Microcrystal glass ceramic composite plate and one-time rapid sintering method thereof

A glass-ceramic, glass-ceramic technology, applied in the field of building materials, can solve the problems of inability to achieve the effect of large-scale decoration, monotonous particle collection style, unfavorable energy saving and emission reduction, etc. Good consumption and exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A glass-ceramic composite plate, which is sintered from glass-ceramic pellets, a seeding agent, and a ceramic green body, wherein:

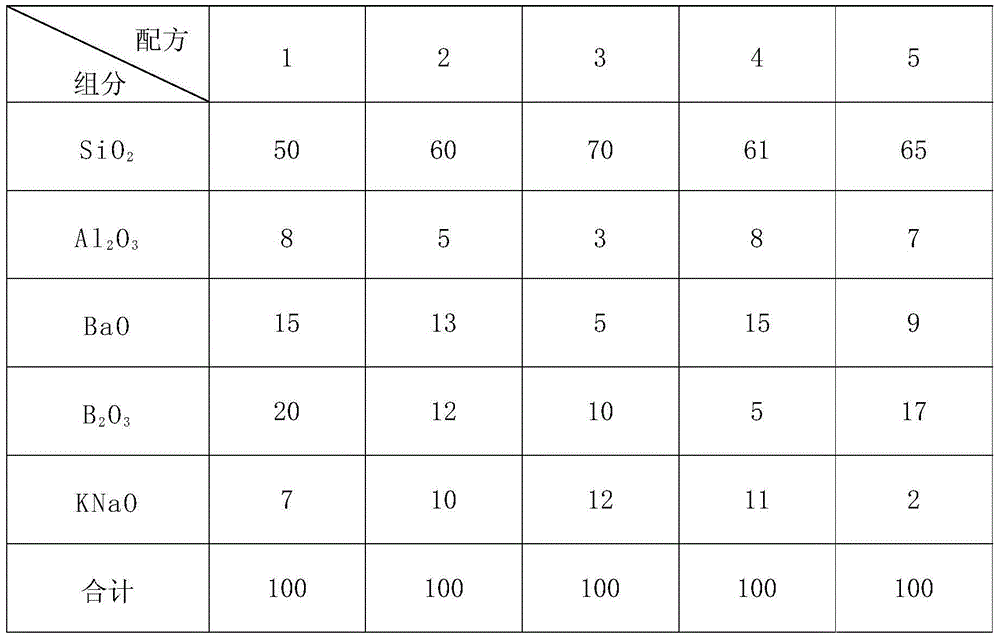

[0032] Seeding agent: use quartz, albite, potassium feldspar, dolomite, soda ash, alumina, sodium nitrate, potassium carbonate, barium carbonate, borax, boric acid and other mineral raw materials, and prepare according to formulas 1 to 5 in Table 1 :

[0033] Table 1 seeding agent formulation table (parts by weight)

[0034]

