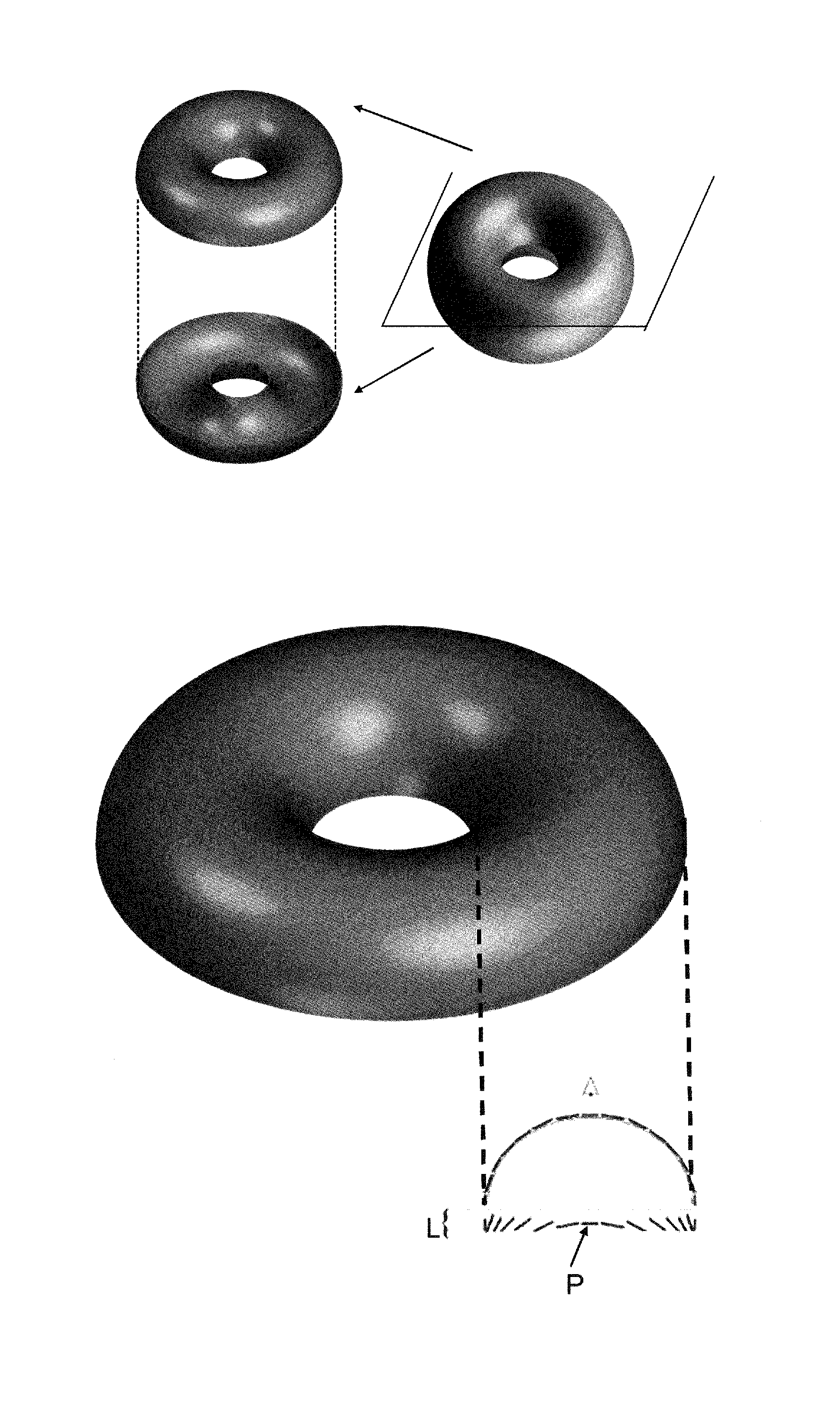

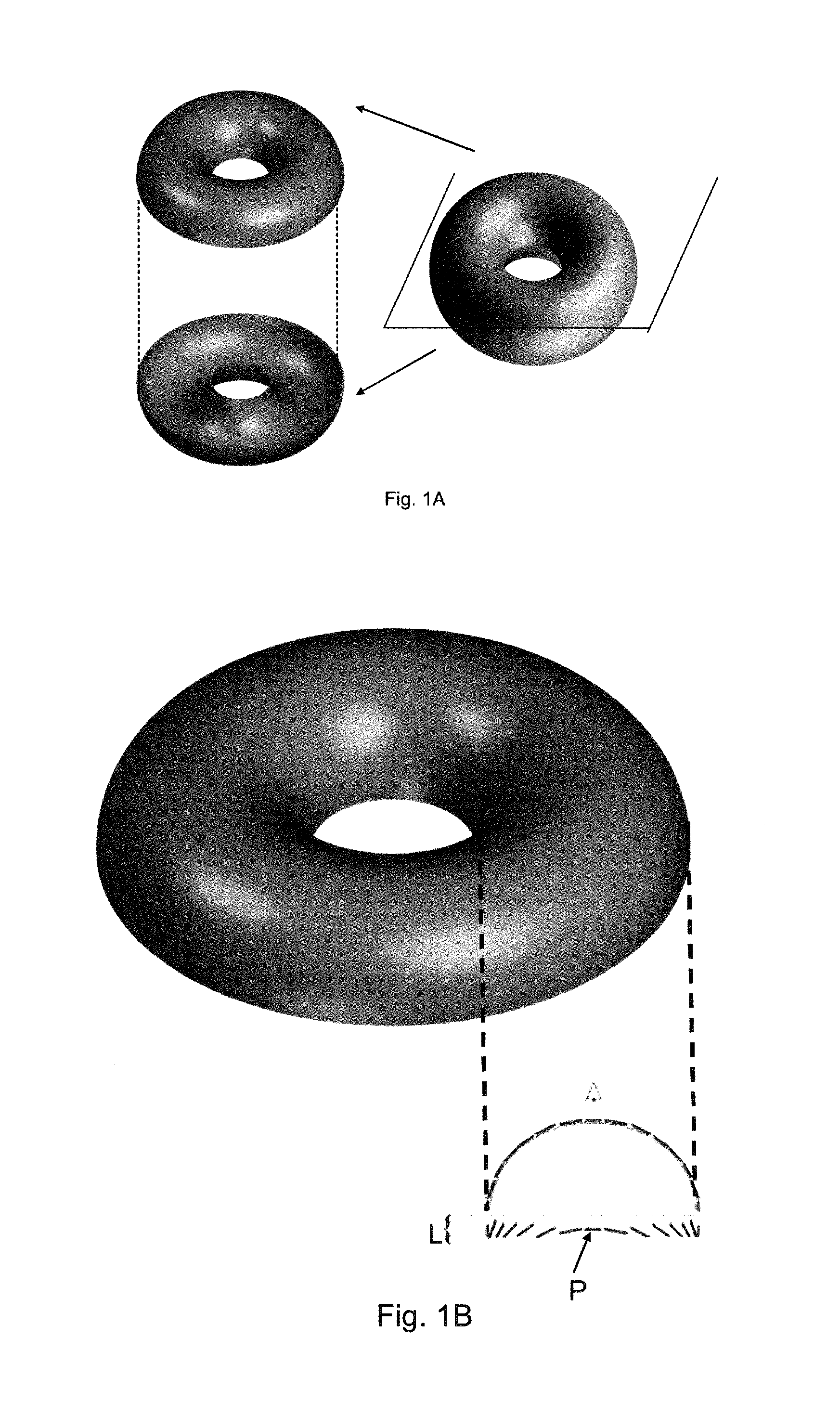

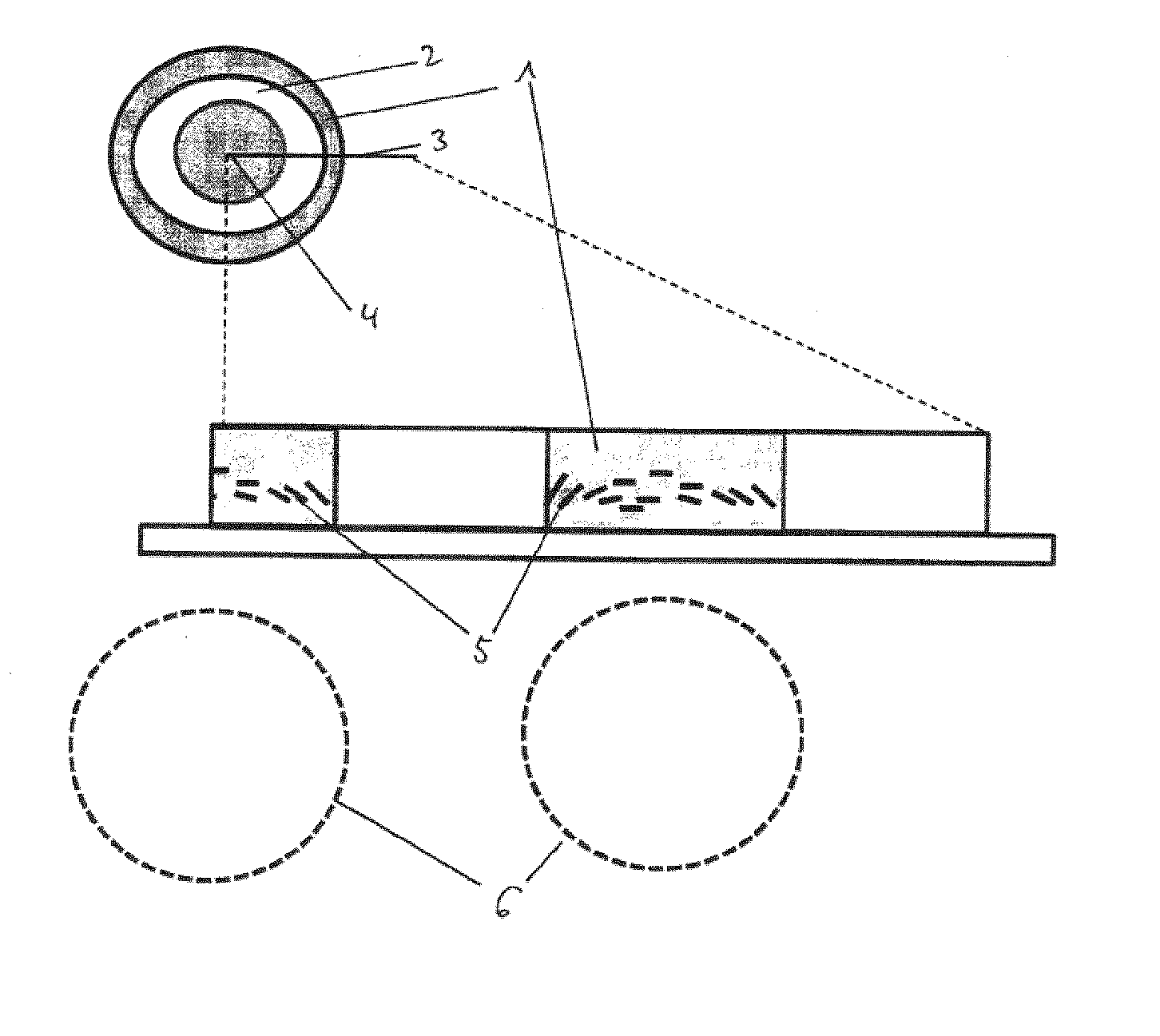

Optical effect layers showing a viewing angle dependent optical effect, processes and devices for their production, items carrying an optical effect layer, and uses thereof

ActiveUS20150352883A1Improve sharpnessIncrease contrastOther printing matterLayered productsComputer scienceInnermost loop

