Ceramic coating material with 3D effect and coating method of ceramic coating material

A 3D effect, ceramic coating technology, used in magnetic coatings, coatings, household appliances, etc., can solve the problems of high temperature resistance, low hardness of silicone coating, single surface of tableware, etc., to achieve strong non-stick and wear resistance , The effect of small particle size distribution and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A kind of coating method of the ceramic paint with 3D effect, its specific steps are:

[0060] One: Pattern design:

[0061] (1) Design graphics on the template or stretched sheet, and draw the positioning points with a pencil;

[0062] (2) The strong magnets are arranged in the same phase and pasted on the positioning point of the bottom plate with 502 glue;

[0063] (3) Correct the pattern arrangement distance of the magnetic blocks;

[0064] The pattern can be the company's trademark, or an animal pattern, or a personalized font, which can be changed according to actual needs.

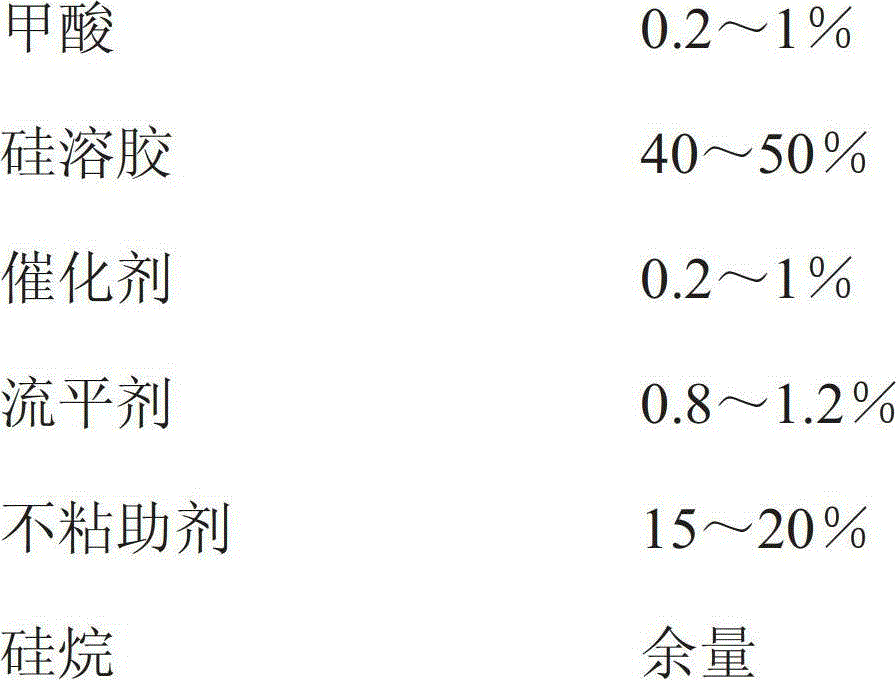

[0065] 2. Proportion of ceramic coating: see Table 1-3;

[0066] three coating

[0067] (1) Substrate blasting and cleaning;

[0068] (2) The base material is preheated at 45-47°C;

[0069] (3) Spray primer with a film thickness of 20-23 μm;

[0070] (4) Place a magnetic block mold with a pattern on the base material, spray the magnetic paint, after the film thickness is 2-3 μm, immedi...

Embodiment 2

[0074] A kind of coating method of the ceramic paint with 3D effect, its specific steps are:

[0075] One: Pattern design:

[0076] (1) Design graphics on the template or stretched sheet, and draw the positioning points with a pencil;

[0077] (2) The strong magnets are arranged in the same phase and pasted on the positioning point of the bottom plate with 502 glue;

[0078] (3) Correct the pattern arrangement distance of the magnetic blocks;

[0079] The pattern can be the company's trademark, or an animal pattern, or a personalized font, which can be changed according to actual needs.

[0080] 2. Proportion of ceramic coating: see Table 1-3;

[0081] three coating

[0082] (1) Substrate blasting and cleaning;

[0083] (2) The base material is preheated at 46-48°C;

[0084] (3) Spray primer with a film thickness of 22-25 μm;

[0085] (4) Place a magnetic block mold with a pattern on the base material, spray the magnetic paint, after the film thickness is 2-3 μm, immediat...

Embodiment 3

[0089] A kind of coating method of the ceramic paint with 3D effect, its specific steps are:

[0090] One: Pattern design:

[0091] (1) Design graphics on the template or stretched sheet, and draw the positioning points with a pencil;

[0092] (2) The strong magnets are arranged in the same phase and pasted on the positioning point of the bottom plate with 502 glue;

[0093] (3) Correct the pattern arrangement distance of the magnetic blocks;

[0094] The pattern can be the company's trademark, or an animal pattern, or a personalized font, which can be changed according to actual needs.

[0095] 2. Proportion of ceramic coating: see Table 1-3;

[0096] three coating

[0097] (1) Substrate blasting and cleaning;

[0098] (2) The base material is preheated at 47-48°C;

[0099] (3) Spray primer with a film thickness of 24-26 μm;

[0100] (4) Place a magnetic block mold with a pattern on the base material, spray the magnetic paint, after the film thickness is 2-3 μm, immedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com