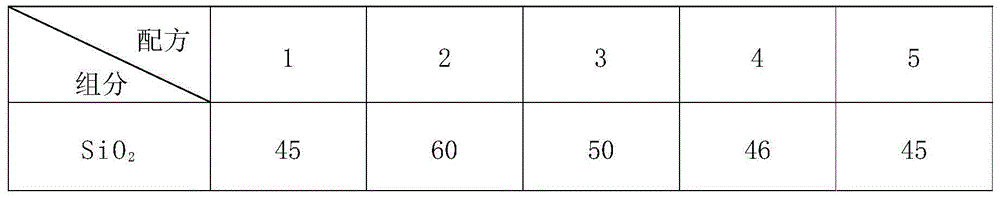

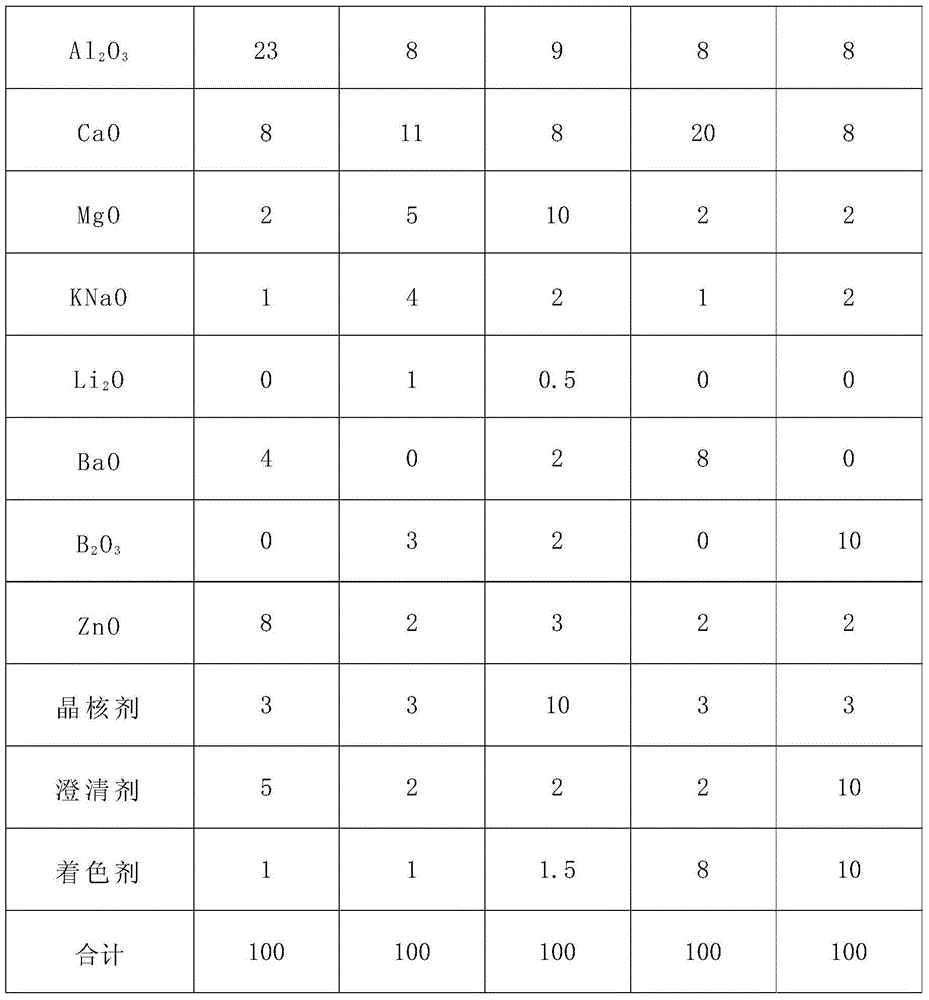

[0035] Glass-ceramic pellets: quartz, sodium potassium feldspar, lithium feldspar, lepidolite, spodumene, calcite, talc, dolomite, soda ash, alumina, sodium nitrate, potassium carbonate, barium carbonate, Raw materials such as oxides of borax, boric acid, zinc, and crystal nucleating agent, clarifier and colorant, are prepared according to formula 1~5 in table: 2:

[0036] Table 2 Glass-ceramic pellet formulation table (parts by weight)

[0037]

[0038]

[0039] The crystal nucleating agent is ZrO, the c...

Embodiment 2

[0045] A method for rapid firing of a glass-ceramic composite plate, comprising the following steps:

[0046](1) Preparation of glass-ceramic pellets: Mix the components in the formula of glass-ceramic pellets (choose one from formulas 1 to 5 in Table 2 in Example 1) evenly, and melt them at a temperature of 1450°C to form a molten glass. liquid, then water quenched, dried, broken, and sieved into 6-purpose glass-ceramic pellets;

[0047] (2) Preparation of seeding agent: Mix the components in the seeding agent formula (choose one from Table 1 formula 1 to 5 in Example 1) evenly, melt into a melt in the temperature range of 1500 ° C, and then Water quenching, drying, crushing, and sieving into 30-mesh seeding agent;

[0048] (3) Preparation of ceramic green body: Mix the components in the ceramic green body formula (choose one from Table 3 formula 1 to 5 in Example 1) evenly, finely pulverize through ball milling, and spray dry into a powder containing 5% moisture Material, ...

Embodiment 3

[0055] A method for rapid firing of a glass-ceramic composite plate, comprising the following steps:

[0056] (1) Preparation of glass-ceramic granules: mix the components in the formula of glass-ceramic granules (choose one from formulas 1 to 5 in Table 2 in Example 1) evenly, and melt them at a temperature of 1520° C. to form a molten glass. liquid, then water quenched, dried, broken, and sieved into 120-mesh glass-ceramic pellets;

[0057] (2) Preparation of seeding agent: Mix the components in the seeding agent formula (any one from Table 1 formula 1 to 5 in Example 1) evenly, melt into a melt in the temperature range of 1560 ° C, and then Water quenching, drying, crushing, and sieving into 120-mesh seeding agent;

[0058] (3) Preparation of ceramic green body: Mix the components in the ceramic green body formula (choose one from Table 3 formula 1 to 5 in Example 1) evenly, finely pulverize through ball milling, and spray dry into a powder containing 7% moisture Material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com