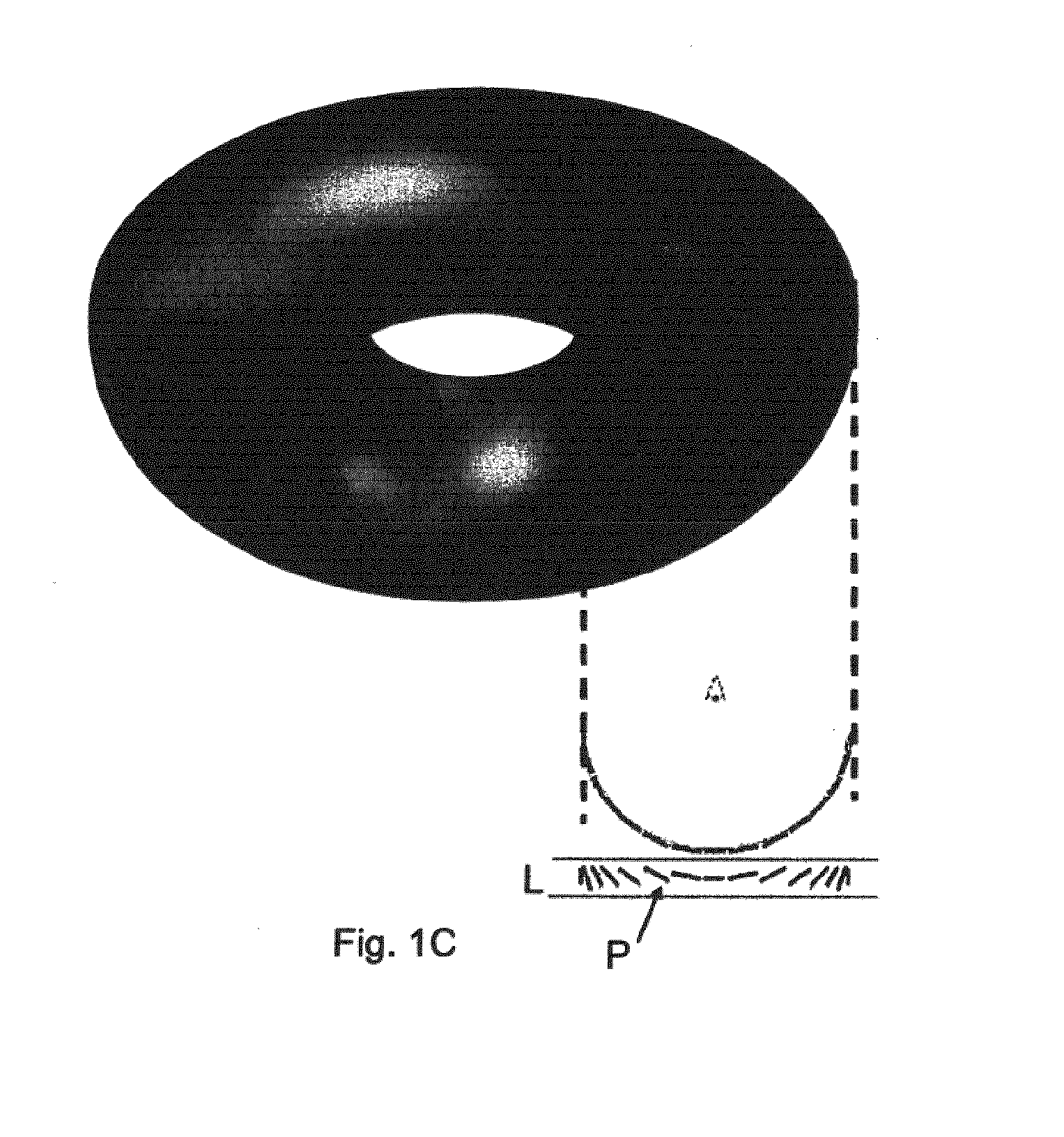

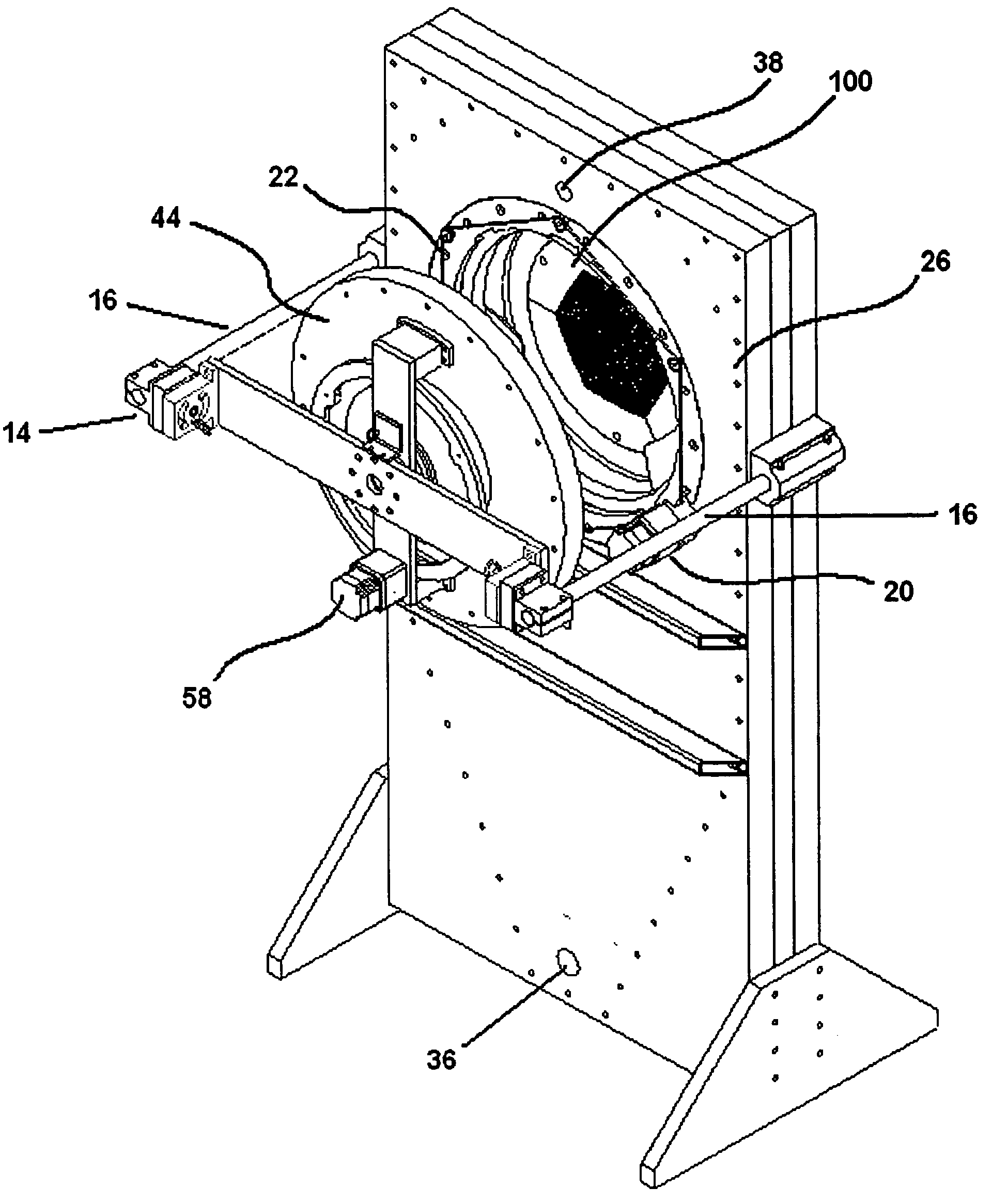

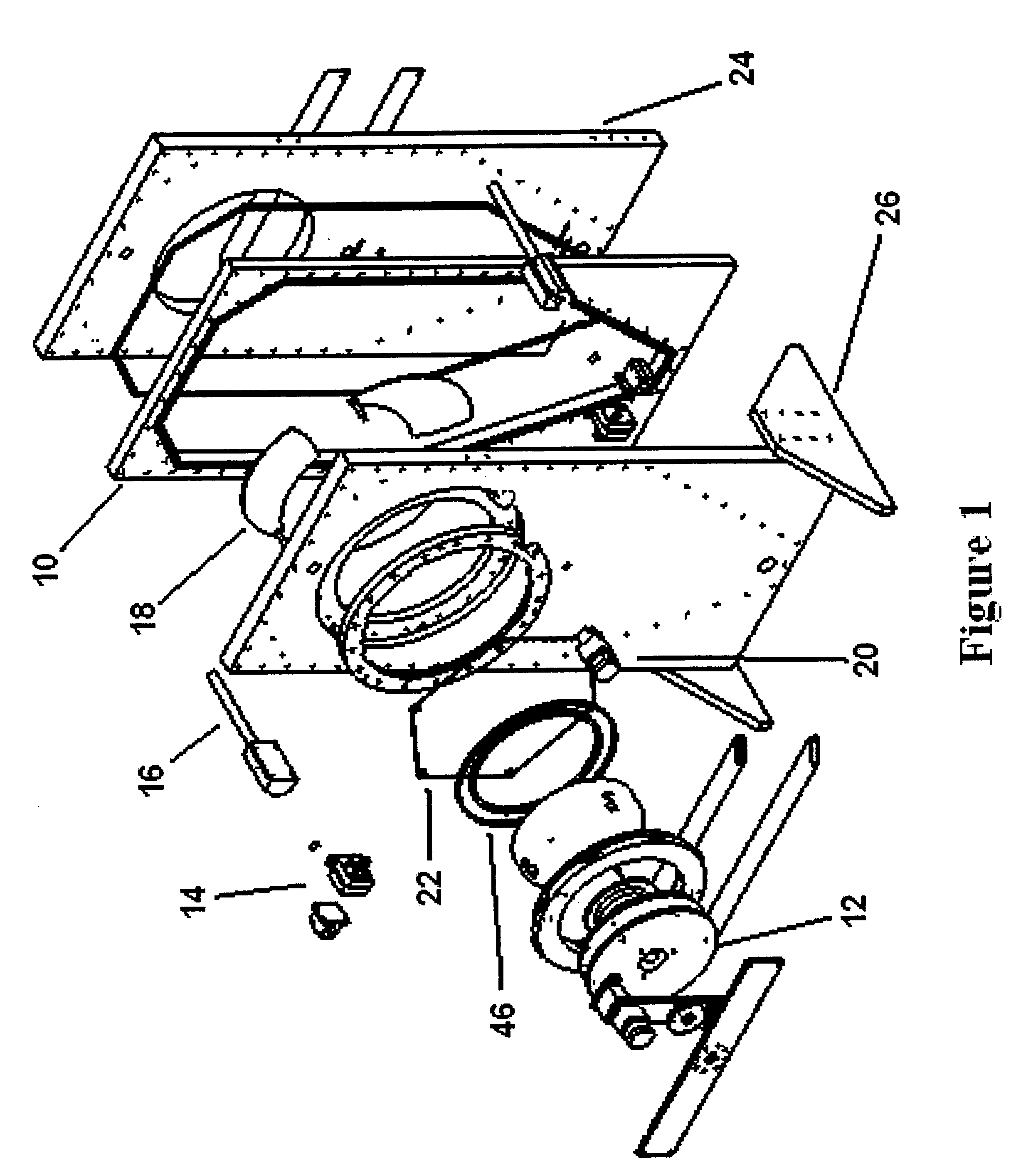

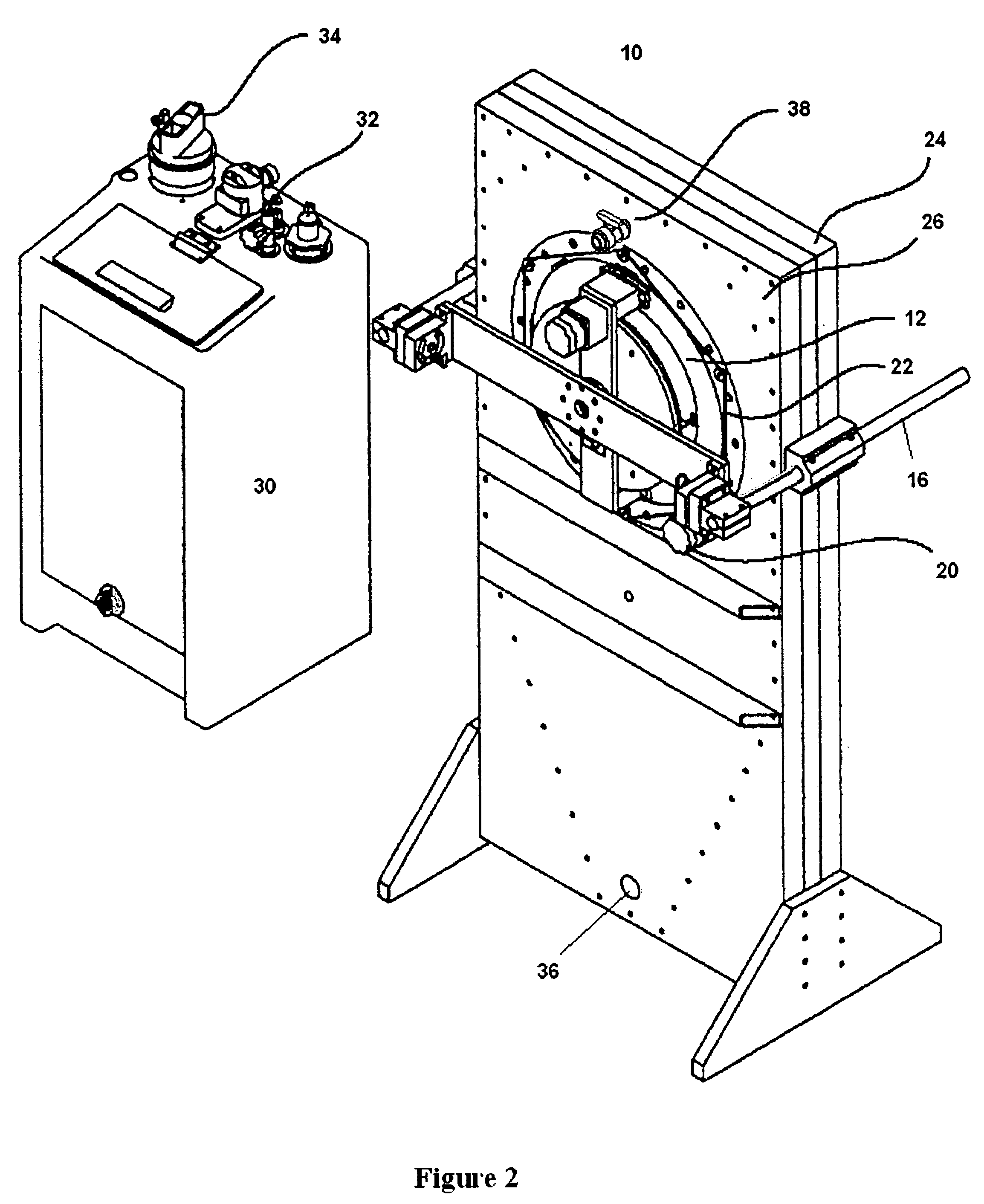

The invention relates to the field of the protection of security documents such as for example banknotes and identity documents against counterfeit and illegal reproduction. In particular, the invention relates to optical effect layers (OEL) showing a viewing-angle dependent optical effect, devices and processes for producing said OEL and items carrying said OEL, as well as uses of said optical effect layers as an anti-counterfeit means on documents. The OEL comprises a plurality of non-spherical magnetic or magnetizable particles, which are dispersed in a coating composition comprising a binder material, the OEL comprising two or more loop-shaped areas, being nested around a common central area that is surrounded by the innermost loop-shaped area, wherein, in each of the loop-shaped areas, at least a part of the plurality of non-spherical magnetic or magnetizable particles are oriented such that, in a cross-section perpendicular to the OEL layer and extending from the centre of the central area to the outer boundary of the outermost loop-shaped area, the longest axis of the particles in each of the cross-sectional areas of the looped-shaped areas follow a tangent of either a negatively curved or a positively curved part of hypothetical ellipses or circles.

Owner:SICPA HLDG SA

Optical effect layers showing a viewing angle dependent optical effect; processes and devices for their production; items carrying an optical effect layer; and uses thereof

ActiveUS20150352888A1Improve sharpnessIncrease contrastOther printing matterPaper-money testing devicesEllipseLong axis

The invention relates to the field of the protection of security documents such as for example banknotes and identity documents against counterfeit and illegal reproduction. In particular, the invention relates to optical effect layers (OEL) showing a viewing-angle dependent optical effect, devices and processes for producing said OEL and items carrying said OEL, as well as uses of said optical effect layers as an anti-counterfeit means on documents. The OEL comprises a plurality of non-spherical magnetic or magnetizable particles, which are dispersed in a coating composition comprising a binder material, wherein in at least a loop-shaped area of the OEL at least a part of the plurality of non-spherical magnetic or magnetizable particles are oriented such that their longest axis is substantially parallel to the plane of the OEL, and wherein, in a cross-section perpendicular to the OEL and extending from the centre of the central area, the longest axis of the oriented particles present in the loop-shaped area forming the impression of the loop-shaped body follow a tangent of either a negatively curved or a positively curved part of a hypothetical ellipse or circle.

Owner:SICPA HLDG SA

Apparatus and method for highly controlled electrodeposition

An apparatus and method for highly controlled electrodeposition, particularly useful for electroplating submicron structures. Enhanced control of the process provides for a more uniform deposit thickness over the entire substrate, and permits reliable plating of submicron features. The apparatus includes a pressurized electrochemical cell to improve plating efficiency and reduce defects, vertical laminar flow of the electrolyte solution to remove surface gases from the vertically arranged substrate, a rotating wafer chuck to eliminate edge plating effects, and a variable aperture to control the current distribution and ensure deposit uniformity across the entire substrate. Also a dynamic profile anode whose shape can be varied to optimize the current distribution to the substrate. The anode is advantageously able to use metallic ion sources and may be placed close to the cathode thus minimizing contamination of the substrate.

