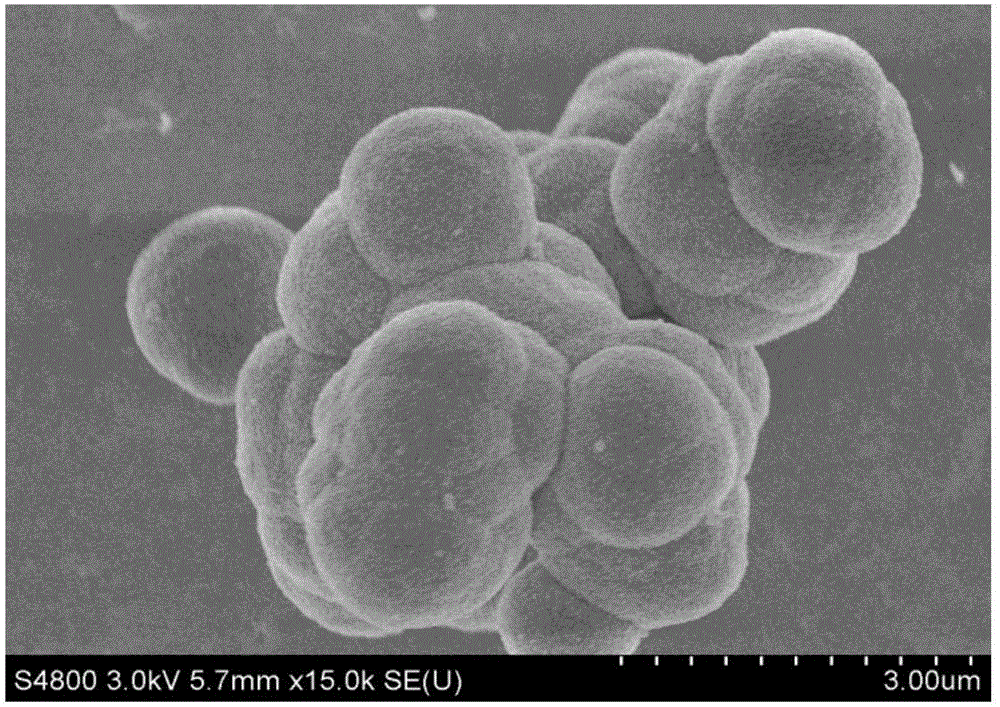

Preparation method for flocculus-shaped SnS<2> negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of small output of nanosheets, incomplete reaction, poor controllability, etc., to achieve The effect of controllable grain growth, uniform morphology and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A pompom-shaped SnS 2 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0026] 1) Sodium thiosulfate (Na 2 S 2 o 2 ) was dissolved in deionized water and prepared into a solution A with a concentration of 0.5 to 1.6 mol / L, according to the molar ratio of elements n Sn :n S =(1.0~2.5):(2.0~4.7) tin chloride pentahydrate (SnCl 4 ·5H 2 O) being dissolved in an equal amount of deionized water (i.e. equal to the deionized water of dissolving sodium thiosulfate) to prepare solution B;

[0027] 2) Add solution B dropwise to solution A under the action of magnetic stirring, and continue to stir to form a uniform mixed solution C, press n under the action of magnetic stirring 硫代硫酸钠 :n 乙二醇 =(1.4~3.8):(2.6~7.9) ratio ethylene glycol is gradually added in the mixed solution C to form a uniformly mixed solution D;

[0028] 3) Under the action of magnetic stirring, add an organic alkali source (triethanolamine, lithiu...

Embodiment 1

[0033] 1) Sodium thiosulfate (Na 2 S 2 o 2 ) was dissolved in deionized water, and prepared into a solution A with a concentration of 0.5mol / L, according to the molar ratio of elements n Sn :n S =1.0:2.0 tin chloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in equal amount of deionized water and be prepared into solution B;

[0034] 2) Add solution B dropwise to solution A under the action of magnetic stirring, and continue to stir to form a uniform mixed solution C, press n under the action of magnetic stirring 硫代硫酸钠 :n 乙二醇 The ratio of =1.4:2.6 gradually adds ethylene glycol into the mixed solution C to form a uniformly mixed solution D;

[0035] 3) Under the action of magnetic stirring, add organic alkali source triethanolamine dropwise to the mixed solution D, and adjust the pH of the solution to 2 to form a solution E;

[0036] 4) Put the E solution into a homogeneous hydrothermal reactor and seal it, and control the filling ratio at 40%, put it into a homogeneo...

Embodiment 2

[0040] 1) Sodium thiosulfate (Na 2 S 2 o 2 ) was dissolved in deionized water, and prepared into a solution A with a concentration of 1.0mol / L, according to the molar ratio of elements n Sn :n S =2.0:3.5 tin chloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in equal amount of deionized water and be prepared into solution B;

[0041] 2) Add solution B dropwise to solution A under the action of magnetic stirring, and continue to stir to form a uniform mixed solution C, press n under the action of magnetic stirring 硫代硫酸钠 :n 乙二醇 The ratio of =2.5:5.3 gradually adds ethylene glycol into the mixed solution C to form a uniformly mixed solution D;

[0042] 3) Under the action of magnetic stirring, add organic alkali source lithium diisopropylamide dropwise to the mixed solution D to adjust the pH of the solution to 6 to form a solution E;

[0043] 4) Put the E solution into a homogeneous hydrothermal reactor and seal it, and control the filling ratio at 50%, put it into a ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com