Owner:COOK BIOTECH +1

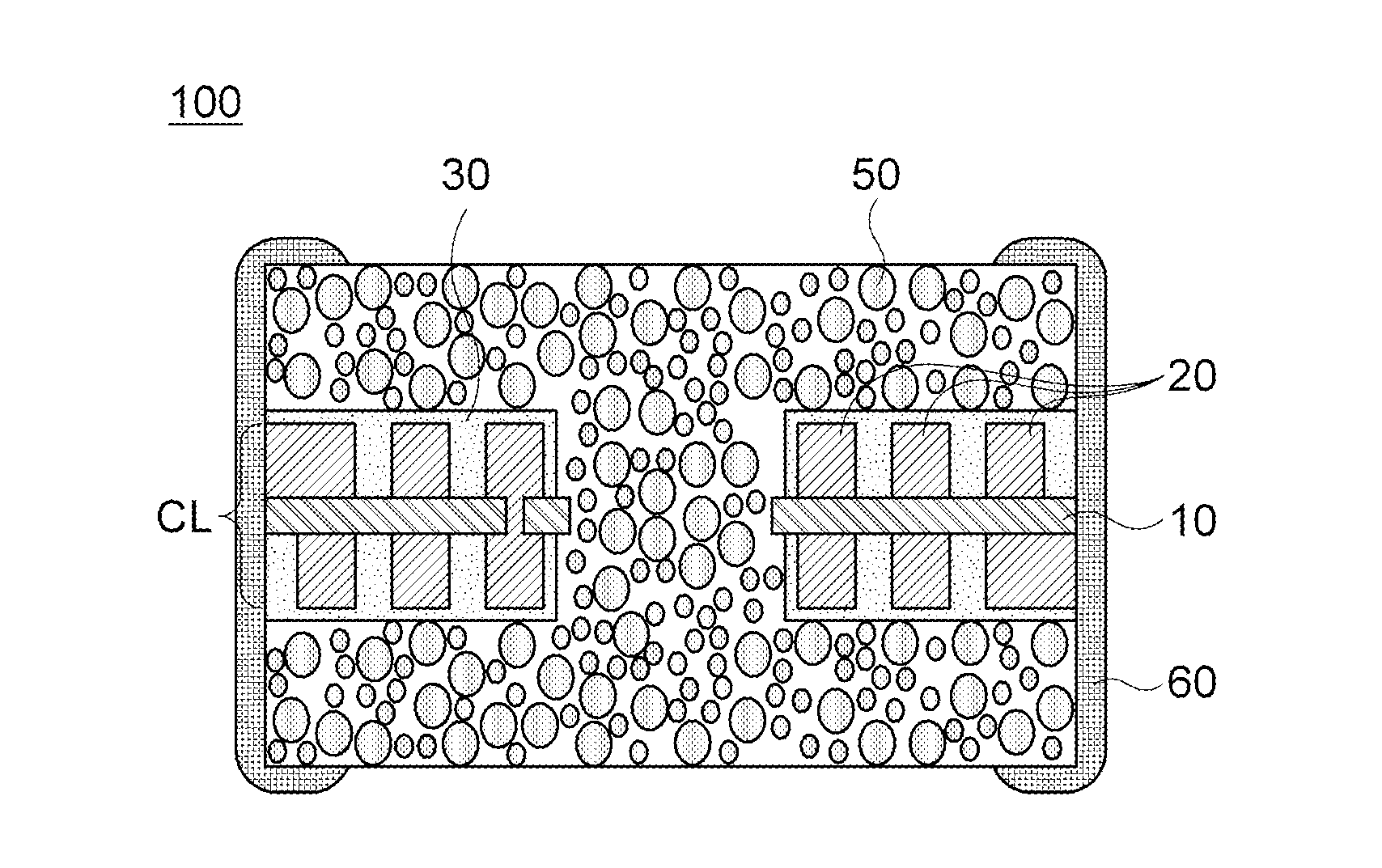

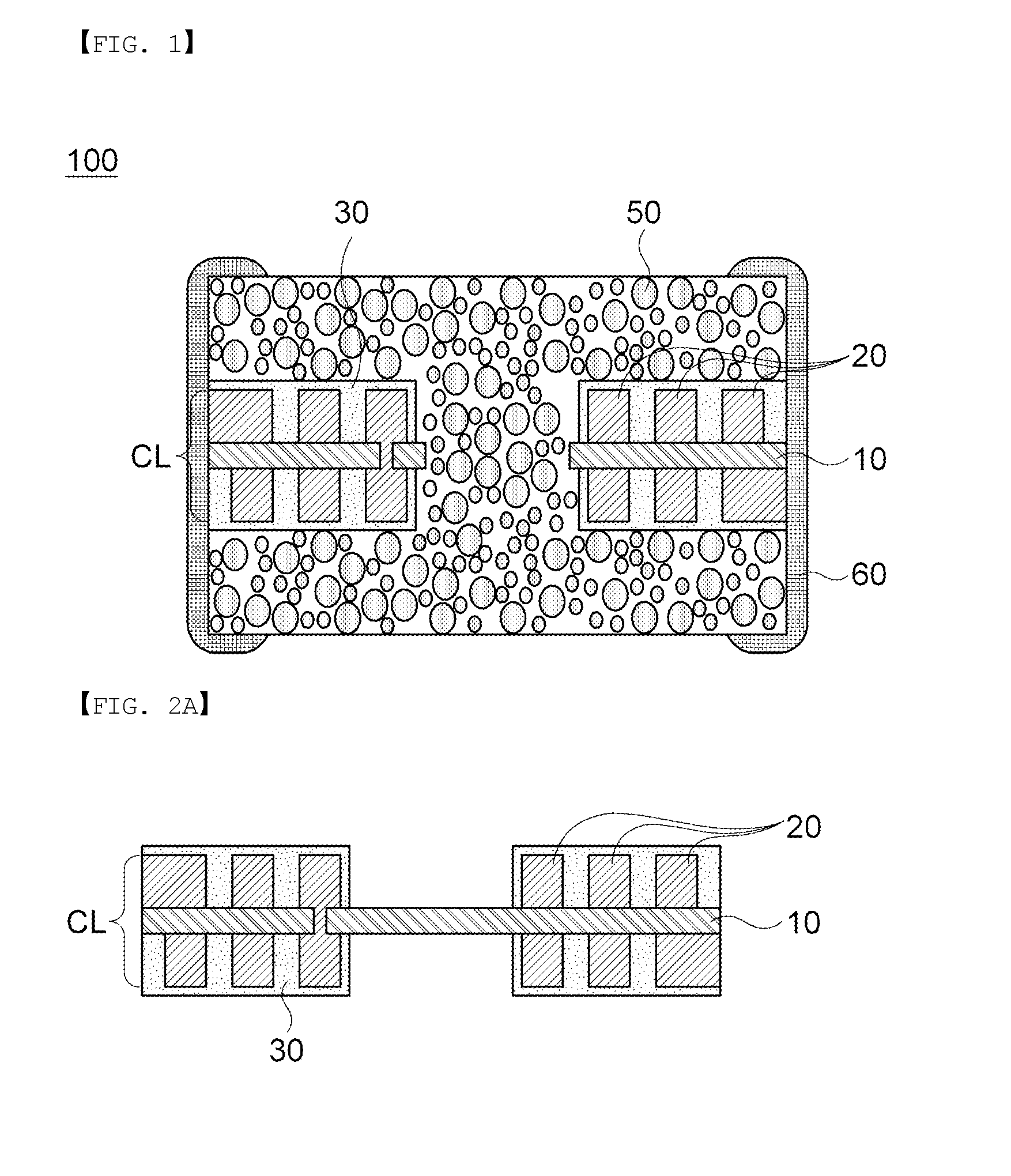

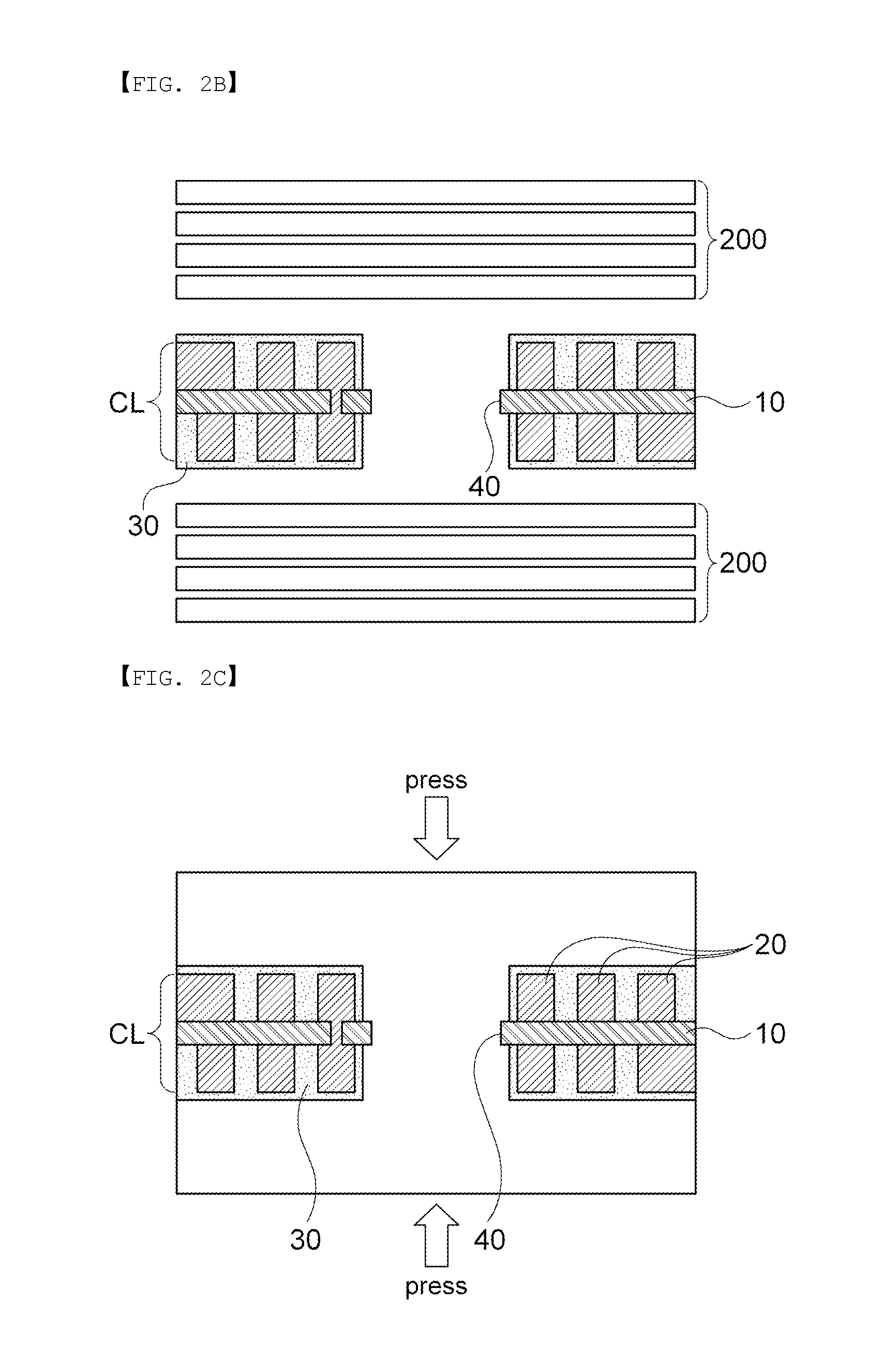

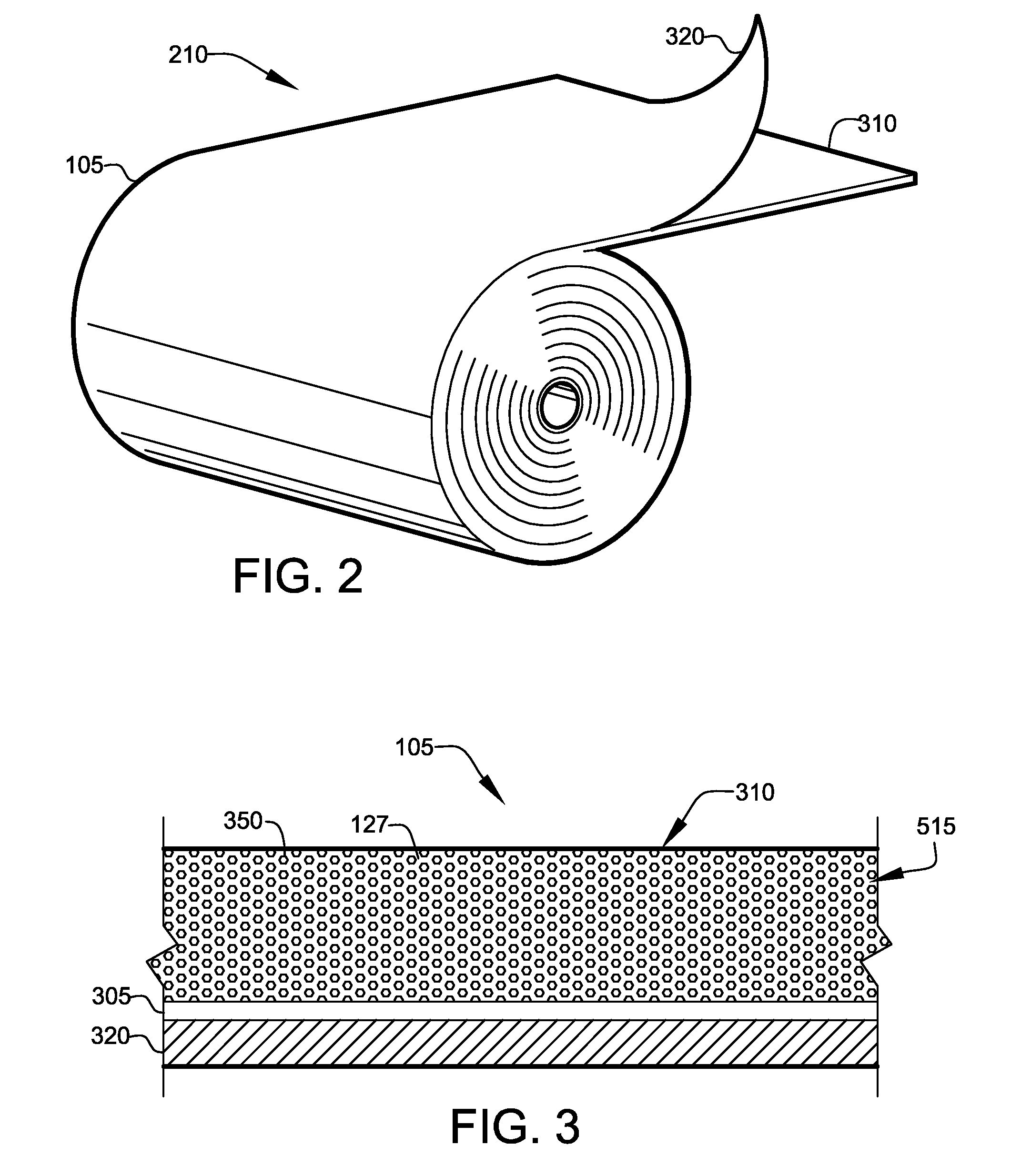

Metal-polymer complex film for inductor and method for manufacturing the same

Disclosed herein are a metal-polymer complex film for an inductor and a method for manufacturing an inductor, the inductor being manufactured by using the metal-polymer complex film for an inductor, including: a metal powder; and an amorphous epoxy resin, wherein the metal-polymer complex film is made in a film type by using a mixture where a weight ratio of the metal powder is 75˜98 wt %, so that a plurality of inductors can be simultaneously manufactured to thereby improve production efficiency and characteristic values of the inductor can be also improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

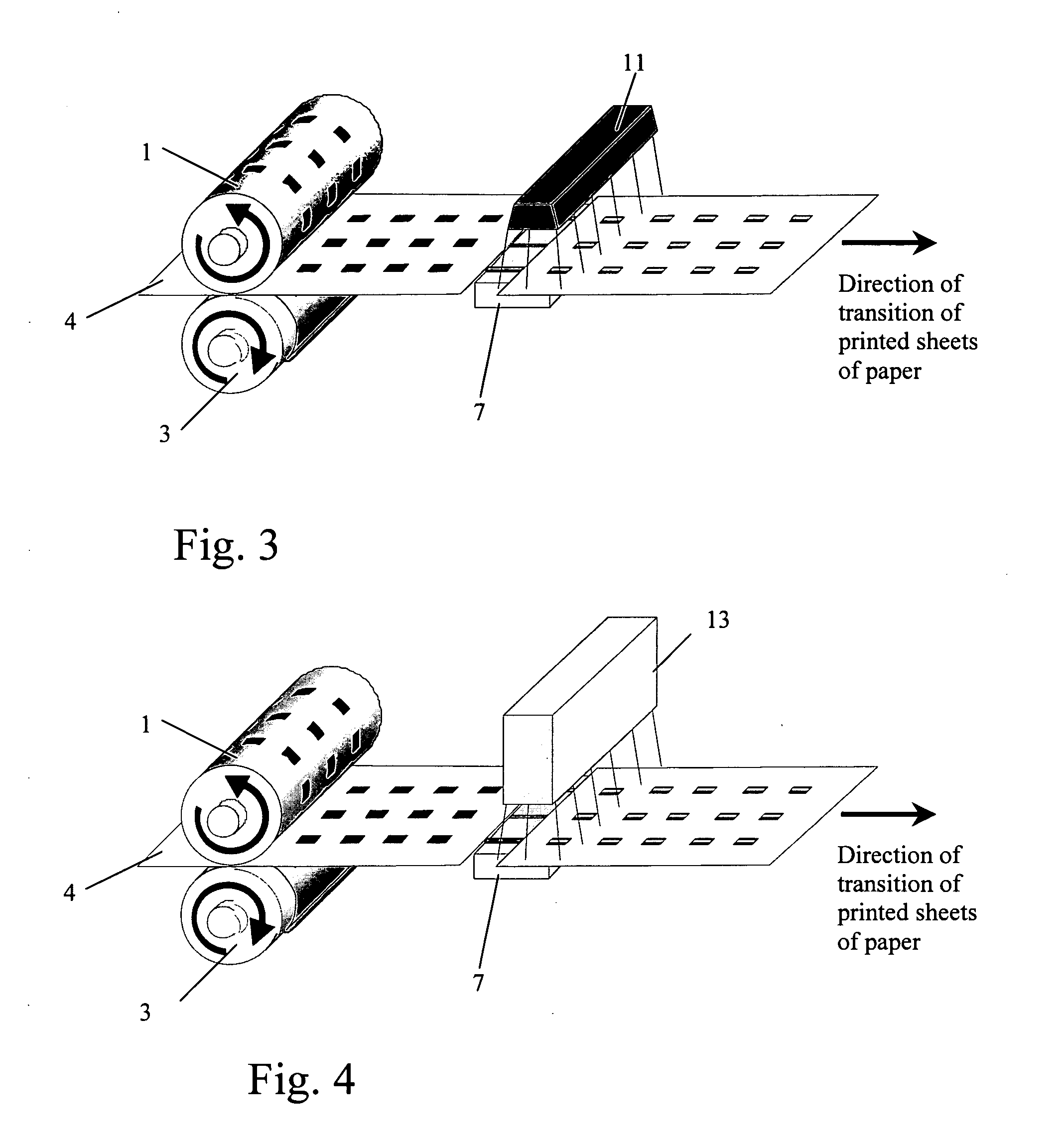

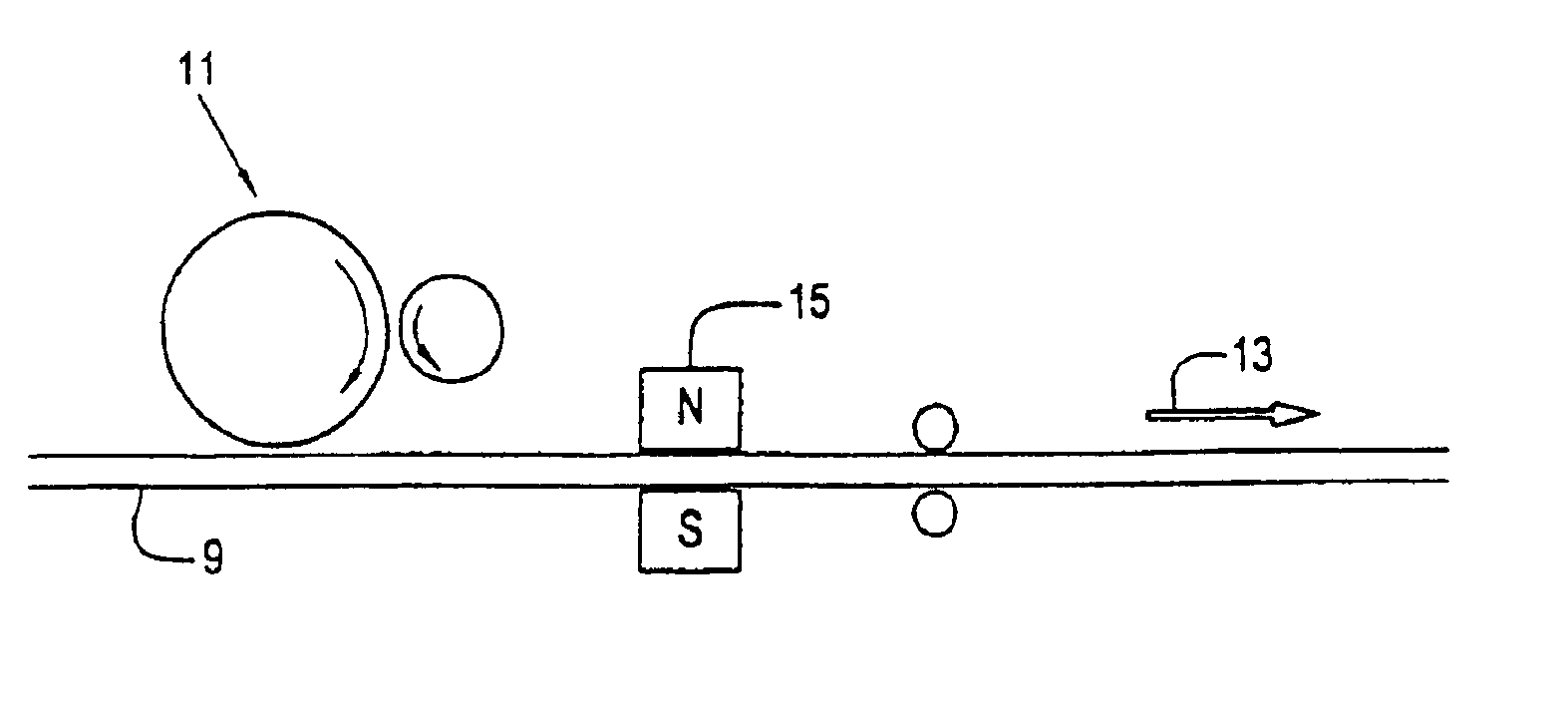

Apparatus and method for making a magnetic coated medium, and a coated medium therefrom

InactiveUS6881450B1Limited penetrationLow costMagnetic paintsLiquid applicationPlastic filmHot-melt adhesive

The invention is directed to a method of magnetically linking a ferromagnetic object to a partially magnetized coating material made by applying a coating to a surface of a continuously-moving medium including the steps of providing a coating material by mixing a binder material suitable for being spread substantially and regularly over the surface and a ferromagnetic component, the binder material being a hot melt adhesive; providing a continuously-moving medium having a top surface to be substantially coated, the surface capable of receiving a substantially and regularly spread coating material; passing the coating material and continuously-moving medium between rollers to form a substantially constant thickness of the coating material substantially covering the top surface and allowing the coating material to set to form the coated medium as a magnetizable component, wherein the medium that is coated is one of a paper, a card, wallpaper, a flexible plastic sheet, a rigid plastic sheet, and walls; partially magnetizing the coating material during continuous movement of the medium to create a magnetized area and an unmagnetized area; and magnetically and temporarily linking a ferromagnetic object to the magnetized area so that the coated medium and ferromagnetic object are held together by magnetic attraction.

Owner:TEXIER CLAUDE

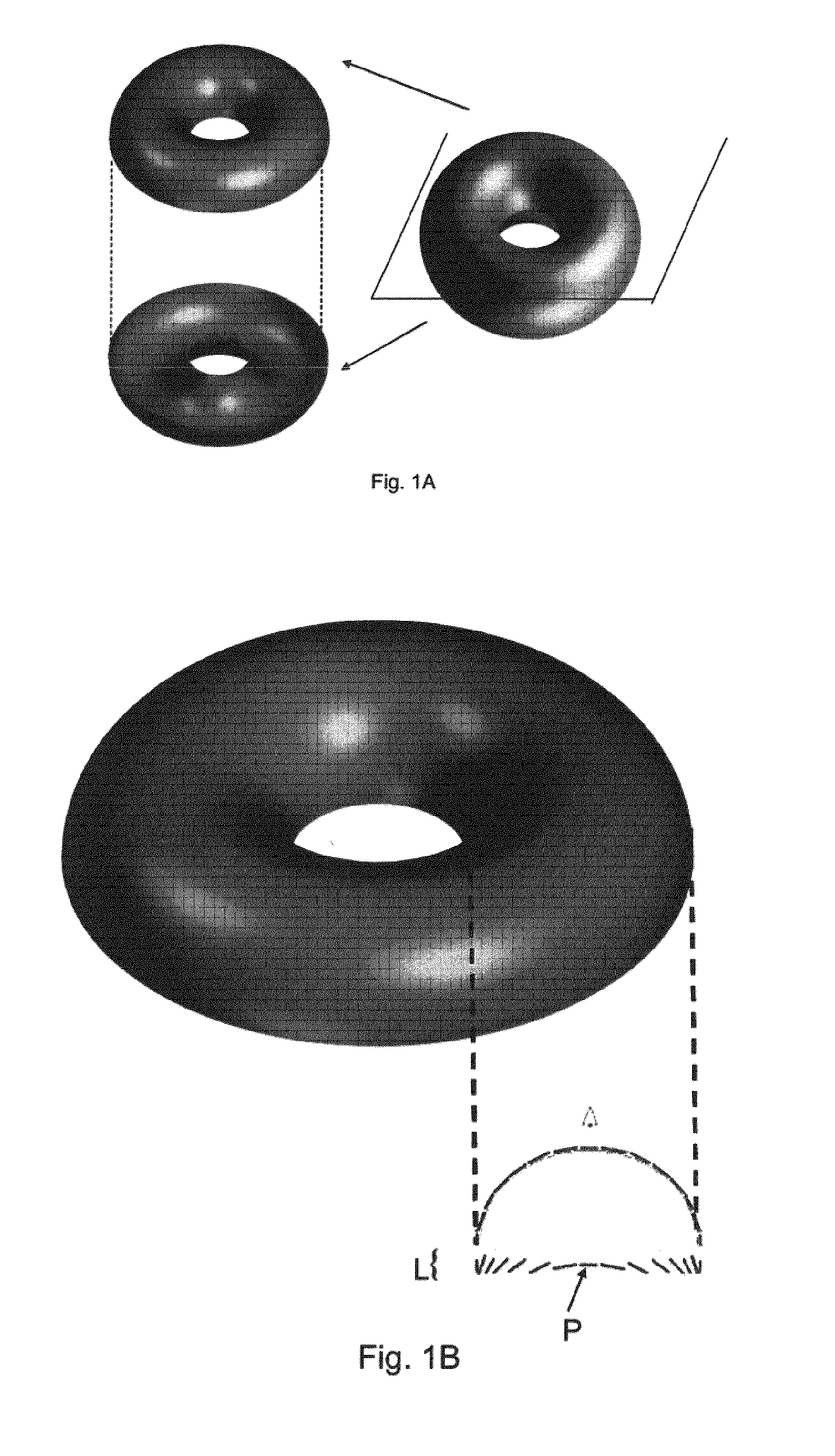

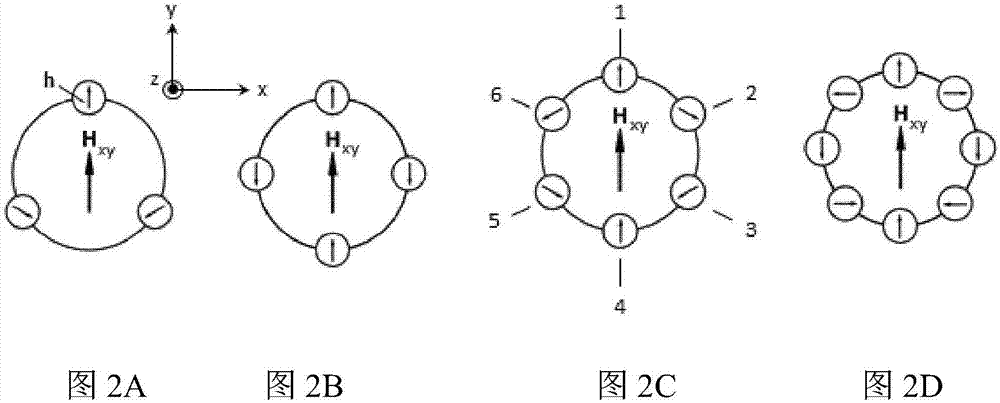

Processes for producing effects layers

ActiveUS20160325310A1Overcome deficienciesReduce thicknessPigmenting treatmentPretreated surfacesMaterials scienceReproduction

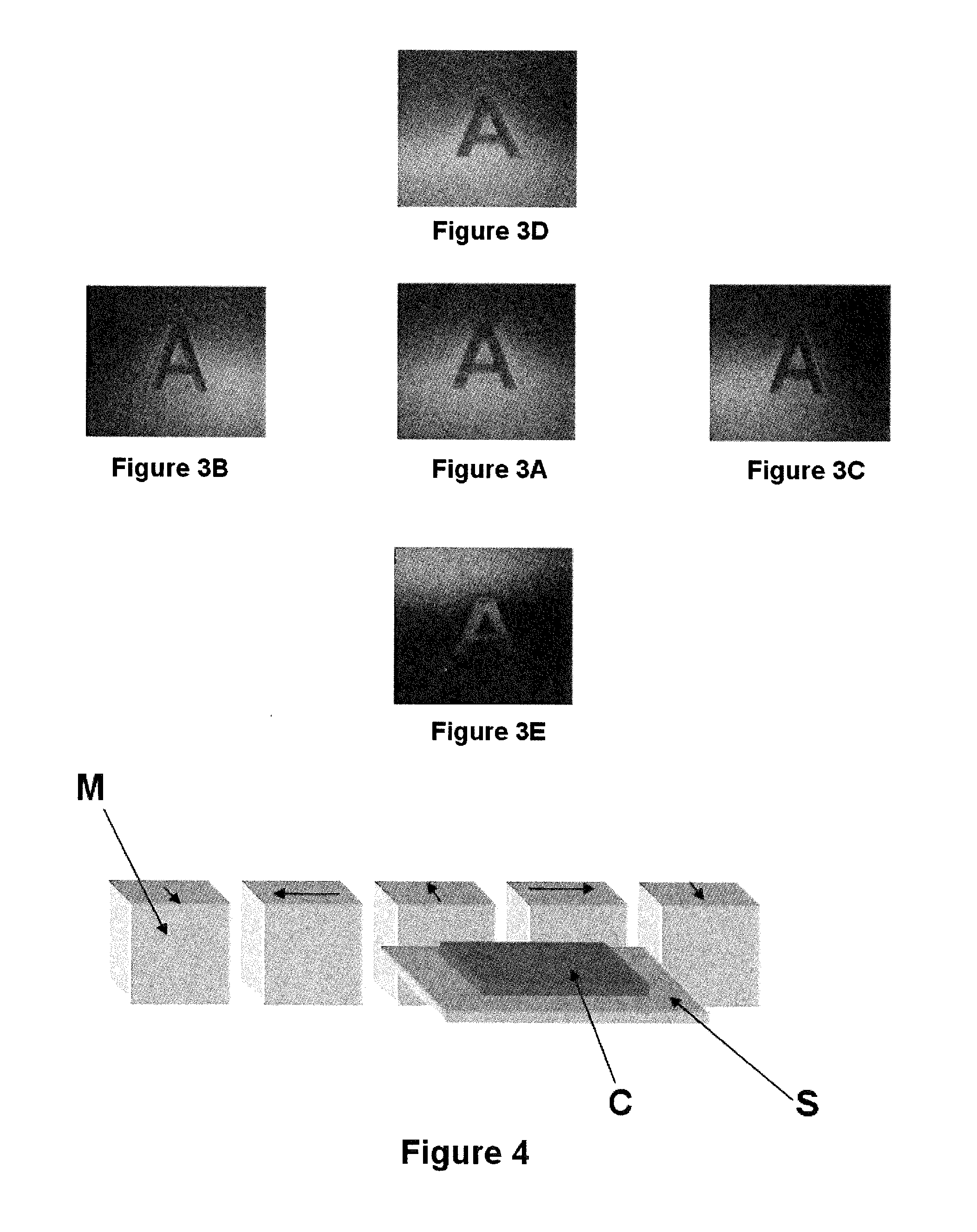

The invention relates to the field of the protection of security documents such as for example banknotes and identity documents against counterfeit and illegal reproduction. In particular, the present invention provides processes for producing optical effect layers (OELs) on a substrate and OELs obtained thereof, said process comprising two magnetic orientation steps: a step of exposing a coating composition comprising platelet-shaped magnetic or magnetisable pigment particles to a dynamic magnetic field of a first magnetic-field-generating device so as to bi-axially orient at least a part of the platelet-shaped magnetic or magnetisable pigment particles and a step of exposing the coating composition to a static magnetic field of a second magnetic-field-generating device, thereby mono-axially reorienting at least a part of the platelet-shaped magnetic or magnetisable pigment particles.

Owner:SICPA HLDG SA

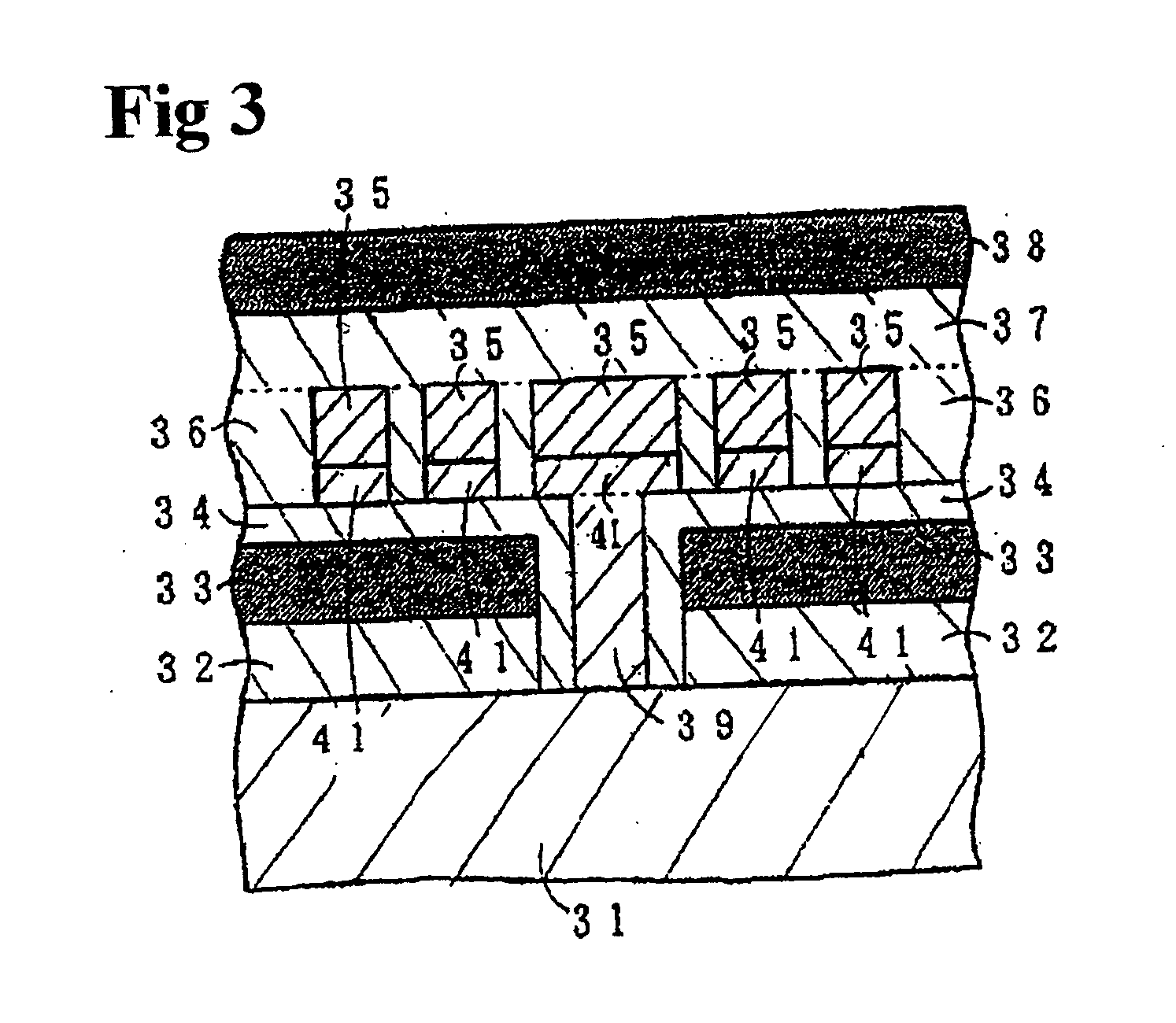

Multilayered ceramic component and manufacturing method thereof

ActiveUS20110181384A1Suppresses migration of silverTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorGlass-ceramic

A laminated ceramic component includes a ferrite magnetic layer and a glass ceramic layer made chiefly of borosilicate glass. The glass ceramic layer is laminated with the ferrite magnetic layer, and has an Ag inner conductor embedded inside. A microscopic region where aluminum and silver coexist is dispersed in the glass ceramic layer.

Owner:PANASONIC CORP

Acid stable aqueous dispersion of metal particles and applications

InactiveUS6811885B1Improve colloidal stabilityProtective coatings for layersMagnetic liquidsMetal particleRecording layer

Aqueous coating compositions containing acid stable metal dispersions, prepared by chemical reduction in aqueous medium, are obtained by using a N-quaternized cellulose derivative as binder. They can be used for the preparation of heat mode recording layers, magnetic layers and conductive layers.

Owner:AGFA GEVAERT AG

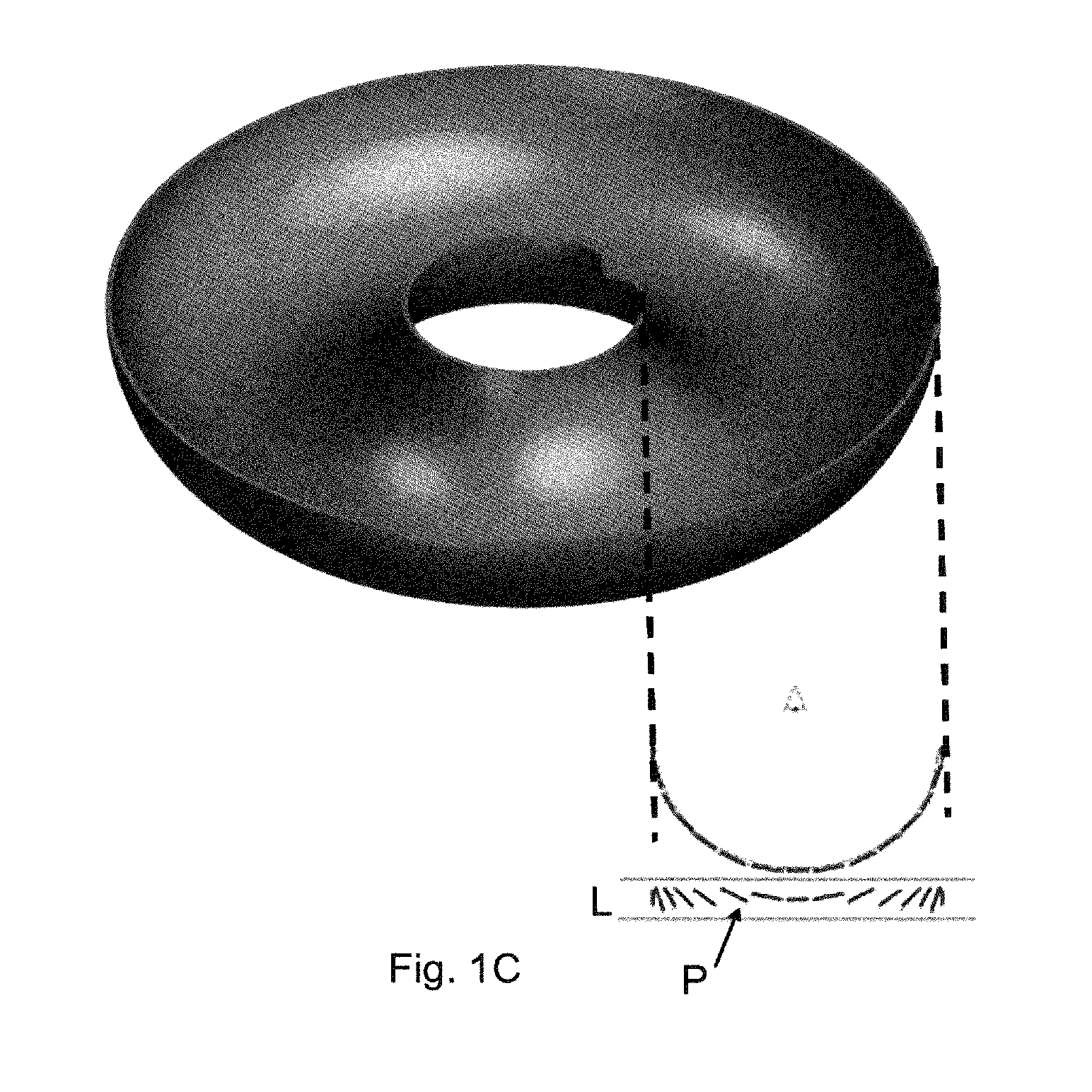

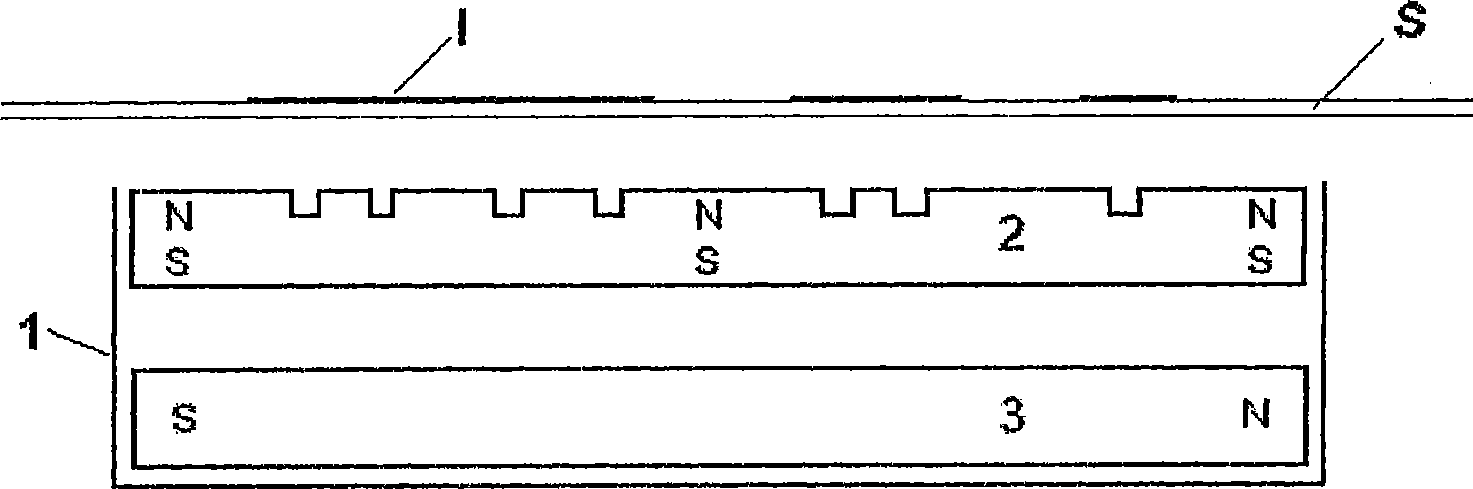

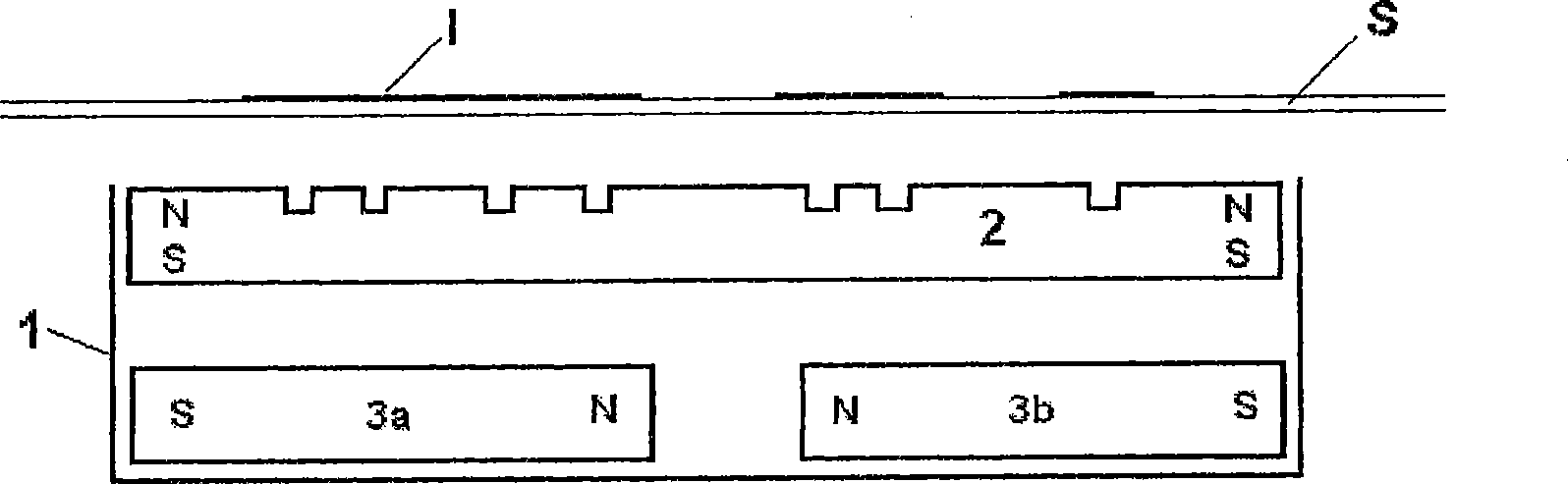

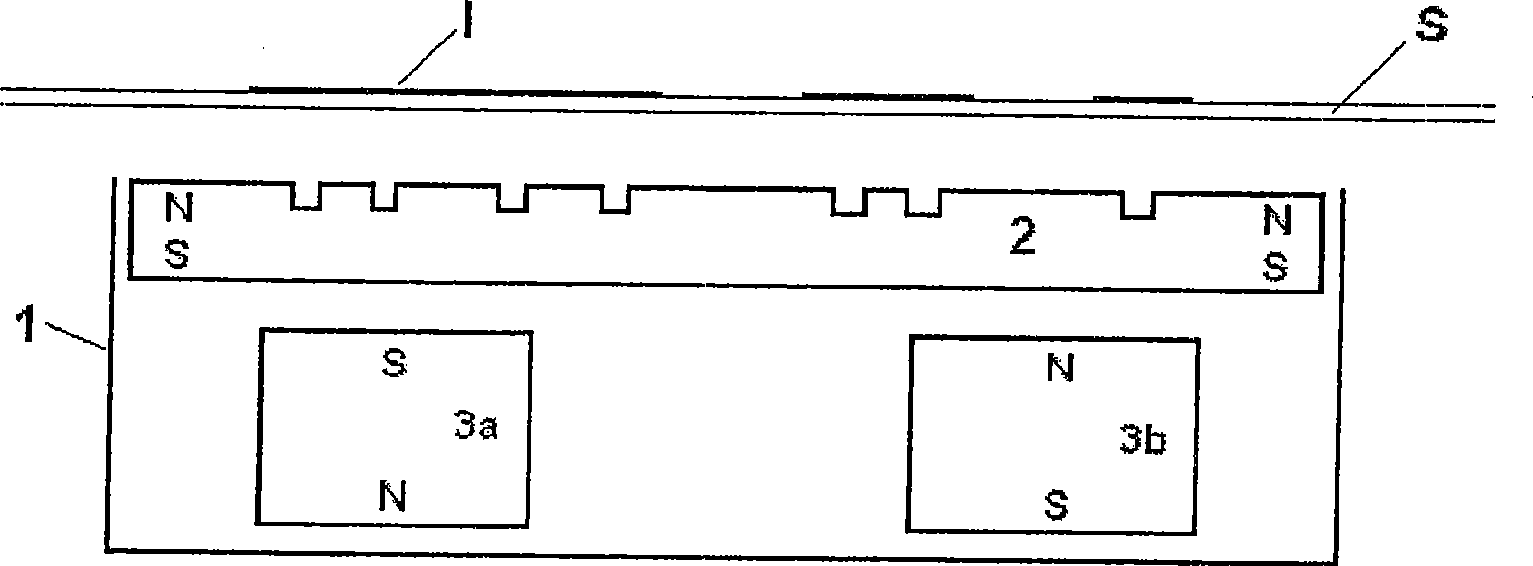

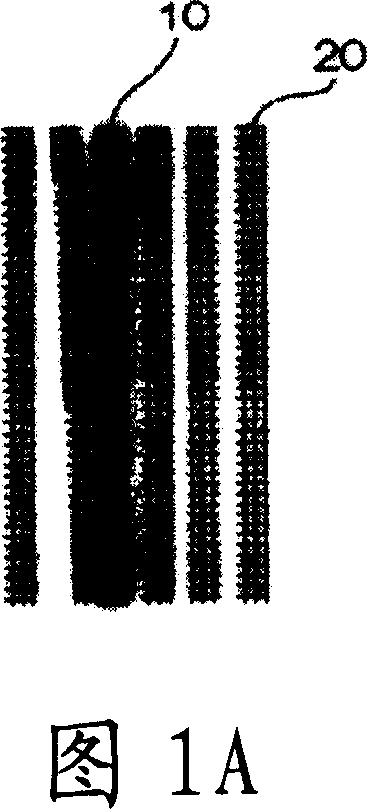

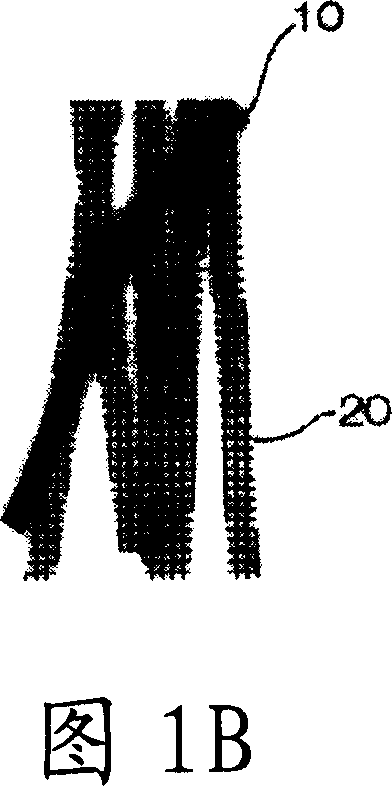

Method and means for producing a magnetically induced indicia in a coating containing magnetic particles

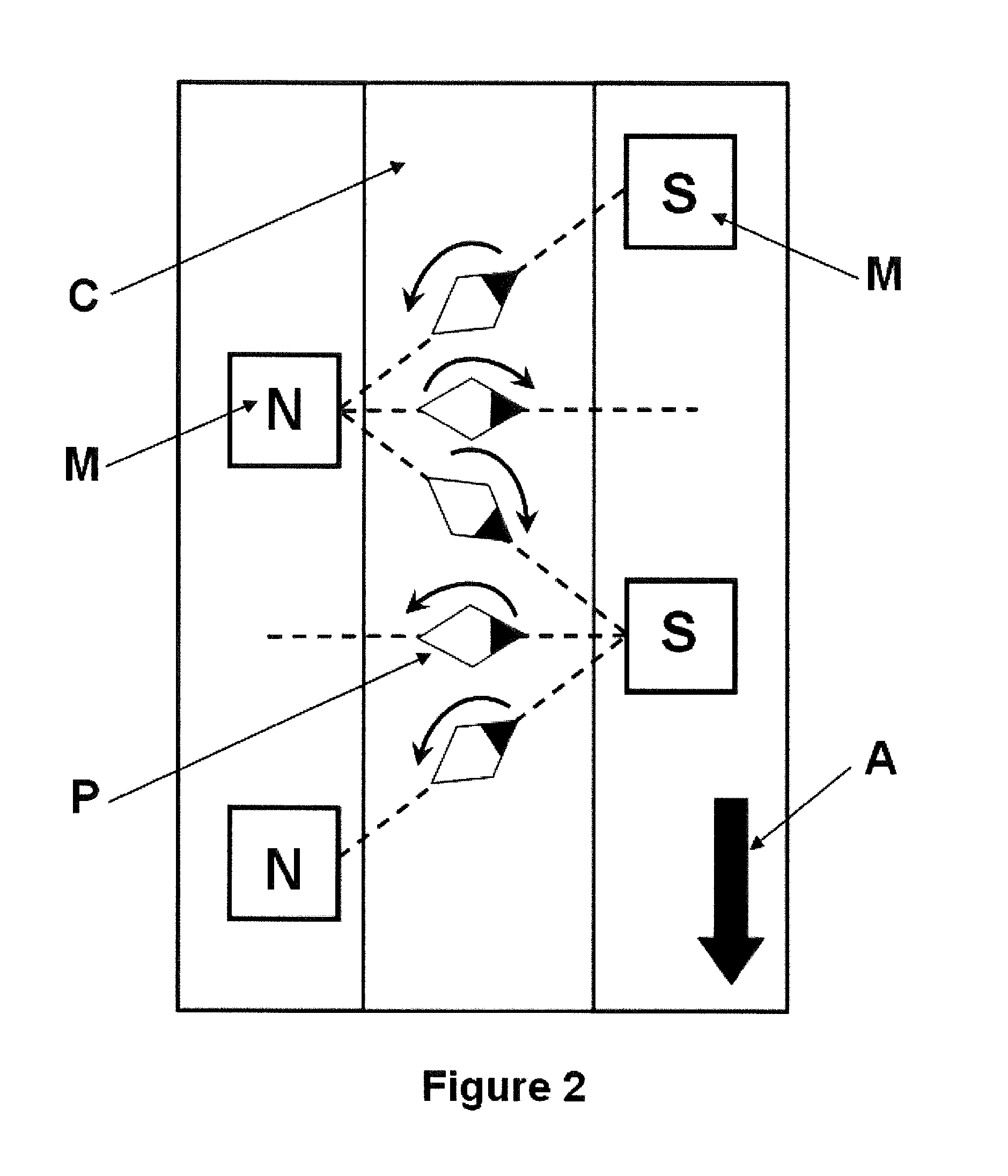

The invention relates to a device for magnetically transferring indicia, such as a design or an image, to a wet coating layer applied on a substrate, such as a sheet or a web, wherein the said coating layer comprises at least one type of magnetic or magnetizable particles; said device comprising a) at least one magnetized permanent-magnetic plate (2) carrying relief, engravings or cut-outs, mounted such that its relief surface remains accessible, b) at least one additional magnet (3), disposed below said at least one permanent-magnetic plate, facing the surface of the magnetic plate which is opposite to the relief, engraving or cut-out, and c) a holder (1), which has the mechanical function to hold the pieces together in fixed positions. A method for producing the device, the use of the device, and magnetically induced designs obtained with the device, which are useful for protecting currency, value- and identity documents, are disclosed as well.

Owner:SICPA HLDG SA

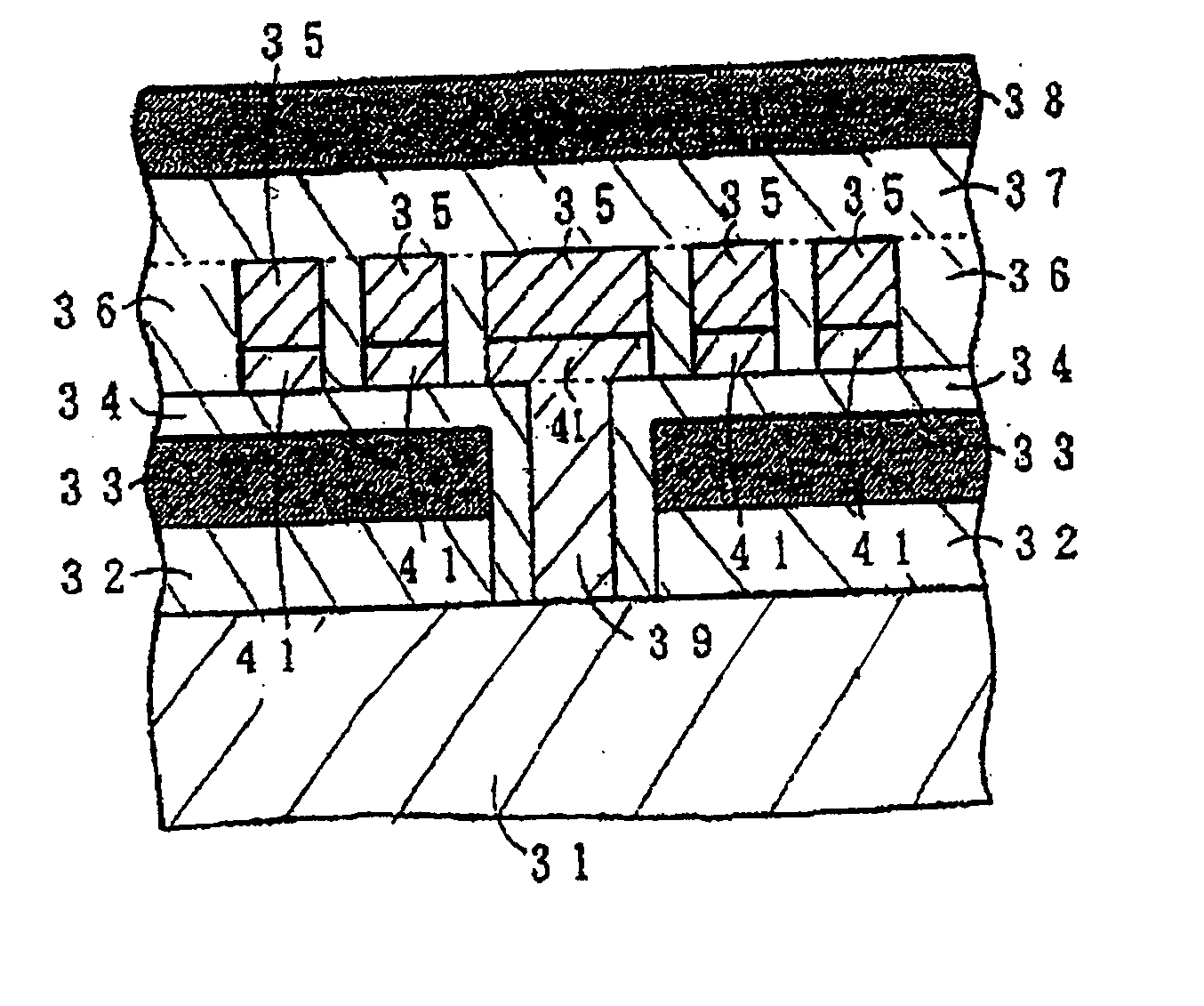

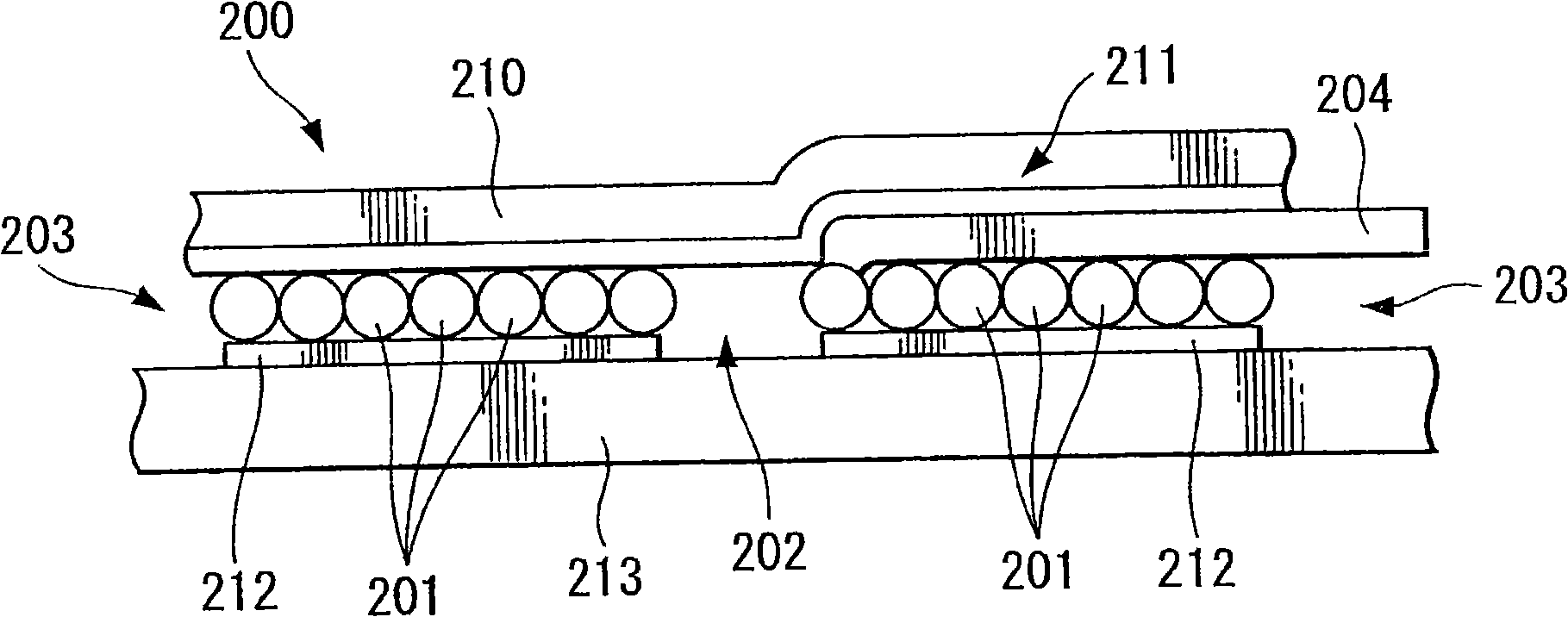

Magnetic thin film, magnetic component that uses this magnetic thin film, manufacturing methods for the same, and a power conversion device

InactiveUS20050094302A1Soft qualityEasy to manufactureNanomagnetismSemiconductor/solid-state device detailsElectric forceElectrical conductor

On top of a silicon substrate, a polyimide film with a thickness of 10 μm is formed. On top of this, a magnetic thin film that is a polyimide film containing Fe fine particles and that has a thickness of 20 μm is formed. On top of this magnetic thin film, a patterned Ti / Au film and a Ti / Au connection conductor are formed. On top of this, a polyimide film with a thickness of 10 μm, and a Cu coil with a height 35 μm, width 90 μm, space 25 μm, and a polyimide layer that fills the spaces in the Cu coil are formed. On top of this, via a polyimide film with a thickness of 10 μm, a magnetic thin film that is a polyimide film containing Fe particles and that has a thickness of 20 μm is formed. This thin film inductor has a small alternating current resistance. The present invention provides a magnetic thin film that is well suited for mass production, can be manufactured easily, can be made into a thick film, has soft magnetic qualities, and is inexpensive. The present invention also provides a magnetic component that uses this magnetic thin film, manufacturing methods for these, and a power conversion device.

Owner:FUJI ELECTRIC DEVICE TECH CO

Magnetic paint

Magnetic receptive Paints and coatings have been developed to allow one to paint a wall with this coating and apply magnets to this surface. The further development of magnetic receptive coatings incorporates the use of multiple size particles giving the finished surface a smoother appearance and increasing the particle load in the dry mill surface. This is useful in the coating of substrates where the need to coat the thinnest possible coating on the surface of a substrate such as papers and films as well as painting on walls, gives you the highest magnetic receptive surface possible at the thinnest mill thickness of applied coating.

Owner:DEETZ DAYTON JOSEPH

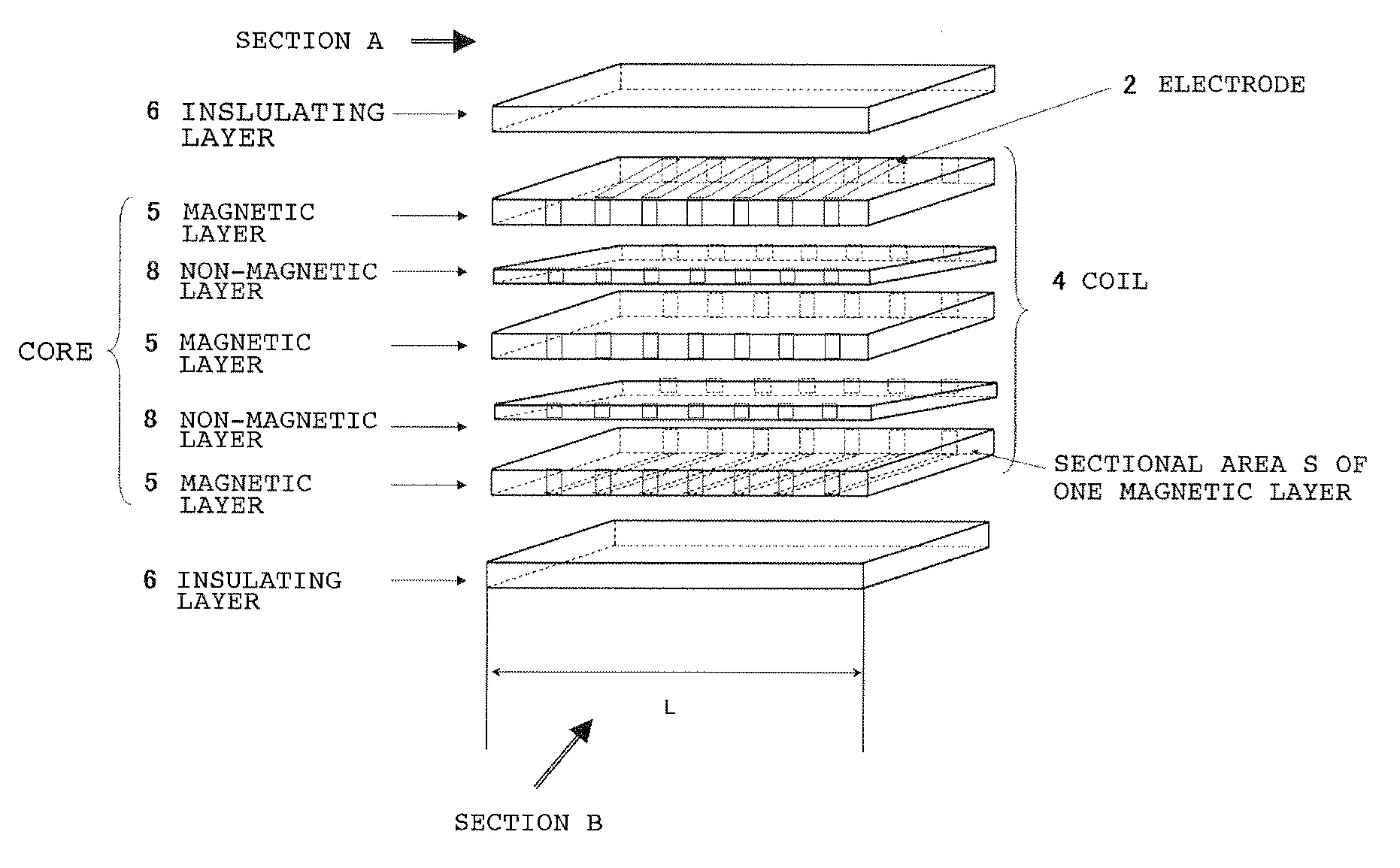

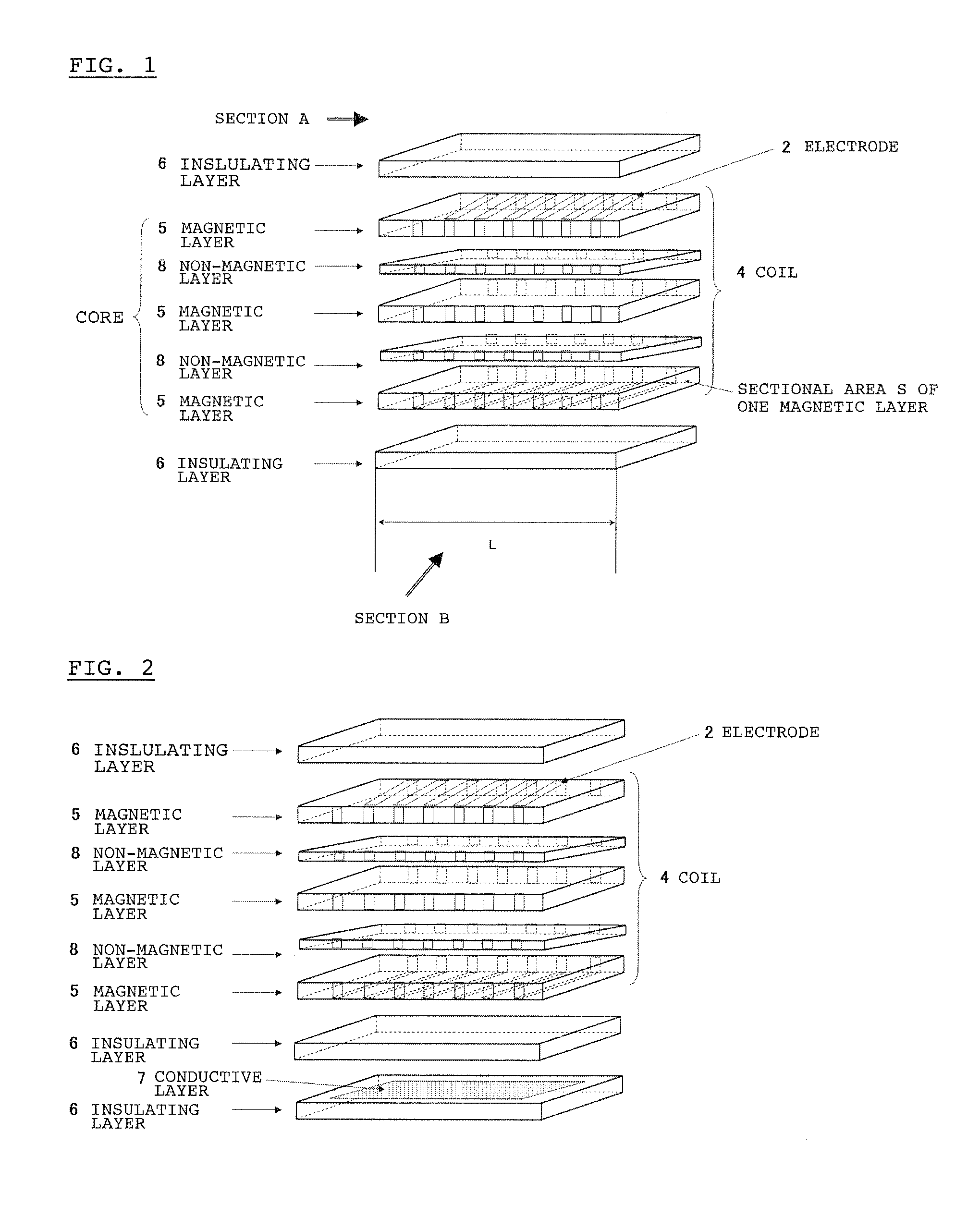

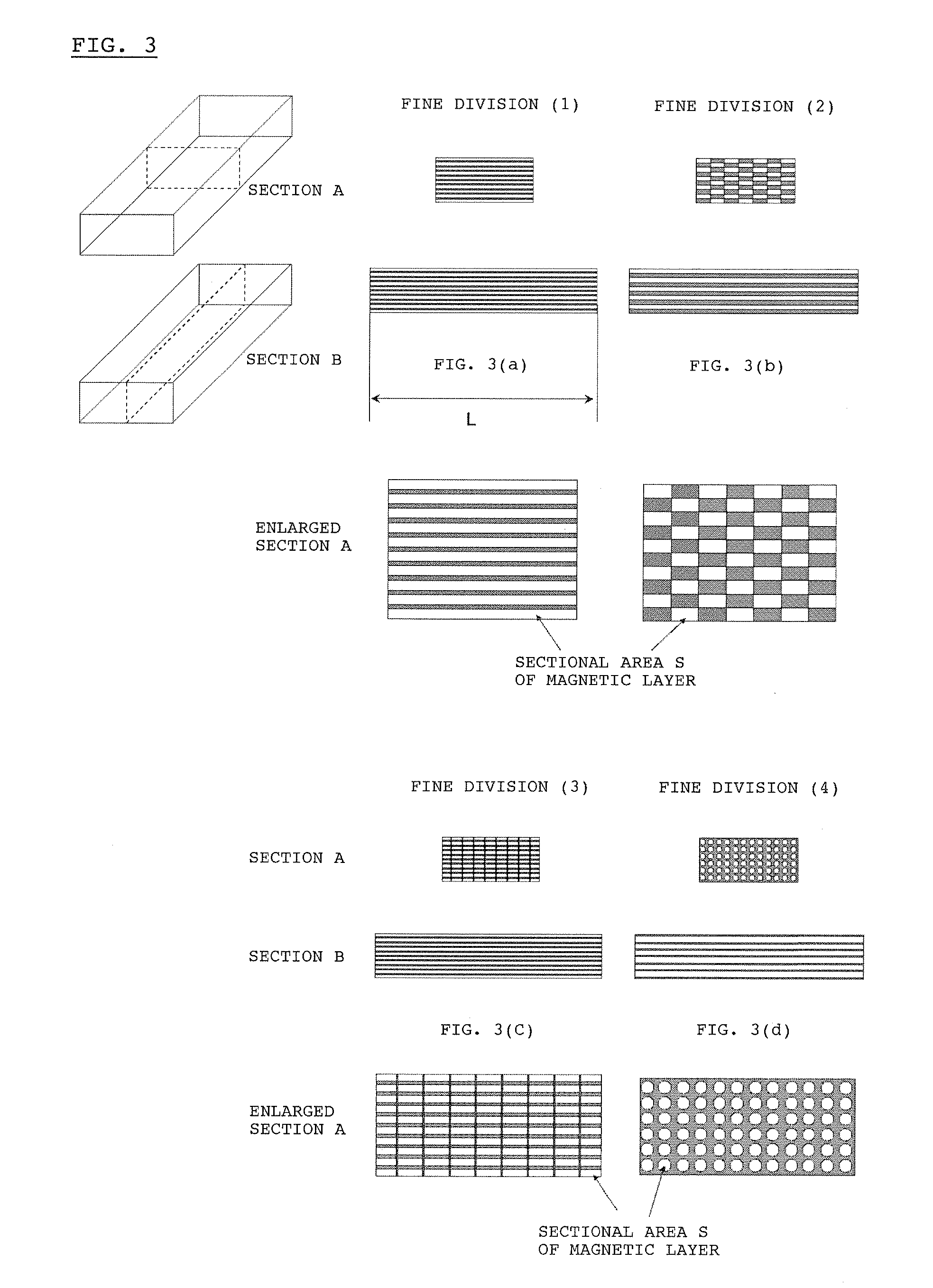

Non-contact power transmission coil, portable terminal and terminal charging device

ActiveCN101304183AHigh power transmission efficiencyCircuit authenticationElectromagnetic wave systemElectrical conductorEngineering

Owner:SONY MOBILE COMM INC +1

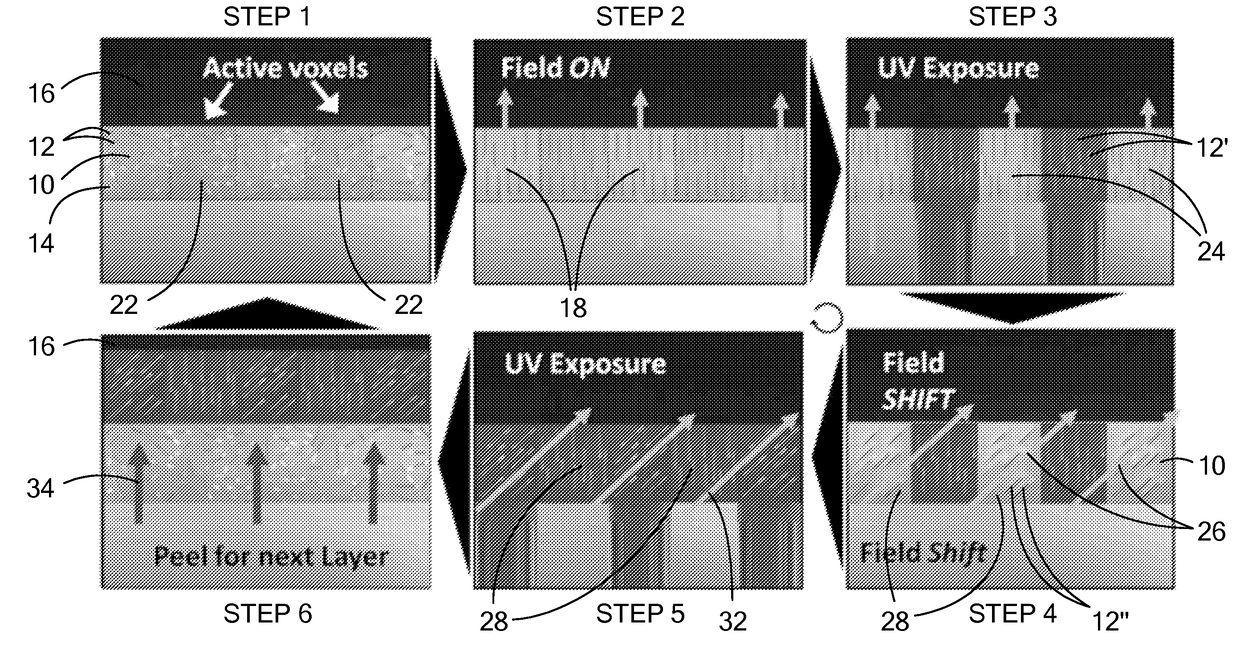

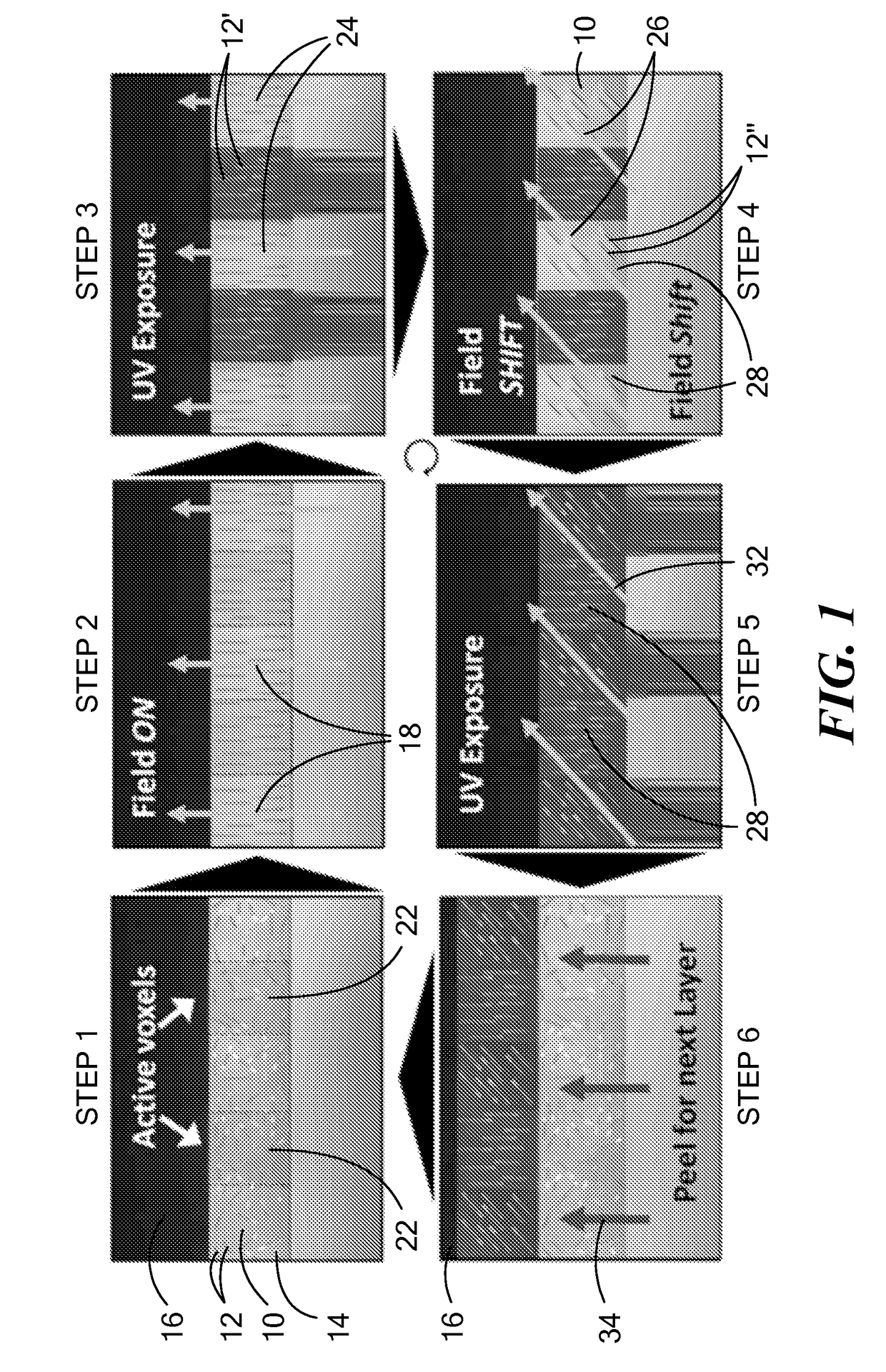

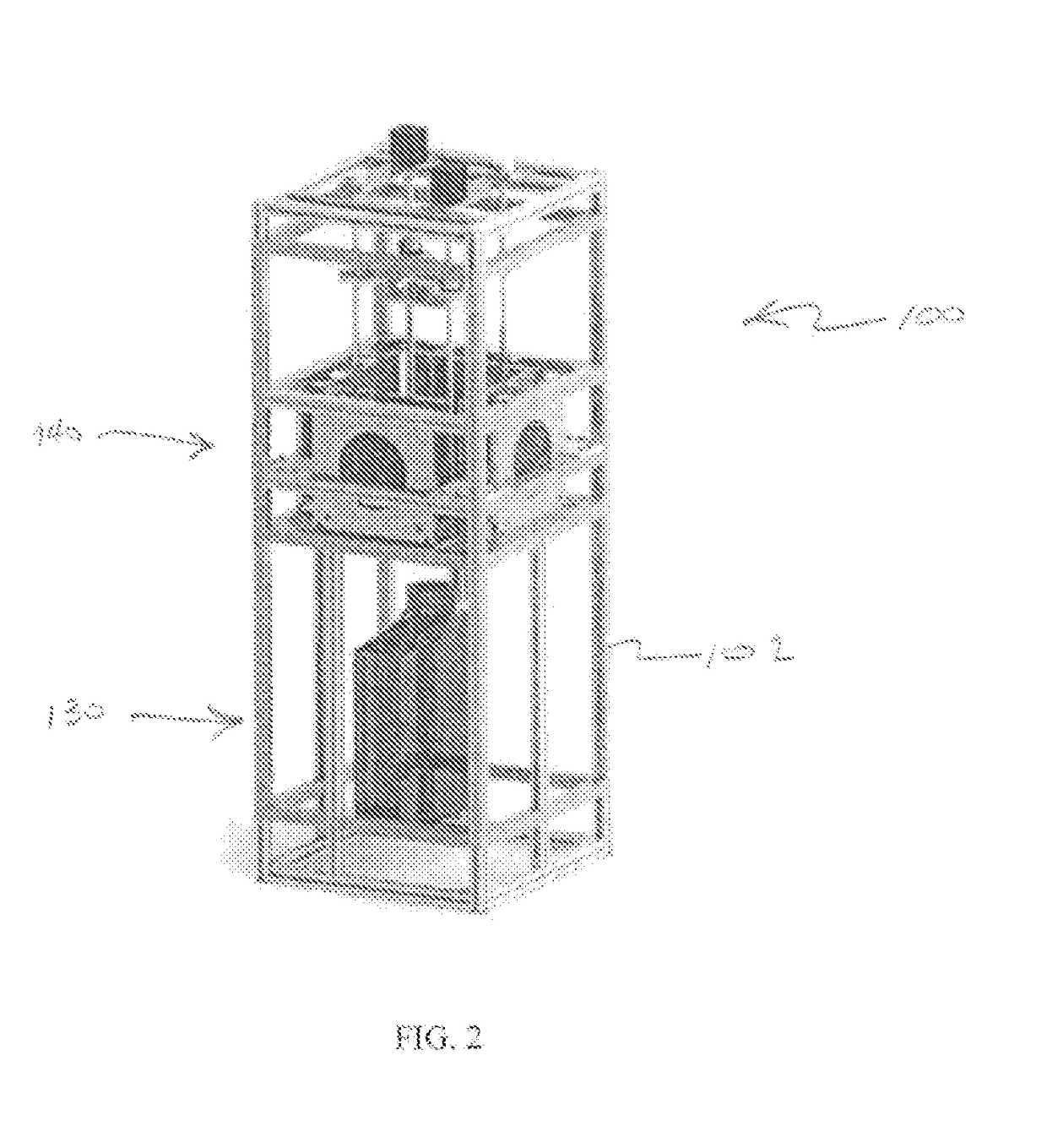

Additive Manufacturing of Discontinuous Fiber Composites Using Magnetic Fields

ActiveUS20170136699A1Highly programmable discontinuous reinforcement architecturesAdditive manufacturing apparatusTransportation and packagingOptical propertyFibrous composites

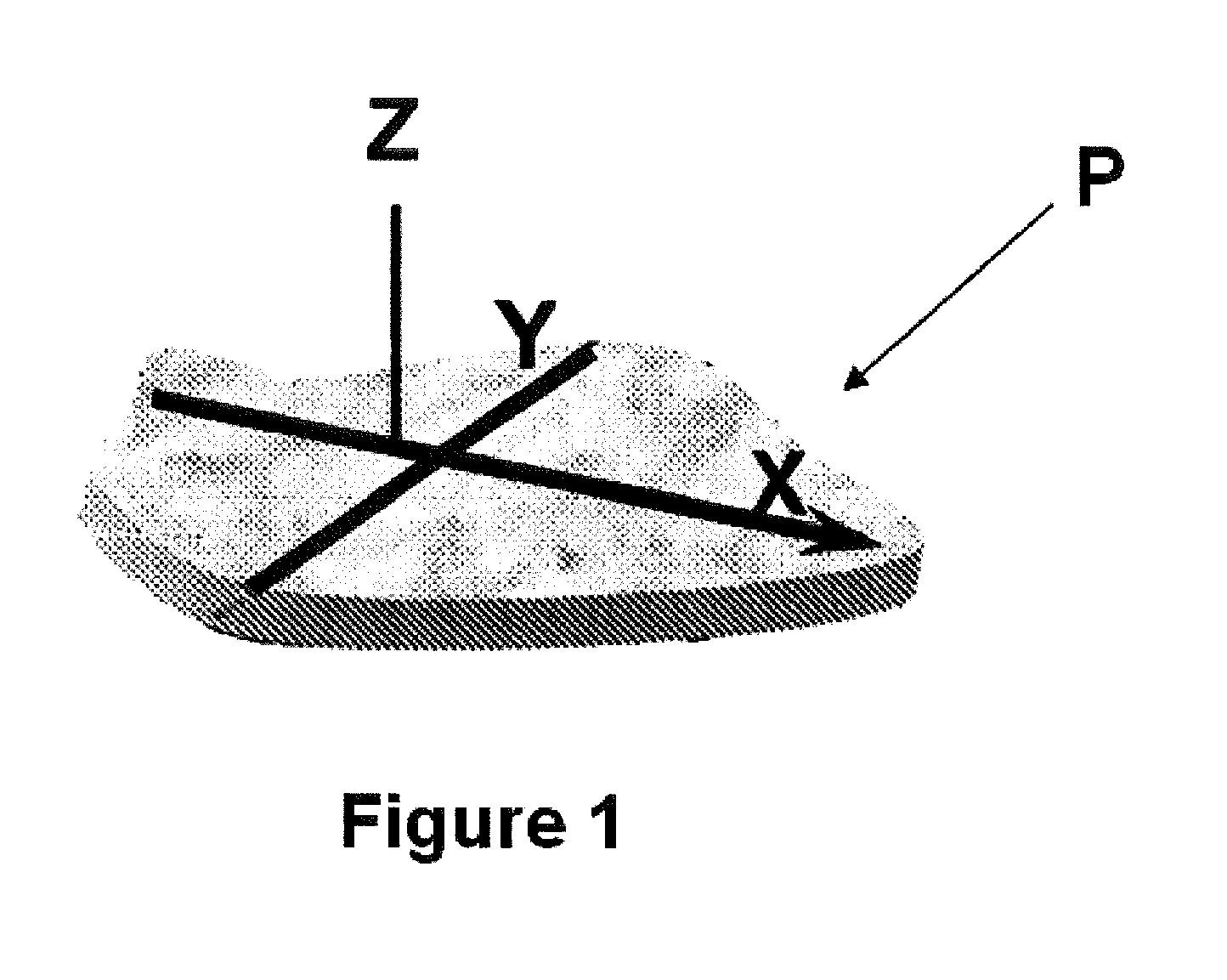

A method and apparatus for producing a composite part are provided to enable composite parts to be assembled with precise control over the orientation and spatial distribution of reinforcing or other particles within a matrix material. The method and apparatus use magnetic fields applied during various additive manufacturing processes to achieve complex particles orientations within each layer of the part. The composite parts can achieve enhanced properties, including mechanical, thermal, electrical and optical properties.

Owner:NORTHEASTERN UNIV

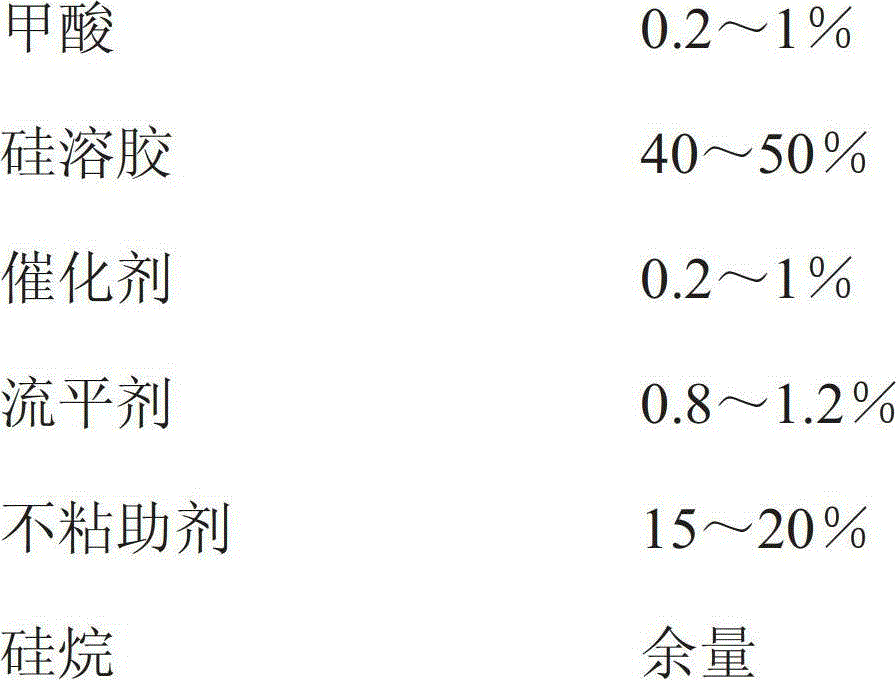

Ceramic coating material with 3D effect and coating method of ceramic coating material

InactiveCN102911537APattern controllableCater to market needsMagnetic paintsParticle applicationCeramic coatingCuring time

The invention relates to a ceramic coating material with 3D effect and a coating method of the ceramic coating material. The coating method specifically comprises the following steps of: 1, designing patterns; 2, proportioning ceramic coating material; and 3, preparing: (1) carrying out shot blasting and cleaning on base material; (2) preheating the base material to 45-50DEG C; (3) spraying priming paint, wherein the thickness of a film is 25-30mu m; (4) putting a magnetic block module with the patterns on the base material, spraying the magnetic powder coating material, wherein the thickness of the film is 2-3mu m, and immediately spraying finish paint, wherein the thickness of the film is 3-5mu m, directly putting the magnetic block module on a clamp before a bottom layer is sprayed so that the rotation speed of the clamp can be slightly slower than the conventional rotation speed, and the arrangement rule of the magnetic powder can not be influenced; (5) withdrawing the module after the finish paint is sprayed, and curing under low temperate, wherein the curing temperature is 80-100DEG C, and the curing time is 8-10minutes; and (6) cutting under high temperature, wherein the curing temperature is 240-280DEG C, and the curing time is 10-20minutes. The ceramic coating material with 3D effect has the advantages that simple to use is simple, low in cost is low, and better in decorative effect is good, patterns are controllable, 3D effect is vivid, and meets the requirement of market; and the coating layer is higher in non-stick property and abrasion resistance.

Owner:SHANGHAI EXCILON NEW MATERIALS

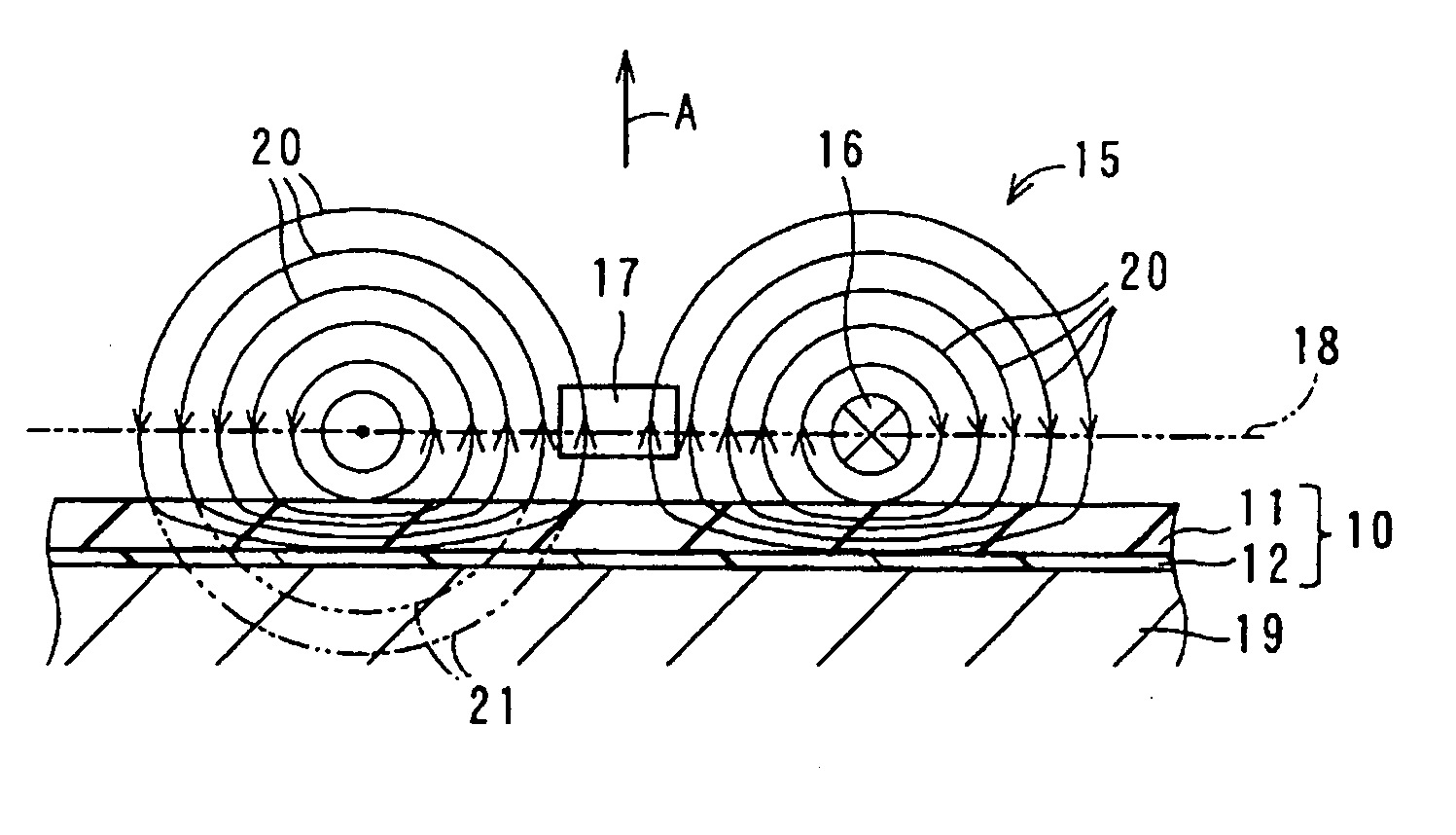

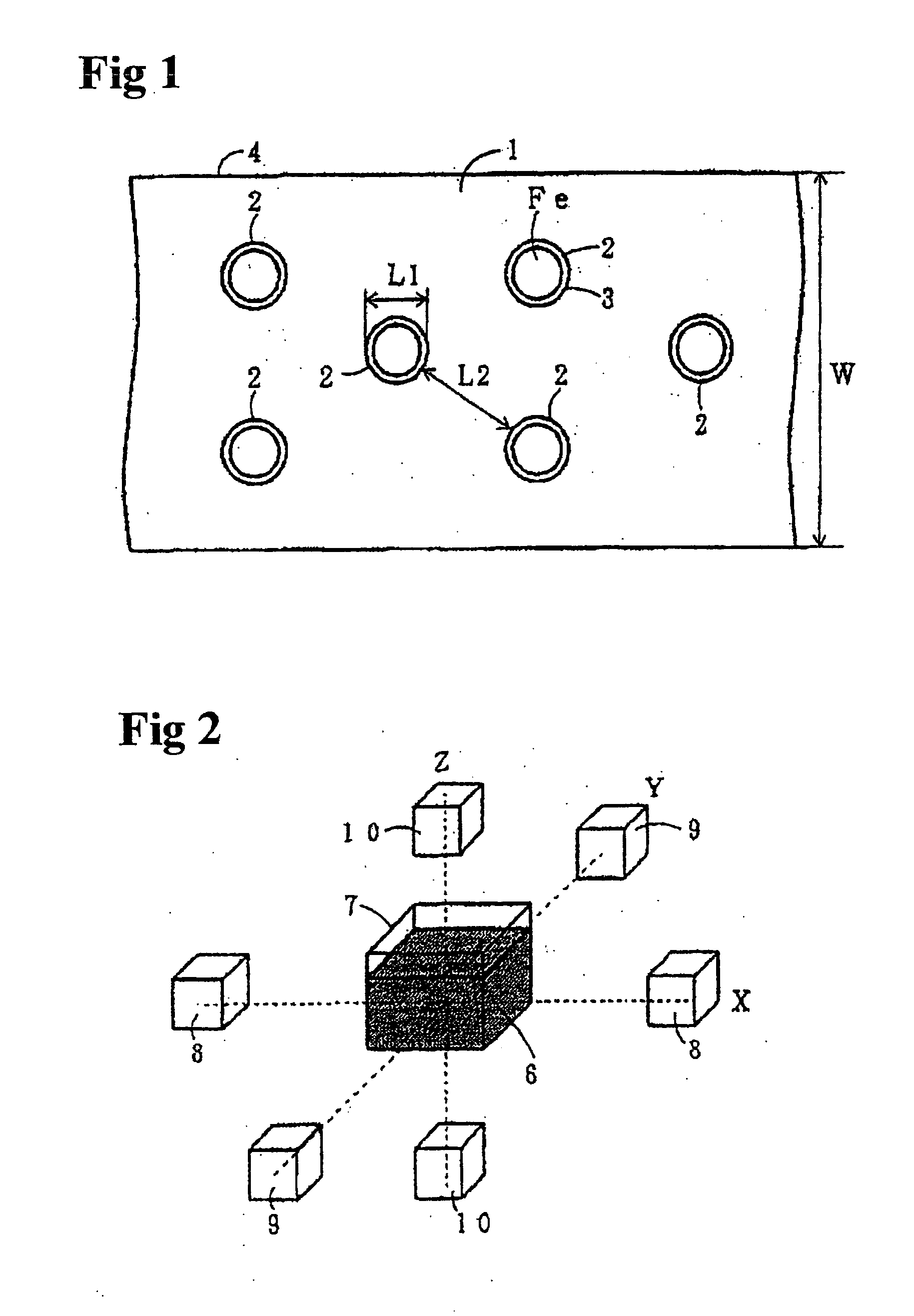

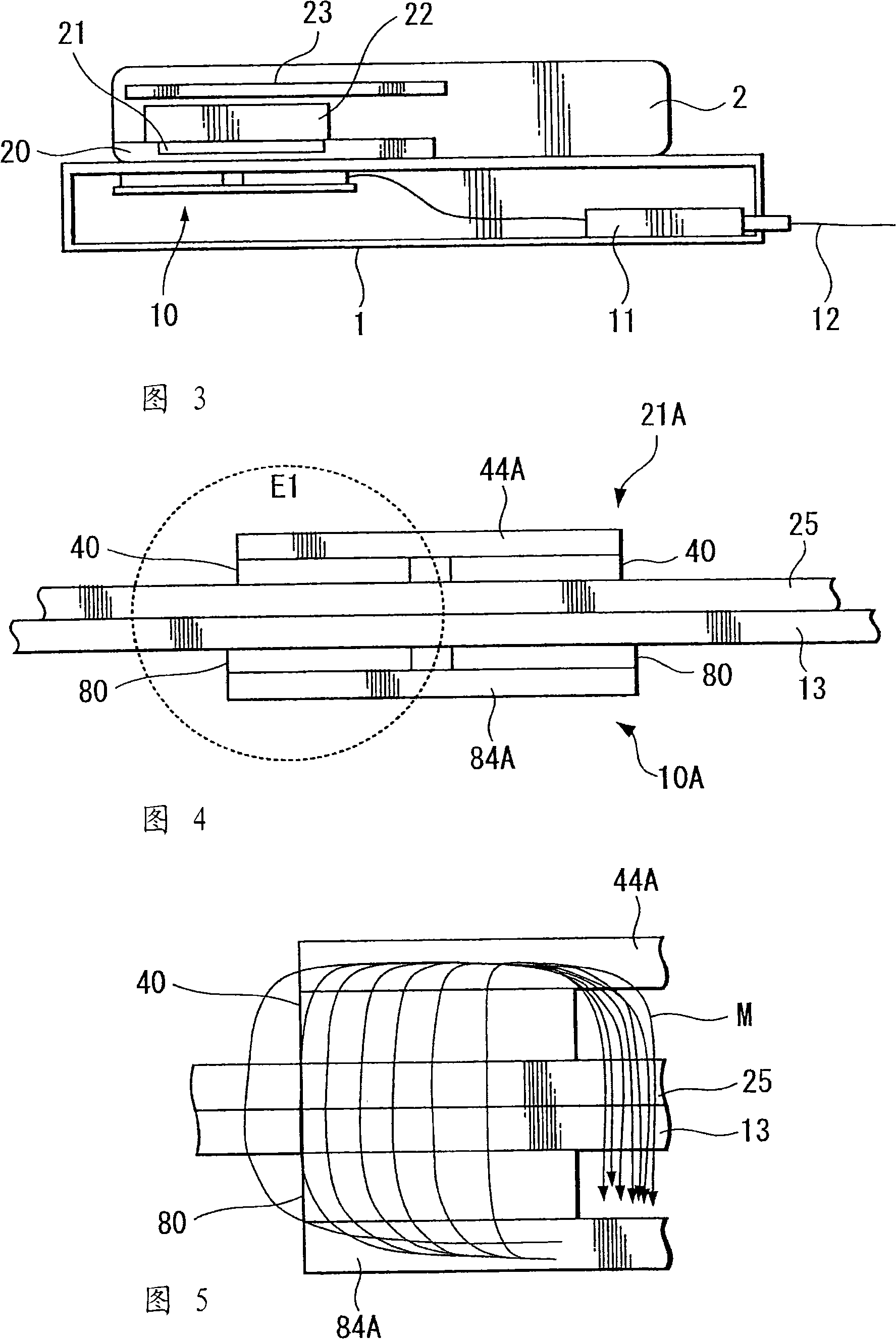

Magnetic antenna, board mounted with the same, and RF tag

ActiveUS20110124299A1High sensitivityAvoid excessive changesLoop antennas with ferromagnetic coreTransformersNon magneticMagnetic flux

The present invention relates to a magnetic antenna for information communication using a magnetic field component which is capable of satisfying both reduction in size and improvement in communication sensitivity. The magnetic antenna of the present invention is used for transmitting and receiving information using an electromagnetic induction method, and comprises a central core formed of a magnetic material and a non-magnetic material, a coil-shaped electrode material wound around the core, and an insulating layer formed on at least one outside surface of the core on which the coil-shaped electrode material is provided, in which the magnetic material is separated into two or more parts through the non-magnetic material when viewed in a section of the core which is perpendicular to a magnetic flux passing therethrough.

Owner:TODA IND

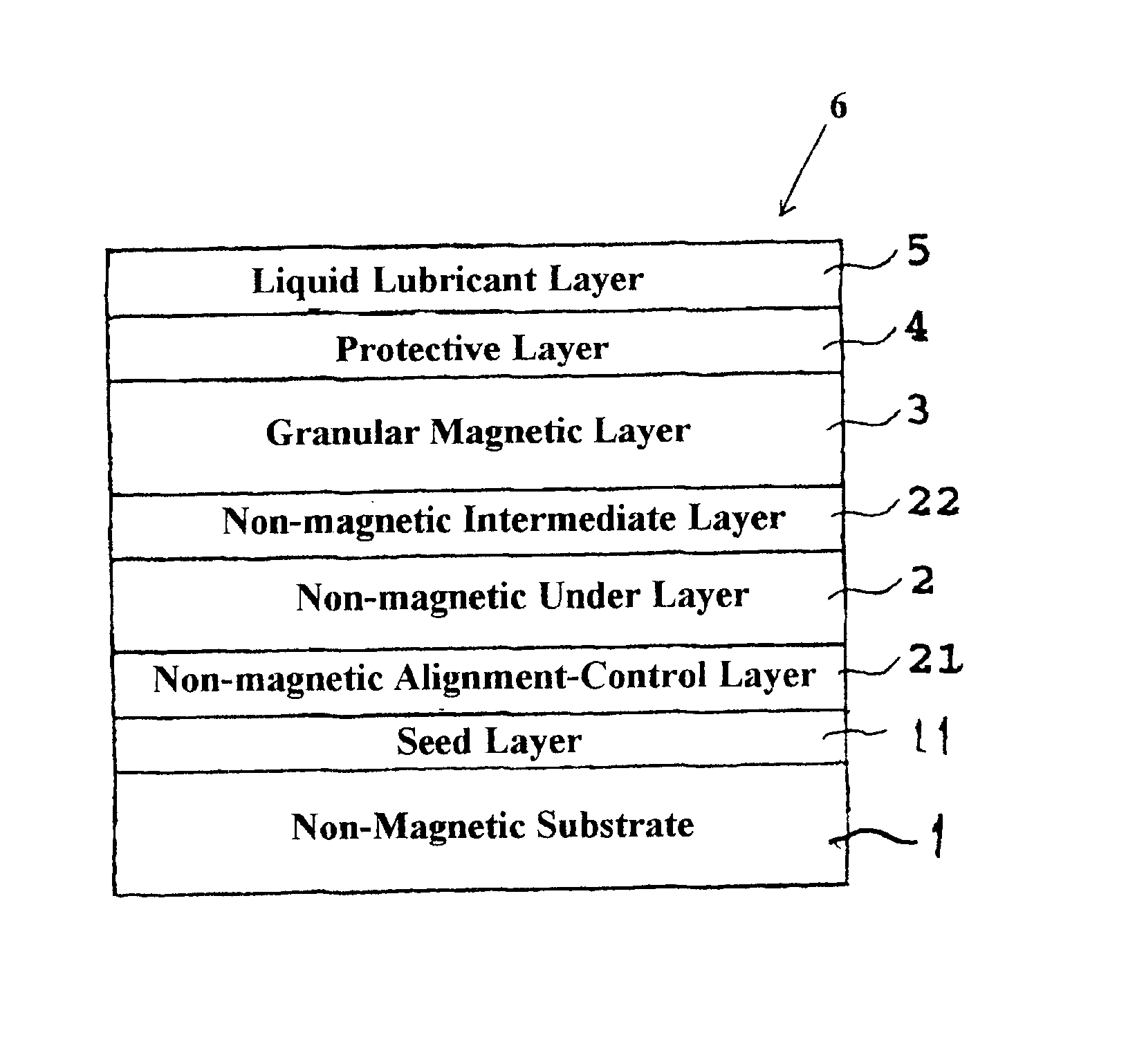

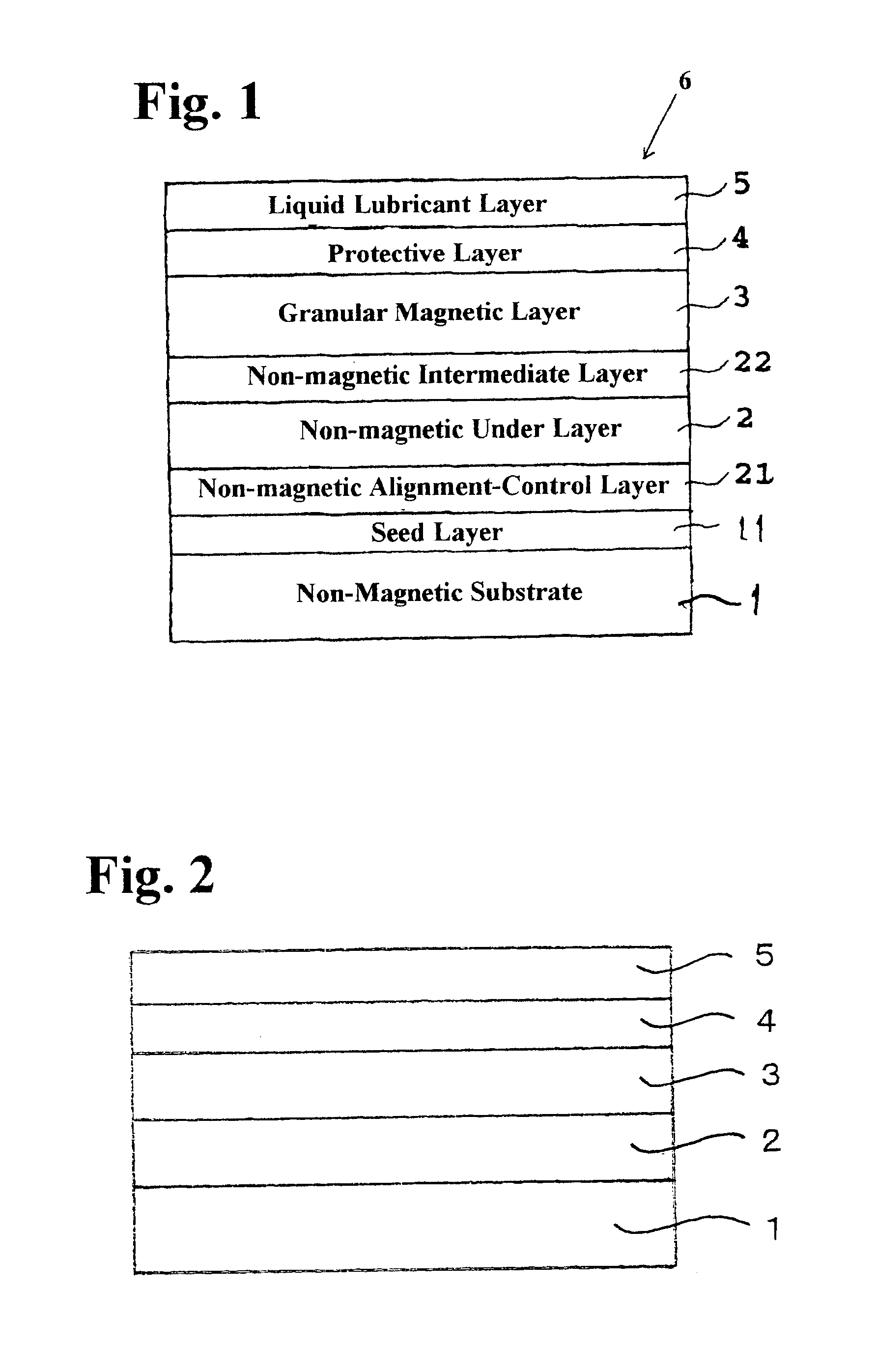

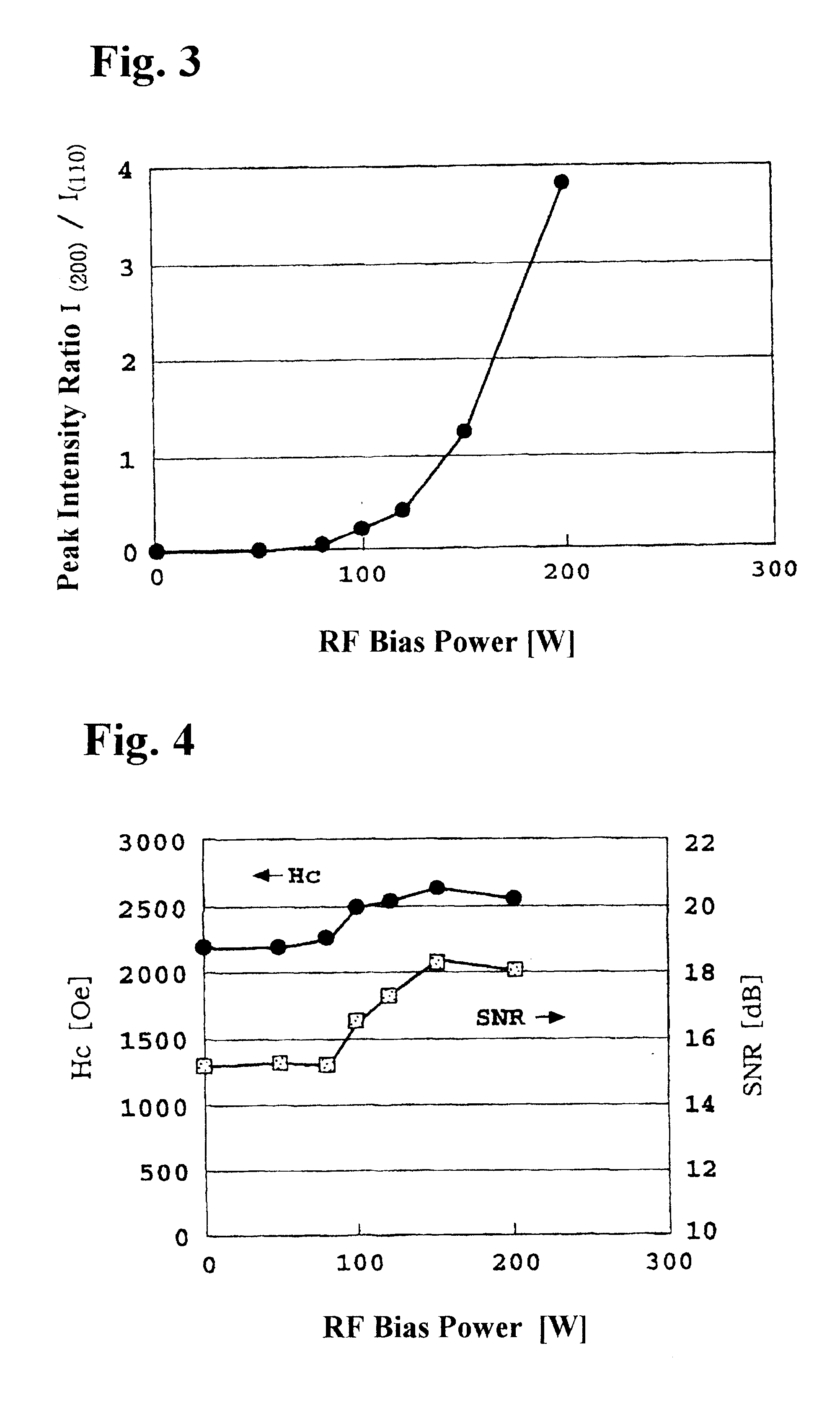

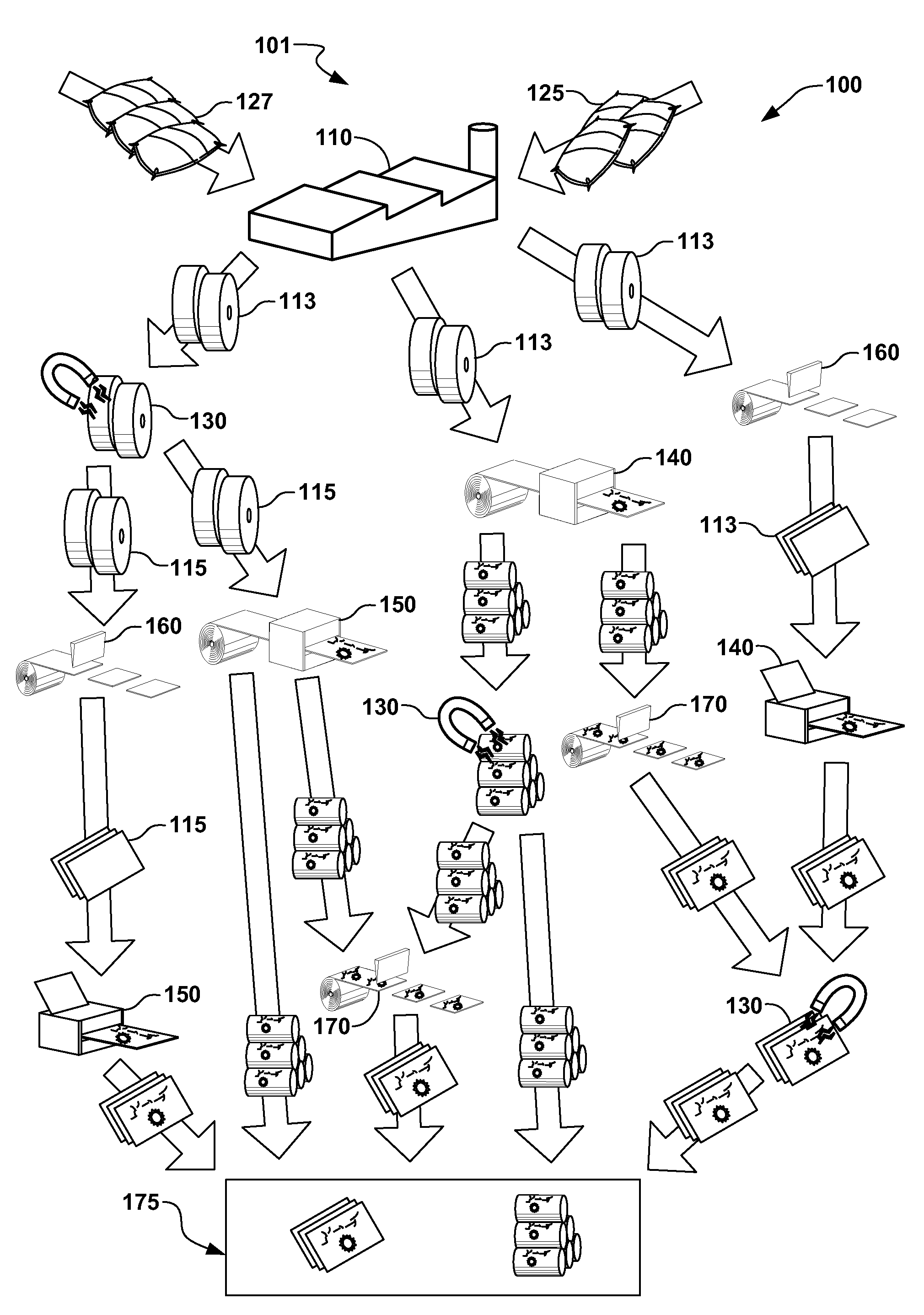

Magnetic recording medium and manufacturing method therefore

InactiveUS6673475B2Easy to controlEasy to produceBase layers for recording layersRecord information storageCrystal orientationNon magnetic

A magnetic recording medium achieves excellent noise reduction by controlling the crystal orientation of a magnetic layer without thermal processing. The magnetic recording medium includes multiple layers laminated to a substrate. These layers include at least the magnetic layer and a non-magnetic under layer. The magnetic layer has a granular structure consisting of ferromagnetic grains with a hexagonal close-packed structure and non-magnetic grain boundaries composed mainly oxide or a nitride. The non-magnetic under-layer is a material having a body centered cubic crystal structure with a preferential orientation along a (200) plane parallel to a film surface of the under-layer.

Owner:FUJI ELECTRIC CO LTD

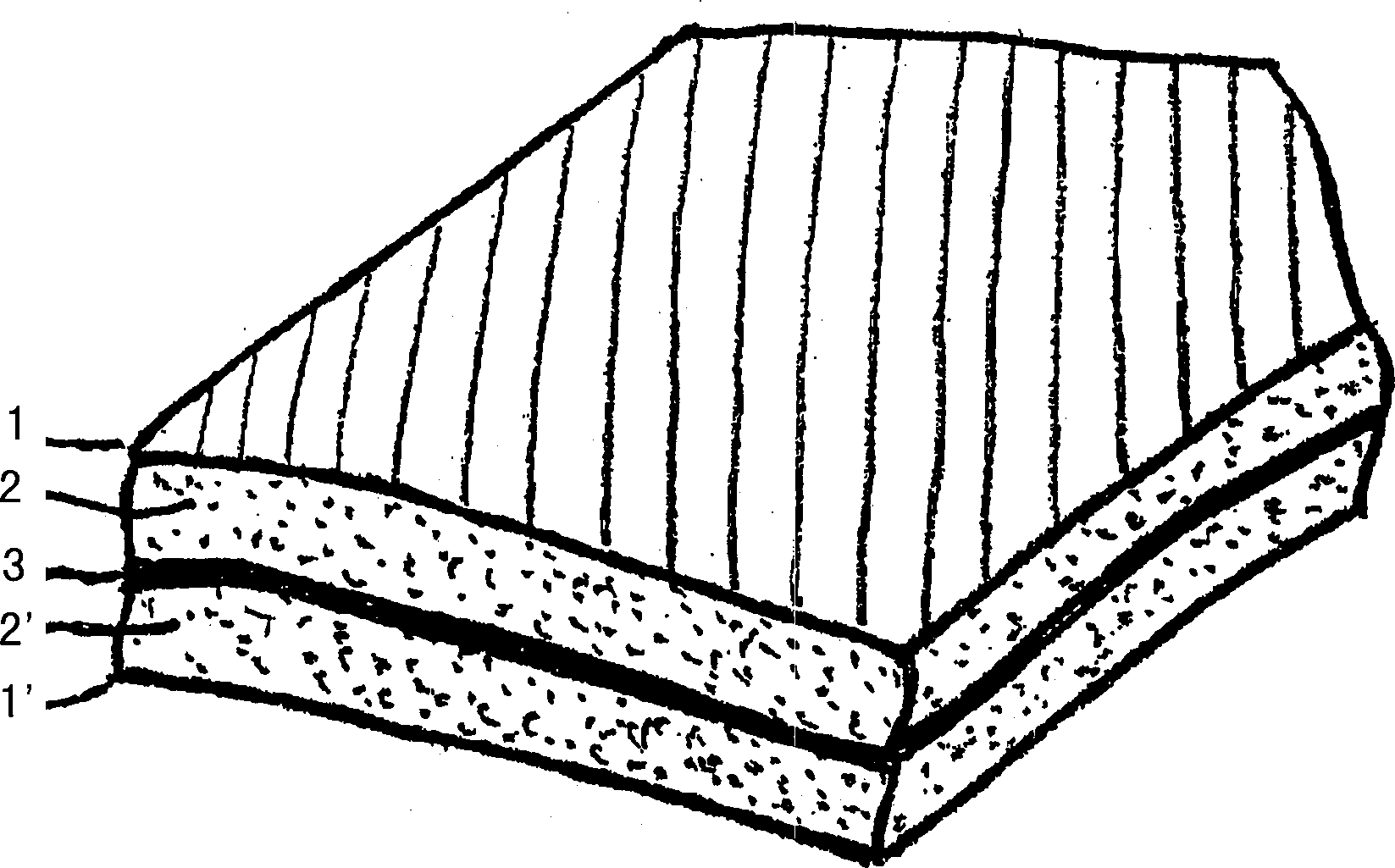

Flexible magnetic sheet systems

InactiveUS20100028667A1Efficient and inexpensiveDuplicating/marking methodsSynthetic resin layered productsHigh energyStrontium

Flexible magnetic sheets made with high-energy strontium ferrite and oriented magnetic particles of strontium ferrite and barium ferrite, such as to decrease thickness while maintaining a strong magnetic energy as well as flexibility.

Owner:MAGNUM MAGNETICS

Electromagnetic interference suppressor, antenna device and electronic information transmitting apparatus

InactiveUS7561114B2Reduce interferenceHigh densityMagnetic/electric field screeningLayered productsVitrificationElastomer

Owner:NITTA CORP

Devices and methods for orienting platelet-shaped magnetic or magnetizable pigment particles

The present invention relates to the field of devices and processes for producing optical effect layers (OEL) comprising magnetically bi-axially oriented platelet-shaped magnetic or magnetizable pigment particles, in particular for producing said OELs as anti-counterfeit means on security documents or security articles or for decorative purposes. The process described herein comprises the step of a) applying on a substrate surface a radiation curable coating composition comprising platelet-shaped magnetic or magnetizable pigment particles, b) exposing the radiation curable coating composition to a dynamic magnetic field of a magnetic assembly comprising a Halbach cylinder assembly, and c) at least partially curing the radiation curable coating composition of step b) so as to fix the platelet-shaped magnetic or magnetizable pigment particles in their adopted positions and orientations, said step c) being carried out partially simultaneously or simultaneously with step b).

Owner:SICPA HLDG SA

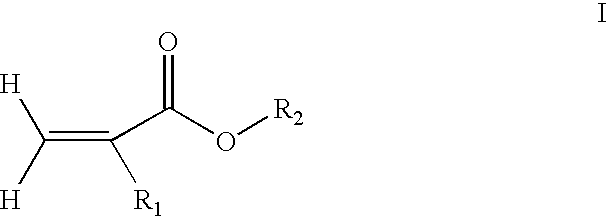

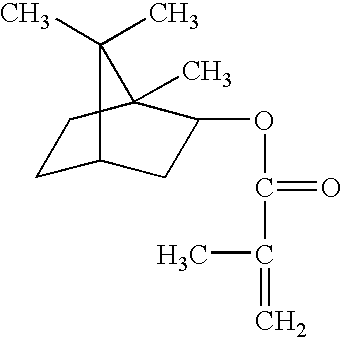

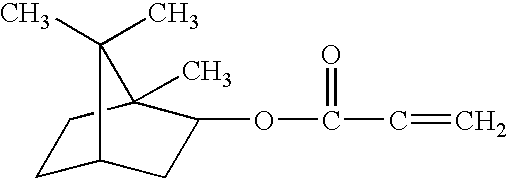

UV curable ferromagnetic compositions

InactiveUS6716893B2High trafficOrganic chemistryPhotomechanical apparatusOrganic solventUltraviolet lights

The present invention discloses an ultraviolet light curable ferromagnetic composition and method for making such a composition that may be used to produce a ferromagnetic coating on a suitable substrate. These coatings may be used to produce printed capacitors and inductors. The disclosed composition does not contain any significant amount of volatile organic solvents that do not become incorporated in the active layer after curing.

Owner:ALLIED PHOTOCHEM

Recording paper

ActiveCN101054782ASuppress wrinklesCoatings with pigmentsMaterials with cobaltFiber orientationWave velocity

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com